Method for forming shallow groove isolation area

A shallow trench isolation area and trench technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems affecting the height of isolation structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

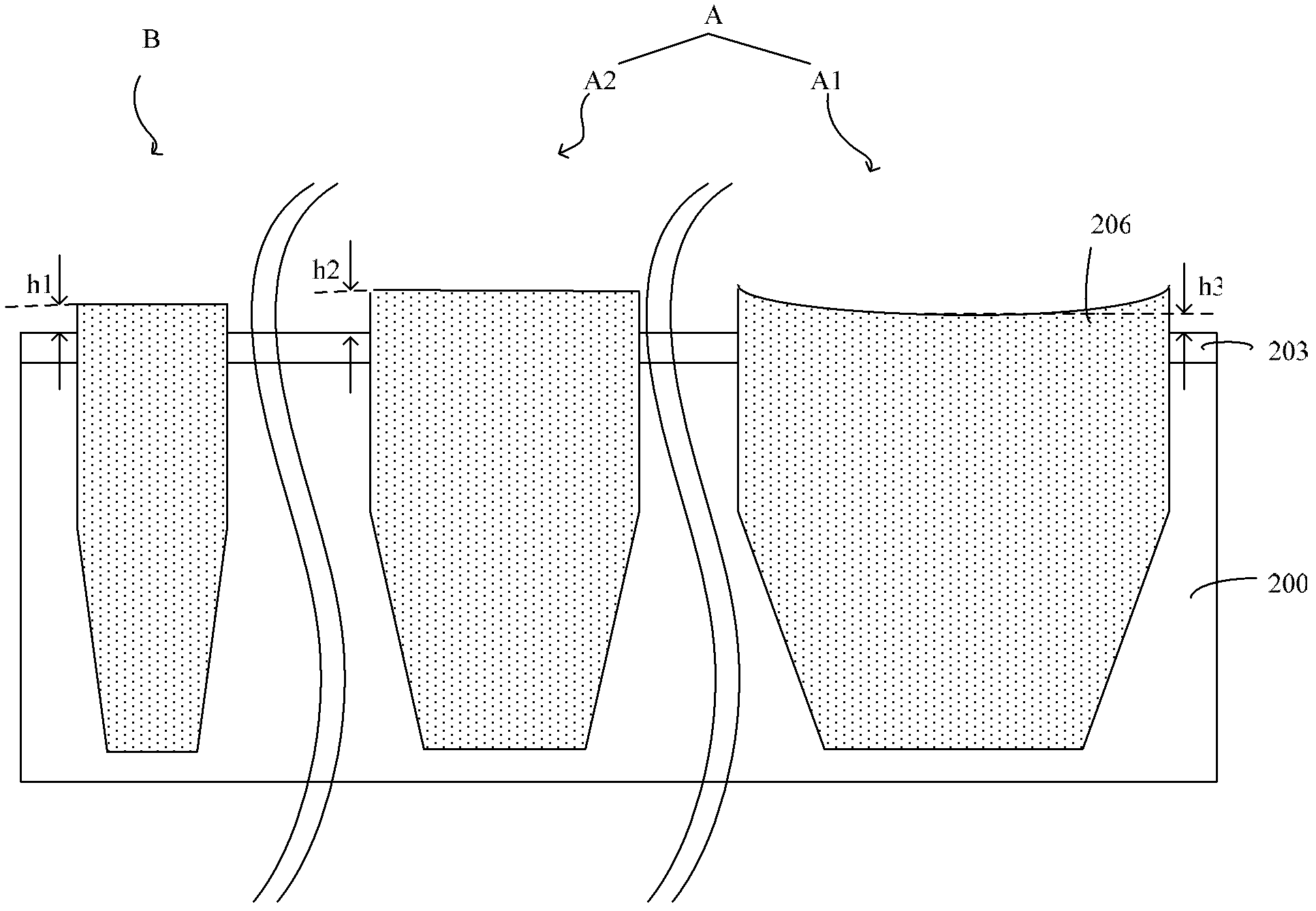

[0042] The present invention divides the planarization of chemical mechanical polishing into two steps by arranging two separated chemical mechanical polishing stop layers, which not only satisfies the requirement that the width of the chemical mechanical polishing is so large that depressions will be generated in the chemical mechanical polishing The recess depth of the insulating oxide layer in the trench is reduced. More importantly, this method can also easily adjust the height of the shallow trench isolation structure in the narrower trench by controlling the process parameters. effect, and enables particularly narrow trenches in which the insulating oxide layer is filled by two depositions in narrower trenches and shallow trenches in relatively wide trenches in which the insulating oxide layer is filled by three depositions The height of the groove isolation structure is consistent.

[0043] In specific implementation, its specific steps may include:

[0044] Provide a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com