Double layer quick energy-saving power distribution line deconcentrator

A technology for distribution lines and splitters, applied in circuits, electrical components, conductive connections, etc., can solve the problems of complicated operation and poor connection effect, and achieve the effect of simple connection method, convenient operation and strong clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

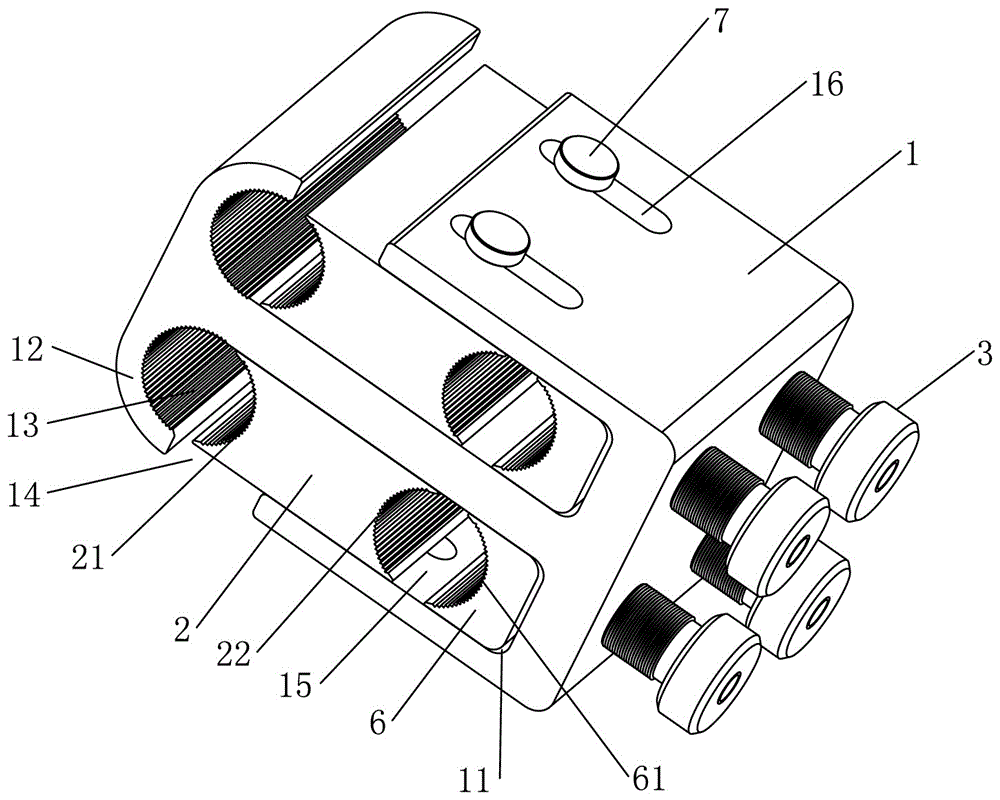

[0026] see figure 1 with figure 2 As shown, a double-layer fast energy-saving power distribution line splitter includes a main line conductive clip assembly, and the main line conductive clip assembly includes a clip jacket 1. Two slide chambers 11 are arranged side by side in the clip jacket 1, and two The sliding cavity 11 is provided with a crimping block 2 assembly, one end of the crimping block 2 assembly is provided with a dynamic crimping surface 21, and the end of the sliding chamber 11 opposite to the dynamic crimping surface 21 is provided with a constant crimping surface 12. A crimping groove 13 is formed between the line surface 21 and the constant pressure line surface 12, and the two sides of the jacket 1 respectively correspond to the constant pressure line surface 12 of each sliding chamber 11. Connected; it also includes the plug-in wire s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com