Method for precisely evaluating sharpness of pattern contour of printing gum

A technology of printing paste and clarity, applied in the field of fabric printing, to achieve the effect of simple and convenient method, accurate result and fine pattern printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for accurately evaluating the outline definition of printing paste patterns, comprising the steps of:

[0023] (1) According to the printing paste prescription: 1% K-type Argosol Red P-4B, 5% urea, 1% resist salt S, 1% sodium bicarbonate, 70% original paste. Adjust the viscosity of the color paste to 10000±1000mPa·s (25±1°C, No. 4 rotor, 30r / min, measured by SNB-2 digital rotational viscometer).

[0024] On a flat screen of 180 mesh, the diameter of the magnetic rod is 8mm, the speed of the vehicle is 6m / min, and the magnetic force is 3 # Cotton fabrics were printed with reactive dyes under certain printing conditions. Print two groups of straight lines, each group consists of three identical straight lines arranged in parallel, one group is a thin line with a length of 10 cm and a thickness of 200 μm, and the other group is a group of thick lines with a length of 10 cm and a thickness of 800 μm.

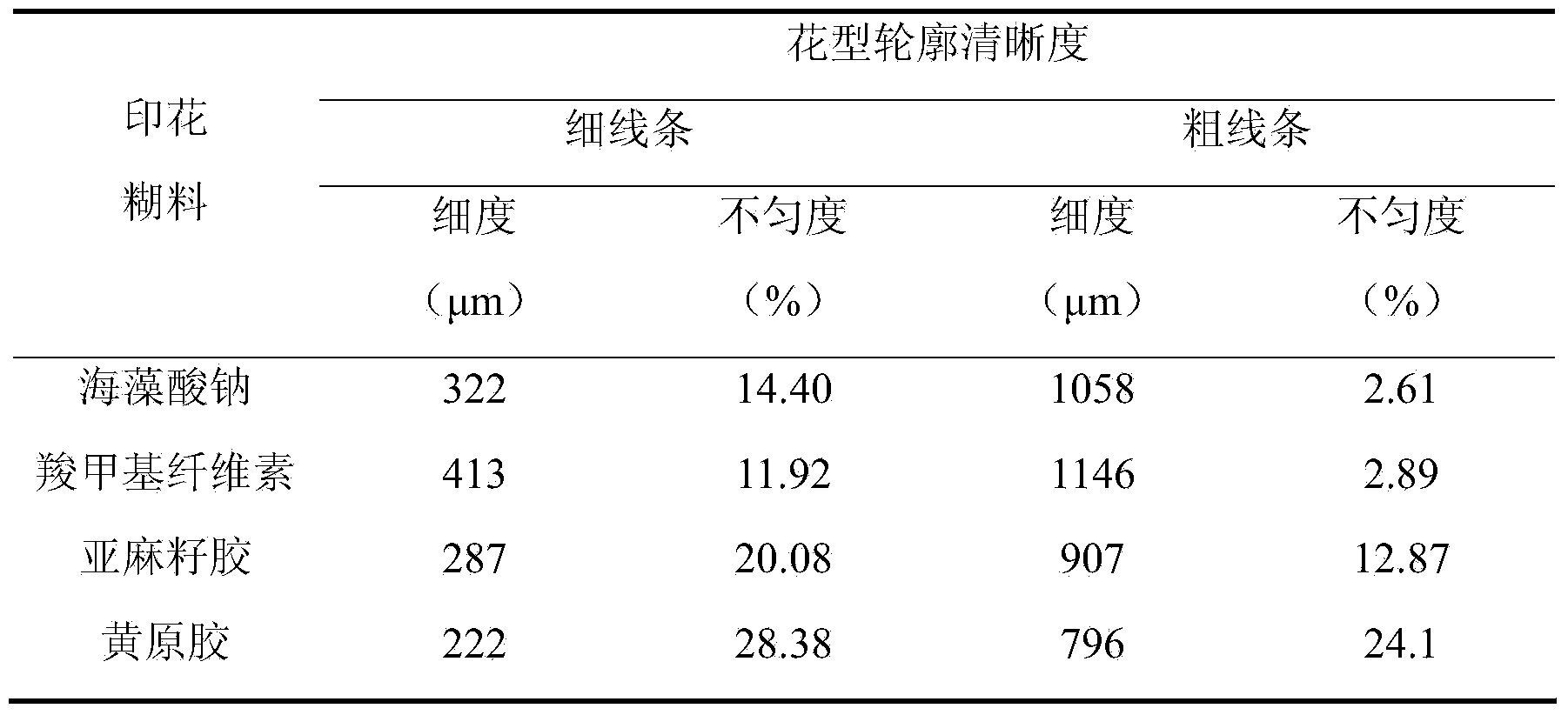

[0025] (2) After drying the printed lines, measure the finene...

Embodiment 2

[0034] A method for accurately evaluating the outline definition of printing paste patterns, comprising the steps of:

[0035] (1) According to the printing color paste prescription: 1% K-type Argosol Red P-4B, 5% urea, 1% anti-staining salt S, 1% sodium bicarbonate, 70% original paste, prepare printing color paste.

[0036] On a flat screen of 180 mesh, the diameter of the magnetic rod is 8mm, the speed of the vehicle is 6m / min, and the magnetic force is 3 # Cotton fabrics were printed with reactive dyes under certain printing conditions. Print two groups of straight lines, each group consists of three identical straight lines arranged in parallel, one group is a thin line with a length of 10 cm and a thickness of 200 μm, and the other group is a group of thick lines with a length of 10 cm and a thickness of 800 μm.

[0037] (2) After drying the printed lines, measure the fineness of the lines on the fabric with an electron microscope, measure the line fineness of a point at...

Embodiment 3

[0047] A method for accurately evaluating the outline definition of printing paste patterns, comprising the steps of:

[0048] (1) Cotton fabric reactive dye printing paste prescription: 1% K-type Argosol Red P-4B, 5% urea, 1% resist salt S, 1% sodium bicarbonate, 70% raw paste (sodium alginate raw Paste mass fraction is 3%).

[0049] Prescription of disperse dye printing color paste for polyester fabric: 1% Artron Red S-G, 1% urea, 0.1% tartaric acid, 70% raw paste (mass fraction of sodium alginate raw paste is 3%).

[0050] Prescription of polyester-cotton fabric dispersion / reactive homogeneous printing color paste: 1% Artron Red S-G, 1% K-type Argosol Red P-4B, 5% urea, 1% resist salt S, 1% sodium bicarbonate, 70% raw paste (mass fraction of sodium alginate raw paste is 3%).

[0051] On a flat screen of 180 mesh, the diameter of the magnetic rod is 8mm, the speed of the vehicle is 6m / min, and the magnetic force is 3 # Two sets of straight lines are printed under the printi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com