Waste cable recycling device

A technology for recycling devices and waste cables, which is applied in the direction of electronic waste recycling, recycling technology, equipment for dismantling/armoring cables, etc., and can solve problems such as polluting the air respiratory tract, high labor intensity, and injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

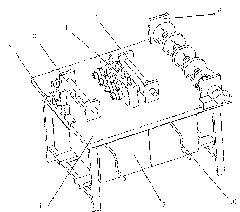

[0020] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 7 Shown: a waste cable recovery device, including a frame 1 as a base, on the frame 1 are sequentially arranged a primary cutter 2, a first support roller 3, a secondary cutter 4, a second support roller 5 and a winding wire Mechanism 6 is provided with a cable sheath recovery box 7 at the bottom of the frame 1. In order to improve the recovery efficiency of the cable sheath, there are two cable sheath recovery boxes 7, which are arranged side by side at the bottom of the frame 1, and each A pair of relatively rotatable driving rollers 8 and driven rollers 9 are arranged above the cable sheath recovery box 7, and a crank handle 10 is also arranged at the outer end of the driving roller 8;

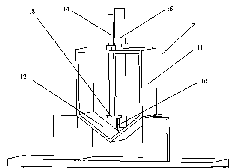

[0021] The primary tool 2 includes a primary fixed frame 11 fixed at the end of the frame 1. The lower end of the primary fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com