Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Square decimeter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anode oxidation method

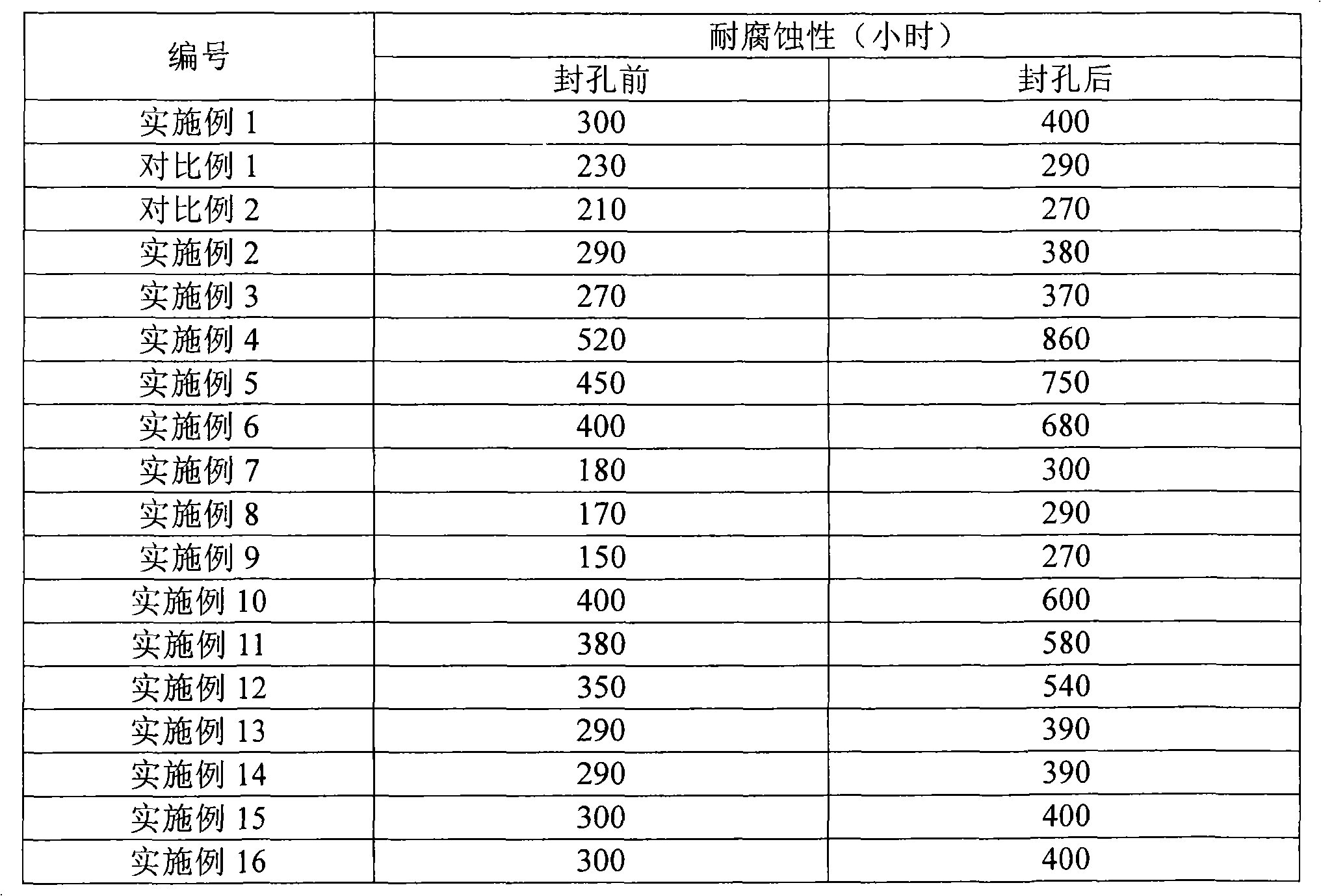

The invention provides an anode oxidation method which comprises the following steps: under the anode oxidation condition, putting light metal material in electrolyte, using the light metal material as an anode, using the conducting material which does not react with the electrolyte as a cathode, and enabling the cathode and the anode to be respectively electrically connected with a positive electrode and a negative electrode of a power source. The anode oxidation comprises constant current density anode oxidation and constant voltage anode oxidation, wherein the current density of the constant current density anode oxidation is 0.5 to 6 amperes / square decimeter, and the voltage of the constant voltage anode oxidation is 20 to 400 volts. Compared with the light metal material which is processed by the prior anode oxidation method, the corrosion resistance of the light metal material which is processed by the anode oxidation method of the invention is greatly improved, and even the light metal material which is processed by the anode oxidation method of the invention is not post-processed by plugging, the corrosion resistance of the light metal material is also stronger.

Owner:HANGZHOU WIN WIN TECH CO LTD

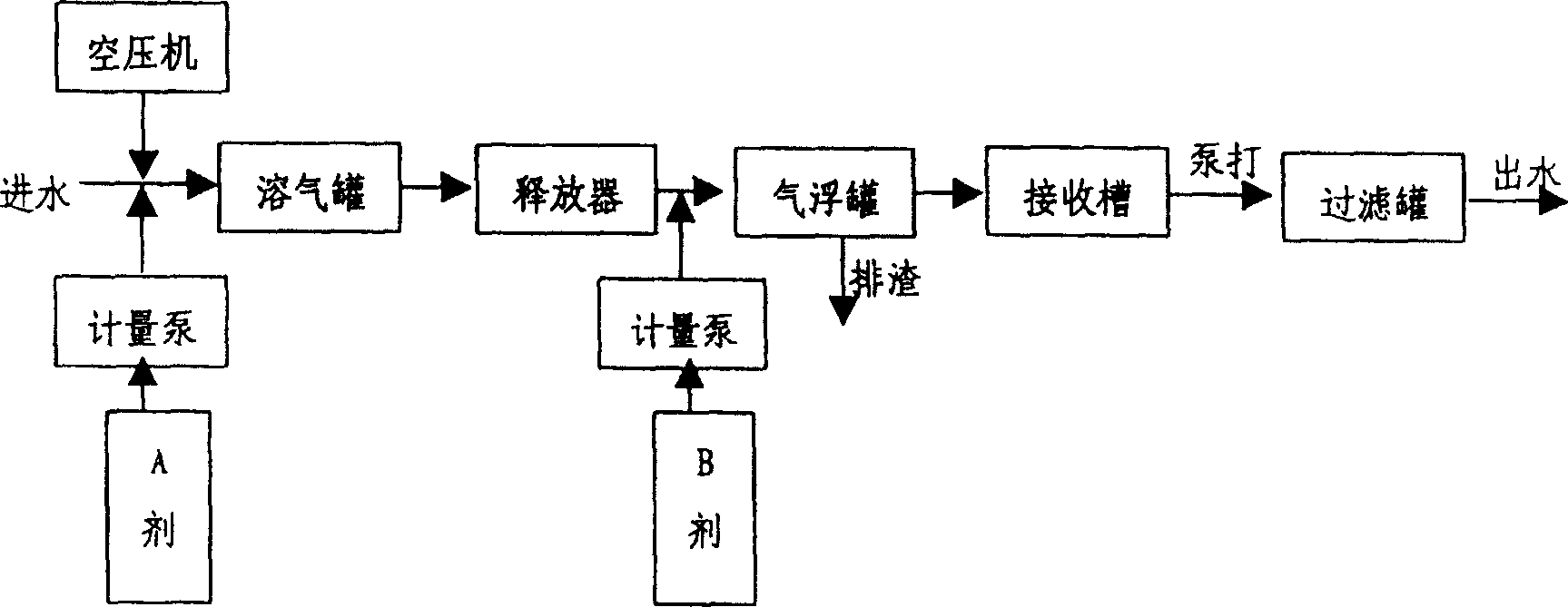

Method for treating naphthenic acid sewage by flocculation-electricity heterogeneous catalysis

InactiveCN1209302CEasy to handleTo achieve the purpose of preprocessingMultistage water/sewage treatmentSquare decimeterCatalytic oxidation

A flocculation-electroheterogeneous catalysis method for treating naphthenic acid wastewater. First, air flotation-flocculation treatment is carried out on naphthenic acid wastewater, the pressure is 0.2-0.4MPa, and the dosage of the agent is 0.01-0.07% of the wastewater volume; after the flocculation treatment, the DC voltage between the electrodes in the electric field is 5-15V, and the current Under an external electric field of 200-400 mA per square decimeter, the organic pollutants in the naphthenic acid wastewater are catalyzed and oxidized on the surface of the catalyst. The experimental results show that the combined technology can be used to treat naphthenic acid wastewater, which can be directly discharged up to the standard, and the operating cost is low.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

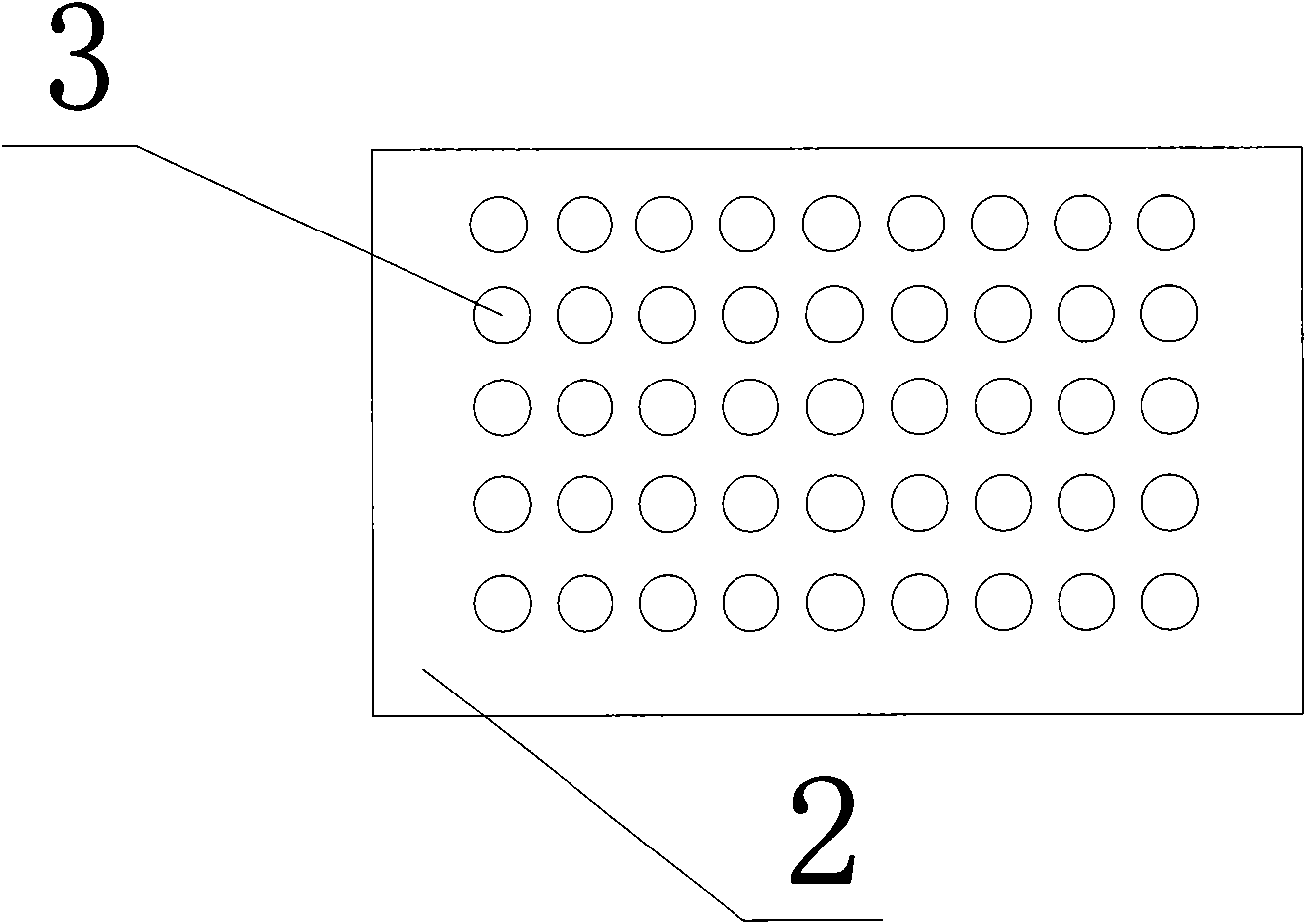

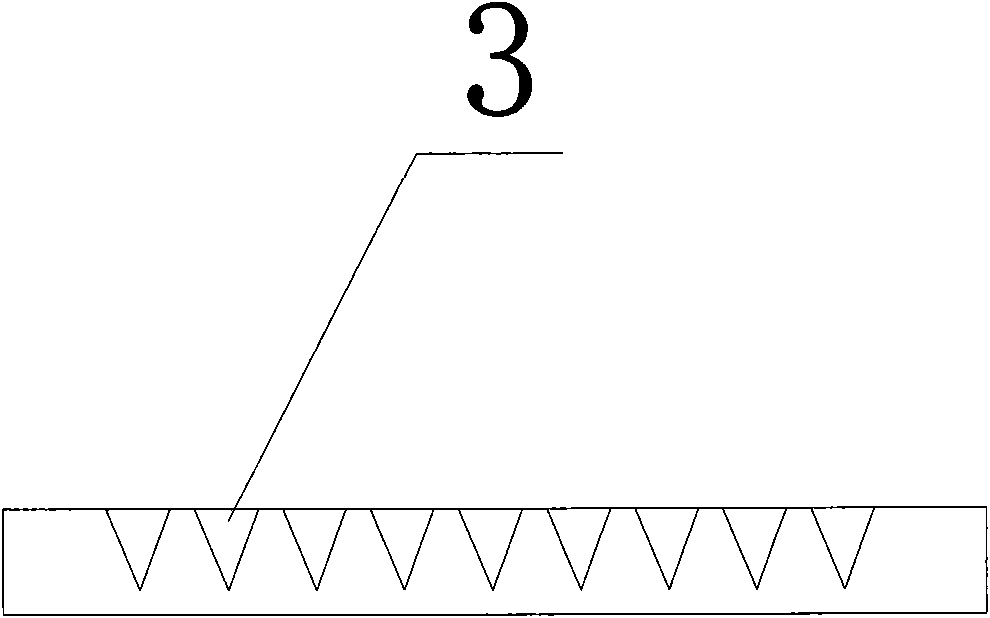

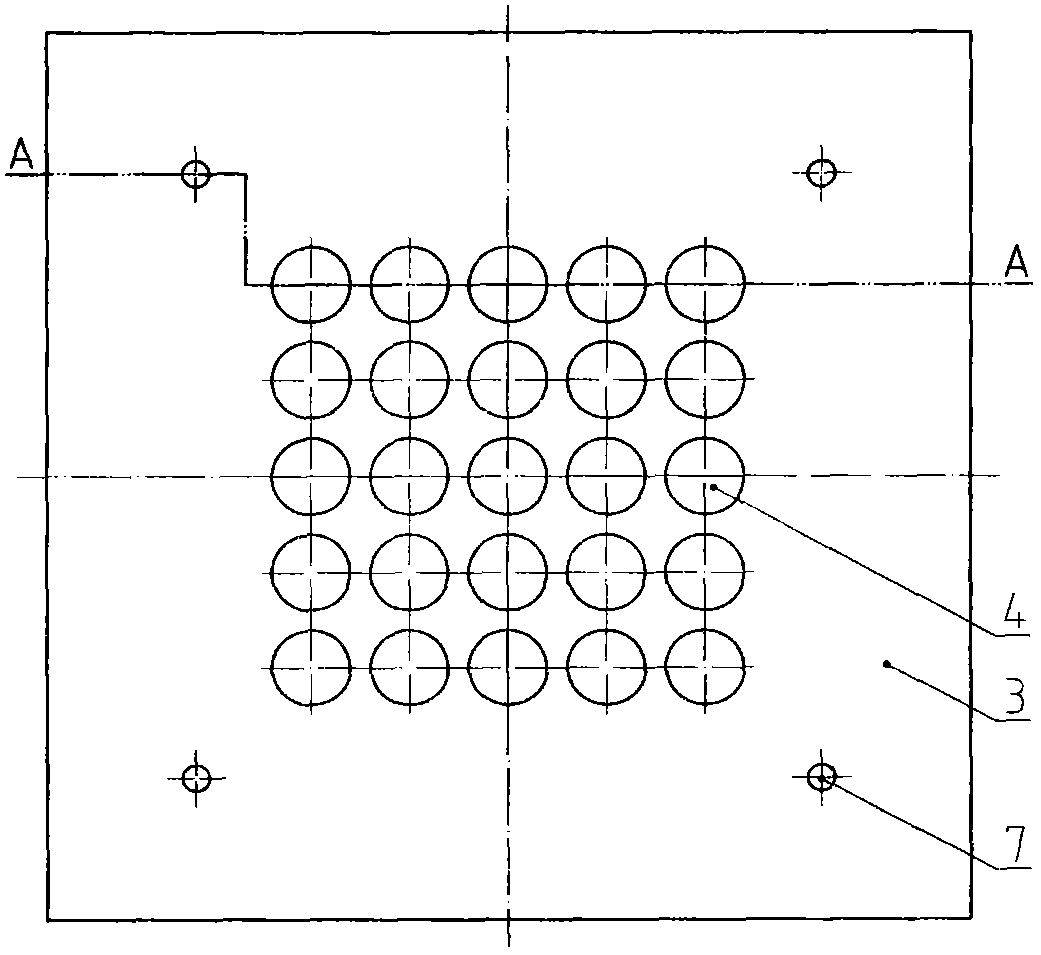

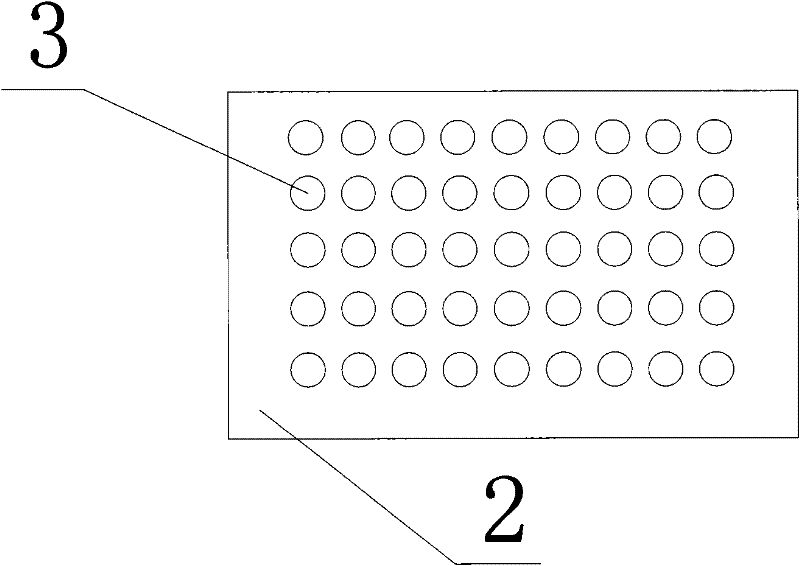

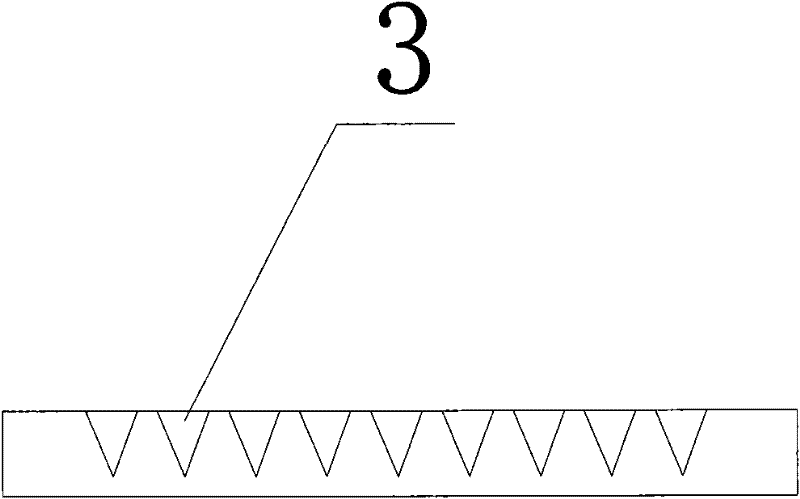

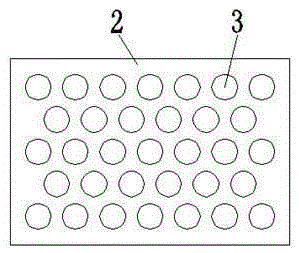

Crucible for growing polysilicon ingot

InactiveCN101597793AGood orientationIncrease percentagePolycrystalline material growthSingle crystal growth detailsSquare decimeterCrucible

The invention relates to a crucible for growing silicon ingot in the field of solar energy, in particular to a crucible for growing polysilicon ingot. The crucible for growing the polysilicon ingot is characterized in that: a bottom plate 2 of the crucible is provided with a plurality of holes 3; and the depth of the holes 3 is 1 to 25 mm, the aperture of the level part of the holes 3 and the bottom plate 2 of the crucible is 1 to 30 mm, and the distributed density of the holes 3 and the bottom plate 2 of the crucible is 1 to 100 per square decimeter. By adopting the crucible for growing the polysilicon ingot to grow polysilicon ingot, the directionality of crystal grains of the polysilicon ingot can be remarkably improved, crystal grains of the polysilicon ingot predominate in and crystal orientation, multiple parallel twins boundaries caused by crystal face are reduced, the number of crystal boundaries is reduced, and simultaneously the percentage of sigma 3 shallow energy level crystal boundary is improved so as to effectively prolong the minority carrier lifetime of a silicon chip, and the conversion efficiency of solar cells made of the silicon chip is improved.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Method of manufacturing a support for a lithographic printing plate

InactiveUS20060213589A1Surface mottlingEliminate the effects ofPrinting pre-treatmentSquare decimeterDissolution

Disclosed is a method of manufacturing a support for a lithographic printing plate, which method includes: a casting step in which an aluminum alloy melt is fed between a pair of cooling rollers by a melt feed nozzle and is rolled as it is being solidified by the pair of cooling rollers, forming an aluminum alloy plate, and a graining treatment step in which a surface of the aluminum alloy plate is subjected to graining treatment which includes at least alkali etching treatment and subsequent electrochemical graining treatment, thereby giving a support for a lithographic printing plate; wherein the surface of the aluminum alloy plate on the side which is subjected to the graining treatment undergoes an amount of aluminum dissolution X per square meter (g / m2) during the alkali etching treatment and has a total amount of electricity Y per square decimeter (C / dm2) applied thereto during an anode reaction in the electrochemical graining treatment such as to satisfy formula (1) below: 1,000>Y≧10X (1). By using this method, a support for a lithographic printing plate which is free of surface mottling is provided.

Owner:FUJIFILM CORP +1

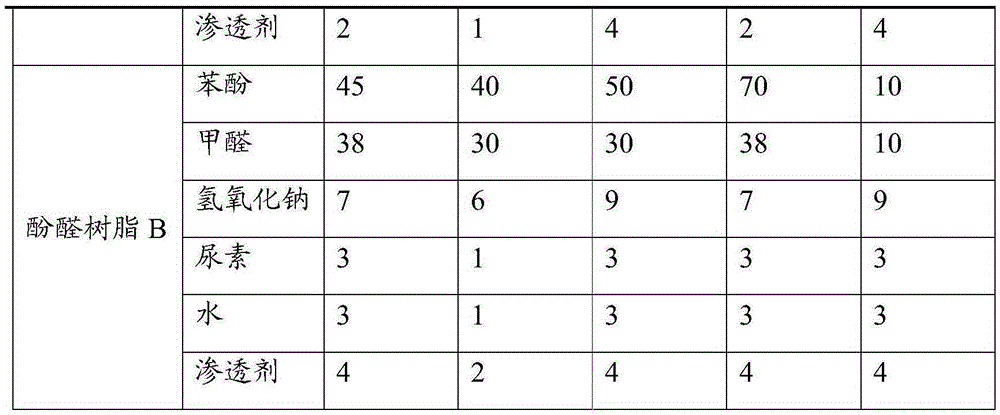

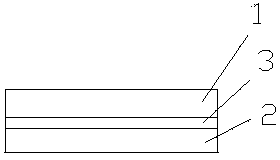

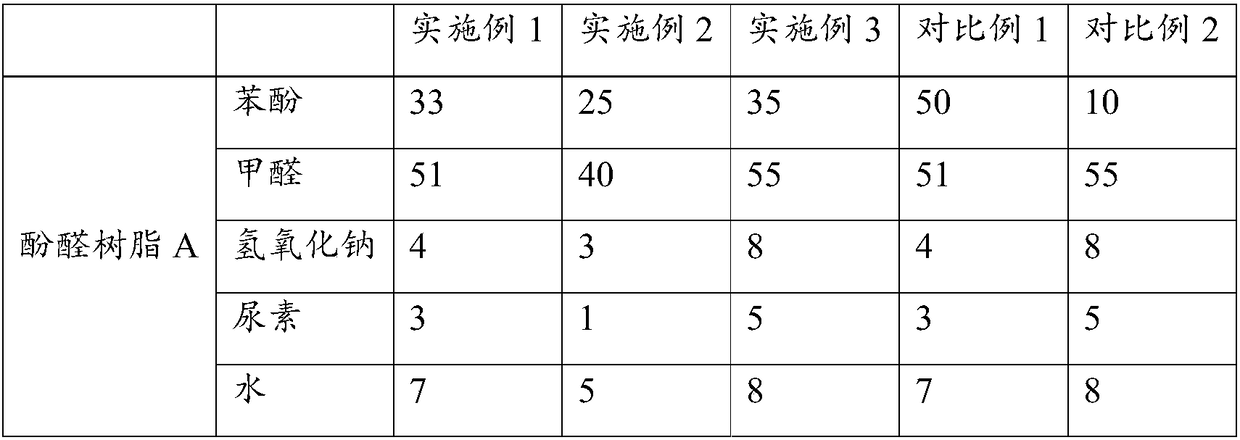

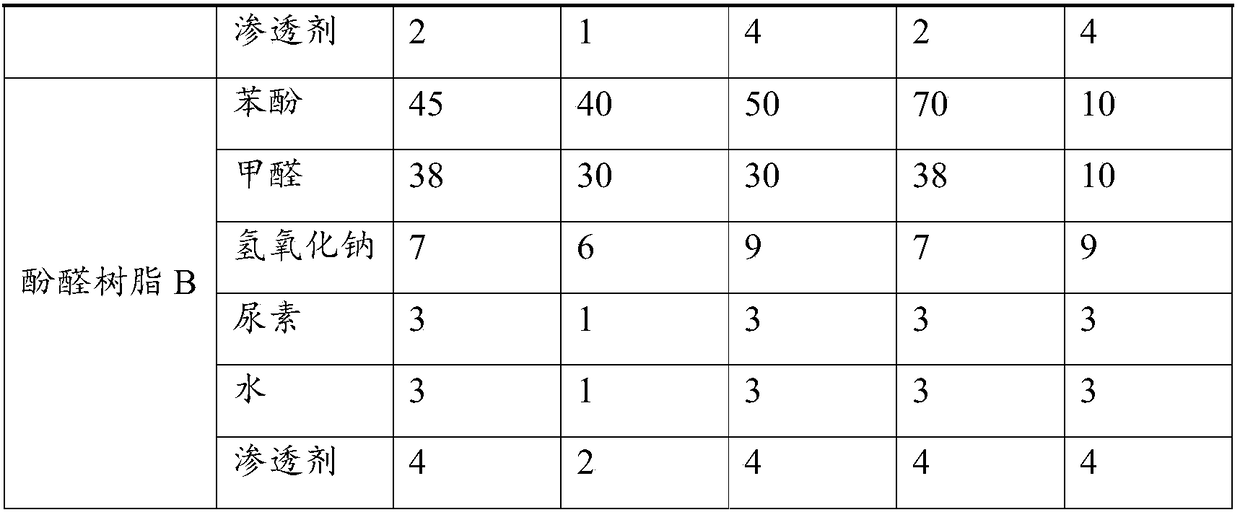

Novel ageing-resistant and combustion-resistant wood-based panel with immersion film paper veneer and preparation method thereof

ActiveCN105383115AReduce formaldehyde emissionGood aging resistance and flame resistanceLamination ancillary operationsSynthetic resin layered productsCombustionSquare decimeter

The present invention provides a novel ageing-resistant and combustion-resistant wood-based panel with an immersion film paper veneer and a preparation method thereof. The method comprises the following steps: (1) sequentially paving an adhesive film, a medium density decal, an adhesive film and a decorative sheet on a substrate layer and assembling; 2) after assembling is completed, placing in a thermocompressor for hot pressing, wherein the adhesive film is film paper which is obtained by soaking kraft paper with gram weight of 40-60 grams / square decimeter by using phenolic resin and then drying and molding, the adhesive dipping amount of the kraft paper is 180%-250%, the medium density decal is film paper which is obtained by soaking kraft paper with gram weight of 210-2400 grams / square decimeter by using phenolic resin, and the adhesive dipping amount of the kraft paper is 30%-35%; and 3) cropping and trimming an ageing-resistant and combustion-resistant decorative panel. The decorative panel provided by the present invention has low formaldehyde emission and good ageing-resistant and combustion-resistant properties.

Owner:DYNEA GUANGDONG

Electrochemical polishing method for bearing retainer

ActiveCN102995099AGood self-lubricating performanceEliminate chromatic aberrationElectrolysisSquare decimeter

The invention relates to an electrochemical polishing method for a bearing retainer. The electrochemical polishing method for the bearing retainer comprises the steps of: preparing, electrochemical polishing, electrolyte mixing, cleaning by using cold water, passivating, cleaning by using hot water, drying and rust preventing; the electrolyte is prepared from phosphoric acid, water and chromic anhydride in a volume ratio of 8:4:1; the temperature of the electrolyte is controlled to be below 40 DEG C; in the electrochemical polishing step, the current density is 35A / square decimeter, the working voltage is 8-10V, the distance between the negative pole of an electrochemical polishing machine and a processed workpiece is 5-10mm, and the electrochemical polishing time is 90s; the preparing step comprises the sub-steps of: preparing the electrolyte, adding the electrolyte in an electrolytic vessel, placing a lead plate in the electrolytic vessel, connecting the lead plate and the negative pole of the electrochemical polishing machine, and preparing the processed workpiece; and the step of preparing the processed workpiece comprises the following sub-steps of: performing oil removing and cleaning on the processed workpiece, cleaning by using hot water, cleaning by using cold water, hanging on a hanger, and connecting the processed workpiece with the positive pole of the electrochemical polishing machine. According to the electrochemical polishing method, the clamping as well as the material charging and discharging are convenient, the occupying area is small, the cost is low, the burr removing effect is good, the labor intensity is obviously reduced, and the time and the labor are saved.

Owner:DEQING TIANMA BEARING CO LTD

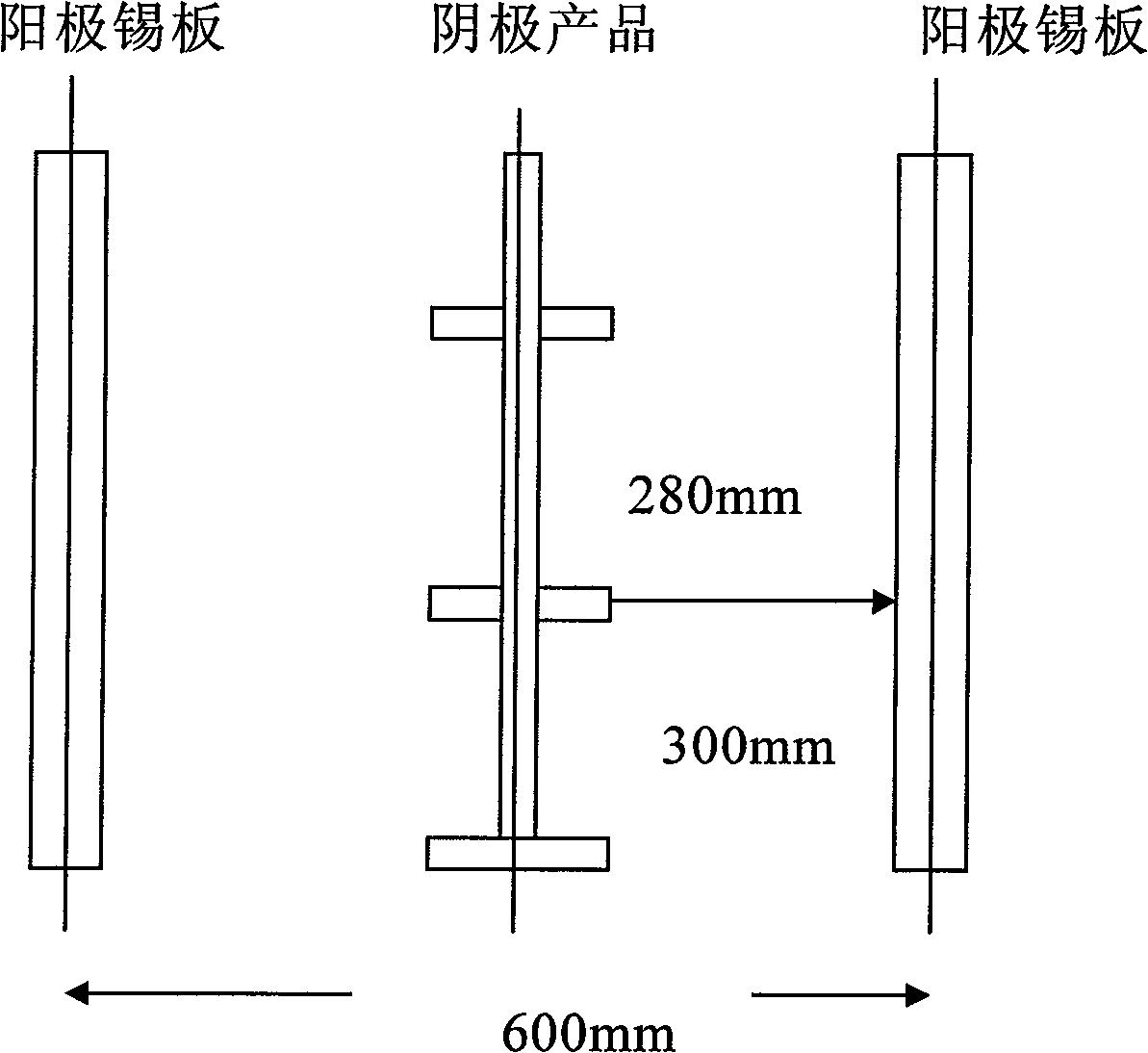

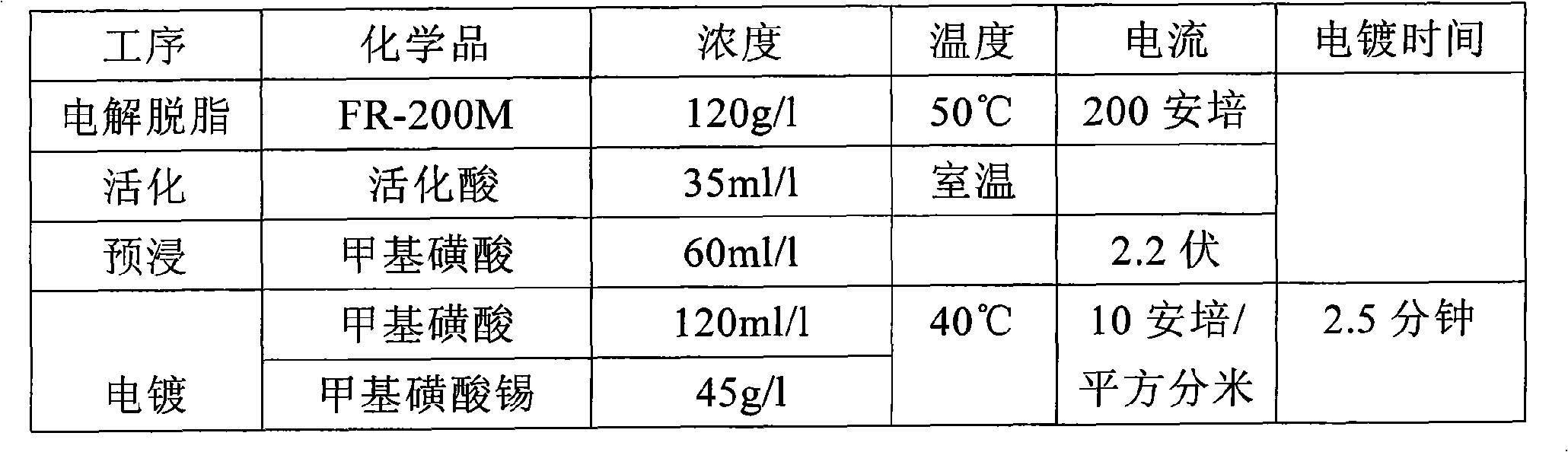

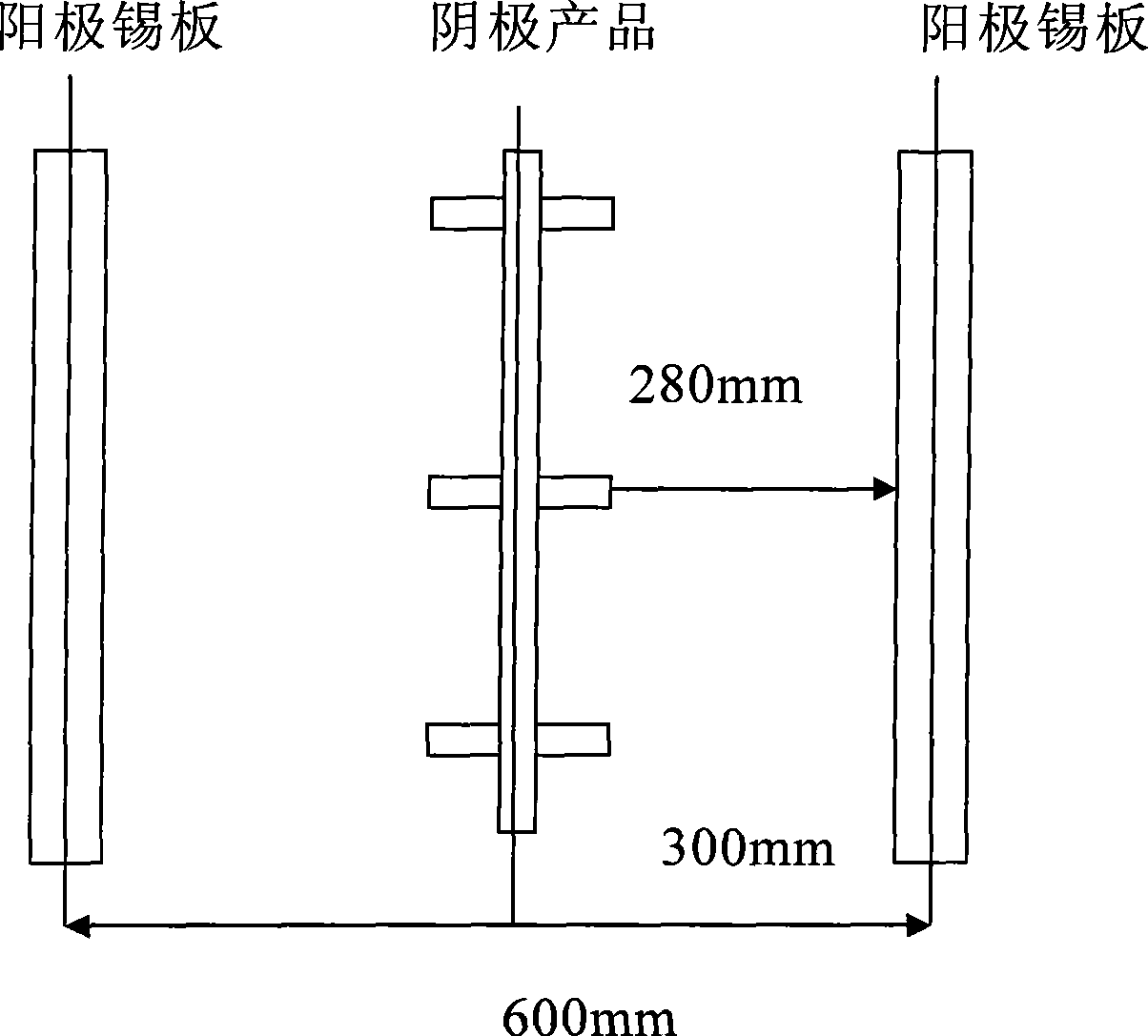

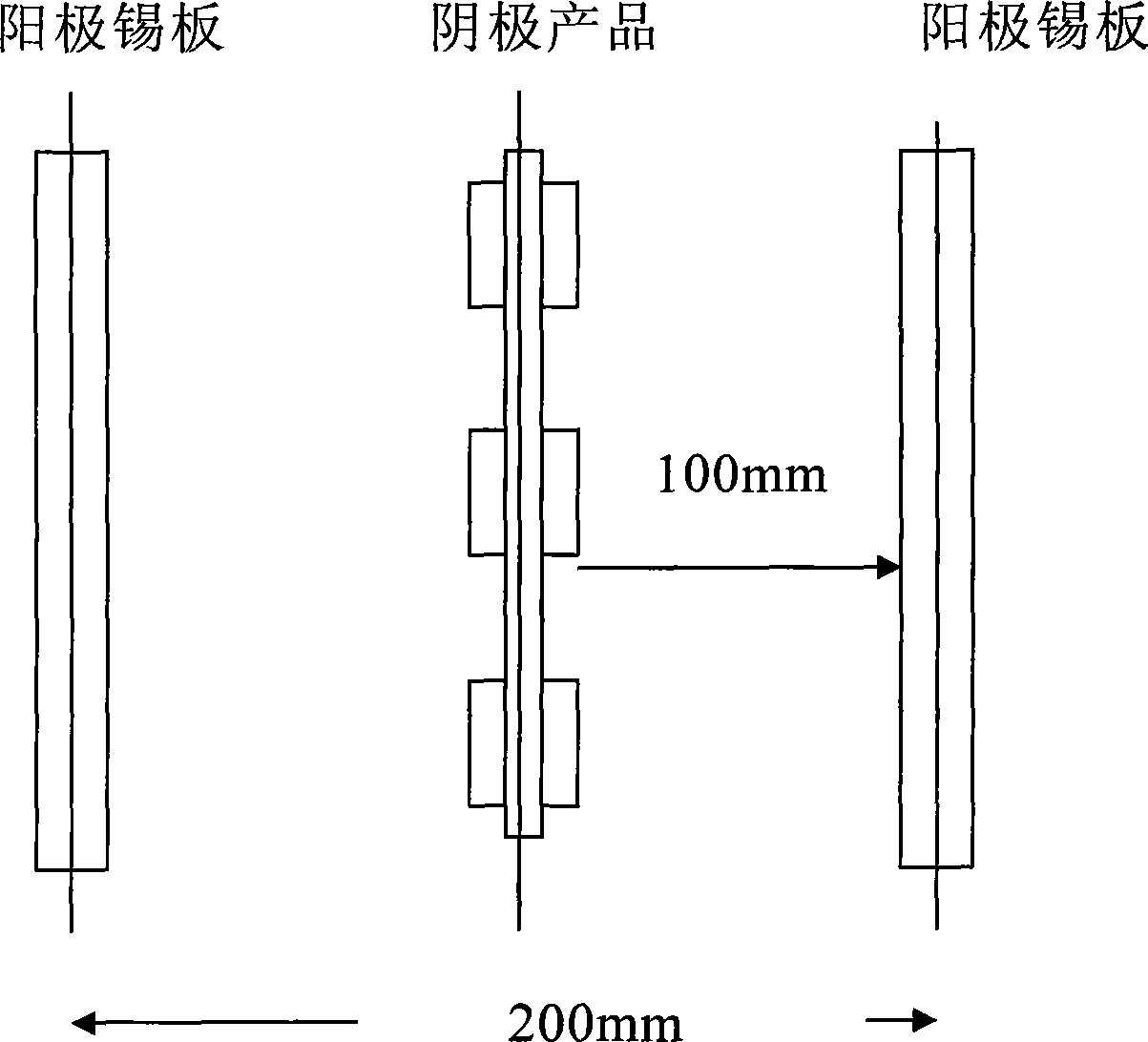

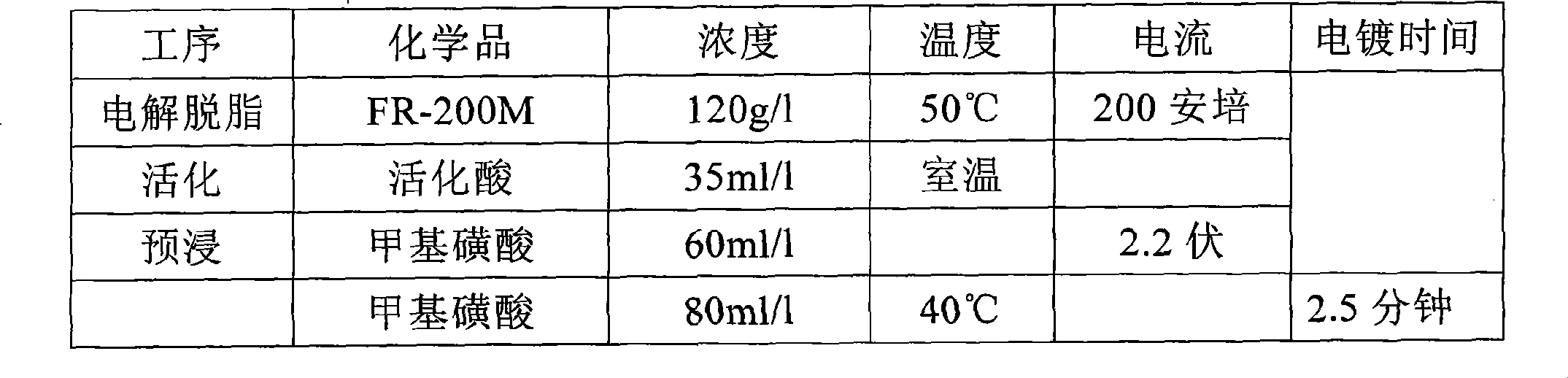

Method for electroplating metals of tin and bismuth

InactiveCN101538726AUniform thicknessEvenly distributed ingredientsSquare decimeterMethane sulfonate

The invention relates to a method for electroplating metals of tin and bismuth, which is characterized by comprising 40-80g / l of tin methane-sulfonate and 1-3g / l of bismuth methane-sulfonate in terms of volume mass ratio, and also comprising 100-280ml / l of methylsulfonic acid, 30-100ml / l of additive SNB31 produced by Dr. Ing Max Schlotter GmbH & Co. KG, 5-15ml / l of additive SNB14 produced by Dr. Ing Max Schlotter GmbH & Co. KG, and the balanced water in terms of volume ratio; and the electroplate liquid is used for electroplating for 1.5-2.5min with a current density of 10-20 ampere / square decimeter and at a temperature of 35-65 DEG C. The cathode plate of the plating tank containing the electroplate liquid is a conveying steel belt, and the distances between an electroplating part and two anode plates are the same. The tin and bismuth metal layers electroplated by the invention have uniform thickness and even distribution of bismuth, and tin and bismuth metal layers have good weldability.

Owner:WUXI WELNEW MICRO ELECTRONICS

Stainless steel electrochemical colouring method

This invention is a kind of electro-chemstry staining method of non-corrosive steel. Firstly, pre-treatment for the semi-manufactured non-corrosive steel is essential. Molybdate water solution of 5.0-200 g / L is filled in the electrolytic bath as staining solution, and then the semi-manufactured non-corrosive steel is put into the solution to be stained. The staining electricity should be controlled between 0.02A / square decimeter and 0.6A / square decimeter, while the staining time is between 10 seconds and 60 minutes. At the same time, the temperature should be controlled between 15deg.C and 60 deg.C. After stained, the semi-manufactured non-corrosive steel is water-scrubbed. Then through desiccation, we can get stained non-corrosive steel. To sum up, the staining solution in this invention has no toxicity, has little pollution and power cost, so it does no harm to the workers' health. The technology is easy, and the stained color is stable and has high authenticity. What's more, the cost of the solution is low. You can get multi-colored, homogeneous and highly brightened product.

Owner:SOUTH CHINA UNIV OF TECH

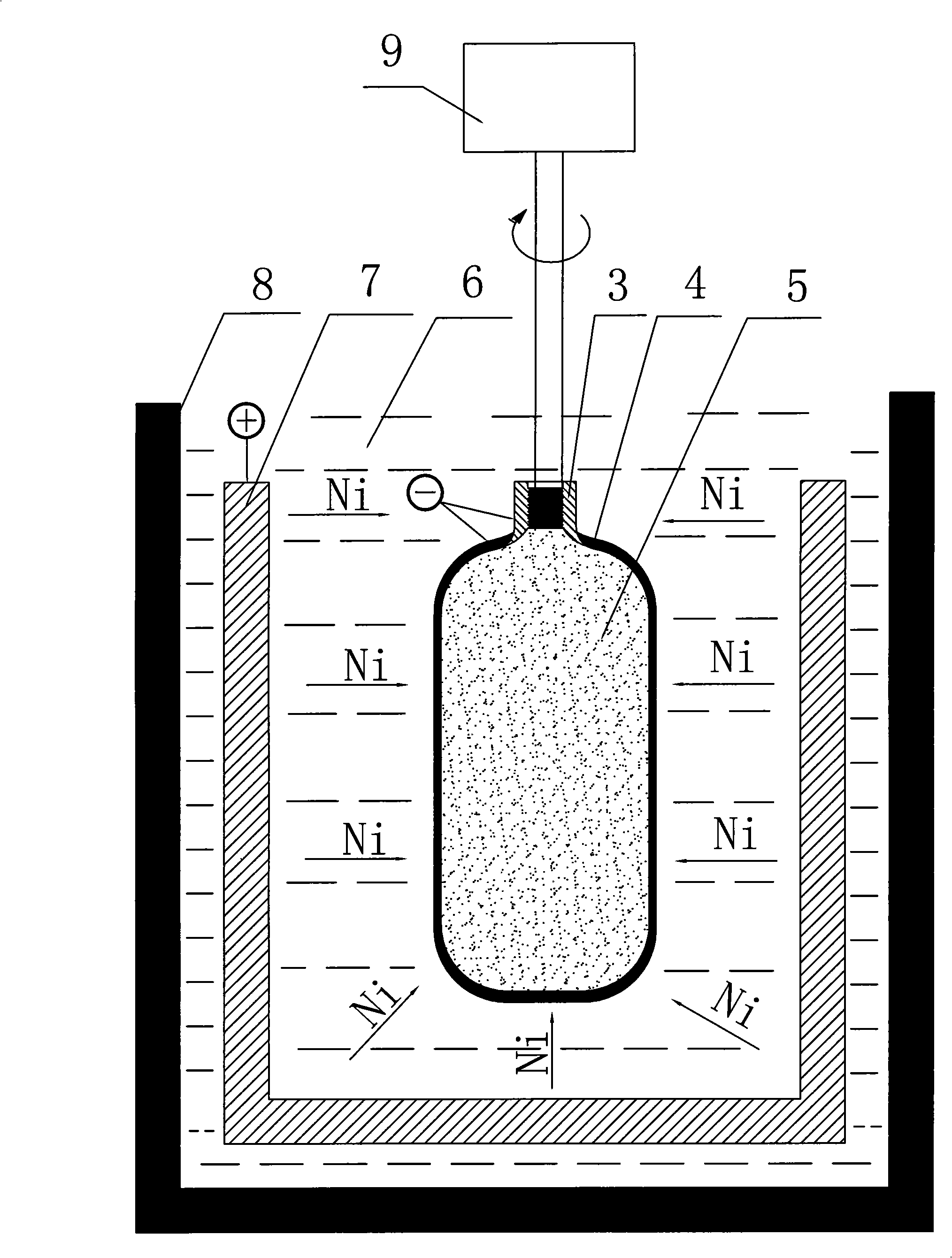

Method for manufacturing pressure container with metallic nickel electrocasting

InactiveCN101319338AEasy to manufactureReduce manufacturing costCompressed gas gunsPressure vesselsSquare decimeterAmpere

The invention relates to a method for manufacturing a pressure vessel by utilization of metal nickel electrotyping, comprising preparation of a mandrel, manufacturing and copying, and demoulding, wherein, the compositions of an electrodeposition cell solution used in the step of manufacturing and copying are 60 to 120 weight portions of nickel sulfamic acid, 10 to 40 weight portions of boric acid, 2 to 6 weight portions of sulfamic acid, 2 to 6 weight portions of nickel carbonate, 2 to 6 weight portions of nickel chlorite and 1,000 weight portions of water; and the operating conditions of the electrodeposition cell solution are as follows: the pH value is between 3.50 and 4.80; the operating temperature is between 45 and 70 DEG C; the operating voltage is between 12 and 15 volts direct current; and the current density is between 0.5 and 6.0 amperes per square decimeter. The method is simple and convenient in manufacturing, does not require a plurality of devices, saves the manufacturing cost, and then is more suitable for practical use.

Owner:武济群 +1

Aluminum profile anodizing method

InactiveCN103451702ANo peelingReasonable workmanshipSurface reaction electrolytic coatingSquare decimeterGlycerol

The invention discloses an aluminum profile anodizing method which comprises steps of oil removal, sand blasting, anodizing, water washing and drying, wherein the current density is increased step by step in the anodizing process. Further, treatment is performed at a current density of 1-1.5 Ampere / square decimeter for 3 minutes; then, treatment is performed at a current density of 2-2.5 Ampere / square decimeter for 5 minutes; and finally, treatment is performed at a current density of 3-3.5 Ampere / square decimeter for 3 minutes. Further, an electrolyte contains 100-200 gram / liter of sulfuric acid, 1-3 gram / liter oxalic acid, 1-5 gram / liter of glycolic acid and 10-20 gram / liter of glycerol; and the temperature of the electrolyte is 15-20 DEG C. Compared with the prior art, the process disclosed by the invention more reasonable; the product obtained through multi-stage anodizing has high weatherability; and customers reflect that no peeling phenomena occur in the use process, and the product is widely accepted on the market.

Owner:HENAN HUILONG ALUMINUM IND

Method of repair nickel coating no metal coated piece

The invention discloses a method to complement nickel-plating of metal plating component. It includes the following steps: cleaning the surface of metal plating component by common method; using HCL 250-400 g / L as electrical acid active electrical acid solution, impressing anode current at 2-4 A per square decimeter on the component, adopting nickel board as cathode and lasting for 1-3 minutes; using common method to complement nickel, cleaning, activating and plating chrome. The invention could make the component has good binding power, and it is simple technology.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

Method for electroplating tin-copper

A method for electroplating a tin copper metal layer is characterized in that the formulation of the electroplating liquid is: in terms of mass volume ratio, 30-80g / l of tin methyl sulphonate and 0.5-3g / l of copper methyl sulphonate; in terms of volume ratio, 50-250ml / l of methyl sulfoacid, 30-80ml / l of additive SNC21 (produced by Germany Schlotter), 50-200ml / l of additive SNC22 (produced by Germany Schlotter), 5-15ml / l of additive SNC23 (produced by Germany Schlotter), and the balance of water; the current density of the electroplating solution is 10-20 ampere / square decimeter, the temperature is 35-65 DEG C, and the electroplating period is 1.5-2.5min. The cathode board in the electroplating tank which contains the electroplating solution servers as a conveying steel band, and the electroplated item has equal or similar distance with the two anode boards. The tin copper metal layer prepared by the method has uniform thickness, evenly distributed copper component, and excellent weldability.

Owner:WUXI WELNEW MICRO ELECTRONICS

Thermal insulation aluminum profile with surface carved with patterns

ActiveCN103831183AImprove mechanical propertiesRealize normal temperature pouringAnodisationLiquid spraying plantsThermal insulationSquare decimeter

The invention relates to an aluminum profile, in particular to a thermal insulation aluminum profile with the surface carved with patterns. A manufacturing method of the thermal insulation aluminum profile with the surface carved with the patterns sequentially comprises the steps of preparation of a polyurethane thermal insulation glue component A and a polyurethane thermal insulation glue component B; manufacturing of the thermal insulation aluminum profile, wherein the component A and the component B are stirred according to the mass ratio of (6-8):1, then are poured into an aluminum profile groove moving at a speed of 0.15-0.2m / s and form the thermal insulation aluminum profile after standing and being cooled and solidified; preparation of modified powder coatings, wherein the mixture melts and is extruded out at the temperature of 130-140 DEG C, and then is cooled and broken to obtain the modified powder coatings; electrostatic spraying and solidification at the temperature of 100-120 DEG C for 10-18min; curving processing, wherein the patterns are carved in the curved surface and colored for the first time, particularly, hard anodizing is carried out in an electrolyte with the electric current density being 4-5 amperes per square decimeter and the temperature being 22-28 DEG C, and the electrolyte contains vitriol, acetic acid and a mixed solution formed by mixing glycolic acid and succinic acid according to the mole ratio of 1:1; the patterns are colored for the second time. The thermal insulation aluminum profile with the surface carved with the patterns has the dustproof and antibacterial performance, and is good in impact resistance, abrasion resistance and weather resistance, and high in glossiness.

Owner:南通旺鑫新材料有限公司

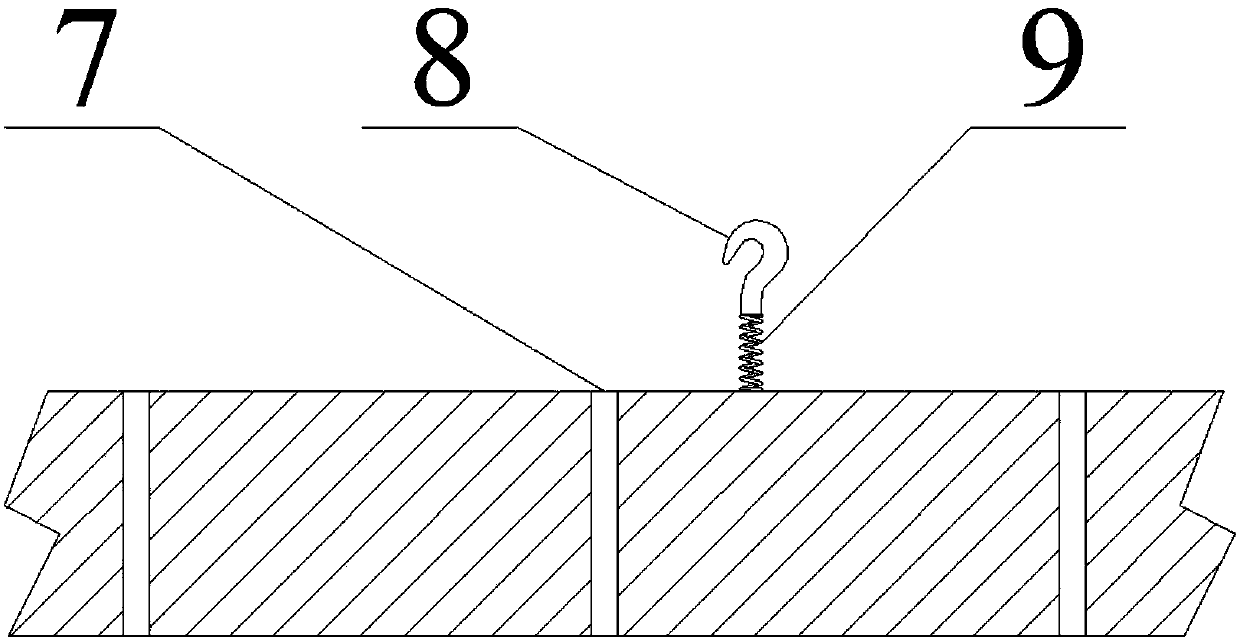

Heat-insulation and compression-resisting plate

InactiveCN104228278AOvercome the illsInsulation hasThermal insulationLayered productsInsulation layerThermal insulation

The invention provides a heat-insulation and compression-resisting plate, relates to a heat insulation part on a plate vulcanizing machine and provides technology improvement aiming at the defects that an existing heat-insulation is poor, compression-resisting force is not enough and the service life is short. The heat-insulation and compression-resisting plate comprises a frame body, wherein an upper compression-resisting plate is mounted on the upper plane of the frame body and a lower compression-resisting plate is mounted on the lower plane of the frame body; one to nine glass columns for supporting are distributed between the upper compression-resisting plate and the lower compression-resisting plate in every square decimeter; heat-prevention and heat-insulation layers are arranged in residual space; the lower compression-resisting plate is provided with thread holes and cushions are mounted in the thread holes; one ends of the glass columns are inserted into the cushions and the other ends of the glass columns are inserted into holes in the upper compression-resisting plate; pressing covers are arranged at the upper parts of the holes in the upper compression-resisting plate; mounting holes are formed in the upper compression-resisting plate; and nuts are fixedly arranged at the bottoms of the mounting holes. Compared with the prior art, the heat-insulation and compression-resisting plate has the advantages of heat insulation, compression resistance, long service life and convenience for installation.

Owner:铁岭奇点节能电气科技有限公司

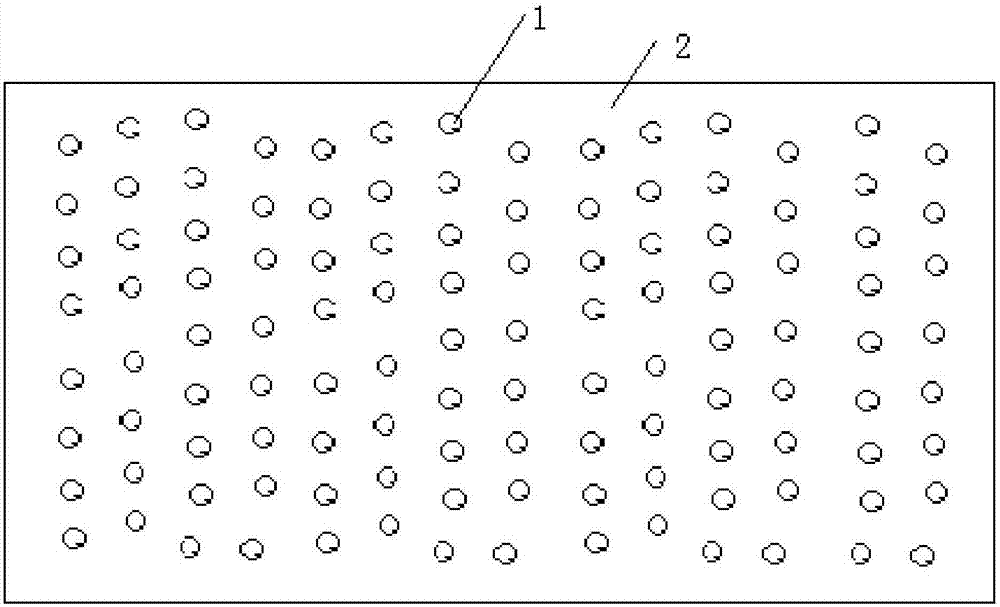

Fa ade landscape lawn cultivation, installation and maintenance method

ActiveCN107548900AReduce weightSuitable for hangingHops/wine cultivationGrowth substratesFiberHigh density

The invention discloses a fa ade landscape lawn cultivation, installation and maintenance method. The method includes the following steps that a fibrous material is selected to make a floppy substrateboard; a reinforcing net made of rigid wires is inserted into the substrate; grass seeds are planted into the substrate board, wherein the planting density is 196-256 seeds per square decimeter; rigid plastic boards are used as rims to form frames, a plurality of hooks extending into the frames are arranged on the rims, a plurality of water seepage holes are formed in the rims, and the water seepage holes in every two adjacent frames are in the corresponding positions; high-density sponges are placed under lawn pieces and placed in the frames together with the lawn pieces, the lawn pieces hook the rigid wires with the diameters of 4-5 mm for fixing through the frame hooks to form a unit, and a plurality of the units fixedly form a fa ade landscape lawn through screws; spraying devices areinstalled in the highest positions above the fa ade landscape lawn, and spraying points aim at the water seepage holes; water is sprayed 0-2 times every day, and a maintenance liquid is sprayed onceevery 3-15 days.

Owner:镇江润祥农业科技有限公司

Bandage cloth with physiotherapy effect and preparation method thereof

InactiveCN107115552APromote circulationRealize the effect of massageRoller massageAbsorbent padsSelf-healingSquare decimeter

The invention discloses bandage cloth with a physiotherapy effect and a preparation method. Elastic particles for massage are uniformly bonded on one side of elastic cloth; the distribution density of the elastic particles is 60-120 per square decimeter; the elastic cloth is plain woven cloth or knitted cloth; the elastic ratio of the elastic cloth is (1:1.2)-(1:3.5); the diameter of the elastic particle is 1-2.5mm; the elastic particle is a styrene-isoprene block copolymer; the elastic particles are uniformly fixed on one side of the elastic cloth through an adhesive. The elastic particles are bonded on one side of the elastic cloth; when in use, the elastic particles on the surface of the elastic cloth stimulate local skin and subcutaneous tissues, the blood circulation and the lymph circulation are promoted, the self-healing ability of the body is enhanced, and an effect of rehabilitation physiotherapy is realized. The adopted elastic particles are soft and light, obvious foreign body sensation is avoided, and excellent comfort is realized.

Owner:SUZHOU MEDSPORT PROD

Novel agricultural plastic film

InactiveCN103650998ASimple structureHigh tensile strengthClimate change adaptationSynthetic resin layered productsFiberSquare decimeter

The invention discloses a novel agricultural plastic film which comprises an upper plastic film layer, a lower plastic film layer and a reinforcing layer arranged between the upper plastic film layer and the lower plastic film layer. The reinforcing layer is latticed and comprises multiple first reinforcing fibers parallel to one another and multiple second reinforcing fibers parallel to one another arranged with the first reinforcing fibers at an angle, multiple lattices are formed among the first reinforcing fibers and the second reinforcing fibers, and the area of the lattice is more than or equal to 0.5 square decimeters. By the means, the novel agricultural plastic film is simple and reasonable in structure, and has high tensile strength and good light transmittance performance.

Owner:CHANGZHOU HEXIANG PLASTIC

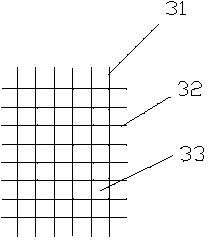

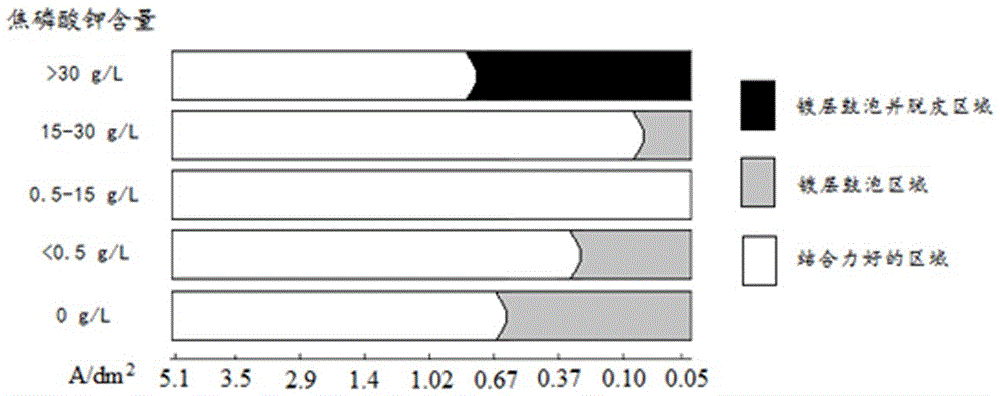

Cyanide-free copper-plated electroplating solution suitable for wide pH range and wide current density range and preparation method for cyanide-free copper-plated electroplating solution

ActiveCN106521574ASolve problems such as narrow pH rangeImprove deep plating abilityCopper platingSquare decimeter

The invention provides a cyanide-free copper-plated electroplating solution suitable for a wide pH range and a wide current density range. The cyanide-free copper-plated electroplating solution comprises amino methylene diphosphonic acid (AMDP) with concentration being 20-90g / L, inositol hexaphosphoric acid (PA) or phytic acid sodium salt hydrate with concentration being 10-70g / L, pyrophosphate with concentration being 0.5-15g / L, and copper salt with concentration being 3-25g / L. The cyanide-free copper-plated electroplating solution provided by the invention has an applicable pH range of 6-13.5, an applicable current density range of 0.2-4 amperes / square decimeter, is simple in formula, is non-toxic, is free of cyanide pollution; and copper is directly plated on iron substrate, a magnesium alloy, zinc or zinc alloy matrix and zinc-immersed aluminum, so that the obtained copper plating is excellent in binding force with the matrix.

Owner:ZHEJIANG UNIV OF TECH

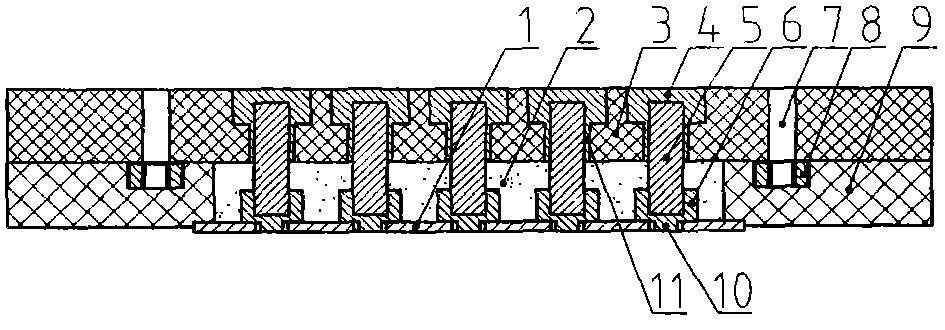

Crucible for growing polysilicon ingot

InactiveCN101597793BGood orientationIncrease percentagePolycrystalline material growthSingle crystal growth detailsSquare decimeterCrucible

The invention relates to a crucible for growing silicon ingot in the field of solar energy, in particular to a crucible for growing polysilicon ingot. The crucible for growing the polysilicon ingot is characterized in that: a bottom plate 2 of the crucible is provided with a plurality of holes 3; and the depth of the holes 3 is 1 to 25 mm, the aperture of the level part of the holes 3 and the bottom plate 2 of the crucible is 1 to 30 mm, and the distributed density of the holes 3 and the bottom plate 2 of the crucible is 1 to 100 per square decimeter. By adopting the crucible for growing the polysilicon ingot to grow polysilicon ingot, the directionality of crystal grains of the polysilicon ingot can be remarkably improved, crystal grains of the polysilicon ingot predominate in <110> and <112> crystal orientation, multiple parallel twins boundaries caused by <111> crystal face are reduced, the number of crystal boundaries is reduced, and simultaneously the percentage of sigma 3 shallow energy level crystal boundary is improved so as to effectively prolong the minority carrier lifetime of a silicon chip, and the conversion efficiency of solar cells made of the silicon chip is improved.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Surface hardening treatment process for aluminum alloy tableware

InactiveCN106400080AHigh surface hardnessIncreasing the thicknessAnodisationSquare decimeterWork in process

The invention relates to a surface hardening treatment process for aluminum alloy tableware. The surface hardening treatment process comprises the following steps of a, adding sulfur acid into purified water, and uniformly stirring to form an anodic oxidation solution containing 160 g-180 g of sulfur acid in every one liter of purified water; pouring the prepared anodic oxidation solution into an anodic oxidation tank, and controlling the temperature of the anodic oxidation solution at -2 DEG C--3 DEG C; placing a semi-finished product of the aluminum alloy tableware into the anodic oxidation tank, switching on a working power supply for the anodic oxidation tank, correspondingly connecting 3 A -4 A working current to every one square decimeter of total surface area of the semi-finished product of the aluminum alloy tableware, and controlling the anodic oxidation time to be within 70 min-75 min; and ending the anodic oxidation time to obtain the aluminum alloy tableware. By using the treatment process disclosed by the invention, the surface hardness of the tableware is greatly increased and can be increased to HV500-HV600, the thickness of an oxidation layer is increased, and surface scratch is not likely to be caused during use; and the treatment process disclosed by the invention is simple in step and convenient to operate.

Owner:SAN NENG BAKE WARE WUXI

Surface-carved thermally-insulating aluminum profile

InactiveCN109836805AImprove mechanical propertiesRealize normal temperature pouringAnodisationAntifouling/underwater paintsSquare decimeterAmpere

The invention relates to an aluminum profile, especially to a surface-carved thermally-insulating aluminum profile, which is successively prepared from the following steps: preparation of a componentA and a component B of a polyurethane heat-insulation adhesive; preparation of thermally-insulating aluminum profile: stirring the component A and the component B according to the mass ratio of 6-8:1and pouring into an aluminium profile groove moving at the speed of 0.15-0.2 m / s, standing, cooling and solidifying to form the thermally-insulating aluminum profile; preparation of modified powder coating: carrying out melt extrusion at 130-140 DEG C, cooling and crushing to obtain the modified powder coating; carrying out electrostatic spraying, and solidifying at 100-120 DEG C for 10-18 min; carving treatment: carving on the carved surface; first coloring: hard anodic oxidation is carried out in an electrolyte with the electric current density of 4-5 amperes / square decimeters and the temperature of 22-28 DEG C, and the electrolyte contains sulfuric acid, acetic acid, and mixed liquor mixed by glycolic acid and succinic acid at the molar ratio of 1:1; and second coloring. The product ofthe invention has dustproof and antibacterial properties, impact resistance, wear resistance, good weatherability and high glossiness.

Owner:宜昌益烟机械设备有限公司

A surface-carved heat-insulating aluminum profile

ActiveCN103831183BImprove mechanical propertiesRealize normal temperature pouringAnodisationLiquid spraying plantsThermal insulationSquare decimeter

Owner:南通旺鑫新材料有限公司

Regenerative wall of organic exhaust gas regenerative thermal incinerator

InactiveCN106678837AIncreased turbulenceAvoid short circuitIncinerator apparatusBrickSquare decimeter

The invention relates to a regenerative wall of an organic exhaust gas regenerative thermal incinerator. The regenerative wall is composed of regenerative bricks; each regenerative brick comprises a cuboid brick body; through holes which are cone frustum holes are uniformly formed in the obverse side of the brick body; and 5-6 through holes are formed in every square decimeter of the obverse side of the brick body. The amount of the holes formed in the unit area of the brick body is reasonable, and exhaust gases are kept to be in contact with a high-temperature region of a furnace hearth, so that the incineration effect is improved.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

Method for acidic copper plating of hardware

InactiveCN108330519AIncrease copper plating speedQuick fill levelCellsCopper platingSquare decimeter

The invention discloses a method for acidic copper plating of hardware. The copper plating comprises of, by mass, 250g / L of copper sulfate, 70g / L of sulfuric acid, and 35mg / L of chloride ion; the copper plating comprises of, by concentration volume, 7.5ml / L of BFJ-210M[um], 0.8ml / L of BFJ-210A, and 0.8ml / L of BFJ-210B; and the copper plating comprises of, by electric current density, 6A / dm<2> of cathode, and 5A / dm<2> of anode. Plating solution is prepared and the method includes the steps that 1, 1 / 2 volume of distilled water is added to a cylinder to be used; 2, the calculated amount of copper sulfate is added to the cylinder to be used; 3, activated carbon solution is added to the cylinder to be used, and the solution concentration is 2g / L; and 4, the calculated amount of sulfuric acid is added to a plating bath. The method for the acidic copper plating of the hardware realizes rapid brightening and has excellent filling degree, and high filling degree can be obtained even in the lowelectric current density region; and the deposition speed is high, at 4.5 amperes per square decimeter of the electric current density, a 1 micron copper layer can be plated per minute, and thereforethe plating time is shortened, thereby greatly increasing the copper plating speed of the hardware.

Owner:FOSHAN JIEYA PLASTIC HARDWARE PROD CO LTD

Anti-aging and flame-resistant wood-based panel with impregnated film paper finish and preparation method thereof

ActiveCN105383115BReduce formaldehyde emissionGood aging resistance and flame resistanceLamination ancillary operationsSynthetic resin layered productsCombustionMedium density

The present invention provides a novel ageing-resistant and combustion-resistant wood-based panel with an immersion film paper veneer and a preparation method thereof. The method comprises the following steps: (1) sequentially paving an adhesive film, a medium density decal, an adhesive film and a decorative sheet on a substrate layer and assembling; 2) after assembling is completed, placing in a thermocompressor for hot pressing, wherein the adhesive film is film paper which is obtained by soaking kraft paper with gram weight of 40-60 grams / square decimeter by using phenolic resin and then drying and molding, the adhesive dipping amount of the kraft paper is 180%-250%, the medium density decal is film paper which is obtained by soaking kraft paper with gram weight of 210-2400 grams / square decimeter by using phenolic resin, and the adhesive dipping amount of the kraft paper is 30%-35%; and 3) cropping and trimming an ageing-resistant and combustion-resistant decorative panel. The decorative panel provided by the present invention has low formaldehyde emission and good ageing-resistant and combustion-resistant properties.

Owner:DYNEA GUANGDONG

Method for catalytic oxidation treatment of anisole waste water

InactiveCN1232449CTo achieve the purpose of preprocessingDirect dischargeWater/sewage treatment using germicide/oligodynamic-processMetal/metal-oxides/metal-hydroxide catalystsChlorine dioxideSquare decimeter

The invention relates to industrial waste water treatment, in particular to a chlorine dioxide-electroheterogeneous catalytic oxidation method for treating anisole waste water. Firstly, anisole is subjected to chlorine dioxide catalytic oxidation treatment, and in the presence of a catalyst, it is treated for 10 to 60 minutes to remove most of the organic matter; after the chlorine dioxide catalytic oxidation treatment, in the presence of a catalyst, the electro-multiphase Catalytic oxidation treatment, in the electric field, the DC voltage between the electrodes is 5-15V, and the current density is 200mA-400mA per square decimeter under the external electric field, so that the organic pollutants in the anisole wastewater are catalyzed and oxidized on the surface of the catalyst. The experimental results show that the combined technology can directly meet the discharge standard for the treatment of anisole wastewater, and the operating cost is low.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Volvaria sheet

PendingCN109315229AImprove water retentionImprove hydrophobicityCultivating equipmentsMushroom cultivationSquare decimeterEngineering

The invention relates to a volvaria sheet which comprises a volvaria body. At least one side face of the volvaria body is provided with first protrusions, second protrusions and third protrusions which are evenly arranged approximately and are of different heights; the distribution density of the first, second and third protrusions is 300-400 / square decimeter. According to the volvaria sheet, bymeans of the lotus effect, at least one side face of the volvaria body is evenly provided with the first, second and third protrusions of different heights, and the resistance of the volvaria sheet for water drops condensed on the surface can be improved, so that resisted large water drops can be reserved on the volvaria sheet, and the volvaria sheet has the good water retention; meanwhile, the resisted small water drops can slide down into a culture bottle at the bottom of the volvaria sheet, the hydrophobicity of the volvaria sheet can be improved, and then a molding cavity can provide the growth environment suitable for needle mushroom growth.

Owner:HEBEI ZHONGER MUSHROOM PLASTIC PACKAGE CO LTD

Anode oxidation method

The invention provides an anode oxidation method which comprises the following steps: under the anode oxidation condition, putting light metal material in electrolyte, using the light metal material as an anode, using the conducting material which does not react with the electrolyte as a cathode, and enabling the cathode and the anode to be respectively electrically connected with a positive electrode and a negative electrode of a power source. The anode oxidation comprises constant current density anode oxidation and constant voltage anode oxidation, wherein the current density of the constant current density anode oxidation is 0.5 to 6 amperes / square decimeter, and the voltage of the constant voltage anode oxidation is 20 to 400 volts. Compared with the light metal material which is processed by the prior anode oxidation method, the corrosion resistance of the light metal material which is processed by the anode oxidation method of the invention is greatly improved, and even the light metal material which is processed by the anode oxidation method of the invention is not post-processed by plugging, the corrosion resistance of the light metal material is also stronger.

Owner:HANGZHOU WIN WIN TECH CO LTD

Electrolytic Polishing Method for Bearing Cage

ActiveCN102995099BGood self-lubricating performanceEliminate chromatic aberrationElectrolysisPower flow

The invention relates to an electrochemical polishing method for a bearing retainer. The electrochemical polishing method for the bearing retainer comprises the steps of: preparing, electrochemical polishing, electrolyte mixing, cleaning by using cold water, passivating, cleaning by using hot water, drying and rust preventing; the electrolyte is prepared from phosphoric acid, water and chromic anhydride in a volume ratio of 8:4:1; the temperature of the electrolyte is controlled to be below 40 DEG C; in the electrochemical polishing step, the current density is 35A / square decimeter, the working voltage is 8-10V, the distance between the negative pole of an electrochemical polishing machine and a processed workpiece is 5-10mm, and the electrochemical polishing time is 90s; the preparing step comprises the sub-steps of: preparing the electrolyte, adding the electrolyte in an electrolytic vessel, placing a lead plate in the electrolytic vessel, connecting the lead plate and the negative pole of the electrochemical polishing machine, and preparing the processed workpiece; and the step of preparing the processed workpiece comprises the following sub-steps of: performing oil removing and cleaning on the processed workpiece, cleaning by using hot water, cleaning by using cold water, hanging on a hanger, and connecting the processed workpiece with the positive pole of the electrochemical polishing machine. According to the electrochemical polishing method, the clamping as well as the material charging and discharging are convenient, the occupying area is small, the cost is low, the burr removing effect is good, the labor intensity is obviously reduced, and the time and the labor are saved.

Owner:DEQING TIANMA BEARING CO LTD

Pyrolyzation-separation heating furnace for inorganic matter and petroleum mixture

The invention discloses a pyrolyzation-separation heating furnace for an inorganic matter and petroleum mixture. The pyrolyzation-separation heating furnace for the inorganic matter and petroleum mixture comprises a boiler body 1, and is characterized by further comprising heating bodies 2, wherein the heating bodies 2 are U-shaped heating bodies, one ends of the heating bodies 2 are each fixedlyconnected to and perpendicular to the inner wall of the boiler body 1, and the distribution density of the heating bodies 2 is two to four per square decimeter. The pyrolyzation-separation heating furnace for the inorganic matter and petroleum mixture has the beneficial effects that the device is rapid in heating, and materials in the boiler can be heated integrally; a heating mode from outside toinside of a burning and roasting mode in the background technology is abandoned; and the heating mode of the pyrolyzation-separation heating furnace for the inorganic matter and petroleum mixture isuniform in heating effect, so that generation of thick smoke from burning and scorching is avoided.

Owner:江苏国瑞特环保工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com