Crucible for growing polysilicon ingot

A technology for growing polycrystals and crucibles, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of low conversion efficiency of solar cells, poor directional impurity removal effect, low minority carrier life, etc., to reduce the grain boundary The effect of increasing the number and conversion efficiency and increasing the minority carrier lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

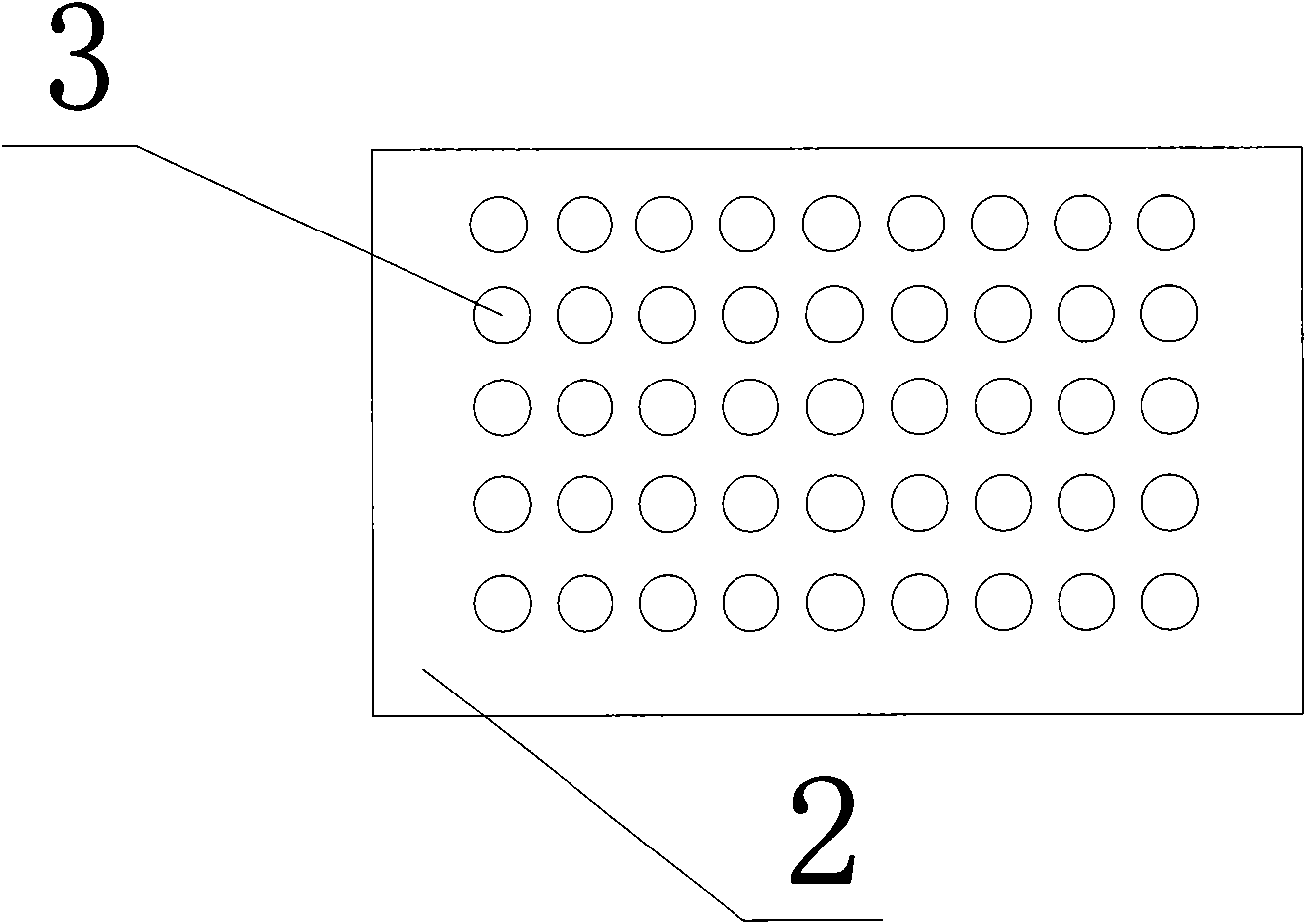

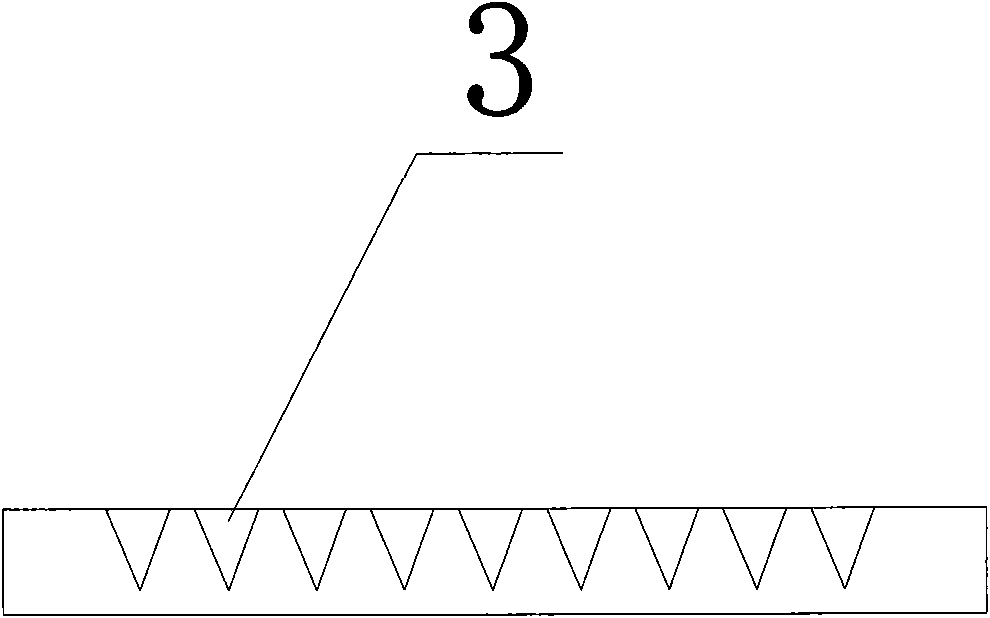

[0041] Embodiment 1. A crucible for growing polycrystalline silicon ingots, wherein: a bottom plate 2 of the crucible is provided with a plurality of holes 3 .

Embodiment 2

[0042] Embodiment 2. A crucible for growing polycrystalline silicon ingots, wherein: the depth of the hole 3 is 0.1 mm. All the other are with embodiment 1.

Embodiment 3

[0043] Embodiment 3. A crucible for growing polycrystalline silicon ingots, wherein the depth of the hole 3 is 0.5. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com