Regenerative wall of organic exhaust gas regenerative thermal incinerator

A thermal incinerator and organic waste gas technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of short circuit of exhaust gas, general incineration effect of furnace, failure to ensure high temperature area of exhaust gas, etc., and achieve the goal of improving turbulence and preventing short circuit of furnace Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

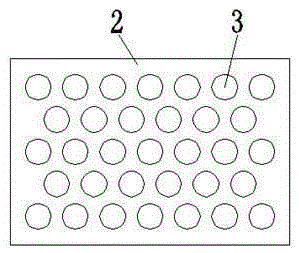

[0013] Such as figure 1 with figure 2 As shown, the organic waste gas regenerative thermal incinerator heat storage wall of the present invention is composed of heat storage bricks 1, and the heat storage bricks 1 include a brick body 2, and the brick body 2 is a cuboid. The front of the brick body 2 is evenly provided with through holes 3, and the through holes 3 are frustoconical holes, and 5-6 through holes 3 are arranged on each square decimeter of the front of the brick body 2; The size is 300mm×200mm, and a total of 33 through holes 3 are evenly arranged on the front of the brick body 2 of 300mm×200mm; the maximum hole diameter of a single through hole 3 is 27.5mm, and the minimum hole diameter is 25mm; the brick body 2 The thickness is 150mm; the brick body 2 is a high alumina brick body. The invention consists of heat storage bricks to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com