Anti-aging and flame-resistant wood-based panel with impregnated film paper finish and preparation method thereof

An anti-aging, membrane paper technology, applied in chemical instruments and methods, paper/cardboard layered products, wood layered products, etc., can solve the aging problem of decorative boards and poor flame resistance, high formaldehyde emission of decorative boards, Toxic gas pollutes the environment and other problems to achieve the effect of omitting gluing equipment, reducing gluing process links, and increasing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

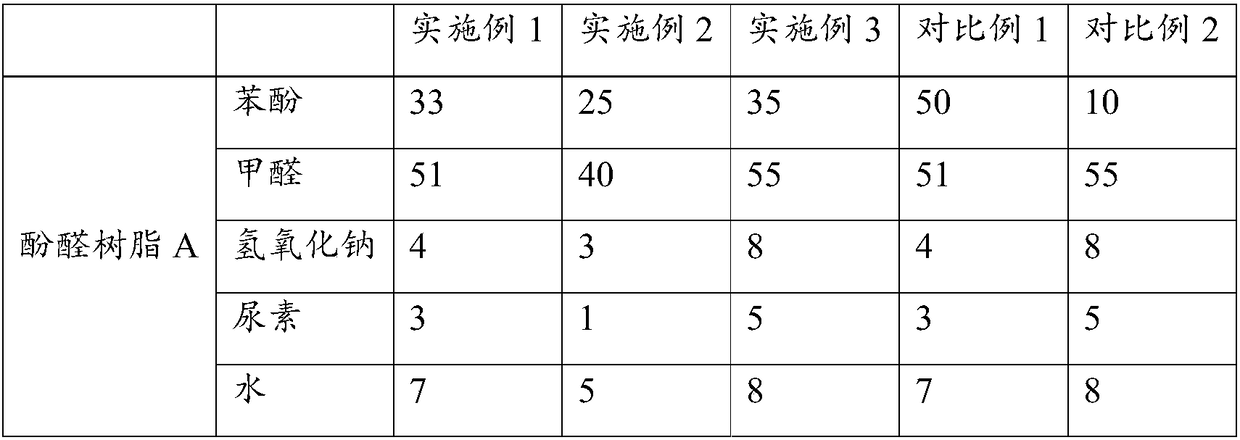

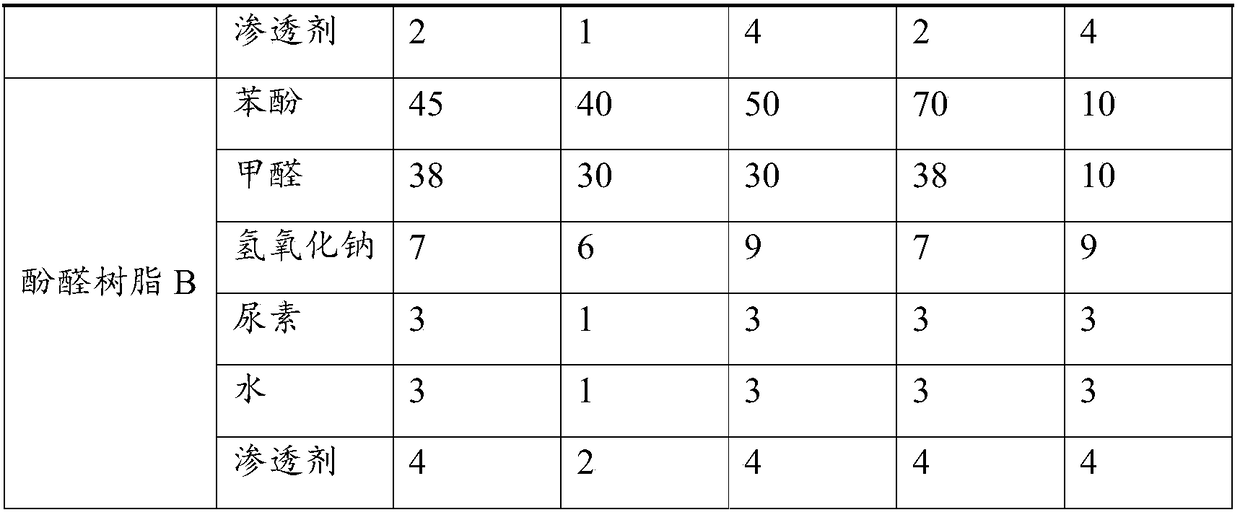

Embodiment 1-3 and comparative example 1-2

[0038] A method for preparing an anti-aging and flame-resistant decorative board with impregnated film paper finish,

[0039] Step 1) Laying adhesive film, medium-density stickers, adhesive film and decorative plates on the substrate layer in sequence to form a blank;

[0040] Step 2) After the blank assembly is completed, put it into a hot press machine for hot pressing. The conditions for hot pressing are: the hot pressing temperature is 130-150°C, the hot pressing time is 5 minutes to 7 minutes, and the hot pressing pressure is 12- 15 kg / cm²;

[0041] The adhesive film is made of kraft paper with a gram weight of 40-60 g / dm2 after being impregnated with phenolic resin, and then dried and formed. The amount of kraft paper impregnated with glue is 180%-250%;

[0042] The medium-density sticker is made of kraft paper with a gram weight of 210-240 grams per square decimeter, which is impregnated with phenolic resin and dried to form a membrane paper. The amount of kraft paper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com