Method for treating naphthenic acid sewage by flocculation-electricity heterogeneous catalysis

A heterogeneous catalysis, naphthenic acid technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , the effect is not ideal and other problems, to achieve the effect of low operating cost, easy operation and simple dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

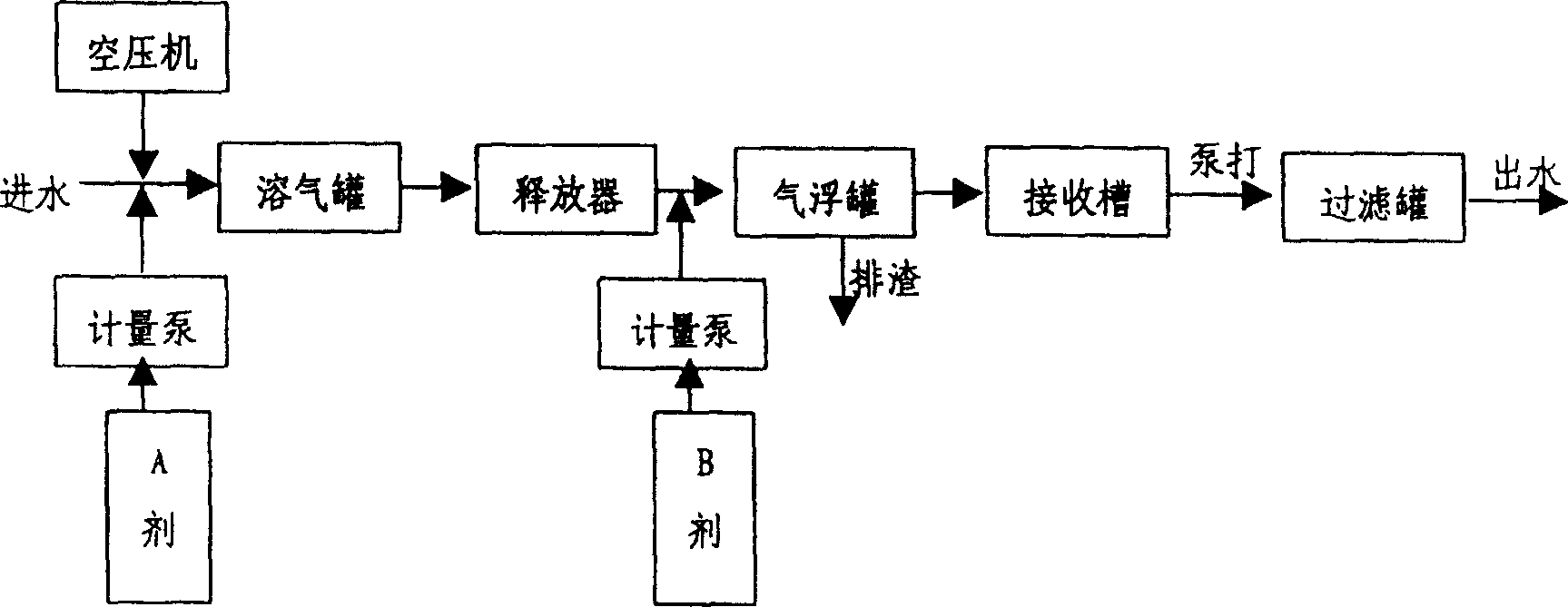

Image

Examples

Embodiment 1

[0026] Effect of Polyaluminum Chloride on Naphthenic Acid Wastewater Treatment I

[0027] Treatment of naphthenic acid wastewater with polyaluminum chloride and anionic polyacrylamide. COD Cr The water quality chemical oxygen demand was determined by the dichromate method (GB11914-89) for analysis, the same below.

[0028] Raw water COD Cr : 1952.6mg / L, pH: 6, the flocculation results are shown in Table 1.

[0029] aggregation

[0030] * The molecular weight of the coagulant used is above 14 million

Embodiment 2

[0032] Effect of Polyaluminum Chloride on Naphthenic Acid Wastewater Treatment II

[0033] Treatment of naphthenic acid wastewater with polyaluminum chloride and cationic polyacrylamide.

[0034] Raw water COD Cr : 1952.6mg / L, pH: 6, the experimental results are shown in Table 2.

[0035] aggregation

[0036] * The molecular weight of the coagulant used is about 5 million

Embodiment 3

[0038] Effect of Polymerized Ferric Sulfate on Naphthenic Acid Wastewater Treatment I

[0039] Naphthenic acid wastewater was treated with polyferric sulfate and anionic polyacrylamide.

[0040] Raw water COD Cr : 1860.1mg / L, pH: 6, the reaction results are shown in Table 3.

[0041] aggregation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com