Method for manufacturing pressure container with metallic nickel electrocasting

A pressure vessel and electroforming technology, applied in the field of manufacturing vessels, can solve the problems of no manufacturing method, complicated inner tank processing, low work efficiency, etc., and achieve the effects of light weight, large randomness of shape and specification changes, and simple and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

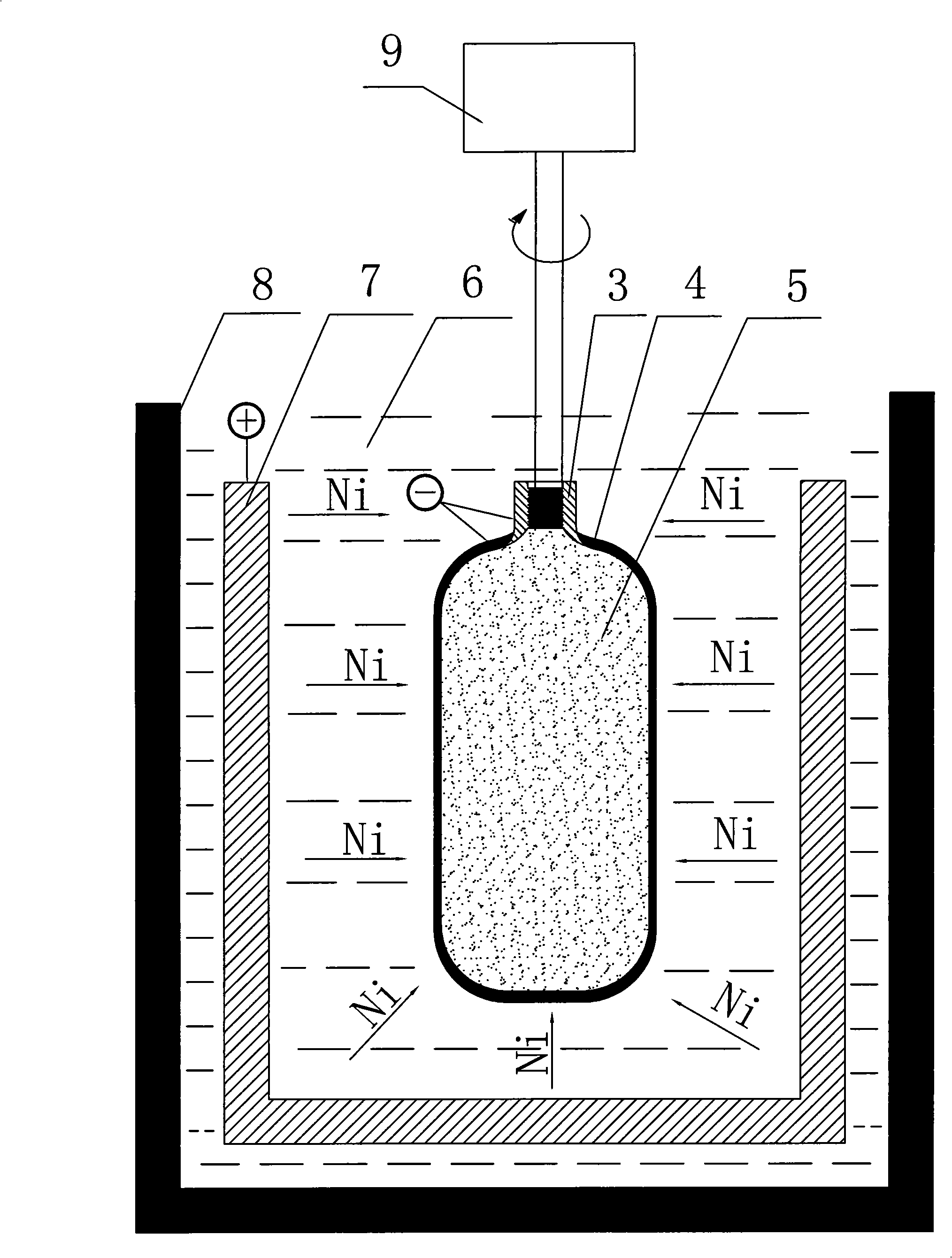

Image

Examples

Embodiment 1

[0027] 1. Mandrel preparation

[0028] Step 1: Make can 3 with metal rods, copper rods are used in this embodiment, but not limited thereto;

[0029] Step 2: Casting a core mold with low melting point paraffin, the shape of the core mold in this embodiment is a cylindrical tank with a length of 100 mm.

[0030] Step 3: Inlay the processed can 3 on the paraffin mandrel 5 .

[0031] Step 4: Evenly coat 4 layers of graphite powder on the outer surface of the paraffin core mold 5. The technical requirements for the graphite powder layer are as follows:

[0032] a. Particle size: 1-20 microns

[0033] b. Thickness: 0.2-0.4 mm

[0034] c. Conductivity: resistance ≤ 0.5Ω

[0035] 2. Preparation of electrodeposition bath solution 6

[0036] 1. Bath composition:

[0037] a. Nickel sulfamate [Ni(SO 3 ·NH 3 )·4H 2 O]120g

[0038] Impurity element control: Fe<2.0PPM, Cu<0.1PPM, Zn<0.1PPM

[0039] b. Boric acid [H 3 BO 3 ] 40 grams

[0040] Impurity element control: Fe<2.0PPM...

Embodiment 2

[0073] Embodiment 2: prepare with blow molding mandrel

[0074] 1. Preparation of blow molding mandrel

[0075] 1. Prepare a cylindrical blow molding mandrel with a length of 100 mm

[0076] 2. Evenly coat conductive paint on the outer surface of the blow molding mandrel. The technical requirements are as follows:

[0077] Conductivity: resistance ≤ 0.5Ω

[0078] 2. Preparation of electrodeposition bath

[0079] 1. Bath composition:

[0080] a. Nickel sulfamate [Ni(SO 3 ·NH 3 )·4H 2 O]60g

[0081] Impurity element control: Fe<2.0PPM, Cu<0.1PPM, Zn<0.1PPM

[0082] b. Boric acid [H 3 BO 3 ]10gram

[0083] Impurity element control: Fe<2.0PPM

[0084] c. Sulfamic acid: [SO 3 ·NH 3 ]6 grams

[0085] Impurity element control: Fe<2.0PPM

[0086] d. Nickel Carbonate [Nico 3 ] 2 grams

[0087] Control of impurity elements: Pb<0.05%, Cu<0.05%, Zn<0.06%CI<0.03%

[0088] e. Nickel chloride [NiCI] 6 grams

[0089] Impurity element control: Fe<2.0PPM, Cu<4.0PPM, Na<30PPM...

Embodiment 3

[0107] 1. Bath composition:

[0108] a. Nickel sulfamate [Ni(SO 3 ·NH 3 )·4H 2 O]90g

[0109] Impurity element control: Fe<2.0PPM, Cu<0.1PPM, Zn<0.1PPM

[0110] b. Boric acid [H 3 BO 3 ]25g /

[0111] Impurity element control: Fe<2.0PPM

[0112] c. Sulfamic acid: [SO 3 ·NH 3 ] 4 grams

[0113] Impurity element control: Fe<2.0PPM

[0114] d. Nickel Carbonate [Nico 3 ] 3.5 grams

[0115] Impurity element control: Pb<0.05%, Cu<0.05%, Zn<0.06%, CI<0.03%

[0116] e. Nickel chloride [NiCI] 4.5 grams

[0117] Impurity element control: Fe<2.0PPM, Cu<4.0PPM, Na<30PPM, Pb<1.0PPM, Zn<30PPM

[0118] f. Pure water: 1L

[0119] 2. Working conditions of bath solution:

[0120] a.PH value: 4

[0121] b. Working temperature: 60°C

[0122] c. Working voltage: 13VDC

[0123] d. Current density: 2.5ASD

[0124] 3, all the other steps are the same as in Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com