Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Multiscale modeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In engineering, mathematics, physics, chemistry, bioinformatics, computational biology, meteorology and computer science, multiscale modeling or multiscale mathematics is the field of solving problems which have important features at multiple scales of time and/or space. Important problems include multiscale modeling of fluids, solids, polymers, proteins, nucleic acids as well as various physical and chemical phenomena (like adsorption, chemical reactions, diffusion).

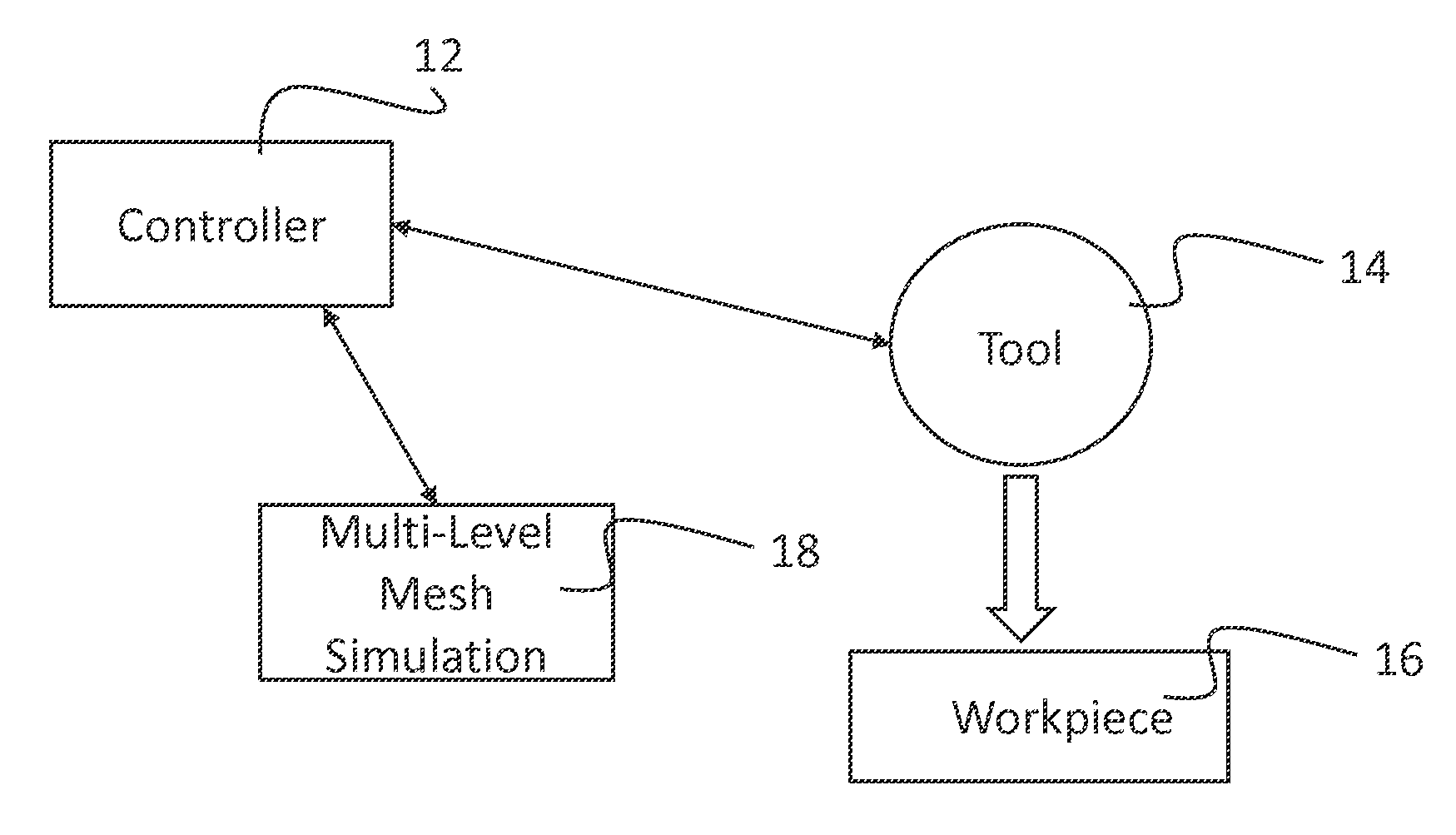

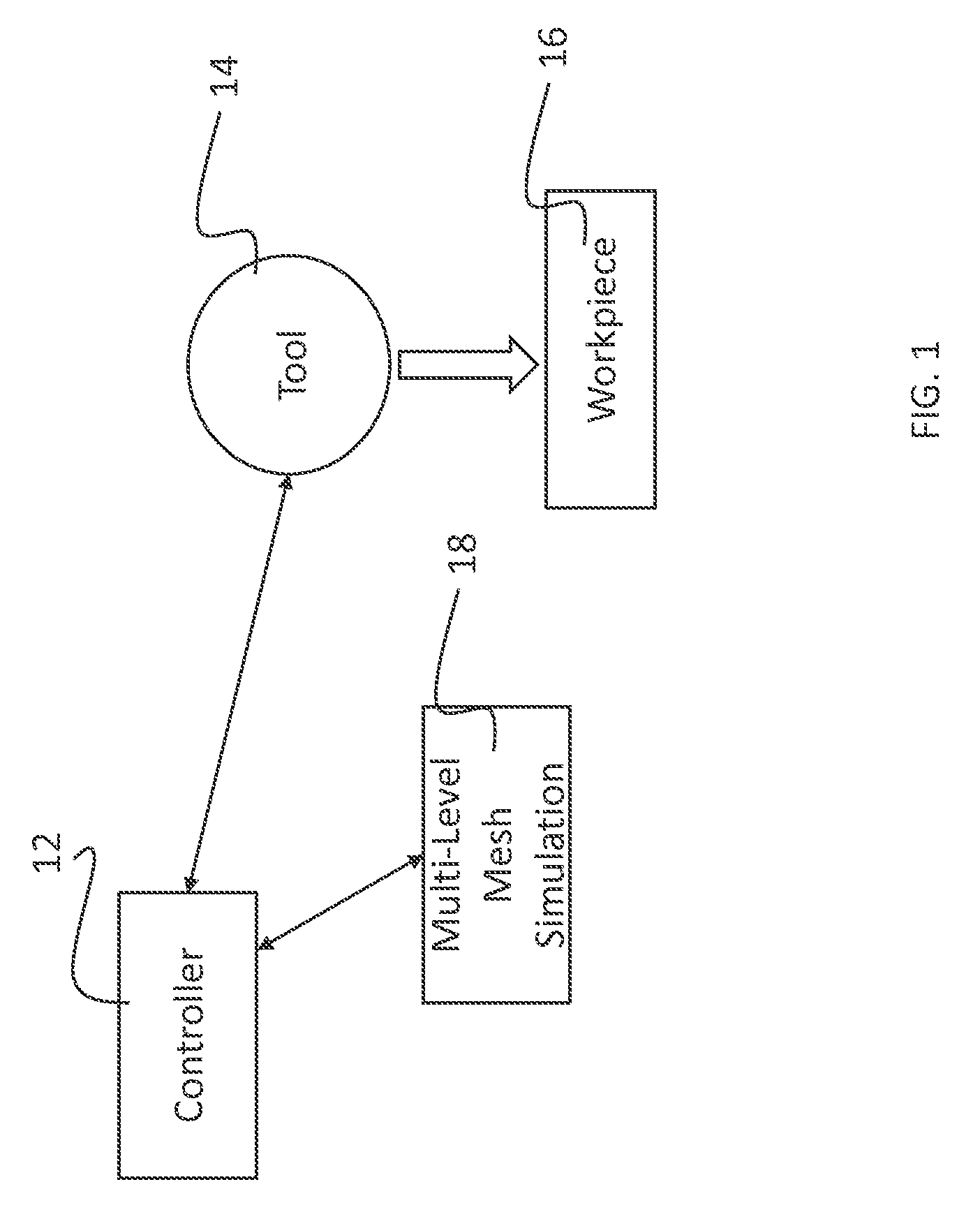

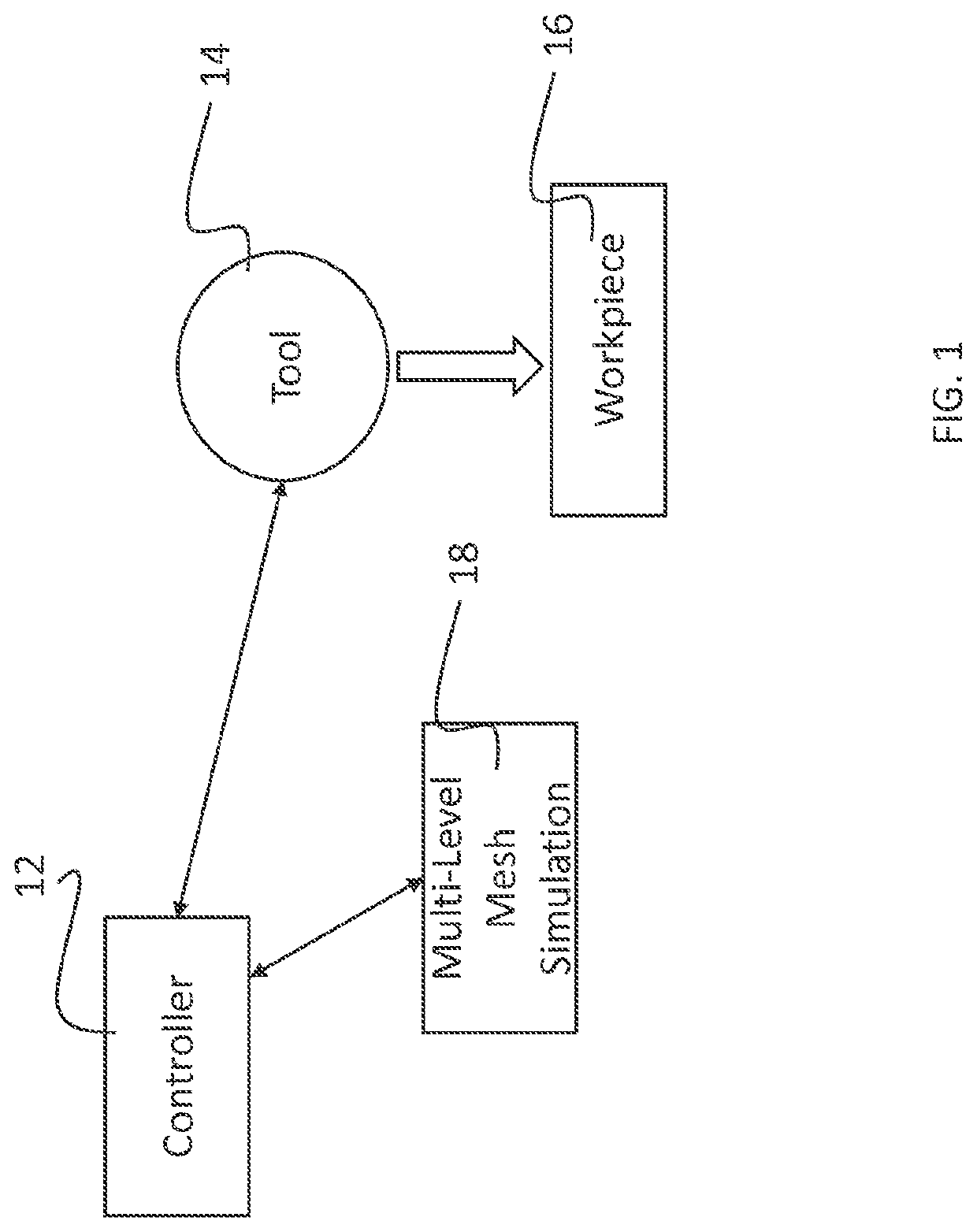

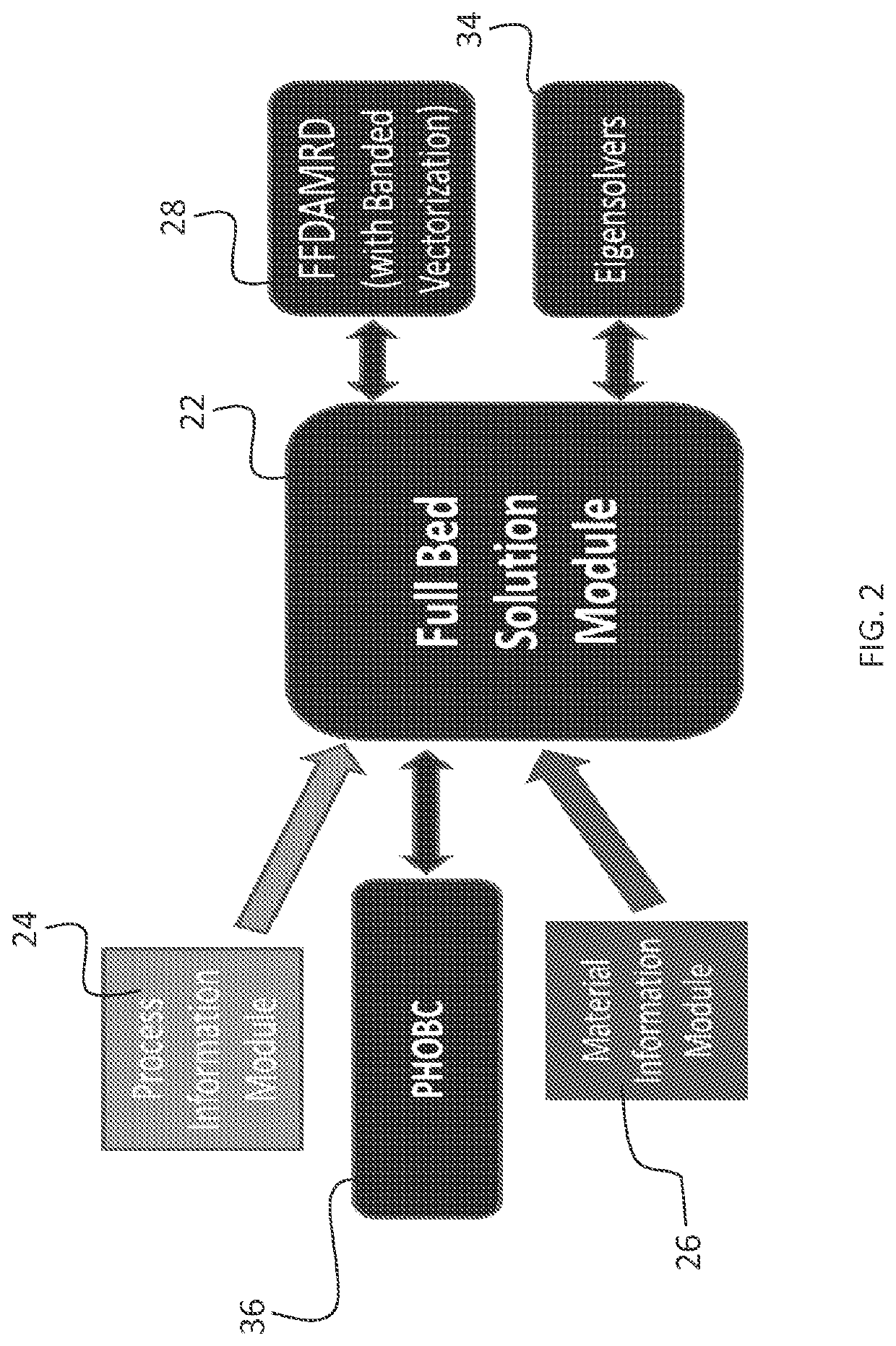

Multi-scale mesh modeling software products and controllers

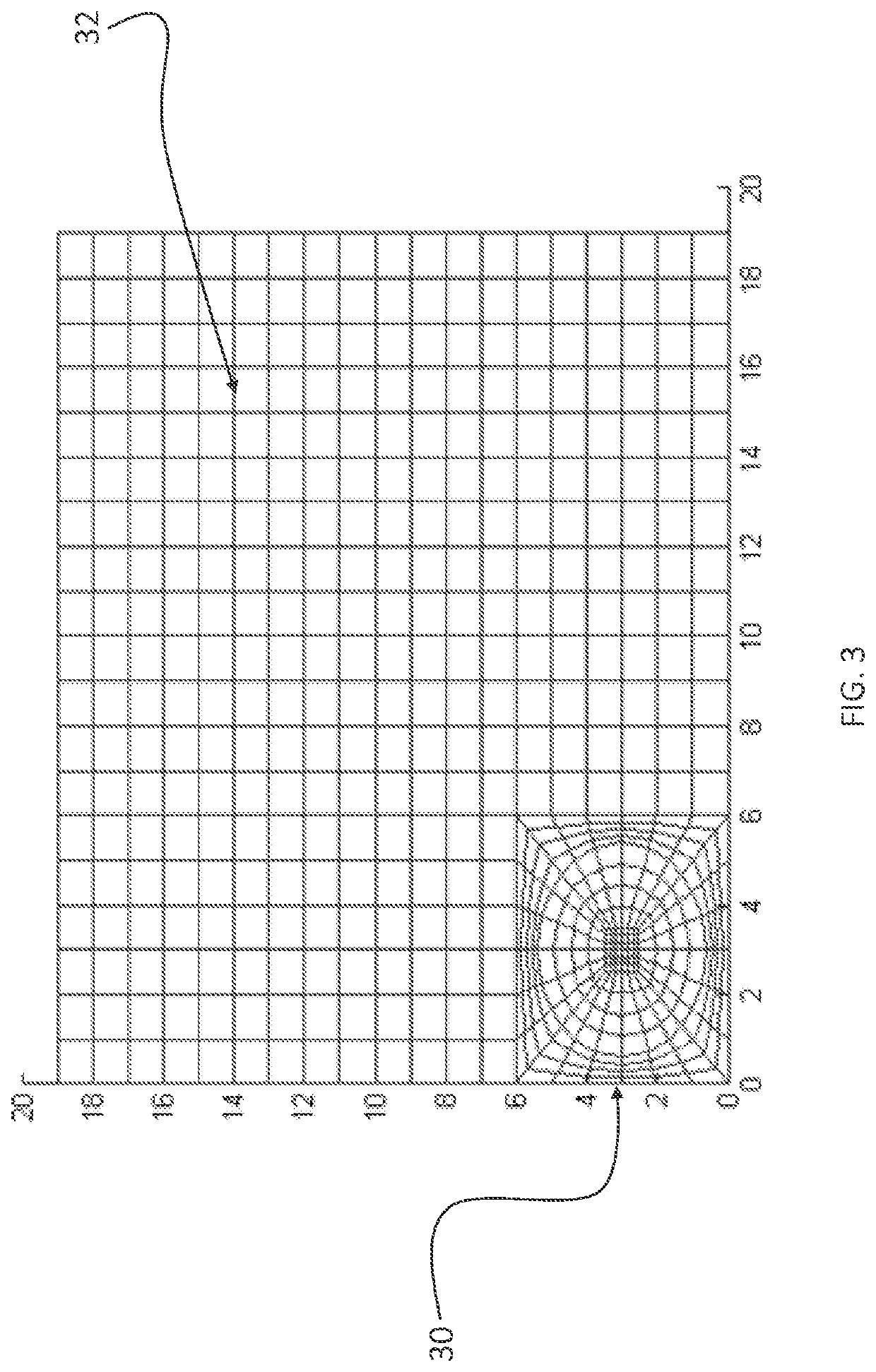

ActiveUS20160321384A1Accurately predict thermalAccurately stress/strain fieldProgramme controlAdditive manufacturing apparatusCoarse meshModeling software

Simulation systems, manufacturing systems, software products and controllers are provided with multi-scale modeling in which a coarse mesh and a fme mesh that models a stimulus are decoupled. The fine mesh can be moved within the coarse mesh with a cut and paste operation. The coarse mesh is updated by sparsely propagated effects through the coarse mesh. Simulations of the invention can be conducted in real-time, and be used as controllers in manufacturing systems, such as additive manufacturing systems. A number of efficient methods are provided for solving meshing determinations that arise from movement of a stimulus modeled within a fine mesh.

Owner:UNIV OF LOUISVILLE RES FOUND INC

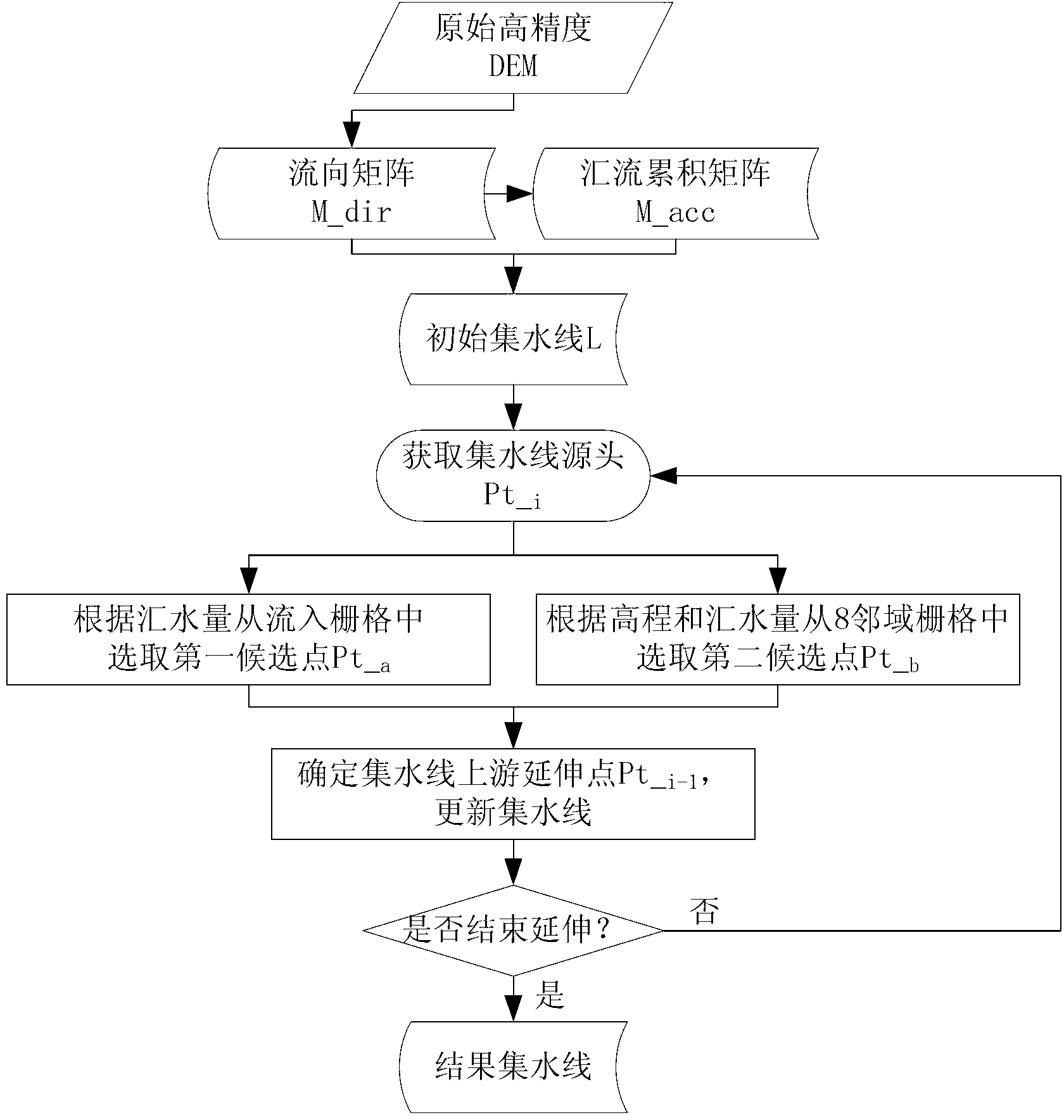

Multiscale DEM (Digital Elevation Model) modeling method giving consideration to contents of surface hydrology

The invention belongs to the field of modeling of a DEM (digital elevation model) and particularly relates to a multiscale DEM modeling method giving consideration to contents of surface hydrology. By carrying out runoff analysis on the DEM to extract a hydrological response region of a topographical surface, a hierarchical structure tree of a watershed area is established; by generalizing hydrological characteristics of a surface elevation point, a hydrological contribution index of the elevation point for a topographic form is calculated; by inspecting weighted topography description error of the elevation point, topographic feature point set is selected; and an elastic position seeking strategy is adopted to automatically regulate an integration degree control parameter so as to implement multiscale DEM automatic integration giving consideration to the contents of surface hydrology. Therefore, the multiscale DEM modeling method has the following advantages that topographic and hydrological features of an original high-accuracy DEM can be effectively kept and topological and logic consistency of the topographic and hydrological features of the multiscale DEM can be ensured; and automation and generating efficiency of the multiscale DEM modeling are improved and the requirement on the scale self-adaptation DEM in the practical application can be met.

Owner:WUHAN UNIV

Module transfer method based on multiscale modeling

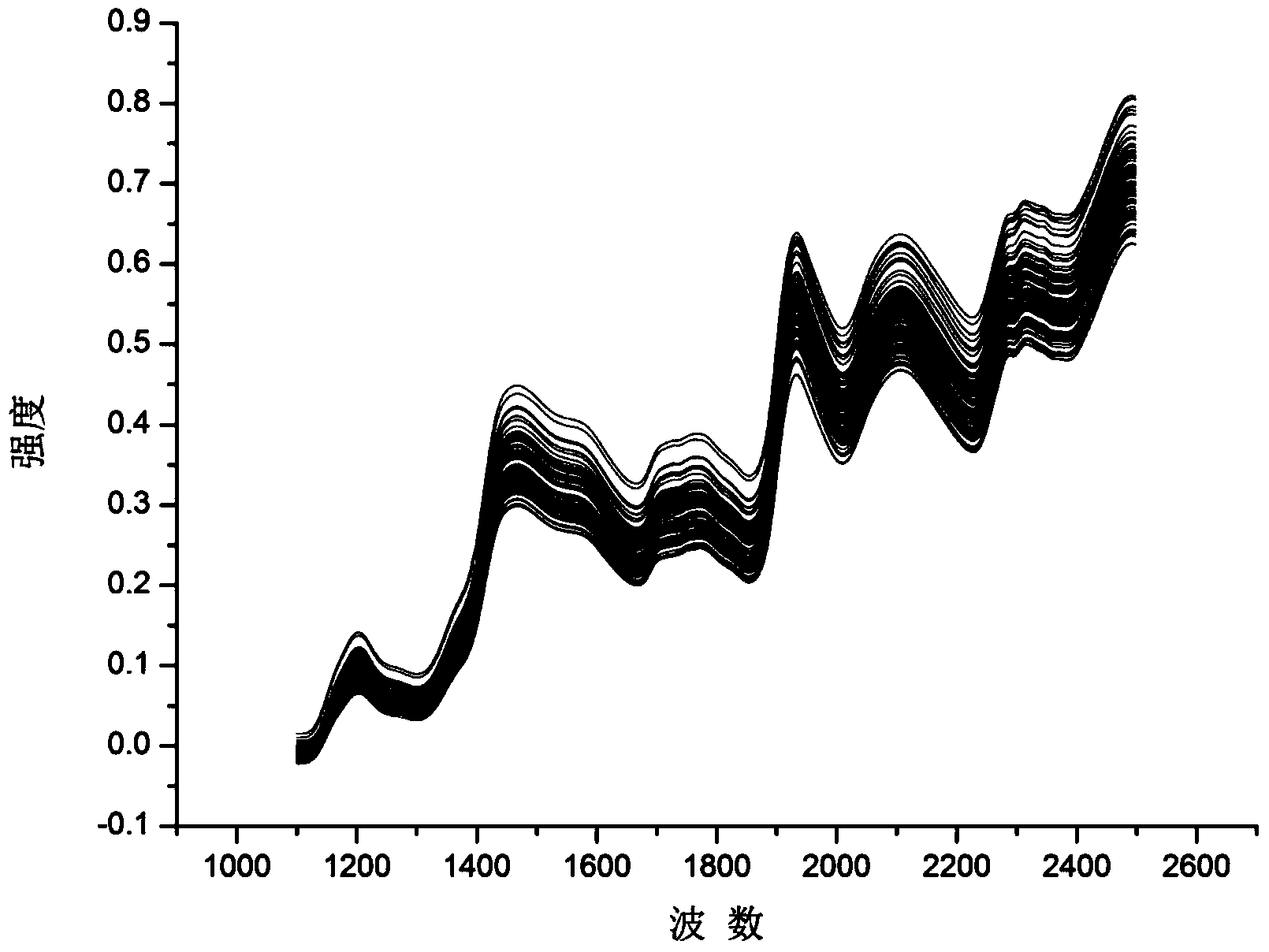

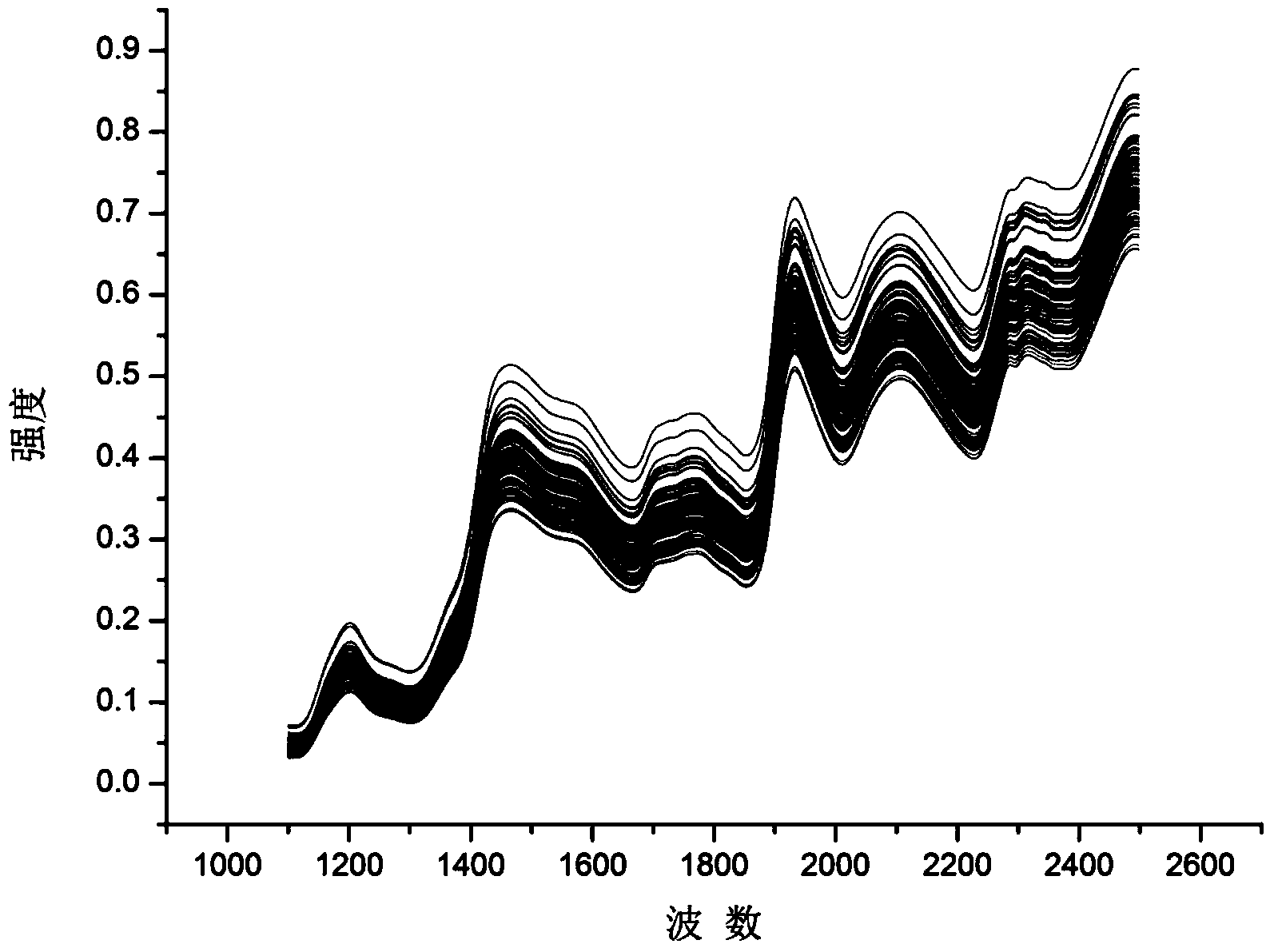

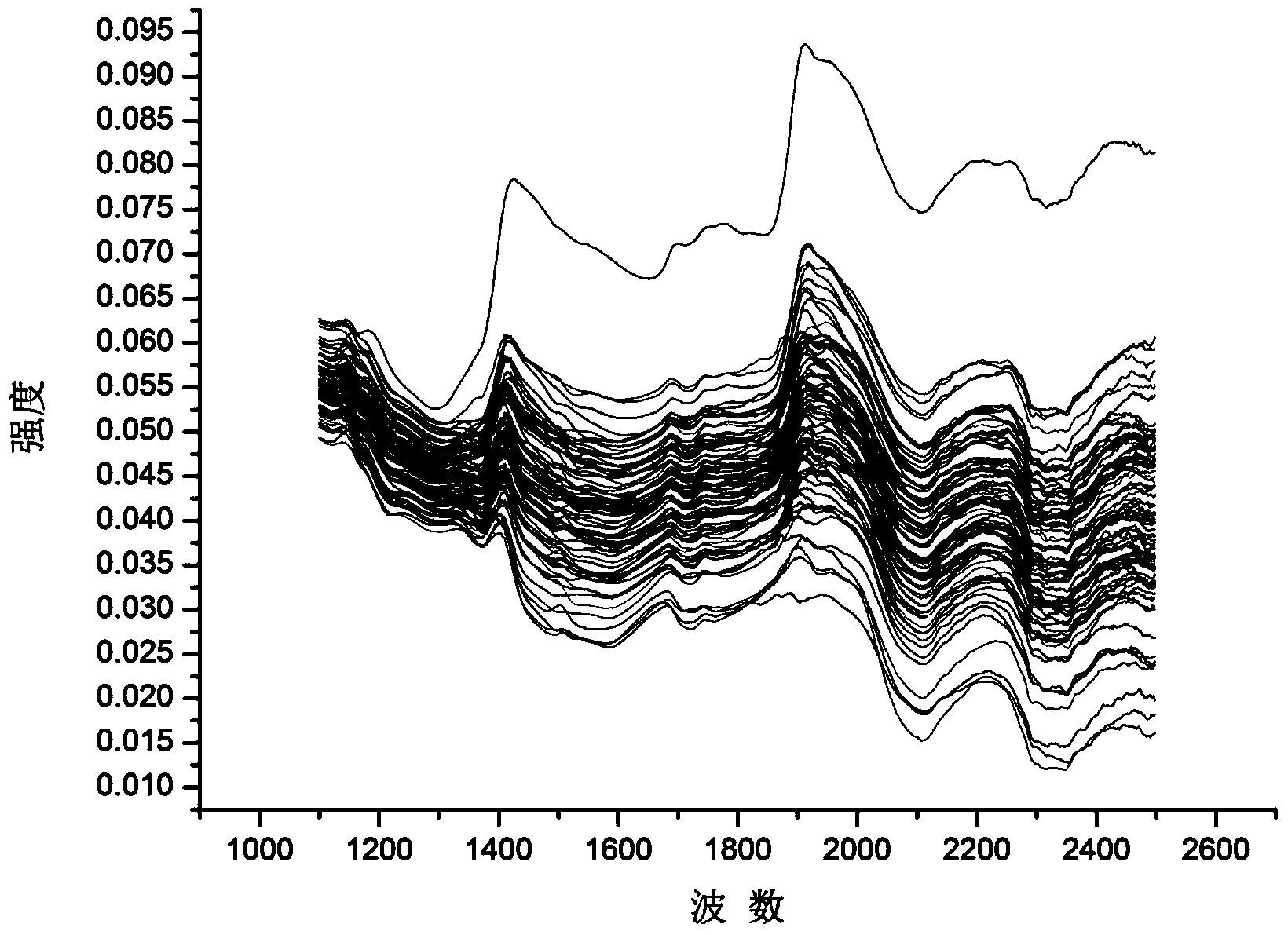

InactiveCN103854305AImprove efficiencyImprove performanceColor/spectral properties measurements3D modellingMultiscale decompositionMultivariate calibration

The invention discloses a module transfer method based on multiscale modeling. The method comprises the following steps: collecting original spectra of a host instrument and a slave instrument; by combining the characteristic of wavelet basis and the characteristic of the original spectrum of a sample, selecting the optimal wavelet basis to carry out wavelet multiscale decomposition on the spectrum to obtain wavelet coefficient; reconstructing the wavelet coefficient; respectively performing multivariate calibration on each layer of reconstructed spectrum; setting up a prediction model based on partial least squares method and leaving one cross-validation method for the spectrum after performing multivariate calibration to obtain a cross-validation root-mean-square error of the prediction model; performing model fusion on the prediction model by using weight number, and calculating the prediction root-mean-square error and related coefficient to evaluate the model transfer effect. Compared with a conventional model transfer method, the method greatly improves the model transfer efficiency and performance, and can be widely applied to fields of near-infrared and Raman spectrum.

Owner:TIANJIN UNIV

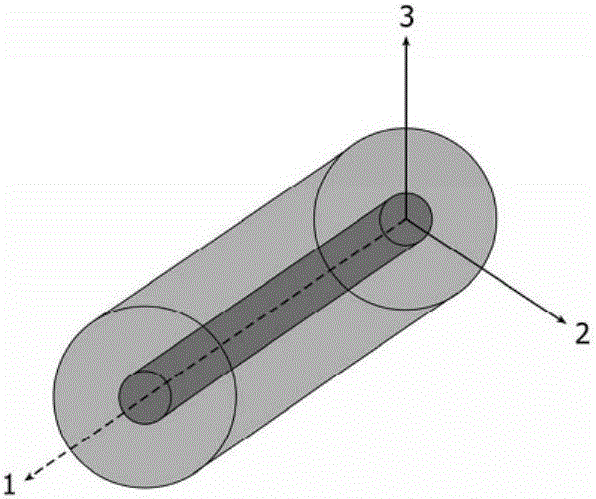

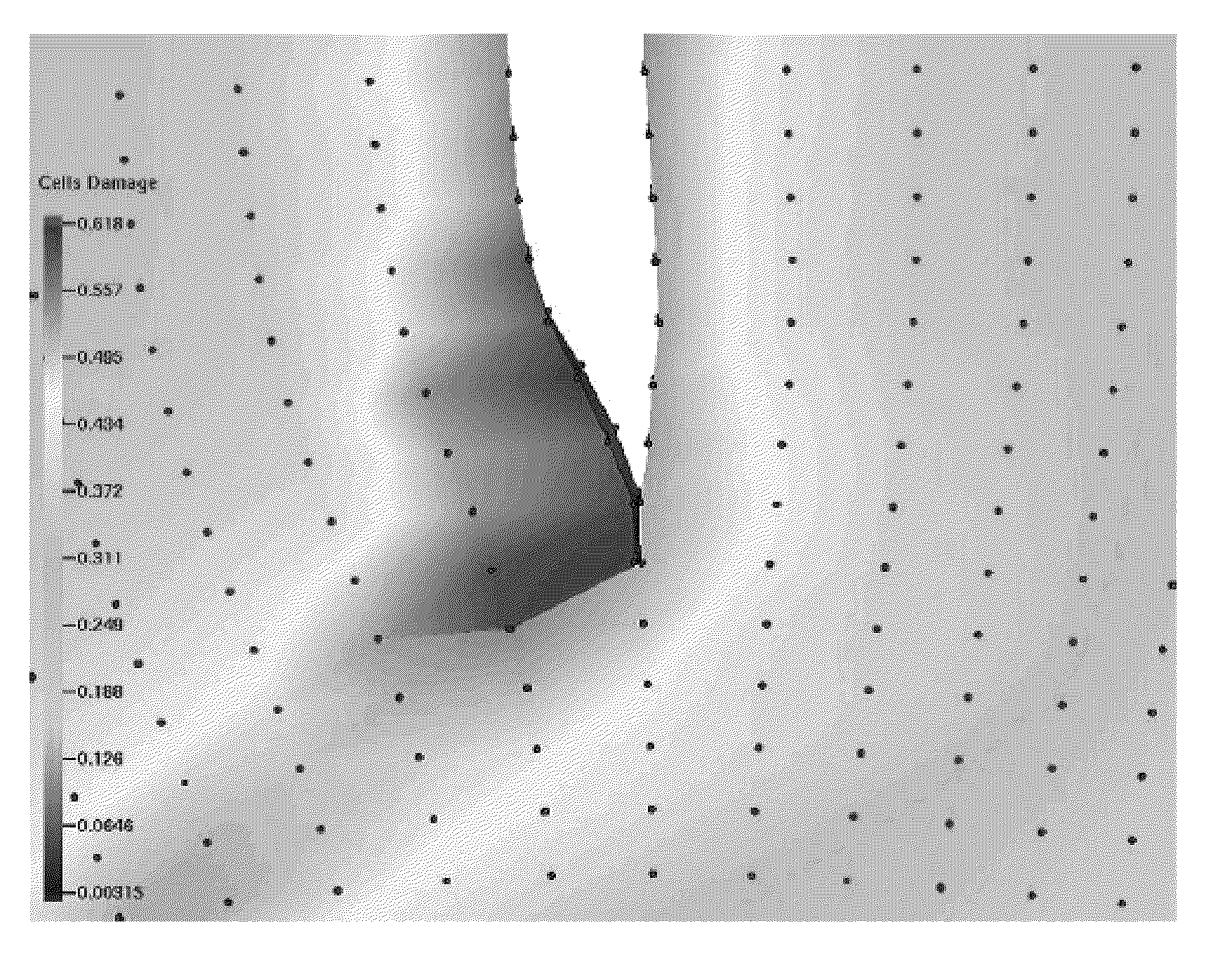

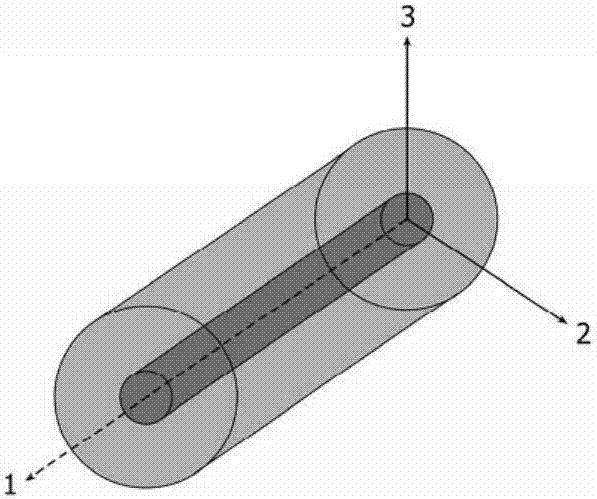

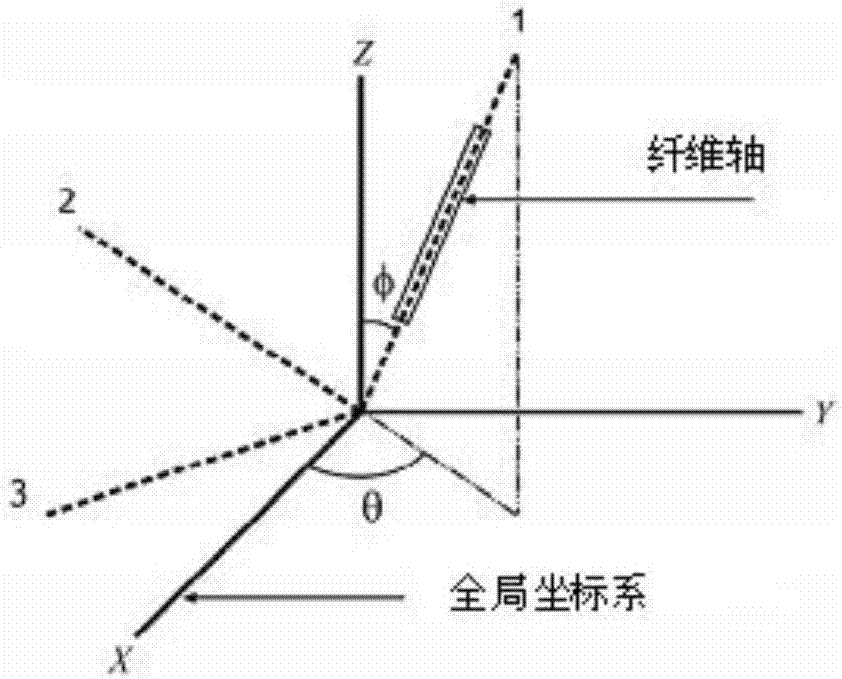

Skeletal muscle mechanical behavior multiscale modeling method

InactiveCN106202739ARealize macro and micro geometry modelingRealize simulationDesign optimisation/simulationSpecial data processing applicationsMuscle tissueMuscular force

The invention relates to a skeletal muscle mechanical behavior multiscale modeling method and aims at solving the problem in the prior art that a complete process from cell electrophysiologic action potential activation to skeletal muscle mechanical output cannot be simulated. The method comprises the steps of S1, determining positions and attitudes of muscle fibers; S2, establishing a skeletal muscle macroscopic geometric model and a skeletal muscle microcosmic geometric model according to the S1; S3, carrying out grid division on the geometric models established in the S2; S4, carrying out skeletal muscle electrophysiologic property modeling according to the S3; S5, carrying out multiscale calculation between cells and muscle tissues according to the S3 and S4; S6, establishing a skeletal muscle multiscale biomechanics model according to the S5; and S7, predicting muscular force according to the S6. The method is applied to the field of biomedical engineering.

Owner:HARBIN UNIV OF SCI & TECH

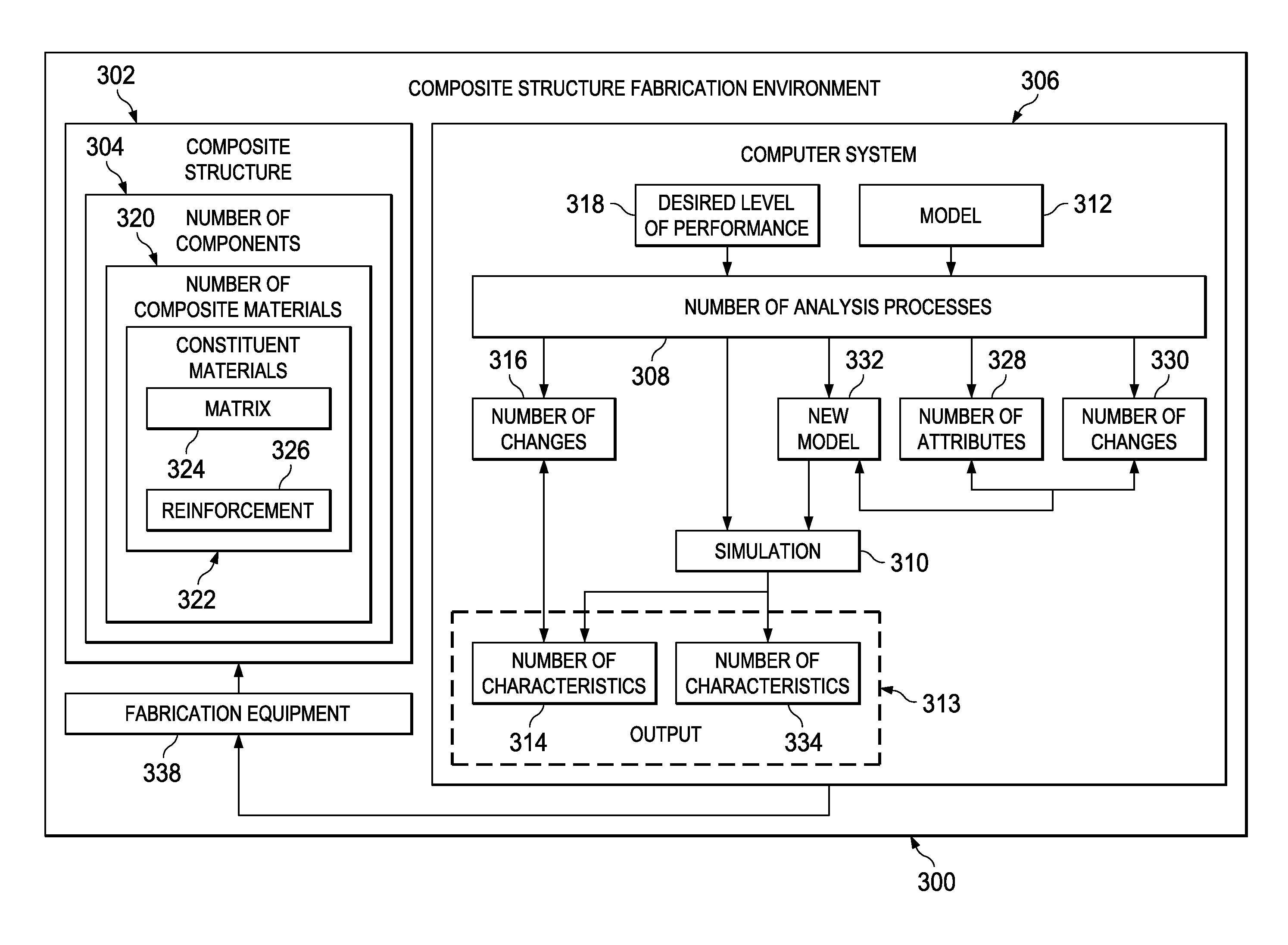

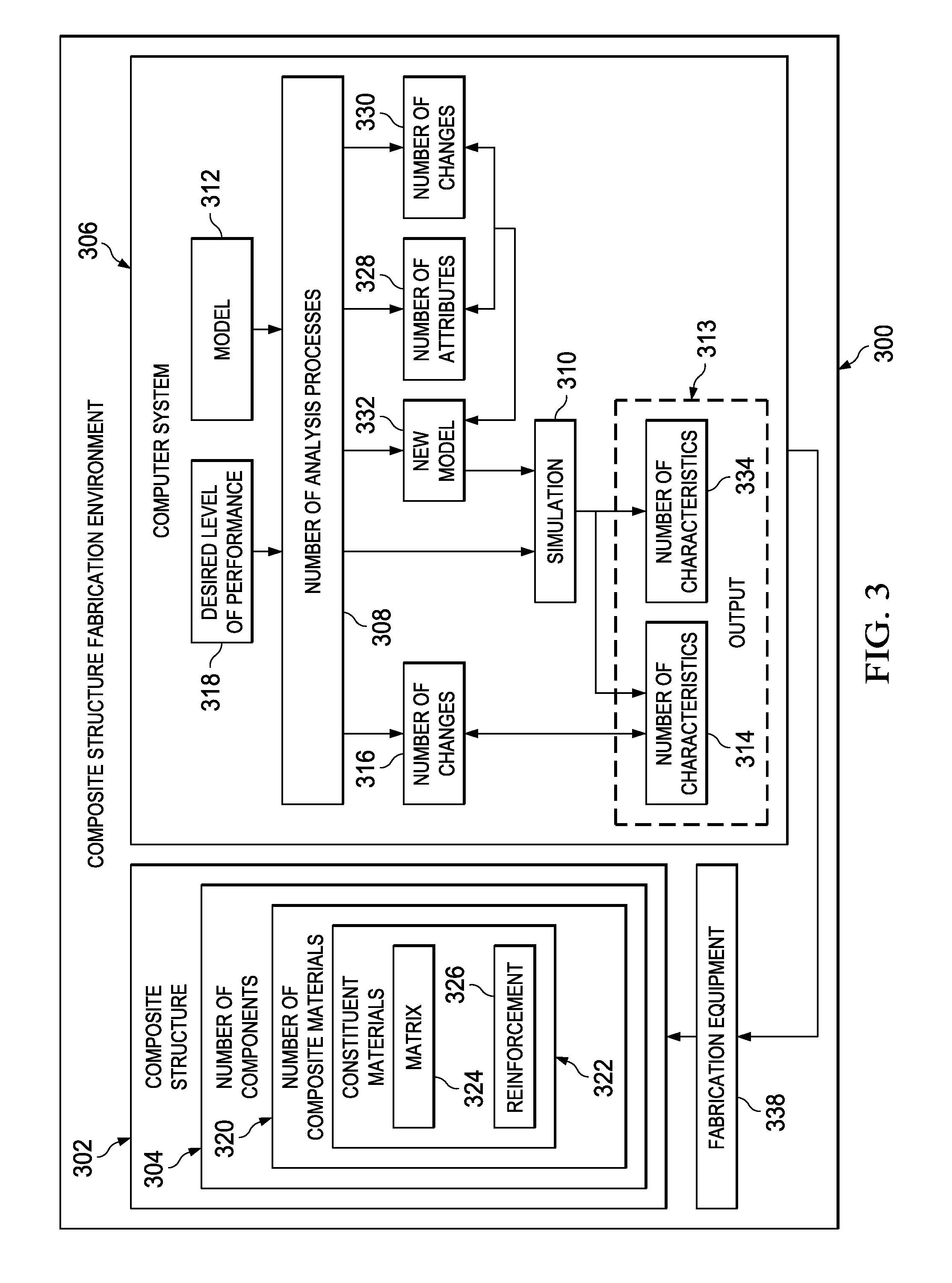

Multi-scale modeling of composite structures

A method, apparatus, and computer program product are present for creating a composite structure. A number of characteristics for a number of components for the composite structure is obtained from a simulation of the composite structure using a model of the composite structure. A number of changes in the number of characteristics needed to meet a desired level of performance for the number of characteristics is ascertained. A number of attributes for a number of composite materials used to form the number of components corresponding to the number of characteristics having the number of changes is identified. The number of attributes for the number of composite materials for the number of characteristics having the number of changes based on the desired level of performance is changed.

Owner:THE BOEING CO

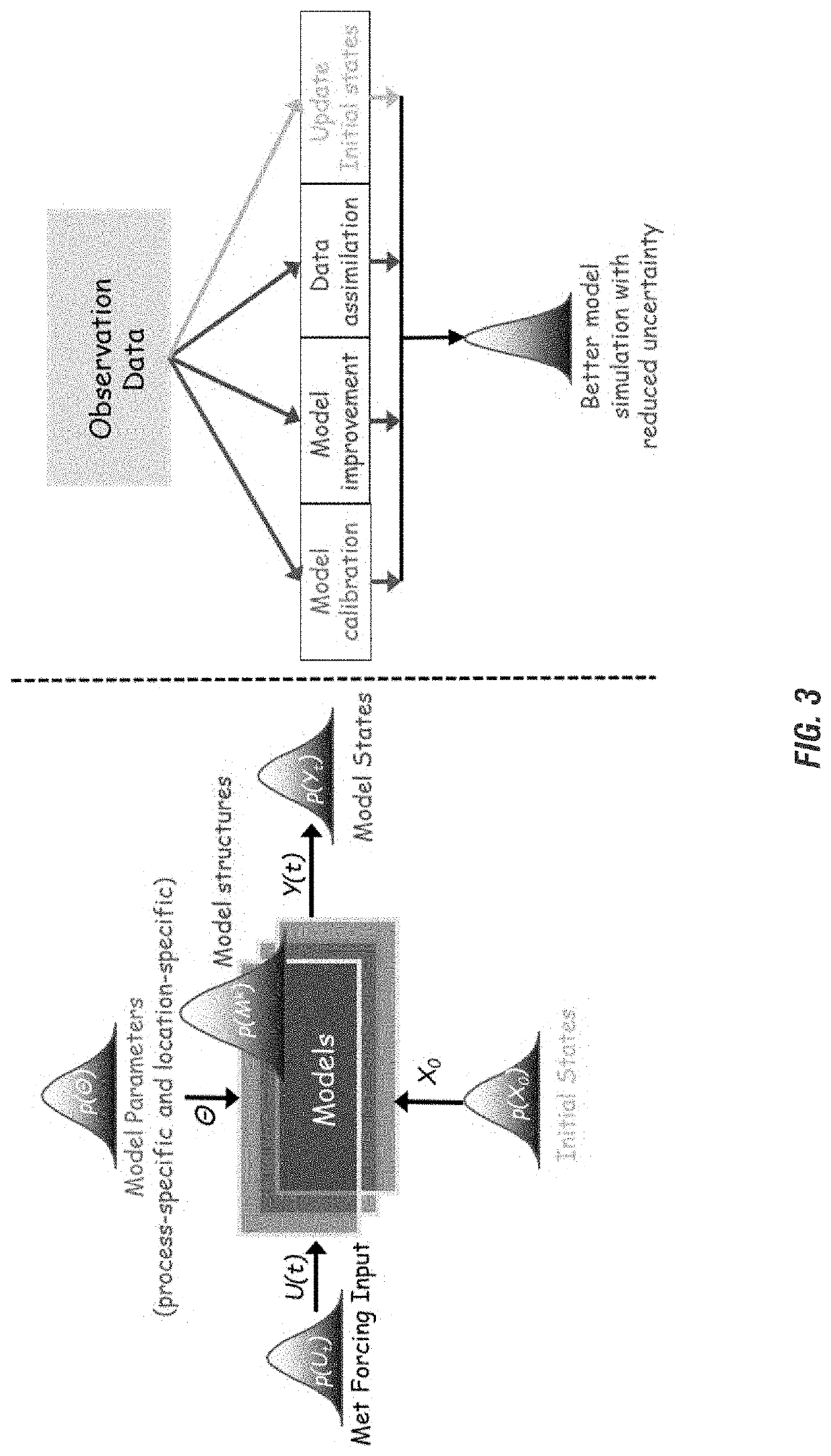

Accessing agriculture productivity and sustainability

PendingUS20220061236A1Efficient communicationImprove accuracyClimate change adaptationWatering devicesAgricultural engineeringGrowing season

An integrated multi-scale modeling platform is utilized to assess agricultural productivity and sustainability. The model is used to assess the environmental impacts of agricultural management from individual fields to watershed / basin to continental scales. In addition, an integrated irrigation system is developed using data and a machine-learning model that includes weather forecast and soil moisture simulation to determine an irrigation amount for farmers. Next, crop cover classification prediction can be established for an ongoing growing system using a machine learning or statistical model to predict the planted crop type in an area. Finally, a method of predicting key phenology dates of crops for individual field parcels, farms, or parts of a field parcel, in a growing season, can be established.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

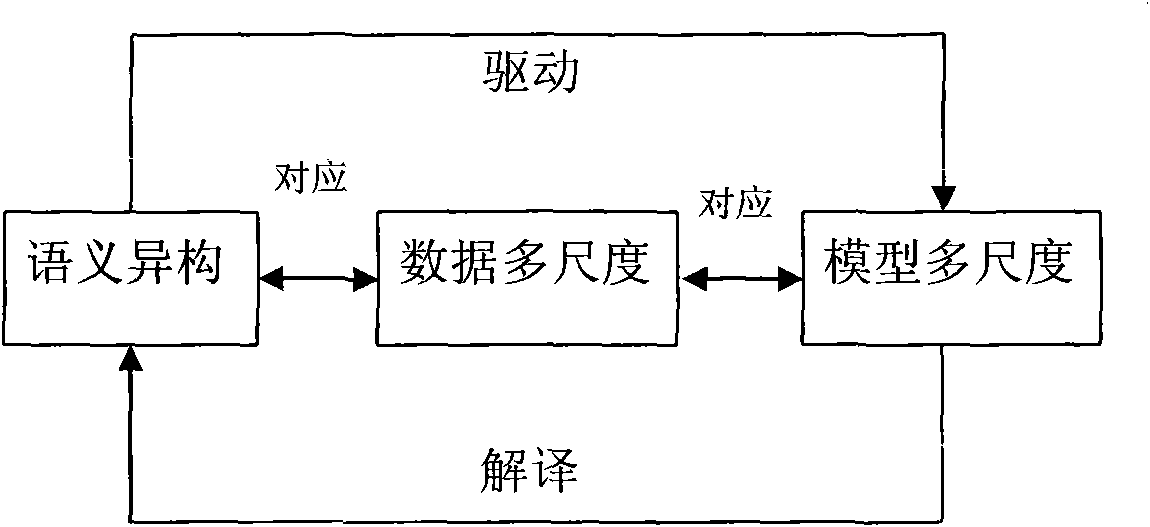

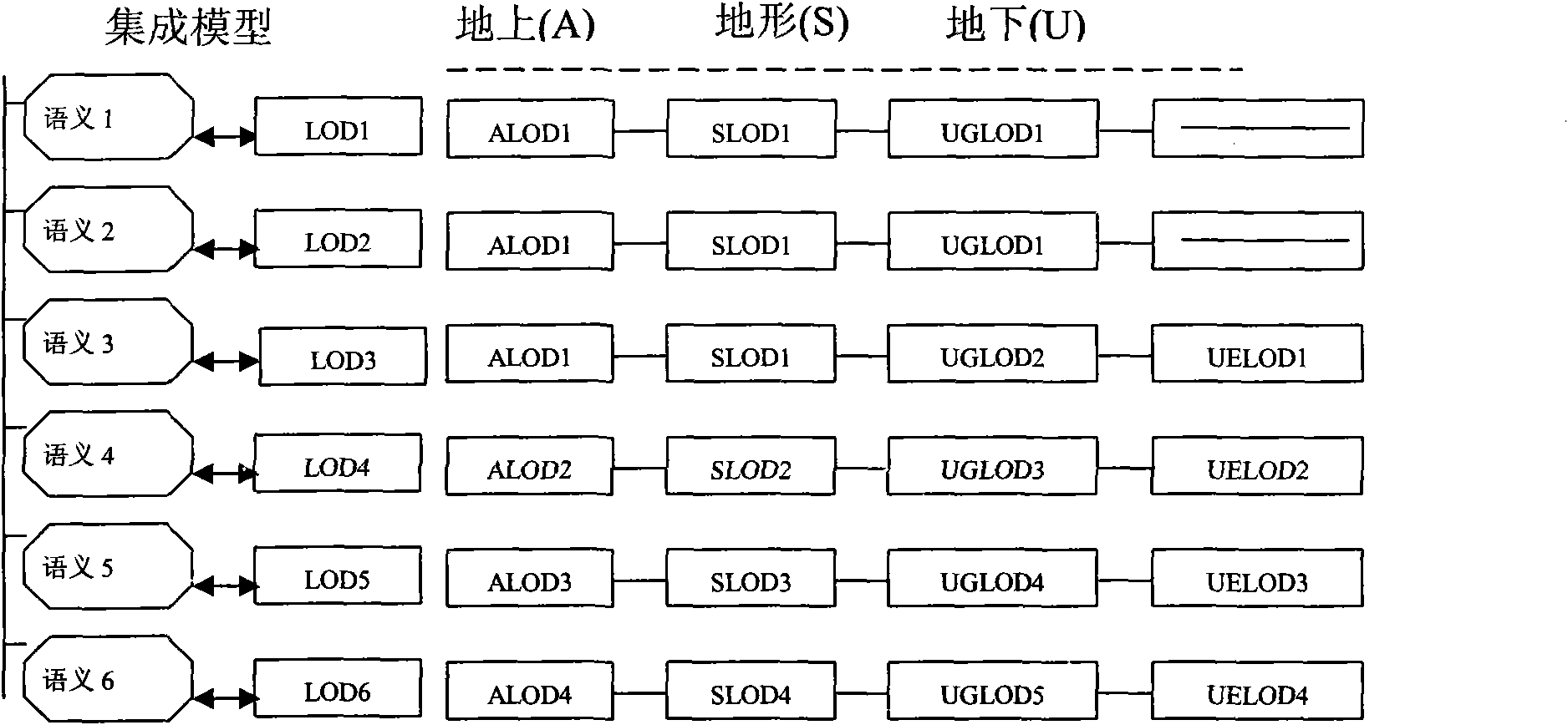

Multi-scale expression method for semantic-considered overground-underground integrated model

InactiveCN102053981AMeet diverse needsRealize multi-scale expressionSpecial data processing applicationsScale modelCognition

The invention discloses a multi-scale expression method for a semantic-considered overground-underground integrated model, which comprises the following steps of: firstly, considering the semantic heterogeneity of geo-science cognition, and carrying out multi-scale division on geo-science data; then, establishing a corresponding semantic-considered multi-scale model sequence; and finally, constructing an architecture which is multi-scale expressed by an overground-underground seamless integrated model and implementing the architecture. The invention fills in gaps of the multi-scale spatial modeling and expression method for the overground-underground integrated model, satisfies the diversified requirements of the geo-science cognition, forms a complete set of architecture of the geo-science cognition and provides a theoretical basis and a technical scheme for the multi-scale modeling and expression of an overground-underground seamless integrated spatial entity.

Owner:吴立新 +1

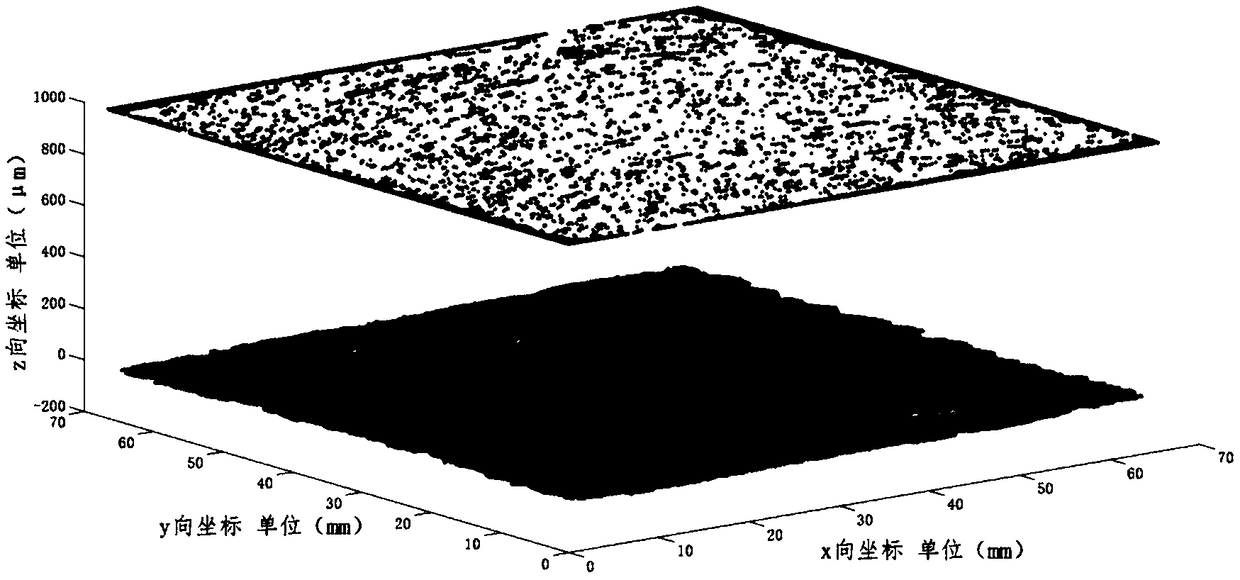

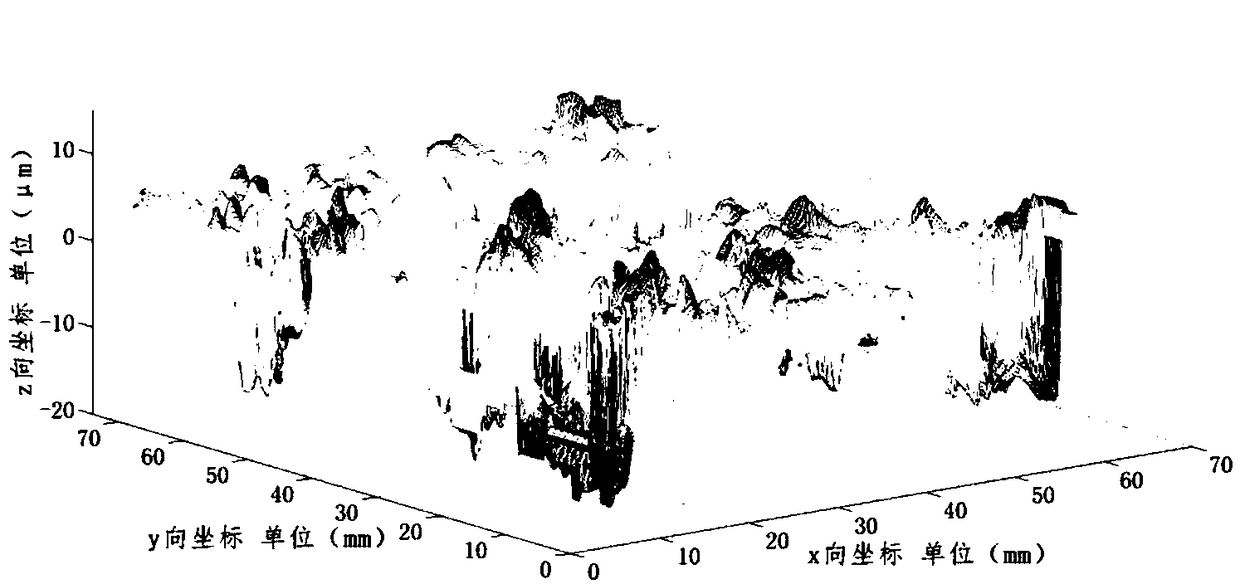

A method for constructing volume model including multi-scale topography features

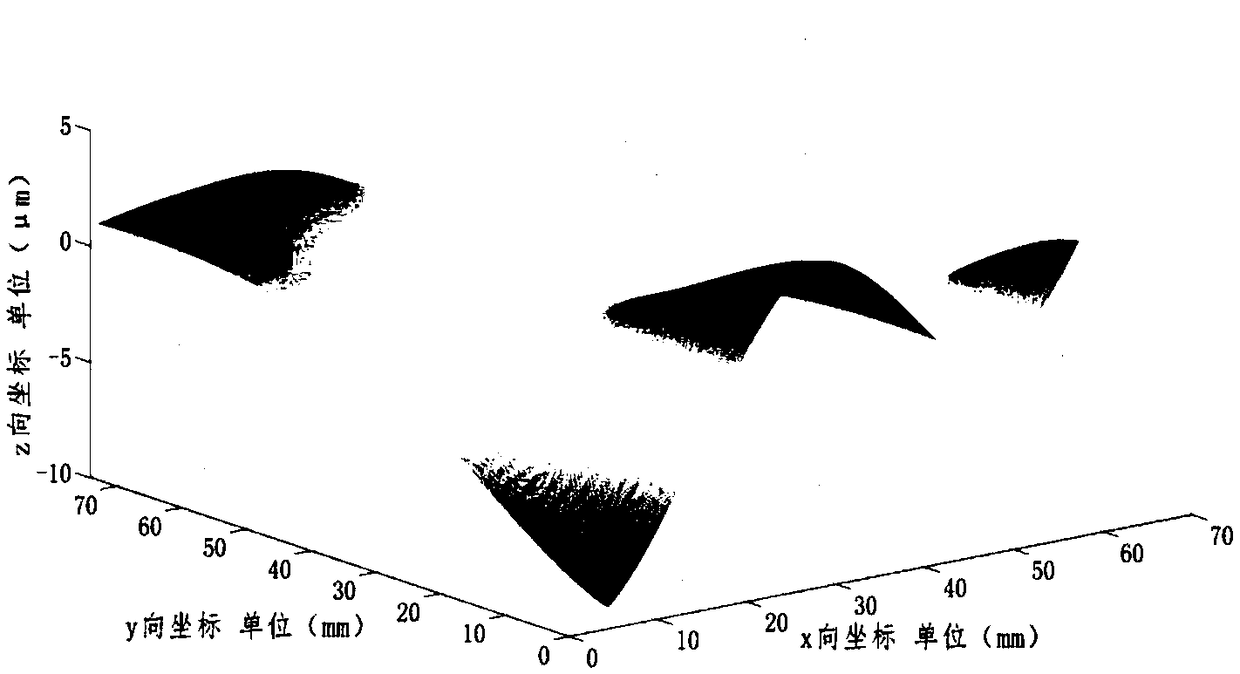

ActiveCN109359333ADesign optimisation/simulationSpecial data processing applicationsMultiscale decompositionTime–frequency analysis

The invention provides a method for constructing a volume model including multi-scale topography features. Starting from a point cloud processing technology and a volume model construction technology,based on measured surface topography data, the measured surface topography data are decomposed in multi-scale, and data components of different scales are identified by combining a time-frequency analysis method. Reverse engineering modeling method is used to construct volume model for the processed data. to the method can identify the point cloud data of different scales, and perform multi-scalemodeling according to the analysis requirements; In the process of modeling, 3D modeling can be carried out in a more intuitive way, and the generated volume model can be Boolean operation, which tosome extent solves the problem of constructing the complex characteristics of bolt holes, grooves and so on in the volume model with surface topography.

Owner:DALIAN UNIV OF TECH

Method for crack and fracture modeling in directed surfaces

ActiveUS8479588B1Analysing solids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansCrazingMechanical equation

A method for three-dimensional crack propagation, morphology, and initiation suited to directed surfaces, or stacks of directed surfaces. An external damage measure and failure criteria can be incorporated, as well as a rule-based crack direction and morphology capability. This method is ideal for laminated composites. Further, the use of external damage and failure, and rule-based crack propagation, this method is ideal for multi-scale modeling and use in applications where knowledge and rules are necessary or desirable for guiding, driving, or influencing failure modes, directions, or other situations that are not directly incorporated into the governing mechanical equations.

Owner:UNIV OF SOUTH FLORIDA

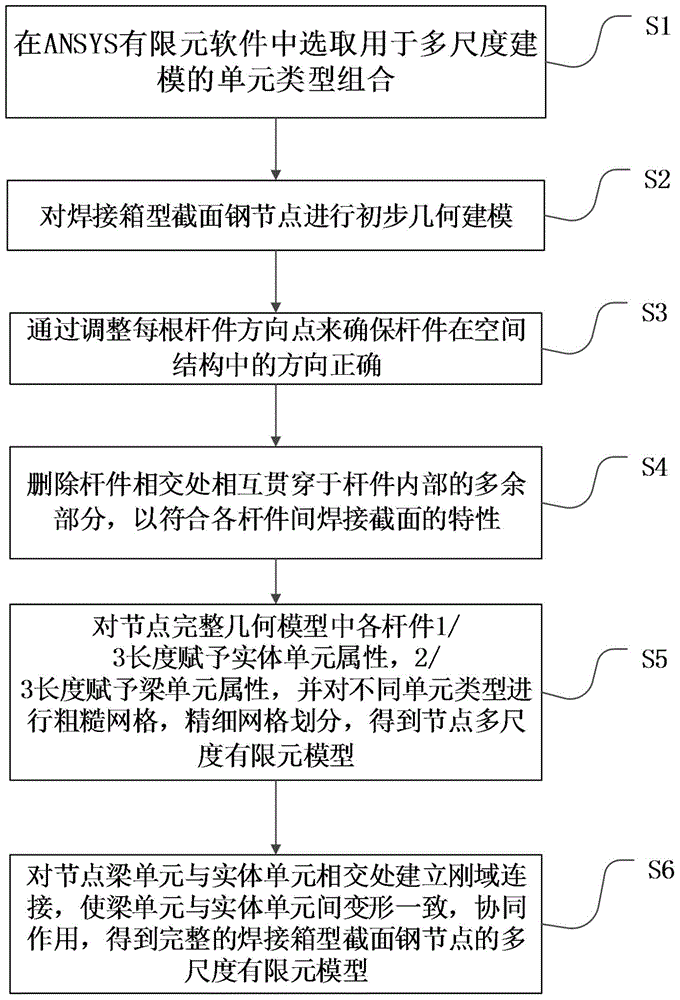

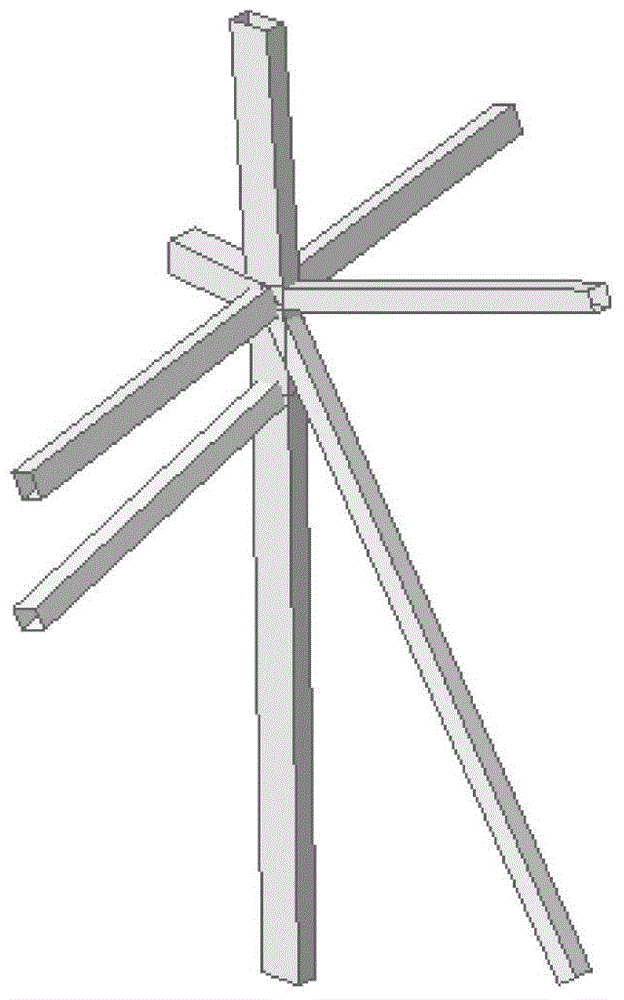

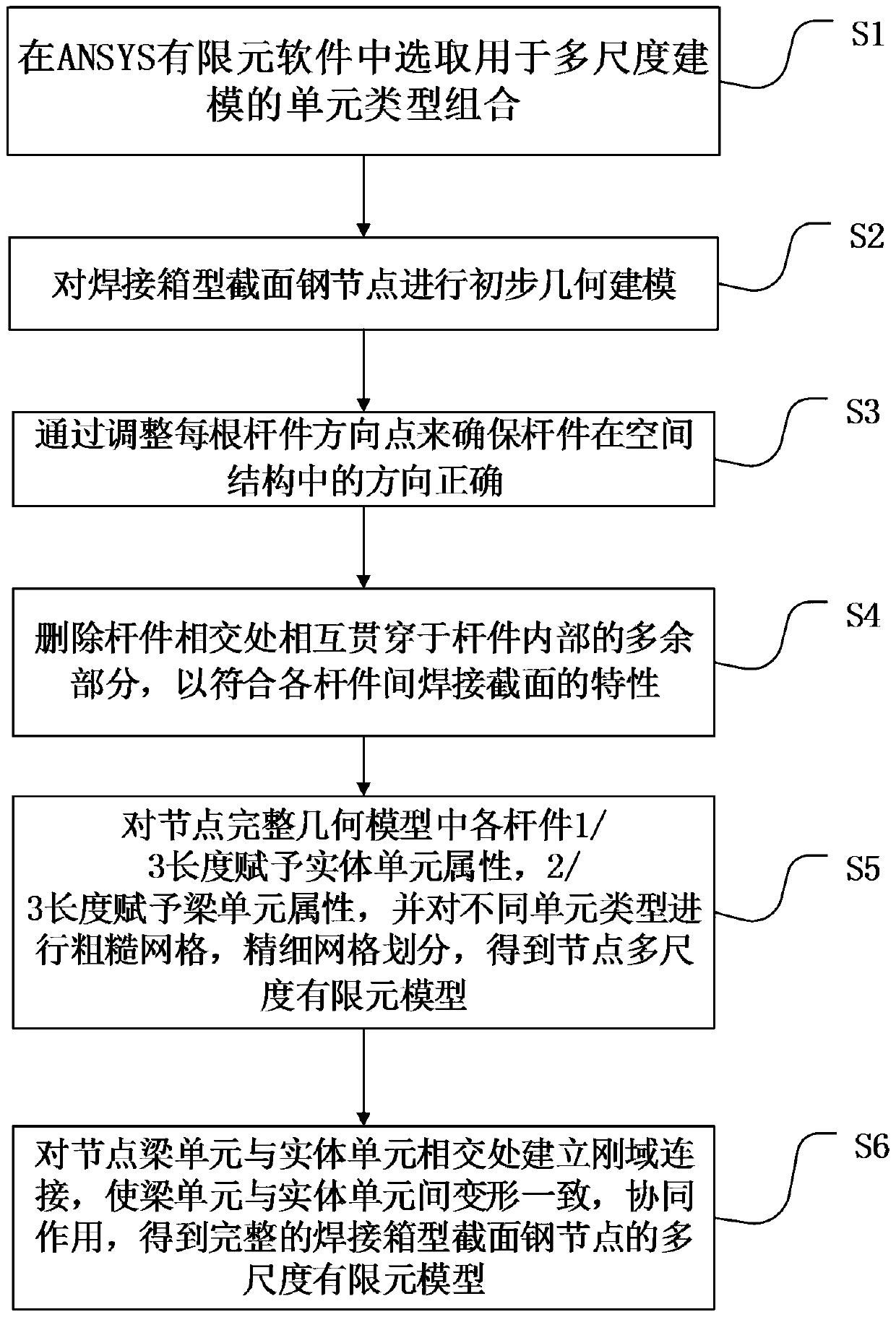

Weld box section steel joint multi-scale finite element modeling method

The invention provides a weld box section steel joint multi-scale finite element modeling method. The weld box section steel joint multi-scale finite element modeling method includes: S1, selecting an element type combination used for multi-scale modeling from ANSYS finite element software; S2, performing initial geometric modeling on weld box section steel joints; S3, guaranteeing correct directions in a spatial structure for rod pieces by adjusting direction points of all the rod pieces; S4, deleting redundant portions at intersections of the rod pieces, which run through the interiors of the rod pieces, so as to conform to characteristics of weld sections among all the rod pieces; S5, assigning solid element attributes to one third of the length of each rod piece in a complete geometric model of the steel joints, assigning beam element attributes to two thirds of the length of each rod piece in the complete geometric model of the steel joints, and dividing coarse grids and fine grids so as to obtain a multi-scale finite element model of the steel joints. The weld box section steel joint multi-scale finite element modeling method is provided according to unique advantages of the multi-scale finite element model, assists a structural health monitoring system, obtains local detail information of the weld box section steel joints, simulates structural real behavior, and guarantees structural safety.

Owner:卢伟

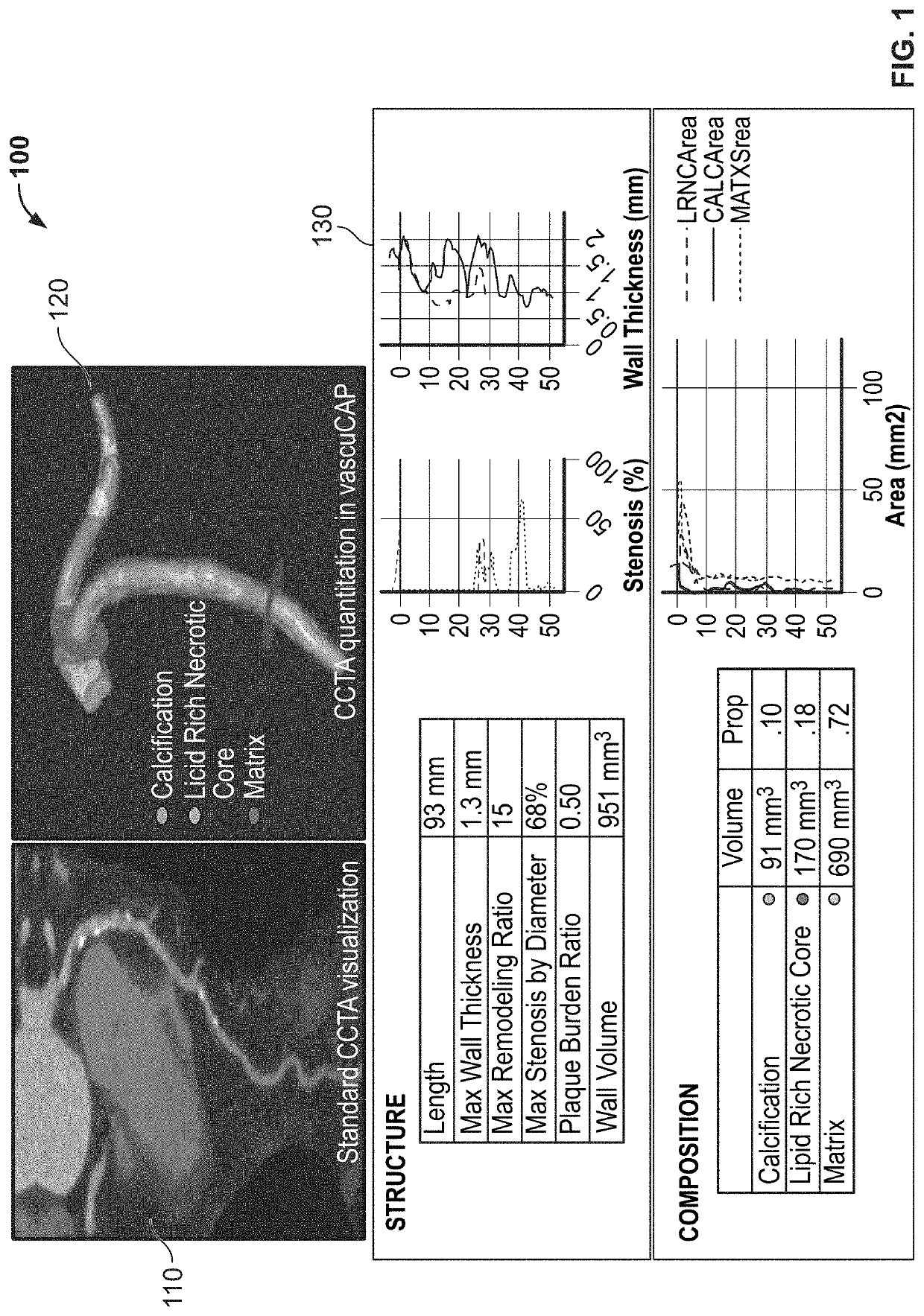

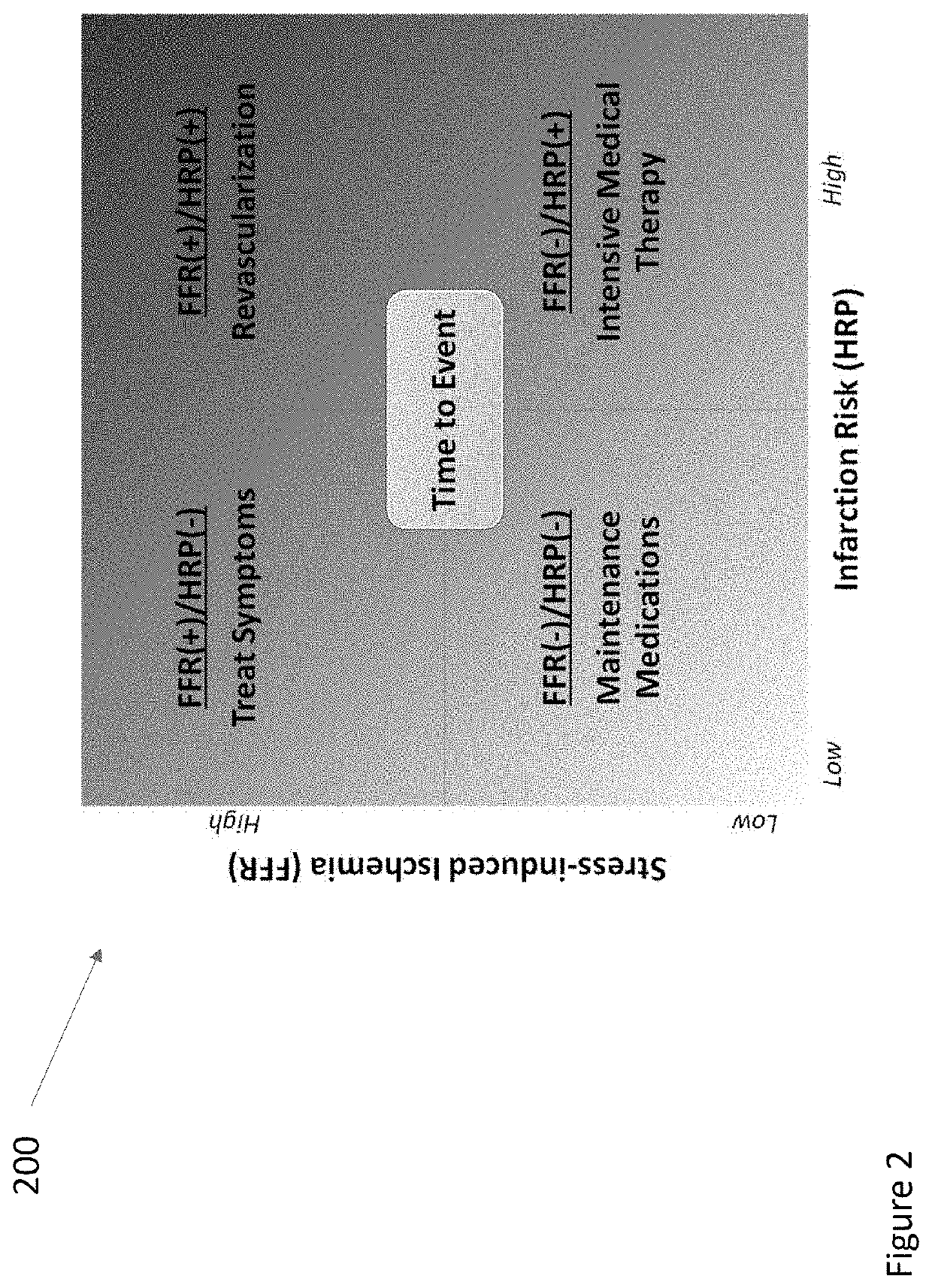

Systems and methods for improving soft tissue contrast, multiscale modeling and spectral ct

ActiveUS20220253992A1Improving soft tissue analysisEasy to analyzeUltrasonic/sonic/infrasonic diagnosticsImage enhancementBlood vesselSoft tissue contrast

Systems and methods for improving soft tissue contrast, characterizing tissue, classifying phenotype, stratifying risk, and performing multi-scale modeling aided by multiple energy or contrast excitation and evaluation are provided. The systems and methods can include single and multi-phase acquisitions and broad and local spectrum imaging to assess atherosclerotic plaque tissues in the vessel wall and perivascular space.

Owner:ELUCID BIOIMAGING INC

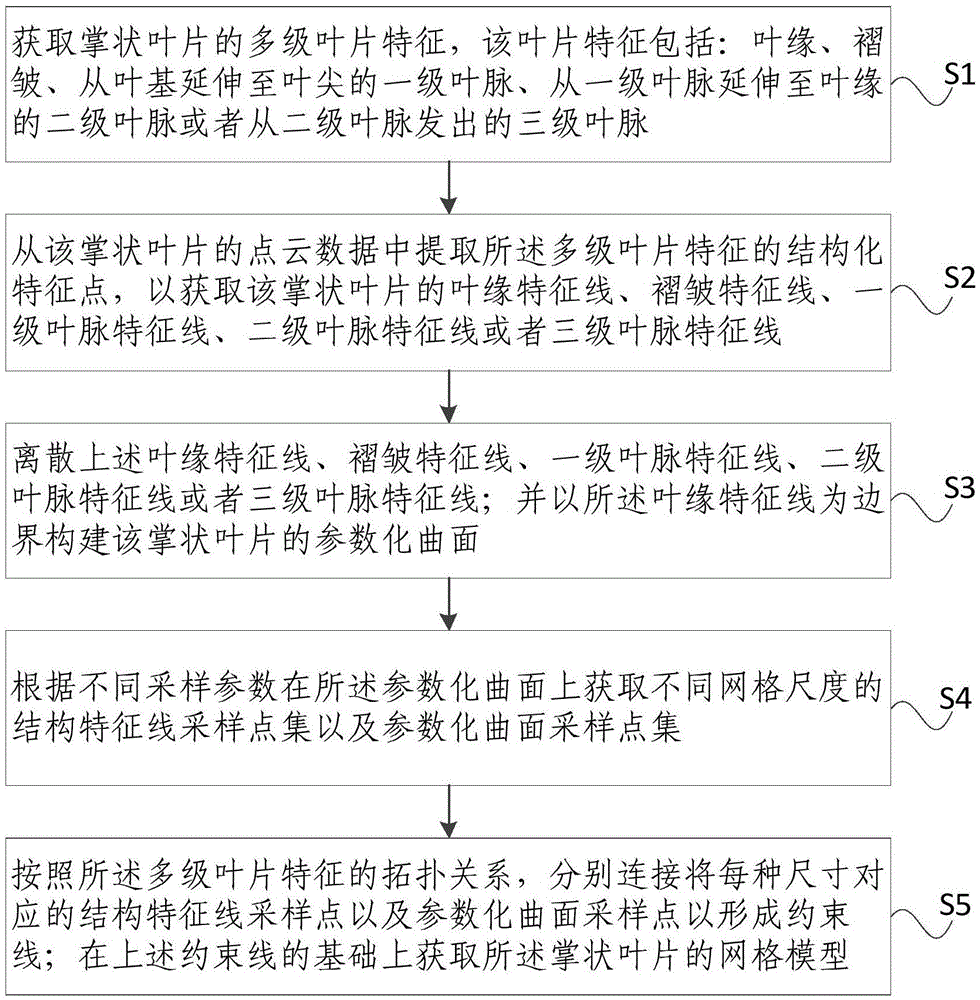

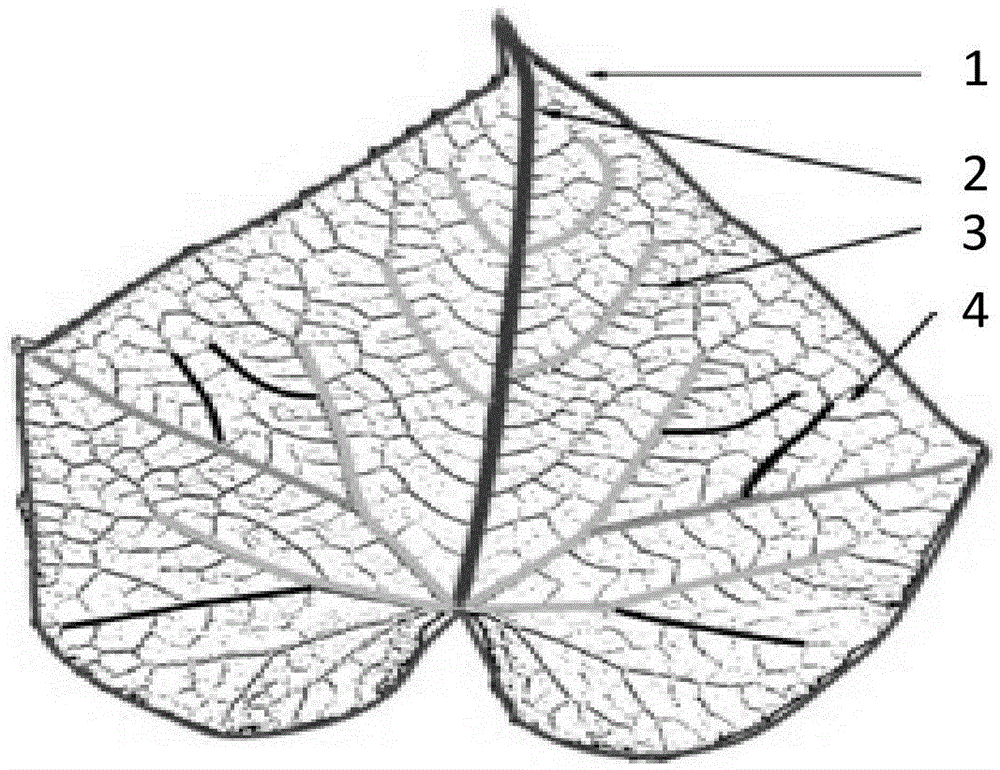

Plant palmate leaf multiscale modeling method

The present invention relates to a plant palmate leaf multiscale modeling method and a device. The method comprises a step of obtaining the multiscale leaf characteristic of a palmate leaf, a step of extracting the structured characteristic points of the multiscale leaf characteristic from the point cloud geometry model of the palmate leaf so as to obtain the leaf edge characteristic line, the fold characteristic line, and first, second and third stages of leaf vein characteristic line of the palmate leaf, a step of carrying out dispersion of the above characteristic lines, a step of constructing the parameter curved surface of the palmate leaf with the leaf edge characteristic line as a boundary, a step of obtaining the structure characteristic line sample point set and parameter curved surface sample point set of different grid scales in the parameter curved surface according to different sample parameters, a step of connecting the structure characteristic line sample point and parameter curved surface sample point corresponding to each size to form a constraint line, and a step of obtaining the grid model of the palmate leaf on the basis of the above constraint line. The device is realized based on the above method. According to the method and the device, the multiscale palmate leaf grid model can be constructed while a leaf vein characteristic is ensured, and the efficiency is improved through reducing a grid quantity.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

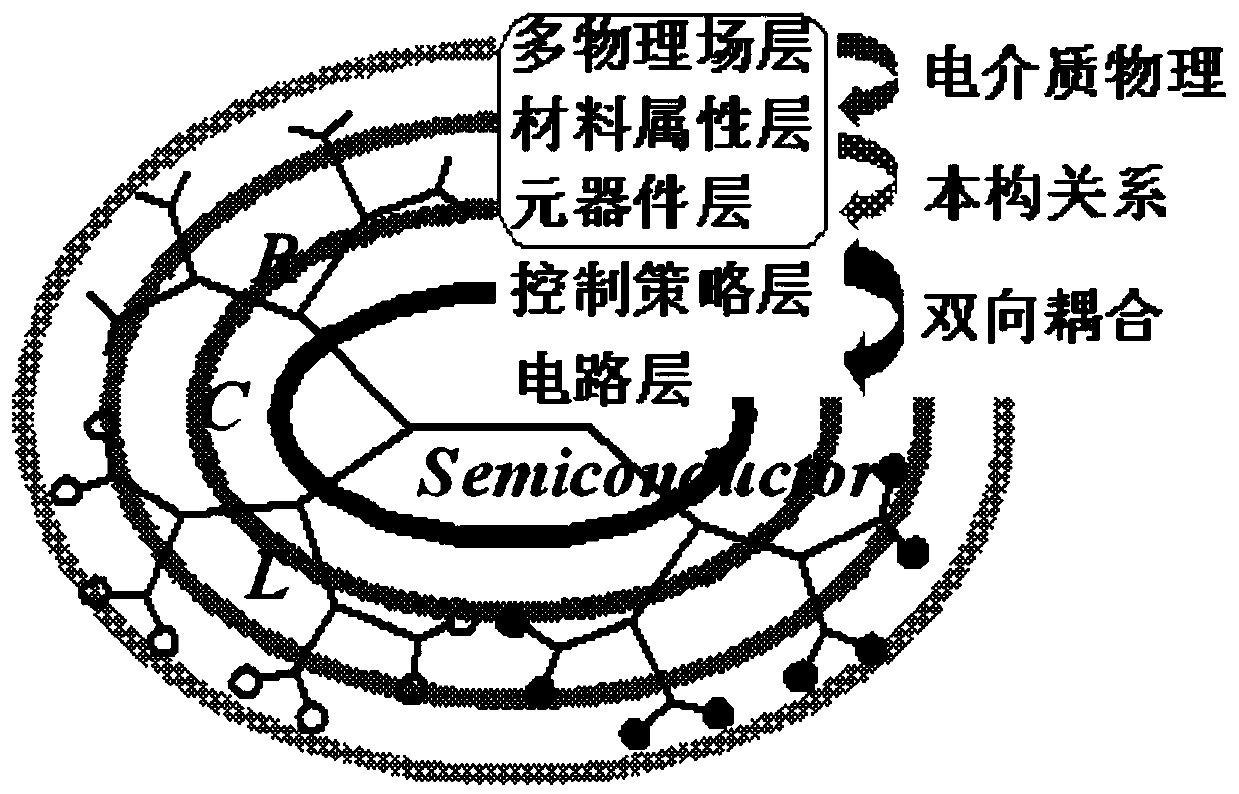

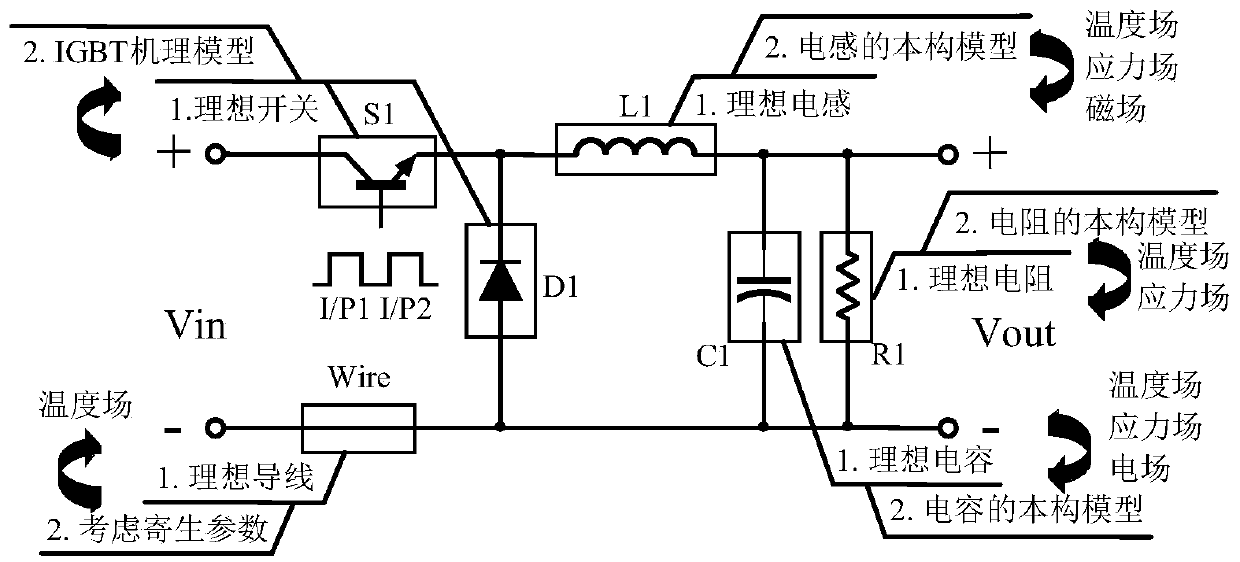

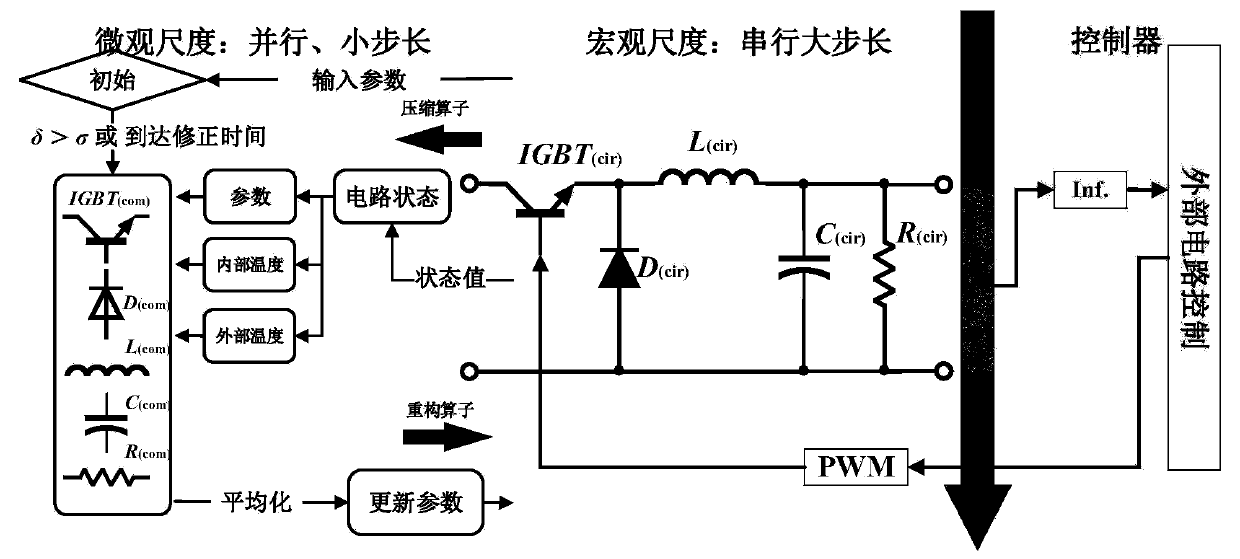

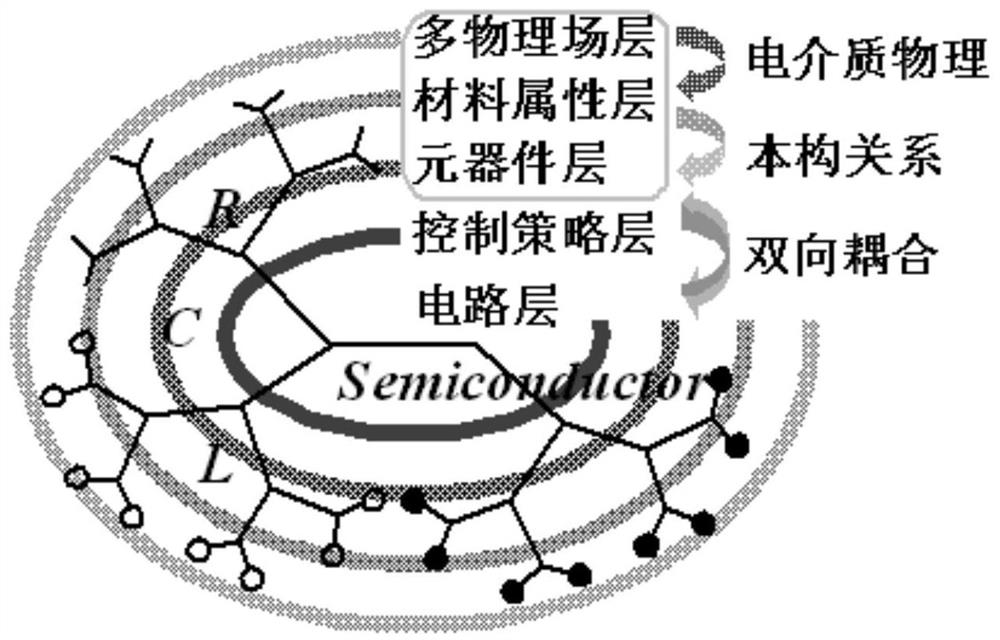

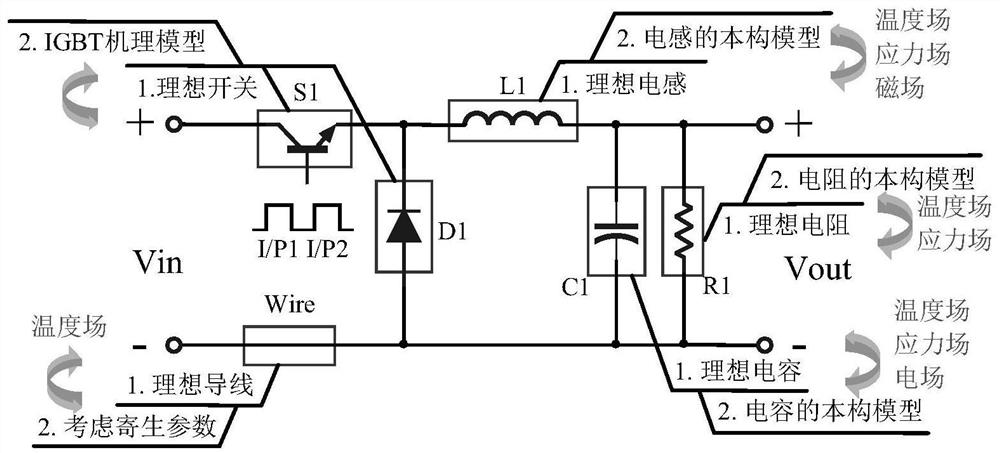

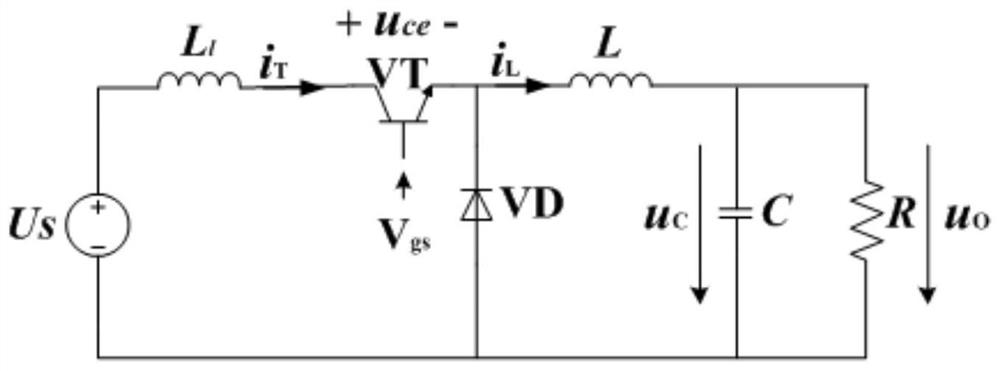

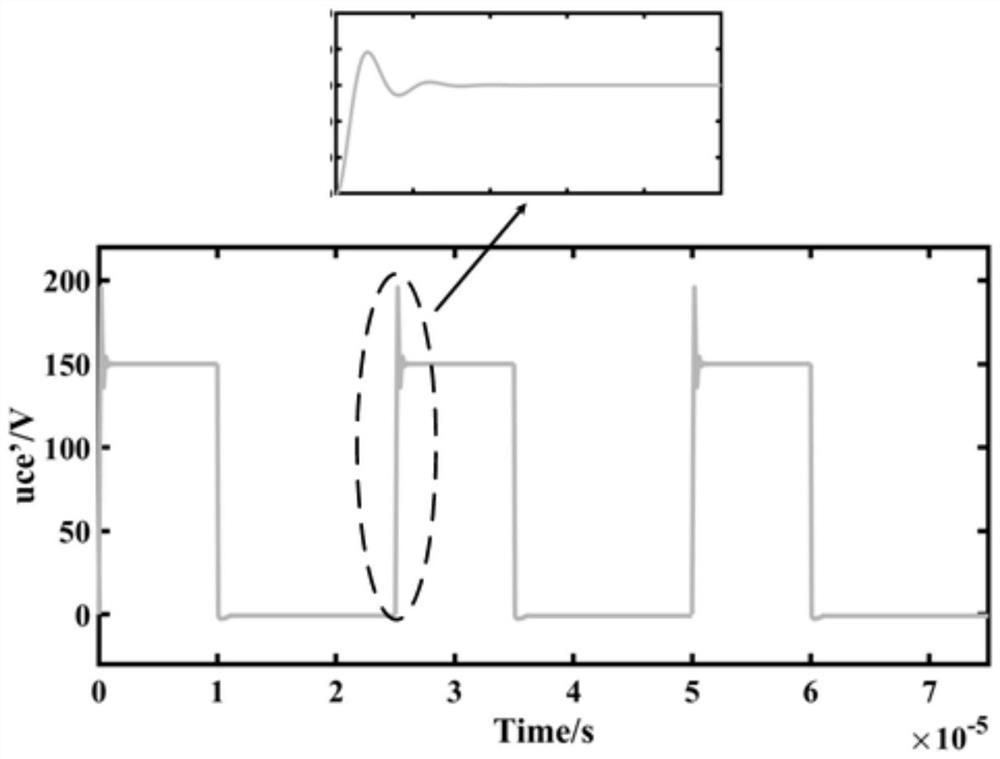

Converter multi-scale modeling method based on microscopic and macroscopic description

ActiveCN110543665ANo missing micro detailsReduce occupancySpecial data processing applicationsMacroscopic scaleObservation point

The invention discloses a converter multi-scale modeling method based on microscopic and macroscopic description. The converter multi-scale modeling method comprises the steps: 1) selecting a topological structure and an auxiliary circuit of a converter, and analyzing the to-be-observed scale of the converter; (2) determining a level needing to be developed in research, and selecting a multi-scalecomponent according to the level; 3) selecting a physical field factor according to the converter operation environment; 4) determining a research mode by utilizing the information; 5) selecting components and nodes for multi-scale observation, and respectively setting a consistency observation point, a reliability observation point and a corresponding error rate delta; and (6) judging an error between the macroscale and a set reference value through an observation point, switching the microscale for calculation when the error of the macroscale is greater than a set error rate delta, and correcting parameters of the macroscale by utilizing an obtained result to finish data conversion between the scales. According to the converter multi-scale modeling method, the coupling relation betweentransient dynamic characteristics of all components and circuits is introduced into modeling of the power electronic converter, and accurate simulation, control and reliability analysis of the systemare achieved.

Owner:SOUTH CHINA UNIV OF TECH

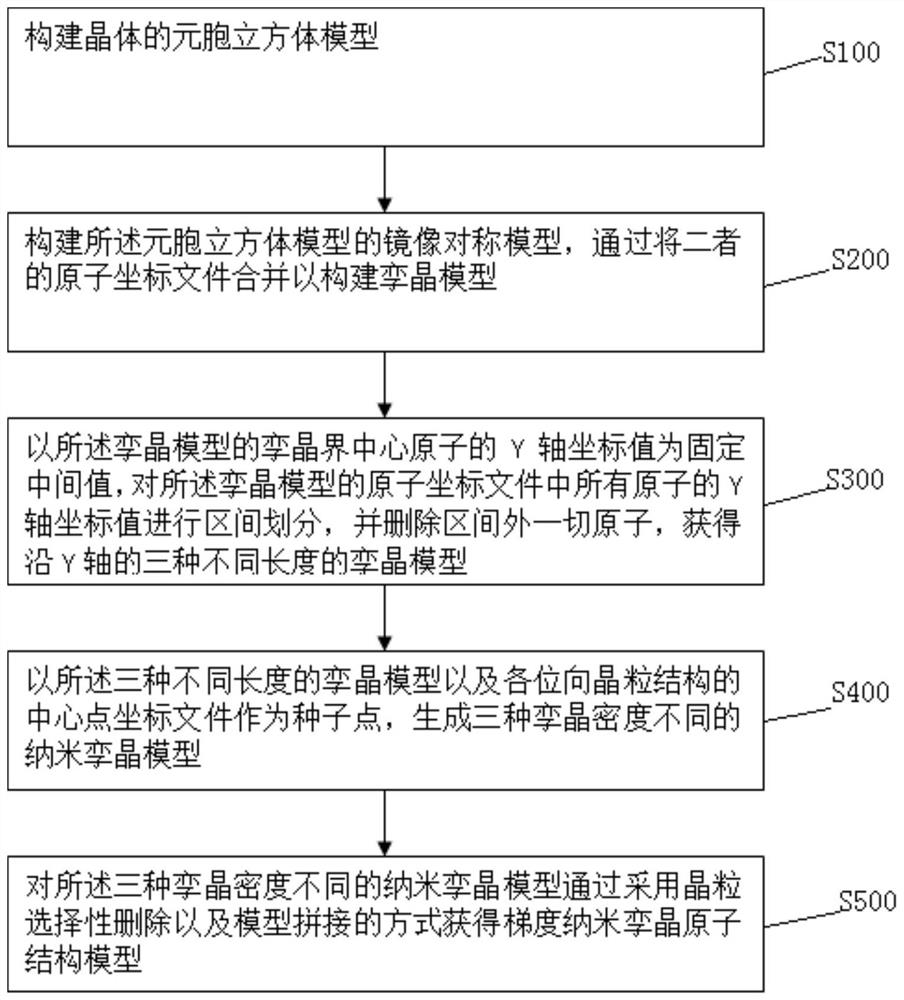

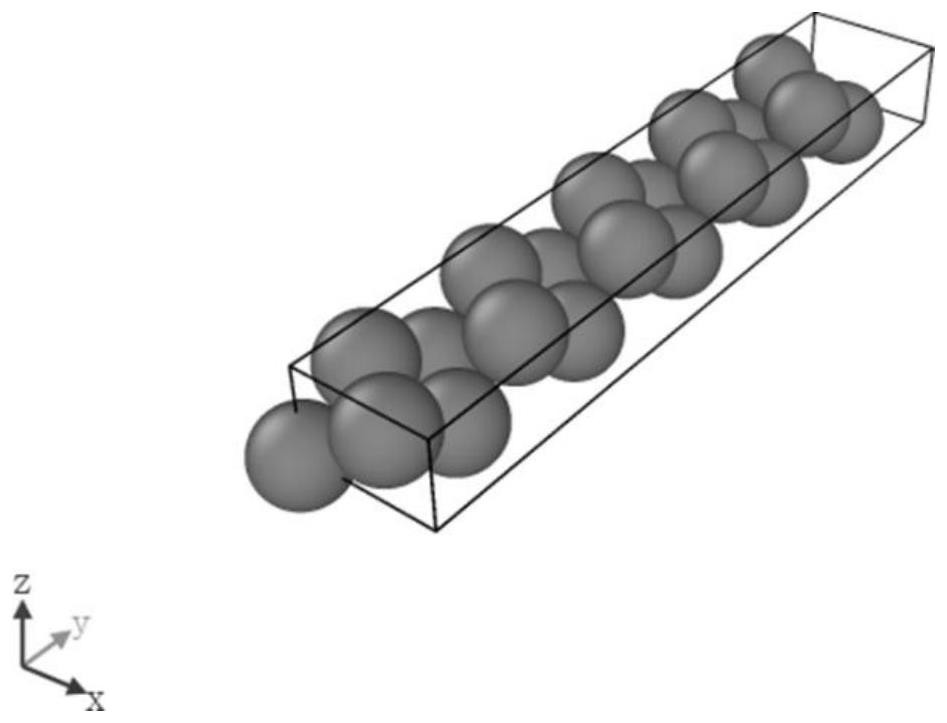

Multi-scale modeling method of gradient nano twin crystal

PendingCN114708920ACheminformatics data warehousingDesign optimisation/simulationGrain structureCrystal density

The invention discloses a multi-scale modeling method for gradient nano twin crystals. The multi-scale modeling method comprises the following steps: constructing a cellular cube model of a crystal; constructing a mirror symmetry model of the cellular cube model, and combining atomic coordinate files of the two to construct a twin crystal model; taking the Y-axis coordinate value of the center atom of the twin boundary of the twin crystal model as a fixed intermediate value, performing interval division on the Y-axis coordinate values of all atoms in the atom coordinate file of the twin crystal model, and deleting all atoms outside the interval to obtain three twin crystal models with different lengths along the Y axis; taking the three twin crystal models with different lengths and the central point coordinate file of each orientation grain structure as seed points to generate three nano twin crystal models with different twin crystal densities; and obtaining a gradient nano-twin crystal atomic structure model for the three nano-twin crystal models with different twin crystal densities by adopting crystal grain selective deletion and model splicing modes.

Owner:XI AN JIAOTONG UNIV

Multi-scale mesh modeling software products and controllers

ActiveUS10664560B2Accurately predict thermal and stress/strain fieldsQuick fixProgramme controlAdditive manufacturing apparatusIndustrial engineeringMesh grid

Simulation systems, manufacturing systems, software products and controllers are provided with multi-scale modeling in which a coarse mesh and a fine mesh that models a stimulus are decoupled. The fine mesh can be moved within the coarse mesh with a cut and paste operation. The coarse mesh is updated by sparsely propagated effects through the coarse mesh. Simulations of the invention can be conducted in real-time, and be used as controllers in manufacturing systems, such as additive manufacturing systems. A number of efficient methods are provided for solving meshing determinations that arise from movement of a stimulus modeled within a fine mesh.

Owner:UNIV OF LOUISVILLE RES FOUND INC

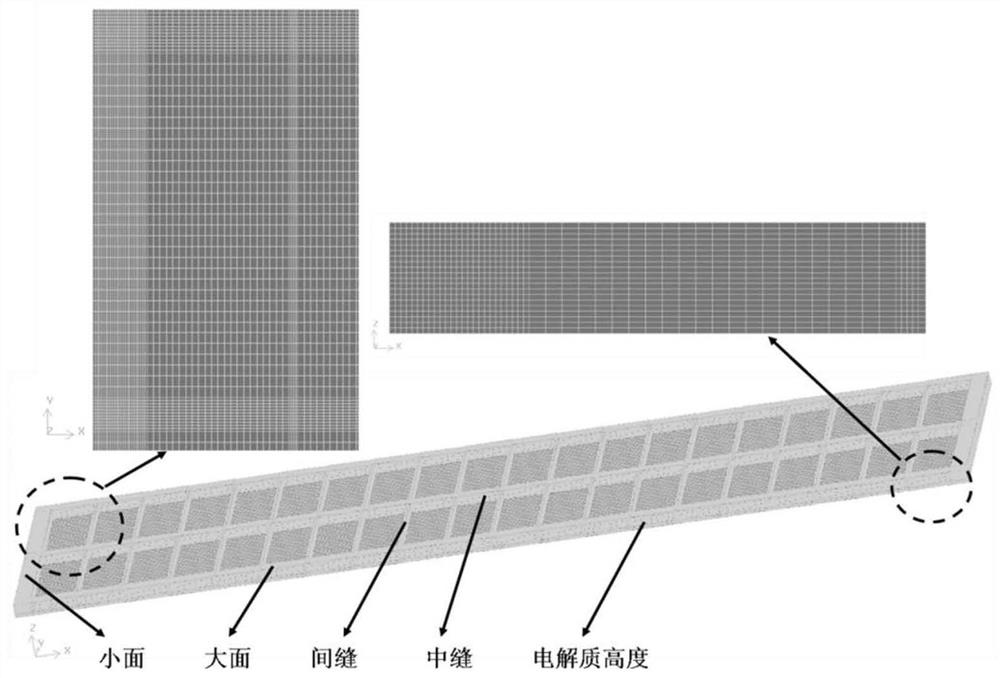

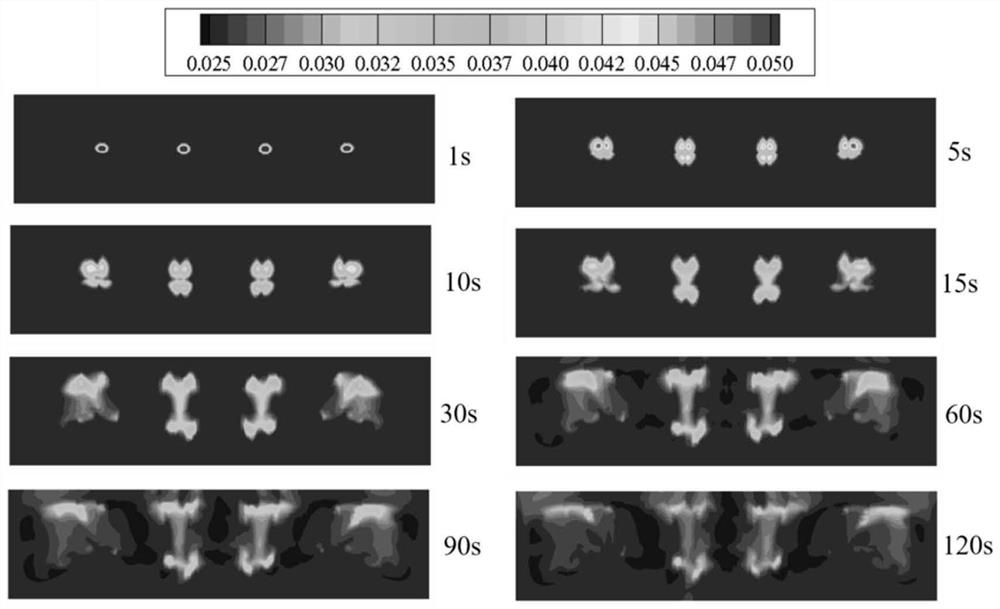

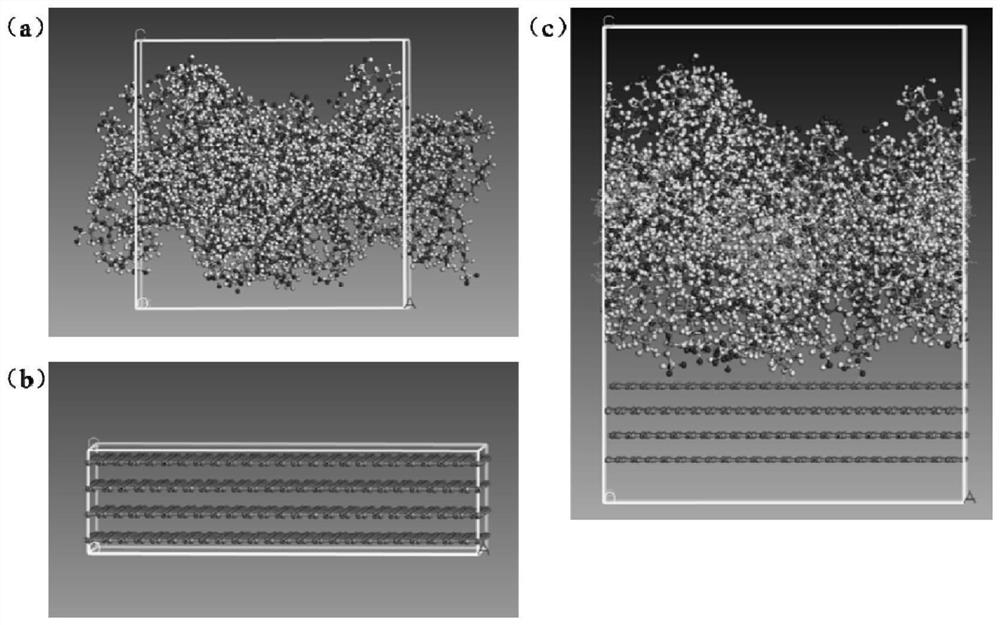

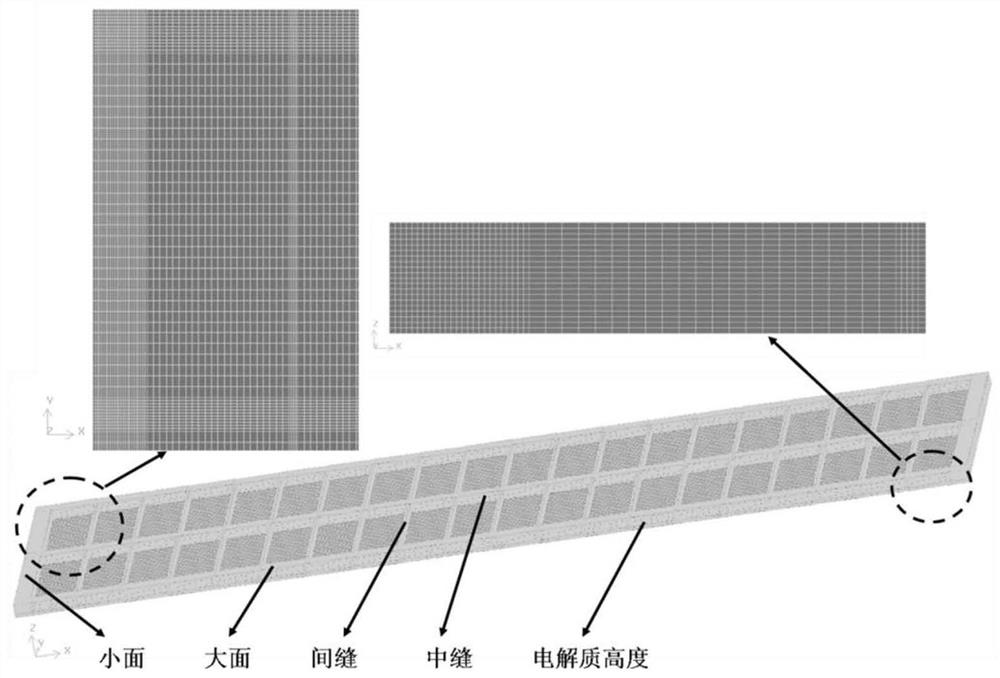

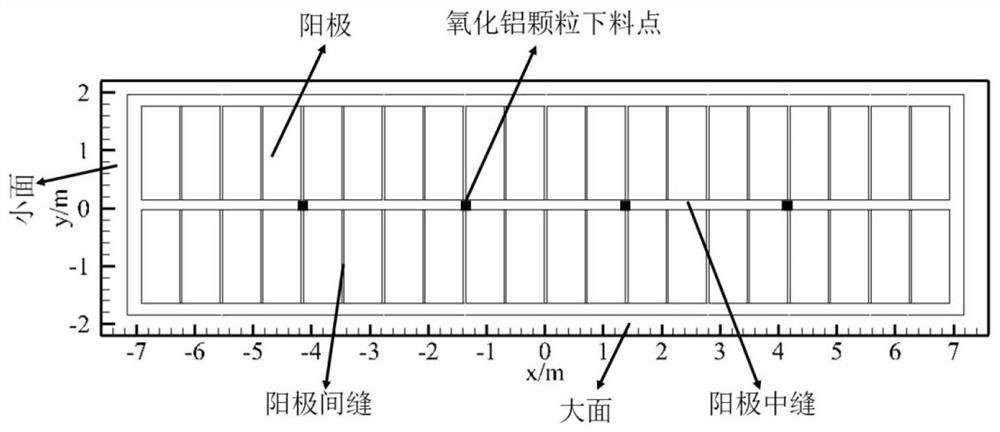

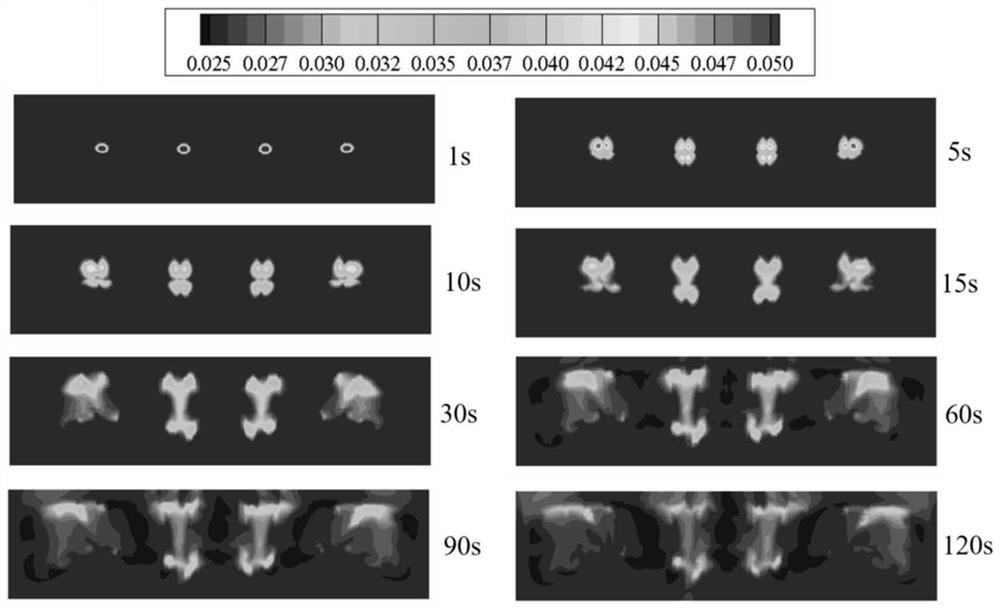

Multi-scale modeling and calculating method for aluminum electrolysis aluminum oxide particle dissolving process

ActiveCN112376083APrecise force between phasesAccurate electrolyte flow field calculation resultsMetallurgyMathematical model

The invention discloses a multi-scale modeling and calculating method for an aluminum electrolysis aluminum oxide particle dissolving process. The method comprises the following steps that a three-dimensional calculation geometric model of a certain industrial aluminum electrolysis cell is established and mesh generation is carried out; a mesoscale mathematical model for accurately describing bubble coalescence and breaking behaviors in a aluminum electrolysis cell melt is established; three-dimensional space gas-liquid interphase acting force data borne by the melt in the aluminum electrolysis cell is precisely exported, and coupling and nesting treatment are carried out on the three-dimensional space data of the electromagnetic force and the gas-liquid interphase acting force borne by the melt; and a multi-scale liquid-solid two-phase flow model for describing the dissolution process of alumina particles in the aluminum electrolysis cell is constructed, and multi-phase flow, multi-physical field action, interphase heat and mass transfer, alumina particle ball shrinkage behaviors and the like are coupled. The method can accurately calculate and predict the dissolution behavior ofthe aluminum oxide particles in the large industrial aluminum electrolysis cell, has good applicability and generalization performance, is beneficial to scientifically guiding the optimal design of the industrial aluminum electrolysis aluminum oxide feeding process, and provides theoretical guidance for the efficient and stable production of the actual aluminum electrolysis cell.

Owner:JIANGSU UNIV

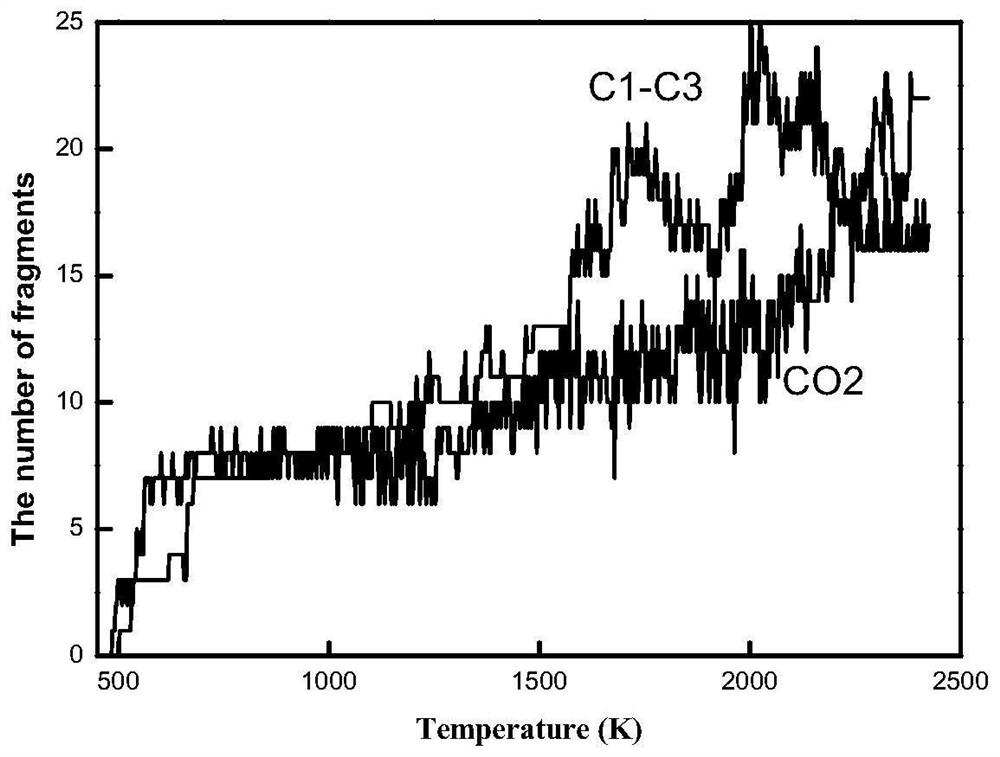

Coal chemical-looping gasification process design method based on multi-scale modeling and application thereof

ActiveCN112487641AMeet production requirementsLow number of carbon atomsDesign optimisation/simulationSpecial data processing applicationsProcess safetyProcess design

The invention relates to the field of clean production, in particular to a coal chemical-looping gasification process design method based on multi-scale modeling and application thereof. The method comprises steps of establishing a coal model and carrying out global energy optimization, carrying out mechanism analysis on CP by adopting ReaxFF-MD simulation, and obtaining an optimal CP temperatureby analyzing the number of fragments; simulating a CLG process by adopting CFD, modeling a fuel reactor, and determining the type and the optimal residence time of an oxygen carrier; based on CP mechanism analysis and CLG hydrodynamic simulation results, conducting steady-state simulation on the CPCLG system, and obtaining key parameters influencing synthesis gas production through sensitivity analysis. High-purity synthesis gas is obtained through multi-scale modeling, comprehensive optimization of various properties of clean production is considered, clean production, low energy consumption,high productivity and multi-reactor dynamic stability can be achieved at the same time, and process safety is guaranteed.

Owner:QINGDAO UNIV OF SCI & TECH

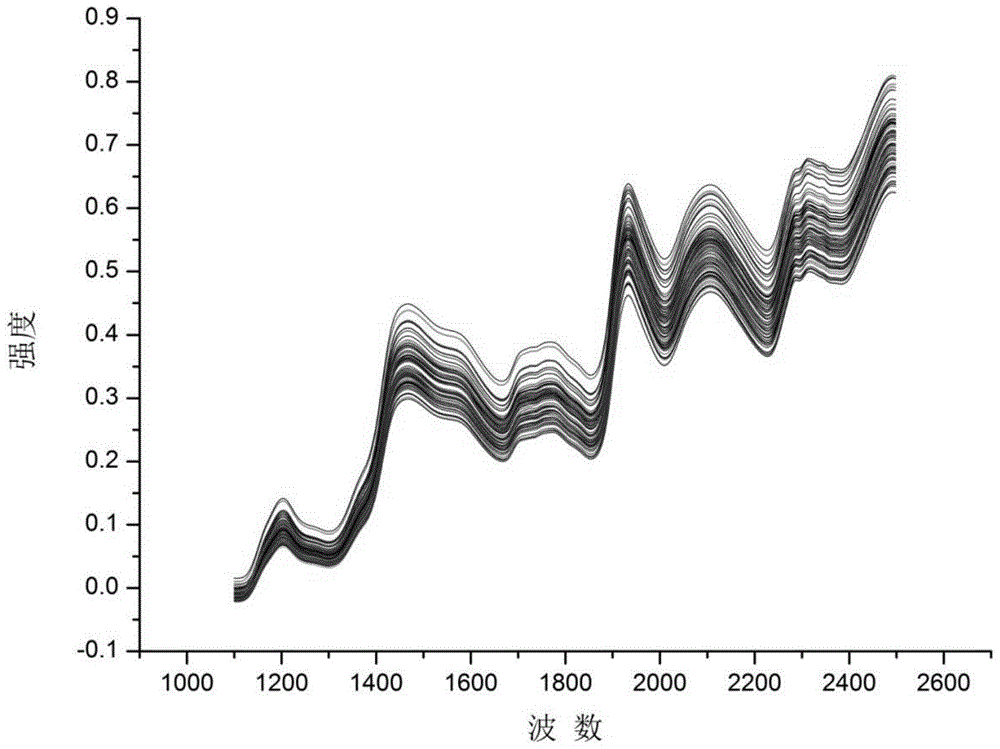

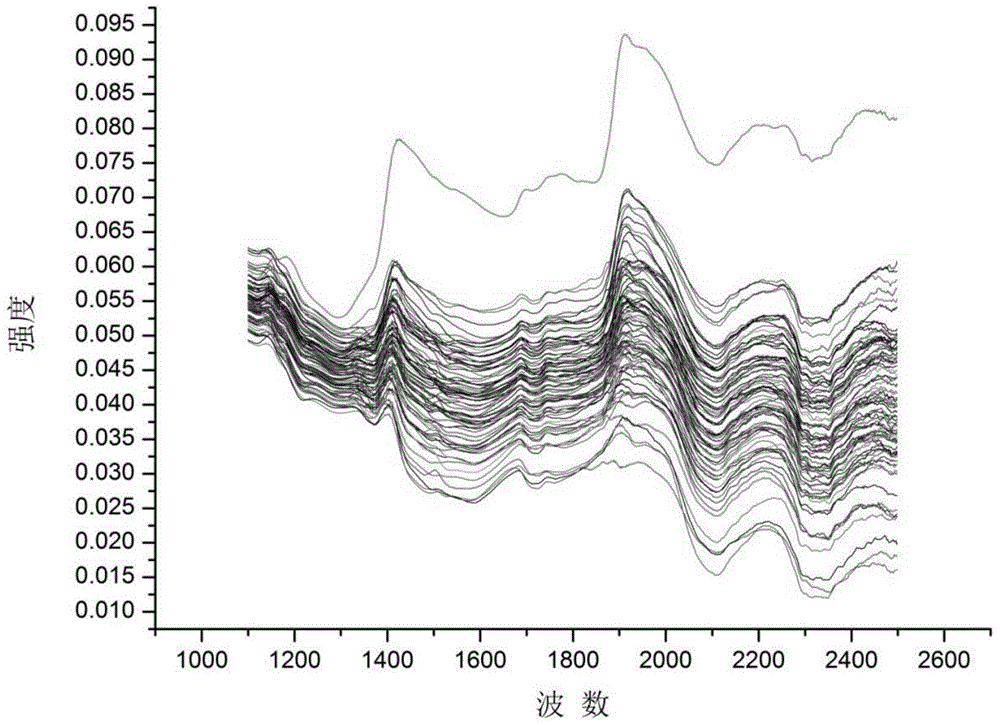

A Model Transfer Method Based on Multi-scale Modeling

InactiveCN103854305BImprove efficiencyImprove performanceColor/spectral properties measurements3D modellingMultiscale decompositionScale model

The invention discloses a module transfer method based on multiscale modeling. The method comprises the following steps: collecting original spectra of a host instrument and a slave instrument; by combining the characteristic of wavelet basis and the characteristic of the original spectrum of a sample, selecting the optimal wavelet basis to carry out wavelet multiscale decomposition on the spectrum to obtain wavelet coefficient; reconstructing the wavelet coefficient; respectively performing multivariate calibration on each layer of reconstructed spectrum; setting up a prediction model based on partial least squares method and leaving one cross-validation method for the spectrum after performing multivariate calibration to obtain a cross-validation root-mean-square error of the prediction model; performing model fusion on the prediction model by using weight number, and calculating the prediction root-mean-square error and related coefficient to evaluate the model transfer effect. Compared with a conventional model transfer method, the method greatly improves the model transfer efficiency and performance, and can be widely applied to fields of near-infrared and Raman spectrum.

Owner:TIANJIN UNIV

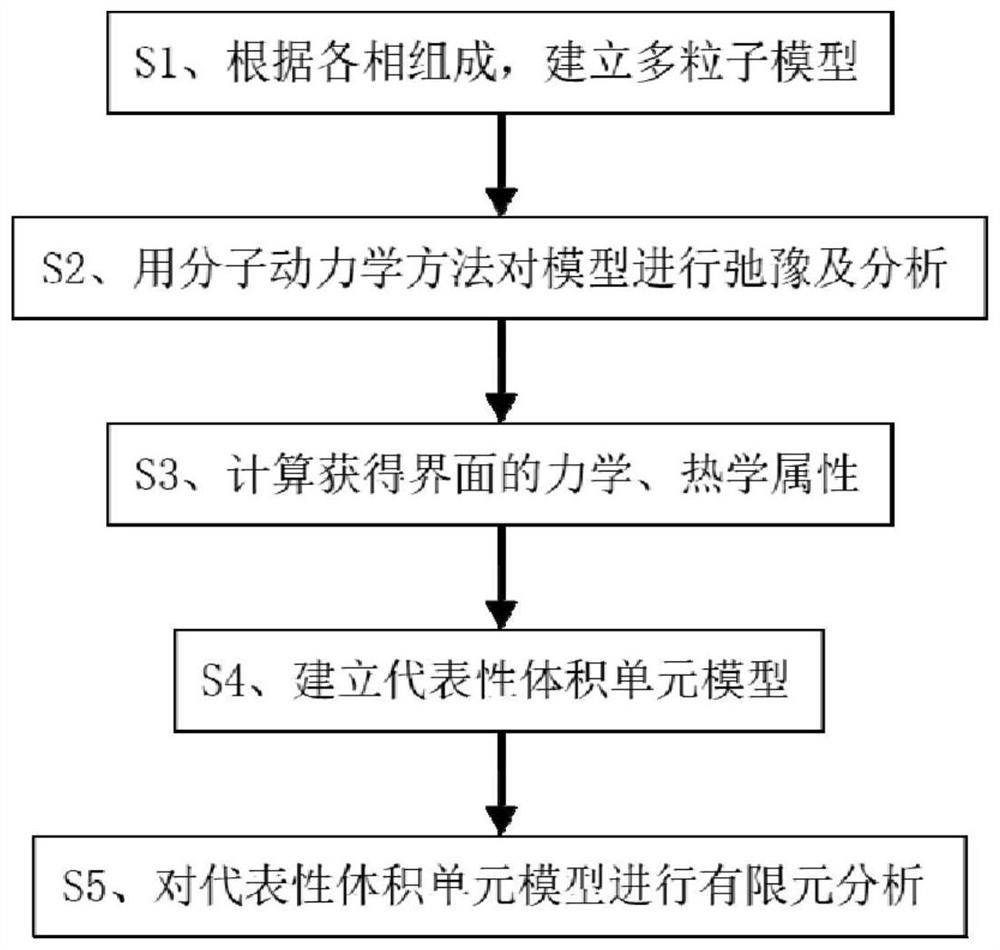

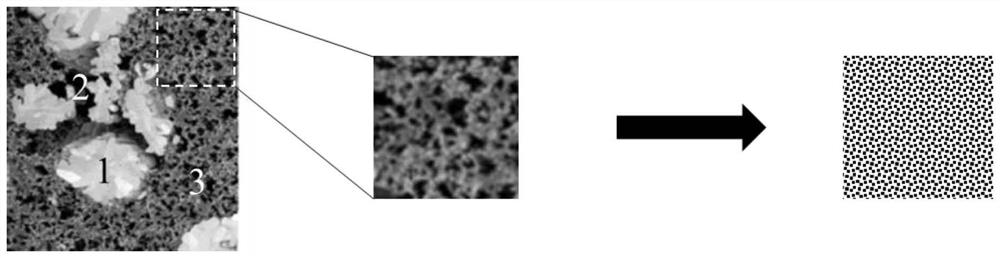

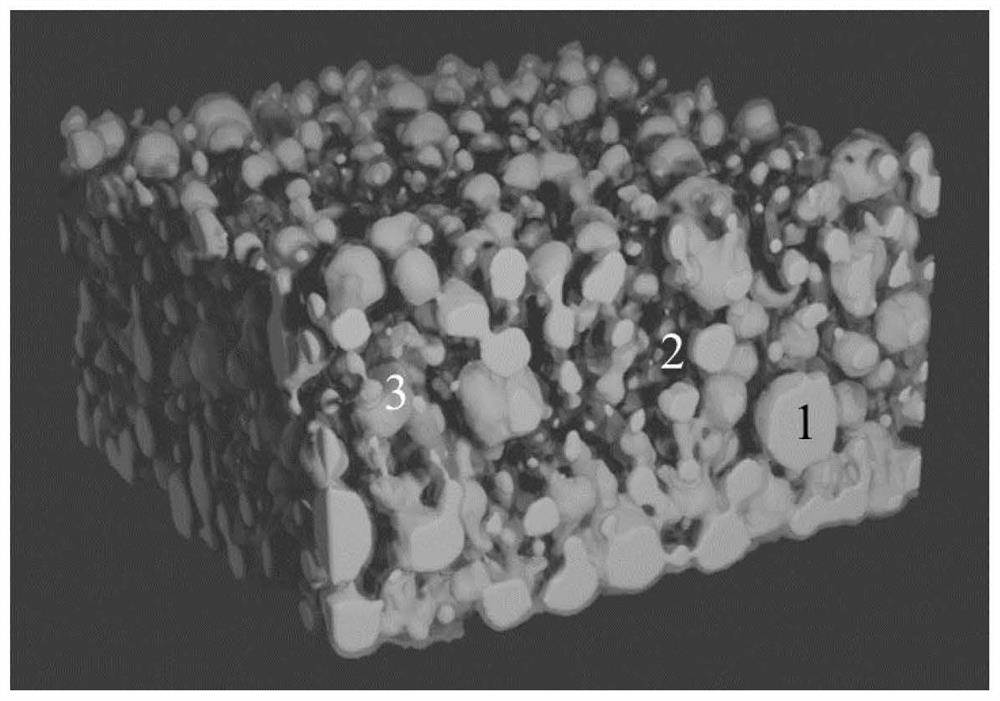

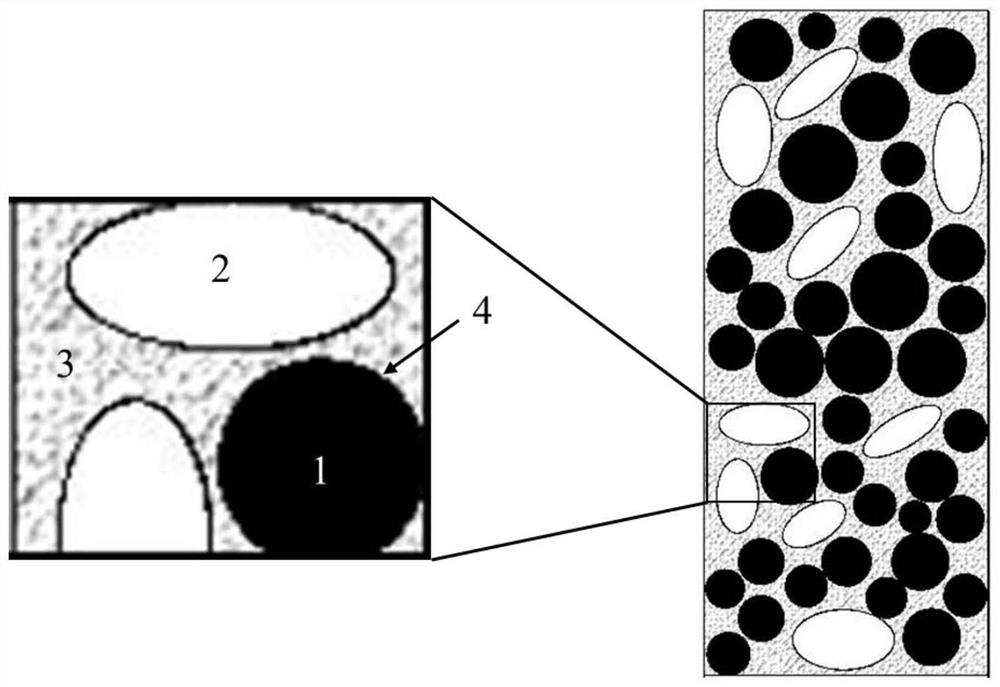

Multi-scale modeling and simulation method for porous composite material

PendingCN114121184ADesign optimisation/simulationComputational theoretical chemistryElement modelElement analysis

The invention relates to a multi-scale modeling and simulation method for a porous composite material, and the method comprises the following steps: S1, building a multi-particle model of each interface in the composite material according to the material components of the composite material; s2, selecting a potential function capable of describing interaction between atoms in the system, and performing system relaxation and thermodynamic and kinetic analysis on the multi-particle model by using a molecular dynamics method; s3, carrying out calculation through a molecular dynamics method to obtain mechanical and thermal related properties of each interface in the composite material; s4, establishing a representative volume element model for the composite material; and S5, performing finite element analysis on the representative volume element. Compared with the prior art, the method can be used for simulation research on the relationship between the microstructure and the physical property of the porous composite material under different use conditions, such as research on the influence of the interface strength, the interface heat conductivity, pores, the size, the distribution and the content of each particle on the heat conductivity, the elastic modulus, the yield strength, the stress distribution, the conductivity and other parameters of the composite material.

Owner:TONGJI UNIV

A multi-scale modeling and calculation method for the dissolution process of aluminum electrolytic alumina particles

ActiveCN112376083BPrecise force between phasesAccurate electrolyte flow field calculation resultsAluminium electrolysisThree-dimensional space

The invention discloses a multi-scale modeling and calculation method for the dissolution process of aluminum electrolytic alumina particles, which establishes a three-dimensional computational geometric model of an industrial aluminum electrolytic cell and performs grid division; establishes an accurate description of the coalescence and coalescence of bubbles in the melt of the aluminum electrolytic cell The mesoscopic-scale mathematical model of crushing behavior; accurately derive the three-dimensional gas-liquid phase force data on the melt in the aluminum electrolytic cell, and couple and embed the three-dimensional space data of the electromagnetic force on the melt and the gas-liquid phase force Set processing; build a multi-scale liquid-solid two-phase flow model describing the dissolution process of alumina particles in the aluminum electrolytic cell, coupling multi-phase flow, multi-physics field effects, heat and mass transfer between phases, and the shrinkage behavior of alumina particles. The method of the present invention can accurately calculate and predict the dissolution behavior of alumina particles in large-scale industrial aluminum electrolytic cells, has good applicability and popularization, and is helpful to scientifically guide the optimization design of industrial aluminum electrolytic alumina blanking process. Provide theoretical guidance for efficient and stable production of actual aluminum electrolytic cells.

Owner:JIANGSU UNIV

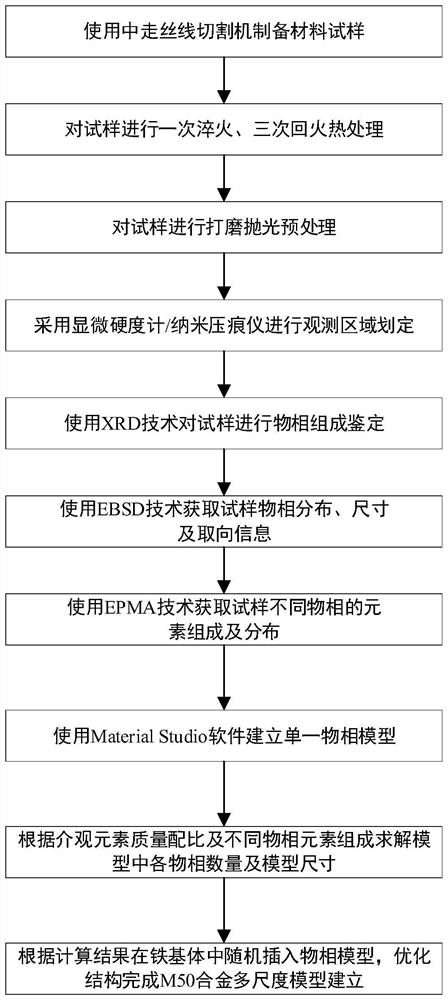

Multi-scale modeling calculation method for bearing steel material M50 alloy

PendingCN114757047ADoping achievedImprove accuracyDesign optimisation/simulationSpecial data processing applicationsScale modelCrystal structure

The invention discloses a multi-scale modeling calculation method of a bearing steel material M50 alloy, and belongs to the field of multi-phase alloy multi-scale modeling. Comprising the following steps: delimiting a sample observation area; carrying out phase type and distribution identification and elemental composition and crystal structure analysis on the sample in the observation area to obtain a mesoscopic element mass ratio and elemental compositions of different phases; establishing an atomic scale model of a single phase according to the phase type and the crystal structure; establishing an equation through the mesoscopic element mass ratio and phase element composition, and solving the number of each phase in the atomic model and the proper size of an iron matrix; randomly inserting several phase structures into the iron matrix according to the obtained phase proportion, and optimizing the structure to obtain a micro-mesostructure model of the bearing steel material M50 alloy; various properties of the alloy can be simulated on the mesoscale based on the model, and the structural transformation process of the alloy on the atomic scale during heat treatment and damage and the damage mechanism of the M50 alloy can be simulated and observed.

Owner:XI AN JIAOTONG UNIV

A Multiscale Modeling Method for Transformers Based on Microscopic and Macroscopic Descriptions

ActiveCN110543665BNo missing micro detailsReduce occupancyDesign optimisation/simulationData transformationMacroscopic scale

The invention discloses a converter multi-scale modeling method based on microscopic and macroscopic description. The converter multi-scale modeling method comprises the steps: 1) selecting a topological structure and an auxiliary circuit of a converter, and analyzing the to-be-observed scale of the converter; (2) determining a level needing to be developed in research, and selecting a multi-scalecomponent according to the level; 3) selecting a physical field factor according to the converter operation environment; 4) determining a research mode by utilizing the information; 5) selecting components and nodes for multi-scale observation, and respectively setting a consistency observation point, a reliability observation point and a corresponding error rate delta; and (6) judging an error between the macroscale and a set reference value through an observation point, switching the microscale for calculation when the error of the macroscale is greater than a set error rate delta, and correcting parameters of the macroscale by utilizing an obtained result to finish data conversion between the scales. According to the converter multi-scale modeling method, the coupling relation betweentransient dynamic characteristics of all components and circuits is introduced into modeling of the power electronic converter, and accurate simulation, control and reliability analysis of the systemare achieved.

Owner:SOUTH CHINA UNIV OF TECH

A Multiscale Modeling Method for Skeletal Muscle Mechanical Behavior

InactiveCN106202739BRealize macro and micro geometry modelingRealize simulationDesign optimisation/simulationSpecial data processing applicationsMuscle tissueMuscular force

The invention relates to a skeletal muscle mechanical behavior multiscale modeling method and aims at solving the problem in the prior art that a complete process from cell electrophysiologic action potential activation to skeletal muscle mechanical output cannot be simulated. The method comprises the steps of S1, determining positions and attitudes of muscle fibers; S2, establishing a skeletal muscle macroscopic geometric model and a skeletal muscle microcosmic geometric model according to the S1; S3, carrying out grid division on the geometric models established in the S2; S4, carrying out skeletal muscle electrophysiologic property modeling according to the S3; S5, carrying out multiscale calculation between cells and muscle tissues according to the S3 and S4; S6, establishing a skeletal muscle multiscale biomechanics model according to the S5; and S7, predicting muscular force according to the S6. The method is applied to the field of biomedical engineering.

Owner:HARBIN UNIV OF SCI & TECH

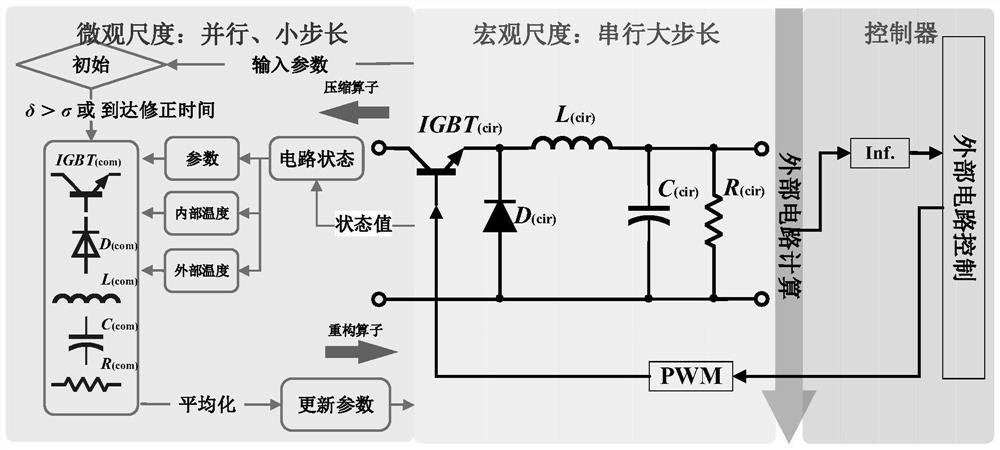

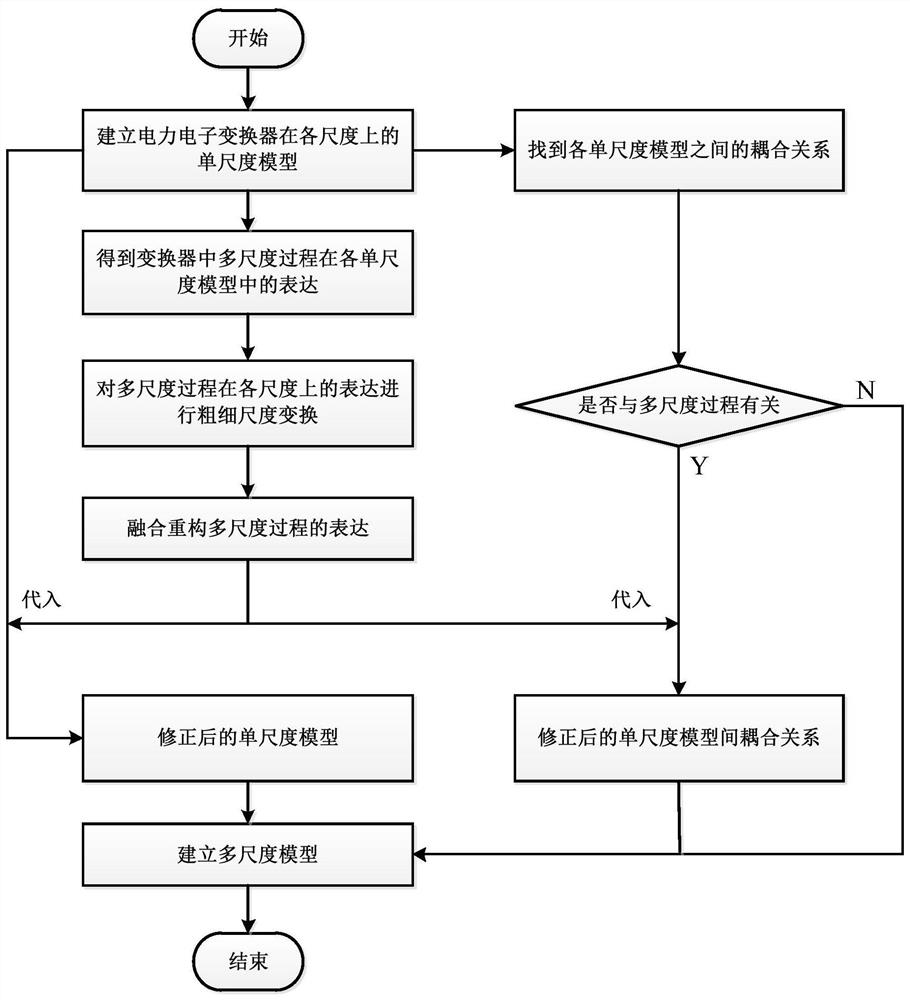

A Multiscale Modeling Method for Power Electronic Converters Based on Coarse and Fine Scale Transformation

ActiveCN110362865BAccurate descriptionImprove stabilityDesign optimisation/simulationSpecial data processing applicationsScale modelCoupling (electronics)

A multi-scale modeling method for power electronic converters based on coarse and fine scale transformation. Firstly, a single-scale model of power electronic converters at different scales is established to obtain the expression of multi-scale processes at different scales; then, based on wavelet multi-scale The coarse and fine scale transformation in the analysis theory reconstructs the multi-scale process in the power electronic converter, and integrates the expression of the multi-scale process in different scale models; then finds the correlation function between variables on different scales, and establishes different scale models Inter-coupling relationship; finally, the expression of the reconstructed multi-scale process is substituted into the single-scale model or coupling relationship, and the model or coupling relationship is corrected, thus obtaining the required multi-scale model. Compared with the traditional single-scale modeling, the method of the present invention can reflect the dynamic characteristics of the power electronic converter on multiple scales and can reflect the changes in the dynamic characteristics of the converter when considering the phenomena on multiple scales at the same time, and the simulation results are more accurate. fit the actual situation.

Owner:SOUTH CHINA UNIV OF TECH

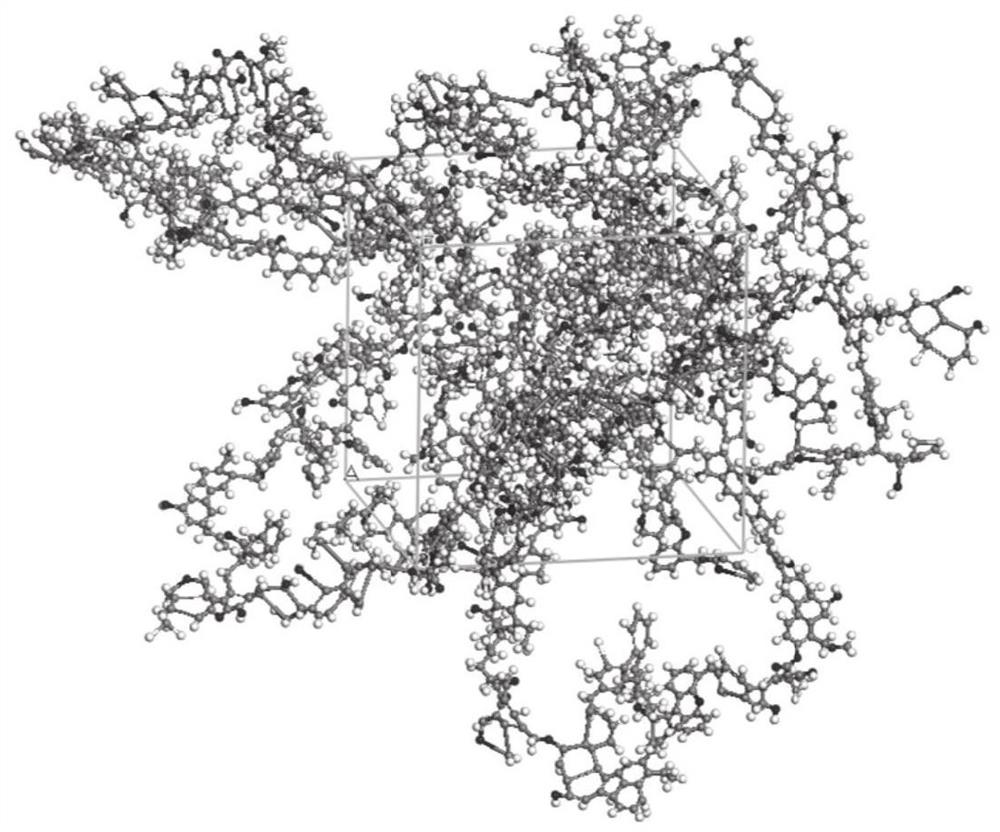

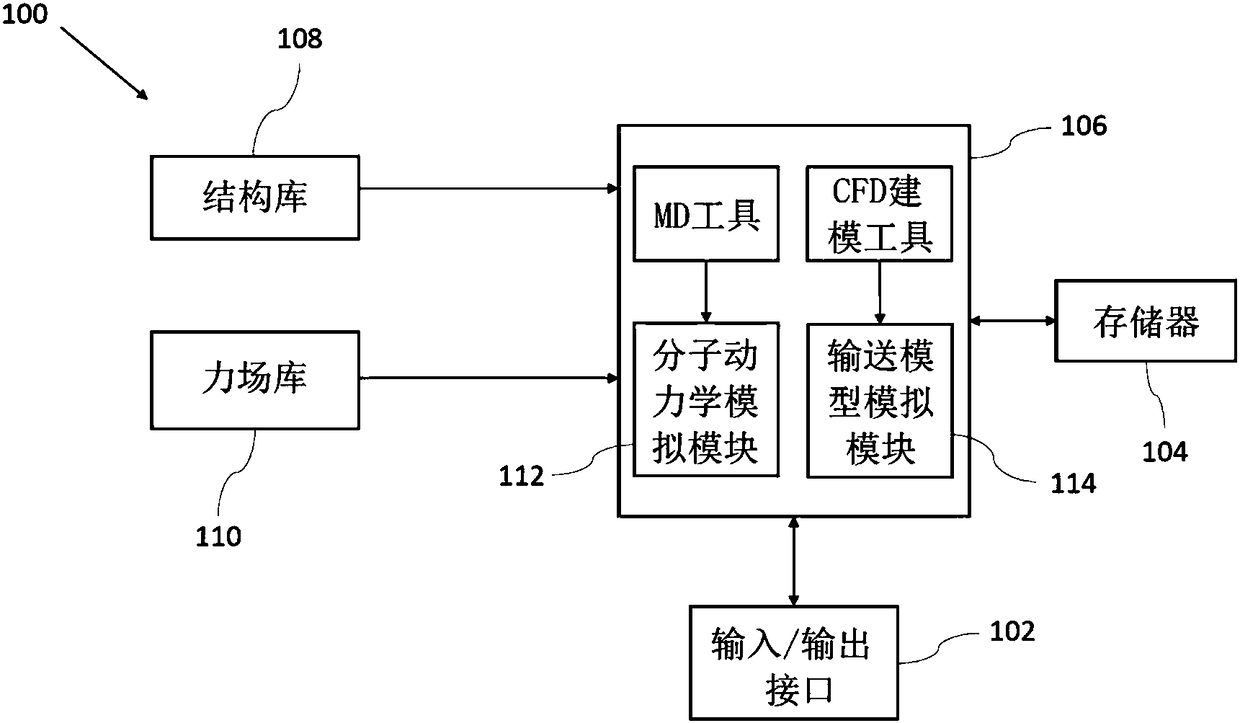

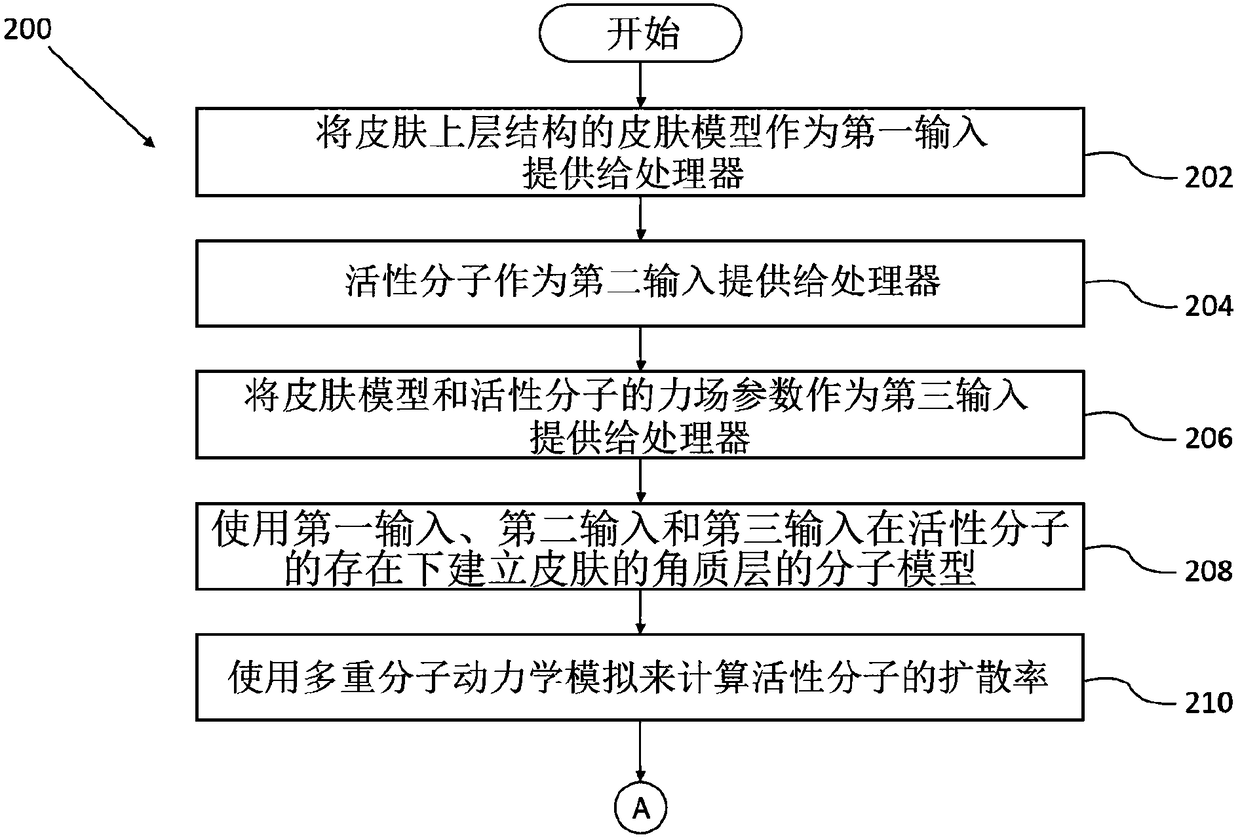

Method and system for in-silico testing of actives on human skin

A method and system for in-silico testing of actives on human skin is described. The present invention discloses a microscopic level model and a macroscopic level model of the skins upper protective layer stratum corneum. The invention presents a multi-scale modeling framework for the calculation of diffusion and release profiles of different actives like drugs, particles and cosmetics through a developed skin model using molecular dynamics simulation and a computational fluid dynamics approach. The systems consist of a molecular model of the skin's upper layer stratum comeum and permeate molecules. The system also consists of a macroscopic transport model of stratum comeum. The transport model is used to generate the release profile of the active molecule.

Owner:TATA CONSULTANCY SERVICES LTD

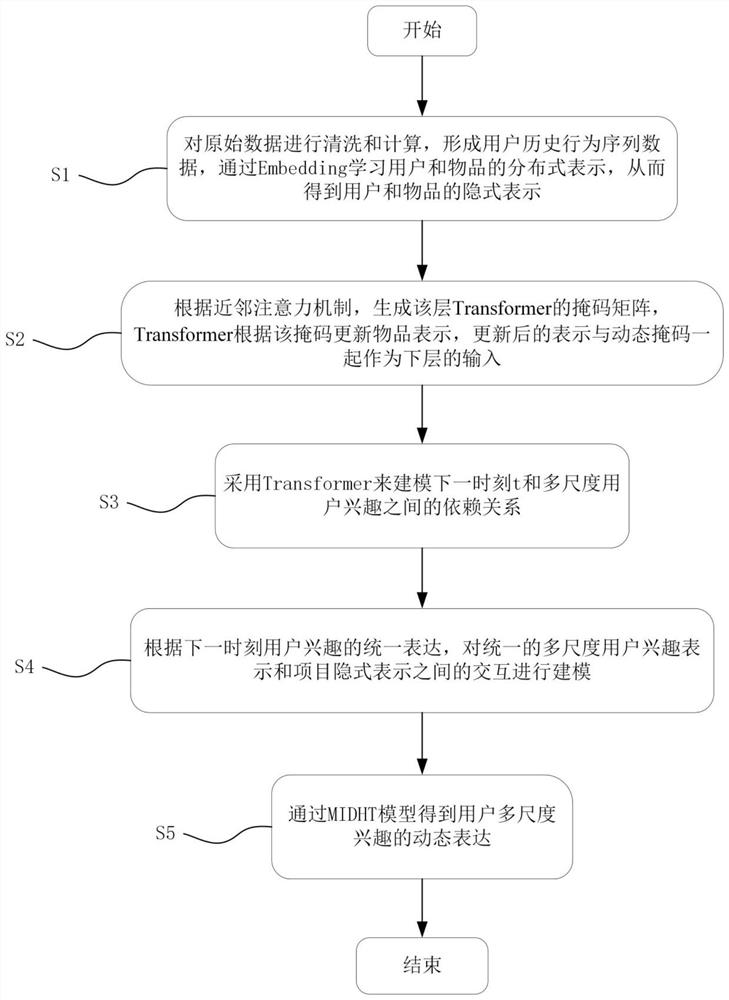

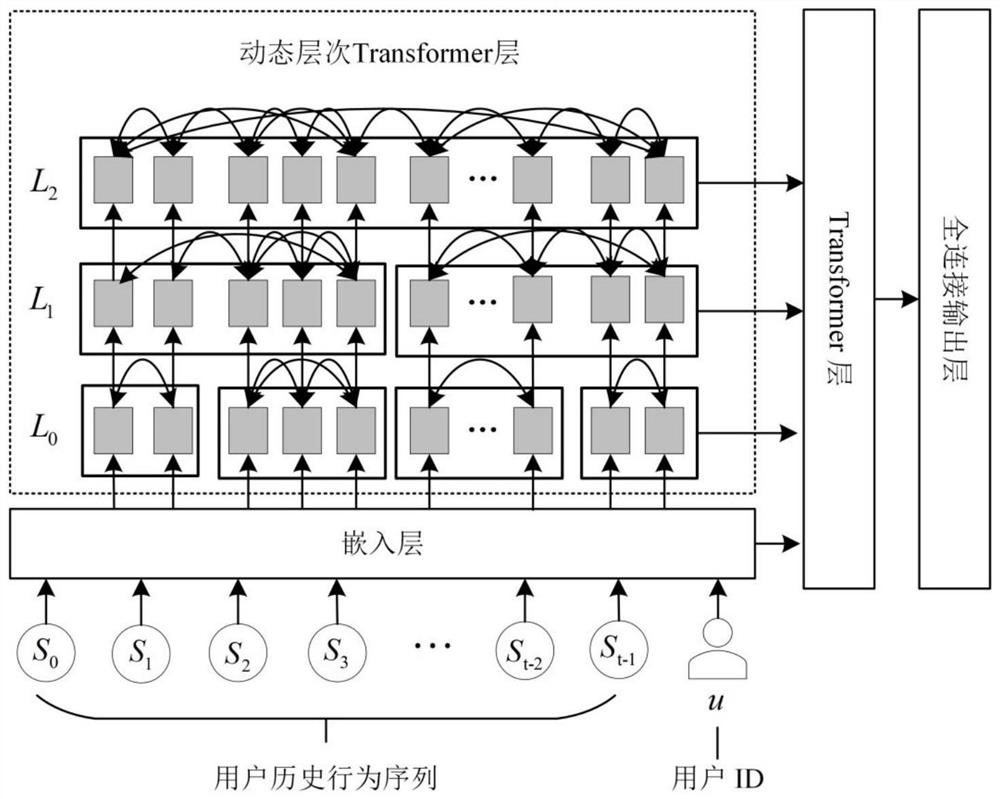

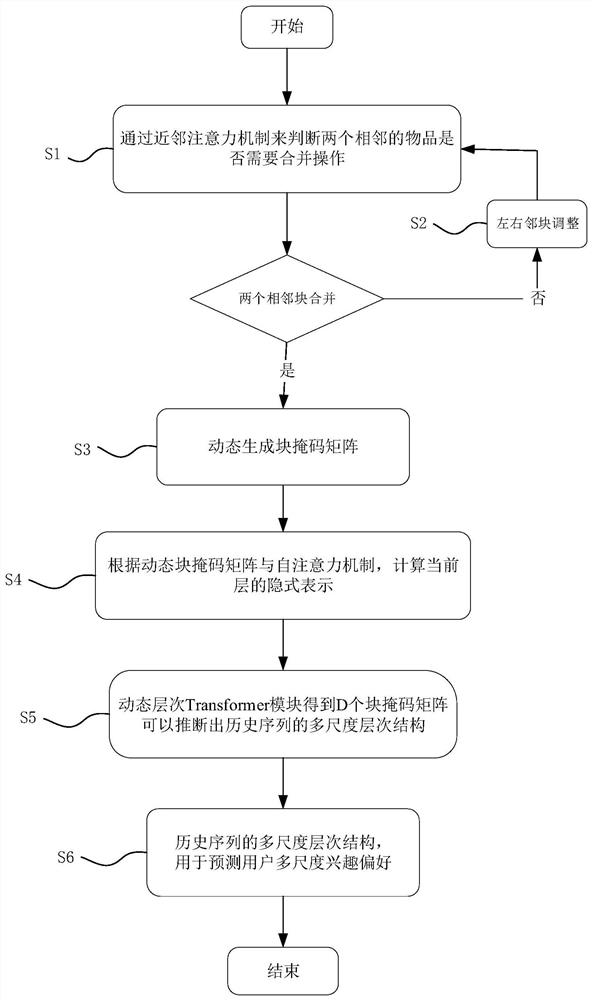

Sequence recommendation method and device based on multi-scale interest dynamic hierarchy Transformer

PendingCN113987336AMeet individual needsImprove accuracyDigital data information retrievalBuying/selling/leasing transactionsPersonalizationRecommendation model

The invention provides a sequence recommendation method and device based on a multi-scale interest dynamic hierarchy Transformer, and the method comprises the steps of carrying out the fine-grained multi-scale modeling of the interest of a user through employing a sequence recommendation model, namely MIDHT (Multi-scale Interest Dynamic hierarchical Transformer); firstly, judging whether two adjacent articles need to be combined or not through a neighbor attention mechanism; 2, dynamically generating a block mask matrix by utilizing a judgment result in the previous step; 3, calculating implicit representation of a current layer according to the dynamic block mask matrix and a self-attention mechanism; and finally, deducing corresponding hierarchical structures from the dynamic block mask matrixes of all layers. The invention has the advantages of being high in operation efficiency and remarkable in individuation effect, and the final interest preference of the user can be well predicted. Therefore, the personalized recommendation performance is excellent.

Owner:WUHAN UNIV

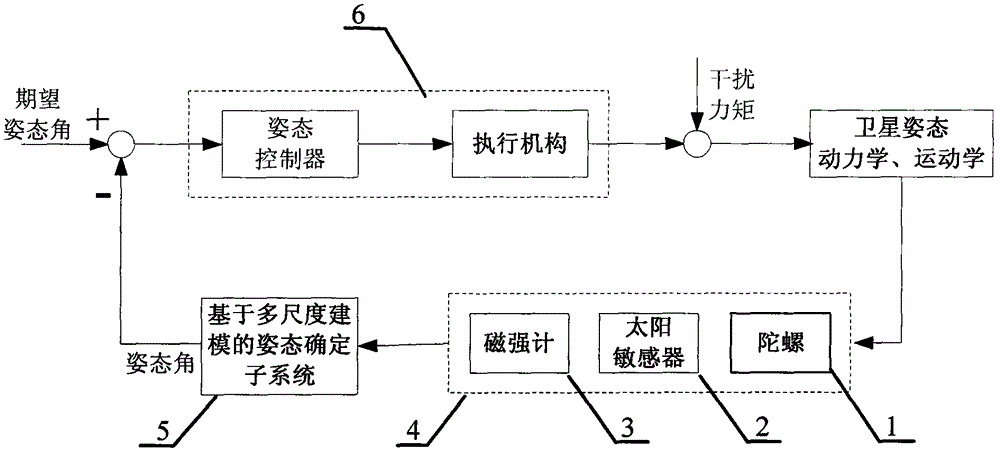

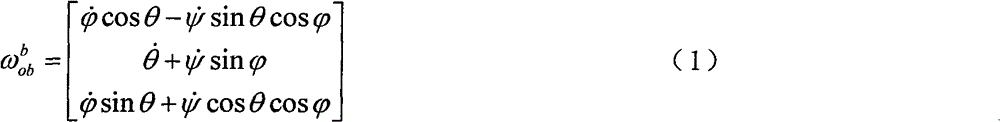

Attitude control feedback loop based on combined fixed attitude of multi-rate sensor

InactiveCN102114918BReduce the complexity of combined pose determinationImprove attitude accuracySpacecraft guiding apparatusScale modelAttitude control

The invention relates to a attitude control feedback loop based on a combined fixed attitude of a multi-rate sensor, which comprises an attitude sensor subsystem, an attitude determining subsystem based on multi-scale modeling, and an attitude control subsystem, wherein the attitude sensor subsystem comprises a gyro, a solar sensor and a magnetometer and outputs attitude measurement information with multi-rate characteristics; the attitude determining subsystem is used for describing measurement information of each sensor from different scales by using a multi-scale analyzing method and estimating the satellite attitude angle on the basis of the established multi-scale model; and the attitude control subsystem is used for controlling the satellite attitude and feeding the controlled attitude information back to the attitude sensor subsystem so as to form the attitude control loop. The attitude control feedback loop is used for carrying out multi-scale modeling by using the multi-scale analyzing method, thereby improving the attitude determining precision while reducing the complexity of an attitude combining and fixing process.

Owner:BEIHANG UNIV

Lithium ion battery electrode multi-phase multi-scale modeling method and system

PendingCN114139371ALower resolution requirementsSmall amount of calculationDesign optimisation/simulationSpecial data processing applicationsElectrochemical responseElectrolytic agent

The invention provides a multi-phase multi-scale modeling method and system for a lithium ion battery electrode, and belongs to the technical field of computer simulation of a lithium ion battery, and the method comprises the steps: calculating the average porosity and tortuosity of a carbon glue phase region; scanning the lithium ion battery electrode sample layer by layer through X ray-CT to establish a three-dimensional geometric reconstruction model; representing the electrochemical reaction rate of the surface of the active material phase by using a reaction kinetic model; establishing a lithium ion transmission equation and a liquid phase potential field equation of an electrolyte region by applying a concentrated solution theory; characterizing a solid-phase potential field on the active material and the carbon glue phase region by adopting an Ohm law; the diffusion coefficient and the conductivity are corrected according to the average porosity and the tortuosity of the carbon gel phase; establishing a concentration field corresponding to substance diffusion in the active material according to the solid phase model; and further, carrying out numerical solution on the model to obtain parameters of the lithium ion battery electrode. According to the method, the accuracy and the efficiency are balanced.

Owner:HUAZHONG UNIV OF SCI & TECH

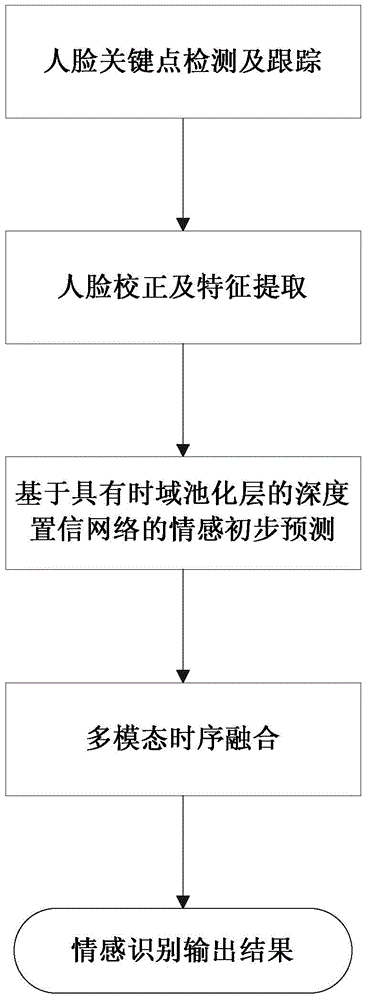

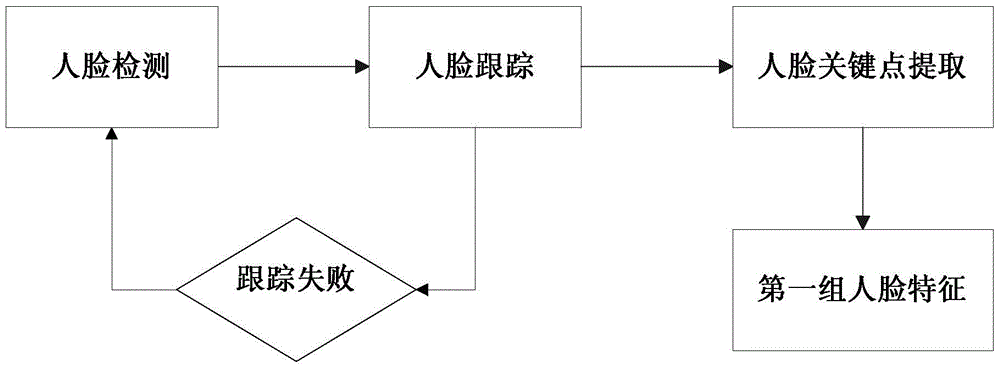

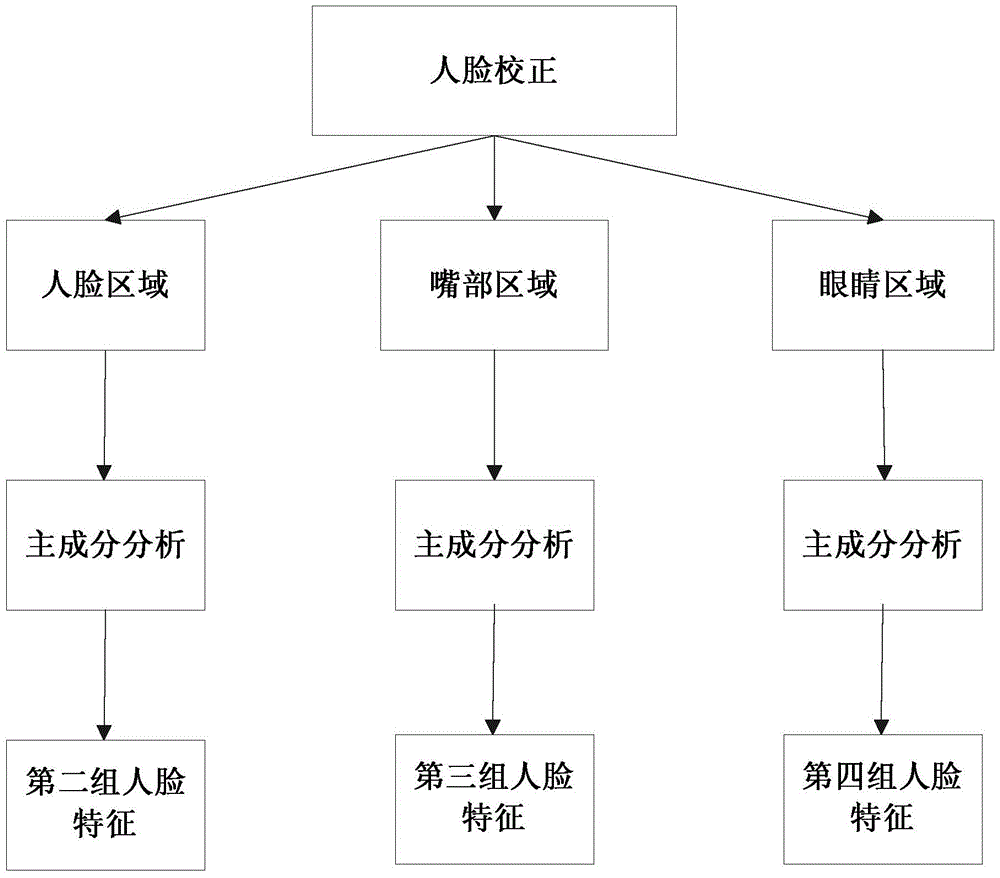

A Dimensional Emotion Recognition Method Based on Multi-scale Time Series Modeling

The invention discloses a dimensional emotion recognition method based on multi-scale time series modeling. The method includes the following steps: performing face detection and tracking for each frame of images in a video sequence, and extracting face key points as a first type group Face features; extract the gray values of the pixels in the face area image, the face mouth area image and the face eye area image as the second, third and fourth groups of face features; The four categories of facial features are used to perform preliminary dimensional emotion prediction; according to the initial emotion prediction results of consecutive N unit time periods t, the linear regression is used to perform time series and modal fusion, and output the emotional prediction value of the video sequence. The method of the invention performs time sequence modeling of different scales on the video sequence signal, and realizes accurate prediction of each time sequence unit in the sequence. The invention is suitable for emotion recognition of face signals in videos, and has the advantages of good real-time performance, and can greatly improve recognition accuracy.

Owner:中科极限元(杭州)智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com