Multi-scale modeling calculation method for bearing steel material M50 alloy

A bearing steel, multi-scale technology, applied in the direction of design optimization/simulation, instrumentation, electrical digital data processing, etc., can solve the problems of less research, low integration of simulation and experiment, and incomplete application of M50 alloy, so as to improve accuracy Effects of Sex and Authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings.

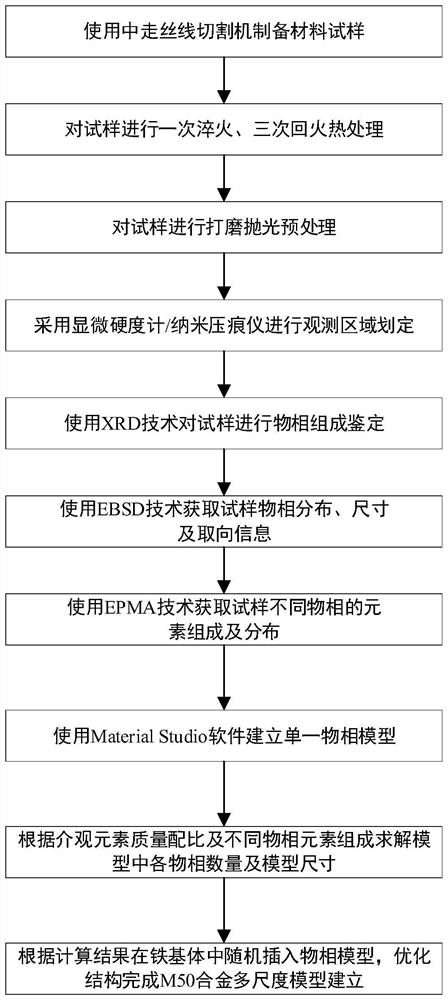

[0030] refer to figure 1 , a multi-scale modeling calculation method of bearing steel material M50, belonging to the field of alloy multi-scale modeling; the multi-scale modeling method comprises the following steps:

[0031] Step 1: Prepare test samples for M50 alloy bars and complete heat treatment;

[0032] Step 2: Pre-treat the samples after heat treatment, and complete the preparation before the test; the specific steps are as follows: use 180#, 400#, 600#, 800#, 1000#, 1500# and 2000# sandpaper to sand the M50 alloy The surface of the sample was polished step by step, using velvet with W7 diamond polishing agent to complete rough polishing, and using woolen wool with W3.5 diamond polishing agent for fine polishing to ensure the surface roughness Ra≤0.1μm, and then ultrasonically cleaned with acetone and anhydrous ethanol in turn. , ultrasonic cleaning time is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com