Multi-scale modeling and simulation method for porous composite material

A porous composite material and simulation method technology, applied in the field of porous composite material analysis, can solve the problems of low accuracy, limited to mesoscopic scale, and lack of microscopic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

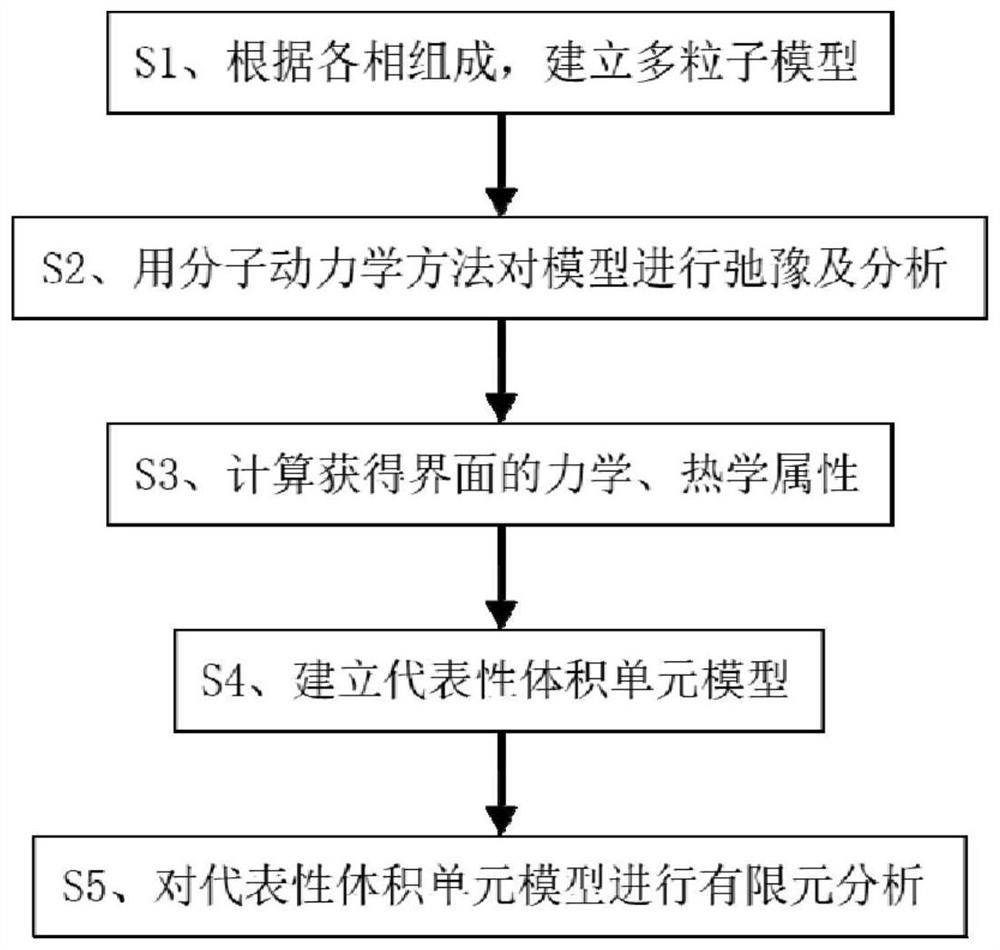

[0050] A multi-scale modeling and simulation method for porous composite materials, such as figure 1 , the method includes the following steps:

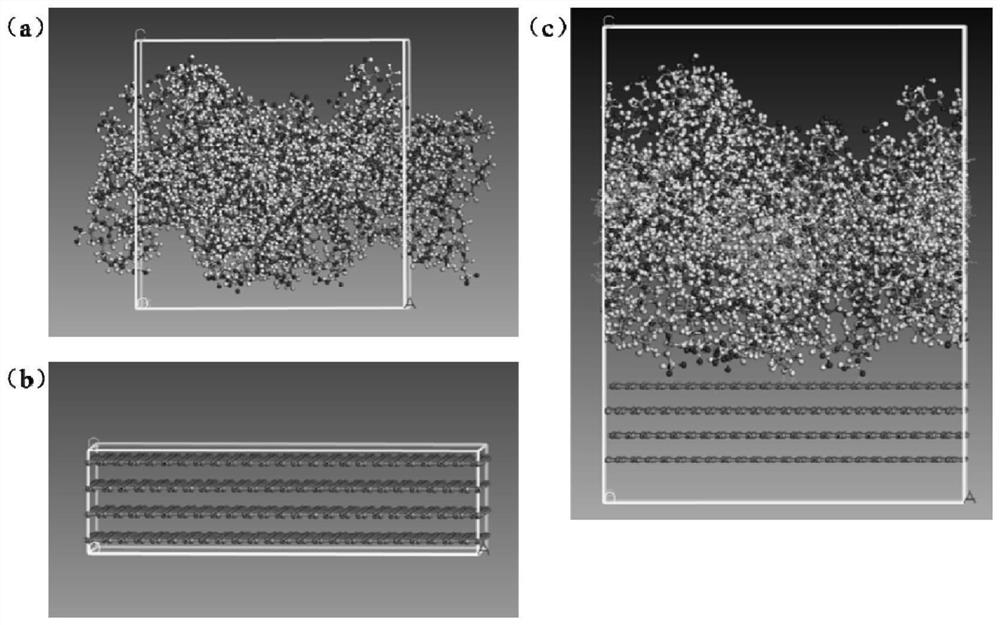

[0051] S1. According to the material composition of the composite material, a multi-particle model of each interface in the composite material is established;

[0052] S2. Select a potential function that can describe the interaction between atoms in the system, and use the molecular dynamics method to perform system relaxation, thermodynamics, and kinetics analysis on the multi-particle model;

[0053] S3. Obtain the mechanical and thermal related properties of each interface in the composite material through molecular dynamics calculation;

[0054] S4. Make model assumptions and geometric settings for the composite material, establish a representative volume element model, and the model interface properties are provided by molecular dynamics results;

[0055] S5. Carrying out finite element analysis on representative volume element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com