Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Methacrylaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold-based catalyst for oxidative esterification of aldehydes to carboxylic acid esters

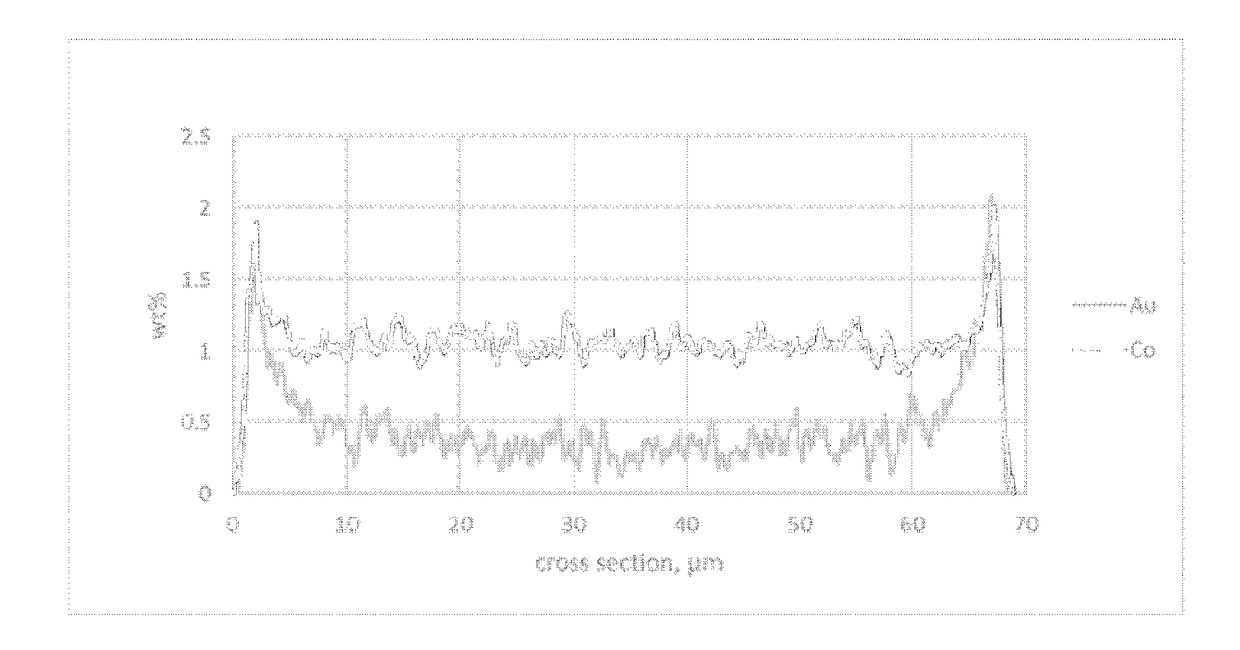

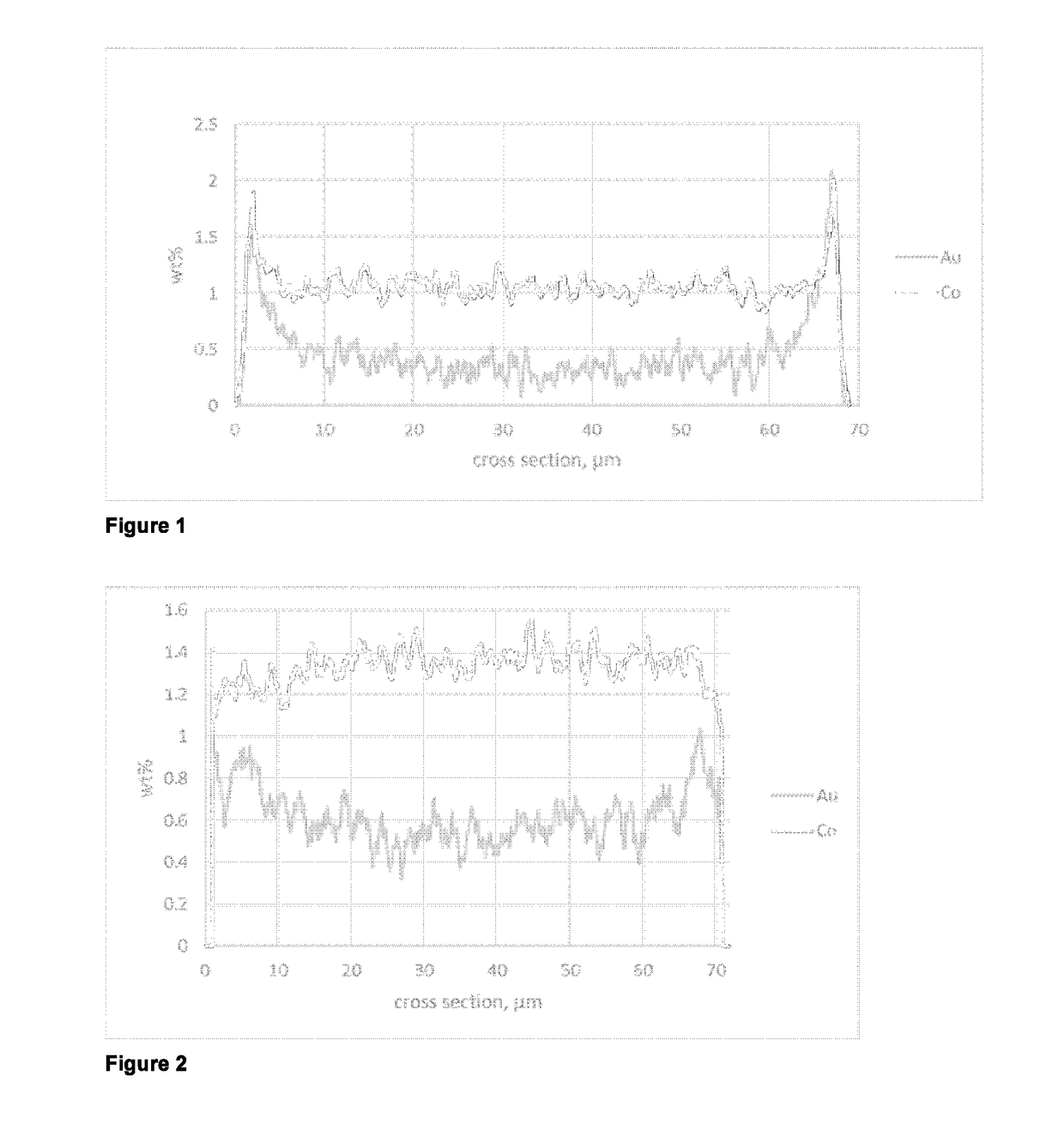

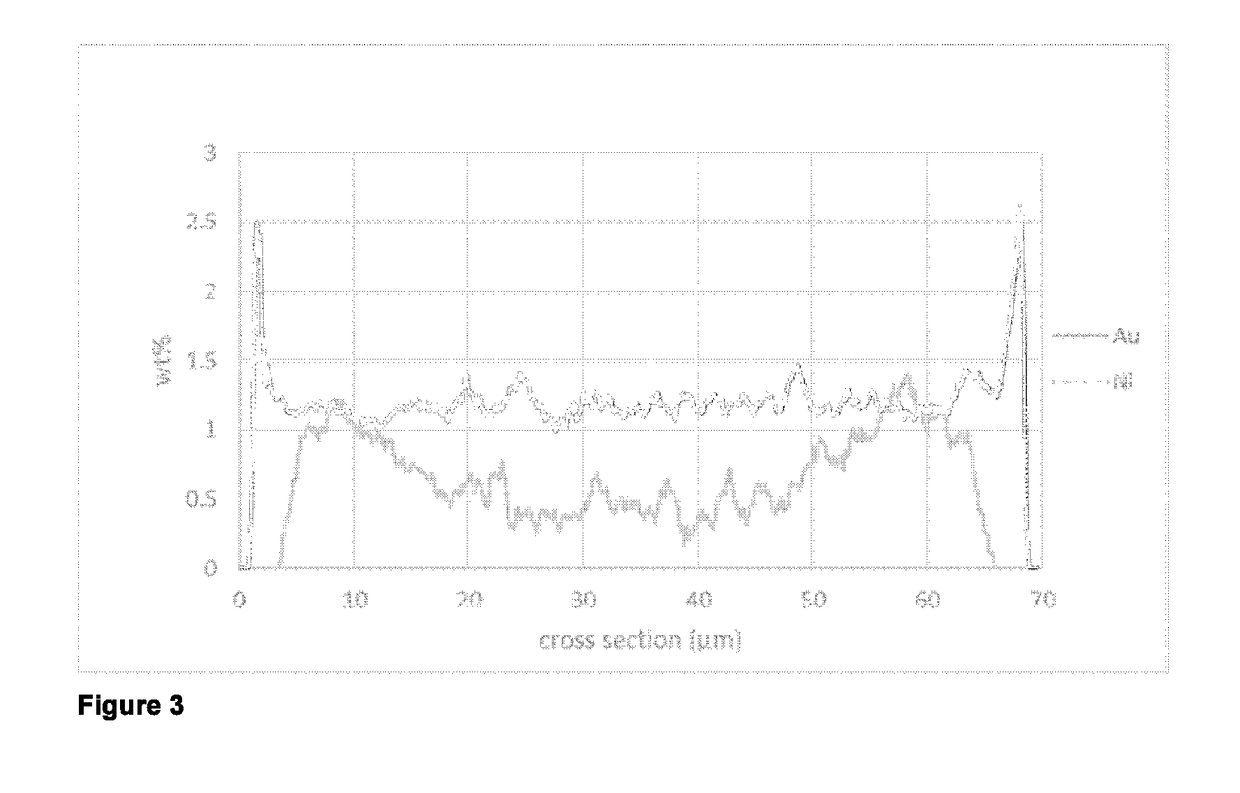

ActiveUS20180326400A1Improve bindingReduce mechanical wearOrganic compound preparationHeterogenous catalyst chemical elementsAcroleinCarboxylic acid

The present invention relates to novel catalysts for oxidative esterification, by means of which, for example, (meth)acrolein can be converted to methyl (meth)acrylate. The catalysts of the invention are especially notable for high mechanical and chemical stability even over very long periods. This especially relates to an improvement in the catalyst service life, activity and selectivity over prior art catalysts which lose activity and / or selectivity relatively quickly in continuous operation in media having even a small water content.

Owner:ROHM GMBH

Gold-based catalyst for the oxidative esterification of aldehydes to obtain carboxylic esters

ActiveUS20180001307A1Reduce wearExtended service lifeOrganic compound preparationHeterogenous catalyst chemical elementsAcroleinChemical stability

Catalysts for oxidative esterification can be used, for example, fro converting (meth)acrolein to methyl (meth)acrylate. The catalysts are especially notable for high mechanical and chemical stability even over very long time periods, including activity and / or selectivity relatively in continuous operation in media having even a small water content.

Owner:ROHM GMBH

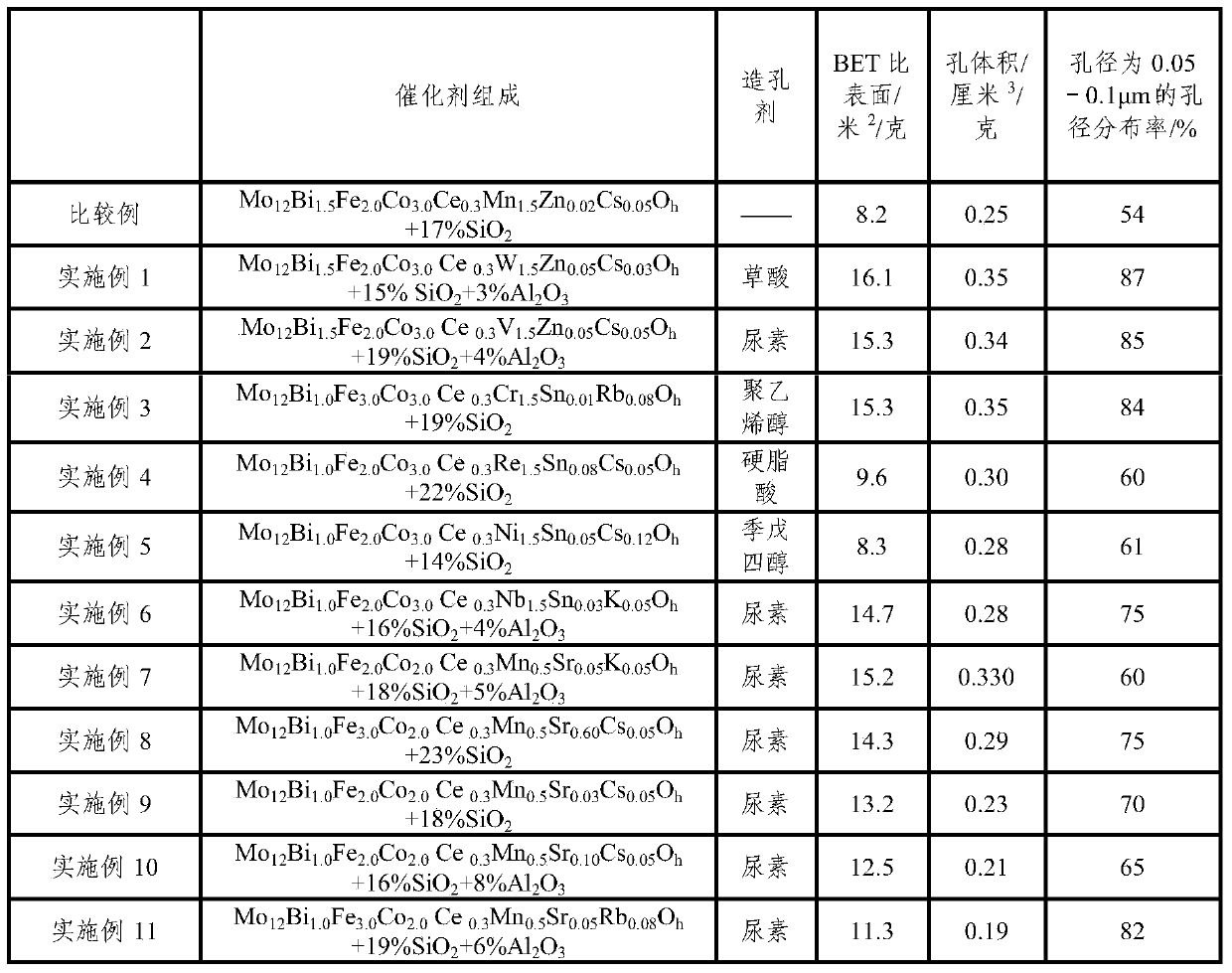

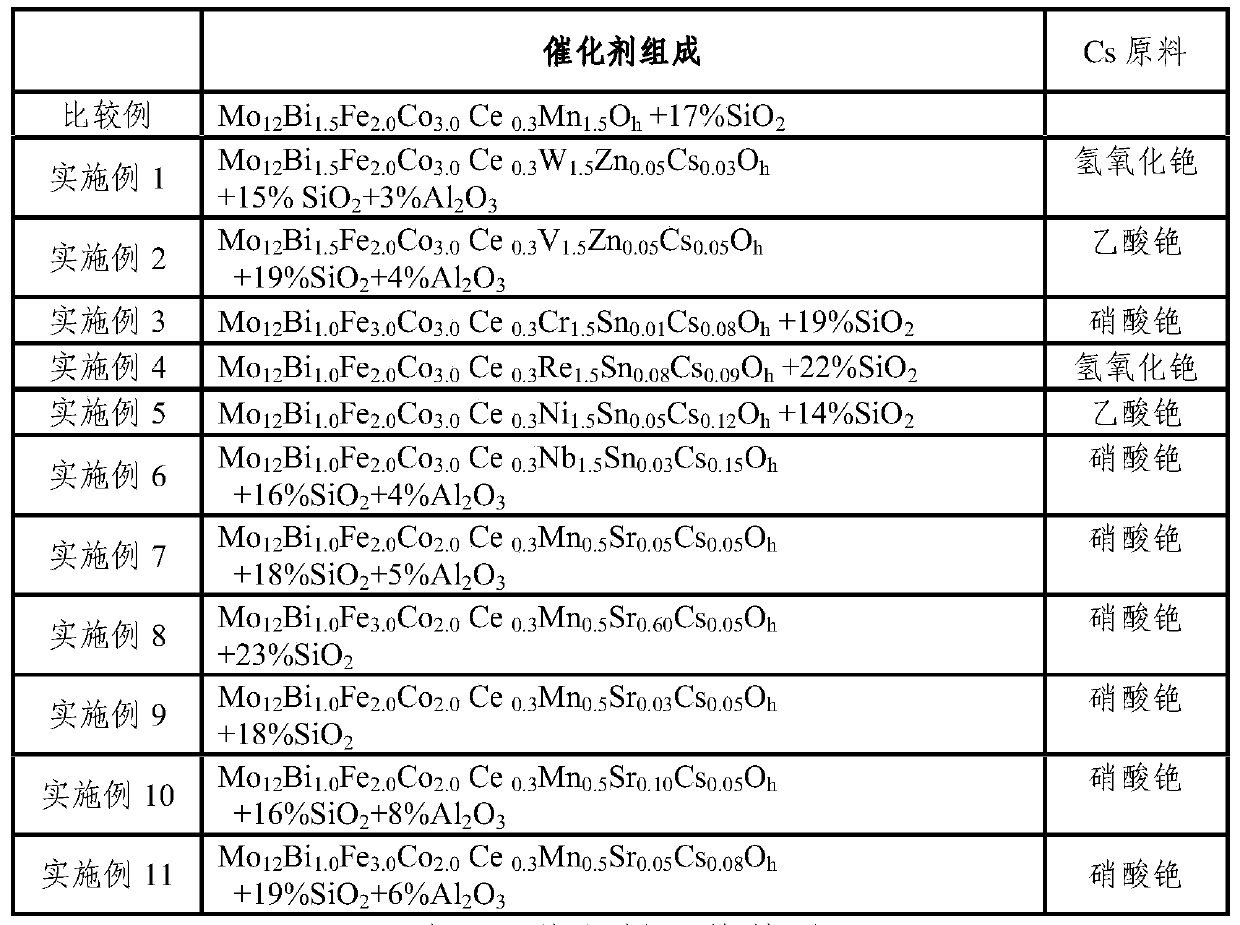

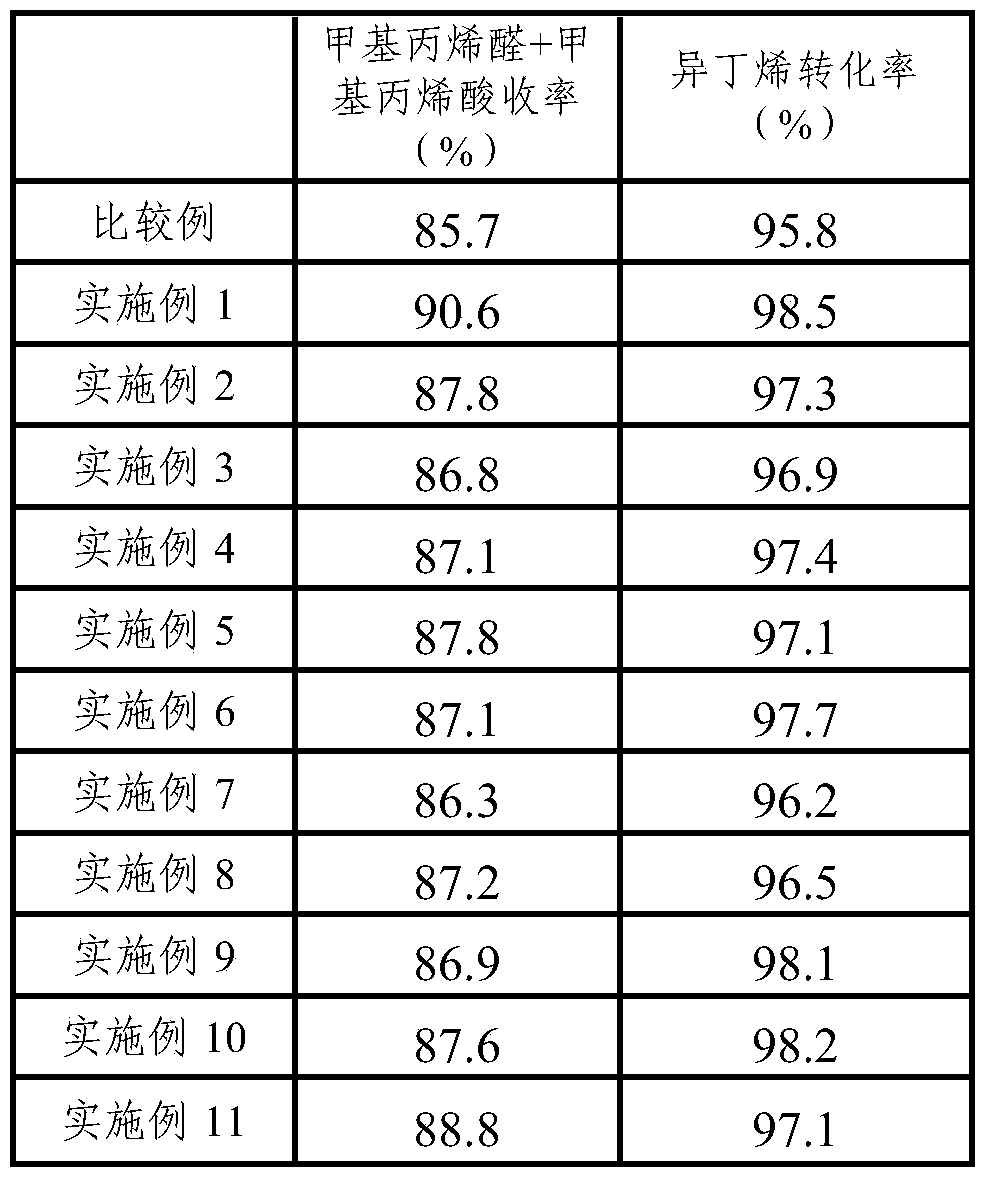

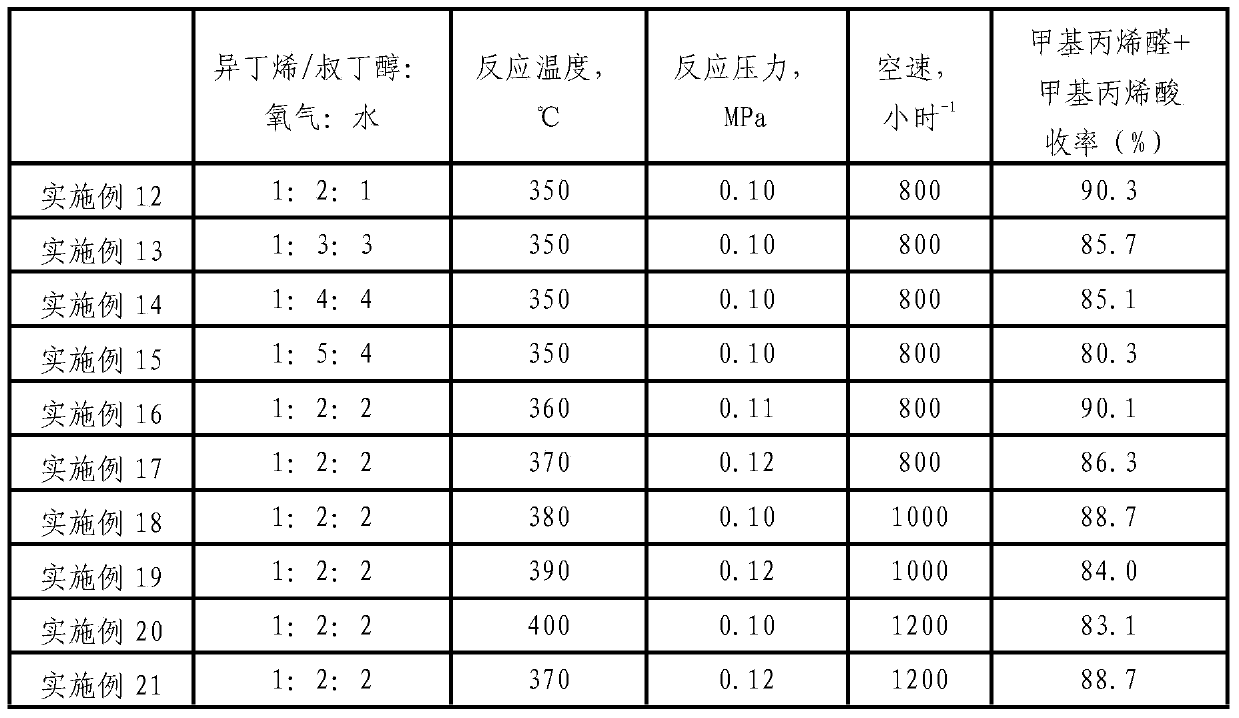

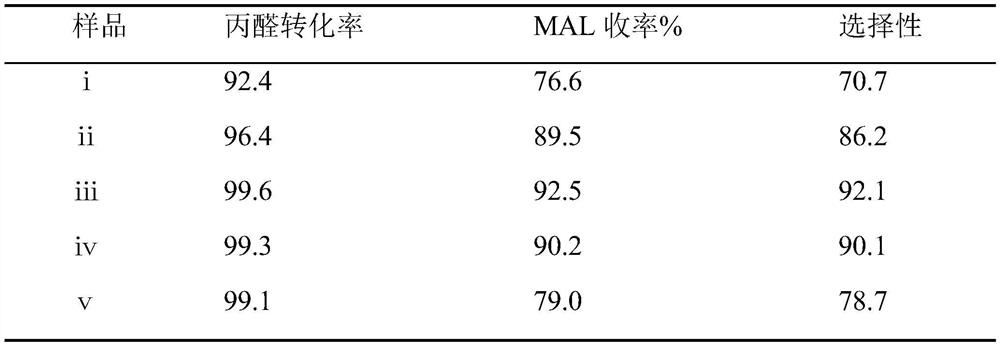

Methacrylaldehyde catalyst and preparation method thereof

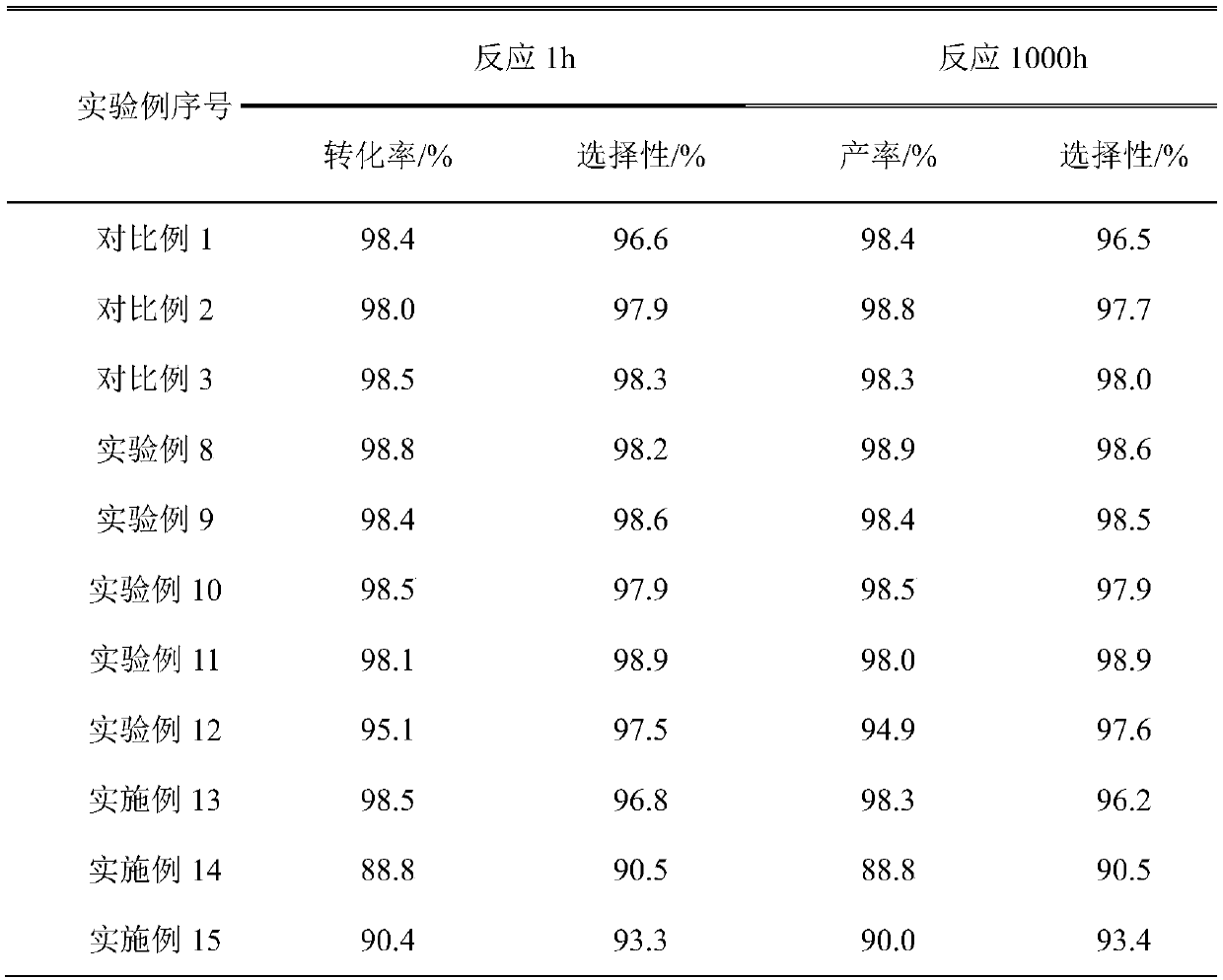

InactiveCN105498795AImprove technical effectHigh yieldOrganic compound preparationCarbonyl compound preparationActive componentSilicon dioxide

The invention relates to a methacrylaldehyde catalyst and a preparation method thereof, and mainly solves the problems of low catalyst reaction yield and undesirable selectivity in the prior art. According to a technical scheme, the methacrylaldehyde catalyst comprises an active component and a carrier, the carrier is silica and / or alumina, the active component has the following formula: Mo12BiaFebCocCedXeYfZgOh, wherein X is selected from at least one of W, V, Ni, Cr, Mn, Nb or Re; Y is selected from at least one of Sn, Sr, Zn, Ti or Zr; Z is selected from at least one of K, Rb, Na, Li, Tl or Cs; and the BET specific surface area of the catalyst is 8-17m<2> / g. The methacrylaldehyde catalyst provided by the invention well solves the problems, and can be used for the industrial production of methacrylaldehyde.

Owner:CHINA PETROLEUM & CHEM CORP +1

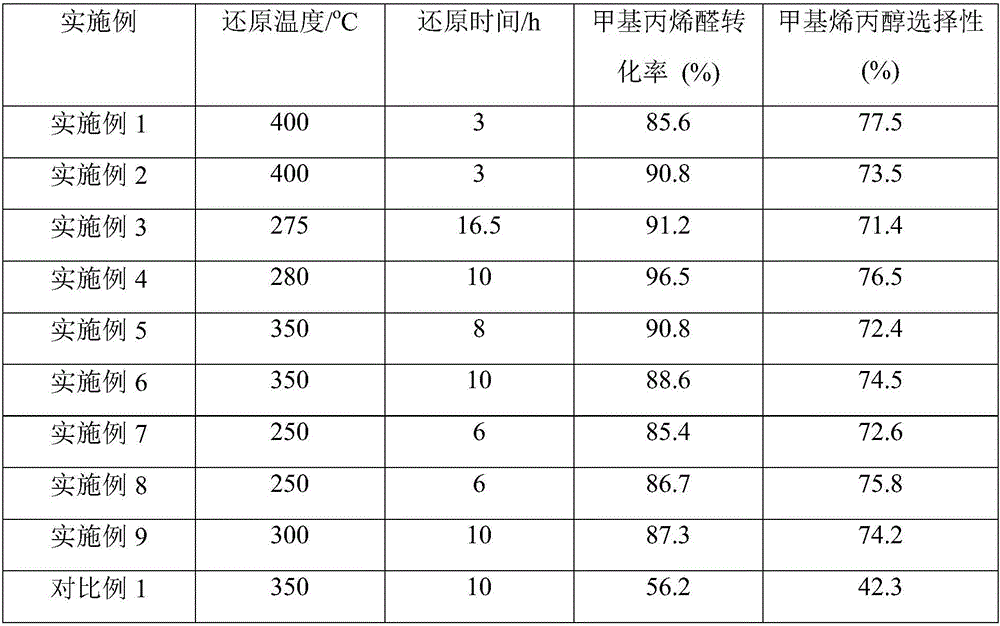

Method for preparing methallyl alcohol through acrylaldehyde selective hydrogenization

InactiveCN106631691ATake advantage ofHigh selectivityOrganic compound preparationHydroxy compound preparationHydrogenation reactionFixed bed

The invention relates to a method for preparing methallyl alcohol through acrylaldehyde selective hydrogenization. The method mainly solves the problems of low production capability, low raw material conversion rate, low product selectivity and separation difficulty of catalysts and products in the prior art. The method adopts the technical scheme that the method of preparing methallyl alcohol through acrylaldehyde selective hydrogenization is used, acrylaldehyde and hydrogen gas are continuously introduced into a fixed bed reactor; under the catalyst reaction condition, the continuous catalysis selective hydrogenization reaction is performed; the generated product is subjected to gas-liquid separation and fractionating; then, a methallyl alcohol product and unreacted acrylaldehyde are obtained; the hydrogen gas obtained after the gas-liquid separation and the unreated acrylaldehyde obtained after the fractionating are cyclically used. The problems are well solved. The method can be used for preparing methallyl alcohol through acrylaldehyde selective hydrogenization.

Owner:SHANGHAI HUAYI GRP CO

Multi-metal oxide catalyst and method for producing (METH)acrylic acid by using the same

ActiveUS20090292086A1High yieldControlled heatingOrganic compound preparationHeterogenous catalyst chemical elementsMethyl t-butyl etherMeth-

The present invention provides a Mo—Bi—Nb based composite metal oxide (with the proviso that Te is not included); a method for producing (meth)acrylic acid from at least one reactant selected from the group consisting of propylene, propane, isobutylene, t-butyl alcohol and methyl-t-butyl ether, in which a Mo—Bi—Nb based composite metal oxide (with the proviso that Te is not included) is used as a catalyst; and a reactor used for producing (meth)acrylic acid from at least one reactant selected from the group consisting of propylene, propane, isobutylene, t-butyl alcohol and methyl-t-butyl ether, in which a Mo—Bi—Nb based composite metal oxide (with the proviso that Te is not included) is used as a catalyst. Further, the present invention provides a method for producing (meth)acrylic acid from at least one reactant selected from the group consisting of propylene, propane, isobutylene, t-butyl alcohol and methyl-t-butyl ether by using a Mo—Bi—Nb based composite metal oxide as a catalyst, without any additional process of convening (meth)acrolein into (meth)acrylic acid.

Owner:LG CHEM LTD

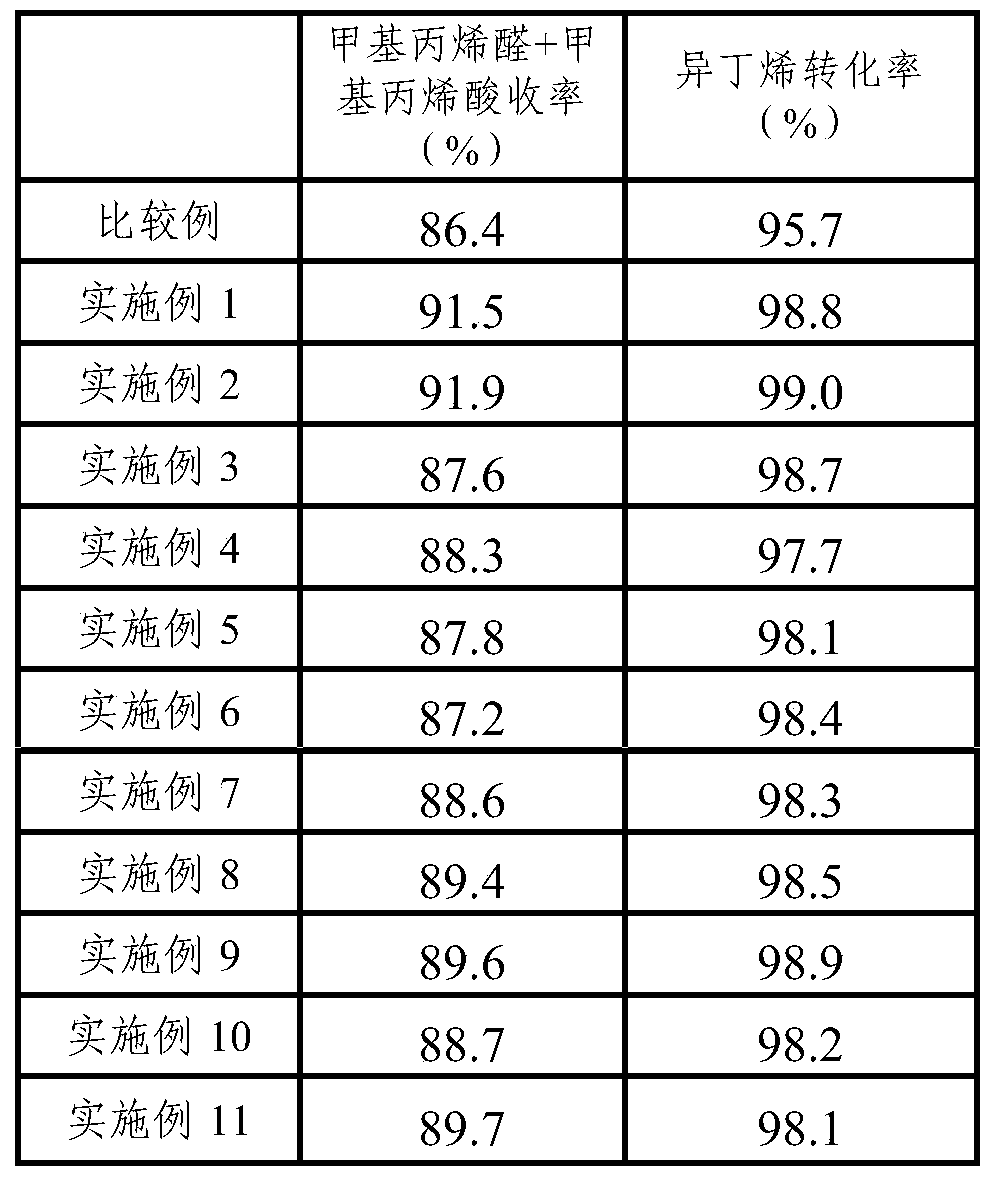

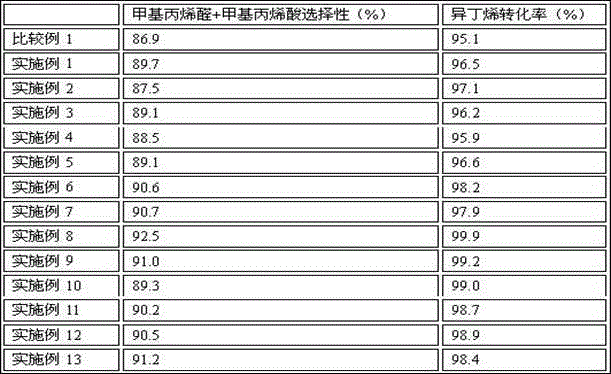

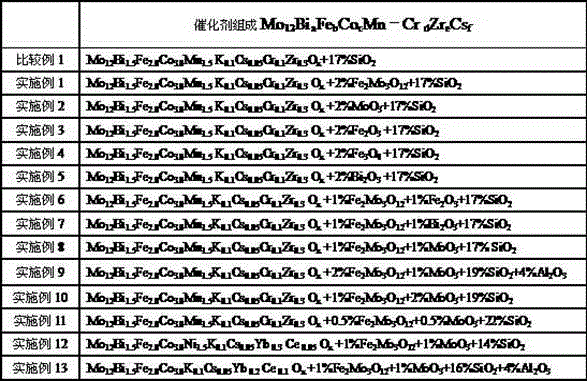

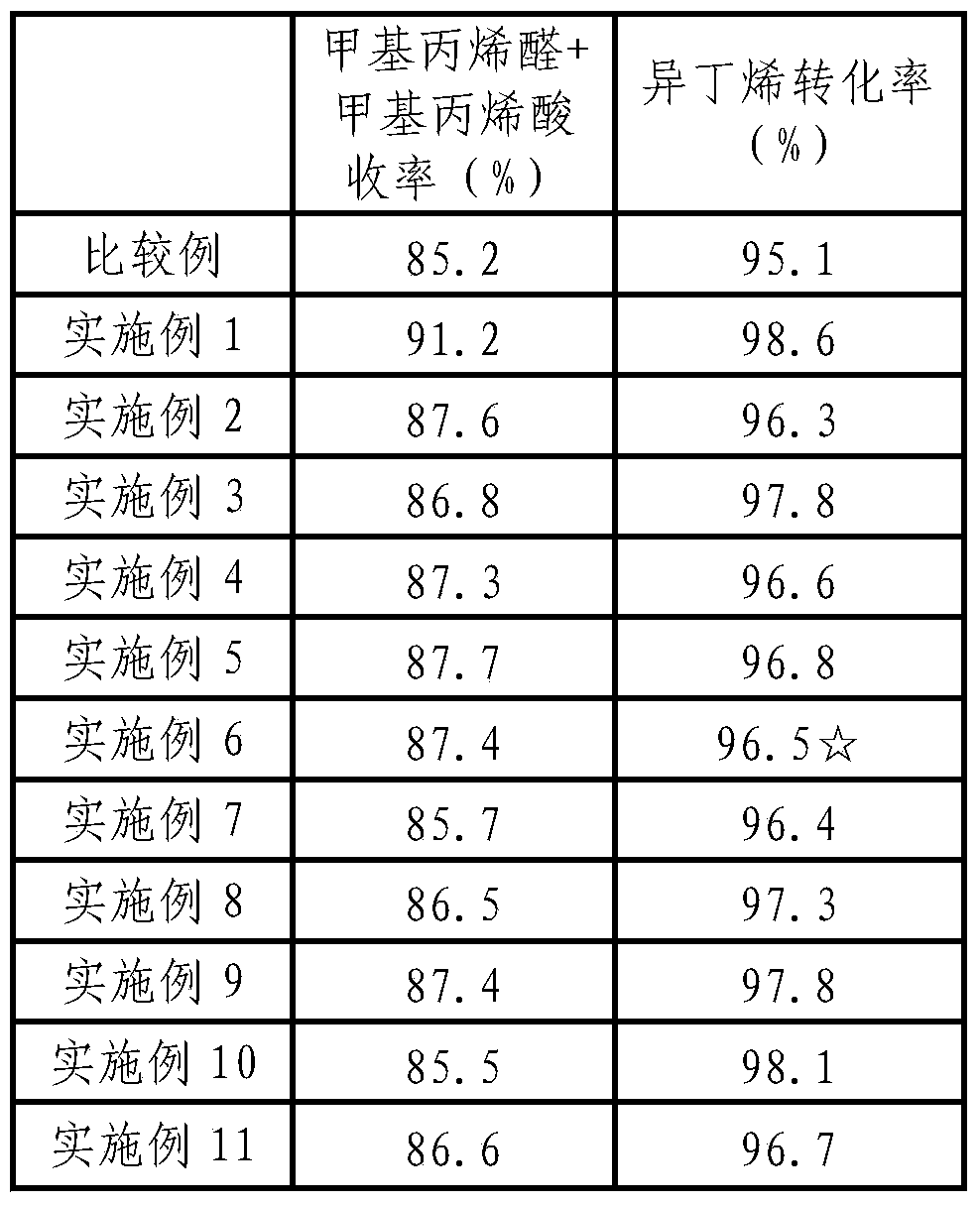

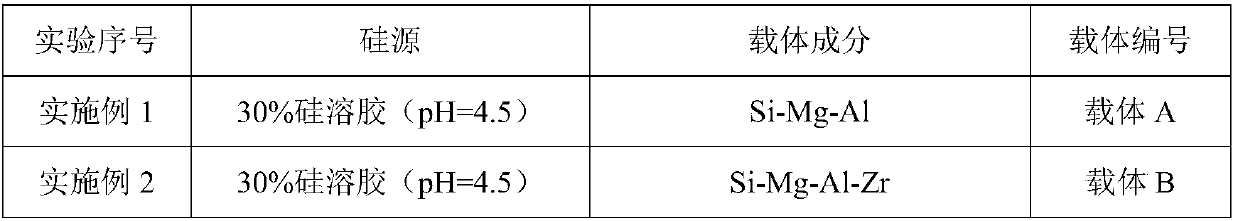

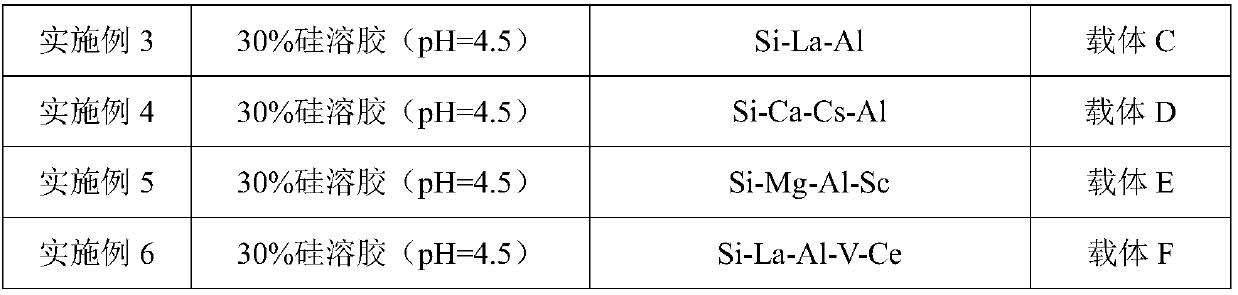

Catalyst of methacrylaldehyde and methacrylic acid, as well as preparation method of catalyst for synthesizing methacrylaldehyde and methacrylic acid

ActiveCN104437533AOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationPolymer sciencePtru catalyst

The invention relates to a catalyst for synthesizing methacrylaldehyde and methacrylic acid, as well as a preparation method of the catalyst for synthesizing the methacrylaldehyde and the methacrylic acid, and a synthesis method of the methacrylaldehyde and the methacrylic acid, and mainly solves the problem that the catalyst used for selective oxidation reaction of isobutylene is poor in stability in the prior art. The active components of the catalyst of the methacrylaldehyde and the methacrylic acid have the following general formula: Mo12BiaFebCocXdYeZfOx, wherein X is selected from at least one of W, V, Ni, Cr, Mn, Nb, Re and La; Y is selected from at least one of Sn, Sr, Zn, Ti or Zr; Z is selected from at least one of Na, Li, Tl, K, Cs, Mg or Ca, so that the problem is relatively well solved, and the catalyst can be used for industrial production of the methacrylaldehyde and the methacrylic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

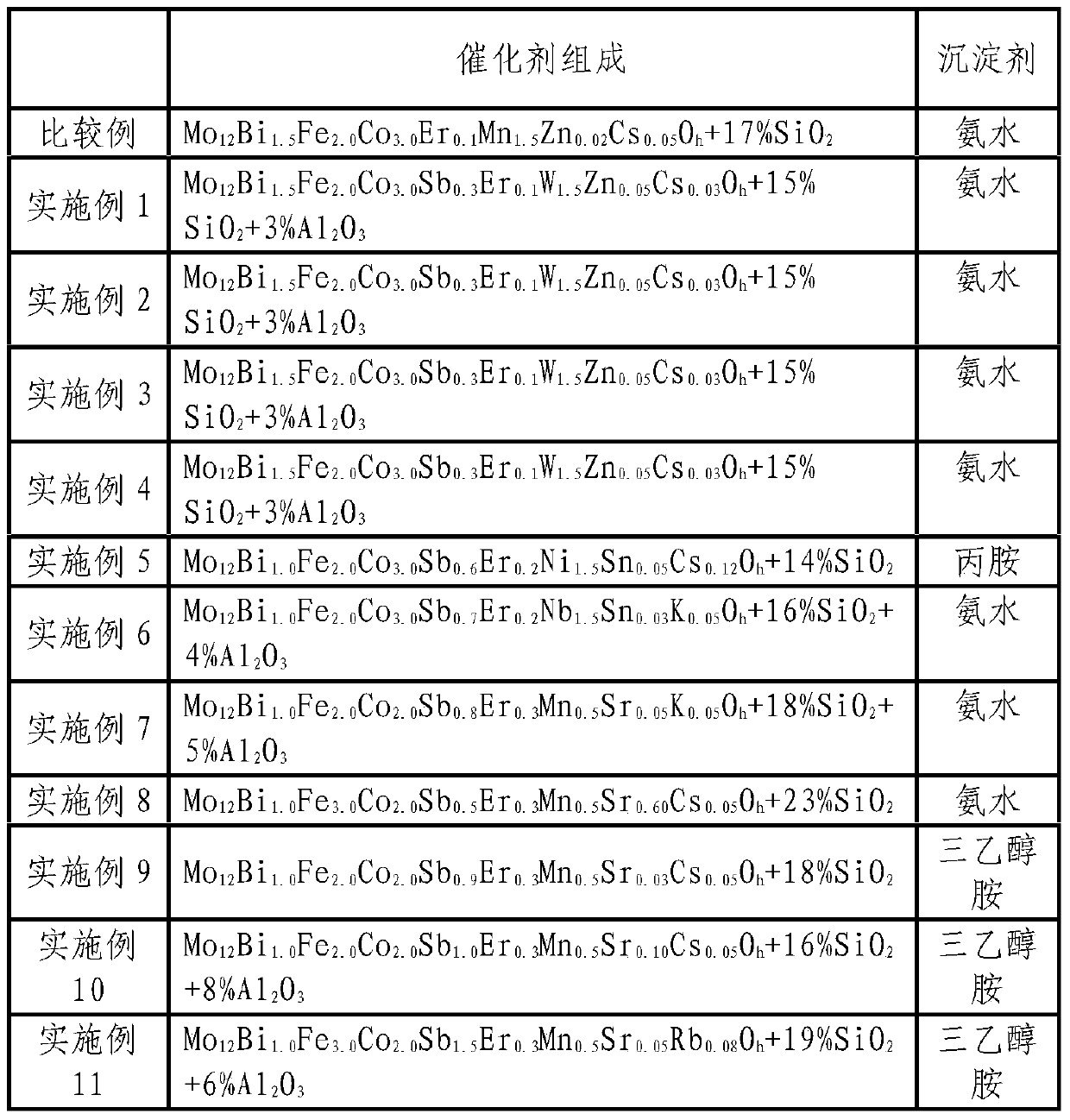

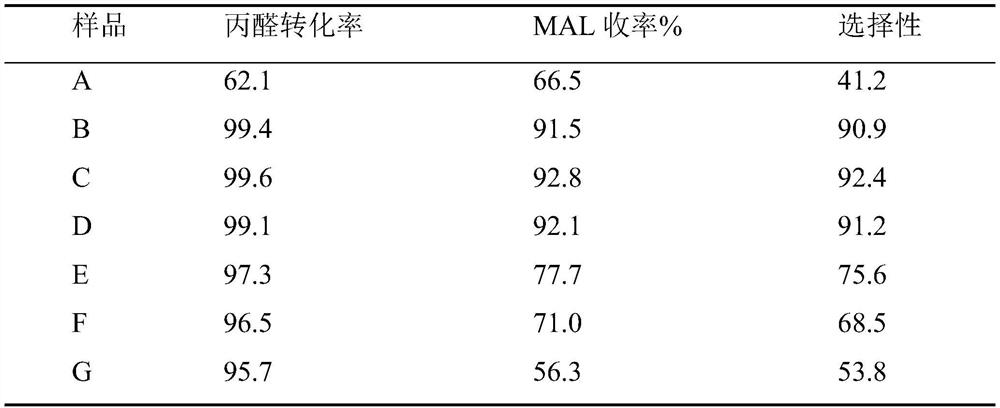

Methacrylaldehyde catalyst

PendingCN105498794AImprove conversion rateHigh yieldOrganic compound preparationCarbonyl compound preparationActive componentSilicon dioxide

The invention relates to a catalyst for synthesis of methacrylaldehyde by oxidation of isobutene or tert-butyl alcohol, and mainly solves the technical problems of low catalyst activity and low yield in the prior art. According to a technical scheme, the catalyst for synthesis of methacrylaldehyde by selective oxidation of isobutene or tert-butyl alcohol comprises a carrier and an active component, the carrier is selected from silica and / or alumina, and the active component has the following formula: Mo12BiaFebCocSbdXeYfZgOh, wherein X is selected from at least one of W, V, Ni, Cr, Mn, Nb Er, or Re; Y is selected from at least one of Sn, Sr, Zn, Ti and Zr; and Z is selected from at least one of K, Rb, Na, Li, Tl or Cs. The methacrylaldehyde catalyst well solves the problems, and can be used for the industrial production of methacrylaldehyde.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-component water-resistant catalyst for preparing carboxylic ester through aldehyde oxidative esterification, preparation and manufacturing of carboxylic ester

PendingCN111229249AImprove water resistanceHigh mechanical strengthOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystReaction temperature

The invention relates to a novel multi-component water-resistant catalyst for preparing carboxylic ester through aldehyde oxidative esterification, preparation of the novel multi-component water-resistant catalyst and preparation of the carboxylic ester. The catalyst is of a core-shell structure and contains a precious metal, cobalt, nickel, silicon, aluminum and one or more than two of lanthanideseries, actinide series elements, cesium, magnesium, calcium, yttrium, vanadium, scandium, cerium, gallium, zirconium, niobium, manganese, lead, bismuth and antimony. Through use of the catalyst, (methyl)acrolein and primary alcohol are subjected to a one-step oxidative esterification reaction to generate the carboxylic ester under the conditions that the reaction pressure is 2-50 bar, the reaction temperature is 40-160 DEG C, and oxygen sources such as oxygen, air or an oxygen-containing mixed gas exist. Compared with an existing catalyst, the catalyst is good in water resistance, high mechanical strength and chemical stability can still be kept in the long-time reaction process, and the catalyst has the advantages of being simple in preparation method, low in cost and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

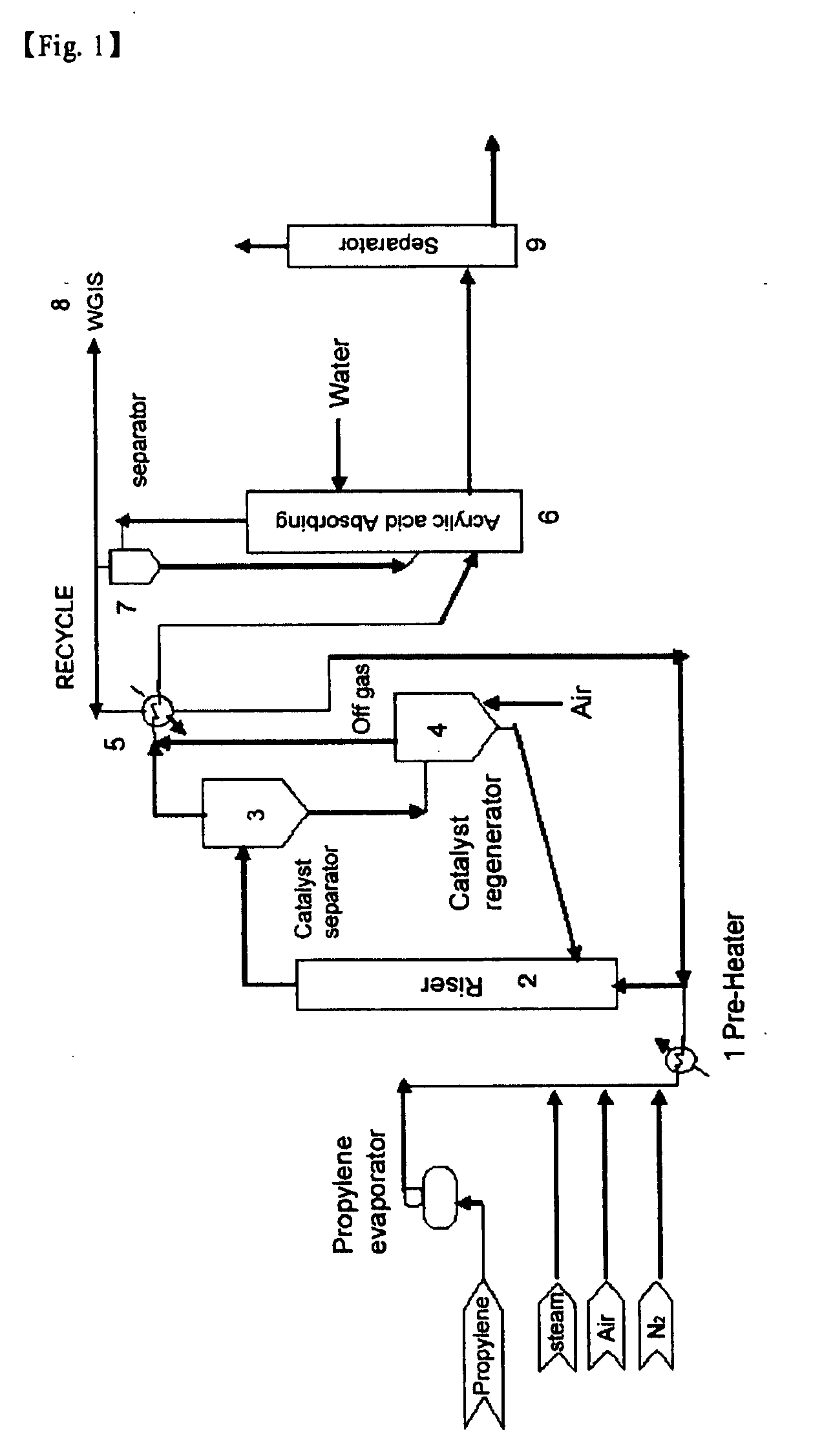

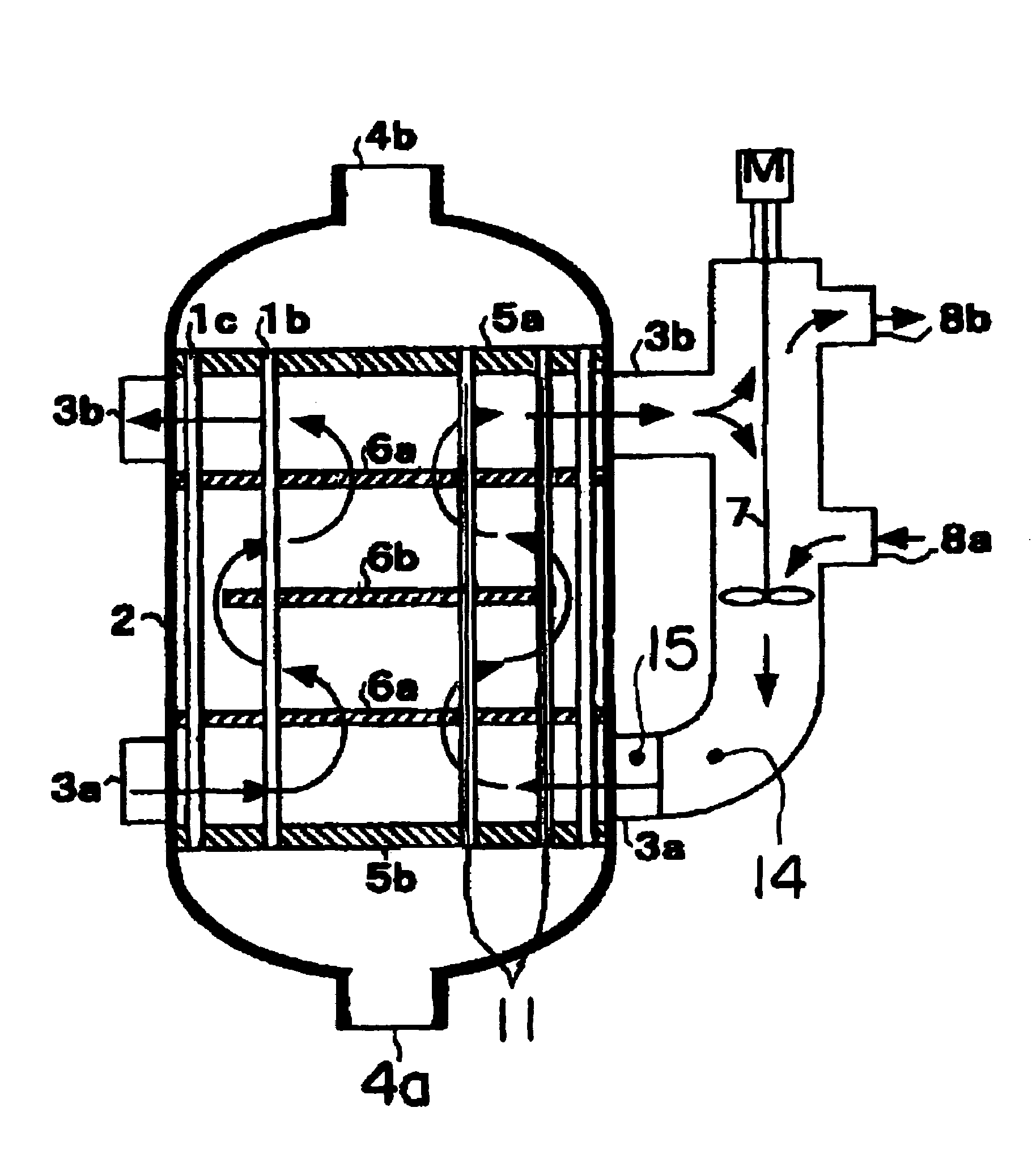

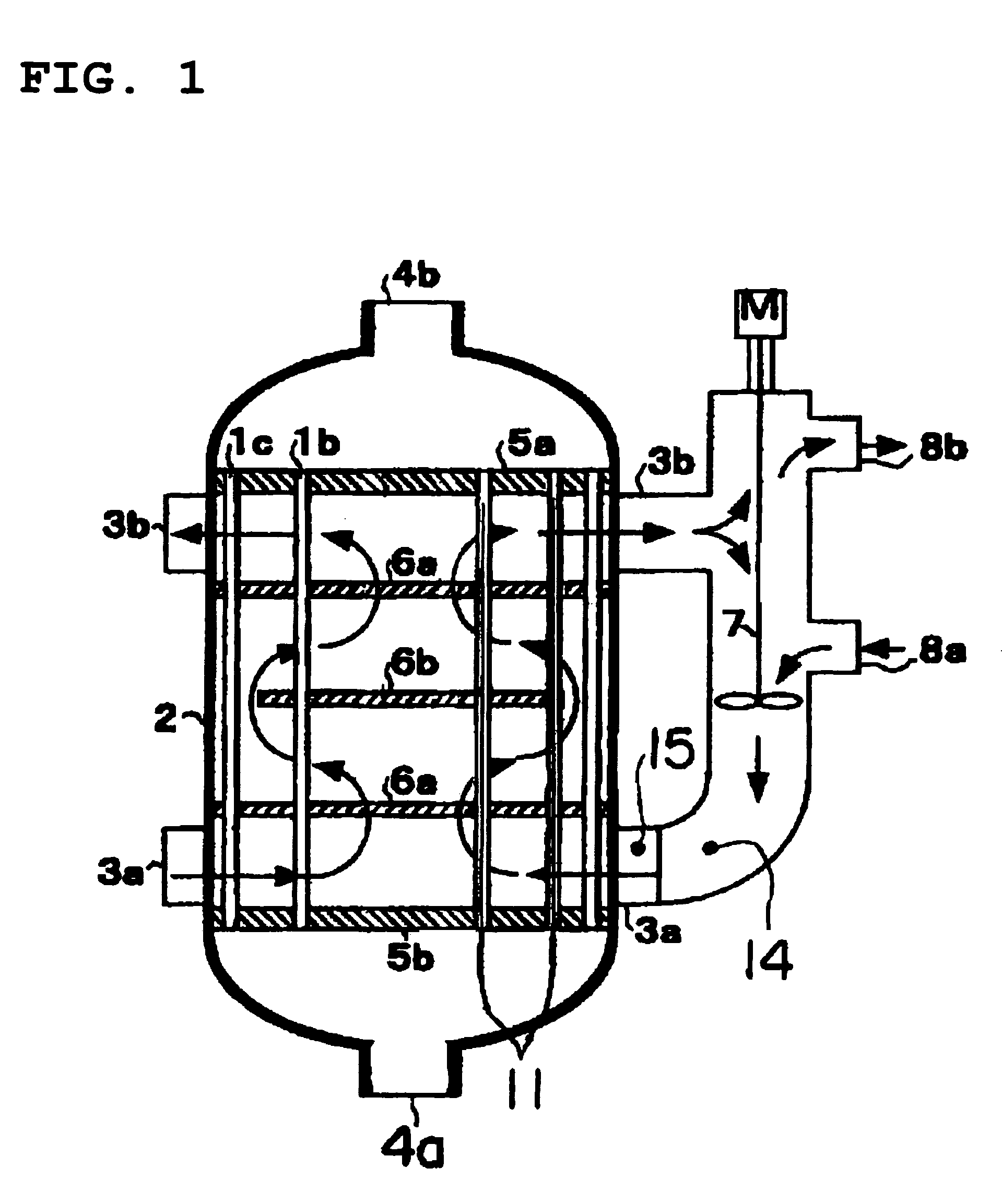

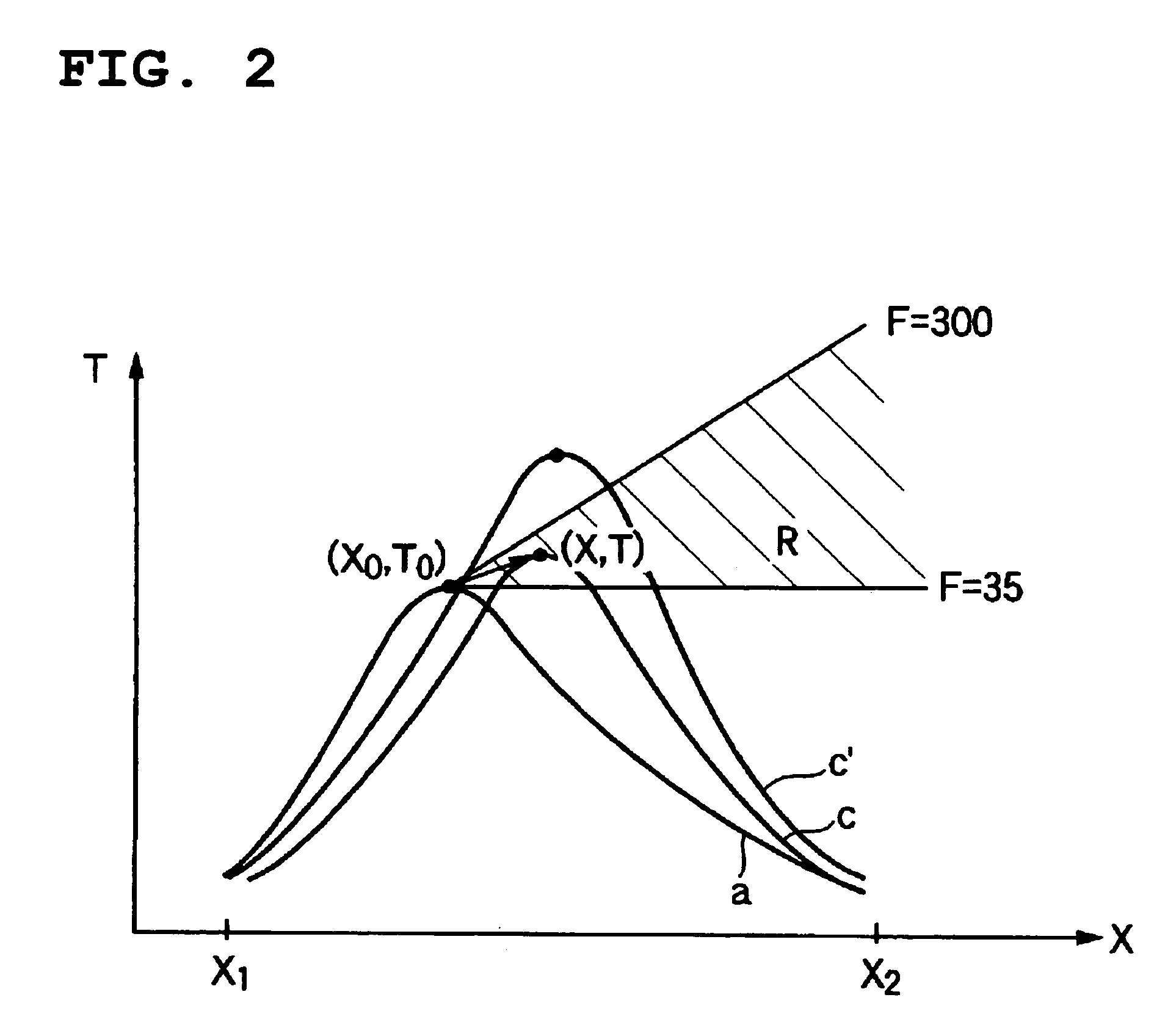

Process for producing (meth)acrylic acid or (meth)acrolein

A producing method of (meth)acrolein or (meth)acrylic acid where by use of a multi-tubular reactor that has a plurality of reaction tubes filled with a catalyst, catalytic gas phase oxidation of propylene, propane, isobutylene or (meth)acrolein is carried out in the presence of a composite oxide catalyst by use of molecular oxygen or a gas containing molecular oxygen, in which method (meth)acrolein or (meth)acrylic acid can be obtained stably in high yield for a long period of time without allowing the activity of the catalyst to decrease locally (disproportionately) and extremely. A temperature difference between a temperature of a heat medium at the beginning of operation and a peak temperature of the catalyst is set in a range of 20 to 80° C., and during operations a change of the peak temperature T of the catalyst in a tube axis direction is maintained in a definite range.

Owner:MITSUBISHI CHEM CORP

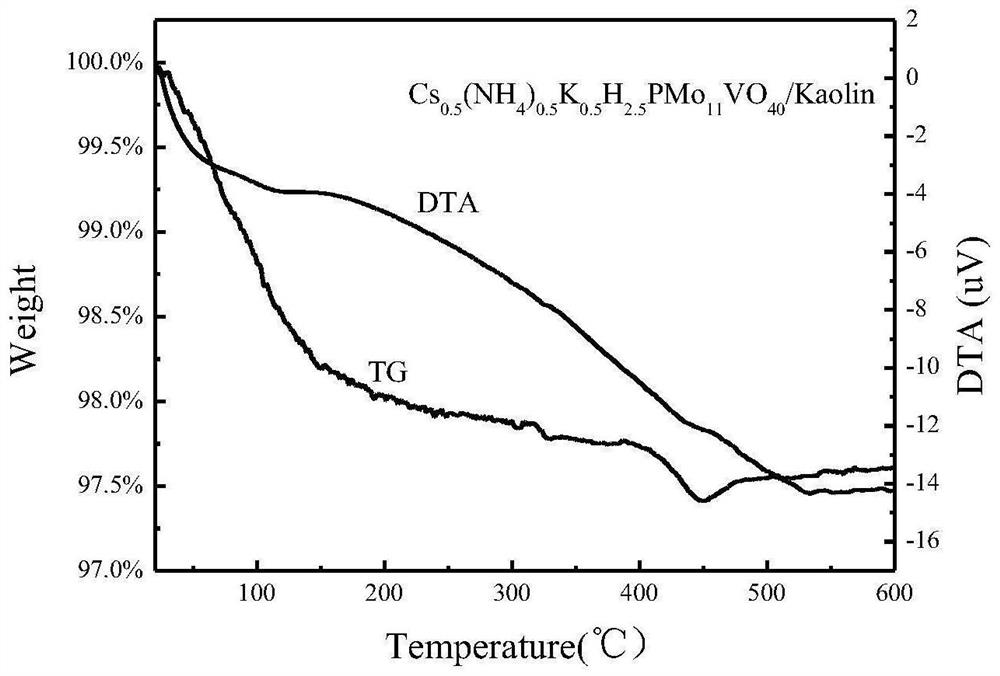

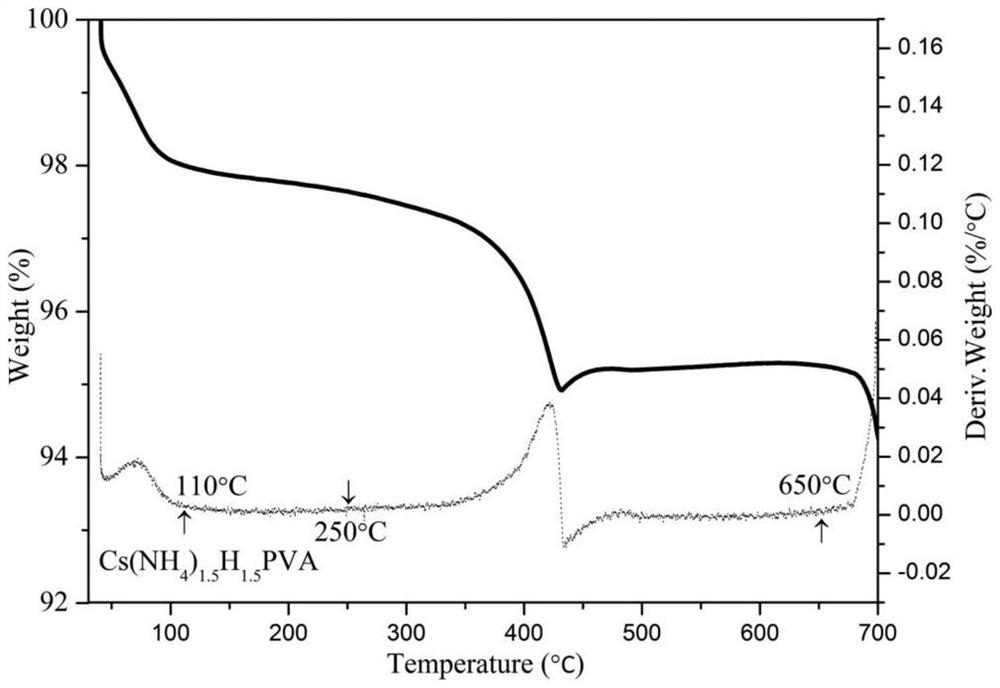

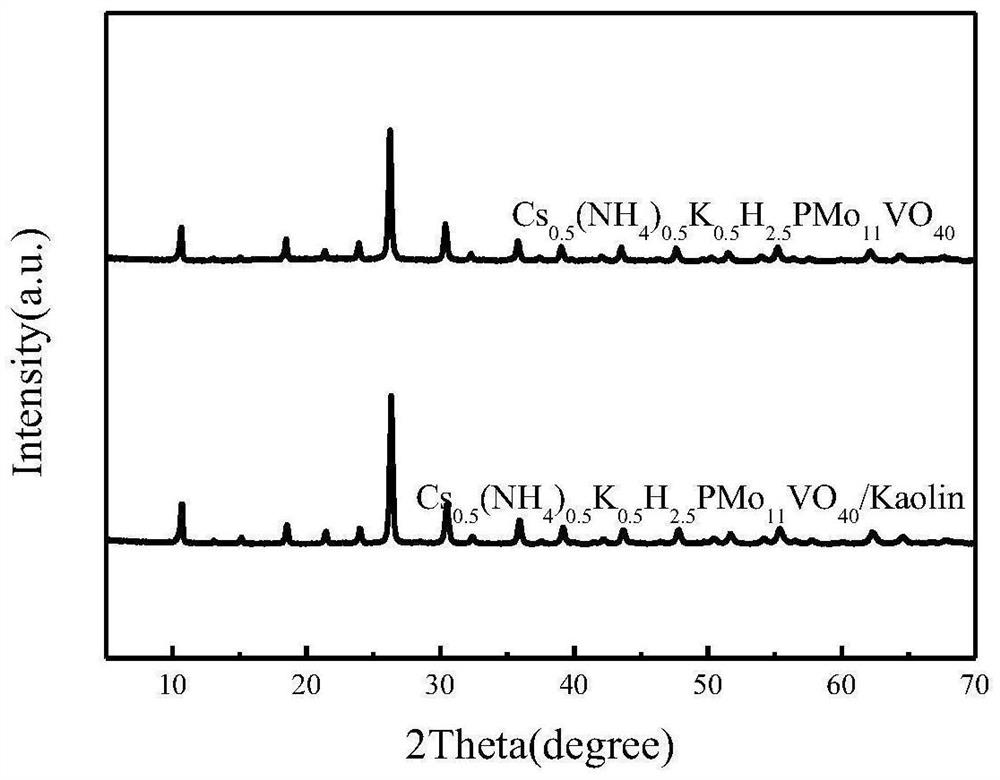

Kaolin-loaded Keggin type heteropolyacid catalyst, preparation and application in methylacrolein oxidation

PendingCN114849747ALarge specific surface areaAbundant and easy to get raw materialsOrganic compound preparationCatalyst activation/preparationPtru catalystHeteropoly acid

The invention relates to a kaolin-loaded Keggin type heteropolyacid catalyst, preparation thereof and application of the kaolin-loaded Keggin type heteropolyacid catalyst in methylacrolein oxidation. The invention provides a Keggin type heteropolyacid loaded composite catalyst with kaolin as a carrier and a preparation method of the Keggin type heteropolyacid loaded composite catalyst, heteropolyacid is highly dispersed and loaded on the kaolin carrier, and the prepared catalyst shows very high selectivity and stability for a reaction for preparing MAA through MAL gas phase oxidation. The composition of the catalyst is XaPMo12-dVdO40 / Kaolin, X is one or more of counter ions, Kaolin represents a kaolin carrier, and a is the atom number of the X element in the catalyst and is 0.5-3; d is the number of vanadium atoms and is 0 or 1; in the supported catalyst, XaPMo12-dVdO40 is used as an active component, and kaolin is used as a carrier. When the catalyst is used for oxidizing methylacrolein into methacrylic acid, the catalyst has high MAL conversion rate and high MAA selectivity.

Owner:TIANJIN UNIV

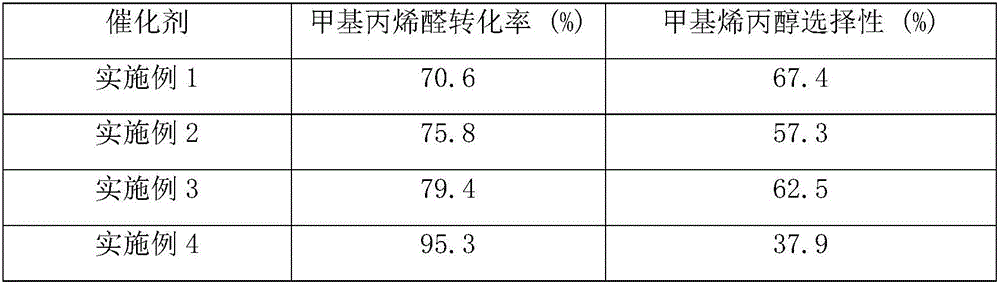

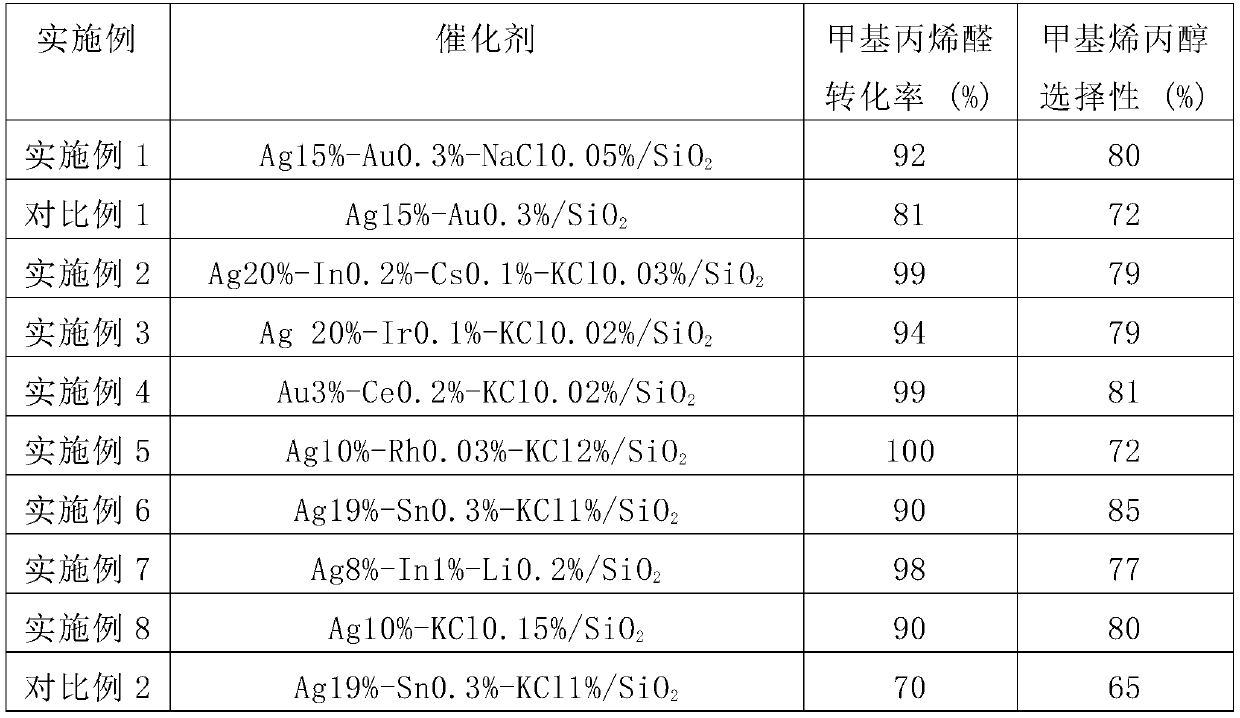

Catalyst for preparing methallyl alcohol by selectivey hydrogenating methylacrolein, and preparation method thereof

ActiveCN110773163AReduce manufacturing costImprove conversion rateOrganic compound preparationHydroxy compound preparationPropanolPtru catalyst

The invention discloses a catalyst for preparing methallyl alcohol through selectively hydrogenating methylacrolein, and a preparation method thereof. The catalyst is a silicon oxide-supported X-Y-Z catalyst, wherein X is one or a mixture of two of Ag and Au; Y is one or a mixture of more of Ir, Pd, Rh, In, Sn, Ce and Cs; Z is selected from an alkali metal chloride, a lithium hydroxide or a mixture thereof; and the catalyst comprises 1-30 wt% of the active X component, 0-5 wt% of the Y component, 0.01-5 wt% of the Z component, and the balance of the silicon oxide carrier.

Owner:SHANGHAI HUAYI GRP CO

Preparation method of catalyst for preparing methacrylic acid

InactiveCN103801398AHigh mechanical strengthLow pulverizationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHeteropoly acid

The invention provides a preparation method of a catalyst for preparing methacrylic acid. The preparation method comprises the following steps: coating catalyst powder containing heteropolyacid and / or salt of molybdenum, molybdenum and phosphor as active ingredient on a carrier, and then roasting the carrier, wherein inorganic binder is used in the coating process, the sol of oxide of Al, Si, Ti or mixture thereof is adopted as the inorganic binder, which is sodium ion type, non-sodium ion type stable sol or mixture thereof; the particle size of the oxide in the sol is 5-30nm, the content of the oxide is at least 5wt%, the particle size of the sol latex particle is at least 500nm, the density is 1.0-1.3g / cm <3>, the pH (potential of hydrogen) is 8.0-11.0; the adding amount of the sol is 2-30wt% of the amount of the active ingredient; the catalyst prepared according to the preparation method for preparing methacrylic acid has the advantages of high mechanical strength, low pulverization degree, high activity and high performance, and can be used for carrying out selective catalytic oxidation reaction on methylacrolein gas with molecular oxygen in a gas phase, so as to produce methacrylic acid.

Owner:SHANGHAI DONGHUA CATALYST +1

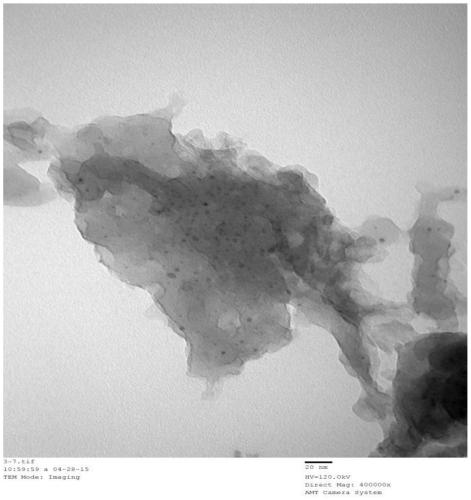

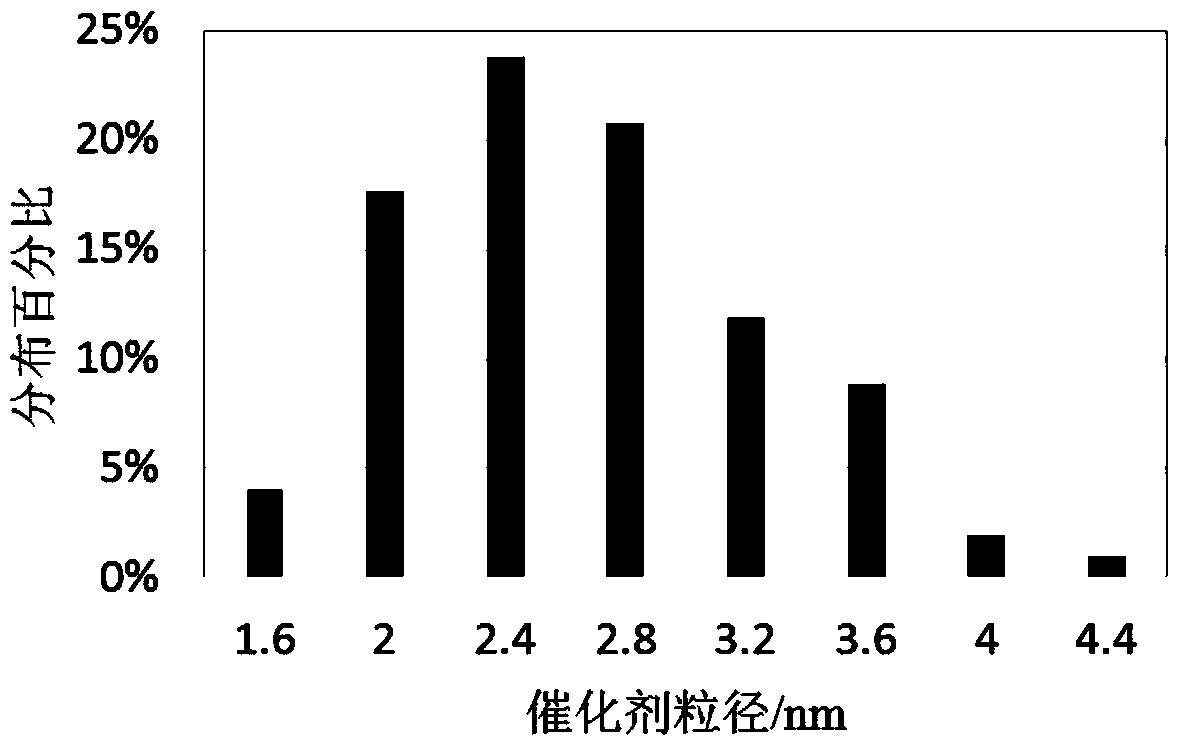

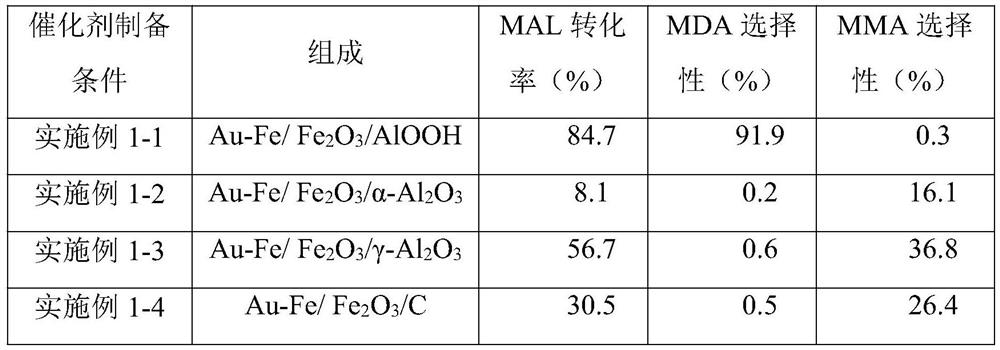

A kind of supported oxidative esterification catalyst and its preparation method and application

ActiveCN107519892BStable structureHigh catalytic activityOrganic compound preparationCarboxylic acid esters preparationLanthanideCarboxylic acid

The object of the present invention is to provide a supported oxidative esterification catalyst and its preparation method and application, wherein the supported oxidative esterification catalyst is made of Al 2 O 3 , one or two or three oxides of MgO, CaO and SiO 2 The composite oxide prepared as a raw material is used as a carrier, gold (Au) and cobalt (Co) are used as active components, and lanthanide elements are supported. The method is to support active components and the like on a carrier through a chemical uniform precipitation method to prepare an efficient and stable oxidative esterification catalyst. In addition to the advantages of high conversion rate and good selectivity, the method also has the characteristics of low consumption of precious metals, high utilization rate and good stability. The catalyst is used for the catalytic synthesis of methyl methacrylate, and its catalytic activity and selectivity exceed those of the existing catalysts. The conversion rate of methacrolein is up to 100%, and the selectivity of methyl methacrylate is up to 97%. The post-treatment cost of other by-products acetal and carboxylic acid. The catalyst has good cycle stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

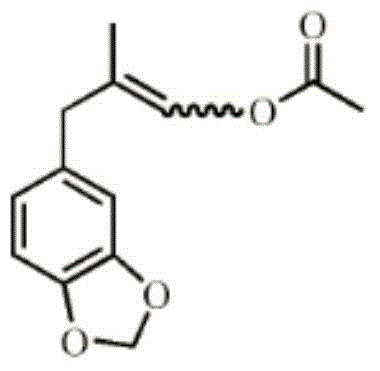

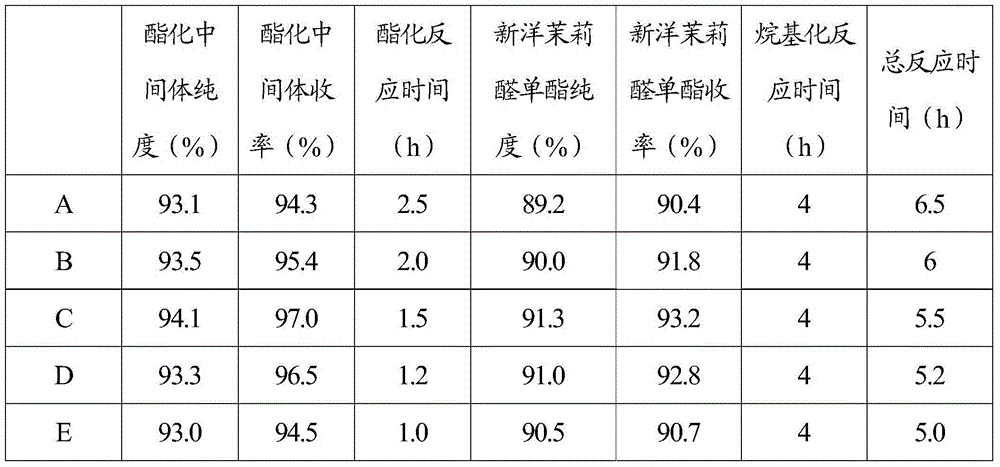

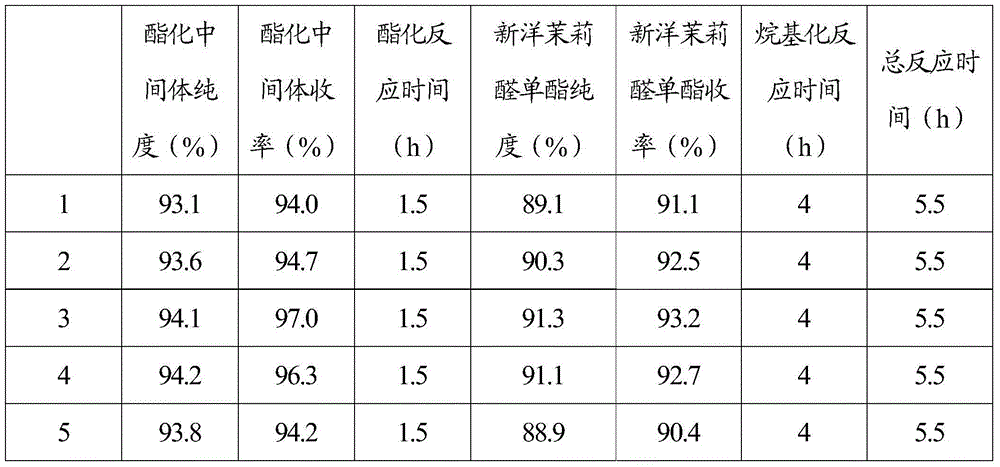

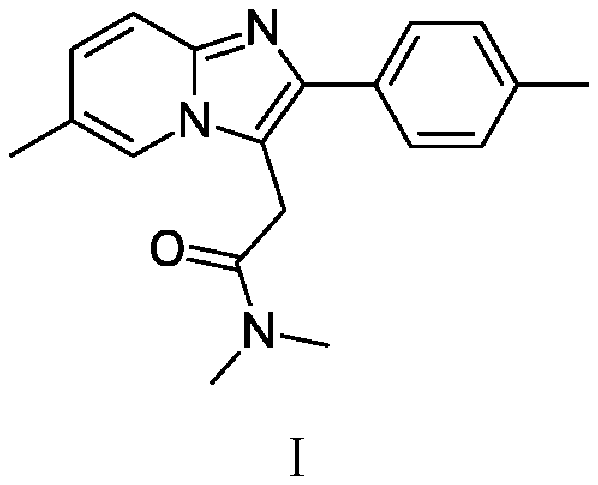

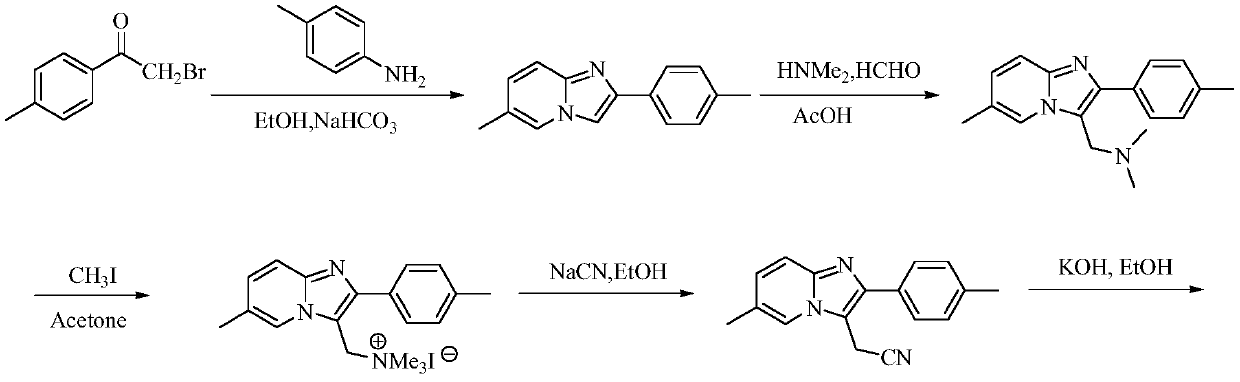

Synthesis process for novel heliotropin monoester

InactiveCN104650028AHigh purityEffective loss controlOrganic chemistryAcetic anhydrideMethyl palmoxirate

The invention discloses a synthesis process for novel heliotropin monoester, which comprises the technical steps of esterification reaction and alkylation reaction. At a temperature between minus 30 DEG C and 30 DEG C, acetic anhydride is added into methylacrolein, an esterification intermediate is obtained after full reaction, the mole ratio of the methylacrolein and the acetic anhydride is 0.5-2, then at a temperature between minus 10 DEG C and 40 DEG C, enzodioxole is added into the esterification intermediate, and the novel heliotropin monoester is separated through alkali washing and water rinsing after full reaction. The steps of the process disclosed by the application can be carried out in the same reaction still, and through changing the temperature, the material ratio, and the catalytic system, the novel heliotropin monoester can be synthesized with a yield higher than 90%; the condition of the process method is mild and controllable, the reaction time is short, the operation is simple, the side products are fewer, and the synthesized novel heliotropin monoester is high in purity.

Owner:成都建中香料香精有限公司

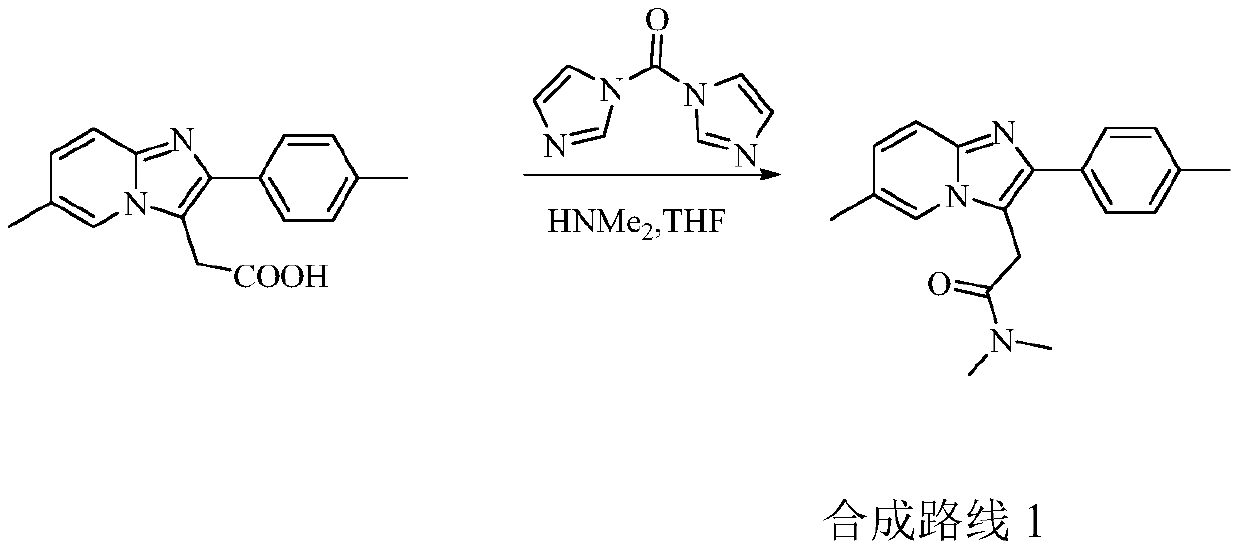

A kind of preparation method of zolpidem

The invention provides a preparation method of zolpidem. The method comprises the following steps: malononitrile and 2-methacrolein which are used as raw materials undergo a 1,4-addition reaction to prepare 2-methyl-4,4-dicyano-n-butyraldehyde, the 2-methyl-4,4-dicyano-n-butyraldehyde and N,N-dimethyl-4-p-methylphenyl-4-oxo-3-amino-n-butyramide undergo a two-stage dehydration condensation reaction, and the obtained reaction product and an acid binding agent undergo an elimination agent to prepare the zolpidem. The method of the invention has the advantages of cheap and easily available raw materials, short process flow, mild reaction conditions, simplicity in operation, low cost, low amount of three wastes, greenness, environmental protection, good selectivity, high yield and high purity of the product, and facilitation of industrial production of the zolpidem.

Owner:XINFA PHARMA

Complex metal oxide catalyst with high (METH) acrylic acid selectivity

ActiveUS20090043127A1Low selectivityHigh selectivityOrganic compound preparationHeterogenous catalyst chemical elementsPolymer scienceMeth-

Owner:LG CHEM LTD

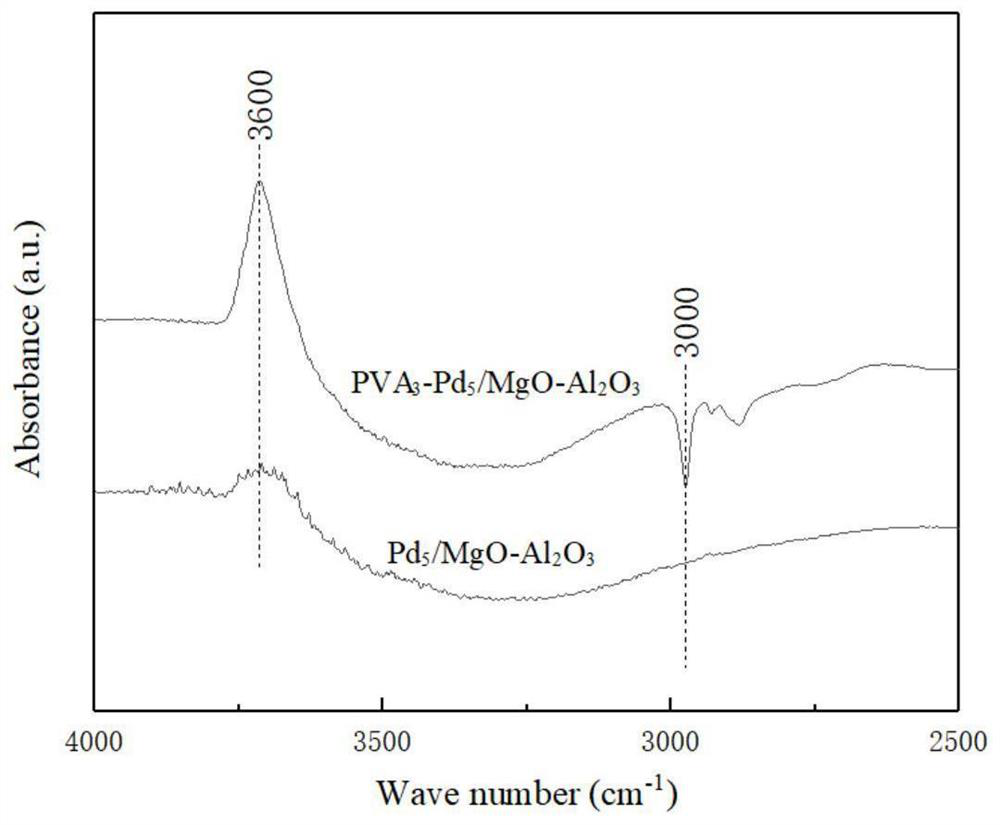

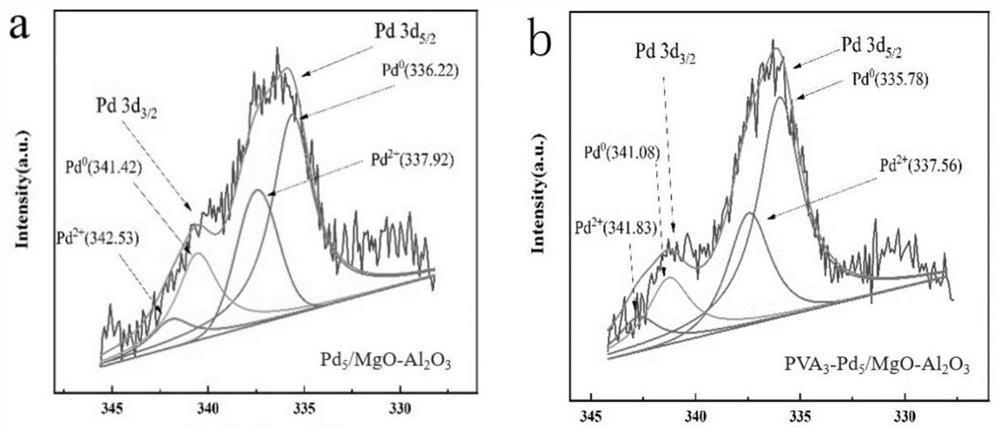

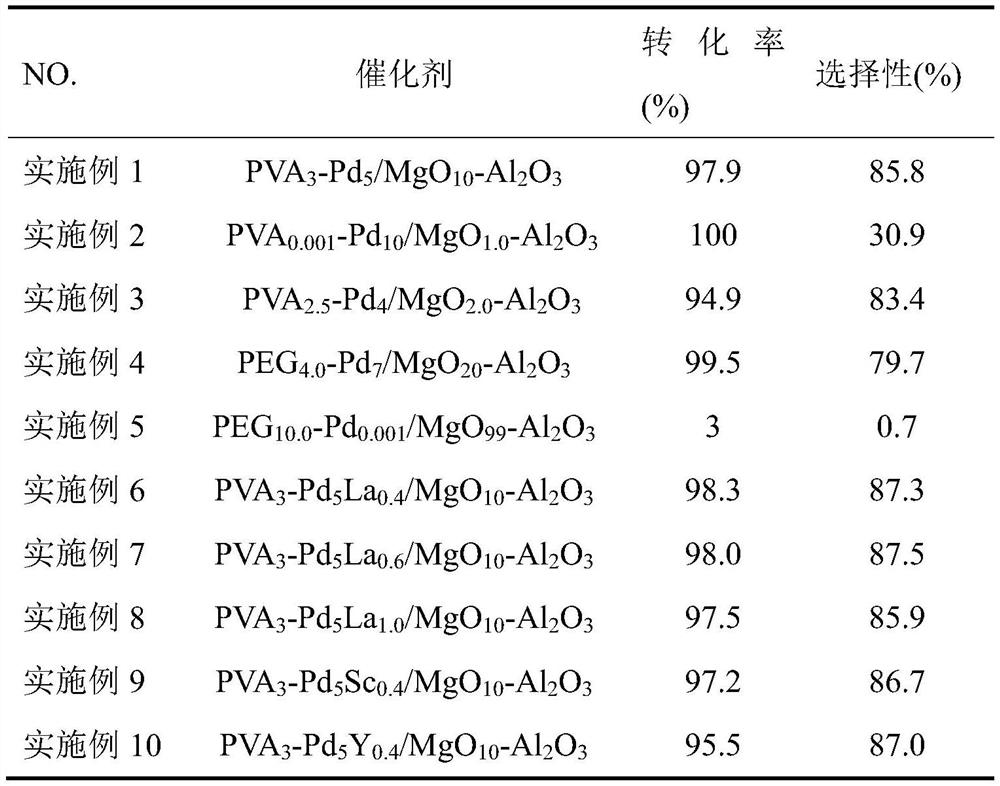

Catalyst for producing methyl methacrylate by one-step oxidative esterification method and its preparation method and application

ActiveCN110075835BIncrease profitReduce dosageOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a catalyst for producing methyl methacrylate by one-step oxidative esterification method and its preparation method and application. The catalyst uses materials containing electron-rich oxides as a composite carrier, metal palladium as an active The metal is the co-active component, and the surfactant is used as the co-agent. Its general chemical formula can be expressed as: X a PD b Y c / M d ‑N, where Pd is palladium, X is a surfactant, Y is one of the rare earth elements scandium, yttrium, lanthanum or cerium, M is an electron-rich oxide, and N is a carrier. The catalyst can be applied to the reaction of methyl methacrylate (MMA) produced by one-step production of methyl methacrylate (MMA) through oxidation of methacrolein and esterification with methanol. The catalyst overcomes some shortcomings of the existing oxidative esterification catalysts by forming a special electron-donating structure between the active component, the carrier and the surfactant, and is applied to the reaction of one-step oxidative esterification to produce MMA in addition to having conversion In addition to the advantages of high yield and good selectivity, it also has the characteristics of simple preparation process and mild reaction conditions.

Owner:XIAMEN UNIV

Process for direct synthesis of (meth)acrolein from ethers and/or acetals

ActiveUS9714205B2Simple operating conditionsLimited amountOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystMethyl palmoxirate

The subject matter of the present invention is a process for direct synthesis of (meth)acrolein from a reactive mixture comprising at least one compound chosen from ethers, acetals or hemiacetals derived from linear alcohols comprising from 1 to 3 carbon atoms. Examples of compounds are dimethyl ether, diethyl ether, methyl ethyl ether, dimethoxymethane, diethoxymethane, dipropoxymethane, 1,1-dimethoxyethane or 1,1-diethoxyethane. The process of the invention comprises two successive phases: oxidation then aldol condensation, which can be carried out in the presence of a solid oxidation catalyst chosen from molybdenum-based catalysts and optionally of an aldol condensation catalyst. These two phases are carried out in a reaction system comprising a single reactor or optionally two reactors in cascade.

Owner:ARKEMA FRANCE SA

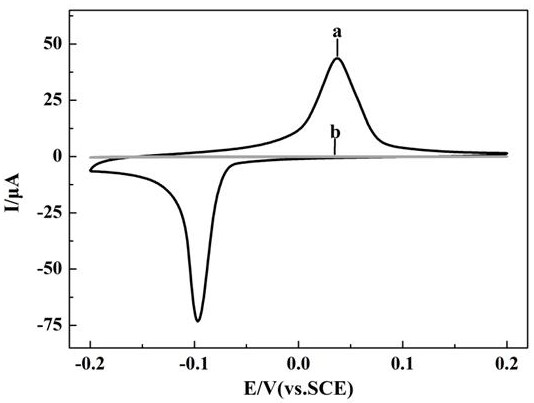

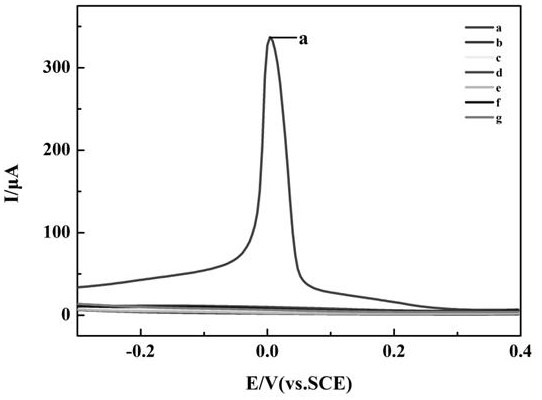

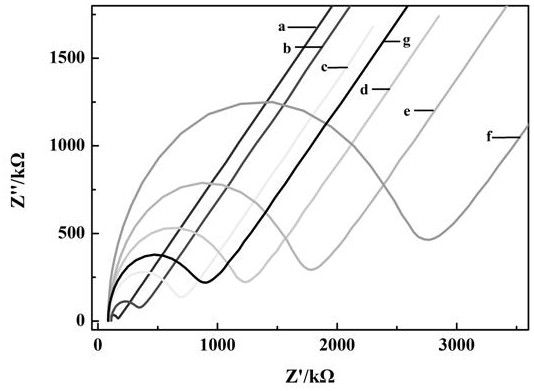

Preparation method of phospholipase C sensor based on atom transfer radical polymerization

PendingCN113933362AAvoid interferenceHigh sensitivityMaterial electrochemical variablesElectrochemical biosensorAtom-transfer radical-polymerization

The invention discloses a preparation method of a phospholipase C sensor based on atom transfer radical polymerization. A polymethylacrolein modified electrode as a working electrode is prepared from a specific ATRP (Atom Transfer Radical Polymerization) polymer solution under an illumination condition, and then silver nanoparticles are effectively introduced into an MVL ATRP molecular chain for signal amplification of the working electrode of the electrochemical sensor. The prepared electrochemical biosensor is very sensitive in PLC detection, the linear detection range of phospholipase C concentration is 1-106 mU / L, and the detection limit is 0.1032 mU / L (S / N = 3). Compared with the prior art, the method has the advantages of high sensitivity, strong operability and the like. In addition, the method is low in background signal, high in selectivity, capable of avoiding interference of false positive results, low in cost and high in benefit.

Owner:LIAONING NORMAL UNIVERSITY

Method for preparing methylacrolein and co-producing methacrylonitrile by oxidizing isobutene

PendingCN114591156AHigh selectivityRealize joint productionOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystAcrolein

The invention discloses a method for preparing methylacrolein and co-producing methacrylonitrile through oxidation of isobutene. Comprising the following steps: 1) mixing isobutene and an oxidizing agent, mixing with a catalyst, and reacting to prepare methylacrolein; and 2) mixing methylacrolein, ammonia, an oxidizing agent and a catalyst, and reacting to prepare the methacrylonitrile. Wherein the catalysts in the step 1) and the step 2) are the same. By controlling the same catalyst and reaction conditions, methylacrolein or methacrylonitrile can be selectively obtained on the same reactor; or further, isobutene can be oxidized into methylacrolein through a mode of connecting reaction tubes in series, and then methylacrolein is subjected to ammoxidation to obtain methacrylonitrile. The problem of strong reaction heat caused by direct ammoxidation of isobutene into methacrylonitrile can be effectively solved, the selectivity of methacrylonitrile is improved, and co-production of methylacrolein and methacrylonitrile can be realized.

Owner:北京水木滨华科技有限公司

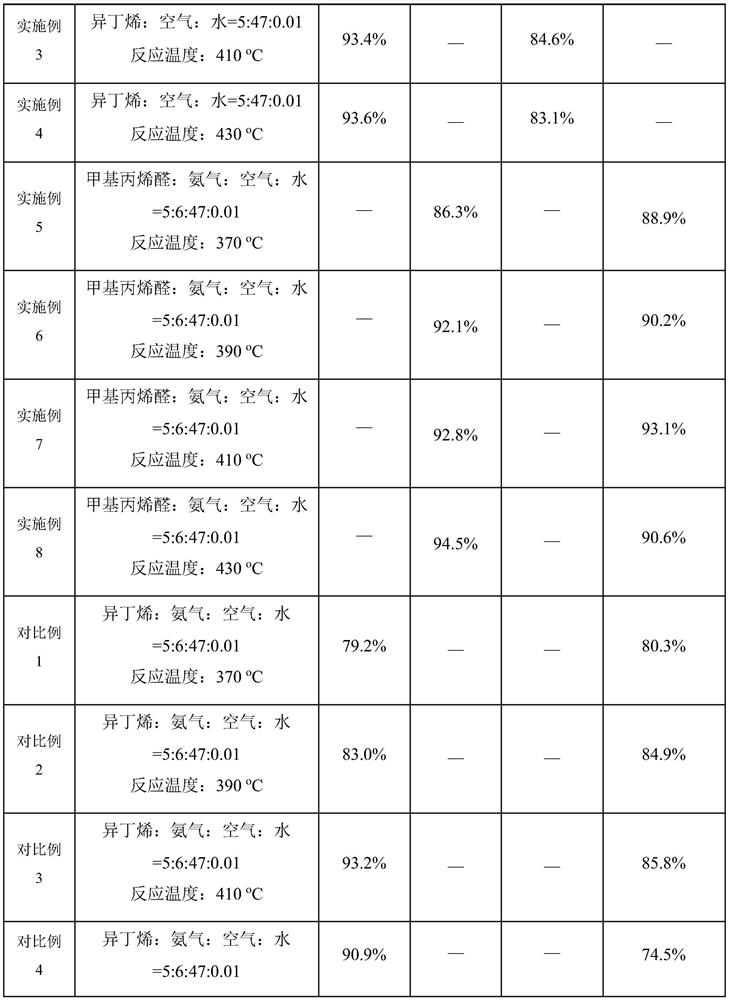

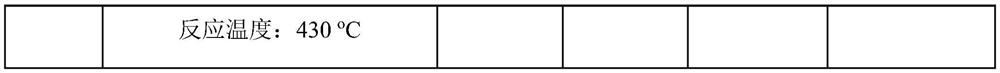

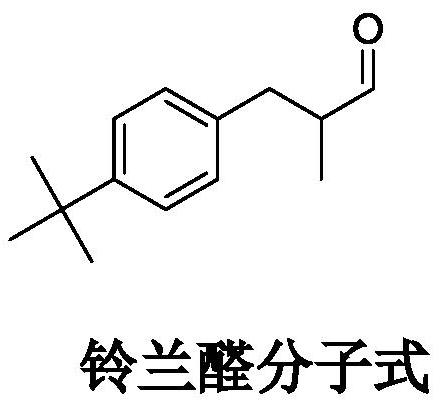

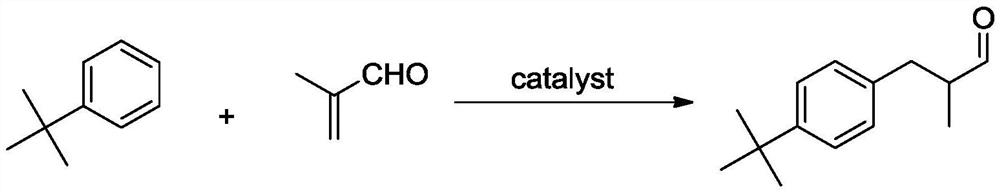

Preparation method of lilial

PendingCN113788745AEasy to recycleSolve the problem of solid wastePhysical/chemical process catalystsOrganic compound preparationPtru catalystHomogeneous catalysis

The invention provides a method for preparing lilial. According to the method, the lilial is synthesized from tert-butylbenzene and alpha-methylacrolein under the catalysis of a Ti-K (Na) / F-Meso-SiO2 heterogeneous catalyst. According to the catalyst, the carrier is modified through the F element, the acidity of the B acid of the catalyst is further enhanced, meanwhile, the Ti metal is doped with K and / or Na, the catalytic activity of the Ti metal is effectively improved, and due to the fact that the catalyst has the B acid site and the L acid site, and the two acidic active centers conduct synergistic catalysis, so that the process conditions are mild, the reaction time is short, the catalyst is easy to recycle, and the problem that a large amount of waste acid and solid waste are generated after a traditional catalyst is used is solved.

Owner:WANHUA CHEM GRP CO LTD

Hollow-structure catalyst and preparation method and application thereof

PendingCN113976179AReduce intensityLow resolutionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHeteropoly acid

The invention provides a hollow-structure catalyst applied to a process for preparing methacrylic acid by oxidizing methylacrolein and a preparation method of the hollow-structure catalyst. The catalyst comprises a multi-component hollow spherical shell and a surface layer, wherein the surface layer is distributed on the surface of the multi-component hollow spherical shell in a layered manner; the component of the surface layer is a catalyst active component, and the multi-component hollow spherical shell is composed of a (catalyst active component)-b (K2O)-c (Al2O3); and the active component of the catalyst is heteropoly acid or heteropoly acid salt with a Keggin structure. Compared with a traditional catalyst, the hollow-structure catalyst has the advantages that the utilization rate of the active components is increased by about 50-100%, the conversion activity of methylacrolein is increased to 96% or above, the selectivity of methacrylic acid is kept at 97% or above, the heat conductivity coefficient is increased by about 30-50%, the bulk density is reduced by about 50-100%, and the highest air speed can be increased to 5000h <-1 > under the condition that the performance is guaranteed.

Owner:淄博市翔力致高新材料有限责任公司

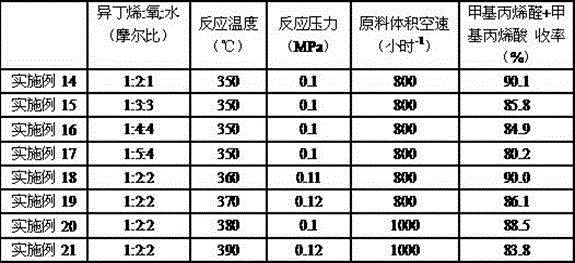

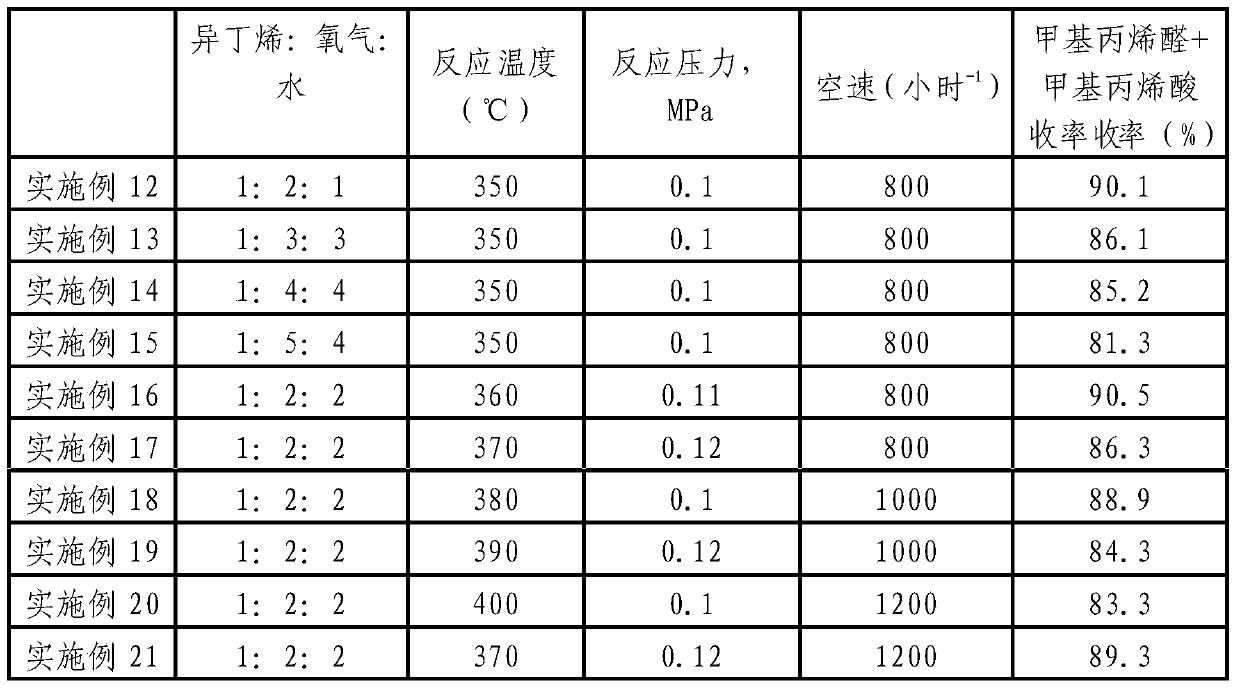

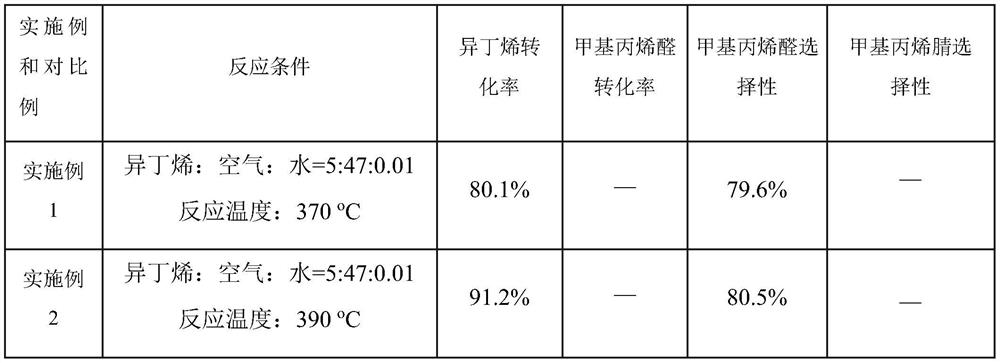

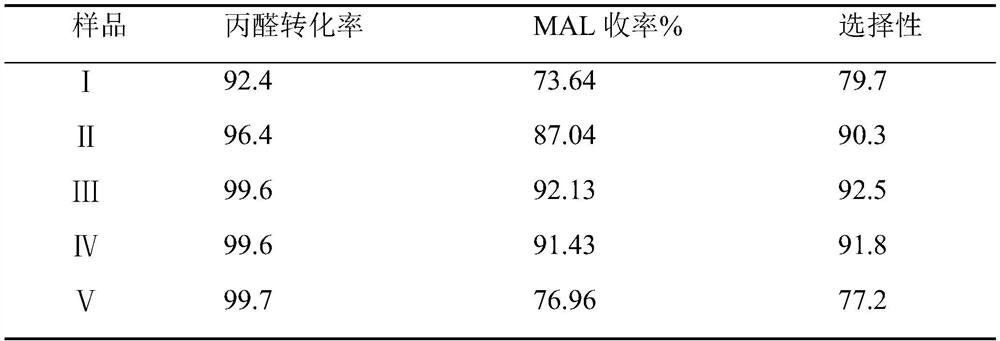

Synthesis method of methacrylaldehyde

InactiveCN105503558AImprove technical effectOrganic compound preparationCarbonyl compound preparationLow activitySynthesis methods

The invention relates to a method for oxidation of isobutene or tert-butyl alcohol to prepare methacrylaldehyde, and mainly solves the problems of low activity and low yield of methacrylaldehyde and methacrylic acid in the prior art. According to a technical scheme, isobutene or tert-butyl alcohol is employed for selective oxidation to synthesize methacrylaldehyde, isobutene or tert-butyl alcohol and oxygen are adopted as the raw materials, water is taken as the reaction diluent, and the raw materials and a catalyst contact to generate methacrylaldehyde. Specifically, the catalyst comprises a carrier and an active ingredient, the active ingredient has the following general formula Mo12BiaFebCocCedCseXfYgOh, wherein X is at least one of W, V, Ni, Cr, Mn, Nb or Re, and Y is selected from at least one of Sn, Sr, Zn, Ti or Zr. The method well solves the problem, and can be applied to the industrial production of methacrylaldehyde.

Owner:CHINA PETROLEUM & CHEM CORP +1

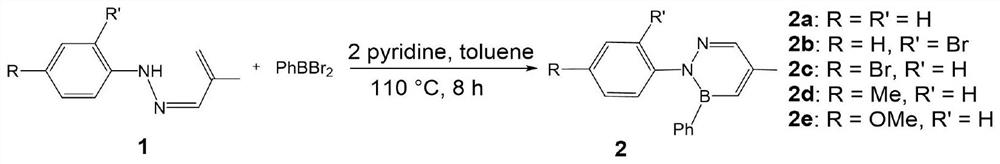

Method for simply preparing boron-nitrogen pyridine compound

PendingCN114736226AWide variety of sourcesImprove universalityGroup 3/13 element organic compoundsMeth-Organic solvent

The invention relates to the technical field of synthesis of boron-nitrogen-pyridine compounds, in particular to a simple preparation method of a boron-nitrogen-pyridine compound, which comprises the following steps: taking a phenylhydrazone derivative generated by reacting phenylhydrazine with different substituent groups with 2-methylacrolein as a reaction substrate, dissolving the reaction substrate, phenyl boron dibromide and pyridine in an organic solvent according to a ratio, and reacting under the protection of argon to obtain the boron-nitrogen-pyridine compound. Heating and stirring at 110 DEG C for 8 hours, pumping the organic solvent after the reaction is completed, and separating and purifying through a column to obtain the boron-nitrogen-pyridine compound. The method has the advantages of being wide in raw material source, low in price and easy to obtain, low in production cost, simple in reaction condition, easy to implement, good in functional group universality, few in by-product, simple in post-treatment and the like.

Owner:NANKAI UNIV

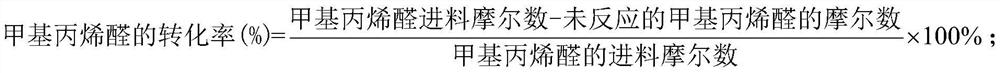

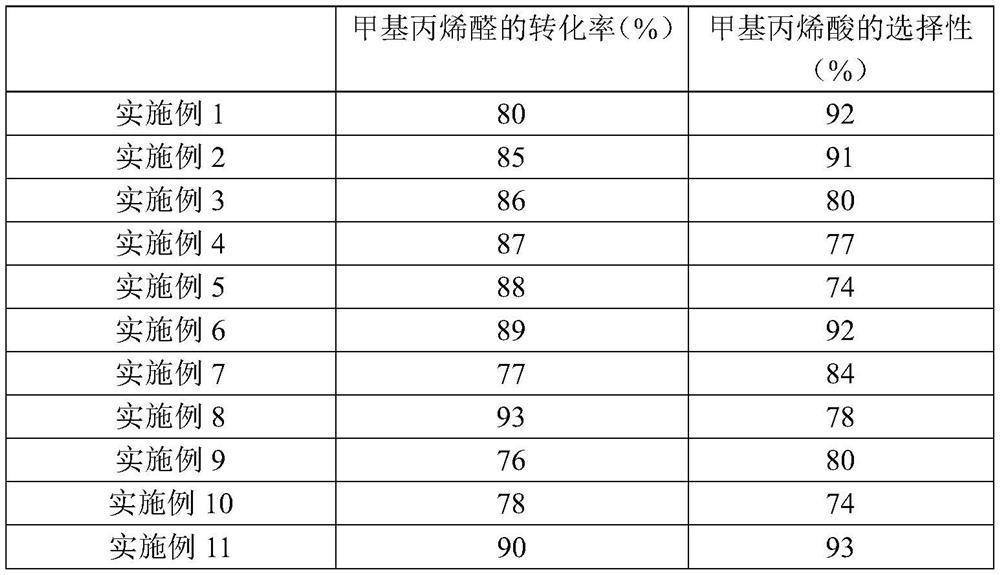

Catalyst for selective oxidation of methacrolein to methacrylic acid, preparation method and use thereof

ActiveCN109731592BMeet the needs of actual industrial productionImprove production efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMeth-

The invention discloses a catalyst for selectively oxidizing methacrylaldehyde to prepare methacrylic acid and preparation and application methods thereof. The catalyst for selectively oxidizing the methacrylaldehyde to prepare the methacrylic acid is composed of PaMobVcXxYyZz1HhOg1-Zz2Og2, wherein X is a combination of at least two from sodium, potassium, rubidium and cesium, Y is a mixture of one or at least two from calcium, magnesium, chromium, manganese, iron, cobalt, copper, nickel, zinc, aluminum, silicon, germanium, antimony, bismuth, lanthanum or cerium, and Z comprises titanium and / or zirconium. Compared with traditional phosphovanadomolybdate catalysts. The catalyst for selectively oxidizing the methacrylaldehyde to prepare the methacrylic acid can be higher in activity when applied to selectively oxidizing the methacrylaldehyde to prepare the methacrylic acid, and during the catalytic process, when the methacrylaldehyde converting rate is 90%, and the selectivity to the methacrylic acid can reach up to 93%, so that the catalyst for selectively oxidizing the methacrylaldehyde to prepare the methacrylic acid can meet the demands of practical industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for direct synthesis of (METH)acrolein from ethers and/or acetals

ActiveUS20170113990A1Simple operating conditionsLimited amountOrganic compound preparationHeterogenous catalyst chemical elementsMeth-Acetal

The subject matter of the present invention is a process for direct synthesis of (meth)acrolein from a reactive mixture comprising at least one compound chosen from ethers, acetals or hemiacetals derived from linear alcohols comprising from 1 to 3 carbon atoms. Examples of compounds are dimethyl ether, diethyl ether, methyl ethyl ether, dimethoxymethane, diethoxymethane, dipropoxymethane, 1,1-dimethoxyethane or 1,1-diethoxyethane. The process of the invention comprises two successive phases: oxidation then aldol condensation, which can be carried out in the presence of a solid oxidation catalyst chosen from molybdenum-based catalysts and optionally of an aldol condensation catalyst. These two phases are carried out in a reaction system comprising a single reactor or optionally two reactors in cascade.

Owner:ARKEMA FRANCE SA

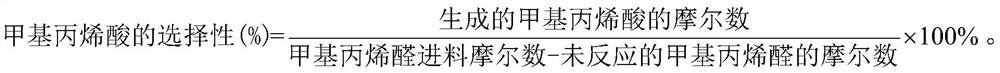

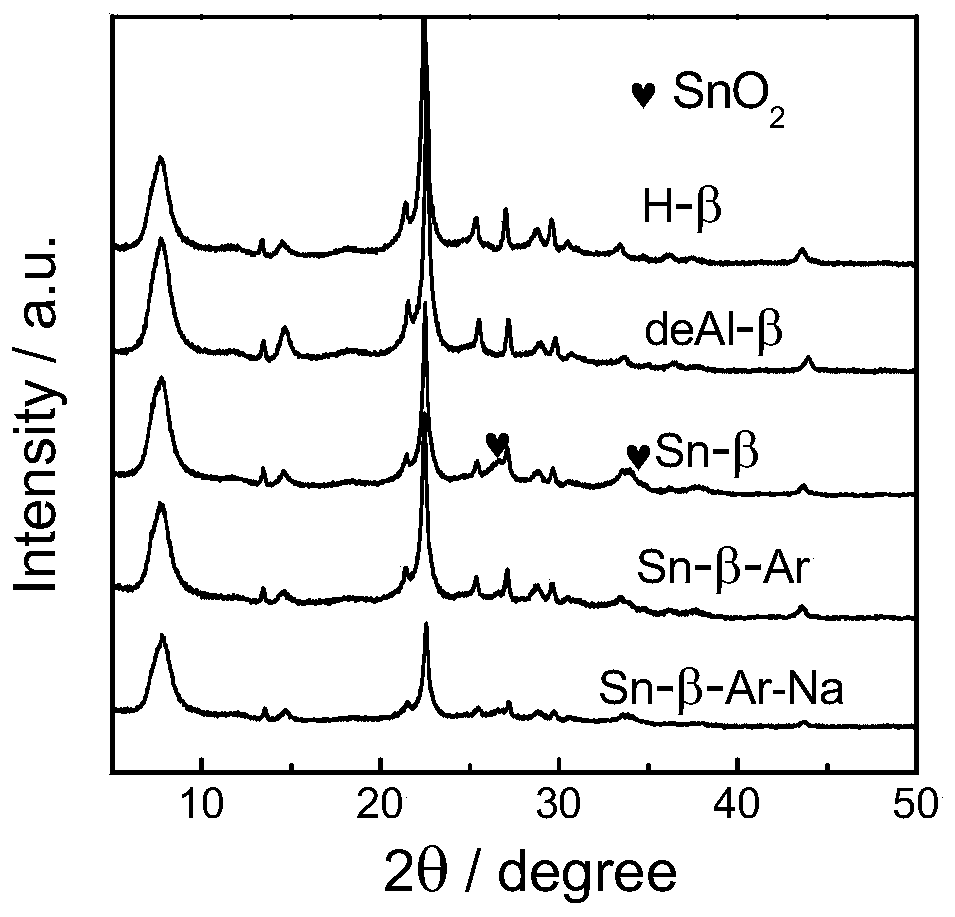

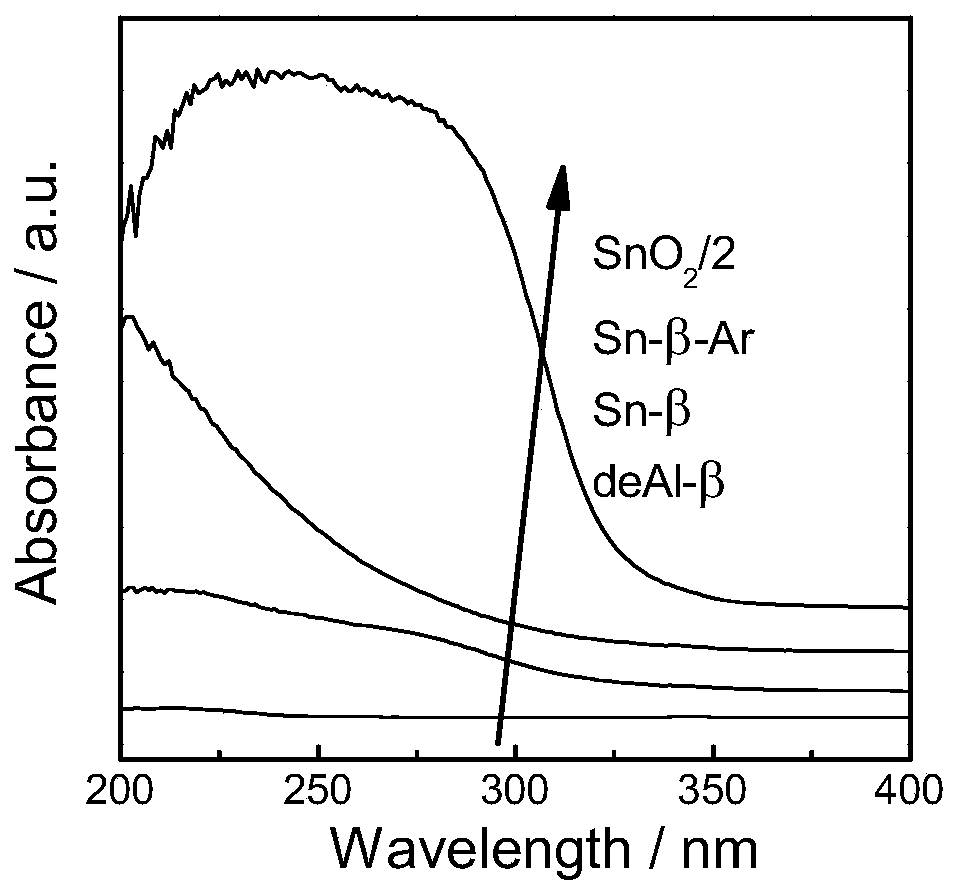

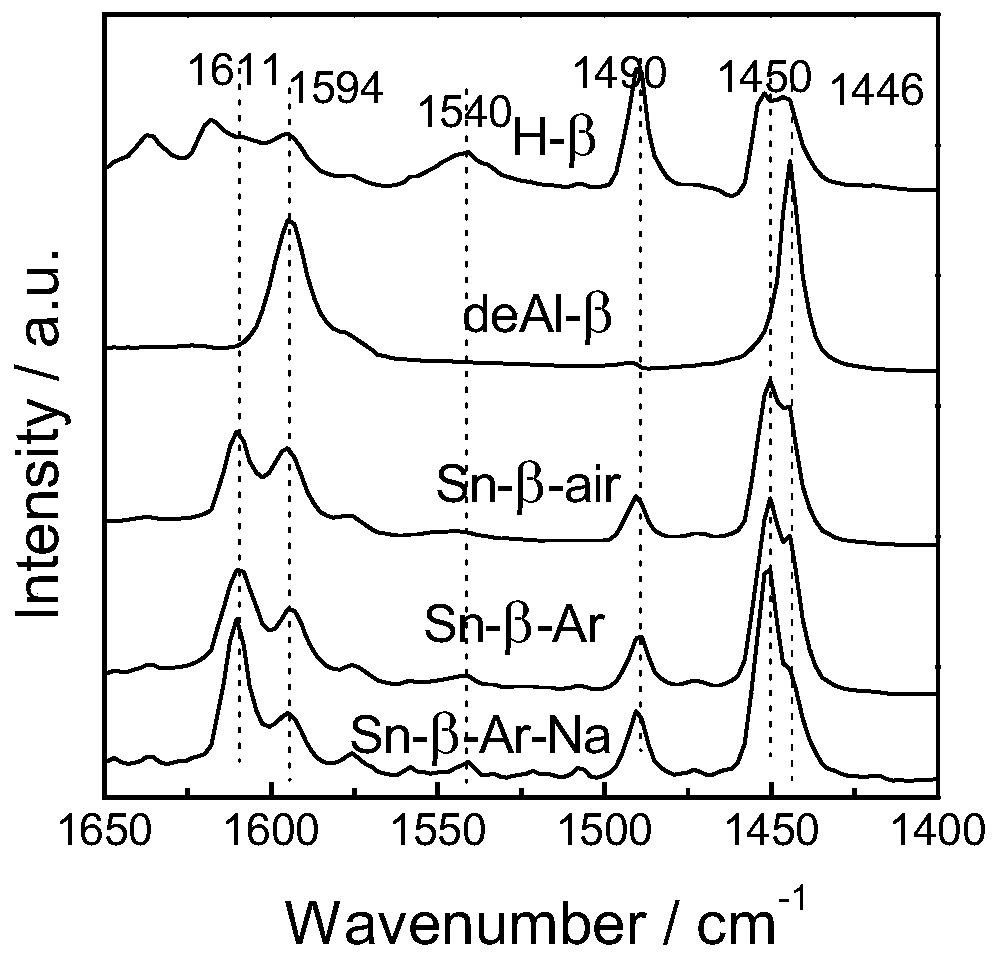

A method for simultaneously preparing methallyl alcohol and acetal by using sn-beta catalysts

ActiveCN106984356BHigh activityImprove stabilityMolecular sieve catalystsOrganic compound preparationPtru catalystEthylic acid

The invention discloses a method for preparing methallyl alcohol and aldehyde acetal simultaneously by using Sn-beta catalysts. The method comprises the following steps: dealuminizing an H-beta molecular sieve serving as a parent, and grinding and roasting the H-beta molecular sieve and stannum acetate to obtain the Sn-beta catalyst Sn-beta; obtaining the Sn-beta catalysts Sn-beta-Ar and Sn-beta-Ar-Na by aftertreatment methods of Ar pretreatment and Na exchange so as to reduce stannum species outside a skeleton and the B acid content of the catalysts and further improve the catalytic activity and selectivity; and preparing two important chemical products methallyl alcohol and aldehyde acetal simultaneously at low temperature by using the above Sn-beta catalysts, taking methylacrolein as a substrate and taking ethanol as a solvent and a hydrogen source. The Sn-beta catalysts have high activity, and the methallyl alcohol with the yield being 90 percent and the aldehyde acetal with the yield being 96 percent can be obtained; the catalysts have high stability and is not deactivated after being circulated for many times; the reaction is conducted at low temperature without high temperature and high pressure; and the reaction system is a multiphase reaction system, and the catalysts and the products are separated simply and conveniently.

Owner:XIAMEN UNIV

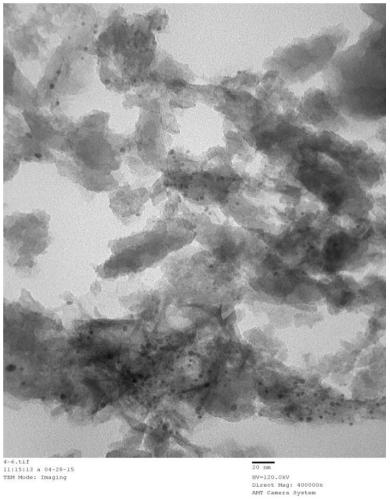

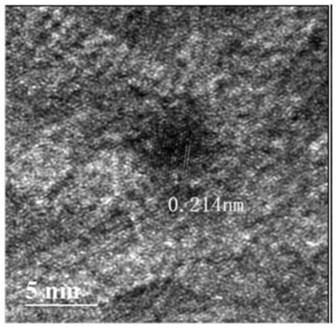

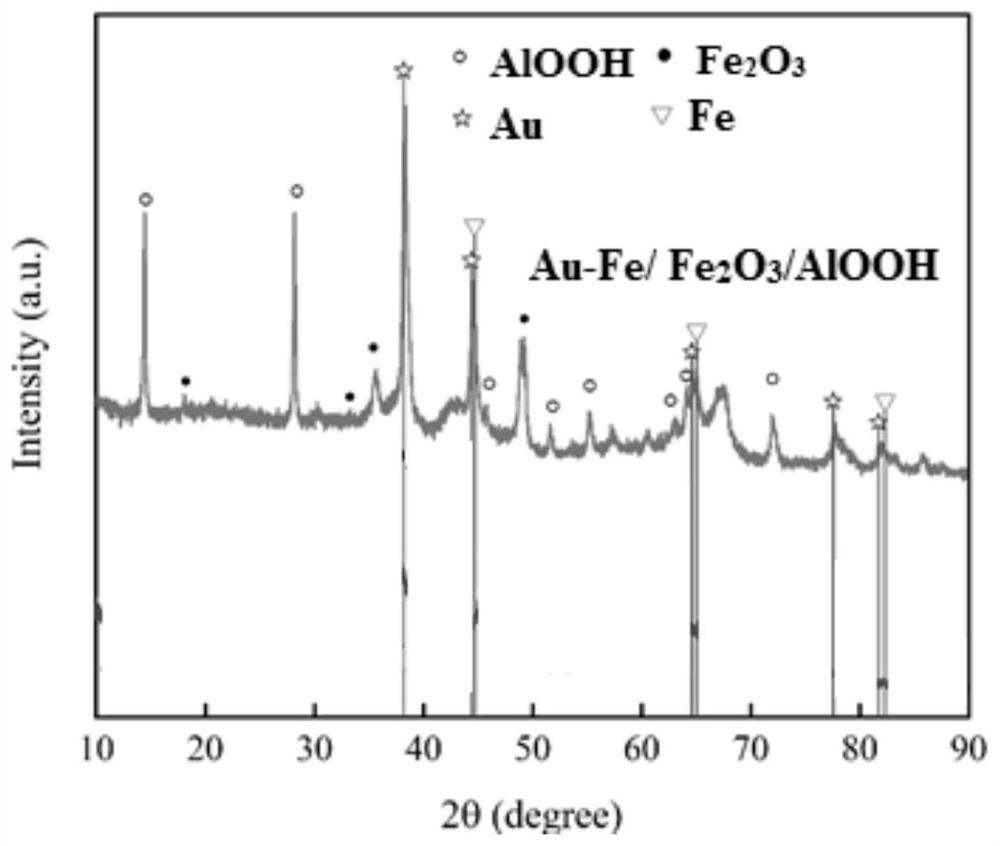

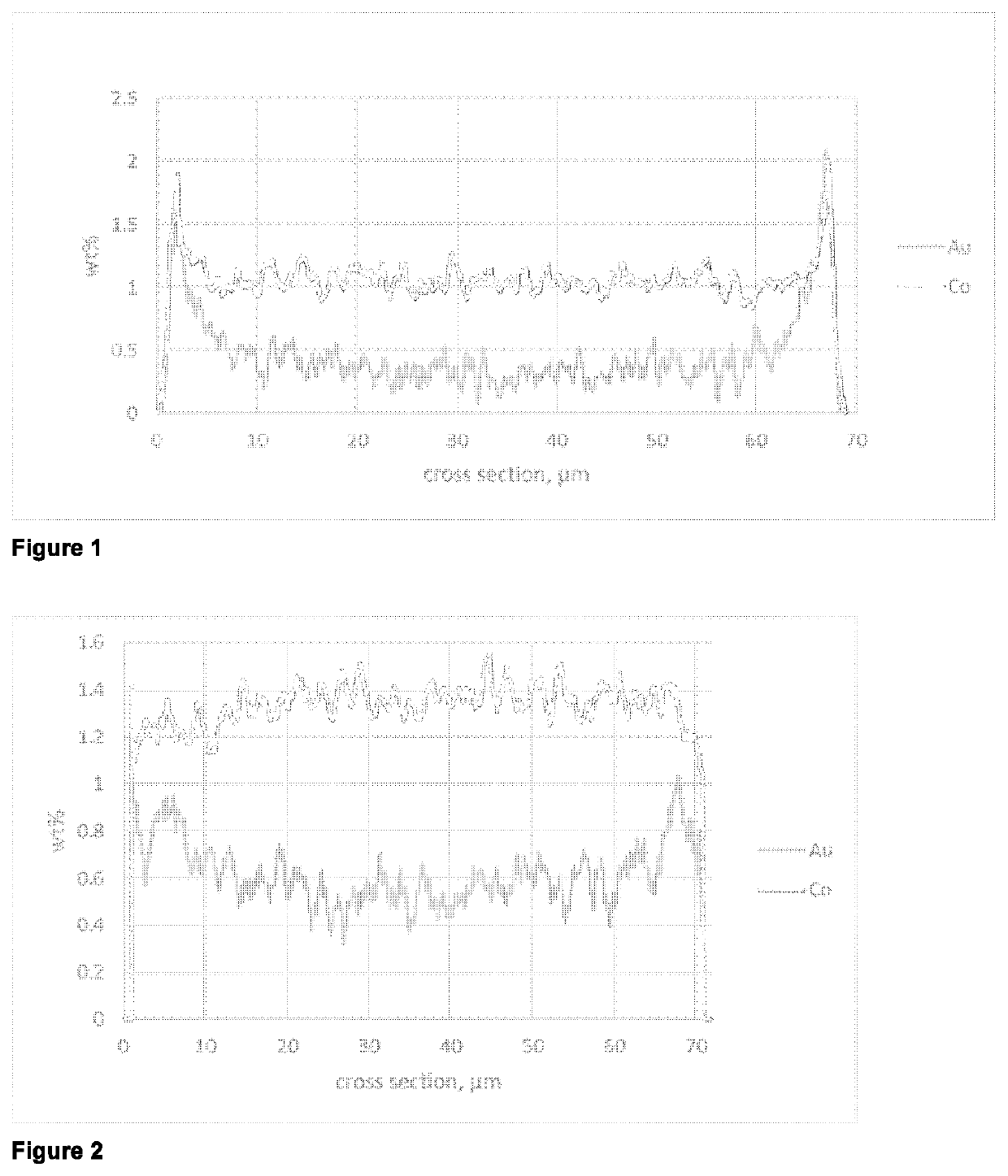

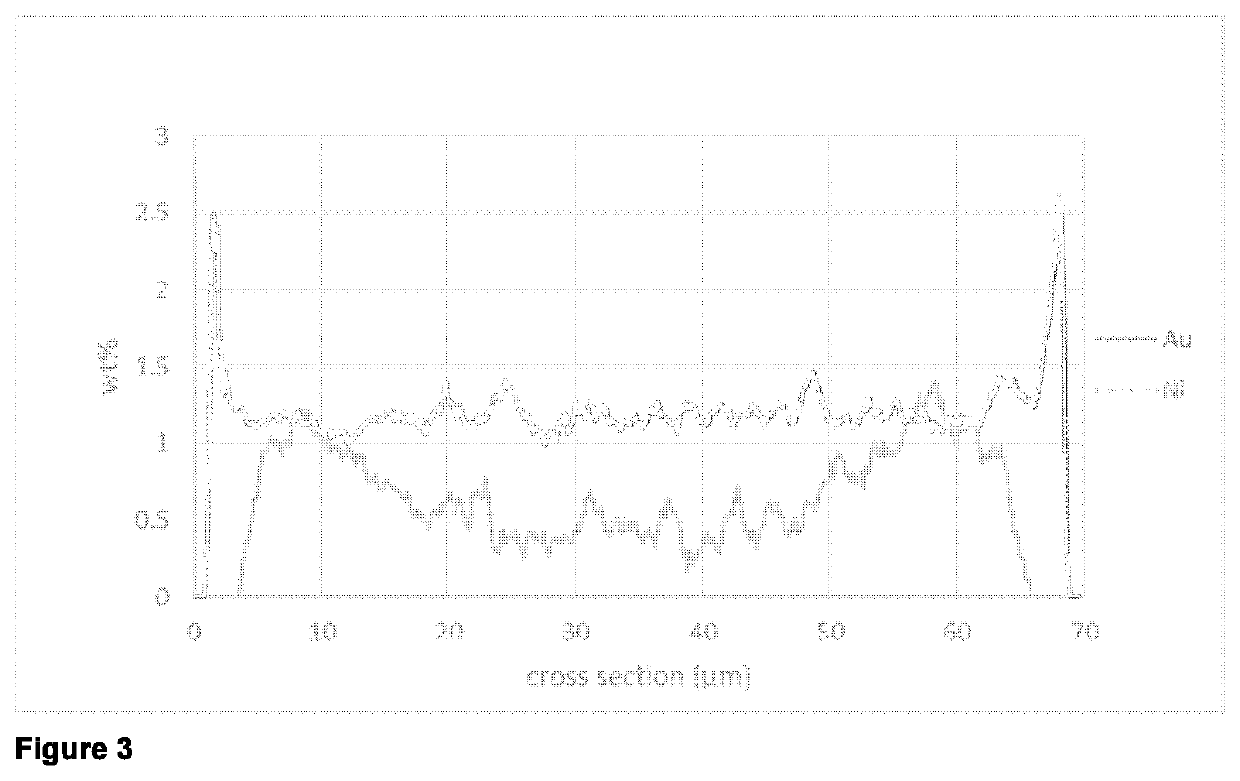

Gold-based catalyst, and preparation method and application thereof

ActiveCN111905758AEvenly dispersedFast and Stable RestoreOrganic chemistryOrganic compound preparationPtru catalystAlloy catalyst

The invention provides a gold-based catalyst and a preparation method thereof, and the application of the gold-based catalyst in MDA preparation reactions. The gold-based catalyst is characterized inthat the gold-based catalyst comprises a carrier, and an active component and an auxiliary agent which are loaded on the carrier, wherein the carrier is hydroxide of aluminum; the active component isgold, and the content of the active component is 0.1-10 wt.%; and the auxiliary agent is iron, or iron and iron oxide. With the gold-based catalyst, in the process of preparing methylacrolein dimethylacetal from methanol, methylacrolein and oxygen as raw materials, the conversion rate of methylacrolein can reach 80% or above, and MDA selectivity is up to 90% or above; and compared with the priorart, the yield of MDA is greatly increased, and large-scale industrial preparation of MDA is realized.

Owner:XIAMEN UNIV

Gold-based catalyst for oxidative esterification of aldehydes to carboxylic acid esters

ActiveUS10906025B2Improve bindingReduce mechanical wearOrganic compound preparationHeterogenous catalyst chemical elementsPolymer scienceMeth-

The present invention relates to novel catalysts for oxidative esterification, by means of which, for example, (meth)acrolein can be converted to methyl (meth)acrylate. The catalysts of the invention are especially notable for high mechanical and chemical stability even over very long periods. This especially relates to an improvement in the catalyst service life, activity and selectivity over prior art catalysts which lose activity and / or selectivity relatively quickly in continuous operation in media having even a small water content.

Owner:ROHM GMBH

Synthesis process of methylacrolein

PendingCN114524721AHigh selectivityHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMannich reactionMorpholine

The invention provides a synthesis process of methylacrolein, which is used for solving the problems that the yield of methylacrolein is difficult to increase, and the yield and high selectivity are difficult to consider at the same time, and a morpholine acetate solution catalyst system is prepared by mixing morpholine and glacial acetic acid. Methacrolein is prepared by catalyzing a mixed solution of formaldehyde and propionaldehyde with a morpholine acetate solution. Formaldehyde and propionaldehyde are subjected to a Mannich reaction process to generate methylacrolein, the addition of acetic acid can effectively promote the transfer rate of protons in the Mannich decomposition process, the addition of a polymerization inhibitor effectively inhibits side reactions, and the reaction yield and selectivity are improved. According to the method, the morpholine acetate solution is used as the catalyst, so that the selectivity and the yield of the methylacrolein are improved; meanwhile, compared with existing condensation reaction conditions, the corrosion is small, the reaction is carried out under the conditions of normal pressure and 30-60 DEG C, the reaction conditions are mild and controllable, and good stability is achieved.

Owner:郑州中科新兴产业技术研究院 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com