Kaolin-loaded Keggin type heteropolyacid catalyst, preparation and application in methylacrolein oxidation

A technology of heteropoly acid and catalyst, which is applied in the field of catalyst preparation and application to achieve the effects of abundant raw materials, high MAL conversion rate and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation steps of the catalyst are as follows: 1) Take 15 g of phosphomolybdic vanadium heteropoly acid, dissolve it in 300 mL of water, and stir evenly. Then take 0.705gCsOH . H 2 O was dissolved in water and added dropwise; then 0.235g KOH was dissolved in water and added dropwise; then 0.332g NH was taken 4 HCO 3 Dissolved in water, added dropwise and stirred for 8h to obtain Cs + , NH 4 + and K + Modified phosphomolybdic vanadium heteropoly acid solution. Then, the solution was evaporated in a rotary evaporator until about 50 mL remained, the sample was transferred to a watch glass, and dried at 80° C. overnight to obtain a heteropolyacid catalyst precursor.

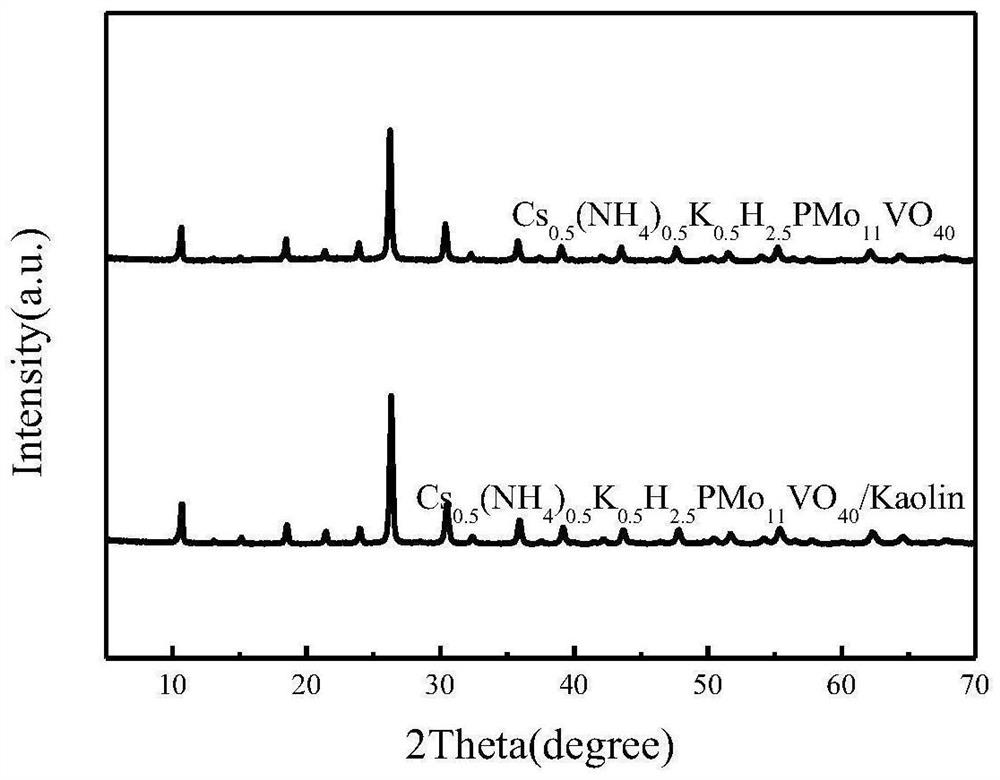

[0035] 2) then get 6g kaolin carrier and put it into the 250mL flask (A); get 8g heteropolyacid catalyst precursor and put it in the beaker, add deionized water to it, stir (B); B is slowly added dropwise to A , stirred for 5 h, then transferred the sample to a watch glass and dried at 80 °C ove...

Embodiment 2

[0039] Dissolve 15 g of phosphomolybdic vanadium heteropoly acid in 200 mL of water and stir evenly. Then take 0.705gCsOH . H 2 O was dissolved in water, added dropwise and stirred for 3h to obtain Cs + Modified phosphomolybdic vanadium heteropoly acid solution. Then, the solution was evaporated in a rotary evaporator until about 50 mL remained, and the sample was transferred to a watch glass and dried overnight to obtain a heteropolyacid catalyst precursor.

[0040] Then get 6g kaolin carrier and put it in 250mL flask (A); Get 5g heteropolyacid catalyst precursor and put it in the beaker, add deionized water to it, and stir (B); B is slowly added dropwise to A, After stirring for 9 h, the sample was transferred to a watch glass and dried overnight to obtain a supported catalyst precursor. The precursor was calcined in nitrogen at 340 °C for 10 h to obtain the target catalyst: Cs 0.5 H 3.5 PMo 11 VO 40 / Kaolin, in which the active component Cs 0.5 H 3.5 PMo 11 VO 4...

Embodiment 3

[0043] Dissolve 15 g of phosphomolybdic vanadium heteropoly acid in 400 mL of water and stir evenly. Then dissolve 0.504g NaOH in water, add dropwise, then dissolve 0.7056g KOH in water, add dropwise, stir for 5h to obtain Na + and K + Modified phosphomolybdic vanadium heteropoly acid solution. Then, the solution was evaporated in a rotary evaporator until about 40 mL remained, the sample was transferred to a watch glass, and dried at 68°C overnight to obtain a heteropolyacid catalyst precursor.

[0044] Then get 7g kaolin carrier and put it in the 250mL flask (A); get 3g heteropolyacid catalyst precursor and put it in the beaker, add deionized water to it, and stir (B); B is slowly added dropwise to A, After stirring for 8 h, the sample was transferred to a watch glass and dried at 70 °C overnight to obtain a supported catalyst precursor. The precursor was calcined in air at 380 °C for 11 h to obtain the target catalyst: Na 1.5 K 1.5 HPMo 11 VO 40 / Kaolin, in which the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

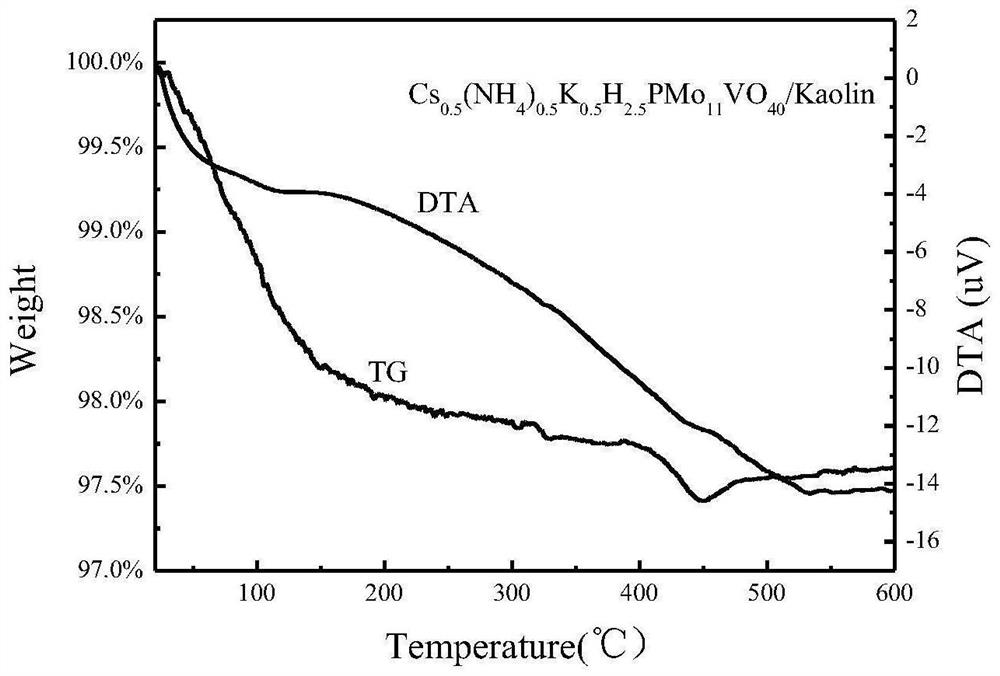

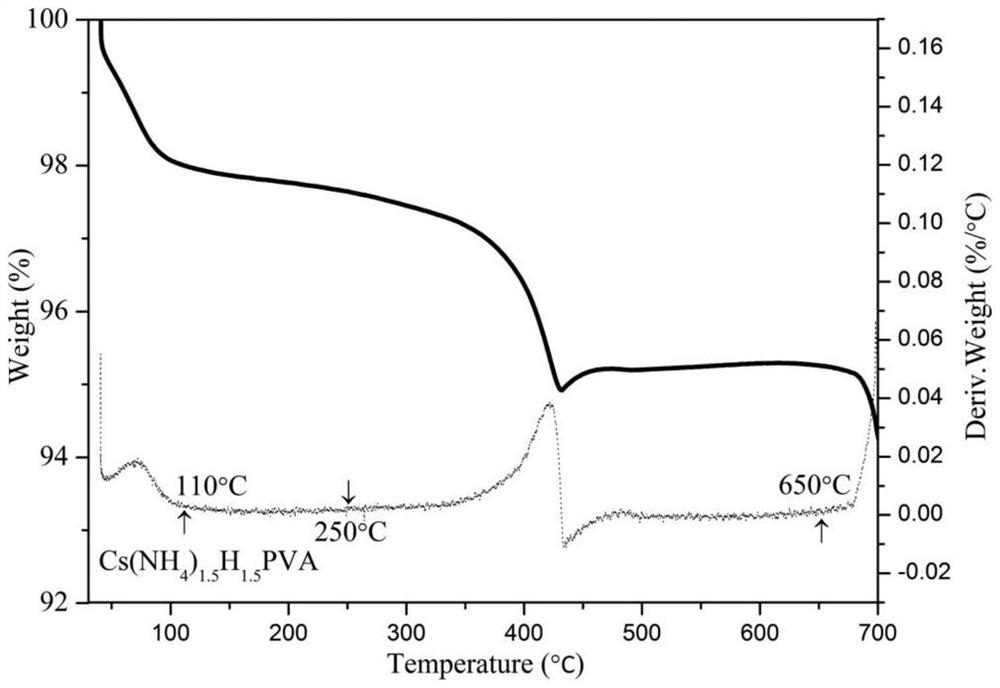

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com