Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Iron cyanide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-loading iron cyanide complex/silicon dioxide hybrid materials

ActiveCN101041123AIncrease loadFast adsorption rateSilicon compoundsRadioactive decontaminationPotassiumSilicon dioxide

The invention relates to a preparing method for ferrocyanide with high load / silica hybrid material, belonging to a preparing method for radionuclide ion absorbing material. The method uses the salt solution with metal ion such as Mn, Sn, Ti, Fe, and Ni so on to react with potassium (sodium) ferrocyanide so as to obtain nanometer particle of ferrocyannide. The particle is fixed by silica solution in water system or is fixed by polymerization siloxane in organic solvent and proper inorganic acid, organic amine or amine water is added to obtain hybrid gel. The hybrid gel is dried, rubbed and screened to obtain ferrocyanide with high load / silica hybrid material. The high load of the material is high and the absorption to nuclide ion is strong. In addition, the material intensity can satisfy the demand of packed bed. The particle diameter can be controlled so as to avoid the problem that the water resistance of bed layer generated by ferrocyanide used alone is overlarge.

Owner:TSINGHUA UNIV

Compound ferrous iron cyanide titanium potassium magnetic ball and preparation method thereof

ActiveCN102794153ALarge adsorption capacityNot easy to parseOther chemical processesSilicon compoundsParticulatesMicrosphere

The invention belongs to the technical field of a method for preparing a compound ferrous iron cyanide titanium potassium magnetic ball, and in particular relates to the compound ferrous iron cyanide titanium potassium magnetic ball and a preparation method thereof. The method comprises the following steps of: preparing a magnetic ferroferric oxide silicon dioxide microballoon by using a ferroferric oxide magnetic particle with the grain diameter of 0.3-0.8 microns as a core and using tetraethoxysilane as a silicon source; then preparing a magnetic ferroferric oxide silicon dioxide-titanium oxide spherical particle by taking dichloro oxotitanium as a titanium source; and finally, preparing the compound ferrous iron cyanide titanium potassium magnetic ball by using potassium ferrocyanide as a soaking agent. The method has simple steps and is mild in experiment condition; and the grain diameter of the prepared compound ferrous iron cyanide titanium potassium magnetic ball is 0.05-0.2mm, the saturation capacity of absorbed cesium is 1.0 mmolCs / g-1.4 mmolCs / g dry compound particles; and therefore, the method for preparing the compound ferrous iron cyanide titanium potassium magnetic ball has the advantages that the absorption capacity of the ferrous iron cyanide titanium potassium to the cesium is preserved under the mild condition, the analysis is difficult to carry out, and the absorbed particles are easy to recover; and particulate matter of the absorbed cesium can be transformed to oxide to be conveniently stored.

Owner:TSINGHUA UNIV

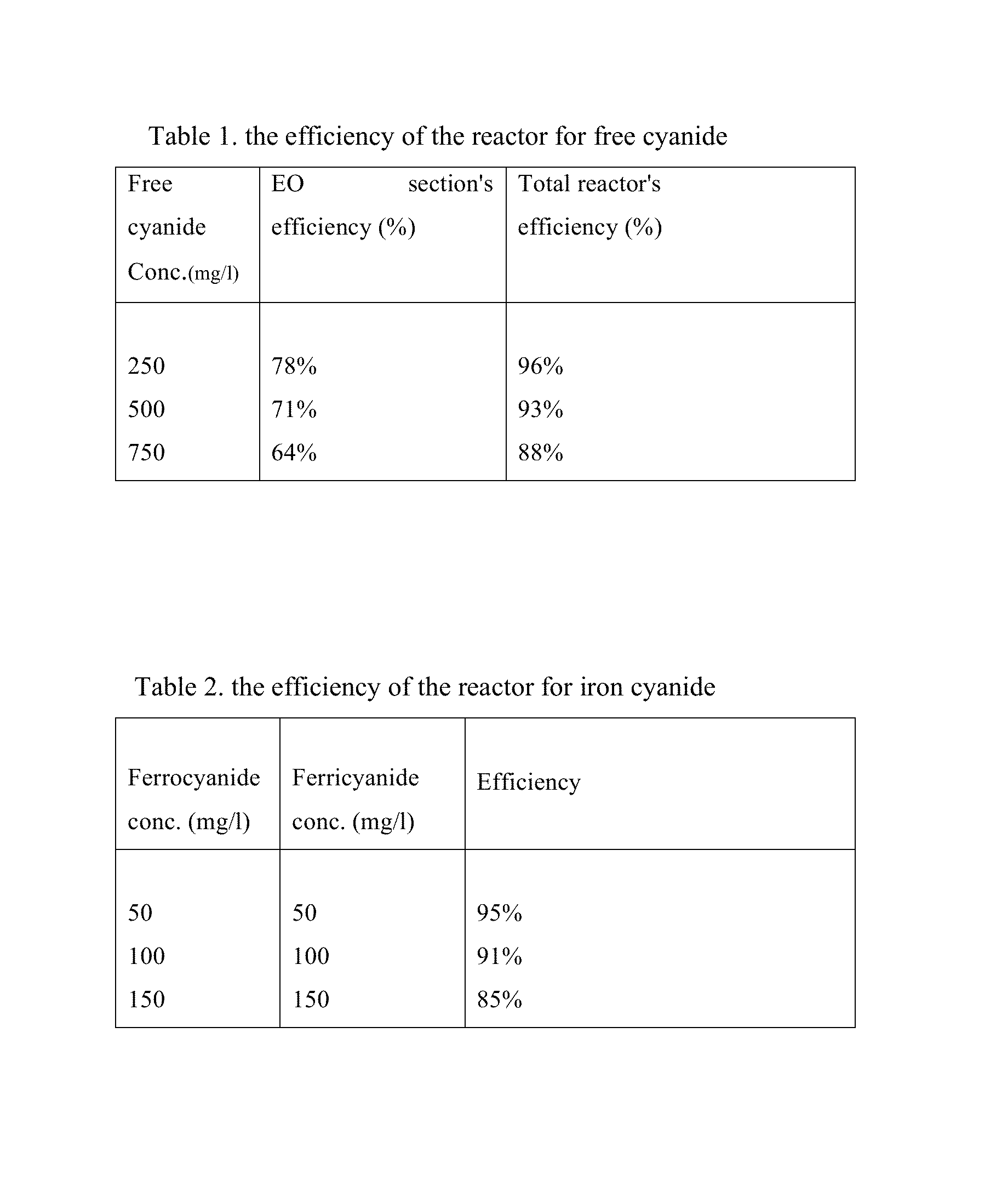

Electrochemical-based reactor for the removal of free cyanides and iron cyanide from industrial wastewater

InactiveUS20140246375A1Increase consumptionVolume of produced increaseWater contaminantsSedimentation separationElectrocoagulationIron cyanide

The present invention relates to a continuous bipolar electrochemically based reactor for the purpose of destroying free cyanide by direct and indirect oxidation and removing its strong complexes like ferrocyanide and ferricyanide by electrocoagulation. The designed reactor consists of four main sections, including electrooxidation, hydraulic mixing, electrocoagulation, and precipitation tank. The order of sections results in having a combination of reactions which separately remove cyanide and its compounds. The designed reactor shows a high flexibility in terms of handling highly variable kinds and concentrations of cyanide in the industrial wastewater effluents.

Owner:GHARIBI HAMED +1

Preparation method of cobalt diiron tetraoxide-carbon cloth lithium battery anode material

ActiveCN106531967ASimplify the manufacturing processIncrease capacityCell electrodesElectron transferCobalt

The invention discloses a preparation method of a cobalt diiron tetraoxide-carbon cloth lithium battery anode material. The preparation method comprises the following steps: providing a Berlin blue solution, wherein raw materials of the Berlin blue solution comprise a cobalt salt and an iron-cyanide salt; using the Berlin blue solution to soak carbon cloth so as to obtain a precursor / carbon cloth composite material; and carrying out heat treatment on the precursor / carbon cloth composite material. According to the preparation method disclosed by the invention, the composite material that CoFe2O4 is grown on a carbon cloth substrate is prepared in an in-situ manner. The manufacturing process of the electrode can be simplified, a direct electron transfer path between an active material and a current collector is provided, and meanwhile huge volume expansion in the lithium intercalation and deintercalation process can be relieved. The cobalt diiron tetraoxide-carbon cloth lithium battery anode material can serve as a lithium battery anode without a binding agent, and the lithium battery anode material has relatively high capacity, outstanding cycle stability and excellent rate capability. Meanwhile, the anode material can be used for assembling a flexible lithium ion battery, and can be applied to more fields.

Owner:HEILONGJIANG UNIV

Restorative method for soil polluted by cyanide

The invention discloses a restorative method for soil polluted by cyanide. According to the characteristics that the soil polluted by cyanide comprises the cyanide, heavy metal and various pollutants and particularly according to the characteristic that the cyanide further comprises metal cyanide complex, such as iron cyanide complex, difficult to treat, firstly, ferrous sulfate and zinc sulfate are selected to fix the iron cyanide complex and various kinds of metal in the soil, and then the cyanide difficult to treat, sulfocyanide and other pollutants remaining in the soil are treated through ozone. The cyanide and various kinds of metal in the treated soil meet the national soil environment quality evaluation requirement.

Owner:CHANGCHUN GOLD RES INST

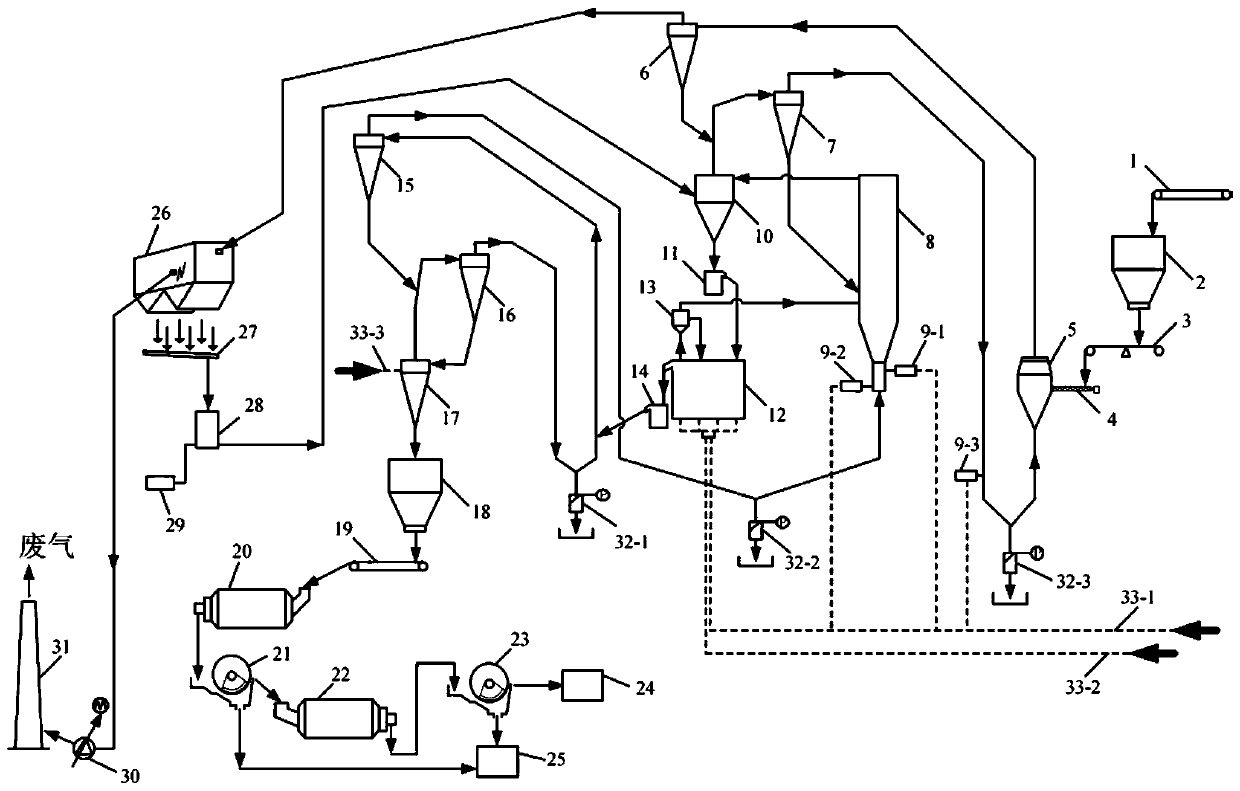

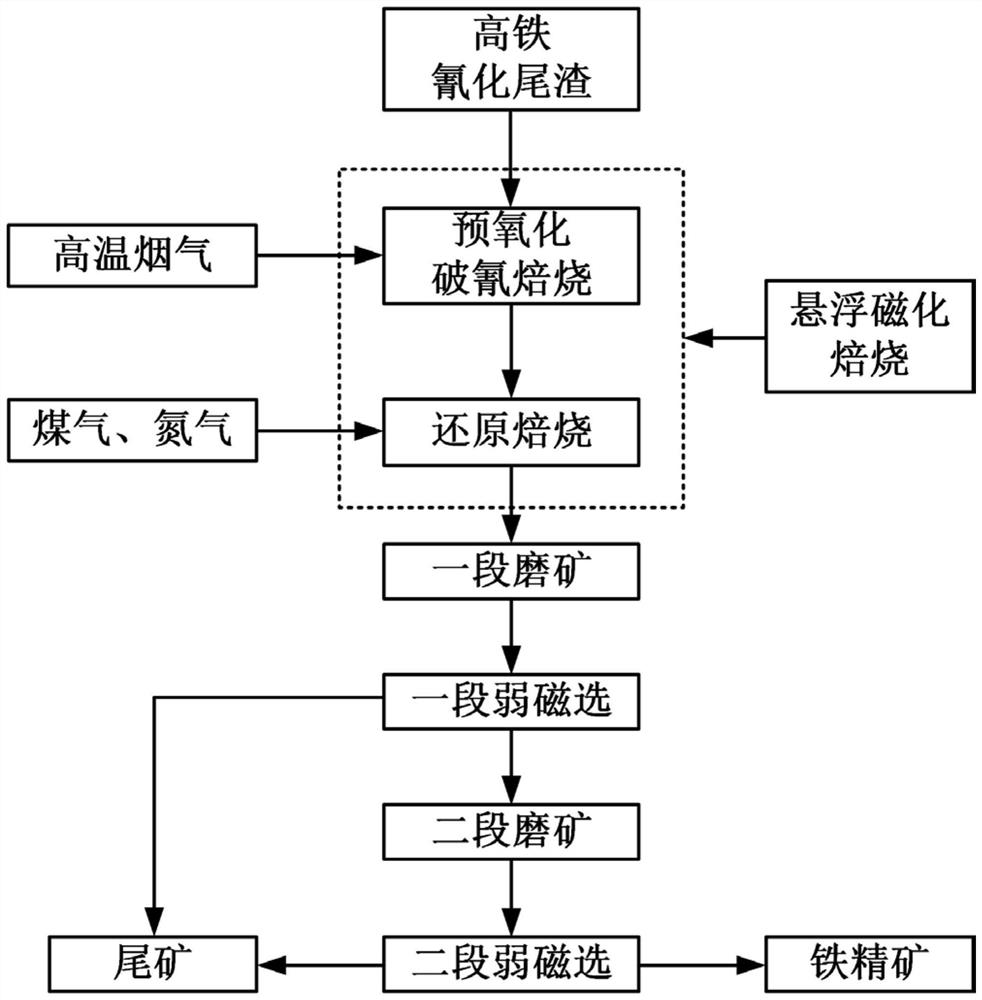

Suspension magnetizing roasting cyanide breakage-weak magnetic separation iron extraction device for high-iron cyanide tailings

ActiveCN111455165ADecompose thoroughlyHigh heat and mass transfer efficiencyMagnetic separationIron cyanideMagnetic separator

The invention discloses a suspension magnetizing roasting cyanide breakage-weak magnetic separation iron extraction device for high-iron cyanide tailings. A venturi dryer, two cyclone preheaters and apre-oxidation suspension roasting furnace communicate with one another in series. The pre-oxidation suspension roasting furnace comprises a combustor and air inlets. The upper portion of the pre-oxidation suspension roasting furnace communicates with a heat separation cyclone barrel through a pipeline, the heat separation cyclone barrel, a first flow sealing valve and a suspension reducing roasting furnace communicate with one another in series, and the suspension reducing roasting furnace communicates with a coal gas source and a nitrogen source. A discharging outlet of the suspension reducing roasting furnace, a second flow sealing valve, a first cooling cyclone barrel, a second cooling cyclone barrel, a third cooling cyclone barrel and a collecting bin communicate with one another in series. An outlet of the collecting bin cooperates with an inlet of a first-stage ore grinding machine, and the first-stage ore grinding machine, a first-stage weak magnetic separation machine, a second-stage ore grinding machine and a second-stage weak magnetic separation machine cooperate with each other in sequence. An air outlet of the first cyclone preheater communicates with a dust collectorand an induced draft fan in series. The suspension magnetizing roasting cyanide breakage-weak magnetic separation iron extraction device for the high-iron cyanide tailings has the advantages of beinghigh in heat transfer and mass transfer efficiency, thorough in cyanide decomposition, high in processing capacity and high in adaptability, being suitable for large-scale industrial production and the like.

Owner:上海逢石科技有限公司

Method for detecting sugar content in sugarcane juice

InactiveCN1932509AChemical analysis using titrationPreparing sample for investigationSucroseSaccharum

The invention discloses the measurement method for the cane sugar. Its method includes the water solution of cane sugar, the reaction of Reducing Sugar and iron cyaniding potassium, second iron cyaniding the electric potential titration of the potassium. The method of the invention has to operate easily, measurement result stability credibility, the measurement variation coefficient of result is small, the error margin is small, but it is easy to carry out instrument to turn.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Method for preparing high-loading iron cyanide complex/silicon dioxide hybrid materials

ActiveCN100469435CIncrease loadFast adsorption rateRadioactive decontaminationSilicon compoundsPotassiumSilicon dioxide

The invention relates to a preparing method for ferrocyanide with high load / silica hybrid material, belonging to a preparing method for radionuclide ion absorbing material. The method uses the salt solution with metal ion such as Mn, Sn, Ti, Fe, and Ni so on to react with potassium (sodium) ferrocyanide so as to obtain nanometer particle of ferrocyannide. The particle is fixed by silica solution in water system or is fixed by polymerization siloxane in organic solvent and proper inorganic acid, organic amine or amine water is added to obtain hybrid gel. The hybrid gel is dried, rubbed and screened to obtain ferrocyanide with high load / silica hybrid material. The high load of the material is high and the absorption to nuclide ion is strong. In addition, the material intensity can satisfy the demand of packed bed. The particle diameter can be controlled so as to avoid the problem that the water resistance of bed layer generated by ferrocyanide used alone is overlarge.

Owner:TSINGHUA UNIV

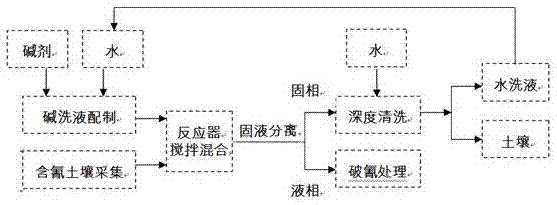

Method for remedying cyanide contaminated soil through alkali solution phase transfer technology

InactiveCN107309262AOvercome the defect of not being able to remove ferricyanide complex in cyanide-containing soilReduce volatilityContaminated soil reclamationResearch ObjectDisposal Technique

The invention discloses a method for remedying cyanide contaminated soil through an alkali solution phase transfer technology. The cyanide contaminated soil is used as a study object, cyanide (mainly iron-cyanide complex) is selected as a target contaminant, the manner of full contact of an alkali solution and cyanogen-containing soil is adopted, maximum-degree liquid phase transfer of soil cyanide can be efficiently and safely achieved by adjusting and controlling parameters such as the solution alkalinity, the solid-liquid contact time and the solid-to-liquid ratio, and the treated soil can reach the B-level standard 8mg / kg of the national Standard of Soil Quality Assessment for Exhibition Sites HJ350-2007. According to the method, the defects that in a cyanide direct oxidation method and other traditional methods, the efficiency of the treatment technology is low, and cyanide is removed not thoroughly are overcome; safe and efficient separation and removal of the cyanide are achieved; and powerful technical support is provided for comprehensive treatment and safe reutilization of a cyanide contaminated site.

Owner:CHONGQING UNIV

A kind of gold mine cyanogen-containing tailings slag processing method

ActiveCN104889134BEasy to handleImprove processing efficiencySolid waste disposalSlagCatalytic oxidation

The invention discloses a method used for processing gold mine cyanide-bearing tailing slag. The method comprises four steps including closed-circuit slurry mixing and processing, coprecipitation pretreatment, neutralization secondary precipitation treatment, and hydrogen peroxide catalytic oxidation, wherein the cyanide-bearing tailing slag is prepared into a slurry with a slurry mixing liquid at a certain liquid-solid ratio; an M agent is added into the slurry so as to release and remove cyanides and iron-cyanide complex compounds; a pH value neutralizer is added so as to adjust pH value to 8.5 to 9.5; a deep oxidation agent and a catalyst are added into obtained waste water so as to remove left pollutants such as cyanides and heavy metals. Closed-circuit slurry mixing and processing, coprecipitation pretreatment, neutralization and arsenic removing, and hydrogen peroxide catalytic oxidation are combined for advanced treatment of gold mine cyanide-bearing tailing slag based on characteristics of gold mine cyanide-containing waste water that pollutants are complex, and processing is difficult to realize; processing effect is excellent; processing efficiency is high; system operation is stable; technology process is simple; and it is convenient for realizing of industrial application.

Owner:CHANGCHUN GOLD RES INST

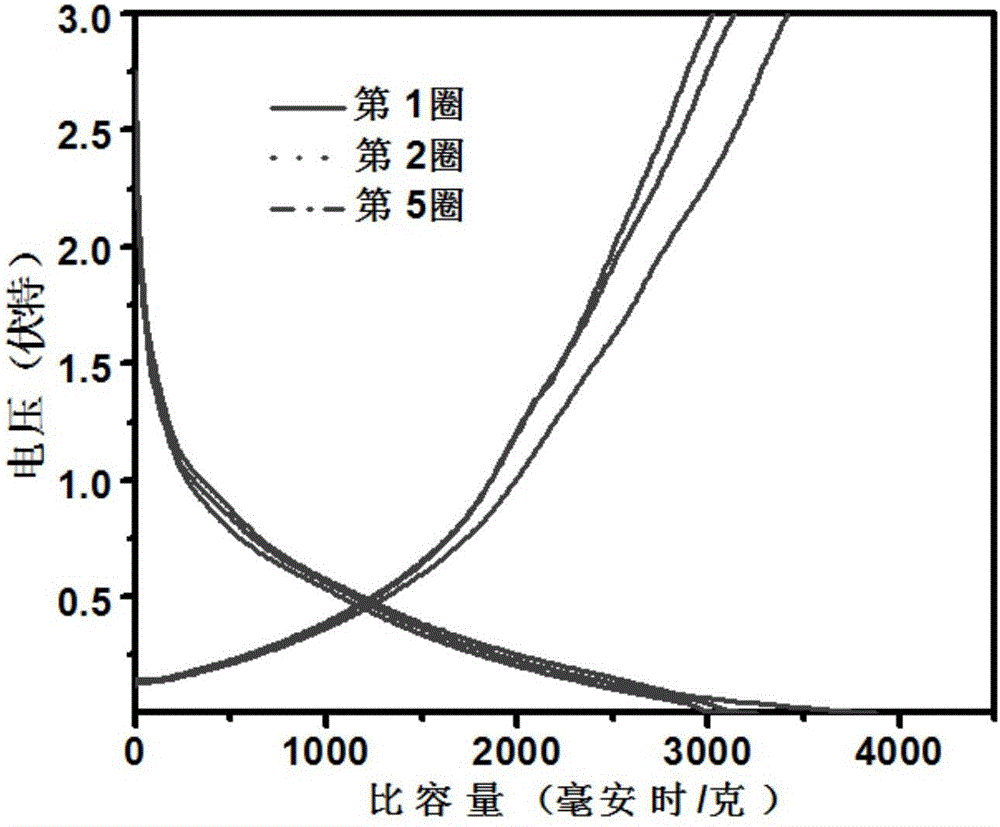

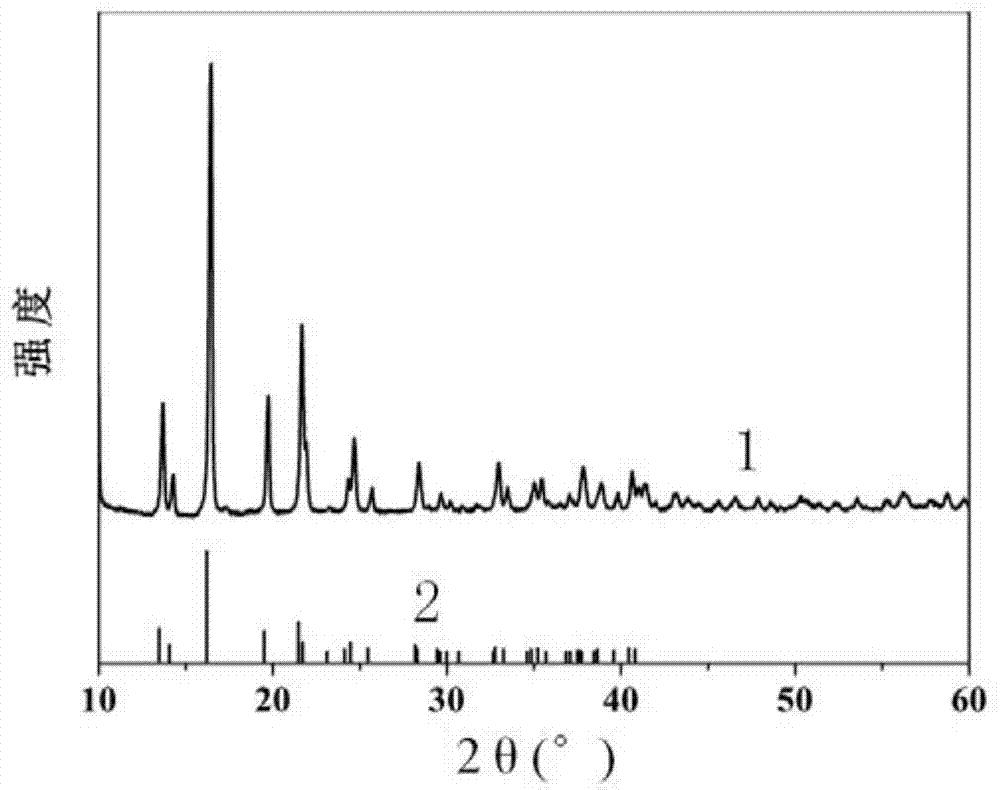

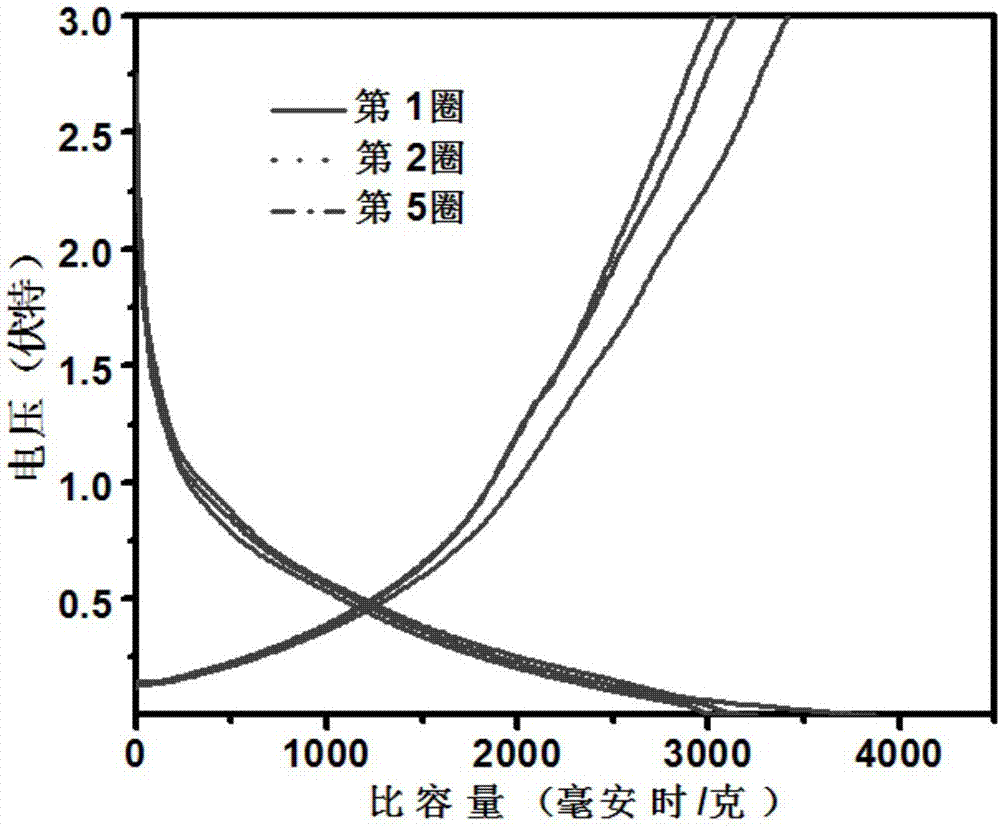

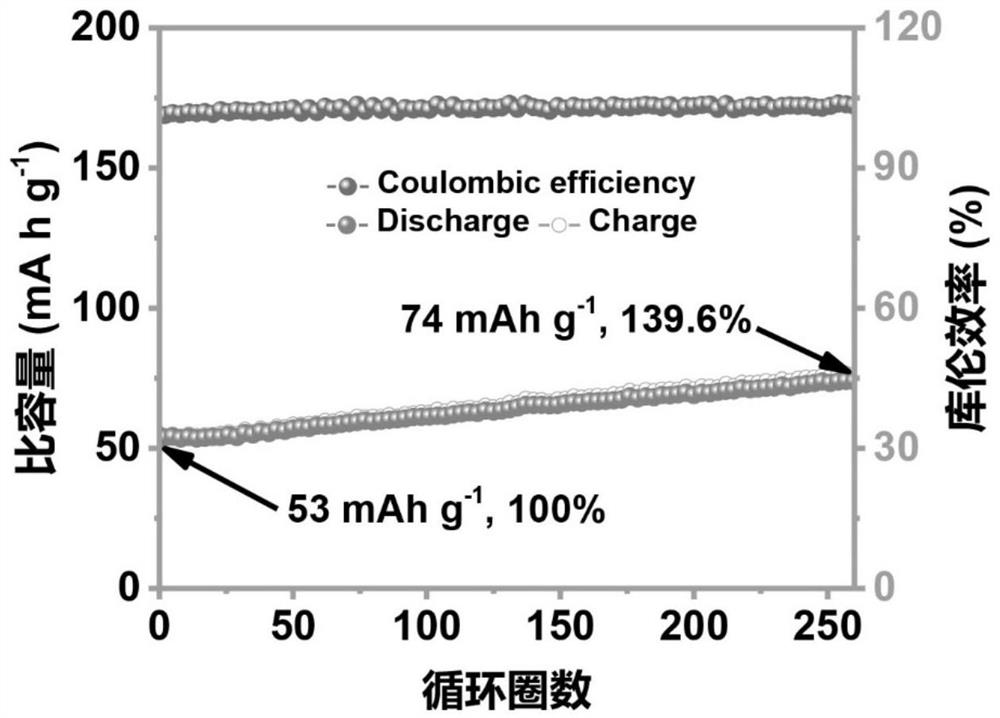

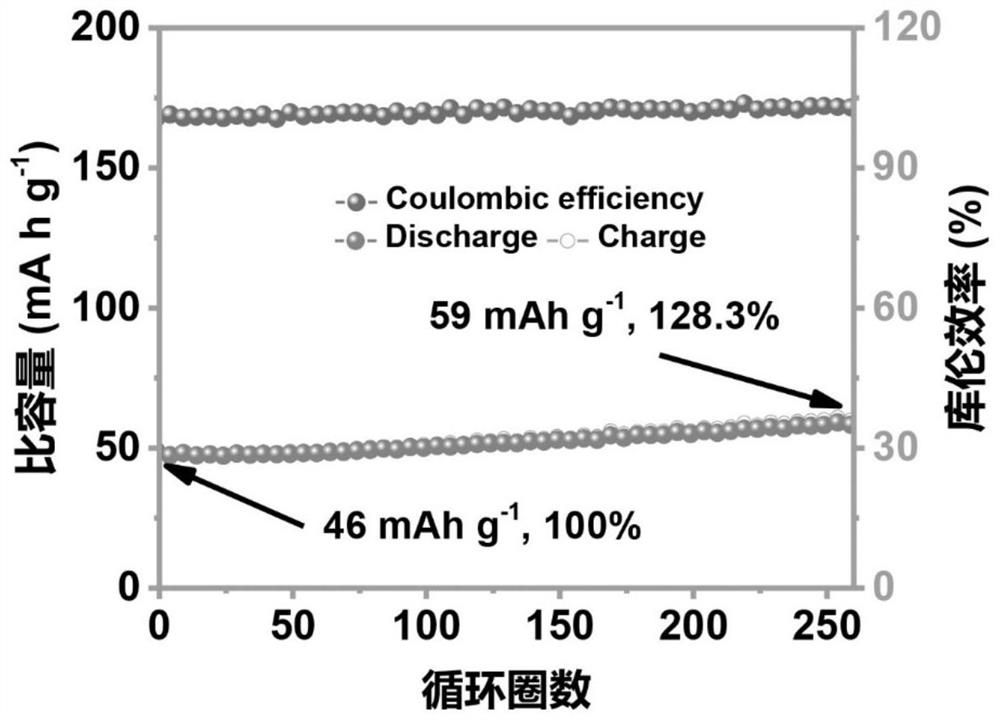

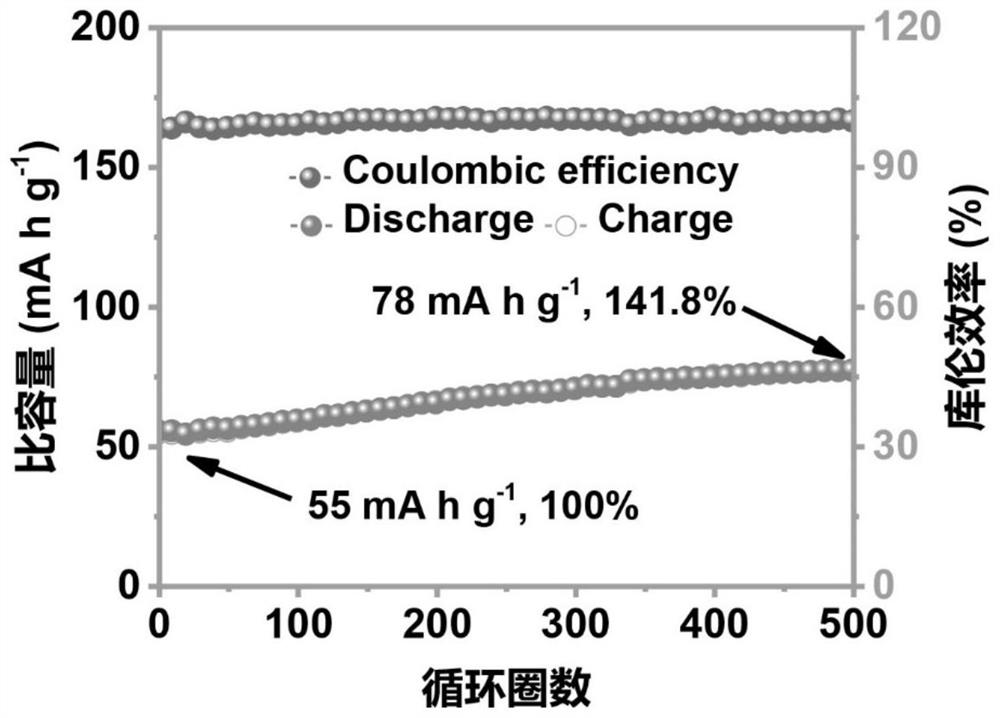

Secondary battery

ActiveCN103972582AImprove Coulombic efficiencyNot prone to explosionCell electrodesSecondary cellsSpace groupIron cyanide

The invention provides a secondary battery. The secondary battery comprises a positive electrode, a negative electrode, and an isolating membrane and electrolyte which are arranged between the positive electrode and the negative electrode; the positive electrode comprises a divalent metal ion iron cyanide complex; the secondary battery adopts the divalent metal ion iron cyanide complex as an positive electrode active material; the divalent metal ion iron cyanide complex is of a rhombohedral structure, belongs to the R-3c space group, and uses (Fe(CN)6) as a structural unit so that a three-dimensional frame network with a special pore passage structure is formed. positive ions can be rapidly embedded into and released from pore passages in a three-dimensional frame, and the three-dimensional frame is stable during embedding and releasing of the positive ions; the secondary battery adopting the divalent metal ion iron cyanide complex as the positive electrode active material has the high coulombic efficiency and the long cycle life; the divalent metal ion iron cyanide complex has the low reaction activity and the prepared battery is difficult to explode.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

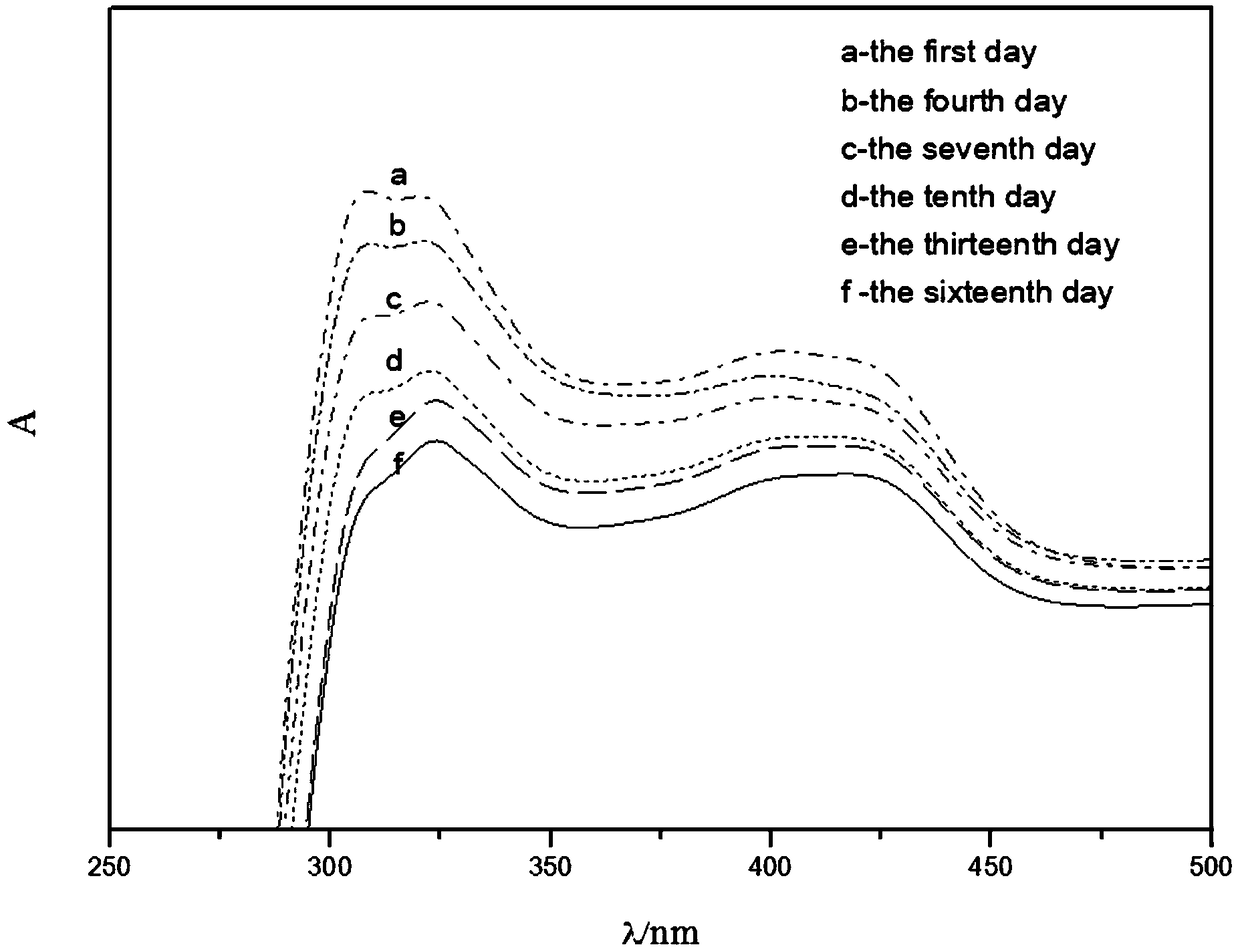

Preparation method and application of illumination time indicating-capable gradient-ramp crack-free gel

ActiveCN109158060AWith time memory functionAnti-crackStampsTenebresent compositionsTetrafluoroborateDecomposition

The invention relates to the technical field of sol-gel, and particularly relates to a preparation method and application of illumination time indicating-capable gradient-ramp crack-free gel. The method specifically comprises the following steps: improving physicochemical properties of gel by adding ionic liquid 1-butyl-3-methylimidazole tetrafluoroborate; preparing gradient-ramp crack-free gel byutilizing light decomposition properties of [Fe(CN)6]<3->; and preparing a novel crack-free sol-gel material having the time-memory function by utilizing the characteristic of color change of iron-cyanide ions under a light condition by changing iron-cyanide ion concentrations so as to indicate the span of lighting time.

Owner:SHENYANG NORMAL UNIV

A method of suspending, magnetizing and roasting high ferricyanide tailings to break cyanide and extract iron by magnetic separation

ActiveCN111485099BDecompose thoroughlyFully contactedSolid separationMechanical material recoverySlagNitrogen gas

A method for suspending, magnetizing and roasting ferricyanide tailings to break cyanide-magnetic separation and extract iron, which is carried out in the following steps: (1) breaking and grinding the ferricyanide tailings; (2) passing it into a pre-oxidation suspension roaster , the high-temperature flue gas enters the pre-oxidation suspension roaster, and the tailings powder is heated to 650-750°C in a suspension state to break the cyanide and roast, and the remaining solid material is the oxide slag powder; (3) The oxide slag powder is passed into the reduction roaster, and the reduction roasting The bottom of the furnace is fed with coal gas and nitrogen, and the oxidized slag powder is in a suspended state and reduced and roasted at 500-600°C, leaving the remaining reduced slag powder; (4) After the reduced slag powder is cooled, a stage of grinding and a stage of weak magnetic separation are carried out; (5) a stage of refining The ore undergoes secondary grinding and secondary weak magnetic separation, and the concentrate of the second stage is iron concentrate. The invention adopts the iron-extracting and cyanide-breaking process by suspending magnetization roasting, which can eliminate the threat of toxic waste water produced by wet cyanide breaking to environmental safety.

Owner:NORTHEASTERN UNIV LIAONING

Processing method using cyanide-containing waste polymer as cement plant substitution fuel

The invention discloses a processing method using a cyanide-containing waste polymer as a cement plant substitution fuel, the processing method includes the following steps: (1) the cyanide-containing waste polymer is detoxified and solidified; (2) an ingredient is added, the detoxified and solidified cyanide-containing waste polymer is stirred with the ingredient; and (3) the material prepared by the step (2) is used as the cement plant substitution fuel; detoxification and solidification is use of ferrous sulfate, sulfuric acid solution and ferric chloride for reacting with cyanogens in the polymer to produce an iron cyanide complex; the ingredient is an industrial waste with the water content below 5% and pH of 7-11; the amount of the ingredient can make the water content in the material not higher than 35%, the calorific value is higher than 2000 cal / g, and the pH is 7-9 as the standard. The processing method can effectively handle high concentration cyanide-containing waste polymer (cyanide content is 300-850 mg / kg), and reduces the cement plant pulverized coal fuel use amount so as to achieve the goal of energy conservation and environmental protection.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

Methods for determining and identifying ferrocyanide ion content and manganese content in potassium manganese ferrocyanide

ActiveCN109507137AReduce testing costsWill not affect the determinationPreparing sample for investigationColor/spectral properties measurementsIron saltsPotassium

The invention belongs to the technical field of analysis and detection, and discloses methods for determining and identifying ferrocyanide ion content and manganese content in potassium manganese ferrocyanide. The method for determining the ferrocyanide ion content in the potassium manganese ferrocyanide comprises the following steps: 1, using a spectrophotometric method to determine the content of iron cyanide radical in a mixed solution in which the potassium manganese ferrocyanide is oxidized into permanganate and iron cyanide radical salt; 2, using a spectrophotometric method to determinethe content of iron cyanide radical in a mixed solution obtained after adding an iron salt solution into the potassium manganese ferrocyanide solution to remove ferrocyanide ions; 3, calculating the ferrocyanide ion content in the potassium manganese ferrocyanide according to the data of the previous two steps. The method has the characteristics of being stable, rapid, convenient and fast, simple,and the like.

Owner:CHANGZHOU INST OF TECH

Method for separating and recovering valuable metals in cyanide-containing wastewater

PendingCN112142070ARaise the gradeAchieve purificationIron cyanidesCopper oxides/halidesSeparation technologyMetal recycling

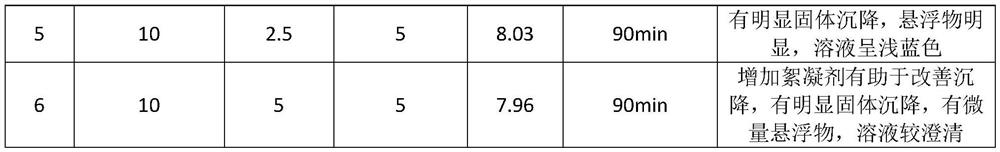

The invention belongs to the technical field of valuable metal recovery, and particularly relates to a method for separating and recovering valuable metals in cyanide-containing wastewater. The methodcomprises the following steps: adding an oxidant into cyanide-containing wastewater containing a large amount of copper and ferricyanide complex ions to carry out cyanide breaking and copper precipitation reaction to generate copper-containing precipitates, separating the copper-containing precipitates by adopting a special high-speed centrifugal separation technology, and adding a co-precipitator into a supernatant after separation to convert the ferricyanide complex ions with strong complexing property into iron-containing suspended precipitates; then combining the coprecipitation technology and the special high-speed centrifugal separation technology to achieve solid-liquid separation of ferrocyanide, and clear liquid obtained after solid-liquid separation returns to the production process or is discharged after reaching the standard after deep treatment. The invention realizes the separation of the chemical suspended matter iron ferrocyanide in the cyanide-containing wastewater containing a large amount of copper and iron cyanide complex ions, has the advantages of simple process flow, good treatment effect, high treatment efficiency and stable operation, and is especially suitable for the treatment process of the cyanide-containing wastewater.

Owner:CHANGCHUN GOLD RES INST

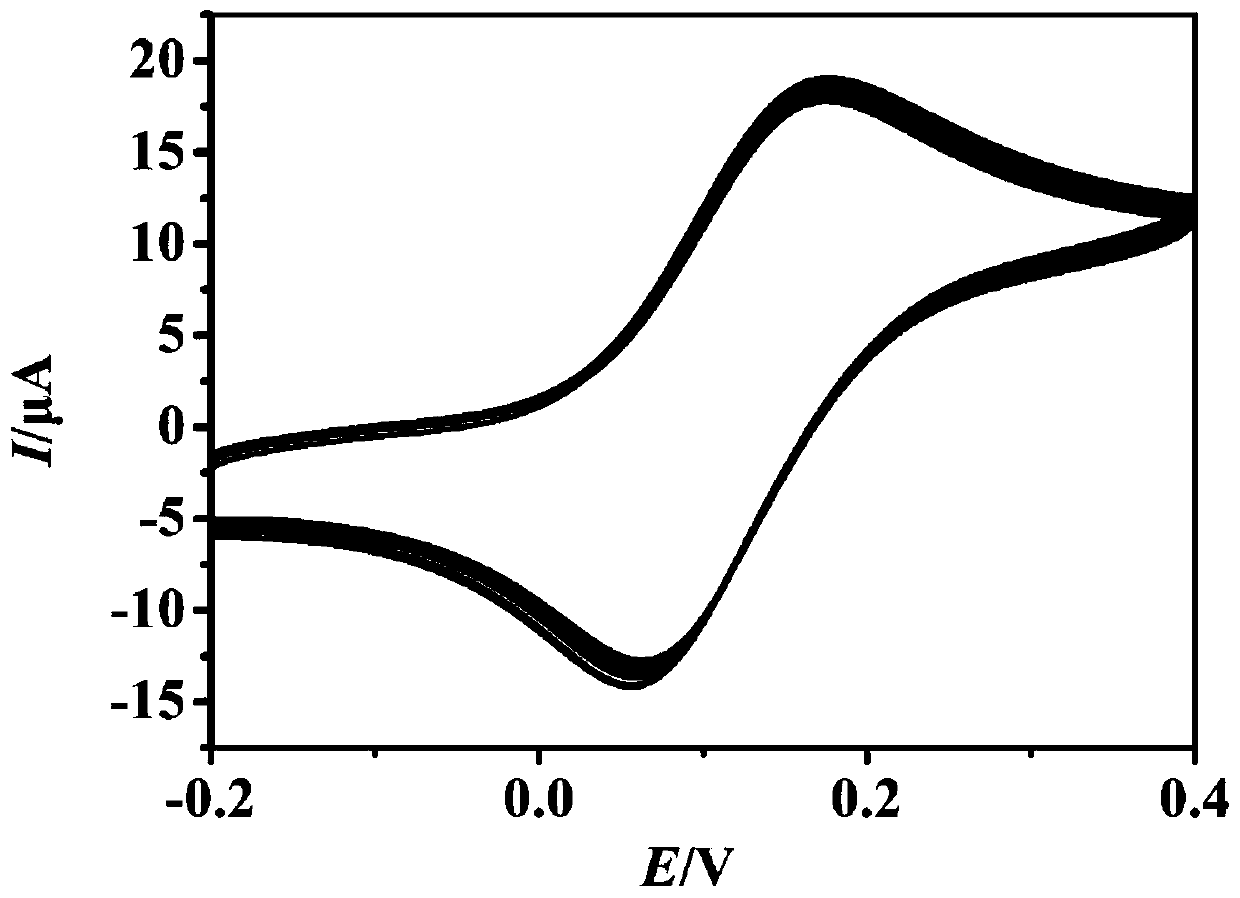

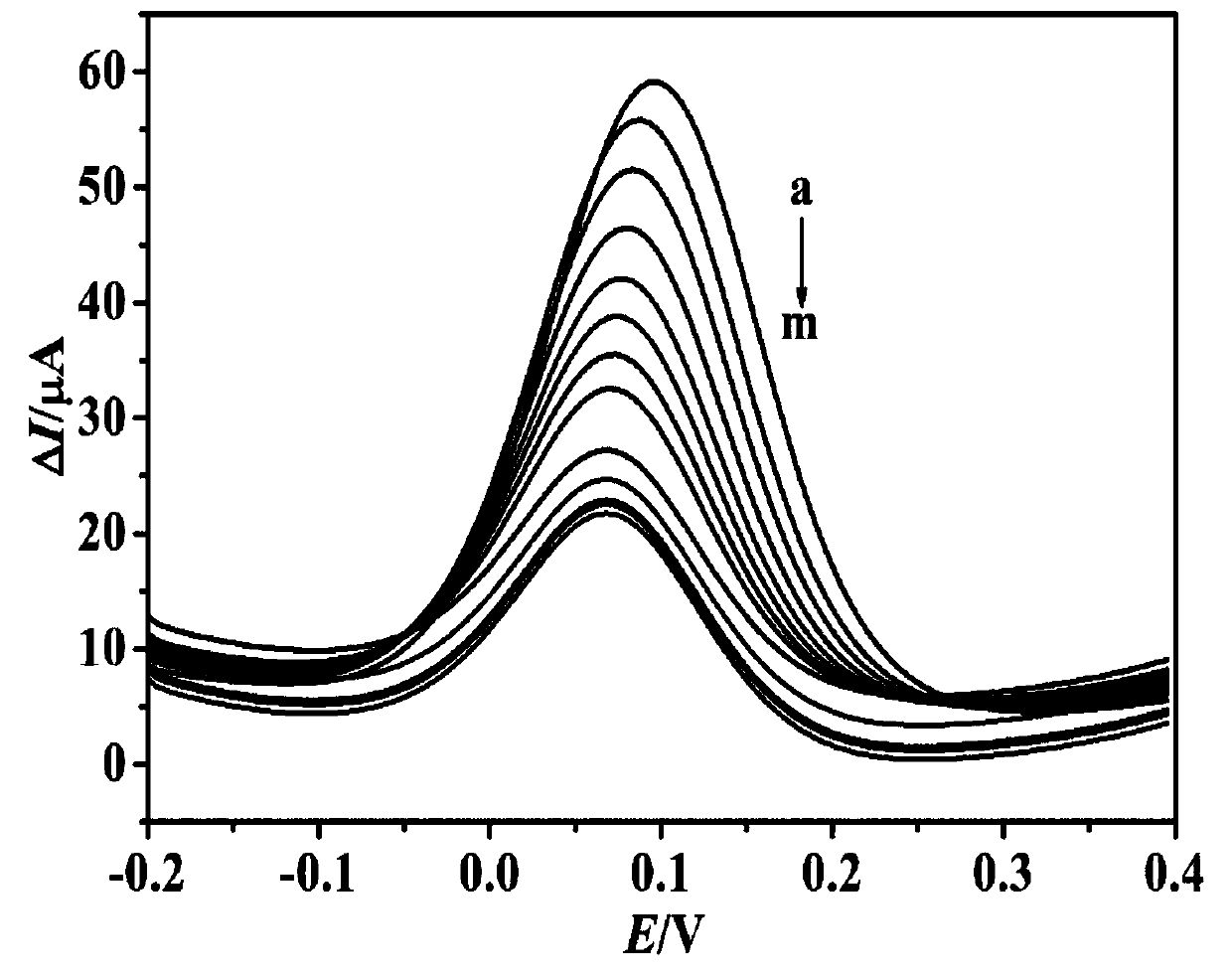

Aptamer-nickel-iron cyanide nanoparticle-RGO electrode preparation method and application

ActiveCN110082414ALarge specific surface areaImprove conductivityMaterial analysis by electric/magnetic meansNanoparticleIron cyanide

The invention relates to an aptamer-nickel-iron cyanide nanoparticle-RGO electrode preparation method and electrochemical analysis method thereof for PCB77. The method is characterized by co-depositing nickel-iron cyanide nanoparticles with a diameter of about 5 nm onto the surface of reduced graphene oxide (RGO) in situ, modifying the obtained material on the surface of a gold electrode, and then, fixing a PCB77 aptamer to the nickel-iron cyanide nanoparticle-RGO composite material through covalent bonding reaction to obtain an aptamer-nickel-iron cyanide nanoparticle-RGO electrode. The prepared electrode is used for rapid and real-time detection of PCB77 in the environment. Compared with an existing PCB77 detection method, the method realizes high-sensitivity and high-selectivity detection of inert molecule PCB77 through combination of a high-sensitivity electrochemical analysis method and the aptamer having high specificity recognition capability; and detection limit can reach 0. 22ng / L. The method has the advantages of simple device and instrument, low analysis cost and being fast and simple and convenient and the like.

Owner:SHANXI UNIV

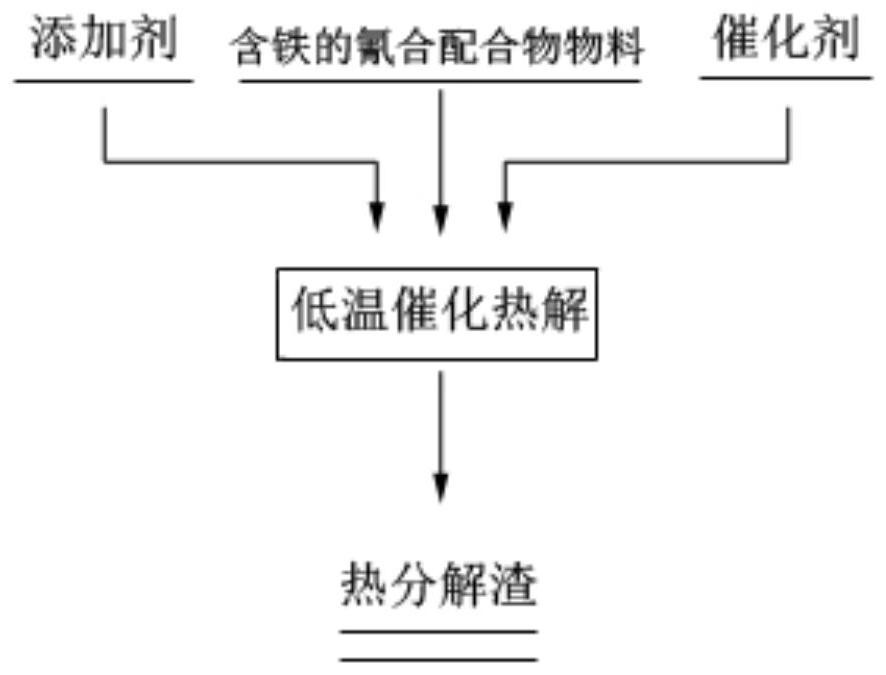

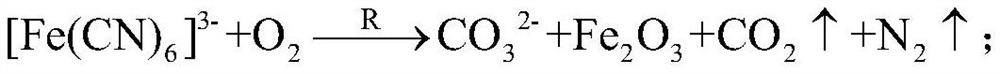

A kind of method of the cyanide complex of low-temperature catalytic pyrolysis iron

A method for low-temperature catalytic pyrolysis of iron cyanide complexes of the present invention, the steps are: adding a catalyst to raw materials, the raw materials being solid iron cyanide complexes or soil or waste residue of iron-containing cyanide complexes , mixed evenly to make a mixed raw material; put the mixed raw material into a pyrolysis device, heat it to 300-550°C for catalytic thermal decomposition, and when the temperature reaches 300-550°C, keep it warm for 0-180min to remove iron cyanide The compound is obtained from pyrolysis slag, which can be directly stockpiled or used for backfill treatment. The beneficial effects of the present invention are: through low-temperature thermal decomposition, oxidizing atmosphere and the action of a catalyst, the clean conversion of solid iron cyanide complexes or iron-containing cyanide complexes is realized, and the iron cyanide complexes are oxidized into The invention has no toxic compound, low cost and good effect of removing iron cyanide complexes, and the removal rate of iron cyanide complexes reaches over 99%. The invention has simple process, less equipment investment, no secondary pollution and is easy to popularize.

Owner:NORTHEASTERN UNIV LIAONING

Compound ferrous iron cyanide titanium potassium magnetic ball and preparation method thereof

ActiveCN102794153BLarge adsorption capacityNot easy to parseOther chemical processesSilicon compoundsParticulatesMicrosphere

The invention belongs to the technical field of a method for preparing a compound ferrous iron cyanide titanium potassium magnetic ball, and in particular relates to the compound ferrous iron cyanide titanium potassium magnetic ball and a preparation method thereof. The method comprises the following steps of: preparing a magnetic ferroferric oxide silicon dioxide microballoon by using a ferroferric oxide magnetic particle with the grain diameter of 0.3-0.8 microns as a core and using tetraethoxysilane as a silicon source; then preparing a magnetic ferroferric oxide silicon dioxide-titanium oxide spherical particle by taking dichloro oxotitanium as a titanium source; and finally, preparing the compound ferrous iron cyanide titanium potassium magnetic ball by using potassium ferrocyanide as a soaking agent. The method has simple steps and is mild in experiment condition; and the grain diameter of the prepared compound ferrous iron cyanide titanium potassium magnetic ball is 0.05-0.2mm, the saturation capacity of absorbed cesium is 1.0 mmolCs / g-1.4 mmolCs / g dry compound particles; and therefore, the method for preparing the compound ferrous iron cyanide titanium potassium magnetic ball has the advantages that the absorption capacity of the ferrous iron cyanide titanium potassium to the cesium is preserved under the mild condition, the analysis is difficult to carry out, and the absorbed particles are easy to recover; and particulate matter of the absorbed cesium can be transformed to oxide to be conveniently stored.

Owner:TSINGHUA UNIV

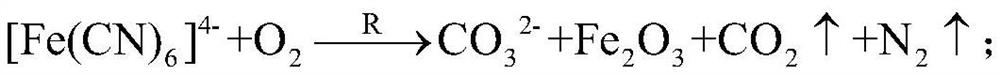

a secondary battery

ActiveCN103972582BImprove Coulombic efficiencyNot prone to explosionCell electrodesSecondary cellsSpace groupIron cyanide

The invention provides a secondary battery. The secondary battery comprises a positive electrode, a negative electrode, and an isolating membrane and electrolyte which are arranged between the positive electrode and the negative electrode; the positive electrode comprises a divalent metal ion iron cyanide complex; the secondary battery adopts the divalent metal ion iron cyanide complex as an positive electrode active material; the divalent metal ion iron cyanide complex is of a rhombohedral structure, belongs to the R-3c space group, and uses (Fe(CN)6) as a structural unit so that a three-dimensional frame network with a special pore passage structure is formed. positive ions can be rapidly embedded into and released from pore passages in a three-dimensional frame, and the three-dimensional frame is stable during embedding and releasing of the positive ions; the secondary battery adopting the divalent metal ion iron cyanide complex as the positive electrode active material has the high coulombic efficiency and the long cycle life; the divalent metal ion iron cyanide complex has the low reaction activity and the prepared battery is difficult to explode.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of preparation method of lithium battery negative electrode material of cobalt ferrite-carbon cloth

ActiveCN106531967BSimplify the manufacturing processIncrease capacityCell electrodesElectron transferLithium-ion battery

The invention discloses a preparation method of a cobalt diiron tetraoxide-carbon cloth lithium battery anode material. The preparation method comprises the following steps: providing a Berlin blue solution, wherein raw materials of the Berlin blue solution comprise a cobalt salt and an iron-cyanide salt; using the Berlin blue solution to soak carbon cloth so as to obtain a precursor / carbon cloth composite material; and carrying out heat treatment on the precursor / carbon cloth composite material. According to the preparation method disclosed by the invention, the composite material that CoFe2O4 is grown on a carbon cloth substrate is prepared in an in-situ manner. The manufacturing process of the electrode can be simplified, a direct electron transfer path between an active material and a current collector is provided, and meanwhile huge volume expansion in the lithium intercalation and deintercalation process can be relieved. The cobalt diiron tetraoxide-carbon cloth lithium battery anode material can serve as a lithium battery anode without a binding agent, and the lithium battery anode material has relatively high capacity, outstanding cycle stability and excellent rate capability. Meanwhile, the anode material can be used for assembling a flexible lithium ion battery, and can be applied to more fields.

Owner:HEILONGJIANG UNIV

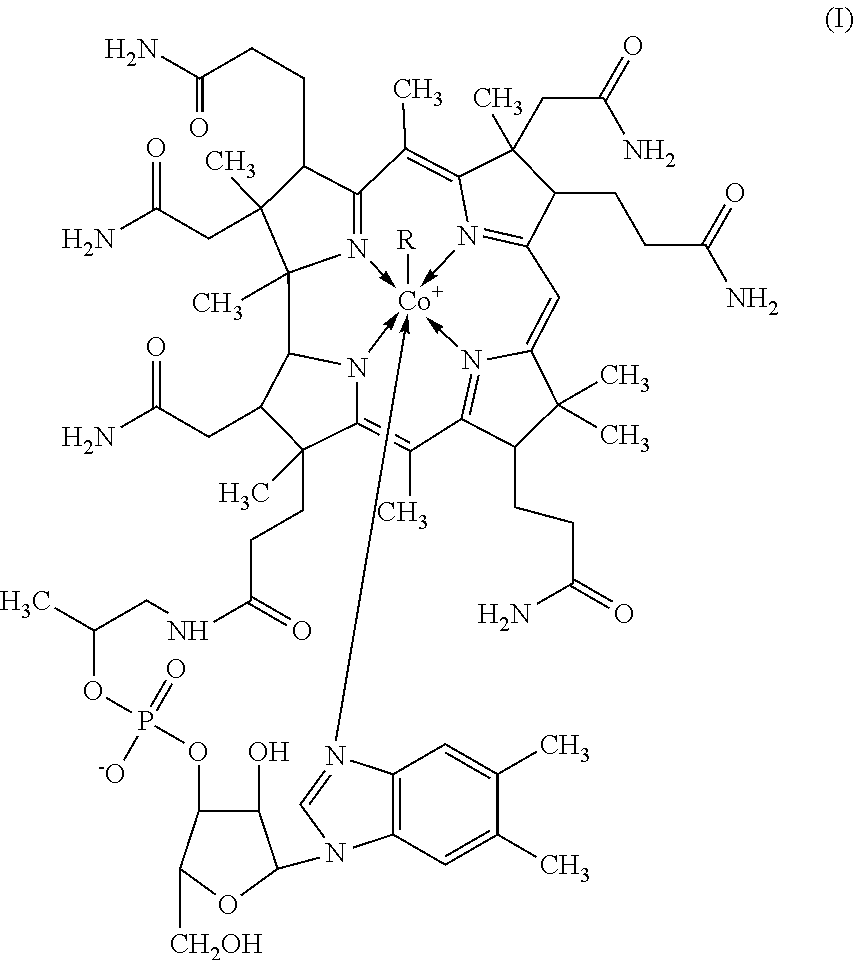

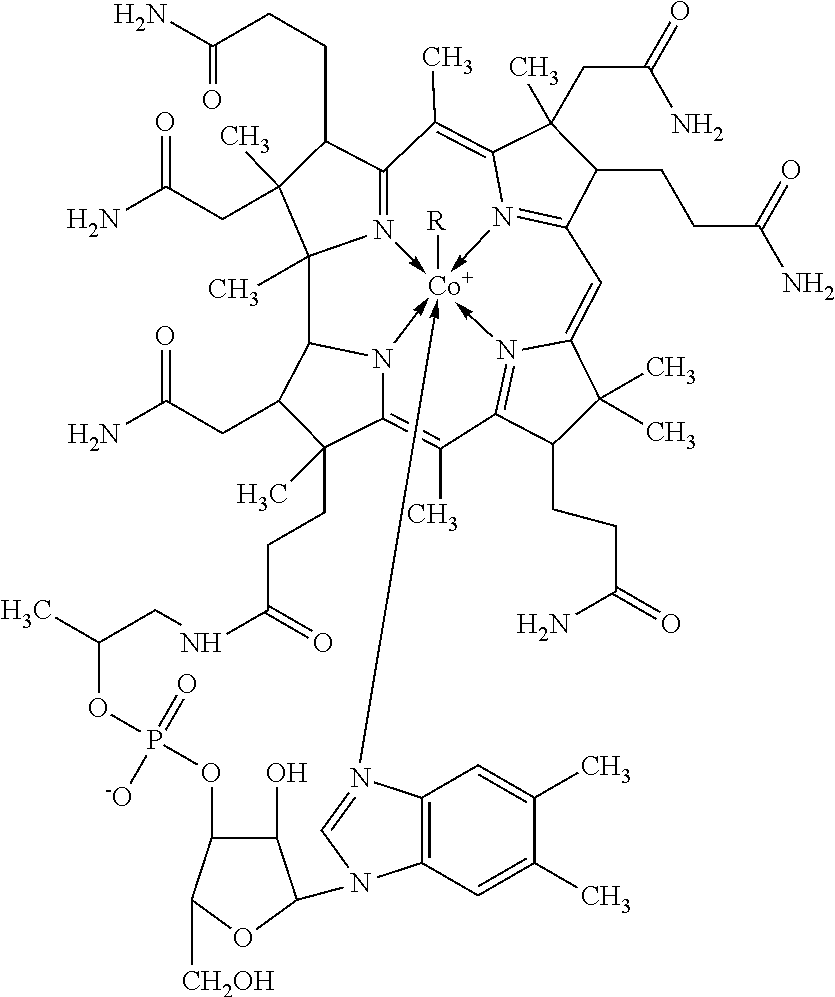

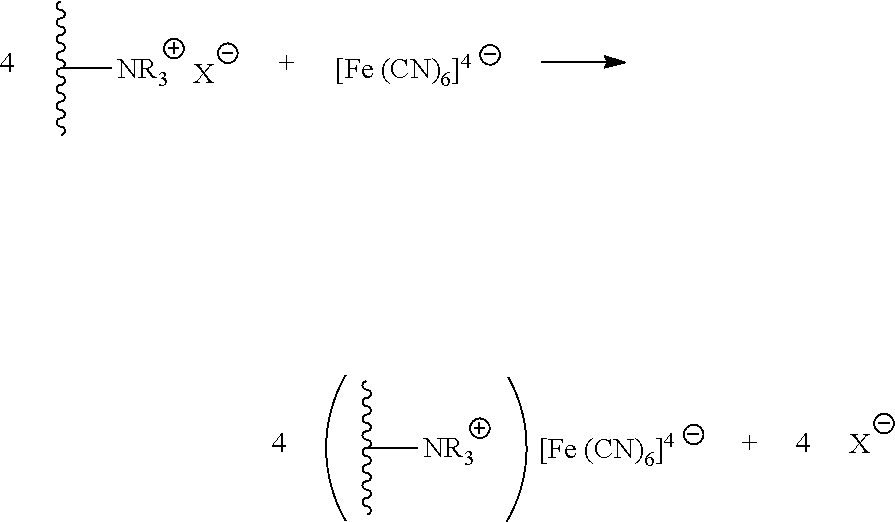

Process for the purification of methylcobalamin

The present invention relates to a process for the purification of methylcobalamin, namely from iron cyanide impurities, comprising contacting a solution comprising methylcobalamin and iron cyanide anions with a strongly basic anion exchange resin. This purification process can advantageously be used for removing iron cyanide impurities from methylcobalamin obtained by reductive methylation of cyanocobalamin and wherein iron (II) salts are used as cyanide scavengers, thus providing methylcobalamin with a reduced iron content. Methylcobalamin (R is methyl).

Owner:HEALTHTECH BIO ACTIVES S L U

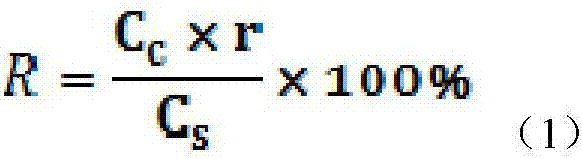

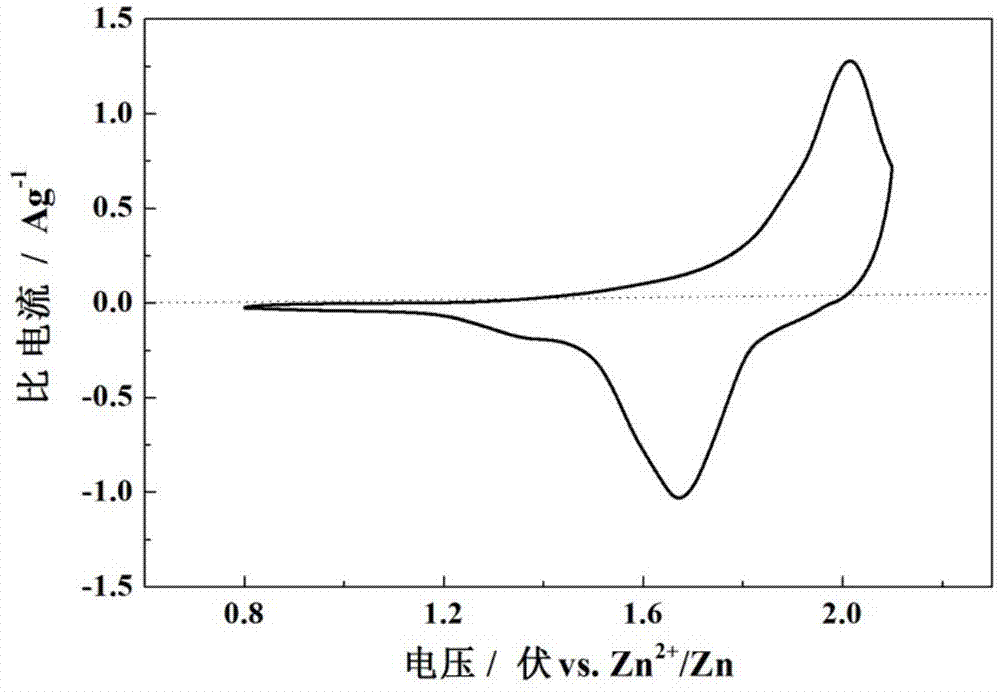

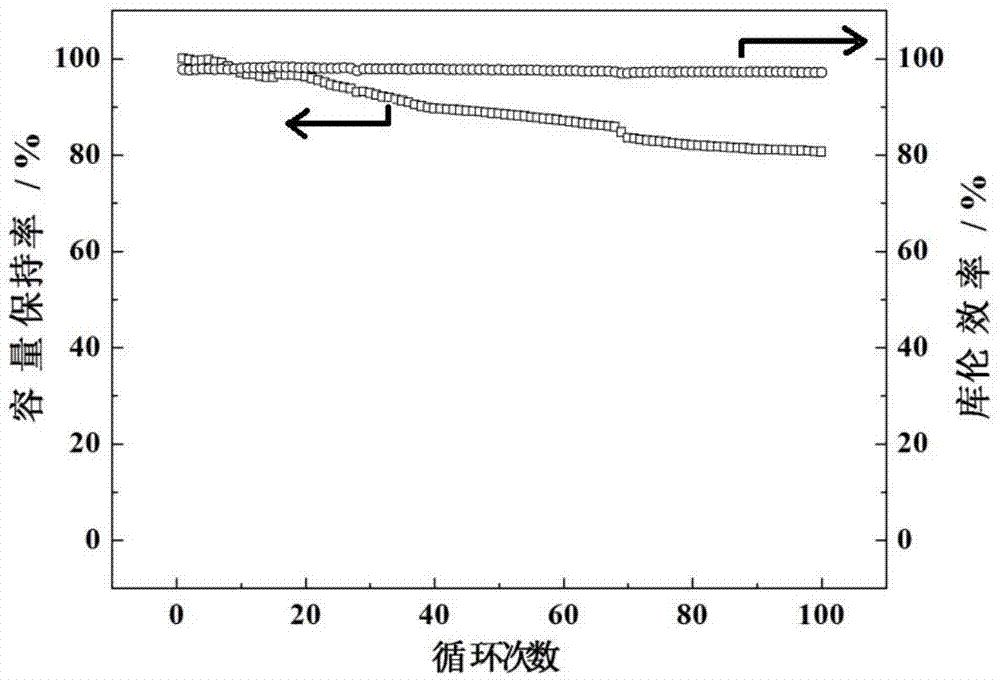

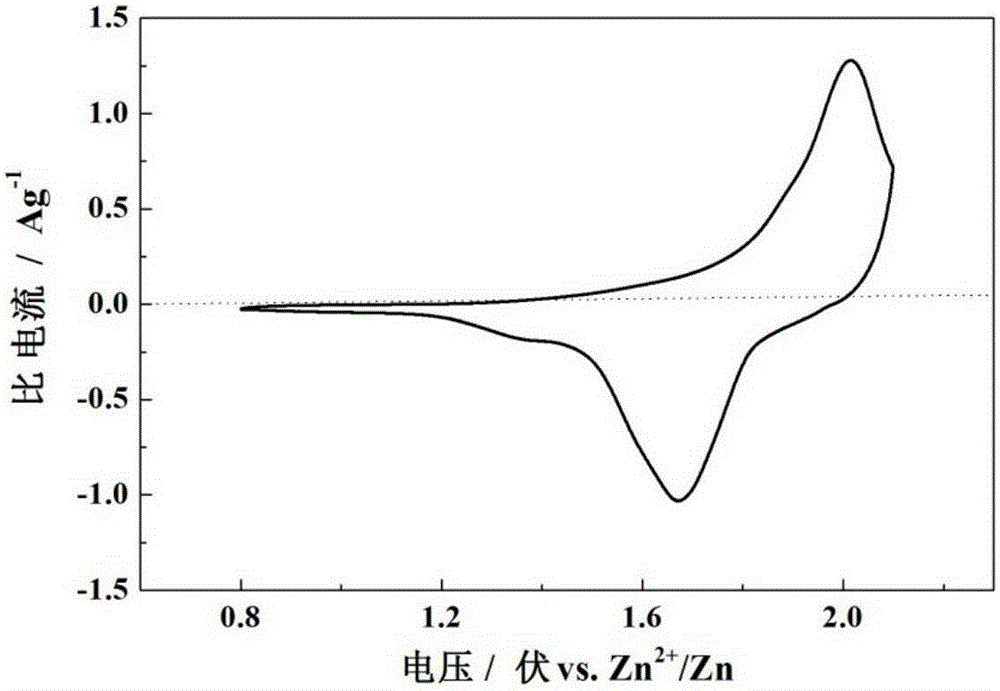

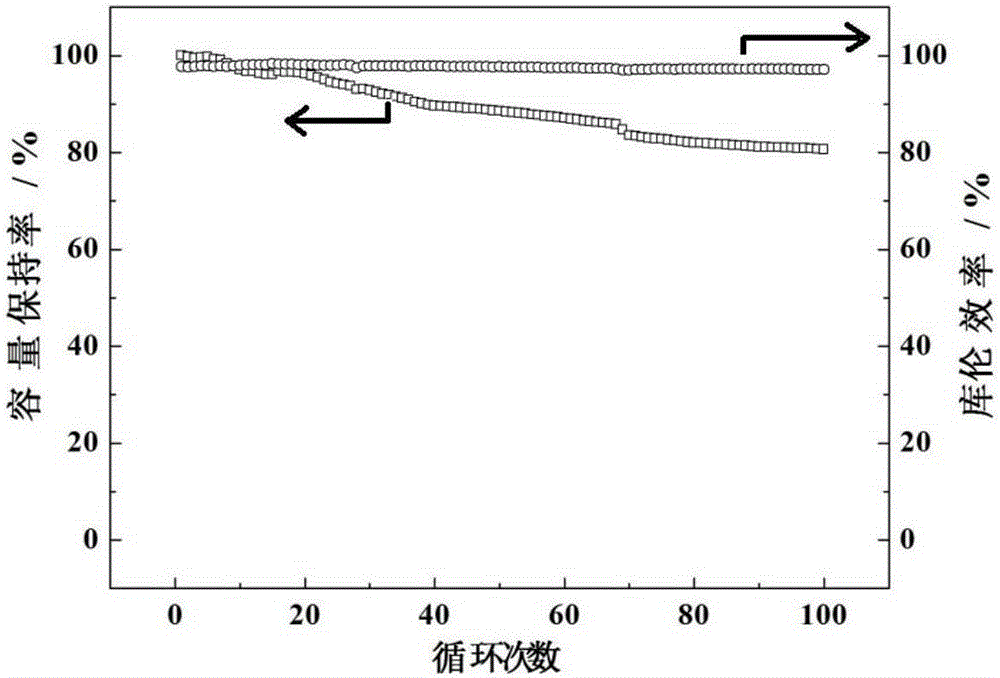

Method for activating ferricyanide and zinc ion battery prepared therefrom

ActiveCN111900381BNormal power supplyGood antifreeze functionCell electrodesSecondary cellsElectrical batteryZinc ion

The invention provides a method for activating ferricyanide and a zinc ion battery prepared thereby. The method comprises the following steps: carrying out high-voltage scanning to the Zn-FeHCF battery; after the high-voltage scanning, carrying out program static to the Zn-FeHCF battery; after the program static, carrying out program discharge to the Zn-FeHCF battery; After discharging, a high-voltage scanning cycle is completed, and 100-1000 cycles are continued to complete the activation. The invention also provides a zinc ion battery using the ferric ferricyanide activated by the above method as a cathode. An electrochemically more stable structure is produced by the activation method of the present invention, so that the Zn-FeHCF battery can achieve a record-breaking cycle performance of higher capacity retention after an ultra-long cycle.

Owner:香港城市大学深圳研究院

A kind of restoration method of cyanide-contaminated soil

The invention discloses a method for repairing cyanide-contaminated soil. According to the characteristics that cyanide-contaminated soil contains various pollutants such as cyanide and heavy metals, especially cyanide also includes difficult-to-handle metal cyanide complexes Ferricyanide complexes, such as ferricyanide complexes, etc., first use ferrous sulfate and zinc sulfate to fix ferricyanide complexes and various heavy metals in the soil, and then use ozone to treat residual refractory cyanide, thiocyanate and other pollutants in the soil . Cyanide and various heavy metals in the treated soil meet the national soil environmental quality assessment requirements.

Owner:CHANGCHUN GOLD RES INST

A method for removing (sub) ferricyanide complex

The invention discloses a method for removing (sub)ferricyanide complexes. The method is to add common complexing agents and acid, and the solution is heated to a certain temperature to destroy the complexation balance between cyanide and iron, so that the iron ion and the added complexing agent are complexed, thereby releasing the process of cyanide ion, the released cyanide ion and acid Combined to generate hydrogen cyanide molecules, which overflow from the solution at high temperature and are absorbed by lye for reuse or further processing. The invention has good treatment effect, high treatment efficiency, stable system operation, and simple process flow; the cyanide ion released during the treatment process can be recovered and reused, and if it is not used, it can be treated with a common simple cyanide treatment method .

Owner:CHANGCHUN GOLD RES INST

Preparation method of nickel-iron cyanide molecular magnet nano particle

The invention discloses a preparation method of a nickel-iron cyanide molecular magnet nano particle. The preparation method comprises the following steps: step one, weighing raw materials; step two, preparing a K3Fe(CN)6 water solution: adding K3Fe(CN)6 weighed in the step one into deionized water, and completely dissolving K3Fe(CN)6; step three, adding NiCl2.6H2O weighed in the step one into a PVP water solution, and stirring to completely dissolve NiCl2.6H2O; step four, under fierce stirring, slowly dropwise adding the K3Fe(CN)6 solution prepared in the step two into the mixed solution prepared in the step three, and after the K3Fe(CN)6 solution is completely added, fiercely stirring the solution for 25 to 40 minutes until the solution is converted into yellow, uniform, and stable sol so as to obtain the nickel-iron cyanide molecular magnet nano particle. The provided method can solve the problems that in the conventional method, the reactions are difficult to control and the particle size of the product is uneven.

Owner:西安艾菲尔德复合材料科技有限公司

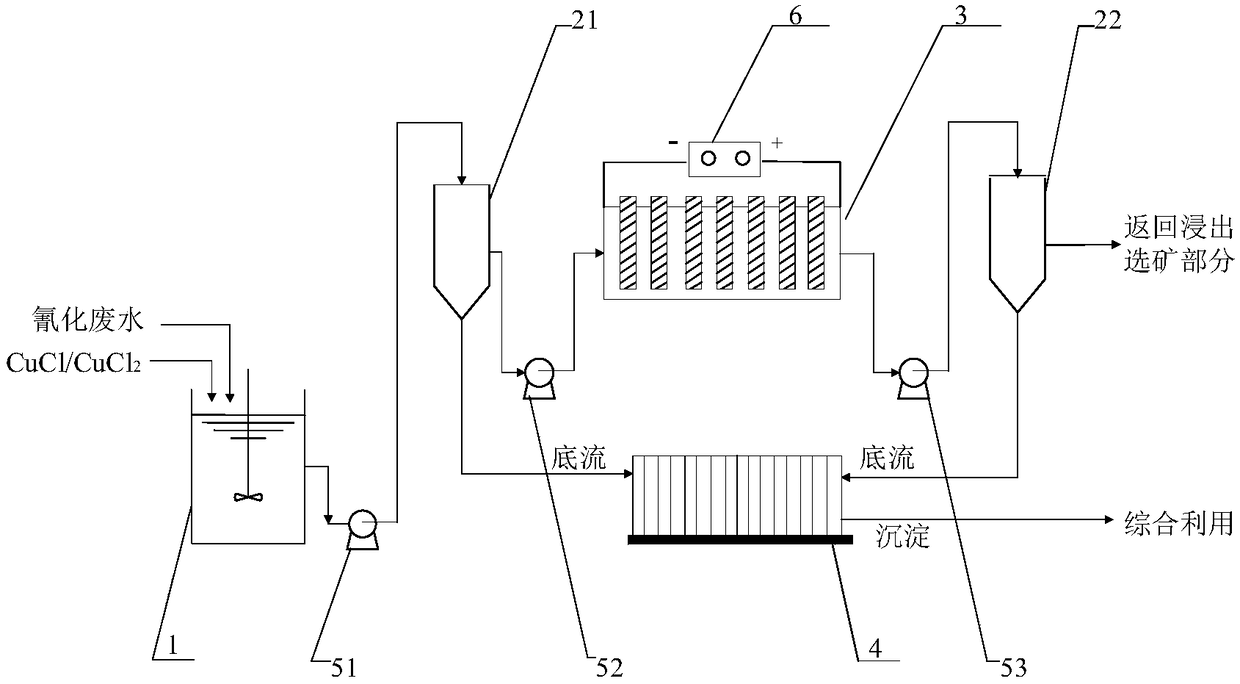

Method for treating ferricyanic gold extraction wastewater by using precipitation-electrolytic oxidation synergistic effect

InactiveCN108840482AEmission complianceEasy to operateWater contaminantsTreatment involving filtrationHigh concentrationTreatment effect

Theinvention discloses a method for treating ferricyanic gold extraction wastewater in a gold smelting plant by using a precipitation-electrolytic oxidation synergistic effect. The method comprises the following steps: firstly, introducing the wastewater into a high-position tank or reactor with a stirring function, adding copper chloride or cuprous chloride to perform precipitation reaction, andconverting iron-cyanide ions and a part of free cyanide and zinc cyanide ions into composite precipitation; and introducing supernatant after reaction into an electrolytic cell, and performing electrolytic oxidation reaction with certain voltage by using a titanium plate or stainless steel plate as positive and negative electrodes so as to enable remaining free cyanide, zinc cyanide and copper cyanide ions in the wastewater to be oxidized to nitrogen and carbon dioxide under the synergistic effect of positive electrode oxidation and chlorine gas or hypochlorite generated in the reaction of chlorine ions, and performing electrolytic deposition on copper and zinc at the negative electrode, wherein the wastewater after treatment can return to mineral separation or leaching systems to be circularly used. Copper chloride or cuprous chloride is not only used as a precipitator, but also used as the source of an oxidizer. The method has the characteristics of being simple in treatment process,short in flow process, low in cost and good in treatment effect and has the great significance on deep treatment and comprehensive utilization of cyanide wastewater containing iron ions with high concentration.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

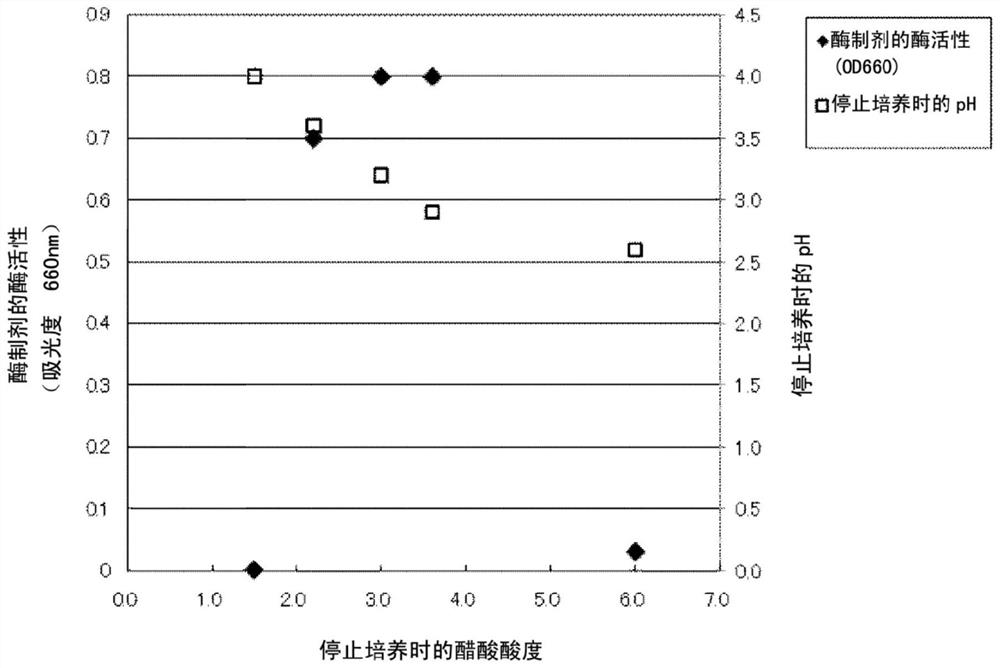

Enzyme

ActiveCN106133134BEfficient removalEasy to useEnzyme stabilisationOxidoreductasesAcetobacter sp.Potassium ferricyanide

The present invention provides an enzyme preparation capable of effectively removing aldehydes with 1 to 10 carbon atoms. The enzyme preparation contains, as an active ingredient, a complex of aldehyde dehydrogenase produced by acetic acid bacteria of the genus Gluconacetobacter and a cell membrane to which the aldehyde dehydrogenase binds. The pH of the enzyme preparation is 4 to 7, and the aldehyde dehydrogenase activity per 0.006 mg of protein derived from acetic acid bacteria is: an aqueous solution of ferrocyanide generated from potassium ferricyanide accompanying the oxidation of acetaldehyde with the enzyme preparation ( 3.9 mL) the absorbance (660 nm) was 0.05-3.

Owner:Q P CORP

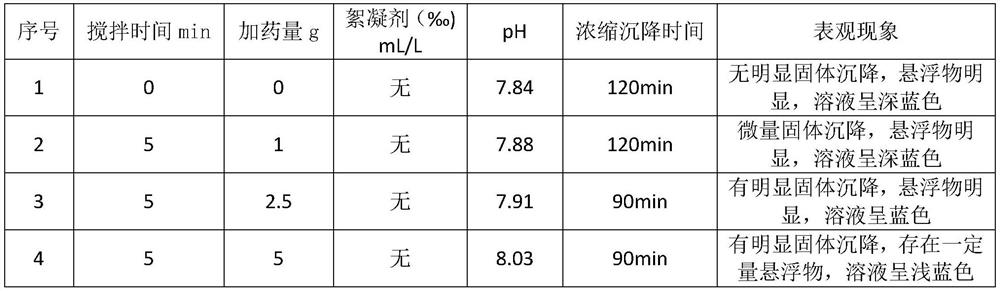

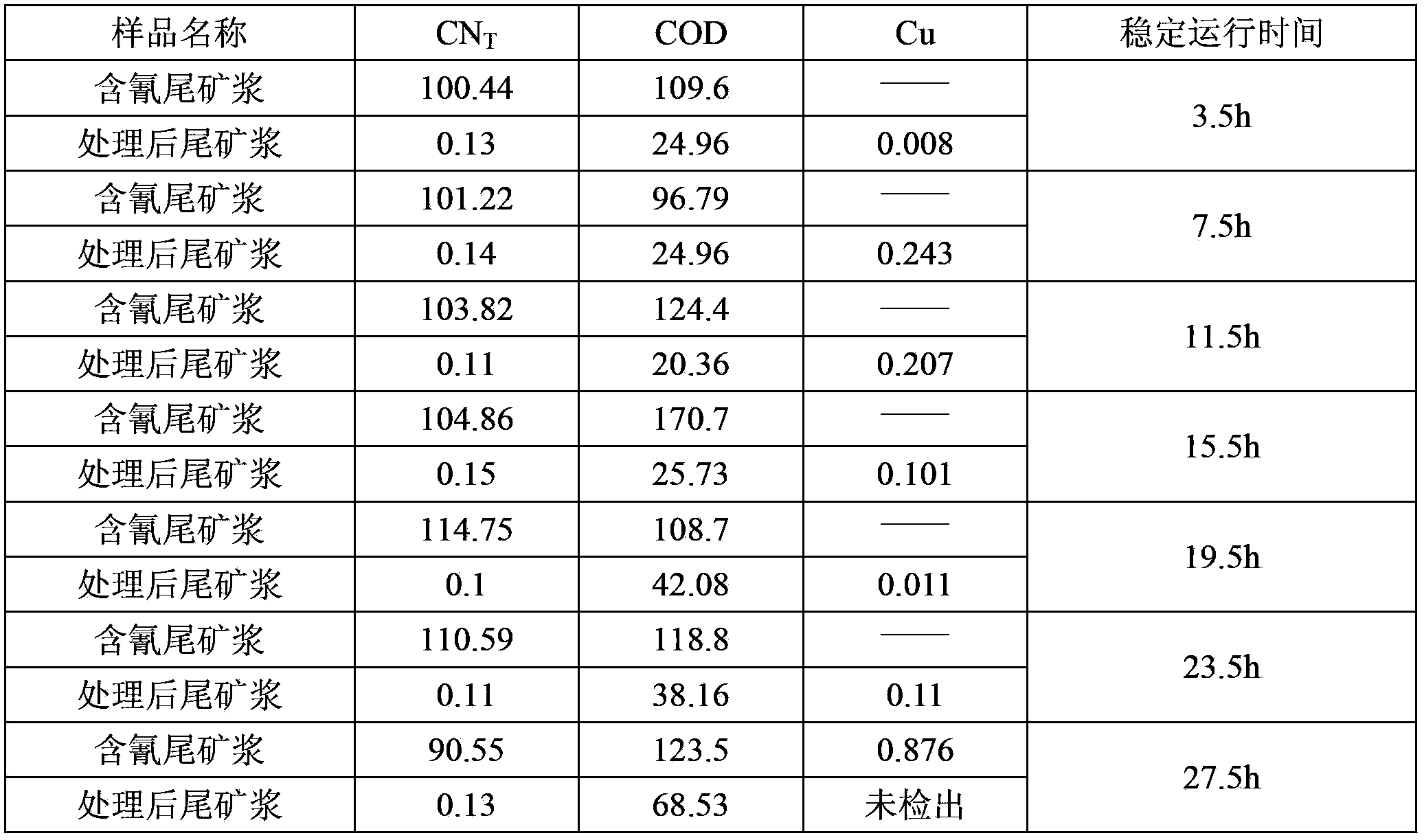

Harmless comprehensive treatment method for cyanide-containing tailing pulp

ActiveCN103086548BReduce loadEasy to handleWaste water treatment from quariesWater contaminantsActivated carbonSlag

A harmless comprehensive treatment method for a cyanide tailing pulp, consisting of three steps: pulp concentration, a cyanide-reducing pre-treatment and oxidation; for the pulp concentration: a concentration of the pulp is increased to 50% by using a thickening device, the thickened supernatant is reused in concentration plant technology, wherein in the thickening device a solid-liquid separation is performed by gravitational sedimentation; for the cyanide-reducing pre-treatment: a cyanide-reducing agent is added into the concentrated pulp; for the oxidation: the oxidation is implemented by a commonly used oxidation method, and meanwhile, activated carbon is added at the oxidation stage. Useful cyanides are recovered using the concentrating treatment, reducing the load of a subsequent treatment; the cyanide-reducing pre-treatment reduces the cyanide load for the oxidation, fixes cyanides which are difficult to oxidize, such as iron cyanide and so on, thus saving the oxidant; the pulp can easily reach the standard during the oxidation treatment, and is stable; and the tailing slag which reaches the standard by processing is a common solid waste.

Owner:SHAANXI TAIBAI GOLD MINING IND CO LTD

Treatment method of cyanide-containing waste polymer as alternative fuel in cement plant

The invention discloses a processing method using a cyanide-containing waste polymer as a cement plant substitution fuel, the processing method includes the following steps: (1) the cyanide-containing waste polymer is detoxified and solidified; (2) an ingredient is added, the detoxified and solidified cyanide-containing waste polymer is stirred with the ingredient; and (3) the material prepared by the step (2) is used as the cement plant substitution fuel; detoxification and solidification is use of ferrous sulfate, sulfuric acid solution and ferric chloride for reacting with cyanogens in the polymer to produce an iron cyanide complex; the ingredient is an industrial waste with the water content below 5% and pH of 7-11; the amount of the ingredient can make the water content in the material not higher than 35%, the calorific value is higher than 2000 cal / g, and the pH is 7-9 as the standard. The processing method can effectively handle high concentration cyanide-containing waste polymer (cyanide content is 300-850 mg / kg), and reduces the cement plant pulverized coal fuel use amount so as to achieve the goal of energy conservation and environmental protection.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com