Method for treating ferricyanic gold extraction wastewater by using precipitation-electrolytic oxidation synergistic effect

A technology of electrolytic oxidation and synergy, applied in the fields of precipitation treatment, flocculation/sedimentation water/sewage treatment, metallurgical wastewater treatment, etc., can solve the problems of high cost, difficulty in reaching the standard of effluent, and imperfect technology, and achieve low cost and operation. Simple, high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

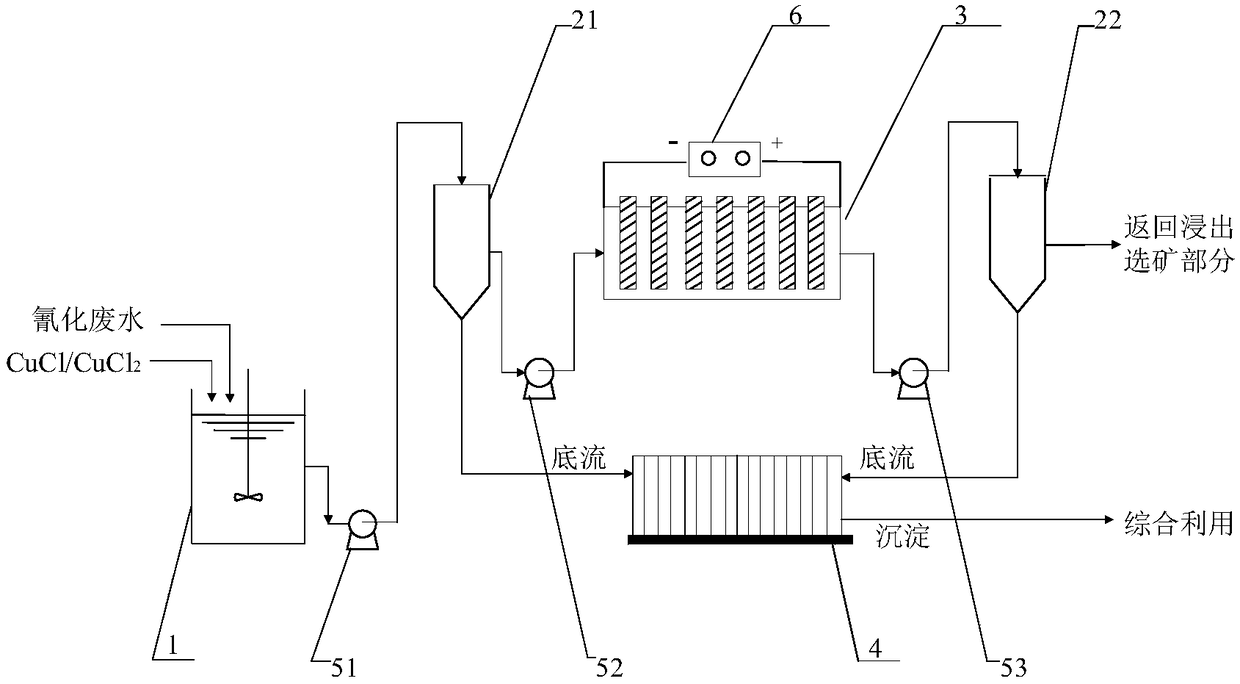

[0022] refer to figure 1 , a method of utilizing precipitation-electrolytic oxidation synergy to treat high-ferricyanide gold extraction wastewater, the steps are as follows:

[0023] 1. Put the cyanidation gold extraction wastewater in the high-level reaction tank 1 with mechanical agitation, add the precipitant cupric chloride with 1% of the wastewater mass, stir to carry out the precipitation reaction, and ferricyanide complex ions combined with strong bonds and some weak Bonded complex ions are transformed into precipitates.

[0024] 2. After the precipitation reaction, the reactant is sent to the settling tank 21 by the pump 51 for precipitation and separation. After the separation, the supernatant is passed into the electrolytic cell 3 by the pump 52, and the stainless steel plate is used as the anode and cathode for electrolytic oxidation. The stabilized power supply is 6 Provide an electrolysis voltage of 4.0V, the distance between the plates is 10mm, and the electrol...

Embodiment 2

[0027] A method utilizing precipitation-electrolytic oxidation synergy to process high ferricyanide gold extraction wastewater adopts the same device as in Example 1, and the steps are as follows:

[0028] 1. Put the cyanidation gold extraction wastewater in a high-level tank with mechanical agitation, add 3.5% of the wastewater mass as a precipitant cuprous chloride, stir for precipitation reaction, and ferricyanide complex ions combined with strong bonds and some weak bonds Combined complex ions are transformed into precipitates.

[0029] 2. Separate the precipitate obtained in step 1. After the separation, the supernatant is passed into the electrolytic cell, and the titanium plate is used as the cathode and anode for electrolytic oxidation. The electrolysis voltage is 10V, the distance between the plates is 10mm, and the electrolysis time is 2h. The combined free cyanide, zinc cyanide, and copper cyanide complex ions are oxidized to nitrogen and carbon dioxide under the sy...

Embodiment 3

[0031] A method utilizing precipitation-electrolytic oxidation synergy to process high ferricyanide gold extraction wastewater adopts the same device as in Example 1, and the steps are as follows:

[0032] 1. Put the cyanidation gold extraction wastewater in a high-level tank with mechanical agitation, add 2% of the wastewater mass as a precipitant copper chloride, stir for precipitation reaction, and combine ferricyanide complex ions with strong bonds and some weak bonds Complex ions are transformed into precipitates.

[0033] 2. Separate the precipitate obtained in step 1. After the separation, the supernatant is passed into the electrolytic cell, and the titanium plate is used as the cathode and anode for electrolytic oxidation. The electrolytic voltage is 5V, the distance between the plates is 10mm, and the electrolysis time is 4h. The residual weak bonds in the wastewater The combined free cyanide, zinc cyanide, and copper cyanide complex ions are oxidized to nitrogen and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com