Equipment and method for treating wastewater difficult to be degraded by biology method of hydrolysis composite membrane

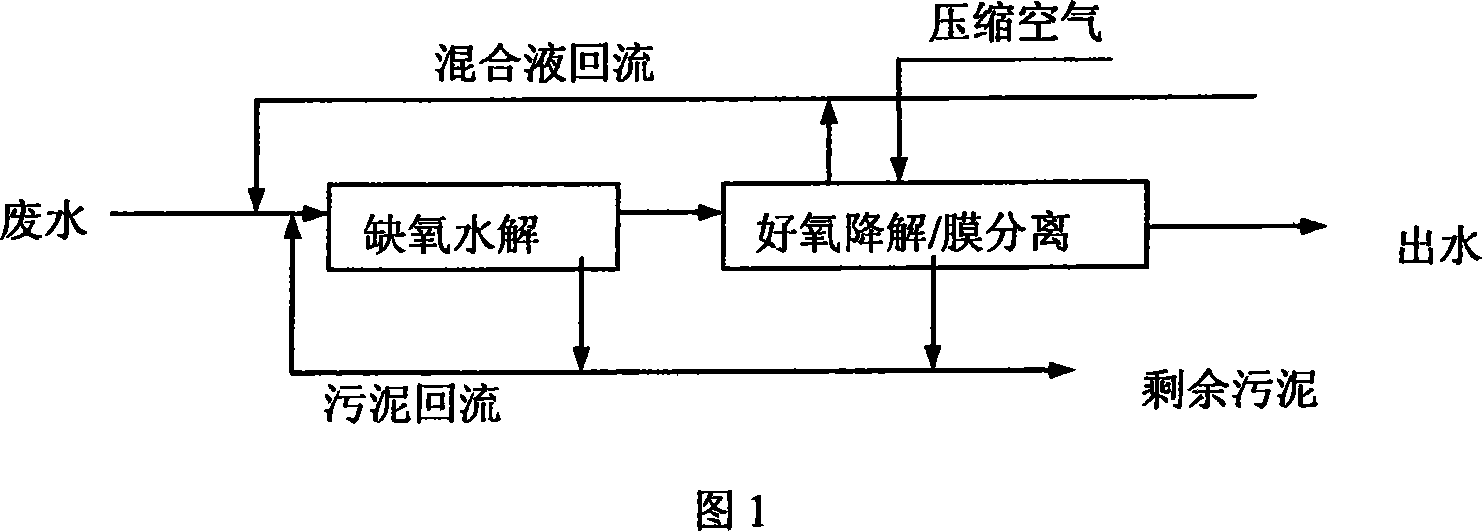

A composite membrane, refractory technology, applied in the field of organic sewage treatment, can solve the problems such as insufficient mixing and contact of wastewater and sludge, inability to guarantee residence time, poor separation of mud and water, etc., to overcome the poor separation of mud and water, improve Biodegradability, the effect of reducing the concentration of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

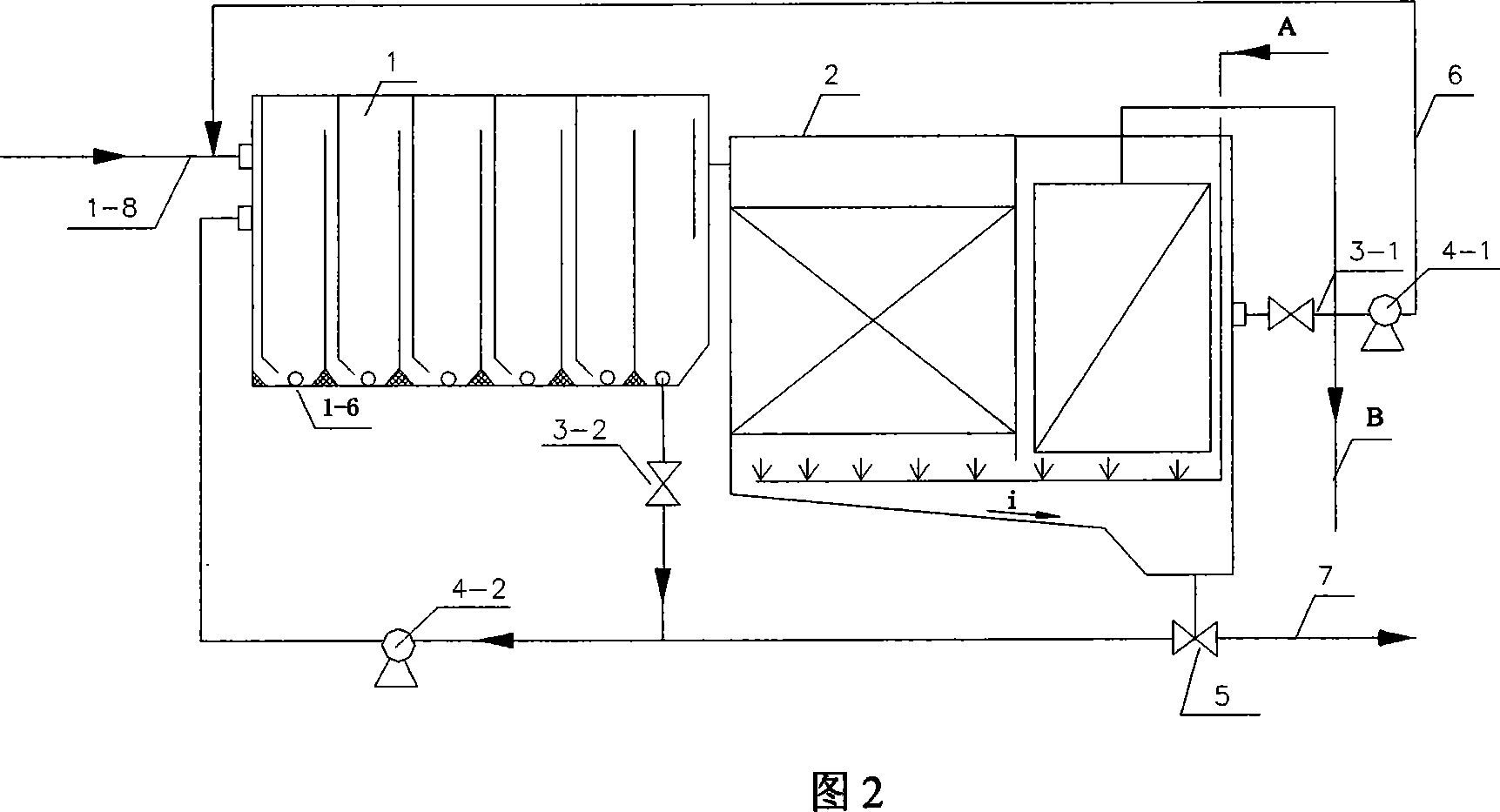

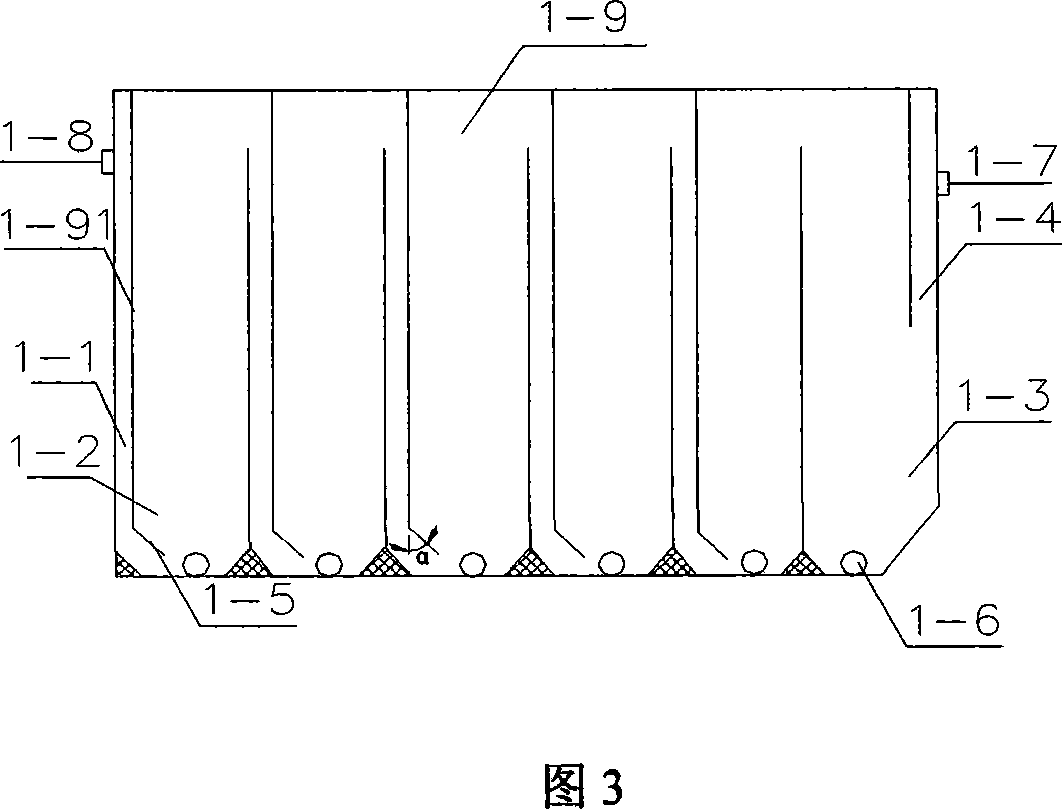

[0032] The device for treating refractory wastewater by hydrolysis-composite membrane biological method of the present invention comprises a multi-compartment hydrolysis reactor 1 and a composite membrane bioreactor 2, wherein the outlet end of the multi-compartment hydrolysis reactor 1 connects with the connecting pipe 1-7 The water inlets 2-8 of the composite membrane bioreactor 2 are connected, and the membrane module in the composite membrane bioreactor 2 is connected with a membrane separation outlet pipe B. In the composite membrane bioreactor 2, through the first control valve 3 -1. The first reflux pump 4-1 and the mixed liquid reflux pipe 6 are connected to the water inlet pipe 1-8 of the multi-compartment hydrolysis reactor 1; the compressed air pipe A and the aeration pipe 2 in the lower part of the composite membrane bioreactor 2- 6-phase connection, the outlet of the mud collection area 2-3 at the bottom of the composite membrane bioreactor 2 is connected to the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com