Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71 results about "Hydrogen sulfide test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Easy to use, do-it-yourself drinking water Hydrogen Sulfide Water Test Kit (also called Hydrogen Sulphide or H2S ). Also can be called "sulfur water test". If you notice a rotten egg smell from your well or tap water , this test can help you detect levels of hydrogen sulfide.

Preparation of electrochemical luminescence paper chip and application of chip in hydrogen sulfide detection

InactiveCN104819976ASpeed up the flowReduce volatilityChemiluminescene/bioluminescenceWaxSignalling molecules

The invention discloses a method for preparing an electrochemical luminescence paper chip and a method for measuring content of signal molecule hydrogen sulfide in MCF-7 by using an electrochemical luminescence sensor. The method is characterized by preparing a hydrophobic region, a semi-hydrophobic region, a hydrophilic region and a hollow channel on paper by utilizing a wax printing technology, cutting the hollow channel by virtue of a laser cutting machine, preparing proper printing ink, printing a corresponding reference electrode and a working electrode on the paper, functionalizing the working area, dripping stock solution in a pretreatment region, and fixing cancer cells; and folding the prepared paper chip, forming a three-electrode system, dropwise adding electrolyte solution in a reaction region, connecting an electrochemical workstation, thus realizing high-sensitivity detection of the low-content signal molecules in the cancer cells.

Owner:UNIV OF JINAN

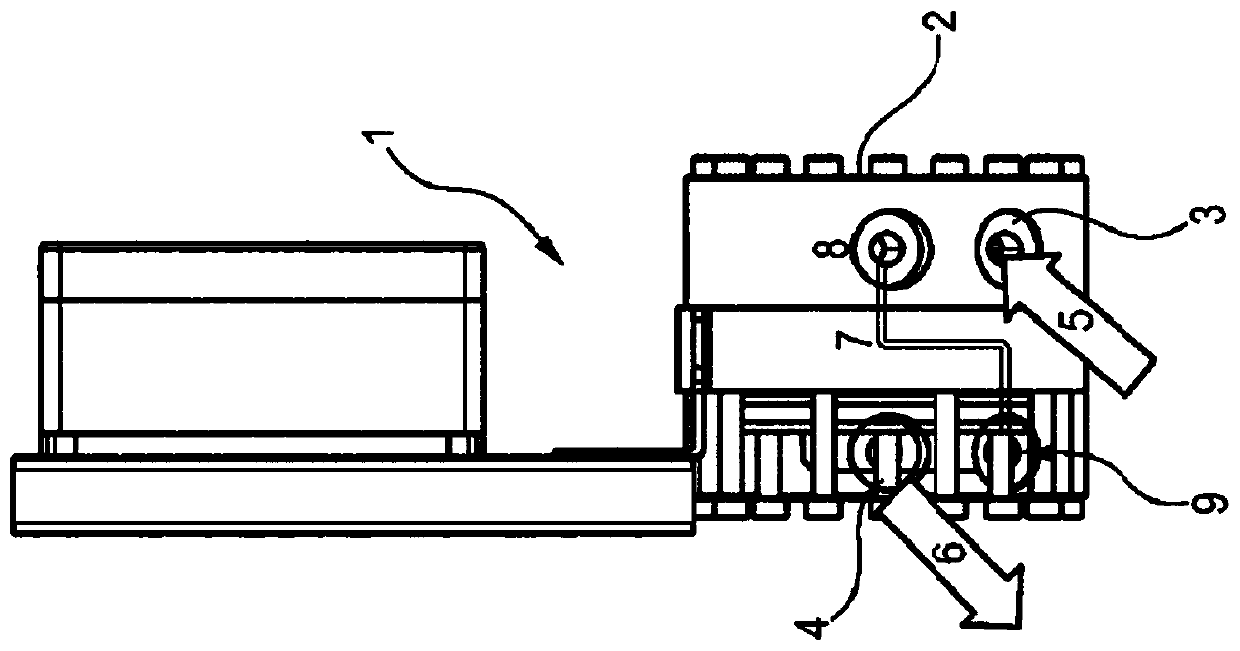

Method and device for generating electricity and gypsum from waste gases containing hydrogen sulfide

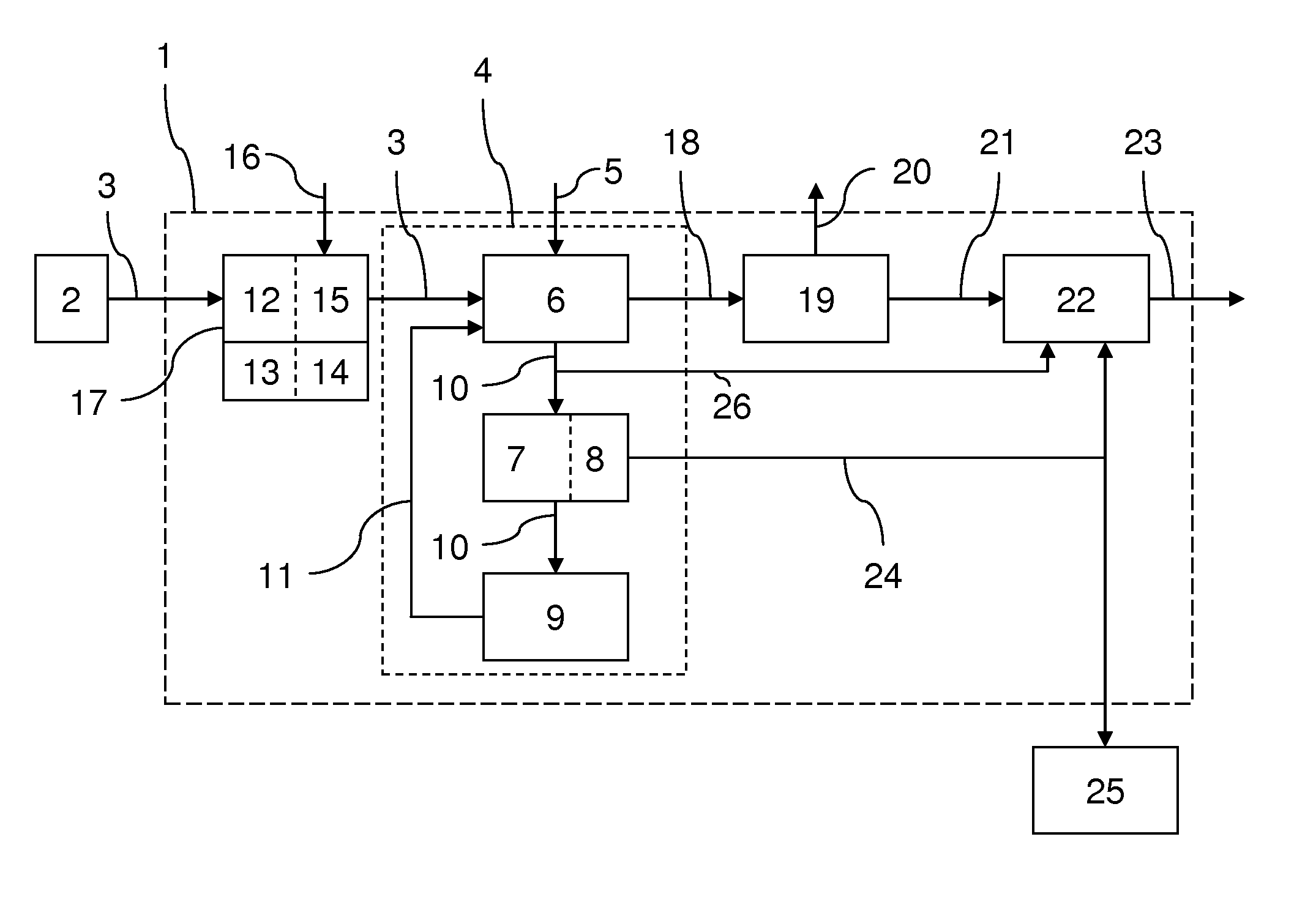

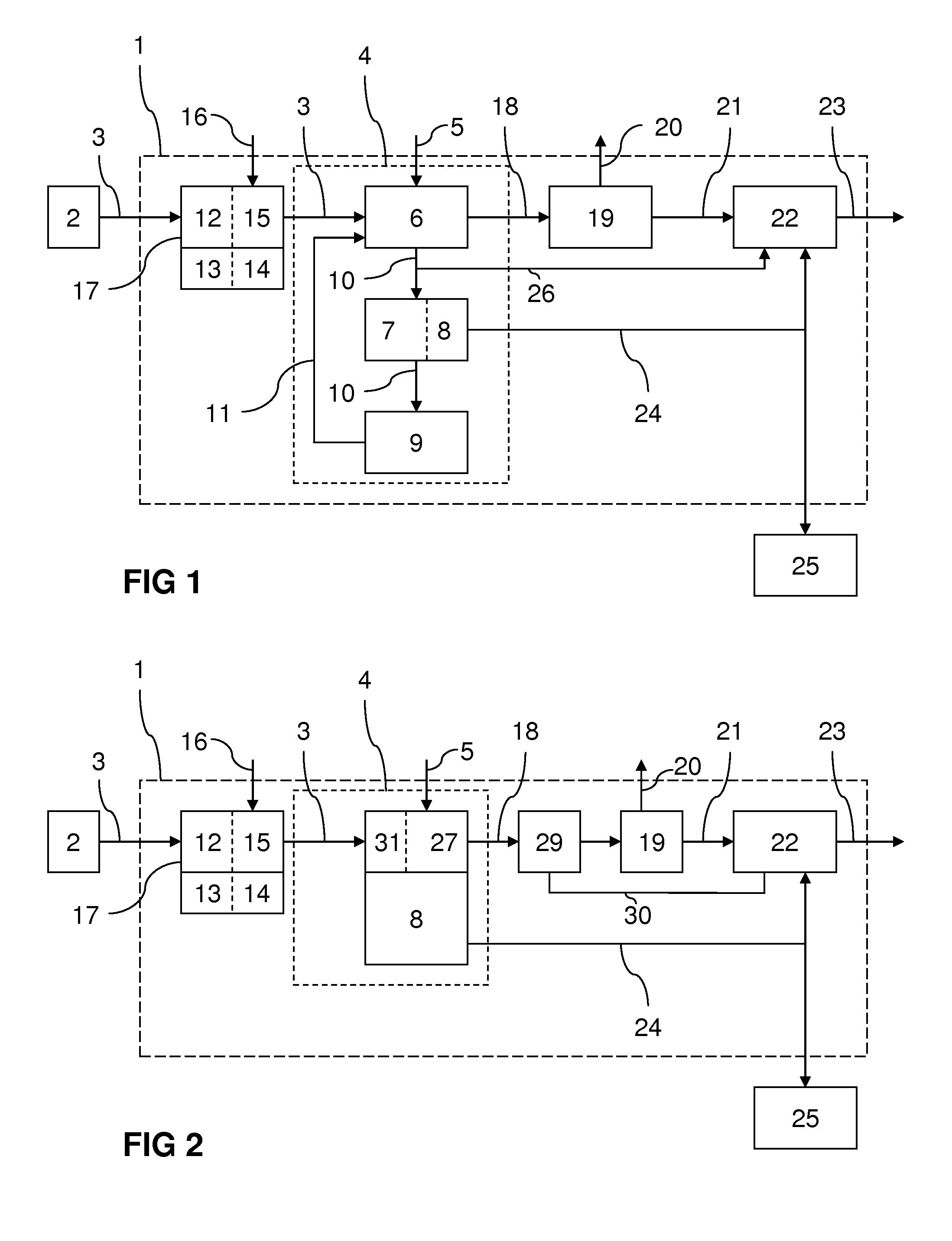

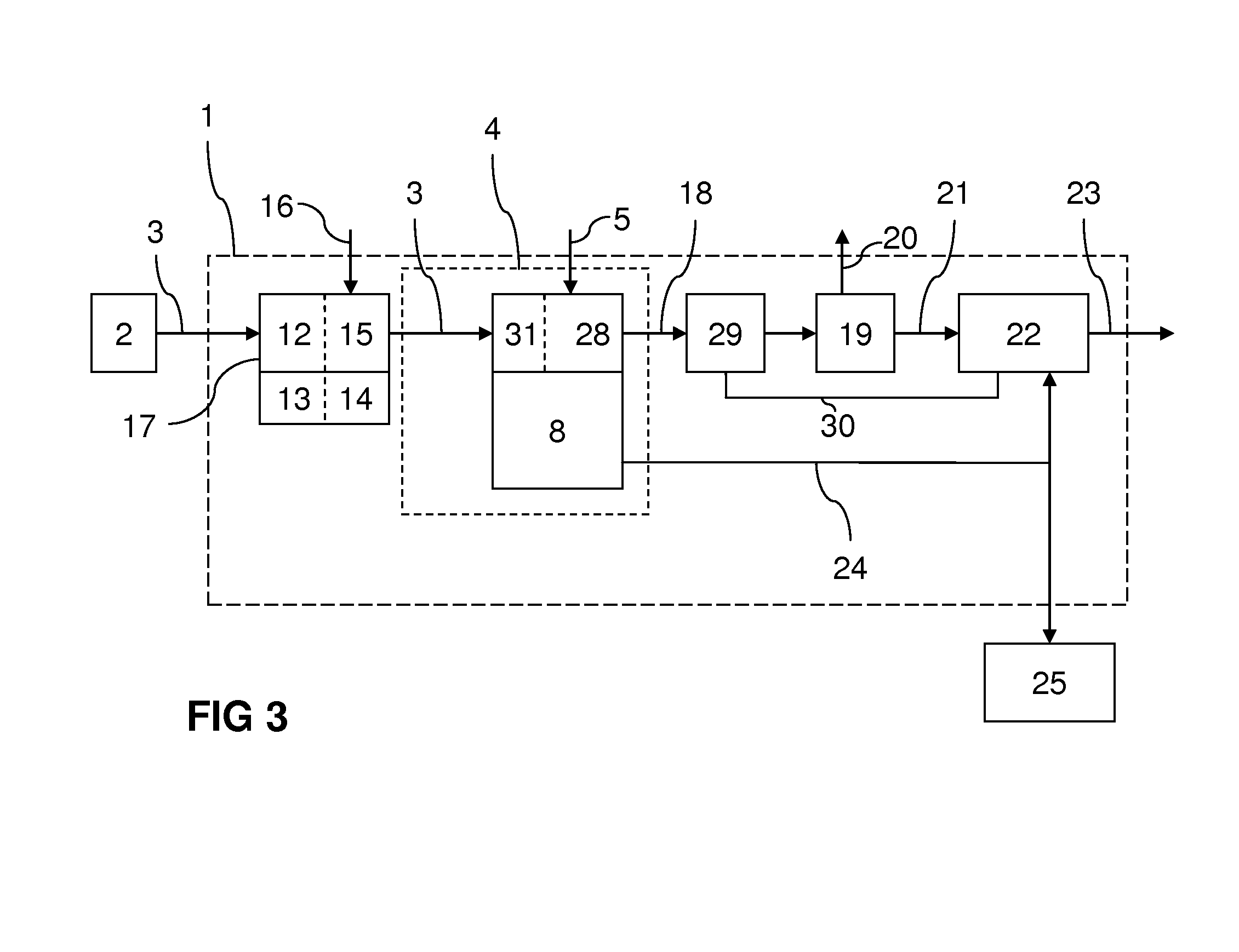

The invention relates to a method and an apparatus for generating current from hydrogen sulphide-containing exhaust gases, particularly from the natural gas industry.The method according to the invention is characterized in that the hydrogen sulphide-containing exhaust gases are delivered to a current generation device and are burnt there, preferably with air being supplied, the energy released during combustion being employed at least partially for current generation.The apparatus according to the invention is characterized by a current generation device in which supplied hydrogen sulphide-containing exhaust gases are burnt, preferably with air being supplied, the energy released during combustion being employed at least partially for current generation.

Owner:KNAUF GIPS KG

Method of removing hydrogen sulfide

ActiveCN103846003AReduce hydrogen sulfide contentReduce production capacityOrganic chemistryDispersed particle separationProcess equipmentDistilled water

The invention relates to a method of removing hydrogen sulfide. The method includes dissolving 0.001-0.010 g of a polyoxometallate adopted as a wet-method desulfurizer into 10-180 mL of distilled water, and feeding a gas mixture containing the hydrogen sulfide into the solution at 10-65 DEG C and under atmospheric pressure to remove the hydrogen sulfide. The structure formula of the polyoxometallate is Cu3(L)6[H3(PMo12O40)2]-nH2O or Cu3(L)6[H5(SiW12O40)2]-nH2O, wherein the L is C8H10N4. The desulfurizer adopted by the method is simple in preparation method, high in oxidation performance, high in stability and free of pollution to pipelines and the environment, and is environmental-friendly. The hydrogen sulfide removing efficiency in the whole process is high and elemental sulfur can be obtained. Process equipment is simple and low in investment.

Owner:PETROCHINA CO LTD

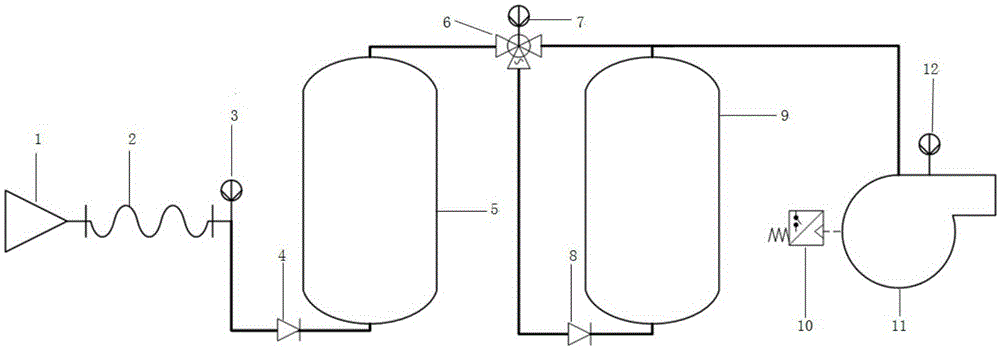

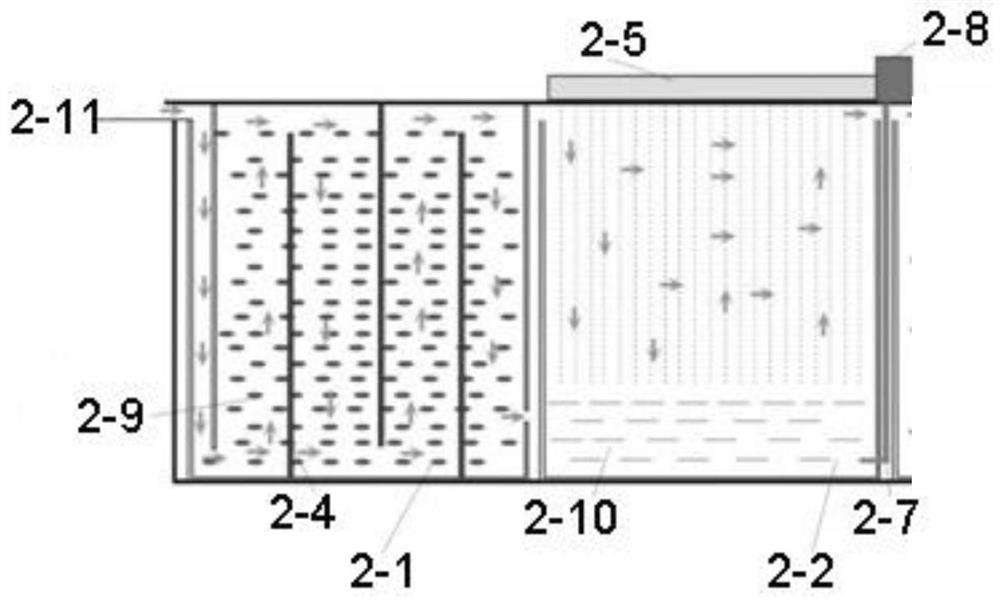

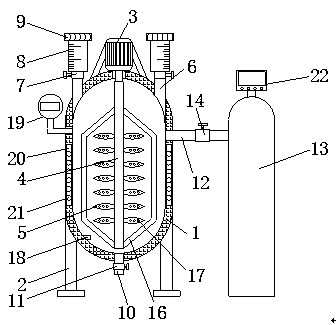

Hydrogen sulfide absorbing device

InactiveCN105233653AEliminate Toxic HazardsImprove securityDispersed particle separationEngineeringTower

The invention relates to a hydrogen sulfide absorbing device. The device is mainly used for collection and elimination of leaked hydrogen sulfide. The device comprises absorption towers, an induced draft fan and hydrogen sulfide testers. One end of a movable hose is connected with a gathering port, the other end of the movable hose is connected with the bottom of the absorption tower A, an outlet in the top of the absorption tower A is connected with an electromagnetic three-way valve, the other two ports of the electromagnetic three-way valve are connected with an outlet pipeline on the bottom of the absorption tower B and an outlet pipeline on the top of the absorption tower B respectively, and the outlet pipeline on the top of the absorption tower B is also connected with the induced draft fan. Due to the adoption of the technical scheme that the hydrogen sulfide testers are arranged on a pipeline between the movable hose and the absorption tower A, on the electromagnetic three-way valve and on an outlet of the induced draft fan, problems are solved. The device can be used for hydrogen sulfide absorption.

Owner:CHINA PETROLEUM & CHEM CORP +1

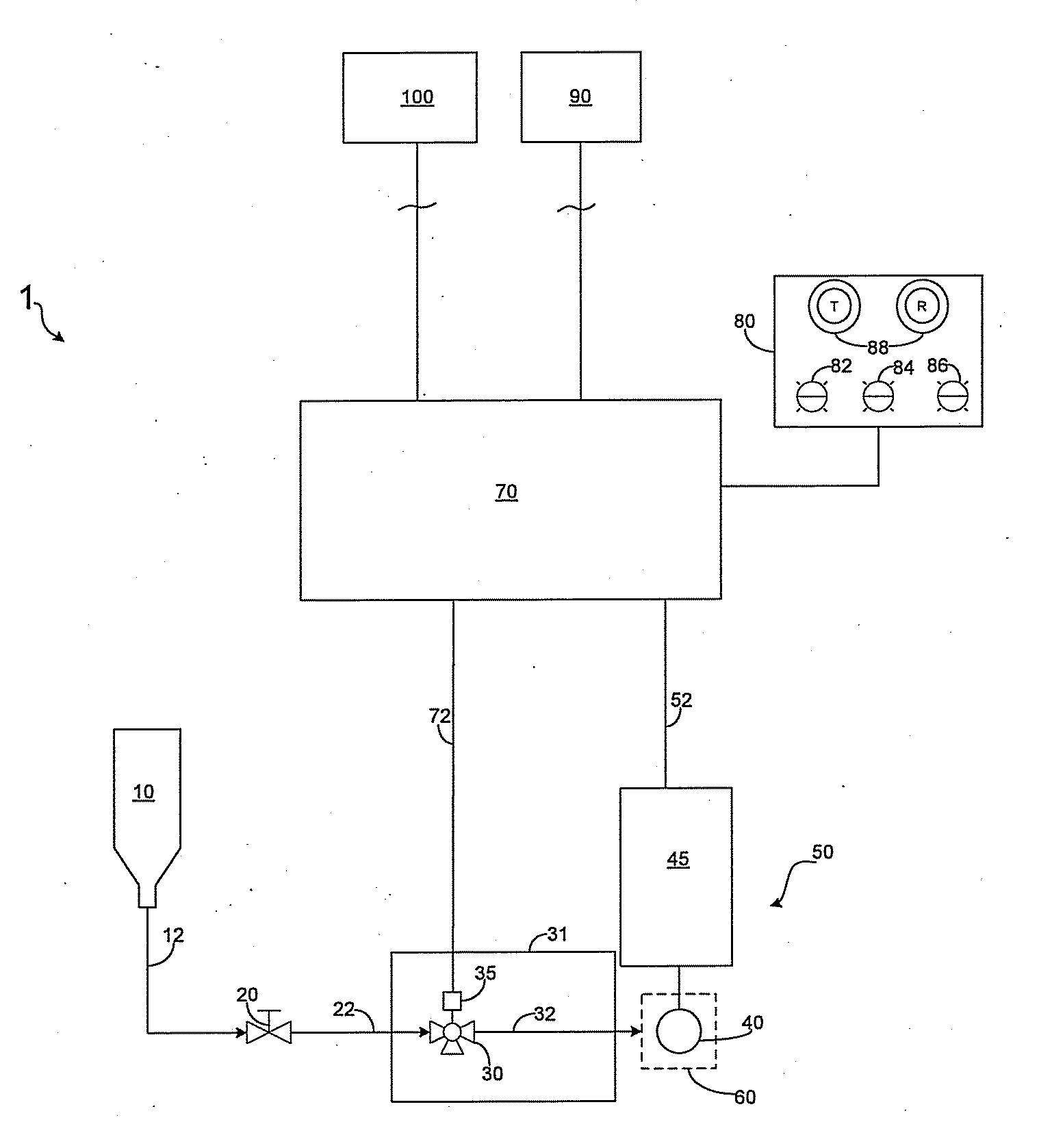

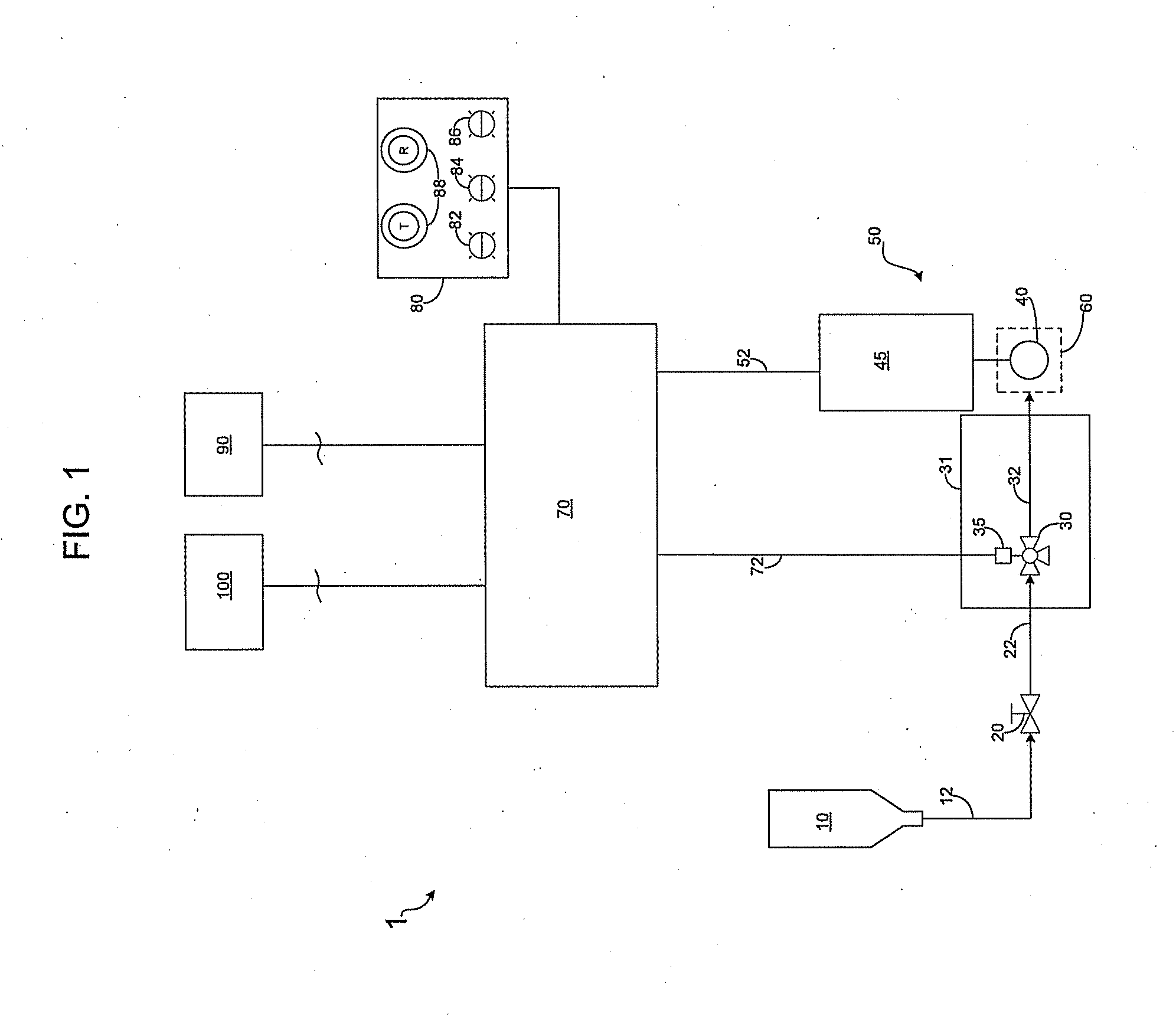

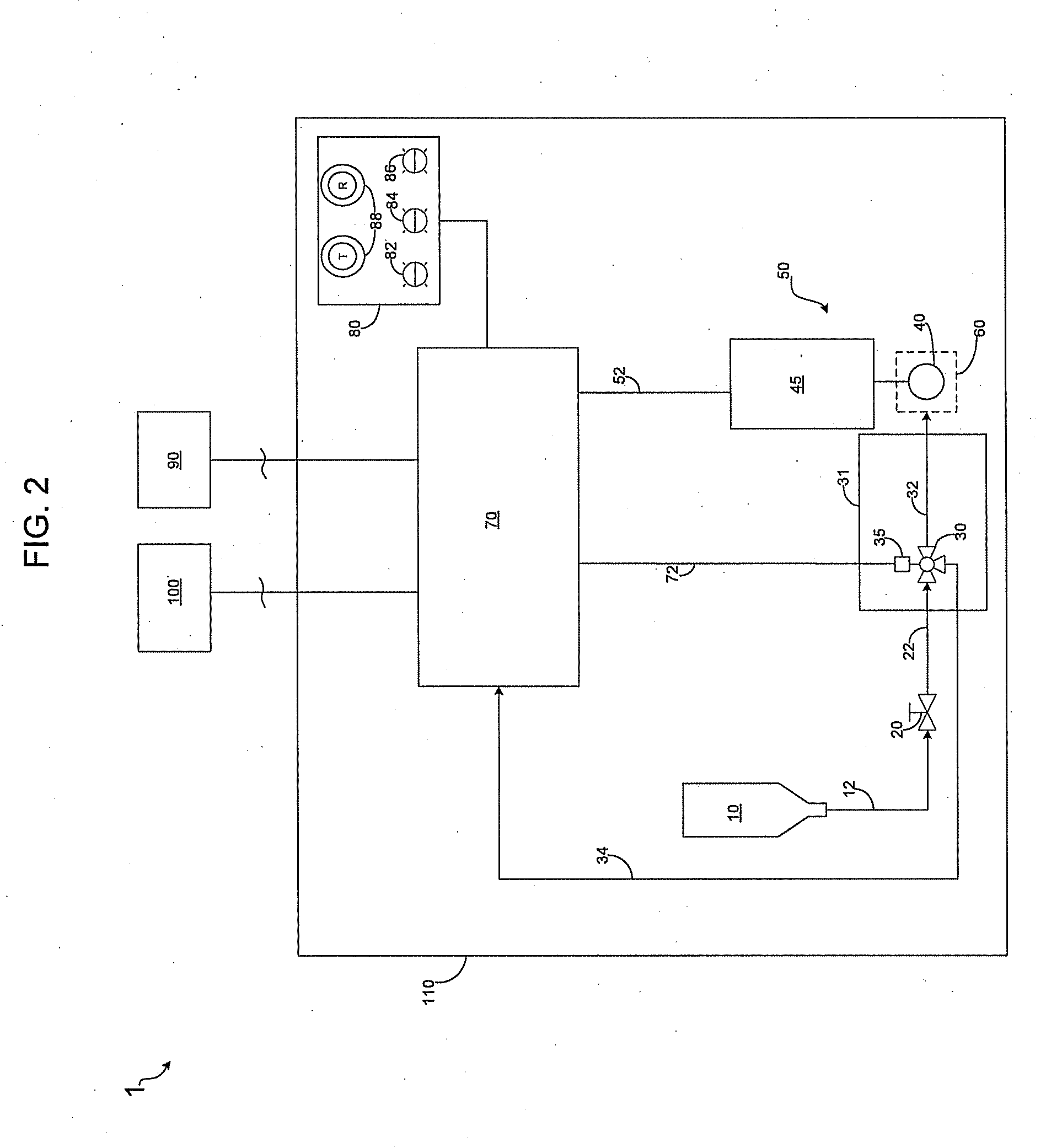

Self-Testing Combustible Gas and Hydrogen Sulfide Detection Apparatus

ActiveUS20130031953A1Simple and convenient and reliableLower potentialInternal-combustion engine testingGas analyser calibrationAutomatic test equipmentCombustible gas

An automated testing apparatus for remotely performing a testing sequence to ensure that a sensor is functioning. The apparatus can include a detector, a storage container, a burst valve in fluid communication with the storage container, a testing control module in communication with the storage container and the burst valve, and a remote user interface remotely located from the detector. Preferably, the automated testing apparatus can simplify the testing procedure, increase the frequency of sensor testings, thereby notifying operations of sensor failures in a more timely fashion without the need for an operator to check the sensor locally.

Owner:SAUDI ARABIAN OIL CO

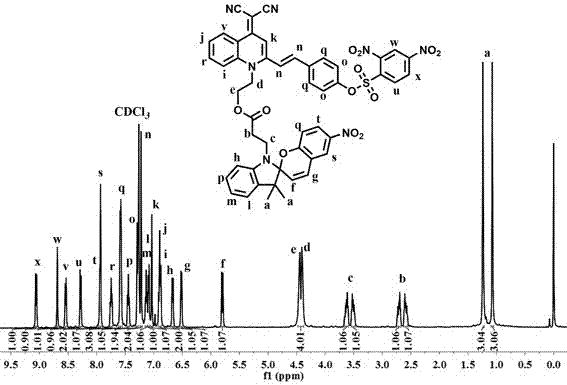

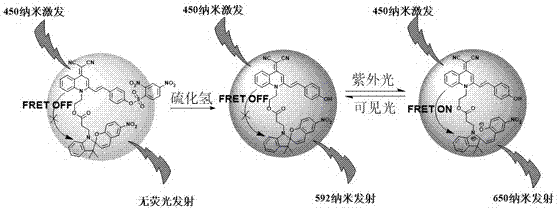

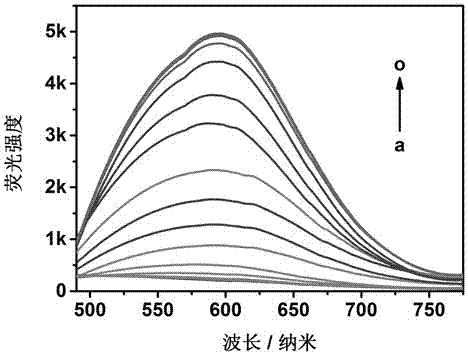

Preparation and application of optical switch fluorescence molecules with hydrogen sulfide recognition function

ActiveCN107502342AGood choiceStrong interference abilityOrganic chemistryFluorescence/phosphorescenceWater basedFluorescence

The invention discloses preparation and application of optical switch fluorescence molecules with a hydrogen sulfide recognition function. According to obtained target molecules, properties of a group with hydrogen sulfide response and a spiropyran group with photoresponse are combined successfully, and the molecules in a water-based solvent not only can perform high-selectivity and high-sensitivity detection for hydrogen sulfide molecules, but also have good optical switch performance and can show rapid and reversible fluorescence switch performance under irradiation of ultraviolet light and green light. The optical switch fluorescence molecules with the hydrogen sulfide recognition function have great application prospect in the technical fields of hydrogen sulfide detection, environmental protection, super-resolution imaging, life science and the like.

Owner:HUNAN UNIV OF SCI & TECH

Near-infrared fluorescent dye THX-Np capable of achieving mitochondrial localization and preparation method and application of near-infrared fluorescent dye THX-Np

InactiveCN108997772AStabilizes the pH fluorescence turn-on effectSignificant absorption peakMethine/polymethine dyesFluorescence/phosphorescenceSolubilityCell membrane

The invention discloses near-infrared fluorescent dye THX-Np capable of achieving mitochondrial localization and a preparation method and application of the near-infrared fluorescent dye THX-Np. The structural formula of the dye is shown in (I). The dye has a stable pH fluorescence opening effect in an aqueous phase under the conditions of different pH values, and 2,4-dinitrophenyl ether derivatives prepared by using the dye can be applied to detection of hydrogen sulfide. The invention has the following advantages that the fluorescent dye has pH stability, large Stokes shift, good water solubility, good cell membrane permeability and excellent mitochondrial localization performance, and hydroxyl groups and carboxyl groups of the dye can be easily modified so as to produce tracers relatedto organisms, the 2,4-dinitrophenyl ether derivatives prepared through etherification of hydroxyl groups of the dye have excellent selective recognition of hydrogen sulfide, and an excellent selectivefluorescent probe of hydrogen sulfide detection.

Owner:CENT SOUTH UNIV

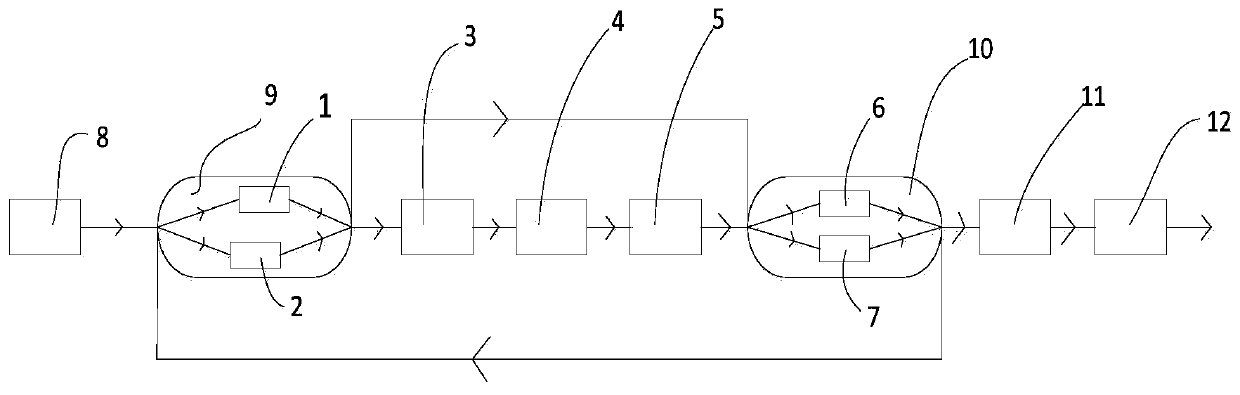

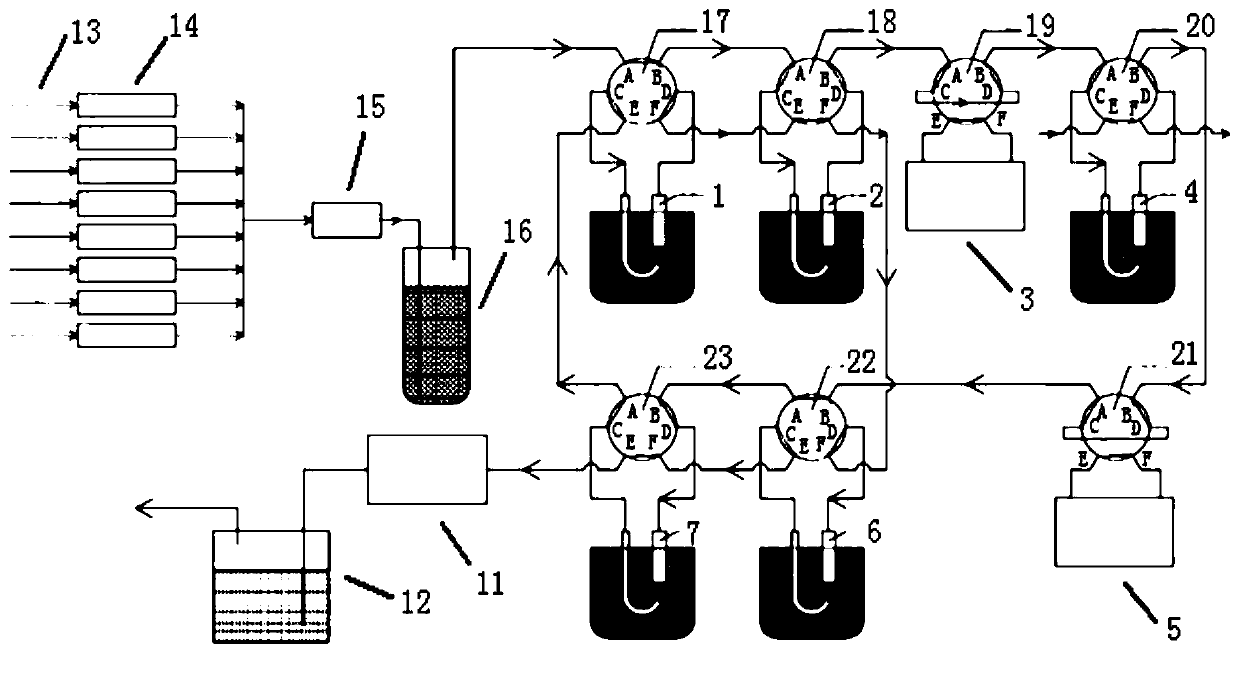

Integrated process and system for detecting and treating toxic gas in deep natural gas

ActiveCN112710804AEfficient and harmless treatmentLiquid degasificationDispersed particle filtrationToxic gasEnvironmental engineering

The invention provides an integrated process and system for detecting and treating toxic gas in deep natural gas. The process comprises the steps; drying deep natural gas after cooling and depressurizing; sequentially carrying out radon, hydrogen sulfide and mercury detection on the dried deep natural gas; if the concentration of mercury, radon and hydrogen sulfide in the deep natural gas reaches the standard after detection, conveying the deep natural gas to a gas conveying pipeline; if it is found that the concentration of radon, hydrogen sulfide and mercury in the deep natural gas does not reach the standard after detection, carrying out harmless treatment on radon, part of mercury, hydrogen sulfide and the rest of mercury in the deep natural gas in sequence; carrying out mercury, radon and hydrogen sulfide detection on the deep natural gas subjected to harmless treatment in sequence, and if the concentrations of mercury, radon and hydrogen sulfide in the deep natural gas reach the standard, conveying the deep natural gas subjected to harmless treatment to a gas conveying pipeline; and if the concentrations of mercury, radon and hydrogen sulfide in the deep natural gas do not reach the standard, carrying out harmless treatment on the radon, part of mercury, hydrogen sulfide and the rest of mercury in the deep natural gas in sequence until reaching the standard.

Owner:PETROCHINA CO LTD

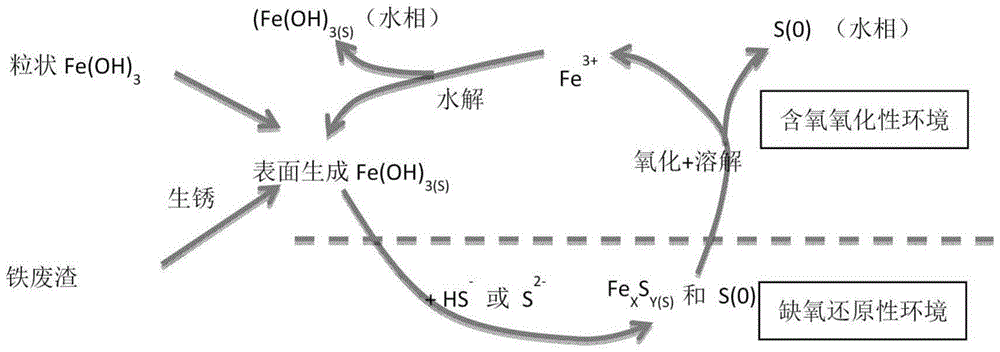

Method for in-situ control of hydrogen sulfide odor in sediments

ActiveCN106495425AAchieve recyclingSolve the problem of hydrogen sulfide odorSludge treatment by oxidationSewer pipelinesSewageSanitary sewer

The invention provides a method for in-situ control of hydrogen sulfide odor in sediments. The sediments are allowed to contact with indissolvable or insoluble particle oxidizing agents to remove hydrogen sulfide in the sediments through an in-situ oxidation and reduction process, and the oxidizing agent is recycled by in-situ regeneration. The method is further used for control of hydrogen sulfide odor of the sediments in rainwater pipelines, rivers or sewage pipelines.

Owner:THE HONG KONG UNIV OF SCI & TECH

Desulfurization catalyst activity evaluation device and method

ActiveCN111579708AShorten evaluation timeAchieve synergyChemical analysis using catalysisGas purification by catalytic conversionPtru catalystProcess engineering

The invention belongs to the field of desulfurization catalyst activity evaluation, and particularly relates to a desulfurization catalyst activity evaluation device and method. The desulfurization catalyst activity evaluation device provided by the invention comprises a gas supply unit, and further comprises a reaction unit which comprises a deoxidation unit, a hydrolysis unit and an adsorption unit which are communicated in sequence, the evaluation device further comprises a detection unit which comprises an oxygen detection unit, an organic sulfur detection unit and a hydrogen sulfide detection unit, the oxygen detection unit is arranged between the deoxidation unit and the hydrolysis unit, the organic sulfur detection unit is arranged between the hydrolysis unit and the adsorption unit, the hydrogen sulfide detection unit is connected with a gas outlet of the adsorption unit, and the gas supply unit is connected with a gas inlet of the deoxidation unit. According to the invention,the performance of several groups of different catalysts suitable for blast furnace gas desulfurization series can be tested at the same time through one-time gas distribution, and the performance iscloser to the real use condition of the catalyst.

Owner:中琉科技有限公司

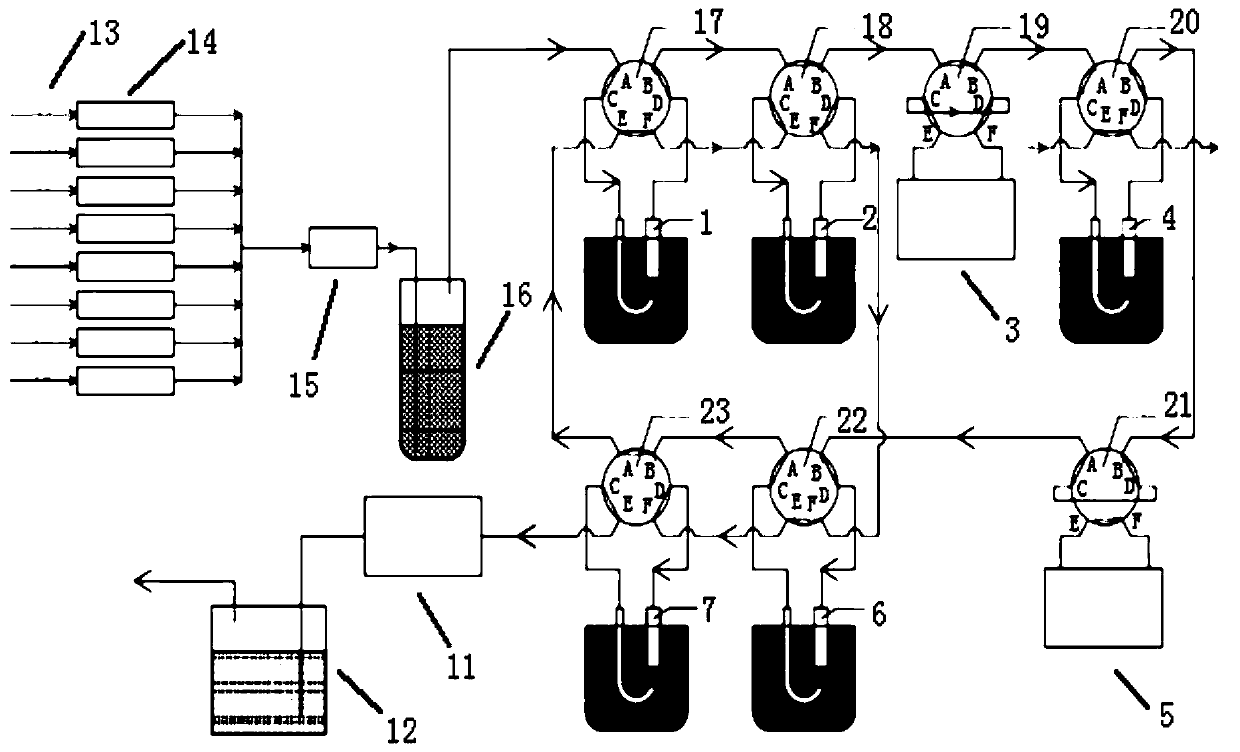

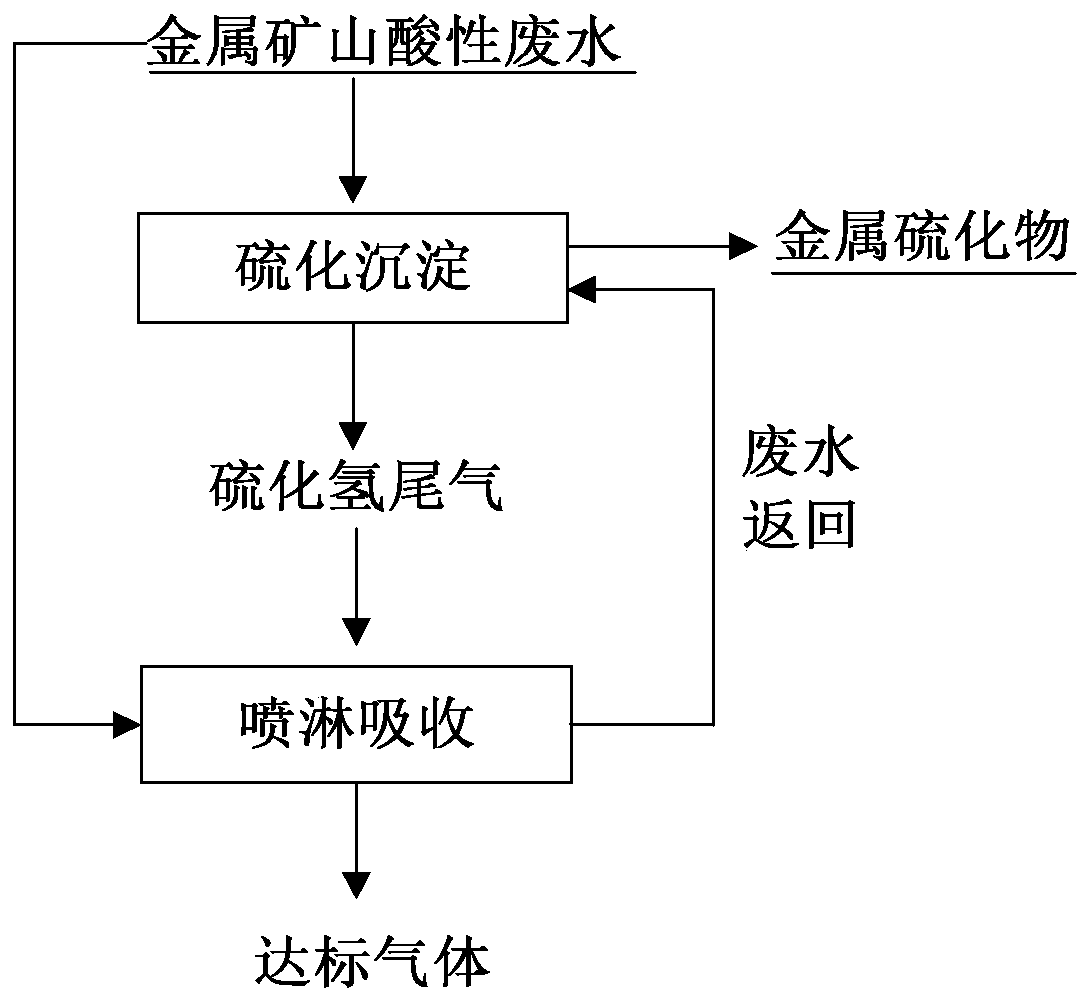

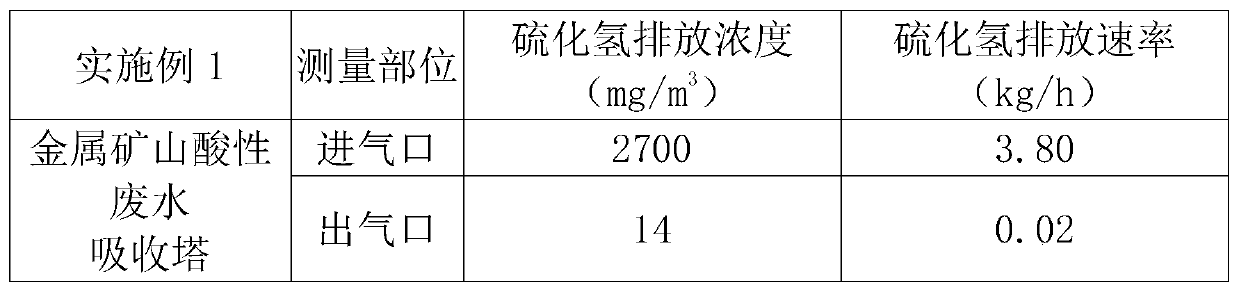

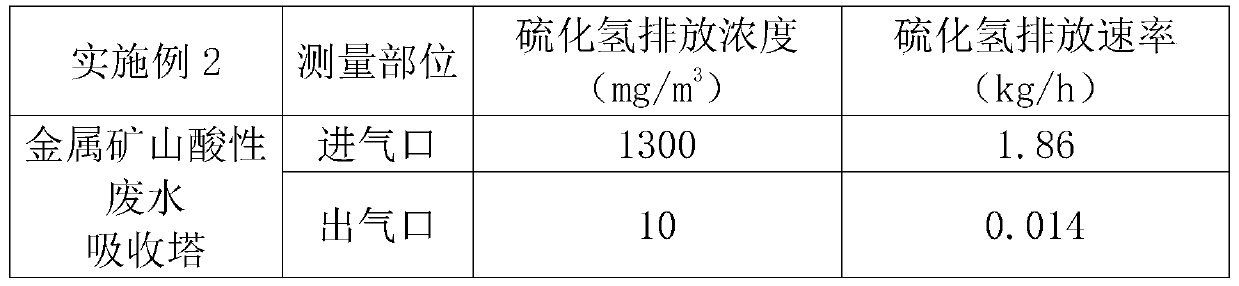

Method for absorbing hydrogen sulfide tail gas in sulfide precipitation system

InactiveCN110117052ANo need to increase investment in environmental protectionSimple processWater contaminantsDispersed particle separationChemical reactionHydrometallurgy

The invention relates to a method for absorbing hydrogen sulfide tail gas in a sulfide precipitation system. The method comprises the steps that metal mine acidic wastewater generated by a metal minein a mining and smelting process enters the sulfide precipitation system, then metal sulfide is generated, and valuable metal is recovered; the hydrogen sulfide tail gas generated in the sulfide precipitation system is uniformly concentrated to a spray absorption device, a part of the metal mine acidic wastewater is drained to the spray absorption device to perform spraying on the hydrogen sulfidetail gas, so that metal ions in the metal mine acidic wastewater react with the hydrogen sulfide gas according to a chemical reaction formula shown in the description, wastewater mixed with the metalsulfide and up-to-standard gas are obtained, and the up-to-standard gas is discharged. The method for absorbing the hydrogen sulfide tail gas in the sulfide precipitation system has the advantages that no drug or special system or equipment is needed, no new harmful impurities are introduced, no addition of environmental protection investment is needed, the metal mine acidic wastewater is used for treating the hydrogen sulfide gas, the purified gas is discharged after reaching the standard, the process is simple and practical, the treatment cost is low, the absorption effect is obvious, and the method is especially applied to metal mines and hydrometallurgical industries.

Owner:ZIJIN MINING GROUP

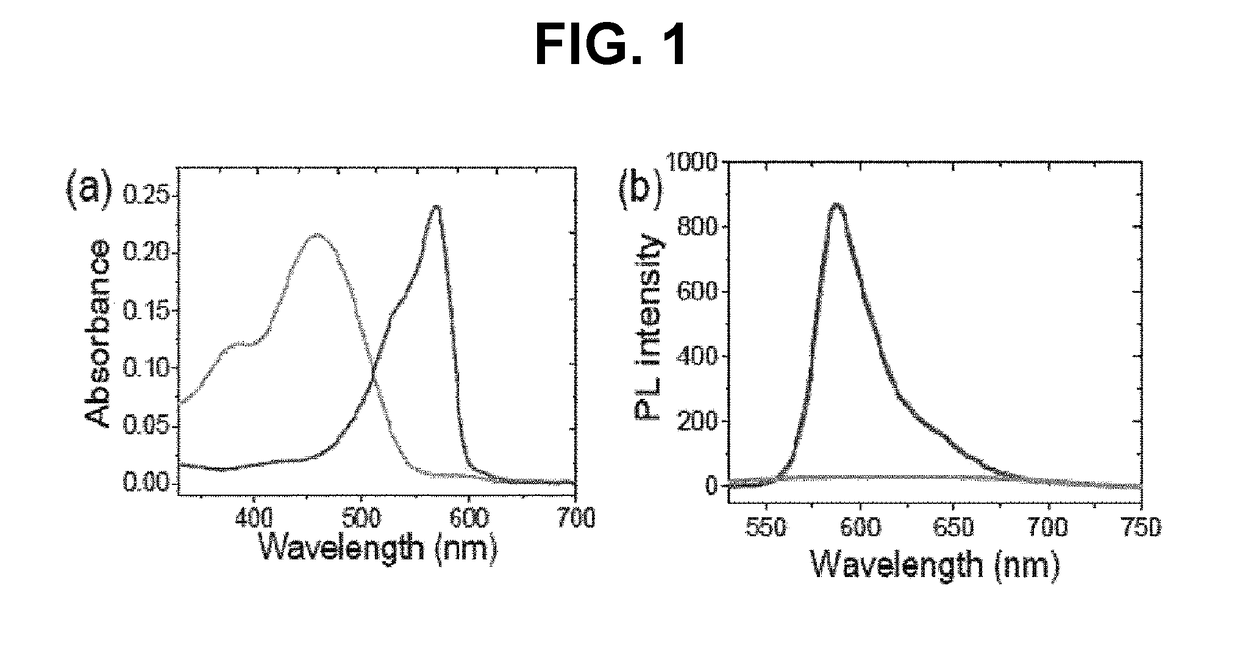

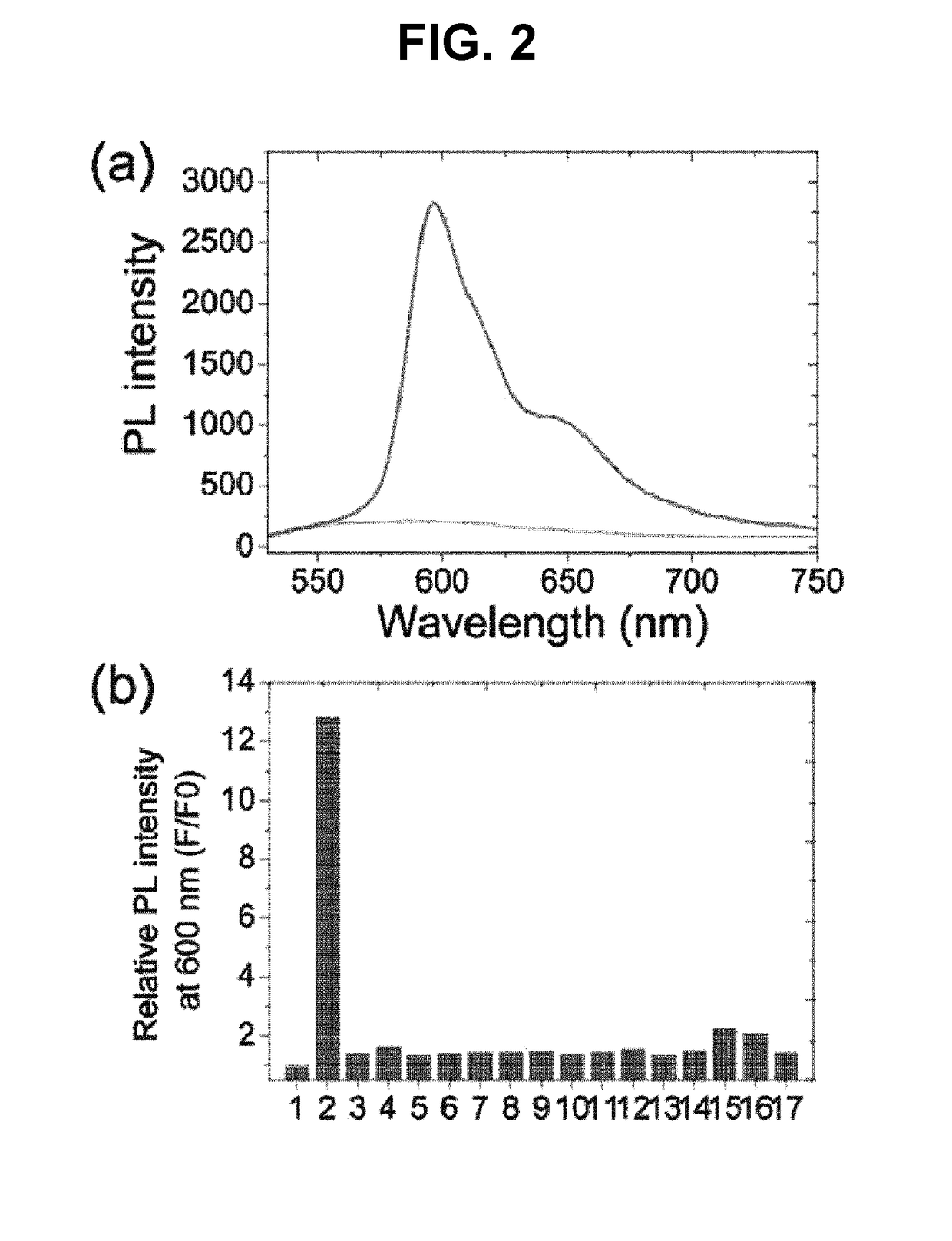

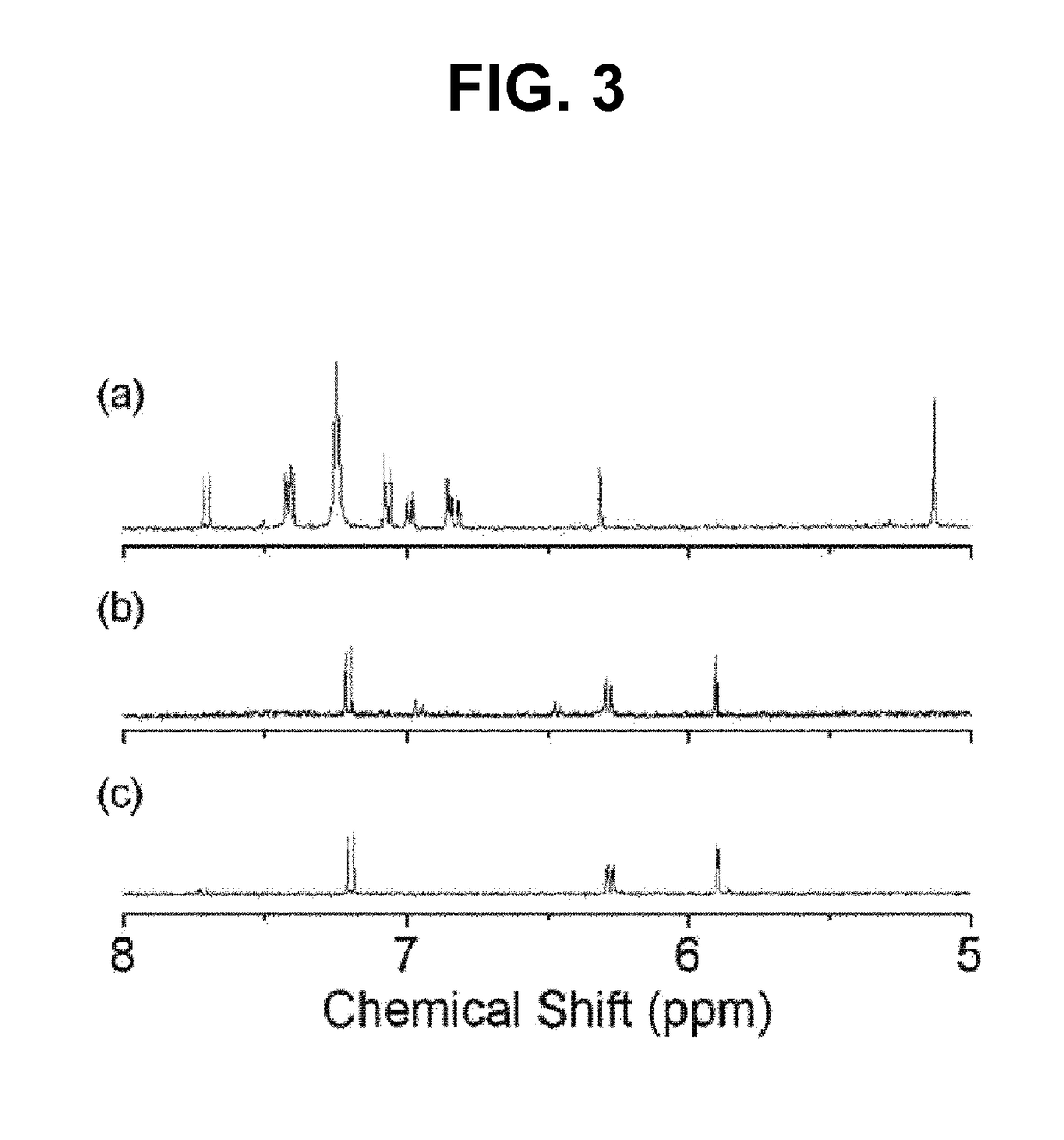

Reactive fluorogenic compound and nanocomposite for sensing hydrogen sulfide comprising the same

ActiveUS20190076554A1Detection moreUseful in detectionOrganic chemistryDispersion deliveryDiseaseFluorescence

The present invention relates to a nanocomposite for detecting hydrogen sulfide; a method for preparing the same; a novel reactive fluorogenic compound to be used in the method; a kit for detecting hydrogen sulfide comprising the nanocomposite; and a method for providing information for the diagnosis of a disease, which causes abnormal secretion of hydrogen sulfide, by using the nanocomposite.

Owner:KOREA INST OF SCI & TECH

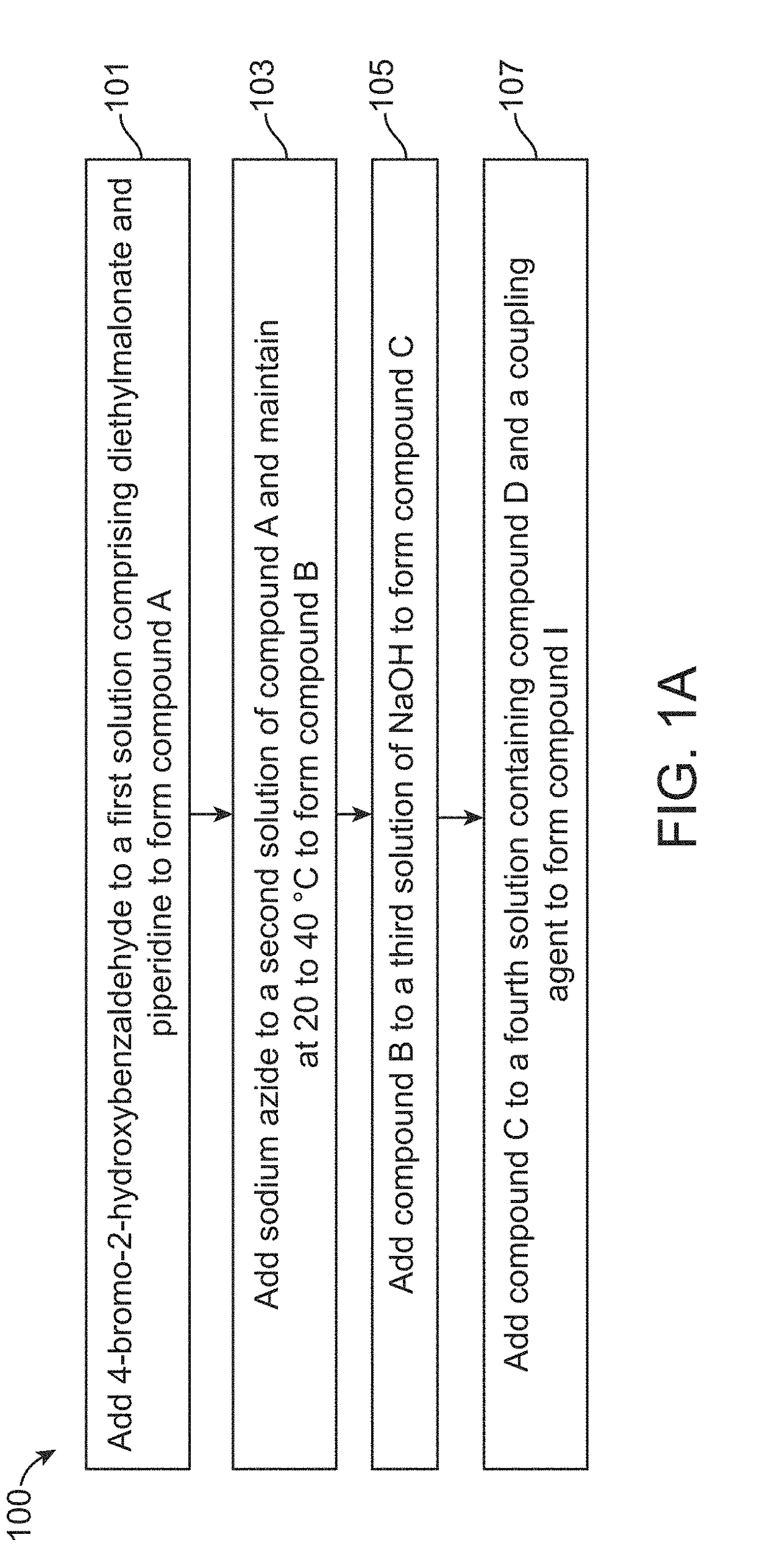

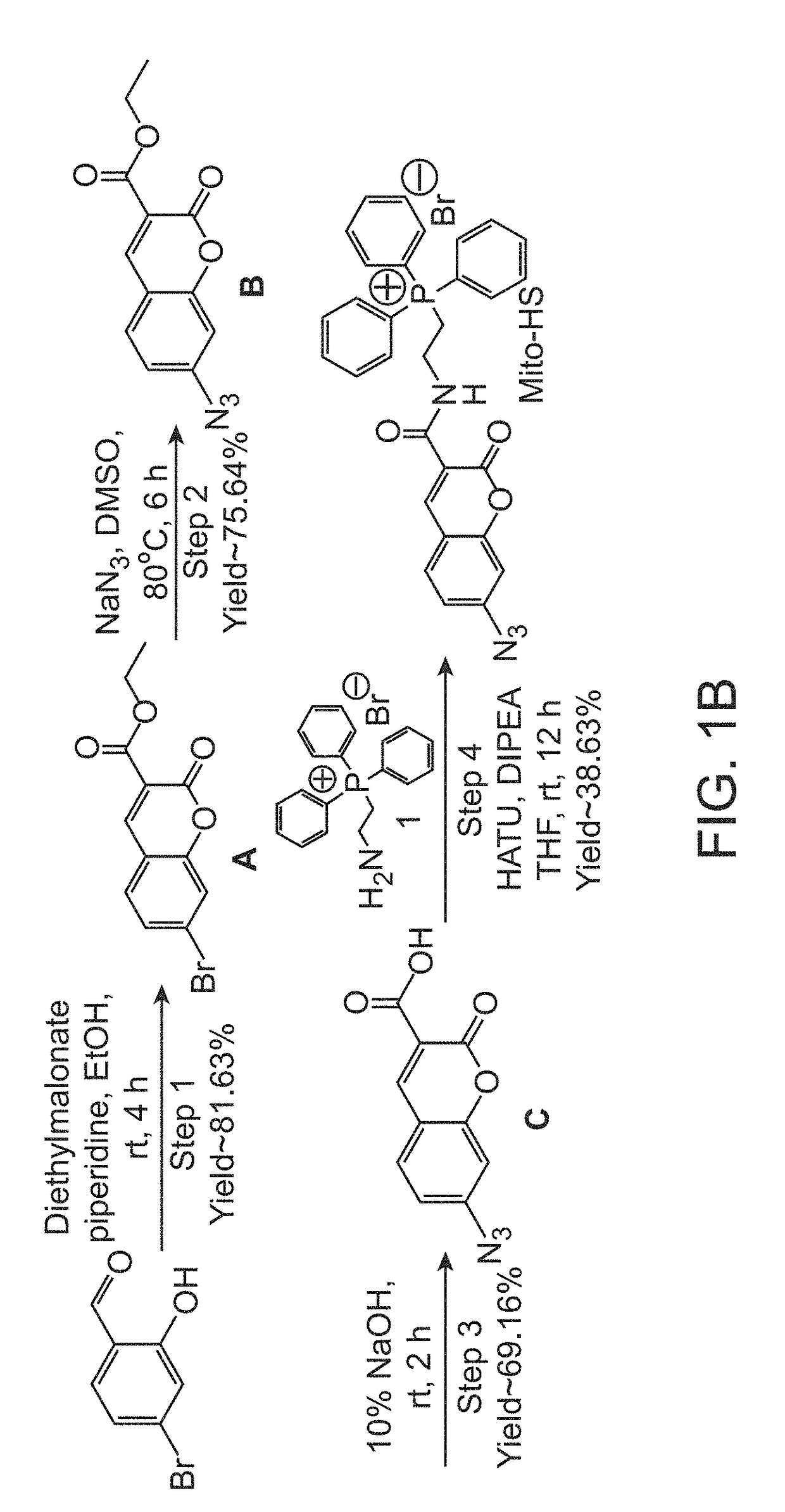

Flourescent exomarker probes for hydrogen sulfide detection

ActiveUS20180306792A1Group 5/15 element organic compoundsBiological testingDiseaseBiomarker (petroleum)

A fluorescence probe with mitochondrial targeting and two-photon property, its preparation method and application in detecting and tracking endogenous H2S in samples or living cells. The fluorescent probe is prepared by a four-step preparation method and demonstrates a UV-vis absorption increment λab=395 nm and ˜43 fold higher fluorescence intensity in the presence of H2S. The probe further demonstrates stability, selectivity for H2S over competing agents and sensitivity as low as 20 nm. A method of detecting endogenous H2S rapidly in the absence of any external stimulators is provided. Samples are contacted with the probe and the changes in fluorescence are monitored to detect H2S levels. The disclosed probe is non-toxic and suitable as a biomarker and therapeutic molecule in cancer and other diseases.

Owner:AMRITA VISHWA VIDYAPEETHAM

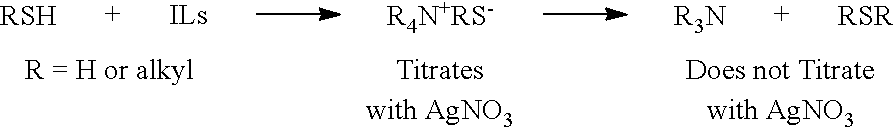

Ionic liquid-based hydrogen sulfide and mercaptan scavengers

Treatment of hydrocarbon streams, e.g. gasoline, with basic ionic liquids (ILs), results in reduction of the sulfur compounds such as H2S thiophenes, disulfides, thioethers, and / or mercaptans that are present to remove these compounds. The IL is a quaternary ammonium compound having the formula R4N+ X− or X− R3N+R′N+R3 X−, where R is independently an alkyl group, an alkylbenzyl group, a hydroxyalkyl group, or a hydroxyalkylbenzyl group, and R is straight or branched and has 1-22 carbon atoms, R′ is a straight or branched alkylene or oxyalkylene having 1 to 10 carbon atoms, and where X− can be hydroxide, carbonate, alkylcarbonate, bicarbonate or alkoxide, where the alkyl group of the alkylcarbonate or alkoxide, if present, is straight or branched and has 1 to 8 carbon atoms. The ILs can be used in applications where liquid or gaseous hydrocarbon fluids are treated by direct injection or by extraction.

Owner:BAKER HUGHES INC

Device for collecting and measuring VSCs gas released by anaerobic stable sludge

The invention discloses a device for collecting and measuring VSCs gas released by anaerobic stable sludge, which relates to the technical field of biological treatment of sludge. The device comprises a box body system and a gas collecting and measuring system. A first conduit, a second conduit, a third conduit, a fan and a temperature sensing probe are arranged at the top of the box body, one ends of the first conduit, the second conduit and the third conduit are communicated with an inner cavity of the box body, and the other ends are respectively communicated with a gas carrier tank or a Suma tank, a portable high-precision hydrogen sulfide detector and a gas buffer sampling bag. A first valve, a second valve and a third valve are respectively arranged on the first conduit, the second conduit and the third conduit; a sampling port is formed in the bottom of the box body. According to the device for collecting and measuring VSCs gas released by anaerobic stable sludge, the box body system and the gas collection and measurement system are combined, so that the measured discharge rate and discharge amount of the VSCs in the anaerobic stable sludge and the daily change condition are more accurate.

Owner:BEIJING UNIV OF TECH

Preparation of an electrochemiluminescent paper chip and its application in hydrogen sulfide detection

InactiveCN104819976BSpeed up the flowReduce volatilityChemiluminescene/bioluminescenceCancer cellSignalling molecules

The invention discloses a method for preparing an electrochemical luminescence paper chip and a method for measuring content of signal molecule hydrogen sulfide in MCF-7 by using an electrochemical luminescence sensor. The method is characterized by preparing a hydrophobic region, a semi-hydrophobic region, a hydrophilic region and a hollow channel on paper by utilizing a wax printing technology, cutting the hollow channel by virtue of a laser cutting machine, preparing proper printing ink, printing a corresponding reference electrode and a working electrode on the paper, functionalizing the working area, dripping stock solution in a pretreatment region, and fixing cancer cells; and folding the prepared paper chip, forming a three-electrode system, dropwise adding electrolyte solution in a reaction region, connecting an electrochemical workstation, thus realizing high-sensitivity detection of the low-content signal molecules in the cancer cells.

Owner:UNIV OF JINAN

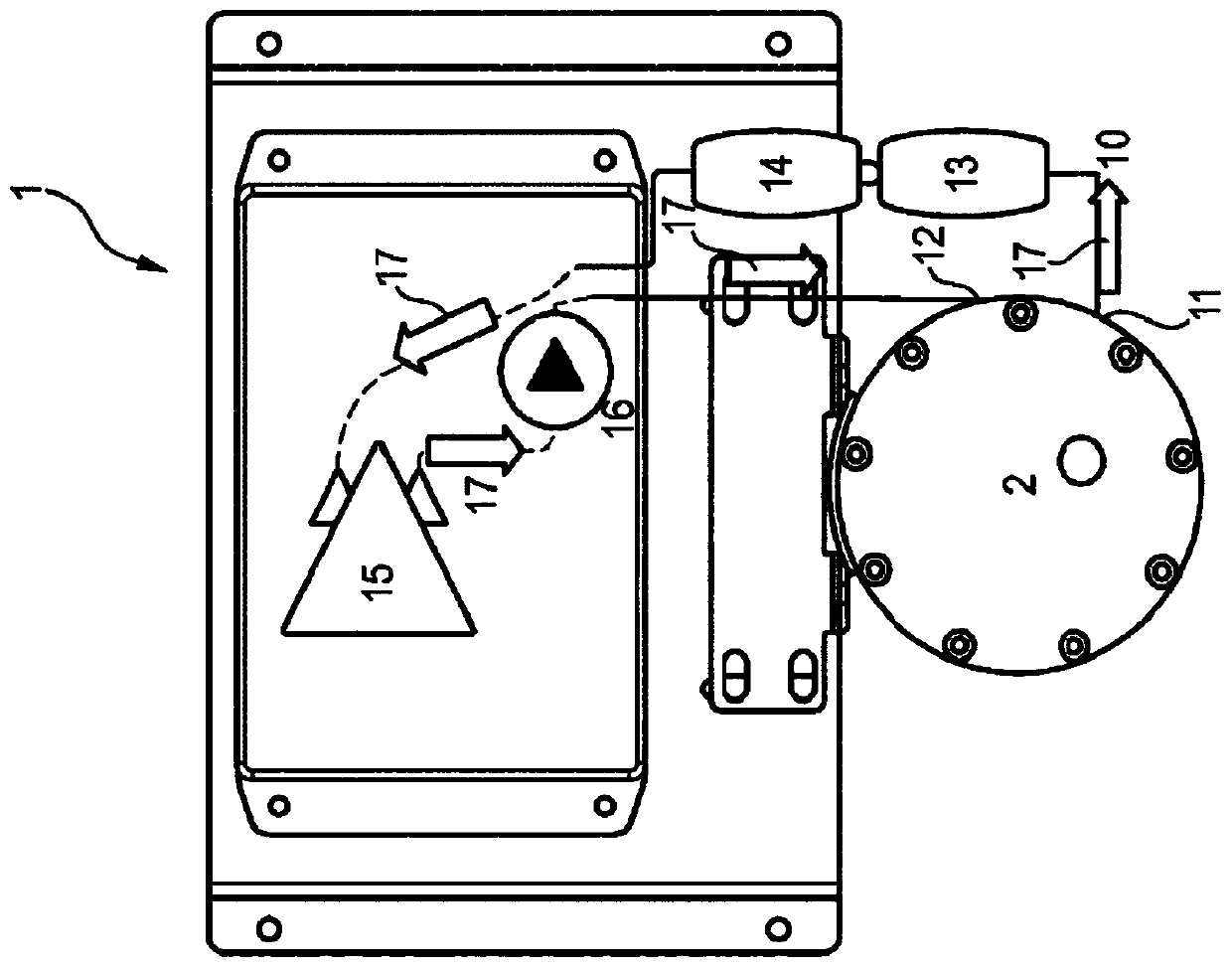

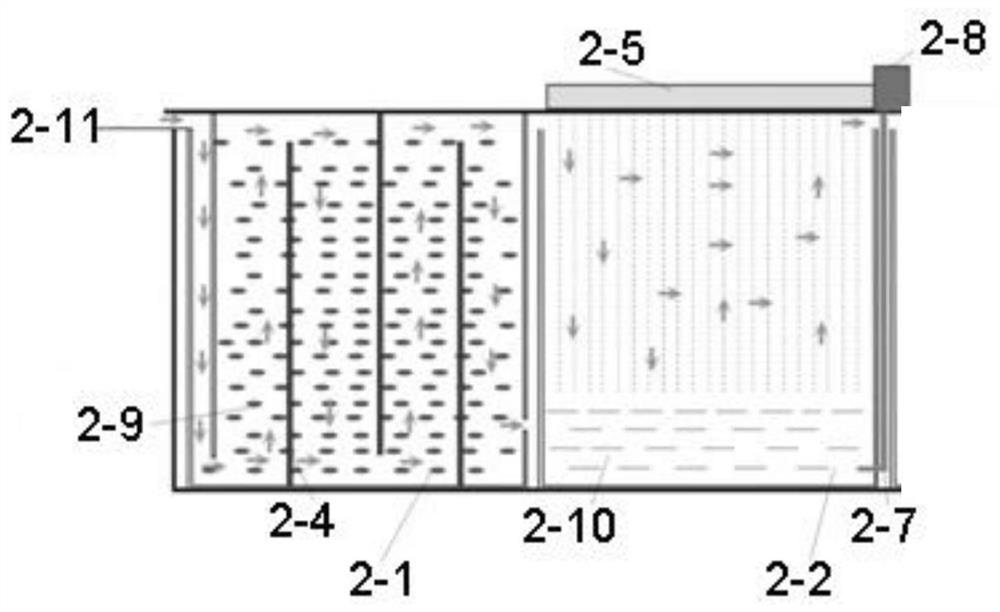

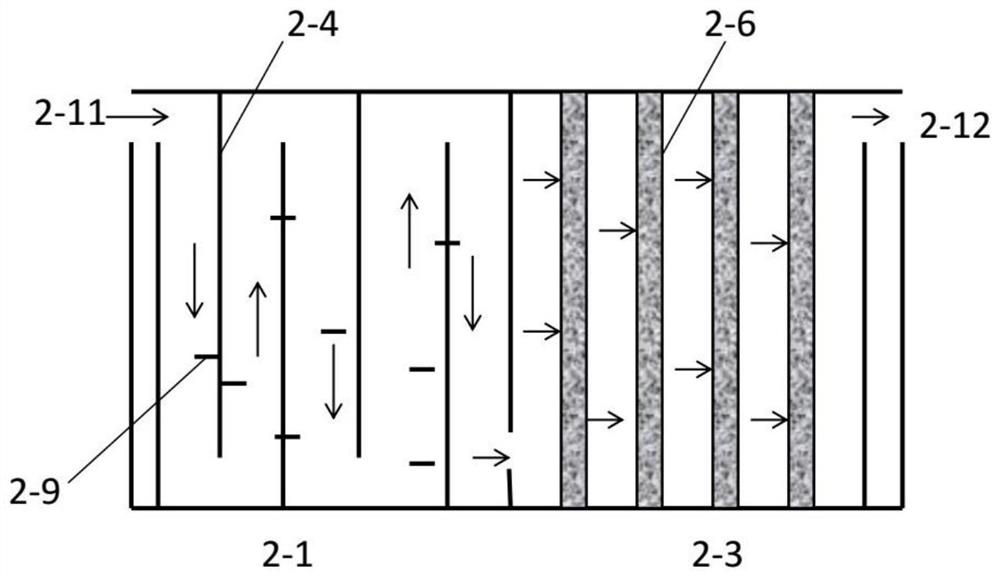

Carbon dioxide and/or hydrogen sulfide detection system and method and use thereof

PendingCN111108381AInvestigating moving fluids/granular solidsTesting waterPhysical chemistrySulfur hydride

Carbon dioxide and / or hydrogen sulfide sampling and detection system and method for determination of the content of gaseous CO2 and / or H2S in aqueous liquids, and / or for the fast and reliable detection of the free CO2 gas, HCO3- and / or total carbonate and / or H2S content in aqueous liquids. Said detection system comprises a membrane block having a liquid sample inlet port and a sample outlet port between which a sample flow path extends. Said membrane block comprises a first membrane unit having a sample flow on the first side of a first permeable membrane element and a carrier gas flow on thesecond side of the first permeable membrane element. Said membrane block further comprises a second membrane unit having a sample flow on the first side of a second permeable membrane element and a carrier gas flow on the second side of the second permeable membrane element. Said first and second membrane units are arranged in series in the liquid sample flow path. The gas flow path is a closed loop that includes gas circulation means, the second gas containing side of the first and second membrane units. The system further comprises a carbon dioxide gas sensor and / or a hydrogen sulfide detection unit, which are arranged in the closed gas circulation loop.

Owner:BLUE UNIT AS

Trace hydrogen sulfide detection reagent and preparation method thereof

InactiveCN104391080ASensitive detectionReasonable formulaMaterial analysisEthylic acidCopper sulfate

The invention relates to a trace hydrogen sulfide detection reagent and a preparation method thereof, belonging to the field of detection reagents. The trace hydrogen sulfide detection reagent is prepared from the following raw materials in parts by weight: 14-26 parts of copper sulfate pentahydrate, 10-18 parts of butyl acetate, 1-5 parts of zinc sulfate, 4-12 parts of sulfamic acid, 8-24 parts of sodium citrate, 5-12 parts of calcium sorbate, 3-12 parts of citric acid, 3-10 parts of dodecyl alcohol and 32-42 parts of water. The trace hydrogen sulfide detection reagent has a reasonable formula, is extremely sensitive to the detection of hydrogen sulfide, and can be used for detecting trace hydrogen sulfide; and the lowest detection amount of hydrogen sulfide can be 0.01mg / L, the detection time is short and the detection efficiency is high.

Owner:DONGCHEN LEADER TESTING

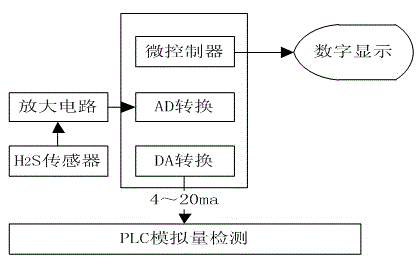

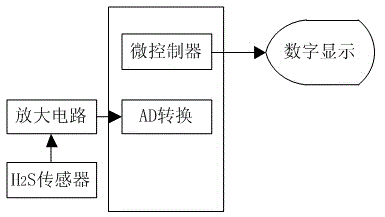

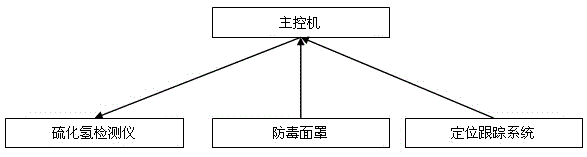

Emergency exercise simulating system applied for toxic gas leakage and simulating method thereof

ActiveCN104865871AConvenient power supplyAchieve positioningProgramme controlComputer controlToxic gasRespirator

The invention discloses an emergency exercise simulating system applied for toxic gas leakage and a simulating method thereof. The emergency exercise simulating system comprises a hydrogen sulfide detector, a respirator, a positioning and tracking system and a master control machine. The positioning and tracking system comprises a plurality of active electronic labels, a plurality of sensors, a network switch and a master control machine. The active electronic labels are arranged on emergency exercise personnel. The master control machine introduces a multidirectional map of the whole monitored area. The receiving end of each sensor receives a signal which is transmitted by the active electronic label and decodes the signal. The transmitting end of the sensor transmits the decoded data to the master control machine through the network switch. The master control machine fits the received data and generates a determination result. According to the emergency exercise simulating system, the active electronic labels are mounted on the emergency exercise personnel; after the active electronic labels are positioned through the sensors, the data are transmitted to the master control machine for fitting, thereby realizing positioning and tracking. The emergency exercise simulating system has advantages of high speed, high accuracy, simple structure, etc.

Owner:SOUTHWEST PETROLEUM UNIV +1

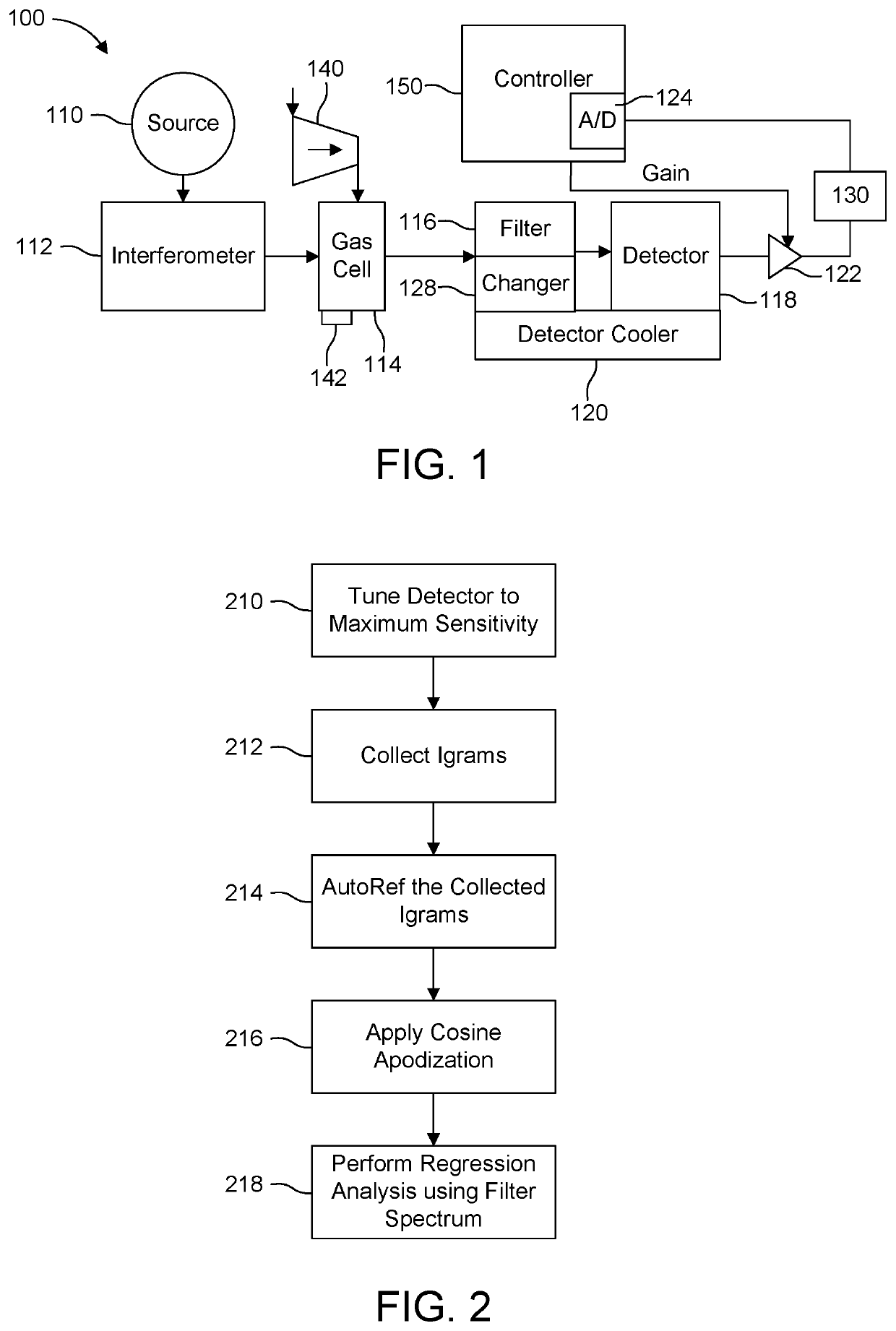

FTIR Spectrometer with cut-off filter for hydrogen sulfide detection

A gas analysis system with an FTIR spectrometer preferably utilizes a long path gas cell, a narrow band detector, and an optical filter that narrows the detection region to measure hydrogen sulfide.

Owner:MLS ACQ INC

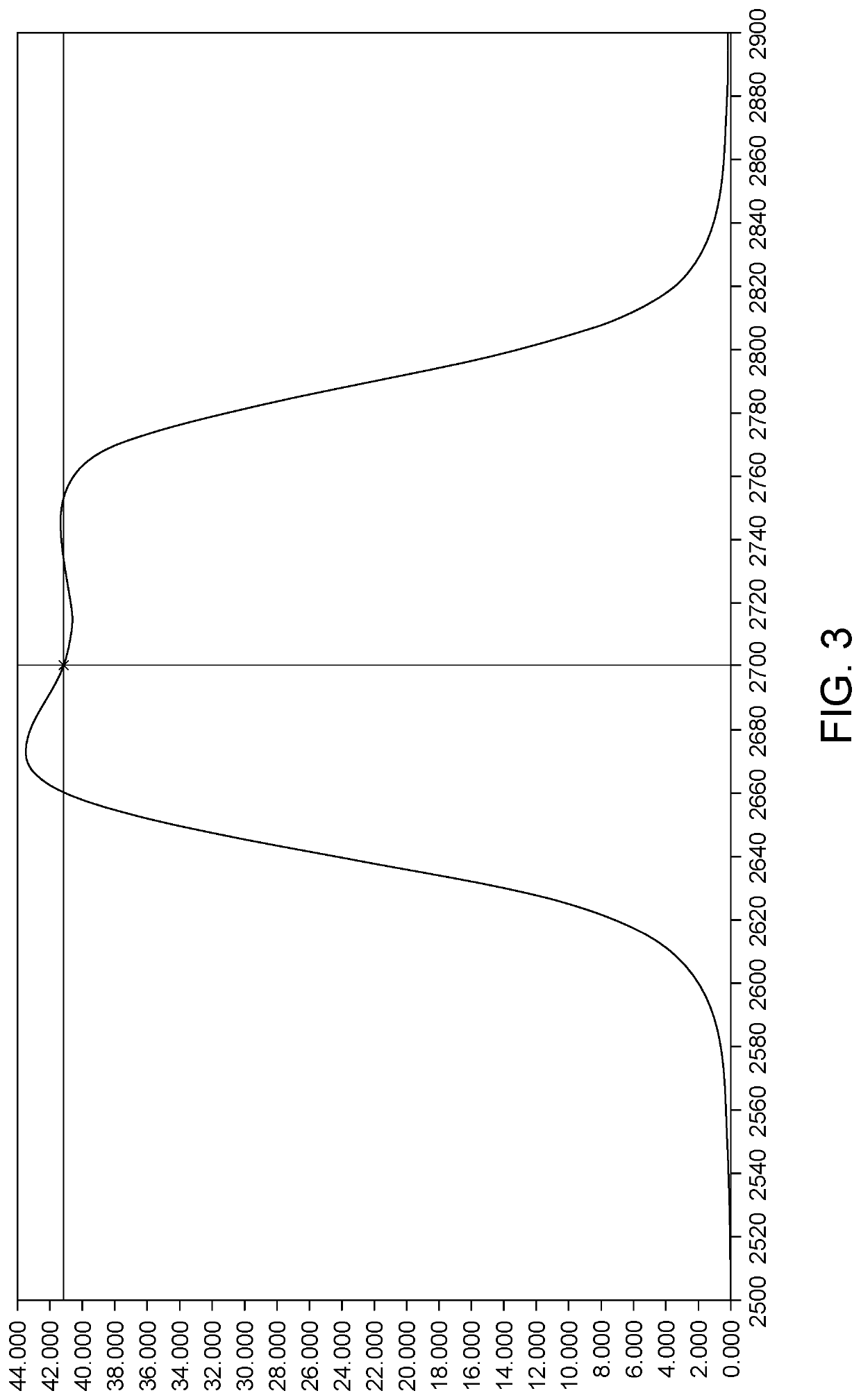

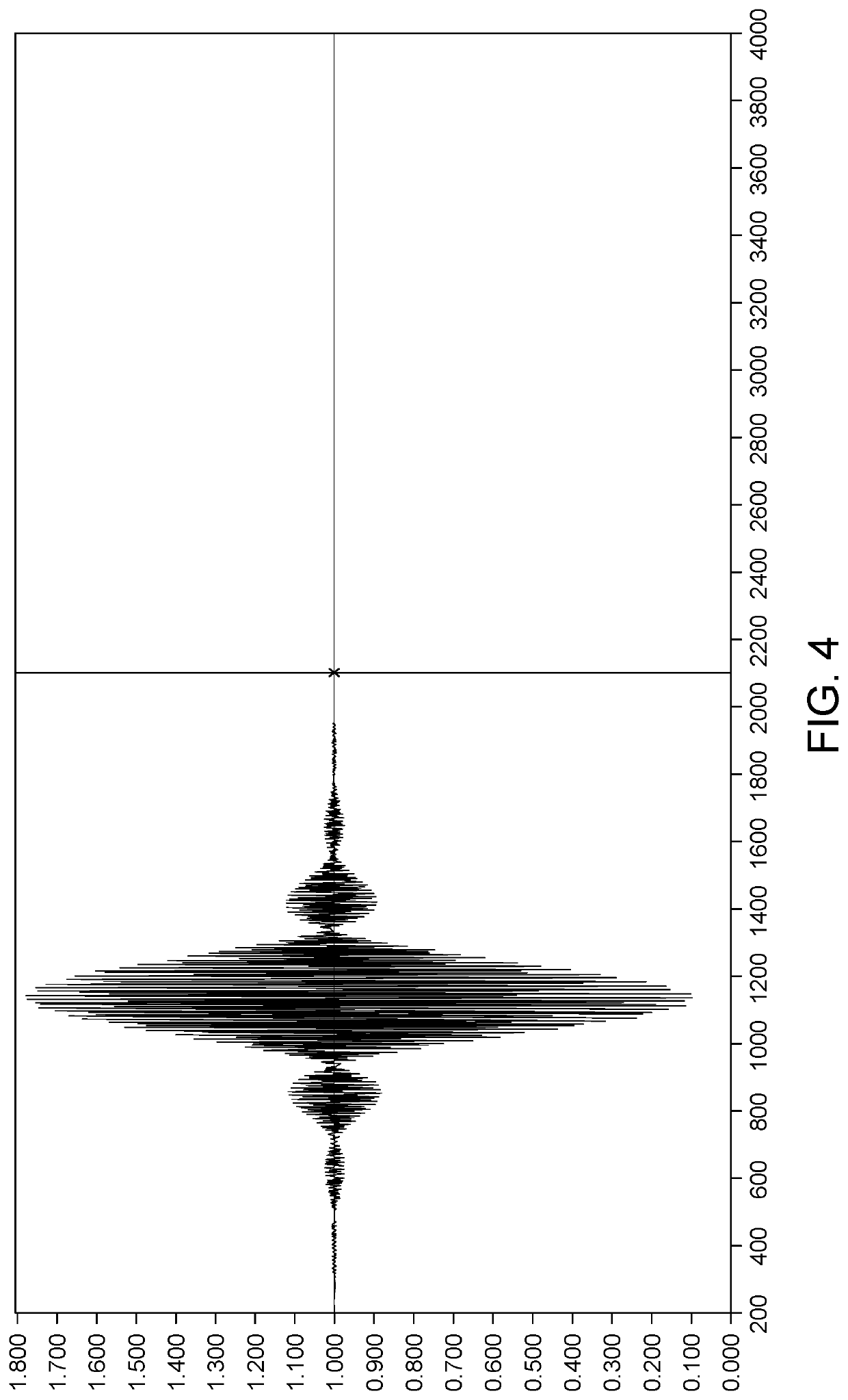

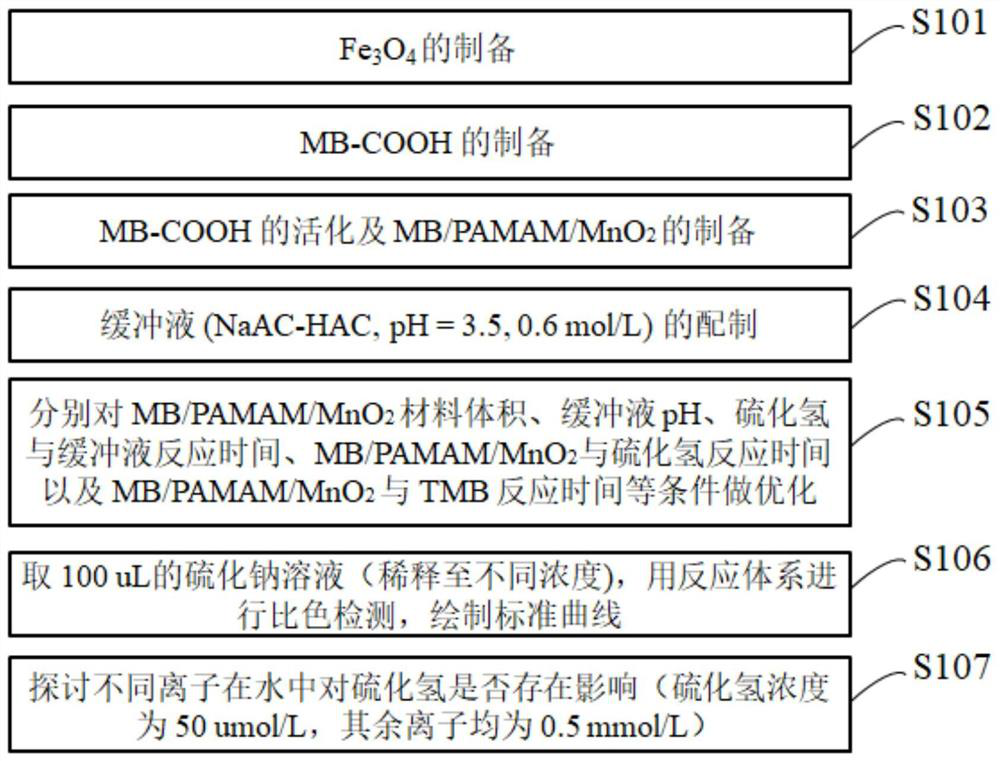

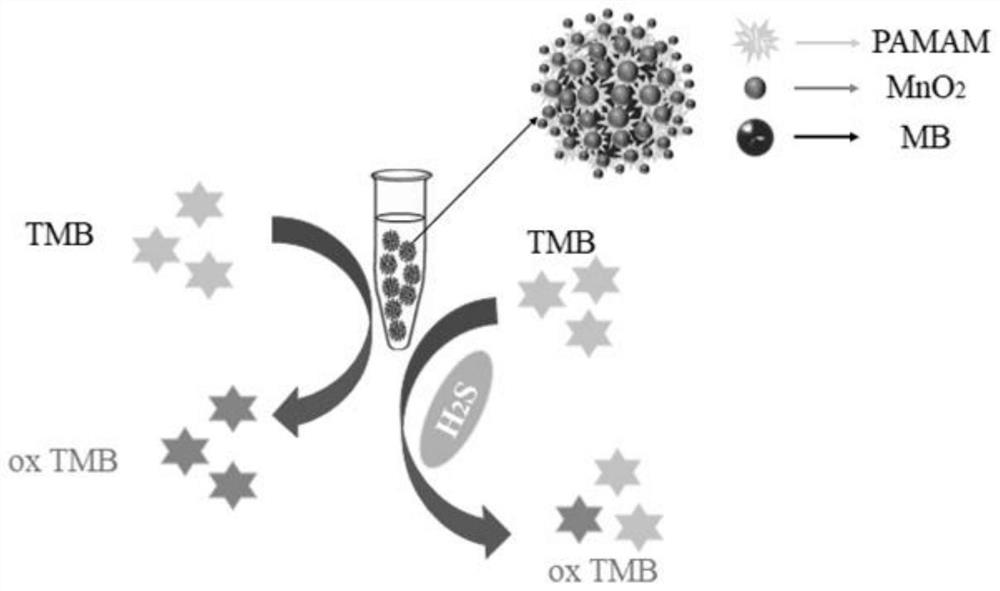

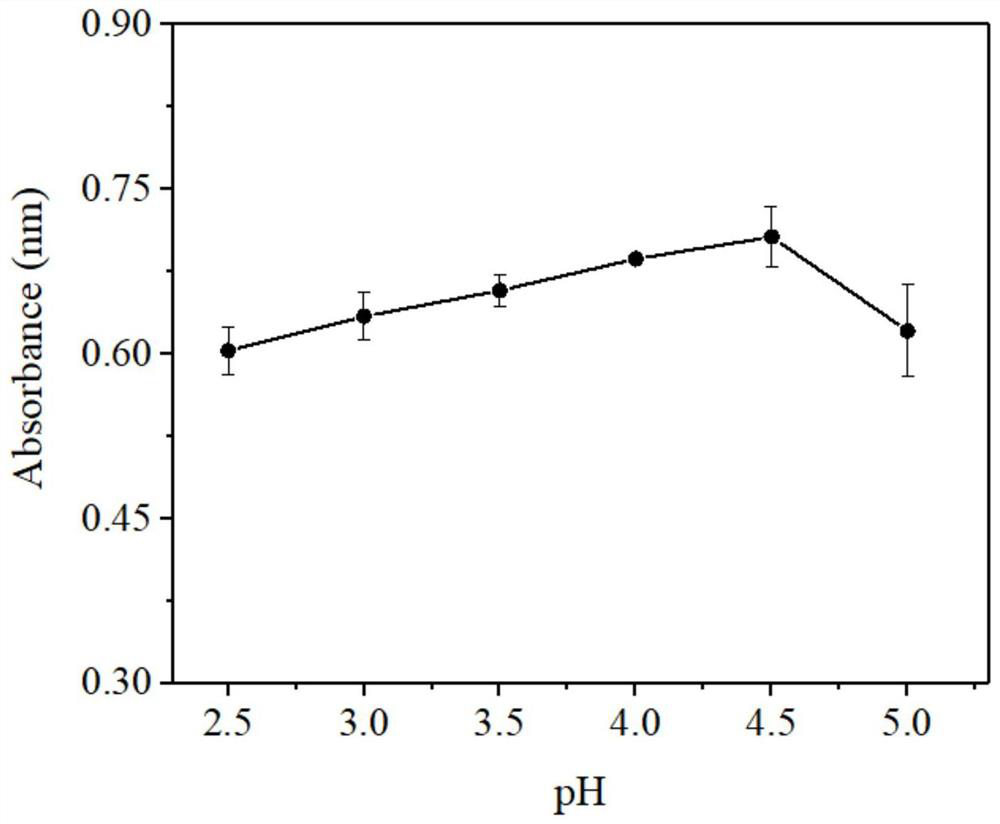

Hydrogen sulfide detection method based on colorimetric analysis and application

PendingCN112557384AHigh sensitivityAvoid the build processMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsCarboxyl radicalMagnetic bead

The invention discloses a hydrogen sulfide detection method based on colorimetric analysis and application. The method comprises the following steps: preparing ferroferric oxide; preparing magnetic bead-carboxyl; activating the magnetic bead-carboxyl to prepare an MB / PAMAM / MnO2 composite material; preparing a NaAcHAc buffer solution and TMB (tetramethylbenzidine); optimizing detection conditions;taking a sodium sulfide solution, adding a NaAc-HAc buffer solution, MB / PAMAM / MnO2 and TMB, carrying out colorimetric detection, and determining the absorbance. According to the hydrogen sulfide detection method based on colorimetric analysis and the application of the hydrogen sulfide detection method, the MB / PAMAM / MnO2 material has relatively strong catalytic performance, high sensitivity to H2Sdetection, strong universality, flexible operation, simple and convenient detection method and high economic benefit, and has important practical significance and development prospect in trace biological small molecule analysis; a simple, low-cost, rapid, high-sensitivity and stable-performance novel detection method is provided for clinical biomolecular detection.

Owner:GUIZHOU UNIV

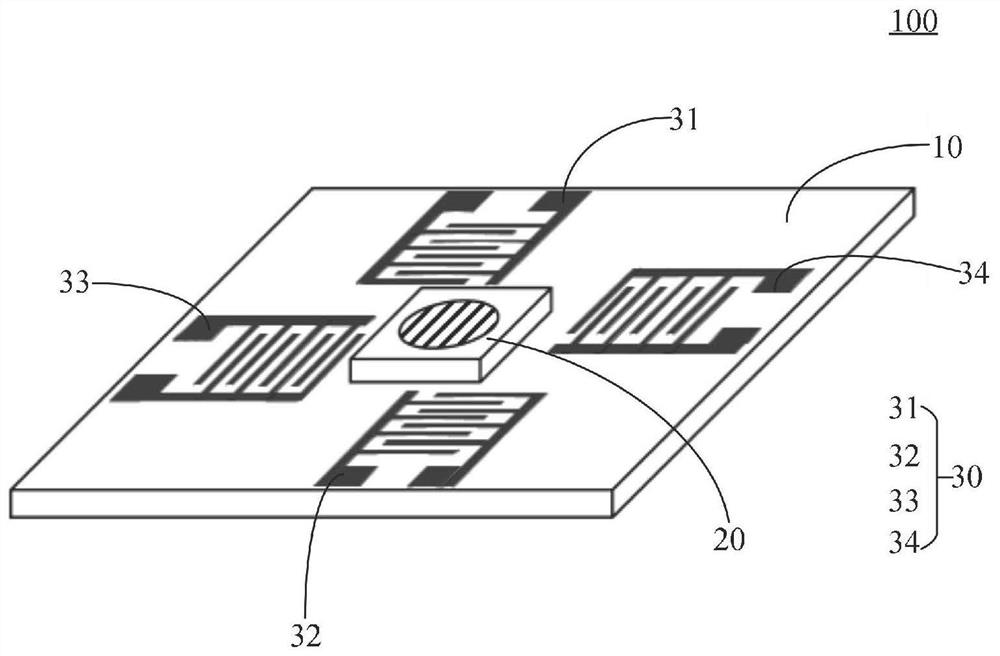

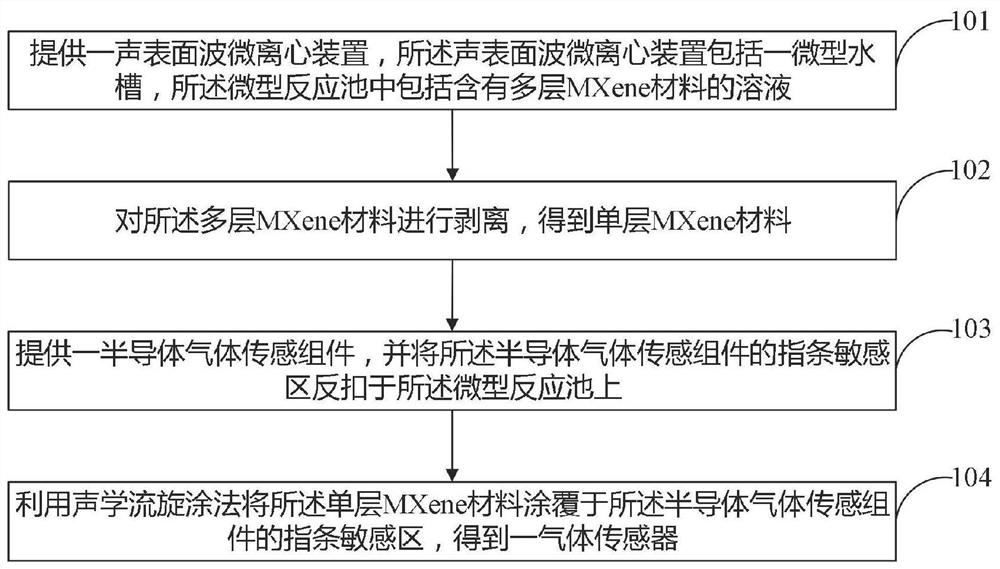

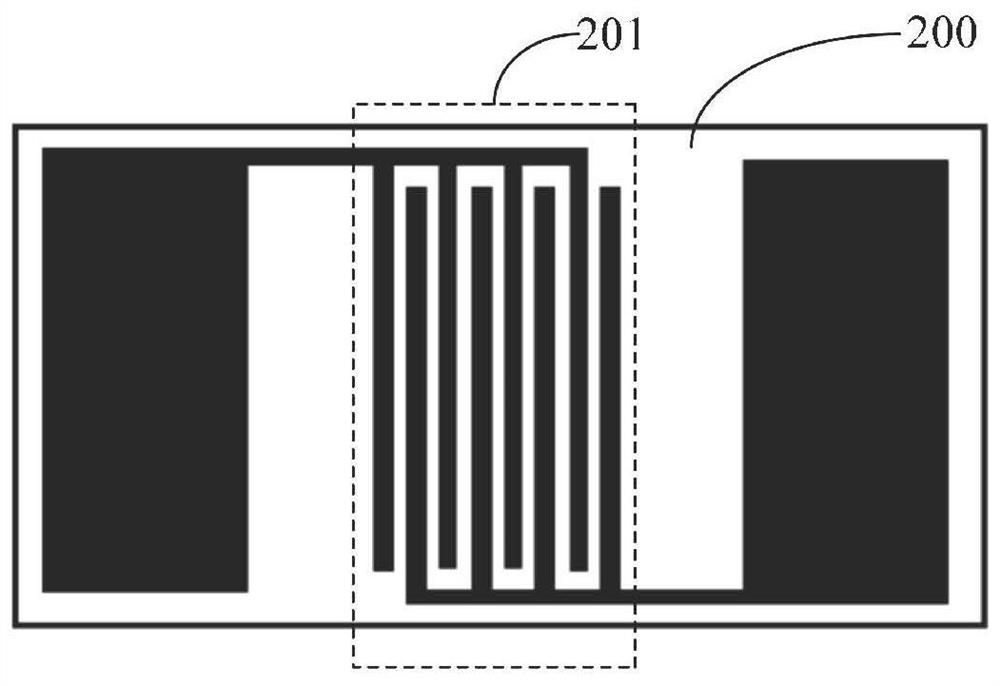

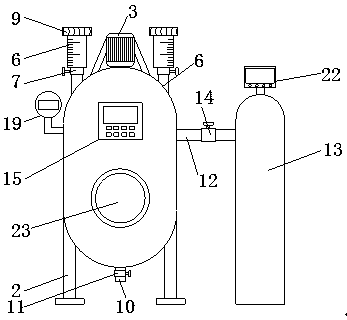

Manufacturing method of gas sensor, surface acoustic wave micro-centrifugal device and gas sensor

PendingCN113376215AHigh sensitivityLiquid surface applicatorsMaterial analysis by electric/magnetic meansEngineeringSurface acoustic wave

The embodiment of the invention discloses a manufacturing method of a gas sensor, a surface acoustic wave micro-centrifugal device and the gas sensor. The manufacturing method of the gas sensor comprises the following steps: providing a surface acoustic wave micro-centrifugal device, the surface acoustic wave micro-centrifugal device comprises a micro reaction tank, and the micro reaction tank comprises a solution containing a plurality of layers of MXene materials; stripping the multi-layer MXene material, and obtaining a single-layer MXene material; providing a semiconductor gas sensing assembly, and reversely buckling a finger strip sensitive area of the semiconductor gas sensing assembly on the micro reaction tank; and coating the single-layer MXene material on the finger strip sensitive area of the semiconductor gas sensing assembly by using an acoustic flow spin-coating method to obtain the gas sensor. The gas sensor manufactured by the scheme can effectively improve the sensitivity of hydrogen sulfide detection.

Owner:HUI YU & TECH

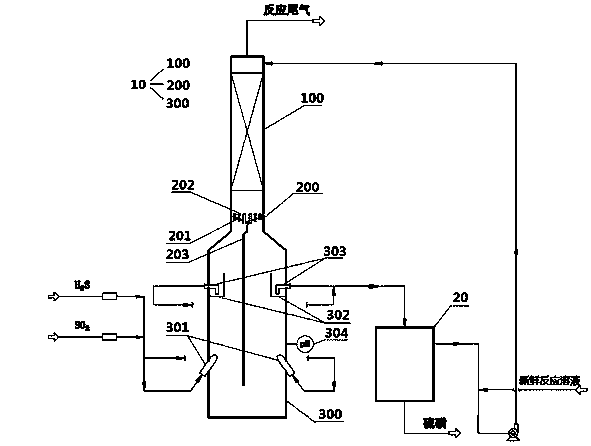

Process device and process method of liquid phase reaction desulfurization of sulfur dioxide and hydrogen sulfide

ActiveCN109529580AIncrease dissolution rateIncrease reaction rateGas treatmentDispersed particle separationReaction rateDissolution

Disclosed are a process device and a process method of liquid phase reaction desulfurization of sulfur dioxide and hydrogen sulfide. The process device includes a reactor and a separator. The reactorincludes a tail gas absorption zone, a liquid holding tank zone and a reaction zone. The liquid holding tank zone includes a separating plate, multiple gas lifting cylinders and a liquid down pipe andcommunicates with the tail gas absorption zone and the reaction zone. The lower part of the reaction zone is provided with at least two nozzles which are symmetrically distributed. The nozzles are obliquely fixed to the device wall of the reaction zone, and nozzle heads extends obliquely upward to the inside of the reaction zone. A liquid collection tank is arranged on the upper part of the reaction zone. A liquid phase extraction pipe is arranged at the bottom of the liquid collection tank and communicates the liquid collection tank and the separator. The other end of the separator is connected to the top of the tail gas absorption zone. Reaction gas is injected into the reactor through the nozzles to be violently mixing with a reaction solution in the reactor by using the process deviceof the invention, which greatly increases the dissolution rate and reaction rate of the gas in the reaction solution. The gas ejected from two symmetrical nozzles reacts in the reaction solution to generate sulfur, and the continuously injected gas pushes the reaction solution entrained with the sulfur to flow obliquely upward into the liquid collection tank. The solution in the reactor is alwaysin a flowing state so as to prevent the sulfur from depositing and scaling on the device wall and the bottom of the reactor to ensure safe, stable and long-term operation of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated process for detecting and treating toxic gas in crude oil produced by oil field

ActiveCN112710812AEnsure safetyGuaranteed production effectGas treatmentPreparing sample for investigationToxic gasOil field

The invention provides an integrated process for detecting and treating toxic gas in crude oil produced in an oil field. The integrated process comprises the following steps: carrying out gas-liquid separation on crude oil produced in an oil field; cooling and depressurizing the gas obtained by gas-liquid separation, and then drying; sequentially carrying out radon, hydrogen sulfide and mercury detection on the dried gas; if it is found that the concentrations of mercury, radon and hydrogen sulfide in the dried gas all reach the standard after detection, conveying the dried gas to a gas conveying pipeline; if it is found that the concentration of radon and hydrogen sulfide or mercury in the dried gas does not reach the standard after detection, carrying out harmless treatment on the radon and hydrogen sulfide or mercury which do not reach the standard in the gas; sequentially carrying out mercury, radon and hydrogen sulfide detection on the gas subjected to harmless treatment, and if the concentrations of mercury, radon and hydrogen sulfide in the gas all reach the standard, conveying the gas subjected to harmless treatment to a gas conveying pipeline; and if the concentration of radon and hydrogen sulfide or mercury in the gas does not reach the standard, continuously performing harmless treatment on the radon and hydrogen sulfide or mercury which do not reach the standard in the gas until the concentration reaches the standard.

Owner:PETROCHINA CO LTD

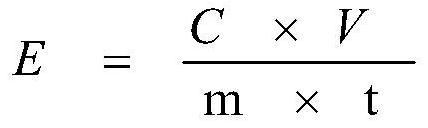

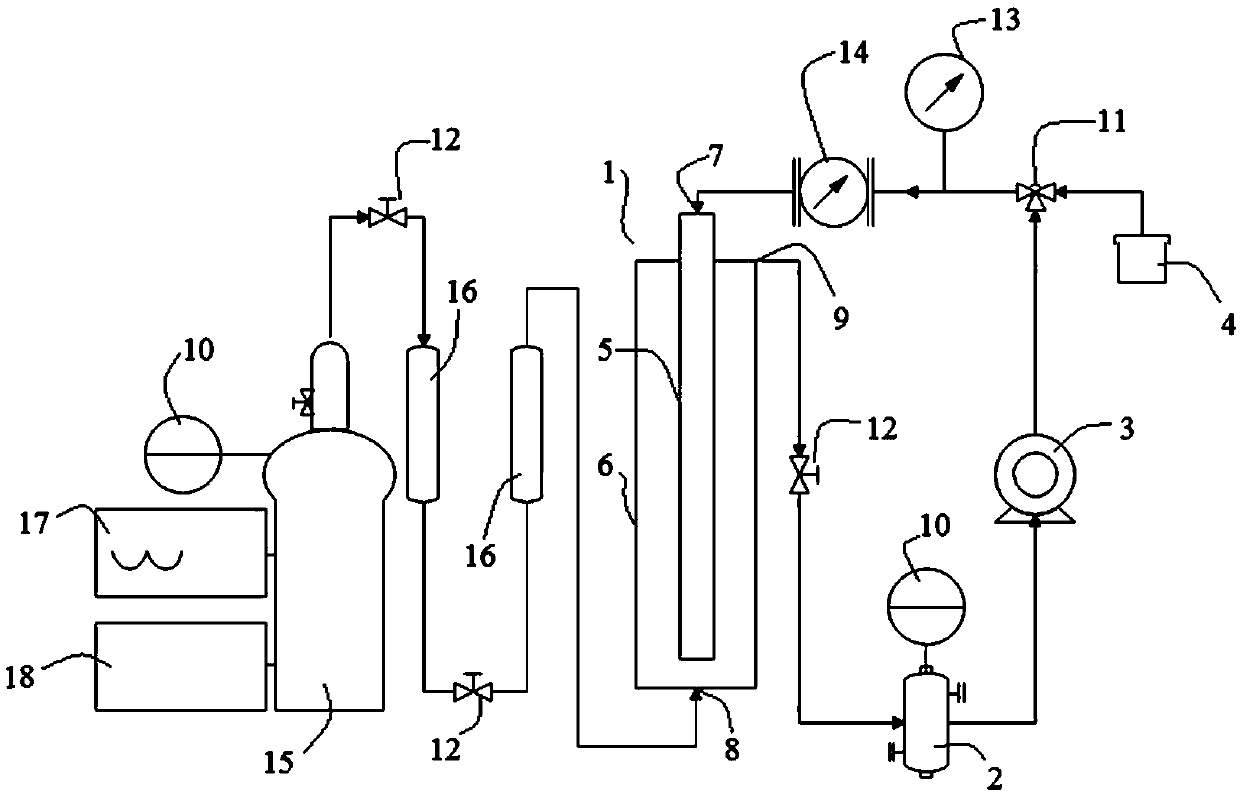

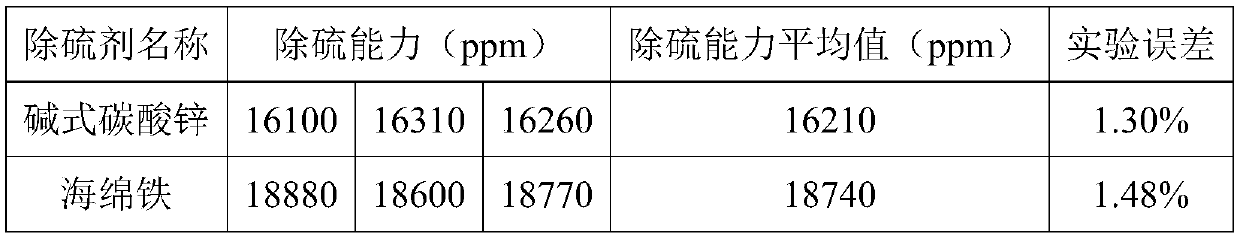

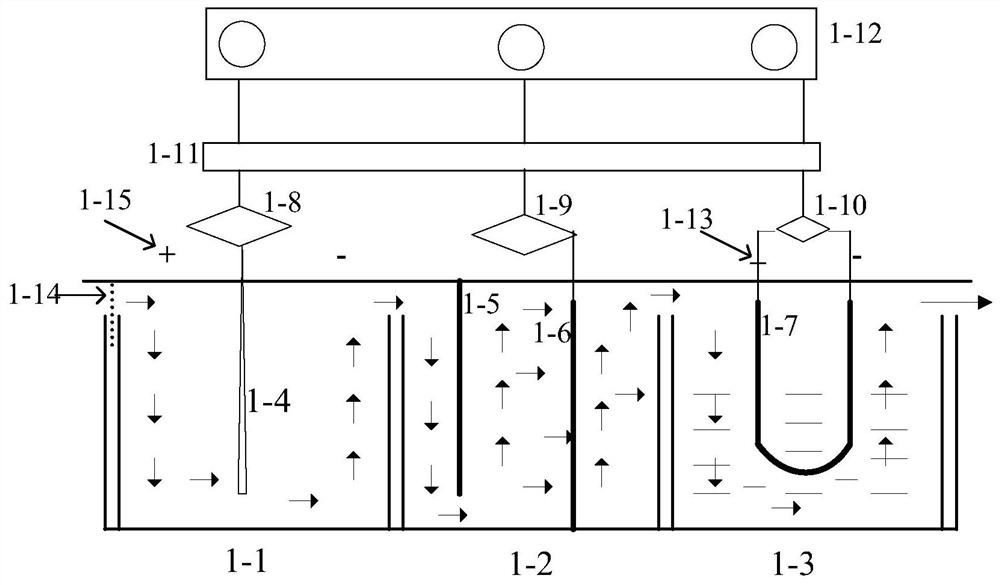

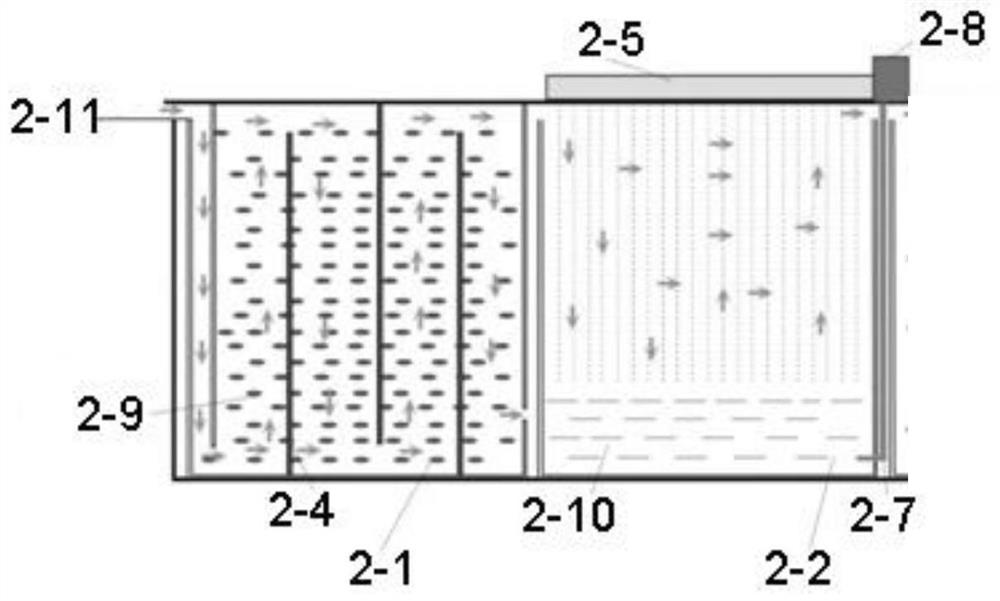

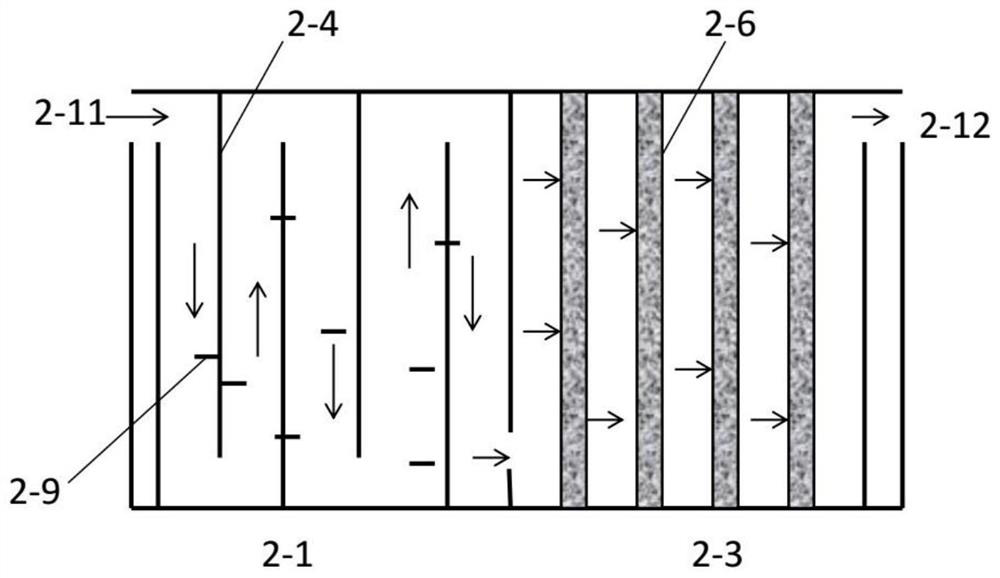

Device and method for evaluating desulfurizing effect of desulfurizing agent

PendingCN111089940AImprove reliabilityAchieving Dynamic Loop ContactMaterial analysisGas compositionProcess engineering

The invention relates to a device and method for evaluating desulfurizing effect of a desulfurizing agent. The evaluation method includes the following steps of: adding a certain amount of working liquid and hydrogen sulfide test gas to a closed circulation circuit to ensure that the working liquid and the hydrogen sulfide test gas circulate in the circulation circuit to form a gas-liquid mixed fluid, detecting the concentration of hydrogen sulfide gas in the gas component of the gas-liquid mixed fluid, and recording the concentration as the hydrogen sulfide concentration M1 before desulfurization; and then, adding a desulfurizing agent to the circulation circuit, forming a gas-liquid mixed fluid containing the desulfurizing agent after circulation flow, detecting the concentration of thehydrogen sulfide gas in the gas component of the gas-liquid mixed fluid containing the desulfurizing agent, recording the concentration as the hydrogen sulfide concentration M2 after desulfurization,and evaluating the desulfurizing effect of the desulfurizing agent based on M1 and M2. According to the method for evaluating the desulfurizing effect of the desulfurizing agent provided by the invention, the test result is closer to the true value, the evaluation result is reliable, and the measurement accuracy is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated system and process for detecting and treating toxic gas in oil field drilled rock core

ActiveCN112710807AEnsure safetyEnsure productivityGas treatmentWithdrawing sample devicesRadonIntegrated systems

The invention provides an integrated system and process for detecting and treating toxic gas in a drilled core of an oil field. The process comprises steps of carrying out wax sealing of the core taken out from a shaft, placing the wax-sealed core in a vacuum container, and collecting the gas escaping from the core through a vacuum gas collection tank; sequentially carrying out radon, hydrogen sulfide and mercury detection on the gas in the rock core; if it is found that the concentrations of mercury, radon and hydrogen sulfide in the gas all reach the standard after detection, the gas being conveyed to a gas conveying pipeline; if it is found that the concentration of radon and hydrogen sulfide or mercury in the gas does not reach the standard after detection, harmless treatment being conducted on the radon and hydrogen sulfide or mercury which do not reach the standard in the gas; mercury, radon and hydrogen sulfide detection being sequentially carried out on the gas subjected to harmless treatment, and if the concentrations of mercury, radon and hydrogen sulfide in the gas all reach the standard, the gas subjected to harmless treatment being conveyed to a gas conveying pipeline; and if the concentration of radon and hydrogen sulfide or mercury in the gas does not reach the standard, continuously performing harmless treatment on the radon and hydrogen sulfide or mercury which do not reach the standard in the gas till the concentration reaches the standard.

Owner:PETROCHINA CO LTD

Reaction kettle mechanism with function of quickly calculating theoretical replenishing quantity of hydrogenated vulcanizing agent

InactiveCN109351312AReduce consumptionReduce work intensityProcess control/regulationChemical/physical/physico-chemical stationary reactorsControl engineeringElectric control

The invention discloses a reaction kettle mechanism with a function of quickly calculating theoretical replenishing quantity of a hydrogenated vulcanizing agent. The reaction kettle mechanism comprises a kettle body, supporting legs are fixedly connected to four bottom corners of the kettle body, a motor is fixedly connected to the top of the kettle body, the bottom of a rotating shaft of the motor penetrates an inner cavity of the kettle body to fixedly connect with a vertical rod, and stirring blades are fixedly connected to two sides of the vertical rods respectively. By cooperation of thekettle body, the supporting legs, the motor, the vertical rod, the stirring blades, vertical pipes, first manual valves, measuring cups, seal covers, a liquid outlet pipe, a second manual valve, a transverse pipe, a high-pressure vulcanizing agent tank, a flow valve and an electric control box, the additive content can be measured in advance to achieve an accurate content value, the added hydrogencatalyst content can be detected, corresponding values can be added, an optimal reaction proportion is calculated, in-process control test frequency in a practical production process can be reduced,work intensity of personnel is relieved, and consumption of hydrogen sulfide test kits is reduced.

Owner:刘帅

Hydrogen sulphide detecting reagent and preparation method thereof

InactiveCN104459042AReduced stabilityDifficult to controlMaterial analysisIron sulfatePolyvinyl alcohol

The invention discloses a hydrogen sulphide detecting reagent and a preparation method thereof, and belongs to the field of gas detecting technologies. The detecting reagent comprises the following components in parts by weight: 5-15 parts of polyvinyl alcohol ammonium phosphate, 2-6 parts of zinc sulfate, 3-7 parts of ferric trichloride, 5-12 parts of potassium iodate, 4-8 parts of sodium thiosulfate, 1-3 parts of calcium phosphate, 1-3 parts of iron sulfate, 3-8 parts of ethyl alcohol and 5-15 parts of water. The preparation method of the hydrogen sulphide detecting reagent comprises the following steps: dissolving, heating in a water bath and determining volumes. The hydrogen sulphide detecting reagent provided by the invention has the characteristics of high sensitivity and high stability, besides, the measuring result is more accurate, and the reagent can be used for detecting hydrogen sulphide in air.

Owner:DONGCHEN LEADER TESTING

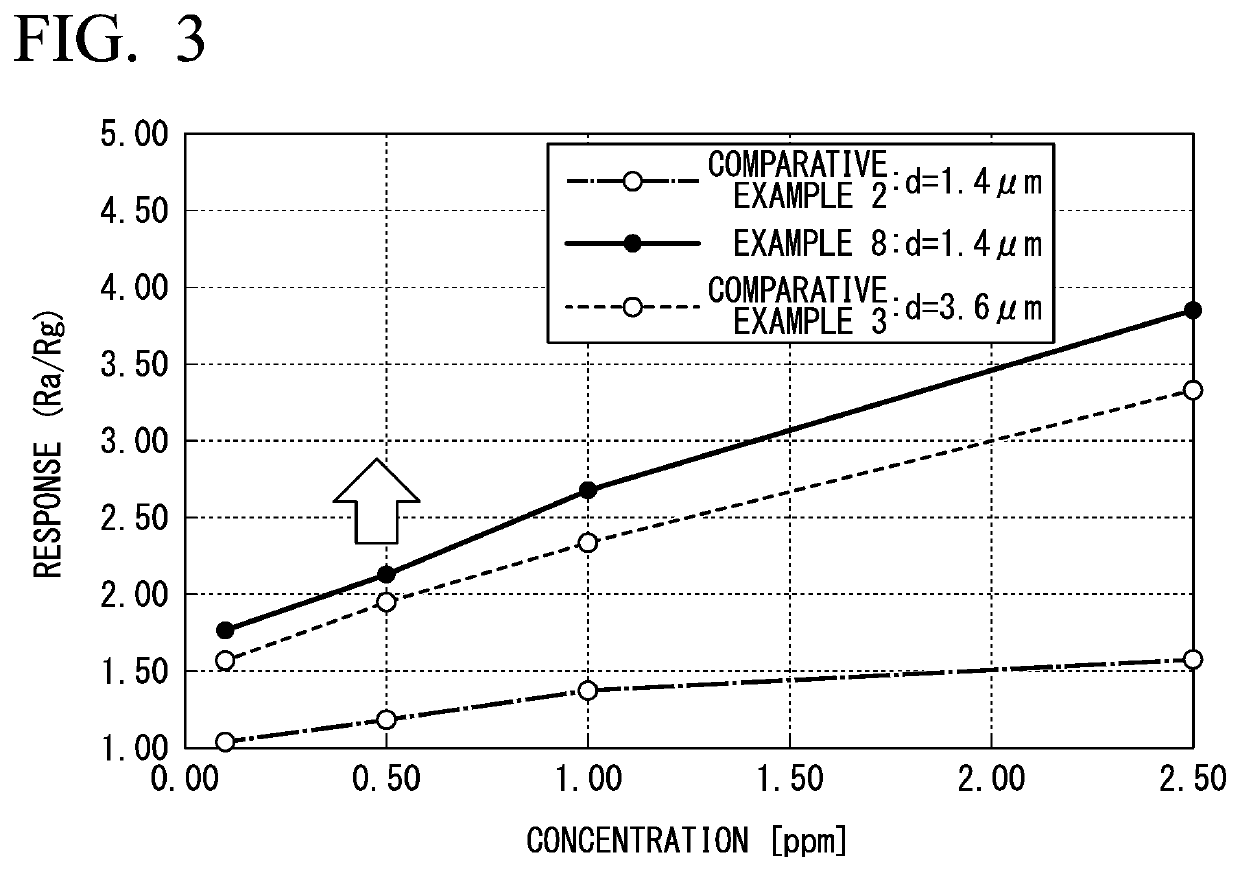

Sensing material for detecting hydrogen sulfide, hydrogen sulfide-sensitive layer, and metal oxide semiconductor-type gas sensor

A sensing material for detecting hydrogen sulfide capable of detecting hydrogen sulfide even having a low concentration, a hydrogen sulfide-sensitive layer containing the sensing material for detecting hydrogen sulfide, and a metal oxide semiconductor-type gas sensor having the hydrogen sulfide-sensitive layer are provided. The sensing material for detecting hydrogen sulfide includes CuFe2O4-type complex oxide (W). The CuFe2O4-type complex oxide (W) contains, as a main component (W1), 35.0 to 49.5 mol % of iron oxide in terms of Fe2O3 and 50.5 to 65 mol % of copper oxide in terms of CuO, and an average particle diameter of particles is 3 μm or less.

Owner:TDK CORPARATION

Monitoring intelligent fireproof door

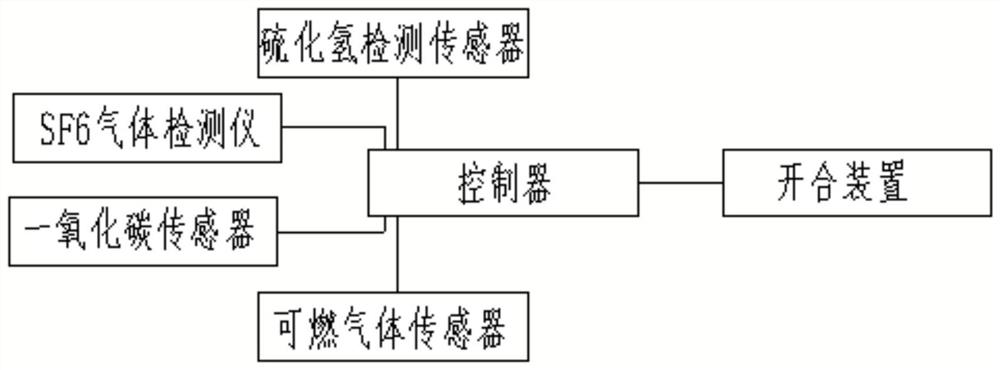

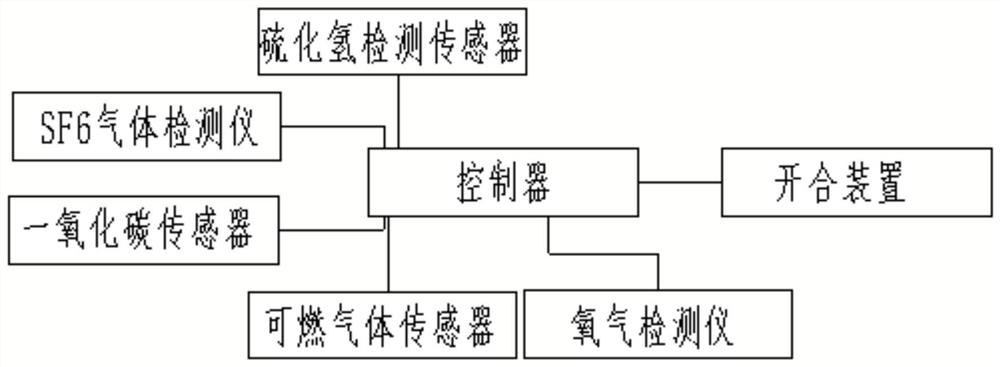

PendingCN114876333AProtect your health and safetyGuarantee personal safetyFireproof doorsGas-insulated enclosed substationsGas detectorCombustible gas

The invention relates to an intelligent fireproof door with a monitoring function. The intelligent fireproof door comprises a fireproof door body, an SF6 gas detector, a hydrogen sulfide detection sensor, a carbon monoxide sensor and a combustible gas sensor, wherein the fireproof door body is arranged on a monitoring area and used for sealing the monitoring area, and the SF6 gas detector, the hydrogen sulfide detection sensor, the carbon monoxide sensor and the combustible gas sensor are arranged on the fireproof door body. An opening and closing device used for controlling the fireproof door body to be opened or closed is arranged on the fireproof door body, and the opening and closing device is electrically connected with the SF6 gas detector and the sensor. When any one of SF6 gas, hydrogen sulfide, carbon monoxide, combustible gas, oxygen content, temperature and humidity in the monitoring area is unqualified, the controller controls the opening and closing device to be closed, the fan is started to exhaust air, and meanwhile the controller starts the audible and visual alarm to give an alarm. When a certain content in the equipment room is detected to be unqualified, the fireproof door is automatically locked, field operation personnel cannot enter the equipment room, and accidents are prevented.

Owner:国网河北省电力有限公司雄安新区供电公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com