Desulfurization catalyst activity evaluation device and method

A desulfurization catalyst and evaluation device technology, which is applied in the purification of impurities catalytic conversion gas, chemical analysis by catalytic action, and combustible gas purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

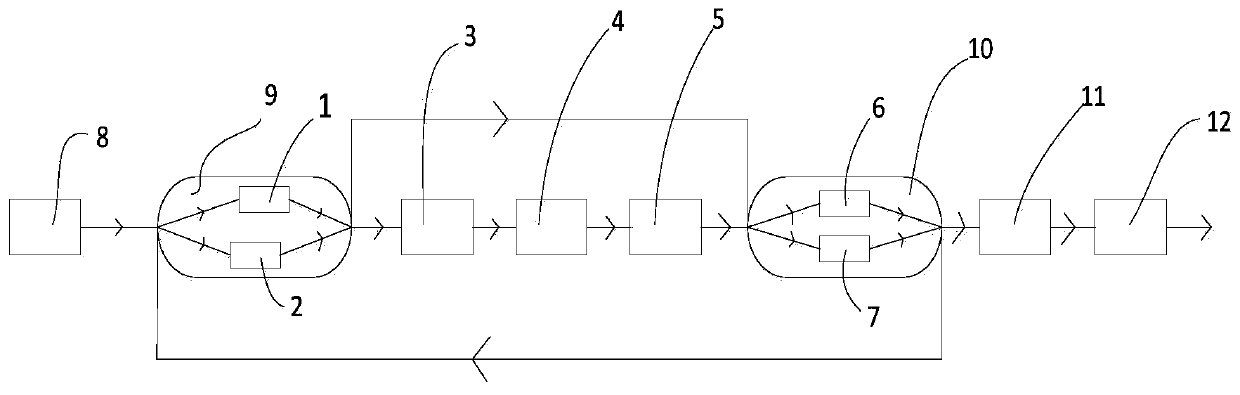

[0038] Such as figure 1 As shown, the present invention provides an activity evaluation device for a desulfurization catalyst, including a gas supply unit 8, and also includes,

[0039] The reaction unit includes a deoxygenation unit 9, a hydrolysis unit and an adsorption unit 10 connected in sequence;

[0040] The detection unit includes an oxygen detection unit, an organic sulfur detection unit and a hydrogen sulfide detection unit, the oxygen detection unit is arranged between the deoxidation unit 9 and the hydrolysis unit, and the organic sulfur detection unit is arranged between the hydrolysis unit and the adsorption unit. Between the units 10 , the hydrogen sulfide detection unit is connected to the gas outlet of the adsorption unit 10 , and the gas supply unit 8 is connected to the gas inlet of the deoxidation unit 9 .

[0041] The present invention passes the simulated blast furnace gas through the deoxidation unit 9 through the gas supply unit 8 to remove the oxygen ...

Embodiment 2

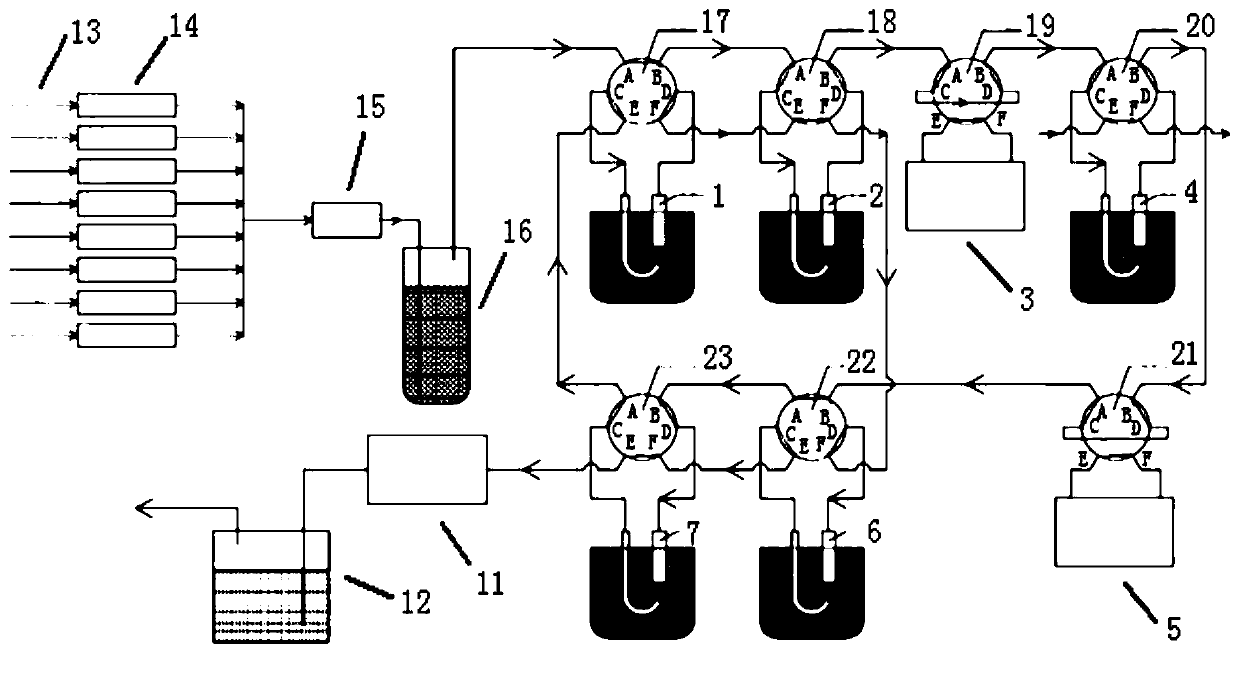

[0061] Such as figure 2 As shown, the present embodiment provides a method for evaluating the activity of a desulfurization catalyst, comprising the following steps:

[0062] 1) Catalyst loading: fill the deactivated deoxidizer in the first deoxidizer 1 (the deactivated deoxidizer is a deactivated honeycomb ceramic carrier supporting ruthenium metal deoxidizer), and fill the deoxidizer in the second deoxidizer 2 (The deoxidizer is a honeycomb ceramic carrier loaded ruthenium metal deoxidizer), and the organic sulfur hydrolyzing agent is filled in the hydrolysis device 4 (the organic sulfur hydrolyzing agent is Na 2 CO 3 / Al 2 o 3 hydrolysis agent), the deactivated hydrogen sulfide adsorbent is filled in the first adsorption device 6 (the deactivated hydrogen sulfide adsorbent is deactivated Fe 2 o 3 / Al 2 o 3 -C 3 N 4 Adsorbent), the second adsorption device 7 is filled with hydrogen sulfide adsorbent (the hydrogen sulfide adsorbent is Fe 2 o 3 / Al 2 o 3 -C 3 N ...

Embodiment 3

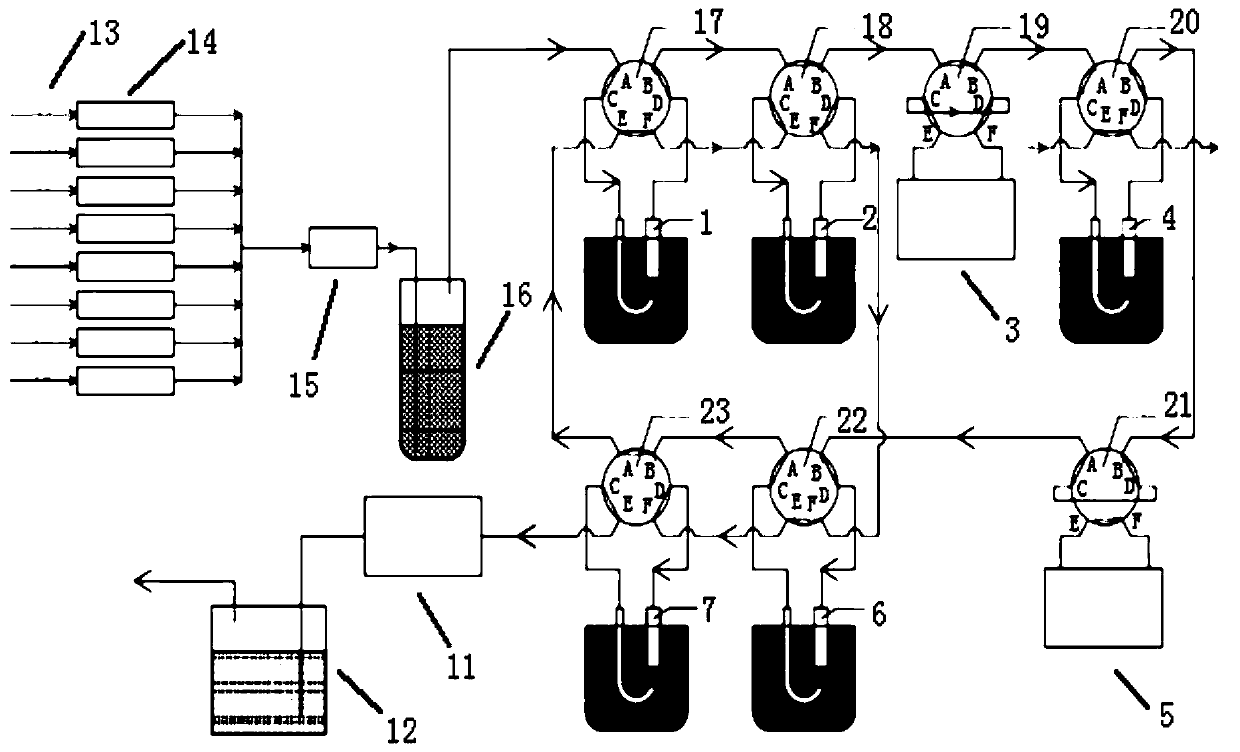

[0067] Such as image 3 As shown, the present embodiment provides a method for evaluating the activity of a desulfurization catalyst, comprising the following steps:

[0068] 1) Loading catalyst: fill the deoxidizer in the first deoxidizer 1 (the deoxidizer is a honeycomb ceramic carrier supporting ruthenium metal deoxidizer), and fill the deactivated deoxidizer in the second deoxidizer 2 (the deactivated deoxidizer The deoxidizer is an inactivated honeycomb ceramic carrier loaded ruthenium metal deoxidizer), and the hydrolysis device 4 is filled with an organic sulfur hydrolyzer (the organic sulfur hydrolyzer is Na 2 CO 3 / Al 2 o 3 Hydrolyzing agent), hydrogen sulfide sorbent is filled in the first adsorption device 6 (the hydrogen sulfide sorbent is Fe 2 o 3 / Al 2 o 3 -C 3 N 4 adsorbent), the second adsorption device 7 is filled with deactivated hydrogen sulfide adsorbent (the deactivated hydrogen sulfide adsorbent is deactivated Fe 2 o 3 / Al 2 o 3 -C 3 N 4 Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com