A Test Structure for AC Hot Carrier Injection Characteristics of Transistors

A technology for testing structures and hot carriers, applied in the testing of single semiconductor devices, electrical solid state devices, semiconductor devices, etc., can solve the problem of not achieving the evaluation effect, difficult to control the synchronization of two signals, and not achieving the best evaluation effect and other issues to achieve the effect of saving evaluation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

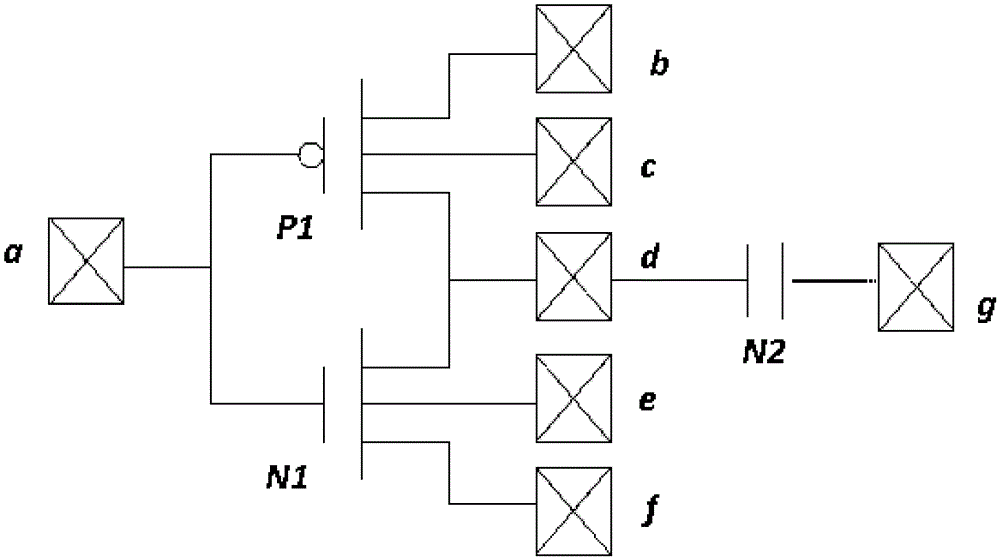

[0012] Such as figure 1 As shown, the test structure of the AC hot carrier injection characteristics of the transistor of the present invention includes: PMOSP1, NMOSN1, and a test capacitor N2;

[0013] The gates of P1 and N1 are connected as the test pin a of this test structure; the source of P1 is used as the test pin b of this test structure; the substrate electrode of P1 is used as the test pin c of this test structure; The drain is connected as the test pin d of this test structure; the substrate electrode of N1 is used as the test pin e of this test structure; the source of N1 is used as the test pin f of this test structure; one end of the test capacitor N2 is connected to the test lead Pin d, the other end is grounded as the test pin g of this test structure;

[0014] The charging time of the test load is consistent with the cycle of the AC signal changing from low potential to high potential, its discharge time is consistent with the cycle of AC signal changing fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com