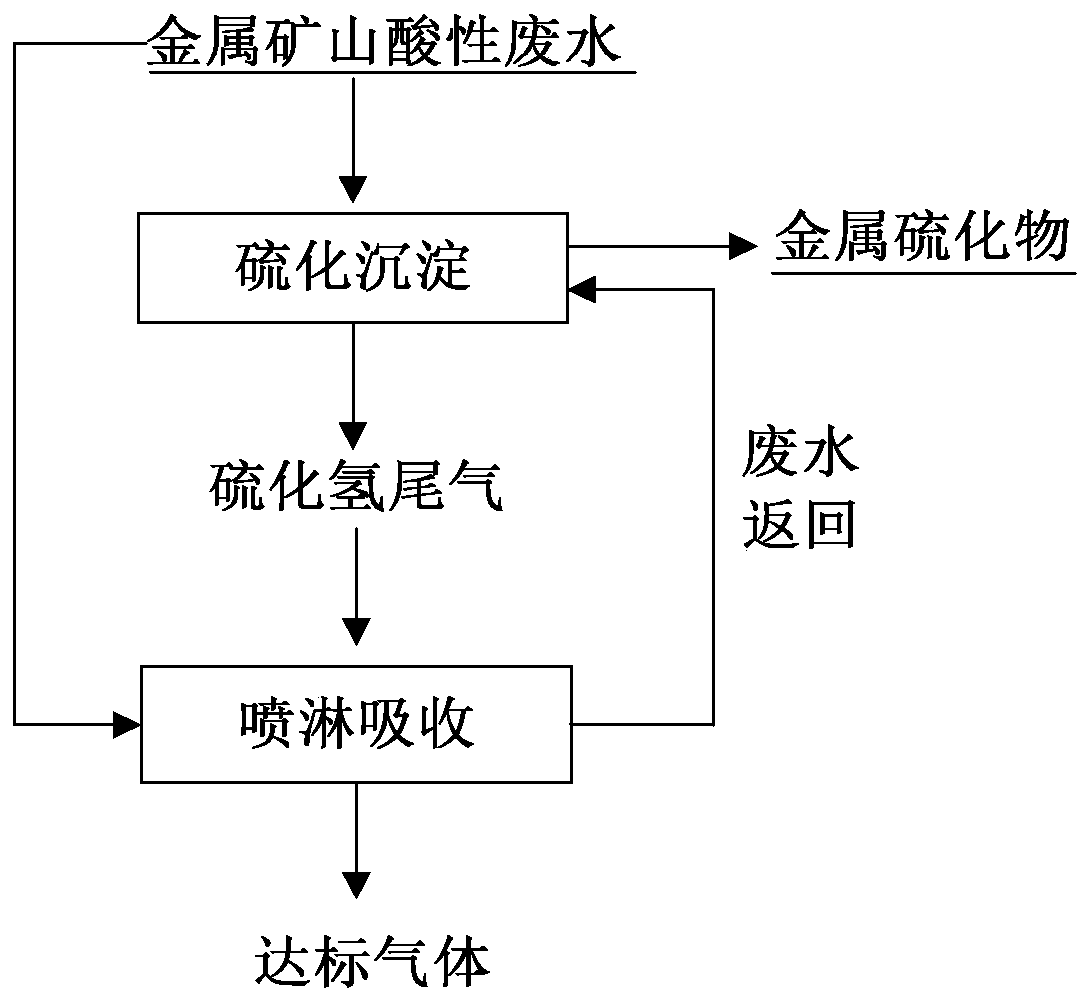

Method for absorbing hydrogen sulfide tail gas in sulfide precipitation system

A technology of sulfide precipitation and hydrogen sulfide, which is applied in chemical instruments and methods, separation methods, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high environmental protection costs, many manpower for alkali preparation, and large alkali consumption, and achieve treatment Low cost, remarkable absorption effect, simple and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

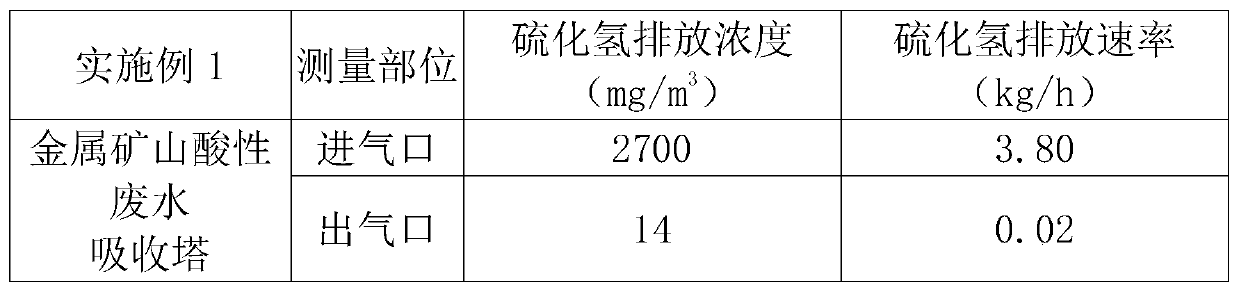

Embodiment 1

[0026] Example 1: The daily treatment capacity of acidic wastewater from metal mines in a mine sulfide precipitation environmental protection treatment system is 30,000m 3 , The water quality of wastewater: pH=2.5, Cu=500mg / L, Fe=6g / L, the system prepares sodium sulfide solution to recover valuable metal copper in wastewater. Sodium sulfide preparation barrels, copper sinking reaction tanks, copper sulfide flocculation tanks, copper sulfide dense tanks, and copper sulfide filter press workshops that generate hydrogen sulfide gas are all made in a closed type, and the induced draft fan connects the collected hydrogen sulfide gas to the Gas absorption tower. The hydrogen sulfide concentration at the inlet of the gas absorption tower is 2700mg / m 3 , the emission rate is 3.80kg / h, and after the acid wastewater spraying and absorption of the third-level metal mine, the concentration of hydrogen sulfide at the exhaust port of the gas absorption tower (height: 15m) is reduced to 14m...

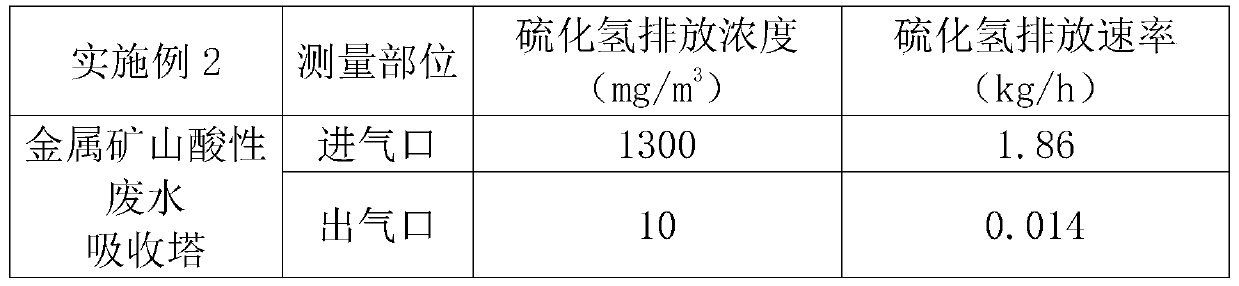

Embodiment 2

[0029] Example 2: The daily treatment capacity of acidic wastewater from metal mines in a mine sulfide precipitation environmental protection treatment system is 30,000m 3 , The water quality of wastewater: pH=2.5, Cu=500mg / L, Fe=6g / L, the system prepares sodium sulfide solution to recover valuable metal copper in wastewater. Sodium sulfide preparation barrels, copper sinking reaction tanks, copper sulfide flocculation tanks, copper sulfide dense tanks, and copper sulfide filter press workshops that generate hydrogen sulfide gas are all made in a closed type, and the induced draft fan connects the collected hydrogen sulfide gas to the Gas absorption tower. The hydrogen sulfide concentration at the inlet of the gas absorption tower is 1300mg / m 3 , the discharge rate is 1.86kg / h, and after the acid wastewater spraying and absorption of the third-level metal mine, the concentration of hydrogen sulfide at the exhaust port of the gas absorption tower (height: 15m) is reduced to 10...

Embodiment 3

[0032] Example 3: The daily treatment capacity of acidic wastewater from metal mines in a mine sulfide precipitation environmental protection treatment system is 30,000m 3 , The water quality of wastewater: pH=2.5, Cu=500mg / L, Fe=6g / L, the system prepares sodium sulfide solution to recover valuable metal copper in wastewater. Sodium sulfide preparation barrels, copper sinking reaction tanks, copper sulfide flocculation tanks, copper sulfide dense tanks, and copper sulfide filter press workshops that generate hydrogen sulfide gas are all made in a closed type, and the induced draft fan connects the collected hydrogen sulfide gas to the Gas absorption tower. The hydrogen sulfide concentration at the inlet of the gas absorption tower is 800mg / m 3 , the discharge rate is 0.85kg / h, and after the acid wastewater spraying and absorption of the tertiary metal mine, the concentration of hydrogen sulfide at the exhaust port of the gas absorption tower (height: 15m) is reduced to 3mg / m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com