Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105 results about "Heavy water reactors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

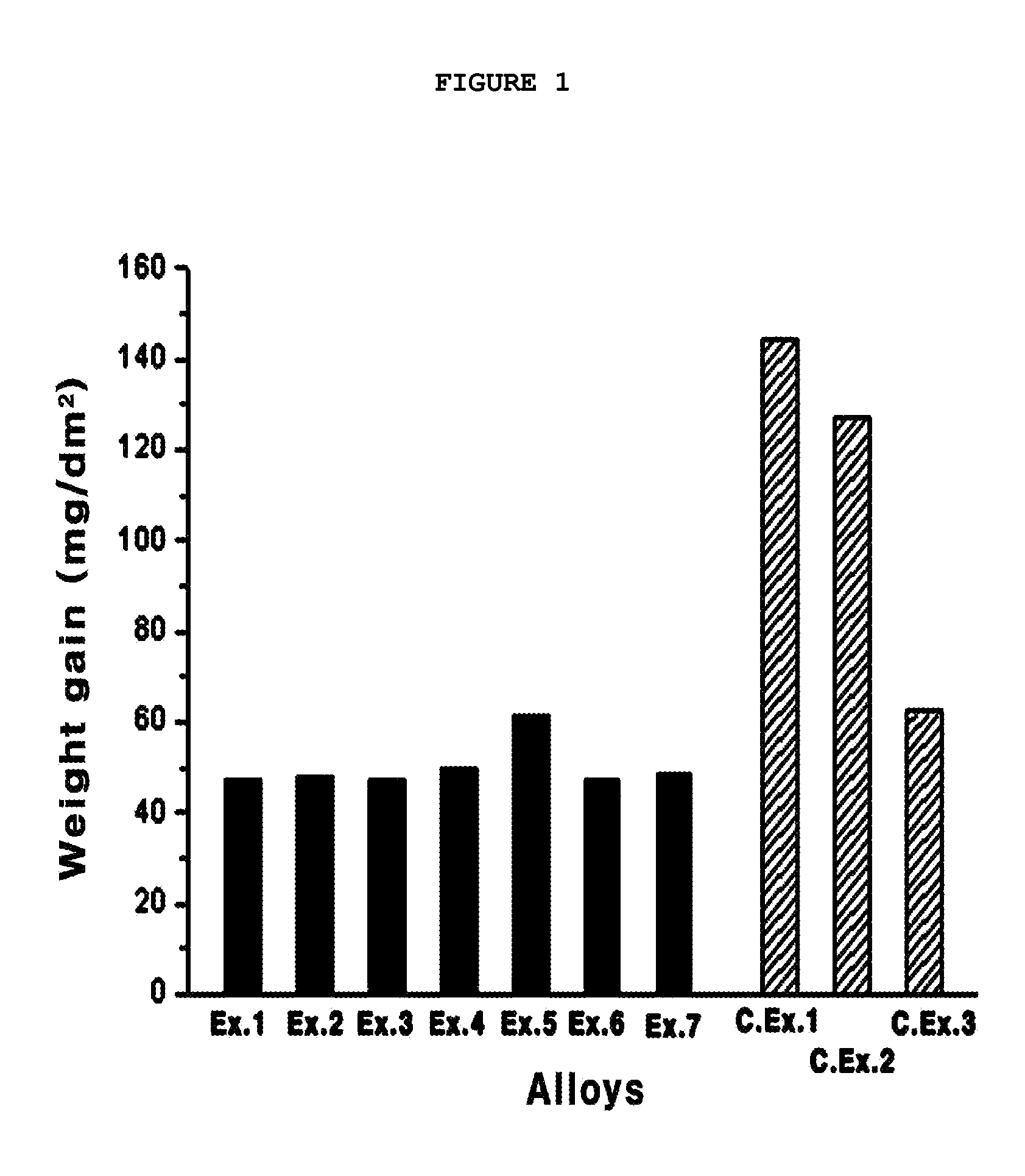

High Fe contained zirconium alloy compositions having excellent corrosion resistance and preparation method thereof

ActiveUS20080192880A1Improve corrosion resistanceHigh cycle operationOptical rangefindersNuclear energy generationNuclear reactor coreNiobium

A high Fe-containing zirconium composition having excellent corrosion resistance and a preparation method thereof. Specifically, disclosed are a high Fe-containing zirconium composition having excellent corrosion resistance and a preparation method thereof, the composition comprising: 0.5-1.0 wt % iron; 0.25-0.5 wt % chromium; 0.06-0.18 wt % oxygen; at least one element selected from the group consisting of 0.2-0.5 wt % tin, 0.1-0.3 wt % niobium and 0.05-0.3 wt % copper; and the balance of zirconium. The zirconium alloy has excellent corrosion resistance, and thus can be used as a material for nuclear fuel claddings, spacer grids and nuclear reactor core structures in light water reactor and heavy water reactor nuclear power plants.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

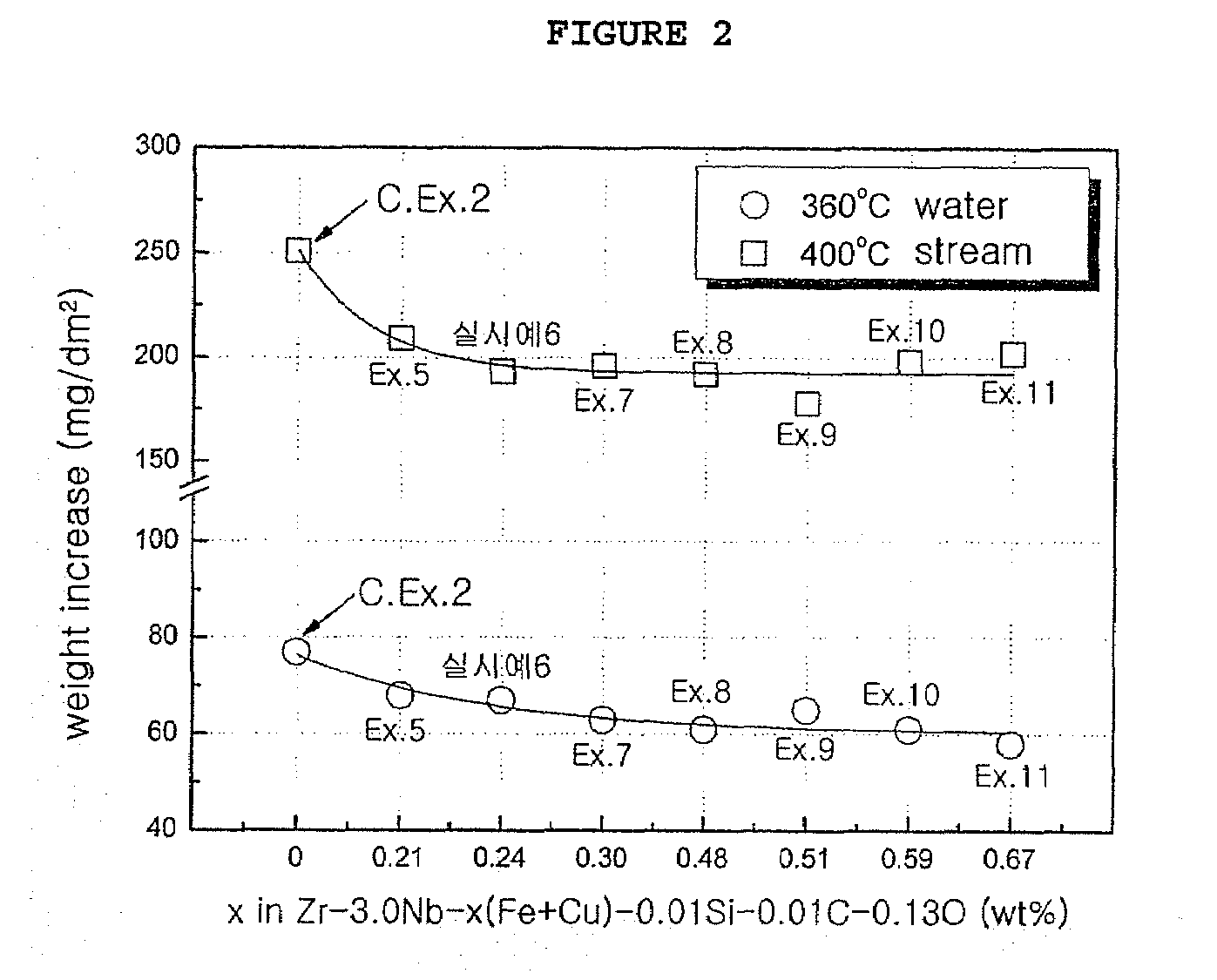

Zirconium alloy composition having excellent corrosion resistance for nuclear applications and method of preparing the same

ActiveCN101195880AImprove corrosion resistanceNuclear energy generationReactor fuel elementsNuclear powerNiobium

The present invention relates to a zirconium alloy composition having excellent corrosion resistance for nuclear applications and a method of preparing the same. The zirconium alloy composition having excellent corrosion resistance for nuclear applications includes 1.3~2.0 wt% of niobium, 0.05~0.18 wt% of iron, 0.008~0.012 wt% of silicon, 0.008~0.012 wt% of carbon, and 0.1~0.16 wt% of oxygen, with the balance being zirconium, or includes 2.8~3.5 wt% of niobium, 0.2~0.7 wt% of at least one of iron and copper, 0.008~0.012 wt% of silicon, 0.008~0.012 wt% of carbon, and 0.1~0.16 wt% of oxygen, with the balance being zirconium. The present invention further relates to a method of preparing the zirconium alloy composition as described above, as well as high burn-up nuclear fuel cladding tubes, nuclear fuel assembly support grids and structural components of nuclear power plants made therefrom. The invention further relates to a method of preparing a zirconium alloy composition as described above, as well as high burn-up nuclear fuel cladding tubes, nuclear fuel assembly support grids and structural components of nuclear power plants made therefrom.

Owner:KEPCO NUCLEAR FUEL CO LTD +1

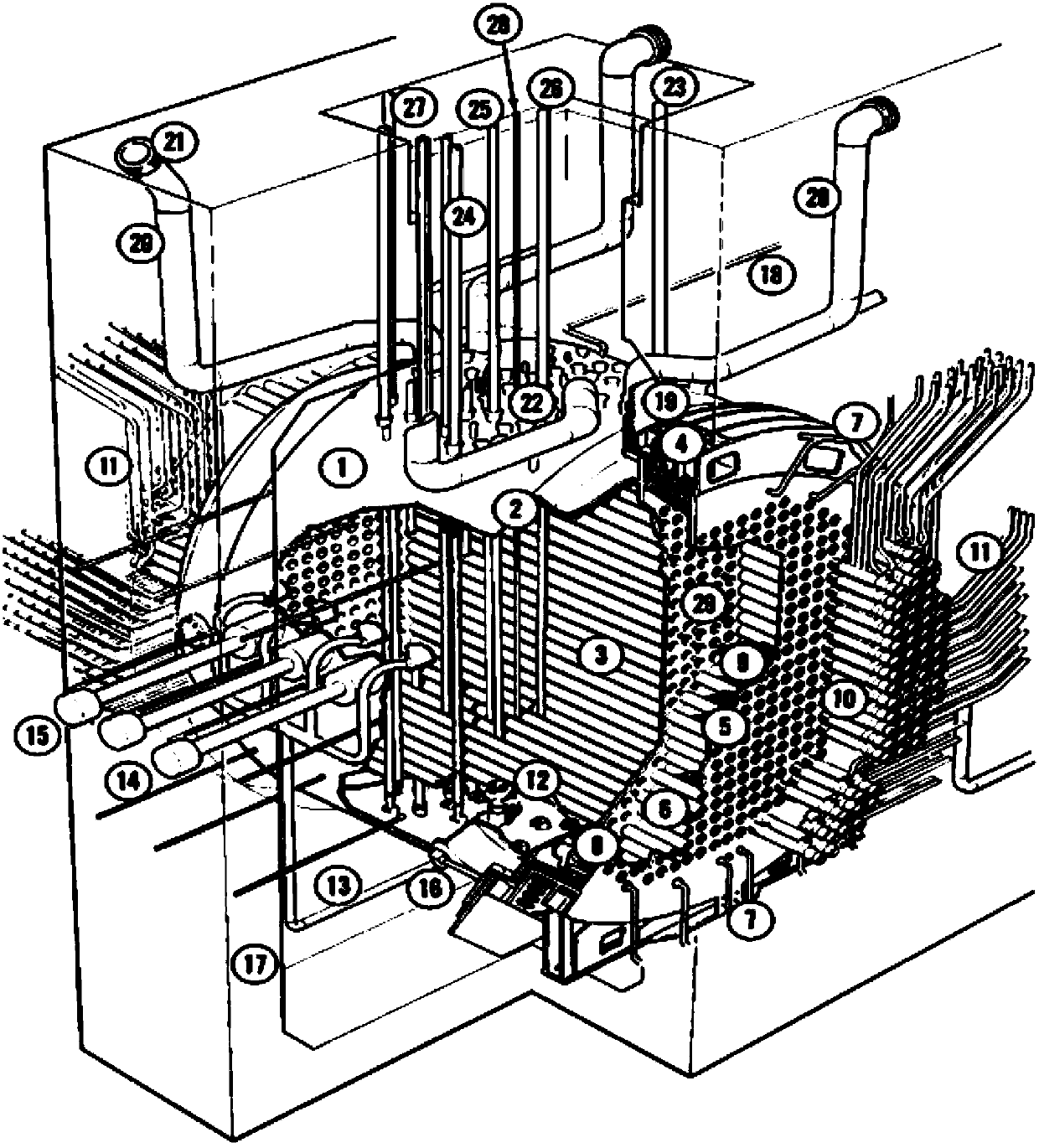

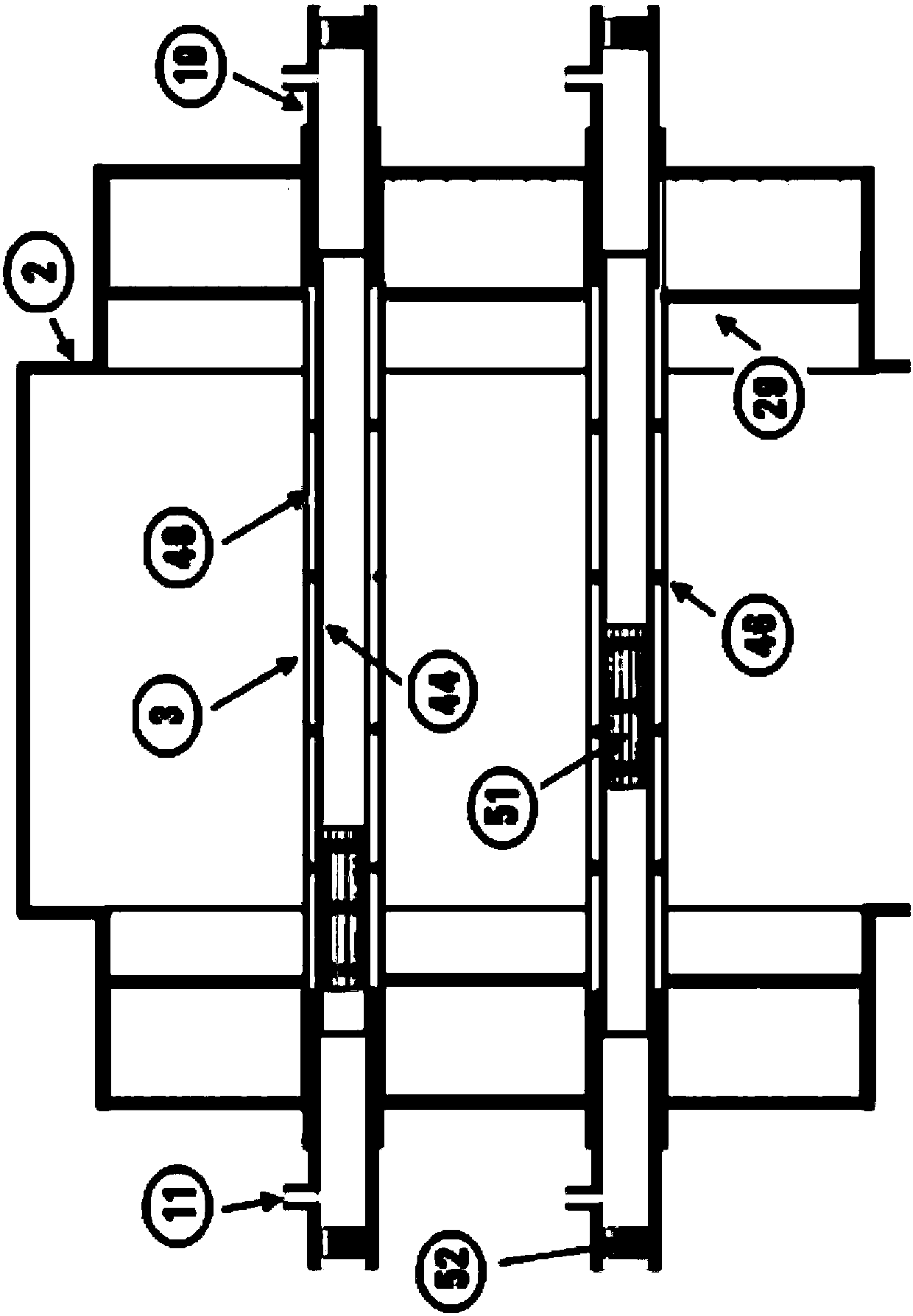

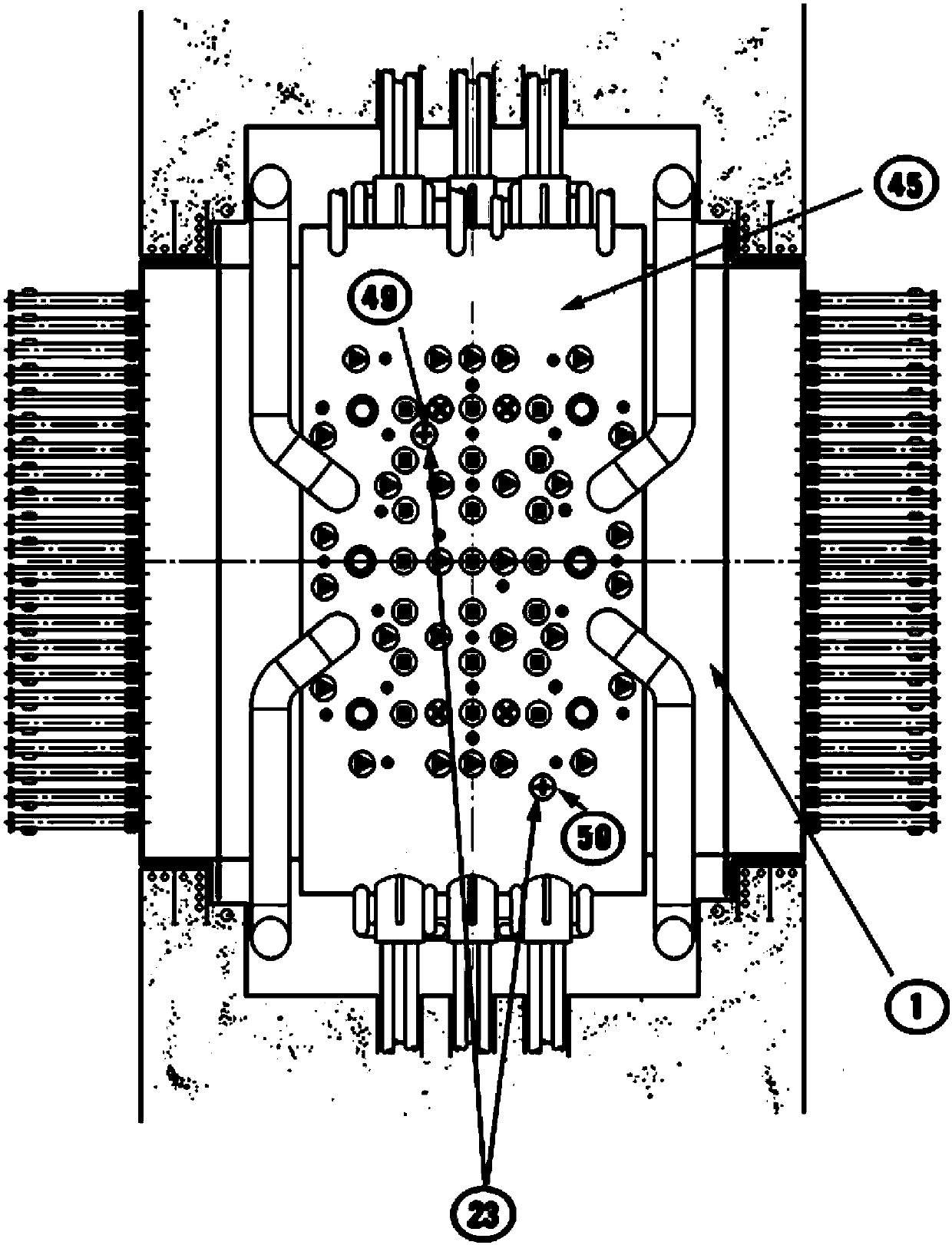

Method of producing radioisotopes using a heavy water type nuclear power plant

A method of producing radioisotopes using a heavy water type nuclear power plant is provided. The method includes inserting targets (37) into a heavy water moderator of the heavy water reactor througha guide tube (30) in a port (55) in a reactivity mechanism deck (45) of the heavy water reactor. The heavy water reactor operates to irradiate the target to convert the target into a radioisotope. The method then includes removing the radioisotope from the moderator of the heavy water reactor via the reactivity mechanism deck. A heavy water nuclear reactor is also provided.

Owner:法玛通加拿大有限公司

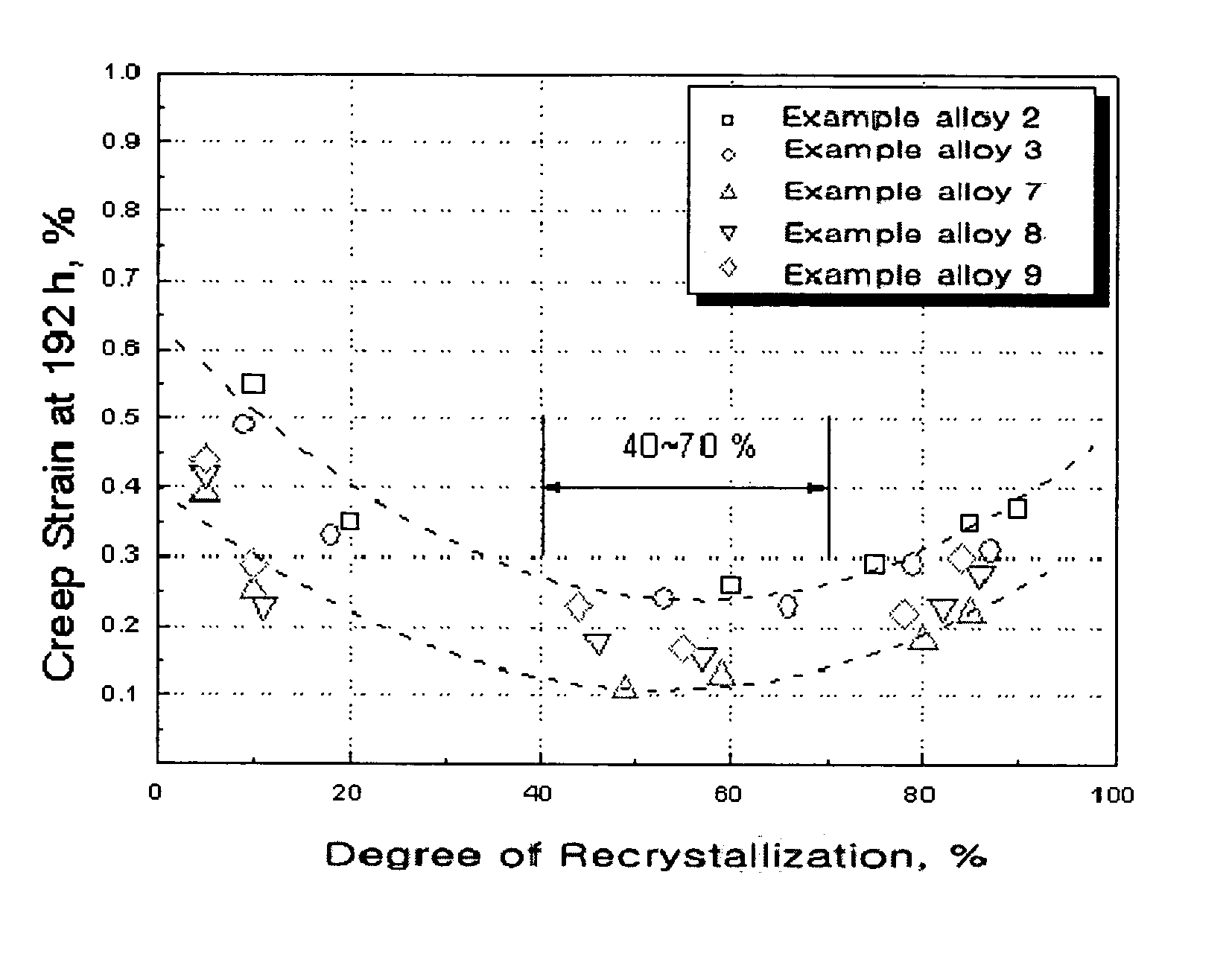

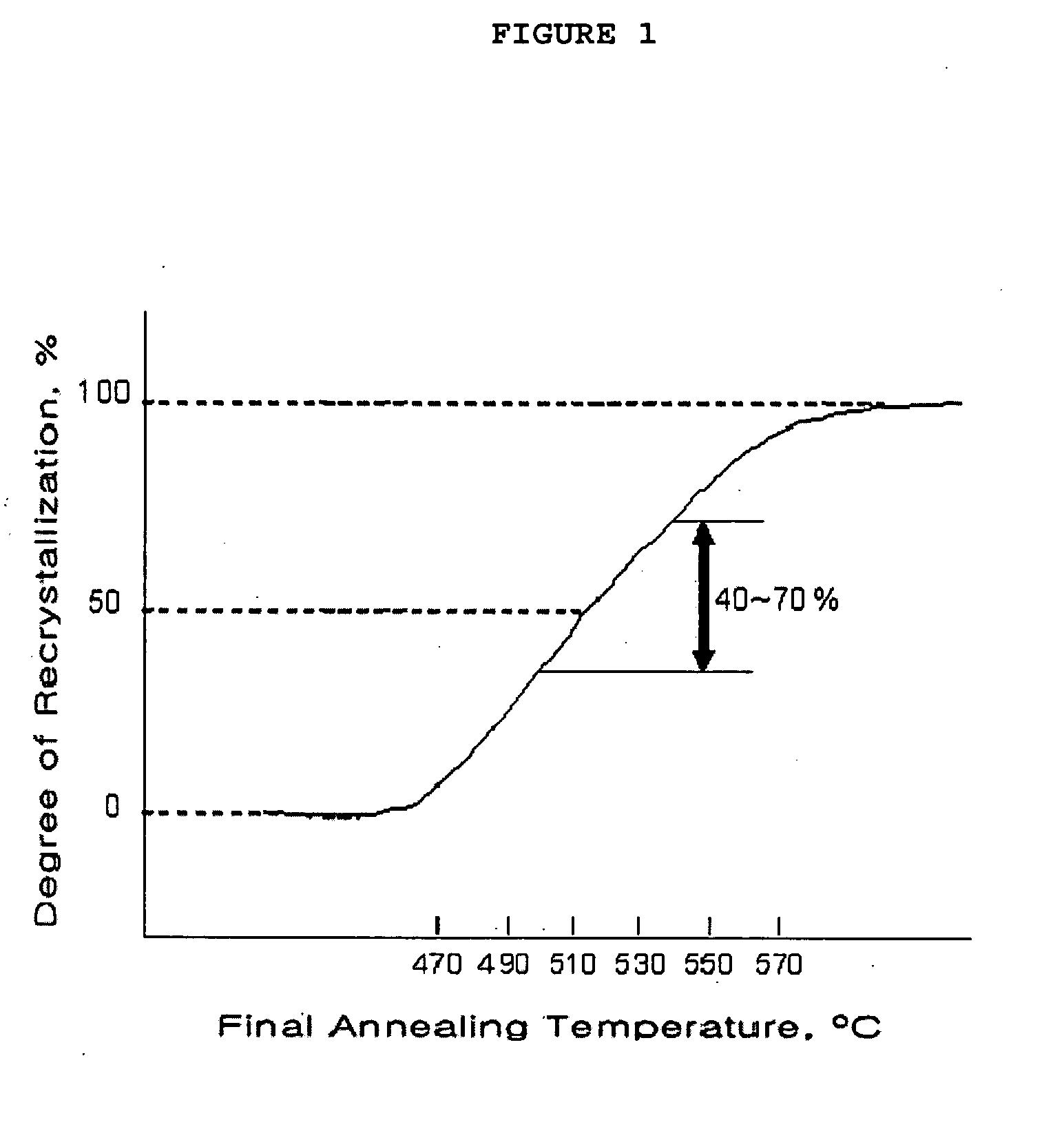

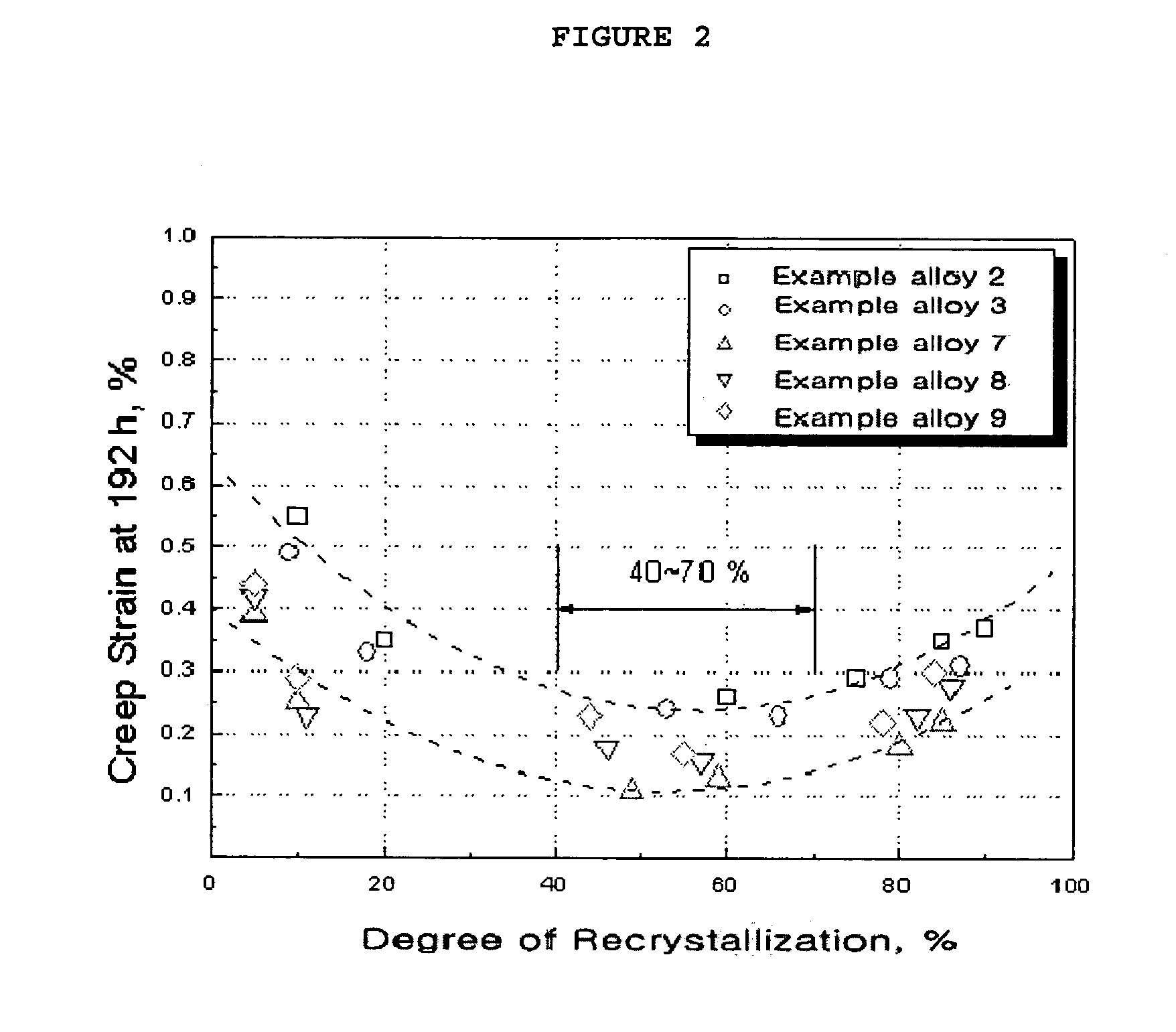

Zirconium based alloys having excellent creep resistance

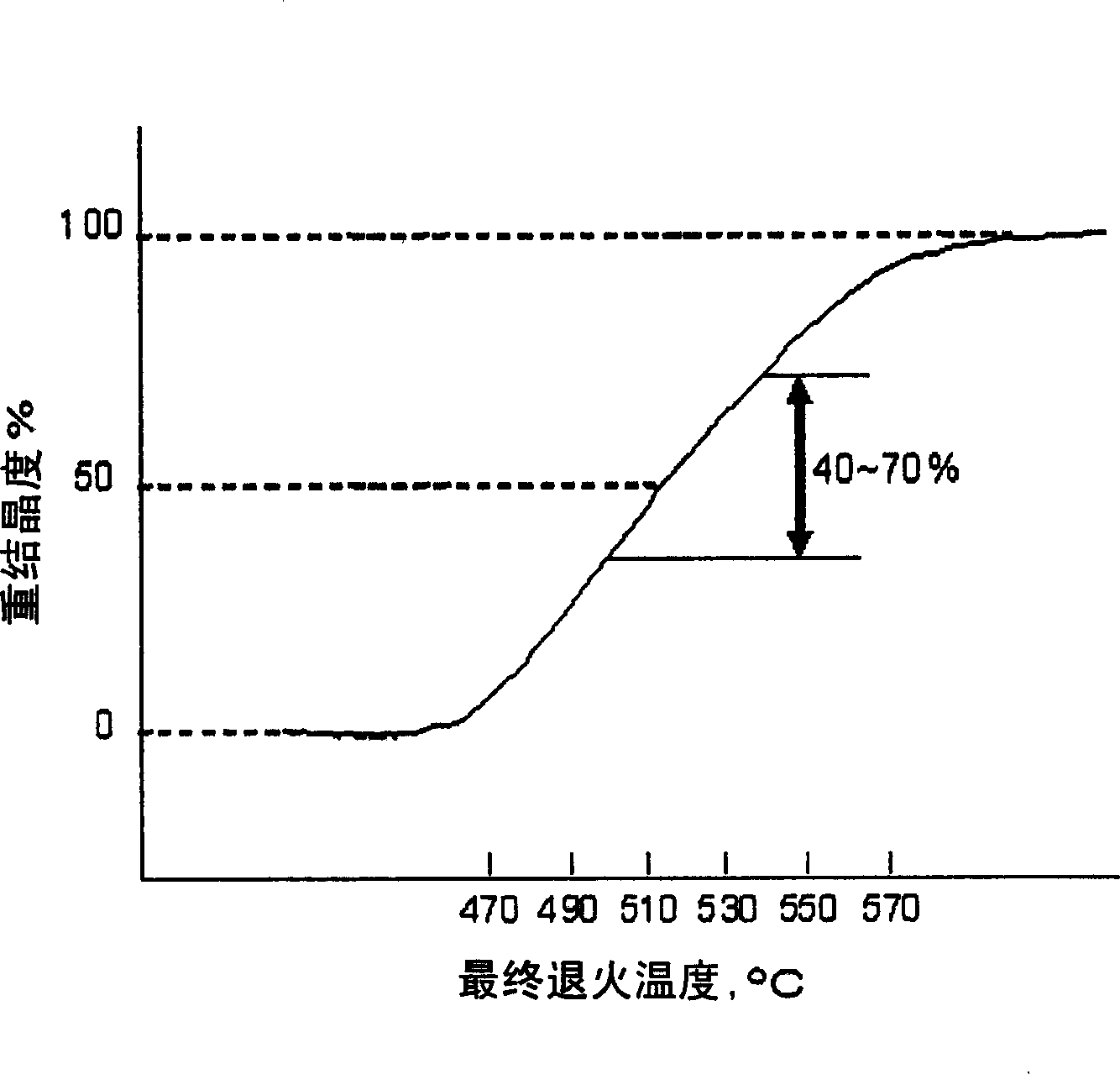

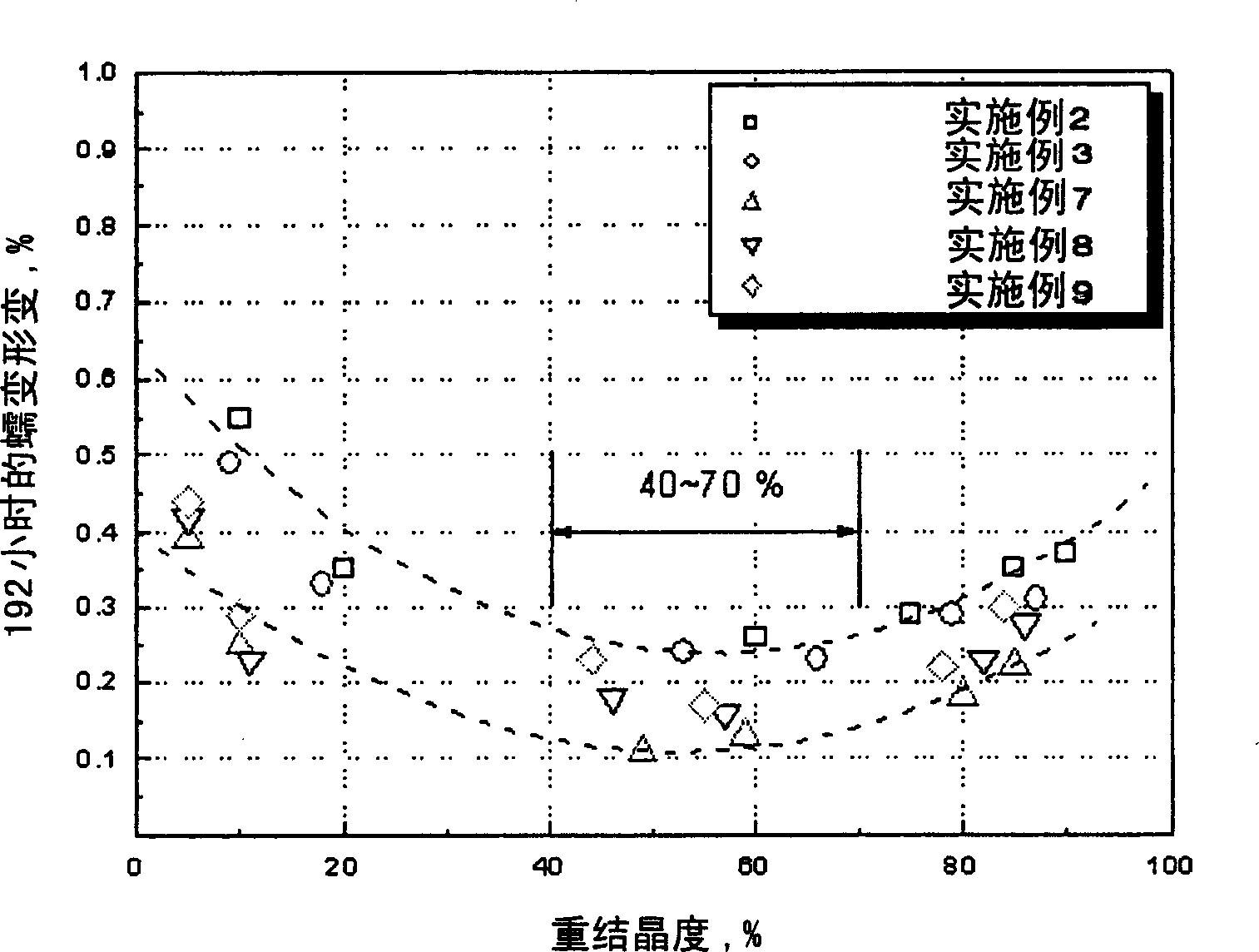

The present invention relates to a zirconium-based alloy composite material with excellent creep resistance, more specifically, to a zirconium-based alloy that undergoes a final heat treatment to improve the creep resistance so that the degree of recrystallization is 40-70% composite material. The zirconium-based alloy comprises 0.8 to 1.8% by weight of niobium (Nb); 0.38 to 0.50% by weight of tin (Sn); selected from 0.1 to 0.2% by weight of iron (Fe), 0.05 to 0.15% by weight of copper (Cu) and 0.12% by weight of one or more elements in chromium (Cr); 0.10-0.15% by weight of oxygen (O); 0.006-0.010% by weight of carbon (C); 0.006-0.010% by weight of silicon (Si); 0.0005-0.0020% by weight of sulfur (S); and the balance of zirconium (Zr). The zirconium alloy prepared with the composition according to the present invention has excellent creep resistance compared with conventional zirconium alloy-4, and can be effectively used as nuclear coating tubes, support grids in nuclear power plants utilizing light water or heavy water reactors and the internal structure of the reactor core.

Owner:KEPCO NUCLEAR FUEL CO LTD +1

Zirconium alloy compositions having excellent corrosion resistance by the control of various metal-oxide and precipitate and preparation method thereof

Disclosed herein are a zirconium alloy composition, which exhibits excellent corrosion resistance by varying the kinds of metal oxides and controlling the size of precipitates of the composition, including: 1.05˜1.45 wt % of Nb; one or more selected from the group consisting of 0.1˜0.7 wt % of Fe and 0.05˜0.6 wt % of Cr; and residual Zr, and a method of preparing the same. The zirconium alloy composition exhibits excellent corrosion resistance by controlling the kinds and amounts of the elements included in the zirconium alloy composition and the heat-treatment temperature and thus varying the kinds of metal oxides formed during an oxidation process and controlling the size of precipitates of the zirconium alloy, so that it can be usefully used as a raw material for nuclear fuel cladding tubes, spacer grids, nuclear reactor internals and the like of a light-water reactor or a heavy-water reactor in a nuclear power plant.

Owner:KOREA ATOMIC ENERGY RES INST

Zirconium based alloys having excellent creep resistance

InactiveUS20060177341A1Improve creep resistanceHigh stability and economical efficiencyNiobiumAlloy composite

The present invention relates to a zirconium based alloy composite having an excellent creep resistance and, more particularly, to a zirconium based alloy composite finally heat-treated to have the degree of recrystallization in the range of 40˜70% in order to improve the creep resistance. The zirconium based alloy comprises 0.8˜1.8 wt. % niobium (Nb); 0.38˜0.50 wt. % tin (Sn); one or more elements selected from 0.1˜0.2 wt. % iron (Fe), 0.05˜0.15 wt. % copper (Cu), and 0.12 wt. % chromium (Cr); 0.10˜0.15 wt. % oxygen (O); 0.006˜0.010 wt. % carbon (C); 0.006˜0.010 wt. % silicon (Si); 0.0005˜0.0020 wt. % sulfur (S); and the balance zirconium (Zr). The zirconium alloy manufactured with the composition in accordance with the present invention has an excellent creep resistance compared to a conventional Zircaloy-4, and may effectively be used as a nuclear cladding tube, supporting lattice and inner structures of reactor core in the nuclear power plant utilizing light or heavy water reactor.

Owner:KOREA ATOMIC ENERGY RES INST +1

High temperature nuclear fuel system for thermal neutron reactors

An improved, accident tolerant fuel for use in light water and heavy water reactors is described. The fuel includes a zirconium alloy cladding having a chromium or chromium alloy coating and an optional interlayer of molybdenum, tantalum, tungsten, and niobium between the zirconium alloy cladding and the coating, and fuel pellets formed from U3Si2 or UN and from 100 to 10000 ppm of a boron-containing integral fuel burnable absorber, such as UB2 or ZrB2, either intermixed within the fuel pellet or coated over the surface of the fuel pellet.

Owner:WESTINGHOUSE ELECTRIC CORP

Use of isotopically enriched nitrogen in actinide fuel in nuclear reactors

InactiveUS20100166133A1Lower the volumeTransuranic element compoundsConversion outside reactor/acceleratorsNuclear reactor coreNuclear reactor

The present invention provides a nuclear fuel comprising an actinide nitride such as 233U, 234U, 235U, 236U, 238U, 232Th, 239Pu, 240Pu, 241Pu, 242Pu, 244Pu, 239Np, 239Am, 240Am, 241Am, 242Am, 243Am, 244Am, 245Am, 240Cm, 241Cm, 242Cm, 243Cm, 244Cm, 245Cm, 246Cm, 247Cm, 248Cm, 249Cm, 259Cm, 245Bk, 246Bk, 247Bk, 248Bk, 249Bk, 250Bk, 248Cf, 249Cf, 250Cf, 251Cf, 252Cf, 253Cf, 254Cf, 255Cf, 249Es, 250Es, 251Es, 252Es, 253Es, 254Es, 255Es, 251Fm, 252Fm, 253Fm, 254Fm, 255Fm, 256Fm, 257Fm, 255Md, 256Md, 257Md, 258Md, 259Md, 260Md, 253No, 254No, 255No, 256No, 257No, 258No and 259No, and optionally fission products such as 97Tc, 98Tc and 99Tc, suitable for use in nuclear reactors, including those based substantially on thermal fission, such as light and heavy water reactors, gas-cooled nuclear reactors, liquid metal fast breeders or molten salt fast breeders. The fuel contains nitrogen which has been isotopically enriched to at least about 50% 15N, most preferably above 95%.

Owner:WESTINGHOUSE ELECTRIC CORP

Method for cycle using multi-stack combined nuclear fuel

ActiveCN101206930AIncrease profitLow costNuclear energy generationNuclear power plant controlFuel reprocessingPressurized water reactor

The invention relates to a nuclear power technology, in particular to a multi-reactor combined nuclear fuel cycle utilization method which is applied to the management design of first core fuel for a nuclear plant. A plurality of reactors with fuel elements which can be interchanged are combined to operate the cycle utilization of nuclear fuel, parts of fuel elements are used in a plurality of reactors in sequence. The invention has the advantages that the utilization ratio of the fuel for the newly-built the nuclear power station at the earlier stage can be improved to the level during the equilibrium cycle at the later stage, and the fuel purchasing cost and the post treatment cost of the fuel are saved; the long cycle refueling of a refueling shutdown reactor type can be realized in the first core. The method also can be used for the optimization of the management design of the reactor core fuel among operating reactors, thereby improving the fuel utilization ratio. The method of the invention is suitable for both the refueling shutdown reactor type and a continuous refueling reactor type and suitable for a pressurized water reactor, a boiling water reactor, a heavy water reactor and a high temperature gas cooled reactor.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY

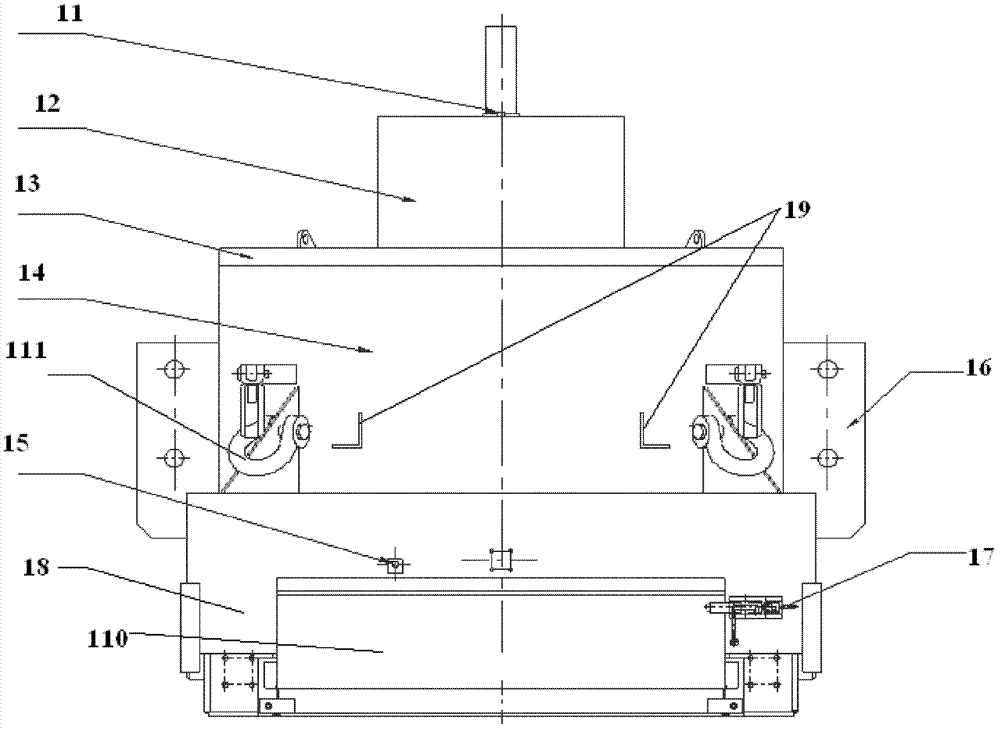

Heavy water reactor spent fuel dry-type storage shielding shipping container

ActiveCN102903410AReduce radiation doseSimple designPortable shielded containersWinding mechanismsOperation safetyHeavy water

The invention belongs to the technical field of heavy water reactor spent fuel dry-type storage shielding shipping container and in particular relates to a heavy water reactor spent fuel dry-type storage shielding shipping container. Two ends of a lifting yoke assembly of the heavy water reactor spent fuel dry-type storage shielding shipping container are respectively connected with two opposite sides of a shielding barrel; an electric chain hoist is arranged at the lower end of the middle part of the lifting yoke assembly, the chain of the electric chain hoist is connected with one end of a gripper head adapter, the other end of the gripper head adapter is connected with a gripper head, and the gripper head adapter and the gripper head are arranged in the shielding barrel; one side of the lower part of the shielding barrel is provided with a rectangular translation gate slot, rails are arranged the left side and right side of the translation gate slot, a rail extension structure is arranged outside the shielding barrel, two rails are paved onto the rail extension structure from the interior of the shielding barrel, a translation gate is arranged between the two rails, a translation gate driving mechanism is arranged at the rear end of the rail extension structure, the translation gate can move between the two rails under the action of the translation gate driving mechanism and can enter into the translation gate slot of the shielding barrel. The operation safety and reliability of the heavy water reactor spent fuel dry-type storage shielding shipping container are higher.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

Nuclear power plant failed desiccant mixed volume reduction solidification treatment method

The invention relates to a radioactive waste solidification treatment technology, and specifically relates to a nuclear power plant failed desiccant mixed volume reduction solidification treatment method. According to the method, low-medium level failed molecular sieve desiccant produced during a heavy water reactor operation process and low-medium level radioactive boron-containing concentrate liquid are subjected to a mixed volume reduction treatment. The volume inclusion rate of the mixed solidified waste can reach 119.1-122.5%. According to the invention, a traditional solidification technology is adopted as a basis, and radioactive waste long-term stability can be realized. With the method, the performance of the prepared solidified body can satisfy related requirements of GB14569.1-2011, including compressive strength, impact resistance, freeze-thaw resistance, soak resistance and the like.

Owner:CHINA INST FOR RADIATION PROTECTION

Zirconium alloy composition for nuclear fuel cladding tube forming protective oxide film, zirconium alloy nuclear fuel cladding tube manufactured using the composition, and method of manufacturing the zirconium alloy nuclear fuel cladding tube

InactiveUS20100108204A1Improve corrosion resistanceNuclear energy generationReactors manufactureWater vaporHigh pressure

Disclosed herein is a zirconium alloy composition for nuclear fuel cladding tubes, comprising: 1.6˜2.0 wt % of Nb; 0.05˜0.14 wt % of Sn; 0.02˜0.2 wt % of one or more elements selected from the group consisting of Fe, Cr and Cu; 0.09˜0.15 wt % of O; 0.008˜0.012 wt % of Si; and a balance of Zr, a nuclear fuel cladding tube comprising the zirconium alloy composition, and a method of manufacturing the nuclear fuel cladding tube. Since the nuclear fuel cladding tube made of the zirconium alloy composition can maintain excellent corrosion resistance by forming a protective oxide film thereon under the conditions of high-temperature and high-pressure cooling water and water vapor, it can be usefully used as a nuclear fuel cladding tube for light water reactors or heavy water reactors, thus improving the economical efficiency and safety of the use of nuclear fuel.

Owner:KOREA ATOMIC ENERGY RES INST +1

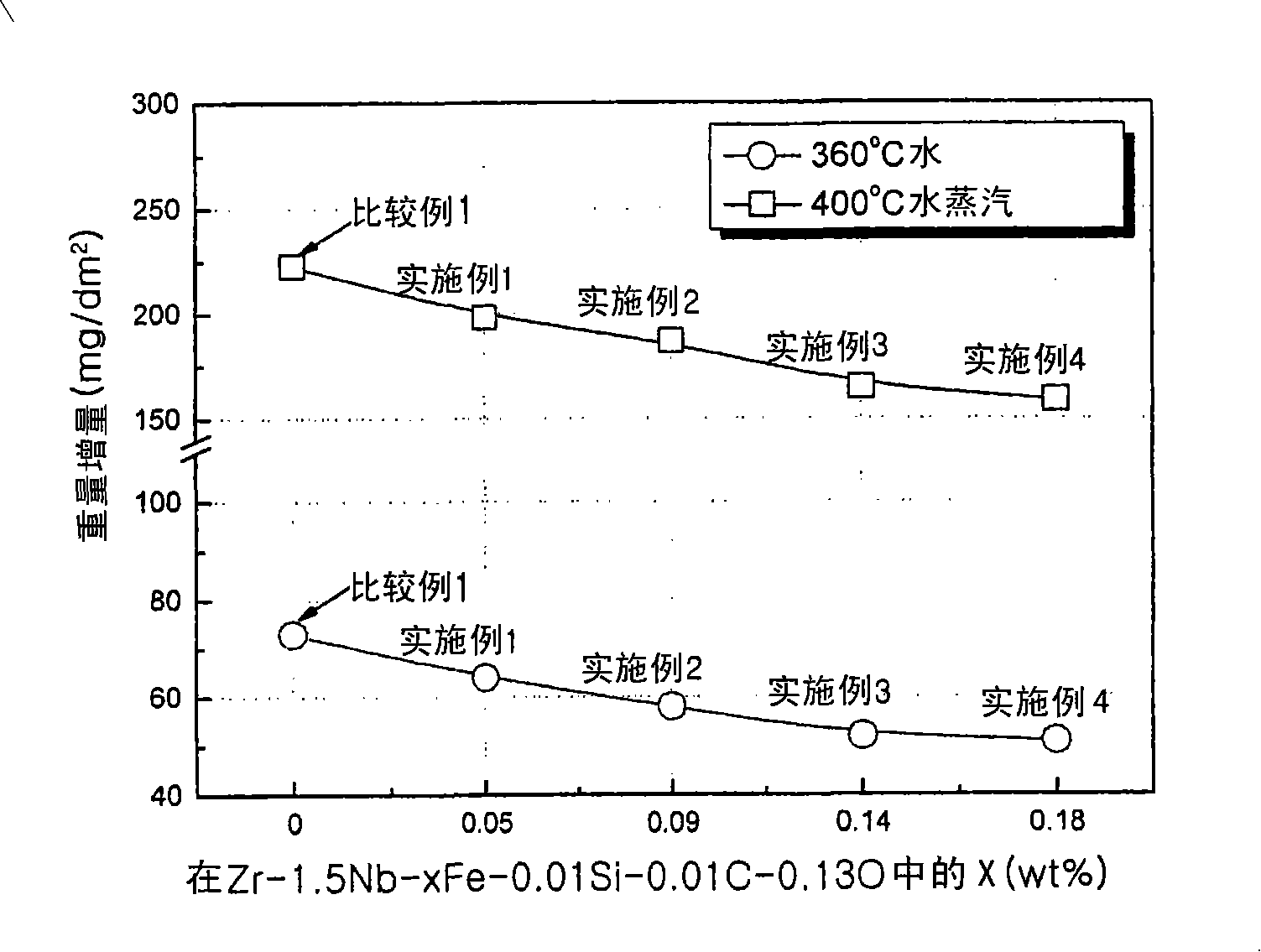

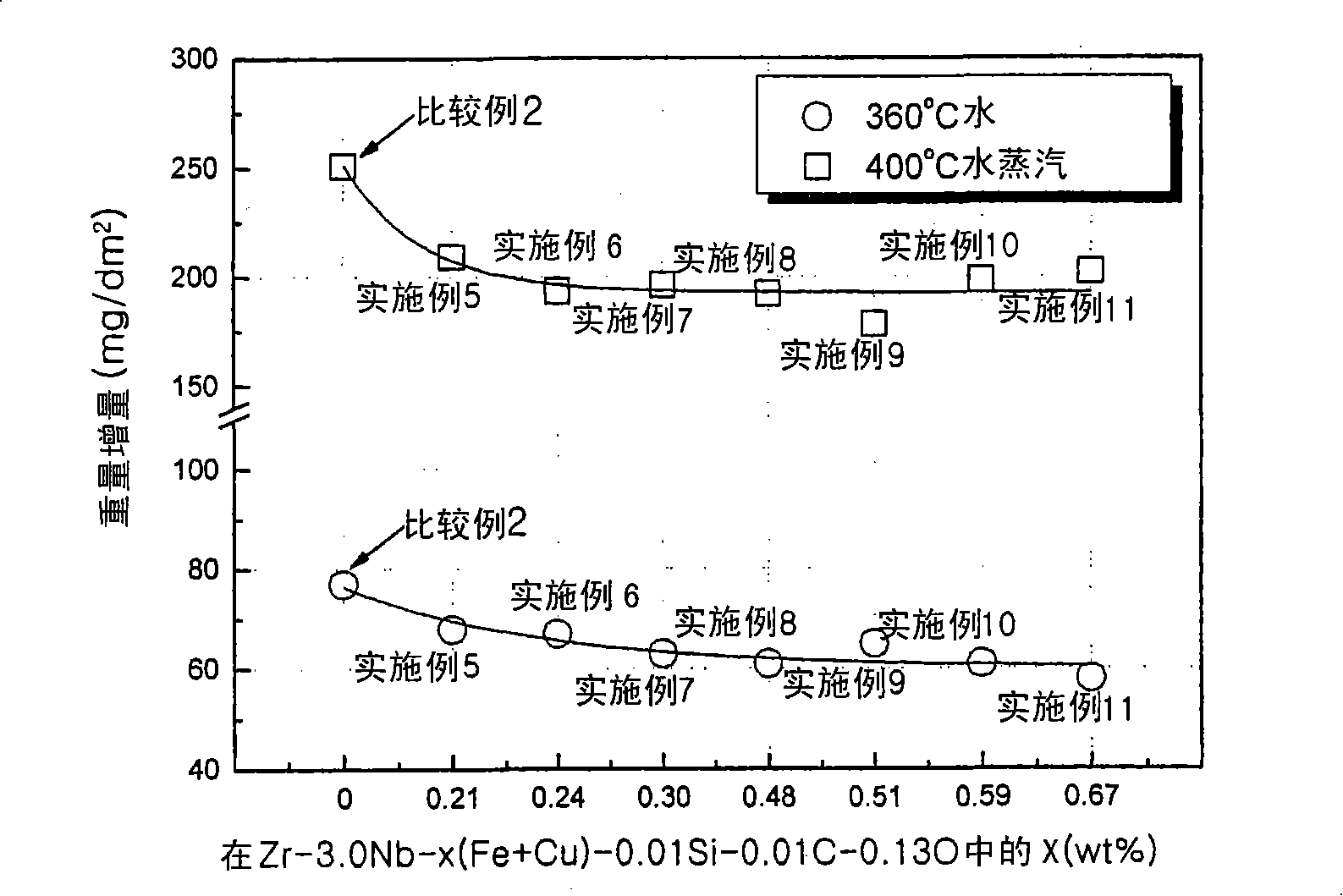

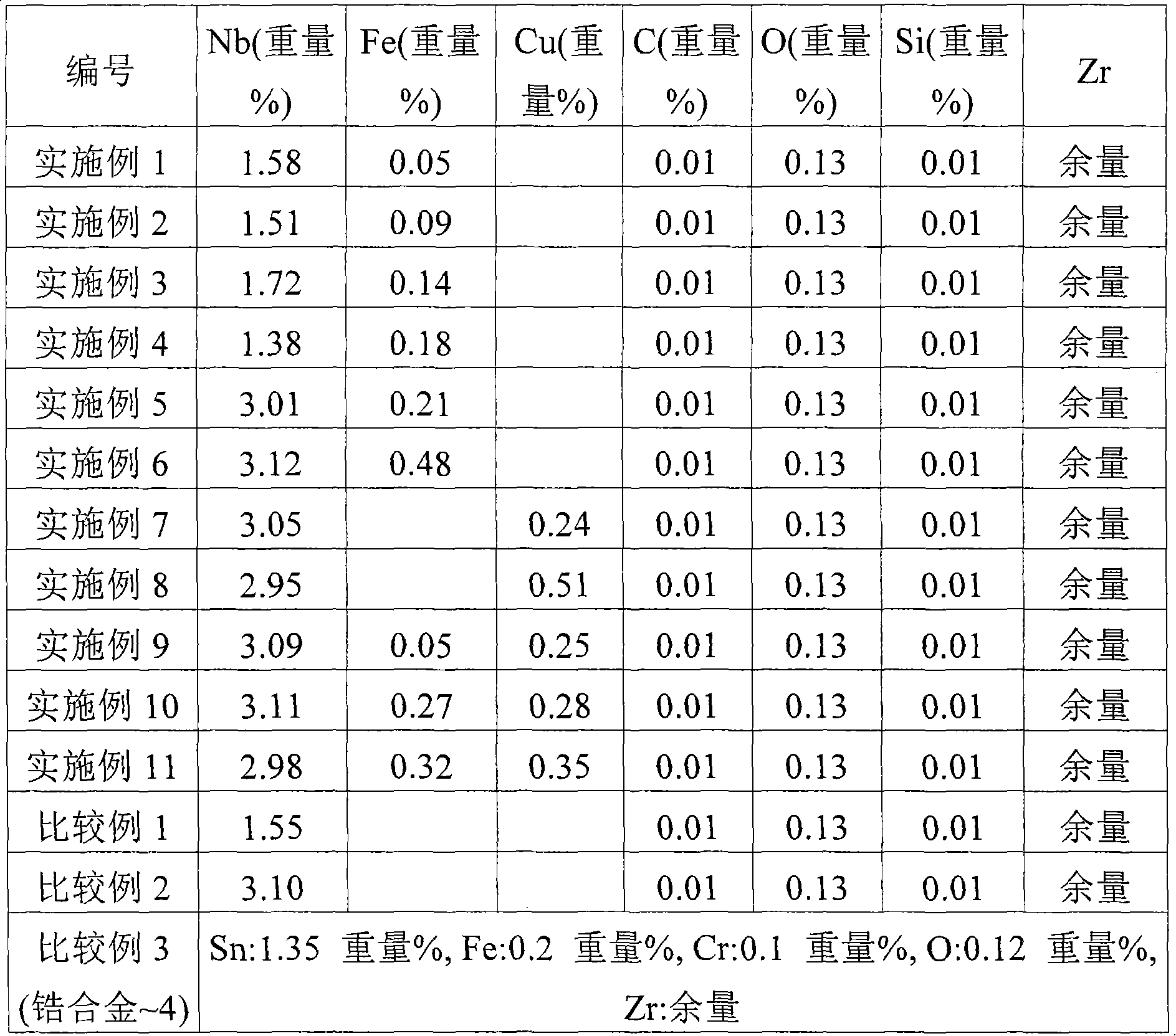

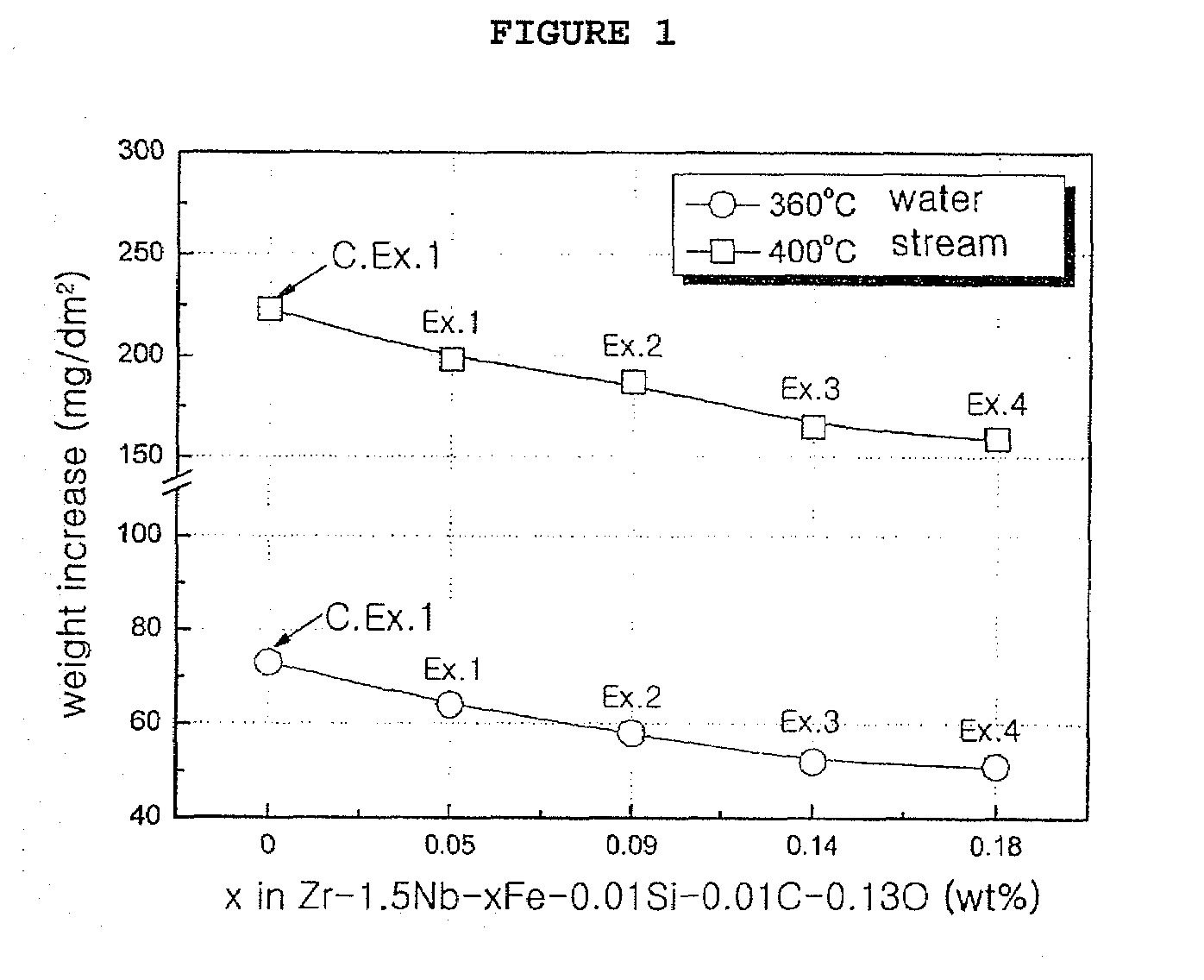

Zirconium alloy composition having excellent corrosion resistance for nuclear applications and method of preparing the same

InactiveUS20080131306A1Improve corrosion resistanceNuclear energy generationReactor fuel elementsNiobiumCore component

The present invention relates to a zirconium alloy composition having excellent corrosion resistance for nuclear applications and a method of preparing the same. The zirconium alloy composition having excellent corrosion resistance for nuclear applications includes 1.3˜2.0 wt % of niobium, 0.05˜0.18 wt % of iron, 0.008˜0.012 wt % of silicon, 0.008˜0.012 wt % of carbon, and 0.1˜0.16 wt % of oxygen, with the balance being zirconium, or includes 2.8˜3.5 wt % of niobium, 0.2˜0.7 wt % of at least one of iron and copper, 0.008˜0.012 wt % of silicon, 0.008˜-0.012 wt % of carbon, and 0.1˜0.16 wt % of oxygen, with the balance being zirconium. The zirconium alloy composition according to the present invention, in which the amount of niobium, acting as a first alloying element, and the amount of at least one of iron and copper, acting as a second alloying element, are appropriately controlled, and silicon, carbon and oxygen are added in appropriate amounts, can exhibit excellent corrosion resistance, and thus can be usefully used as materials for nuclear fuel cladding tubes, support ribs, and core components of light water reactors and heavy water reactors.

Owner:KOREA ATOMIC ENERGY RES INST +1

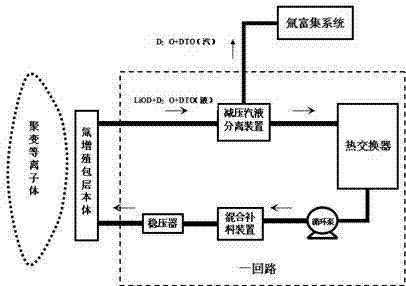

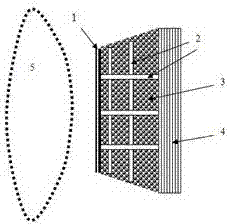

Tritium breeding blanket system based on lithium deuteroxide heavy water solution

InactiveCN103500588ALiquidEasy to processNuclear energy generationThermonuclear fusion reactorLithiumLiquid metal

The invention relates to a tritium breeding blanket system based on lithium deuteroxide heavy water solution, which consists of a tritium breeding blanket body, a primary loop system and a tritium enrichment system. Heavy water saturated solution of lithium deuteroxide is used as tritium breeder and coolant. Since the system unifies the tritium breeder and the coolant, a blanket structure is simplified and the manufacturing of the blanket body is facilitated; since the tritium breeder has flowability, online refueling is easy to realize. Compared with a traditional liquid blanket system, the system avoids the problems of magnetic flow caused by liquid metal flowing and the corrosion caused by liquid metal to structural materials and improves the safety of the blanket system. A primary loop and heavy water tritium extraction technology related to the system has already been applied on a large scale in heavy water reactors. Compared with the existing solid and liquid tritium breeding blanket scheme, the technology is mature and reliable.

Owner:罗天勇 +1

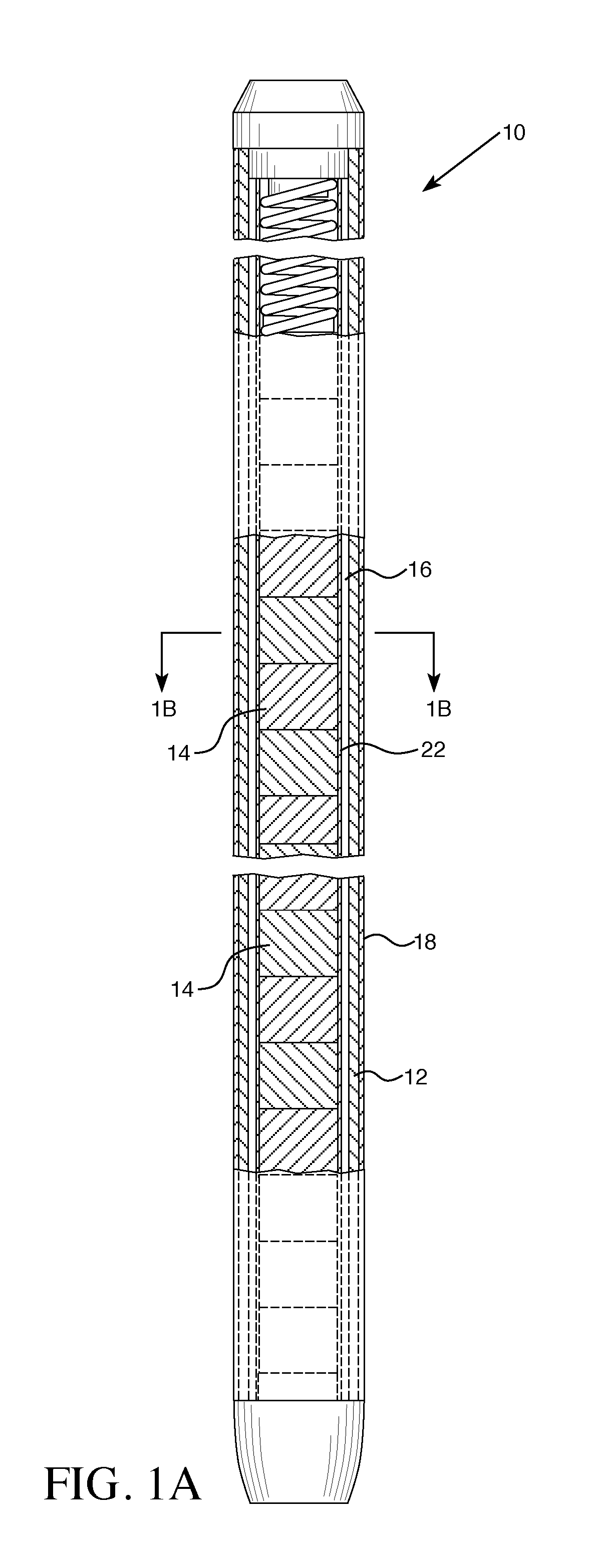

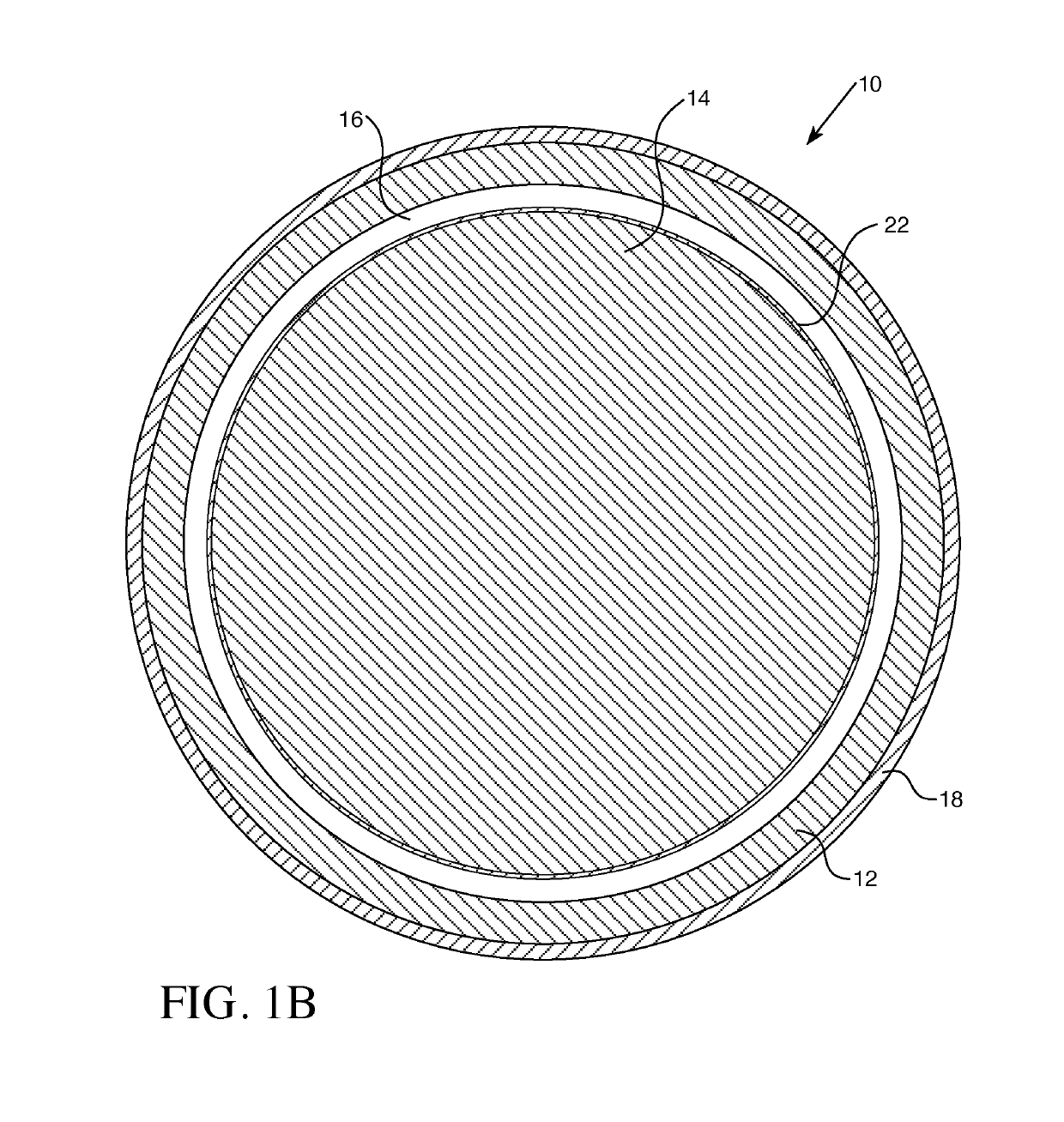

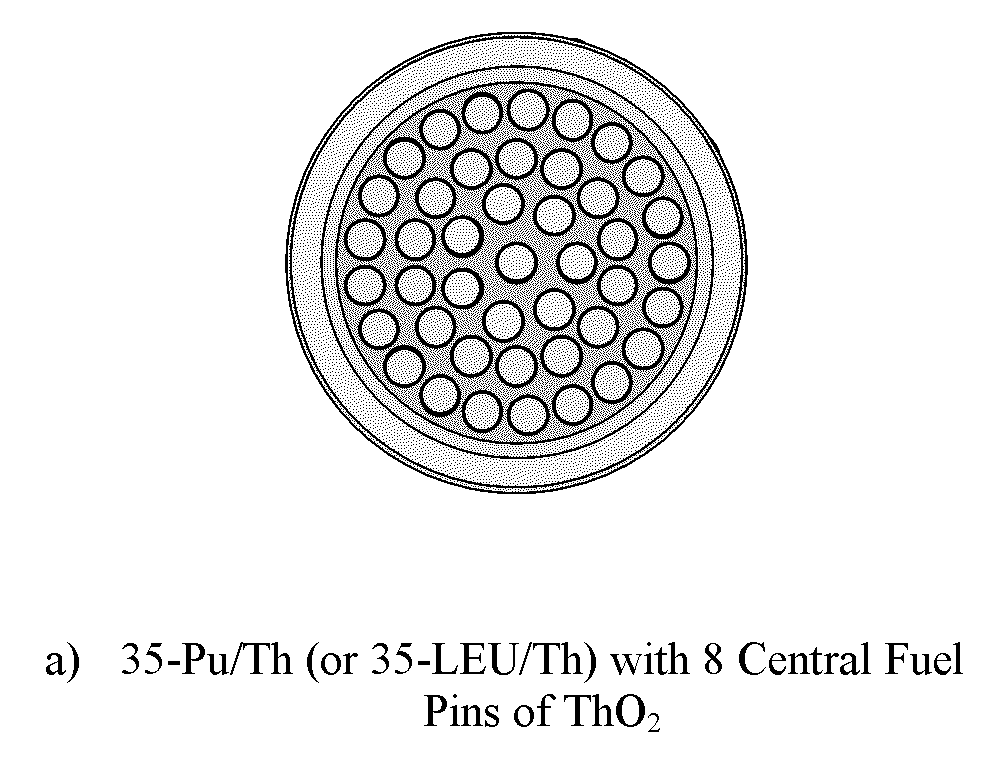

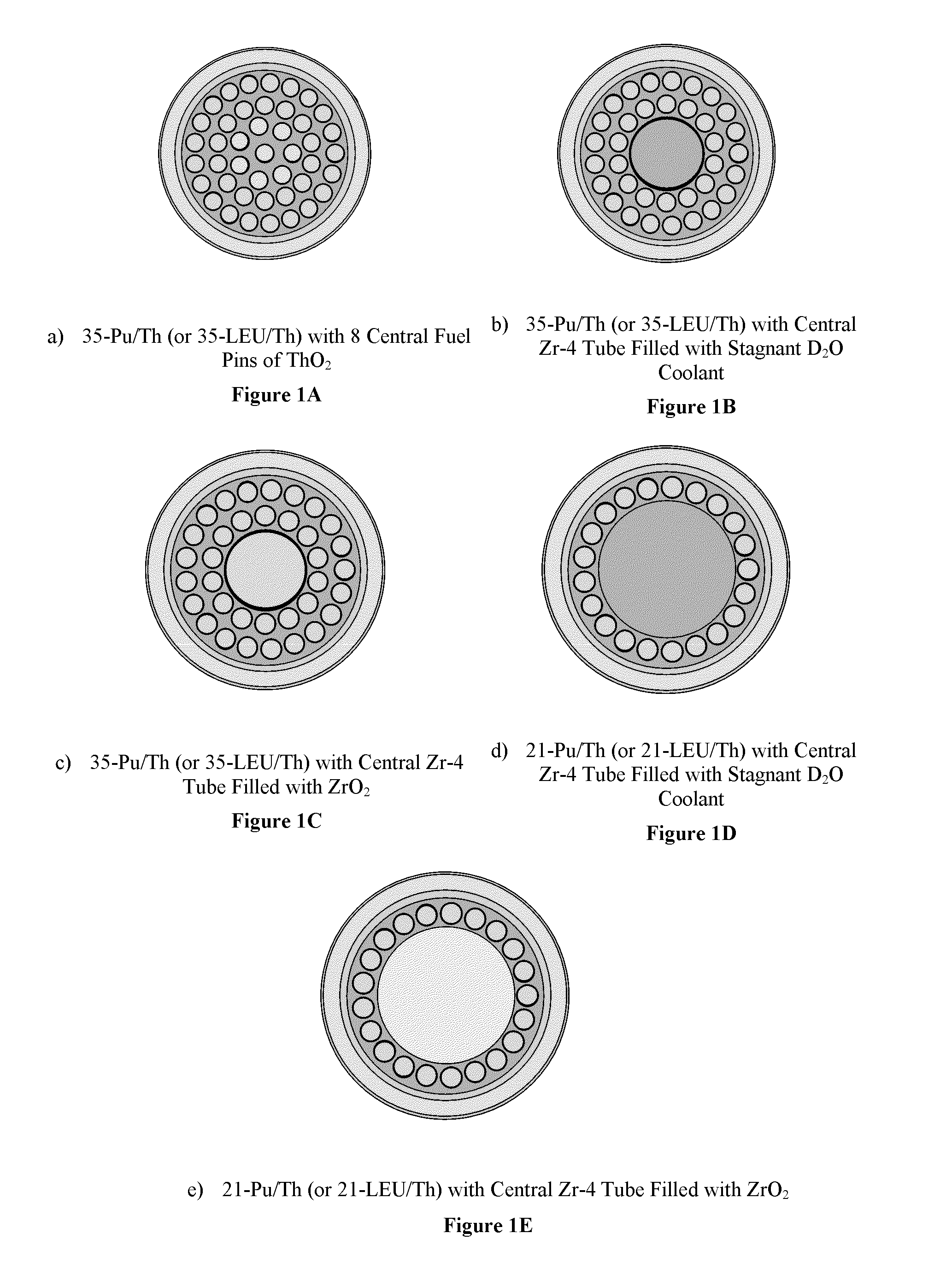

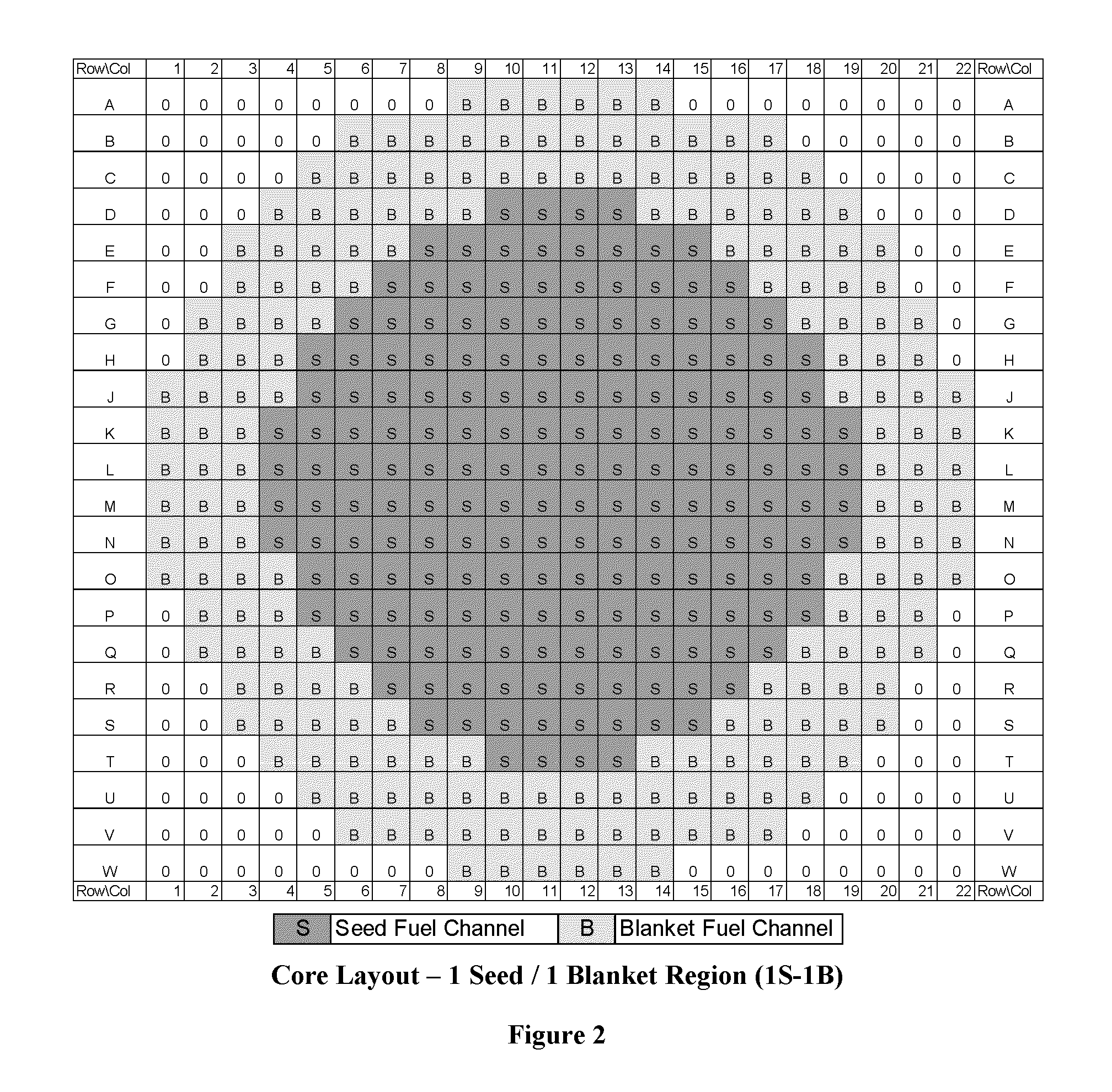

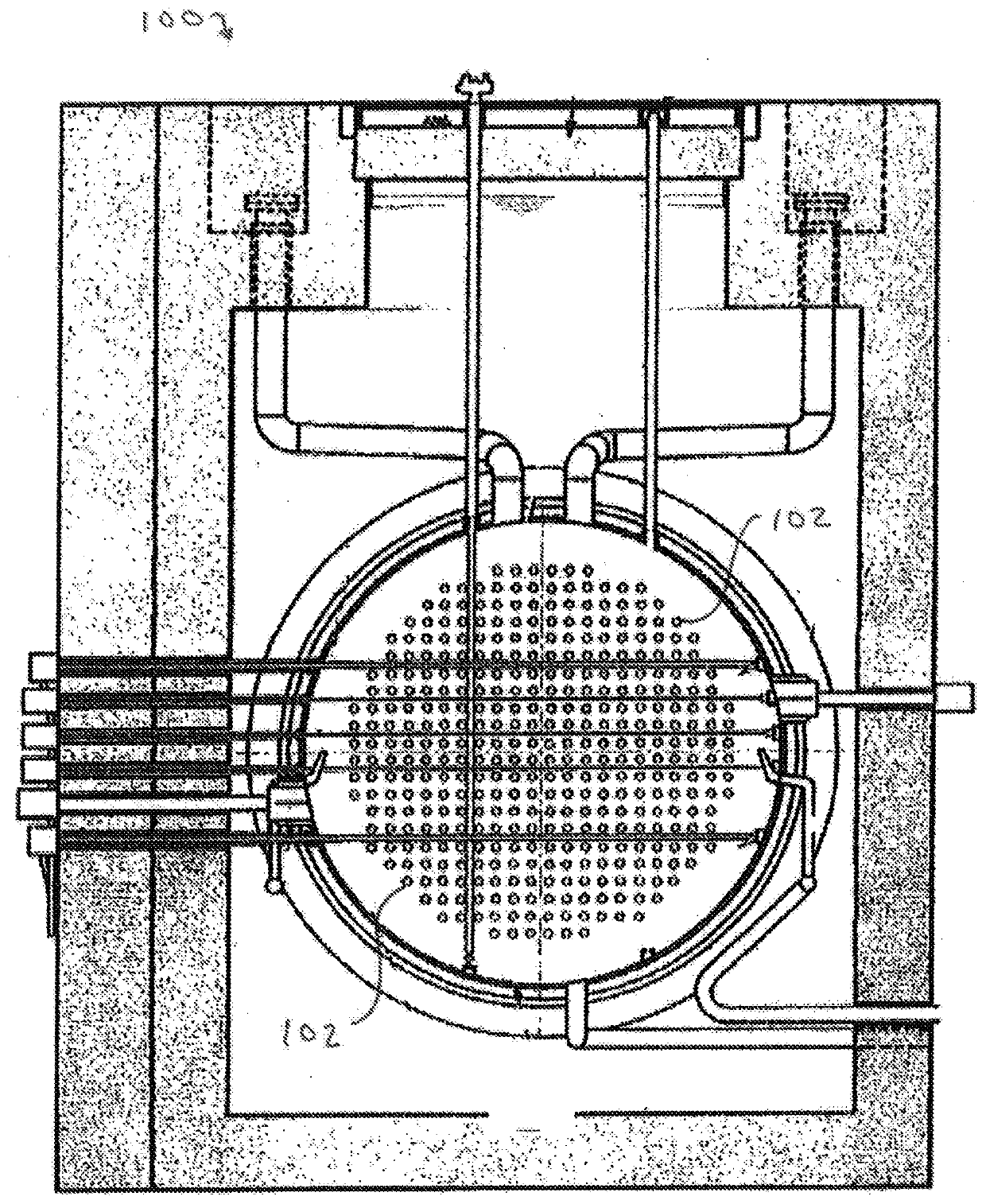

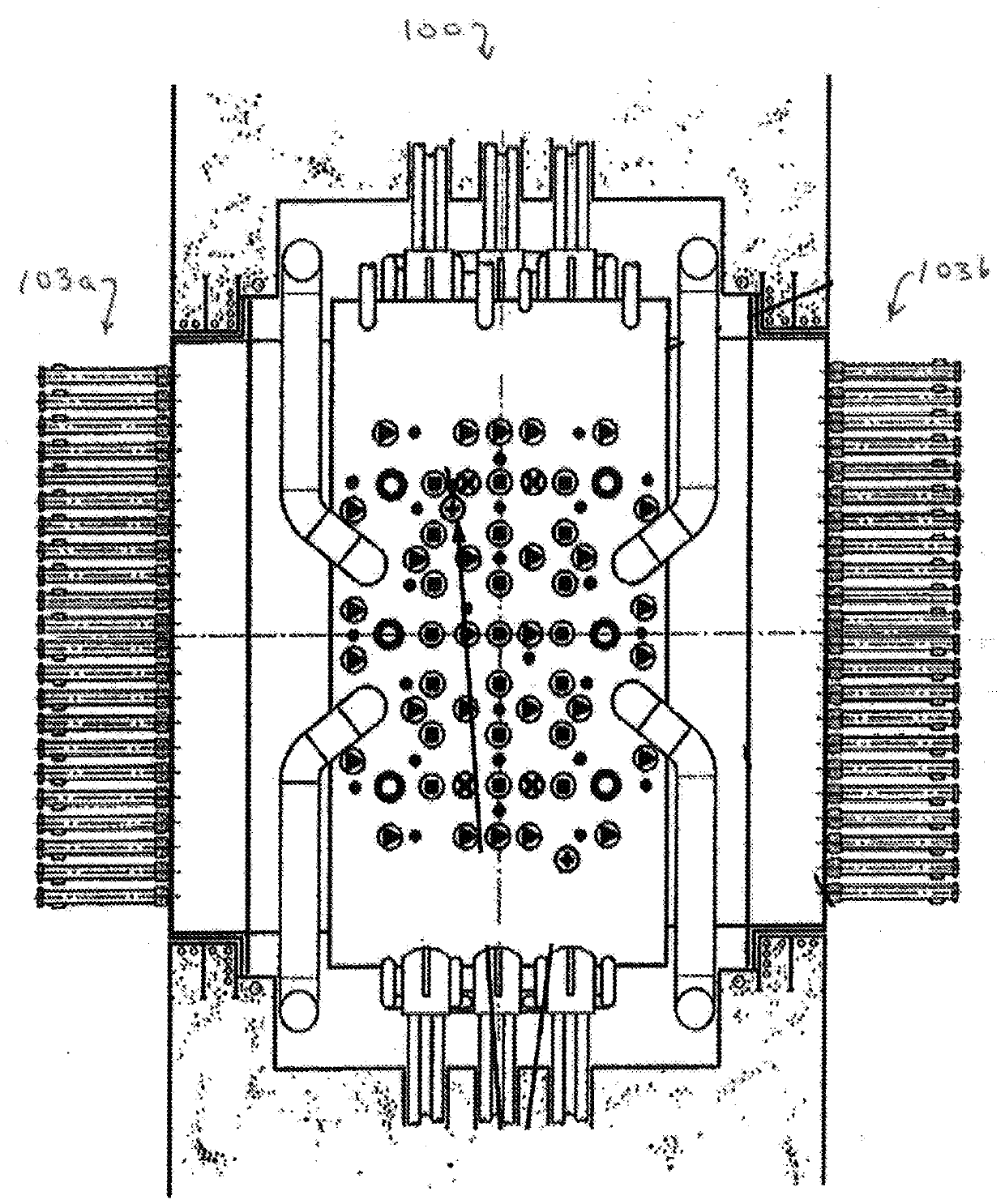

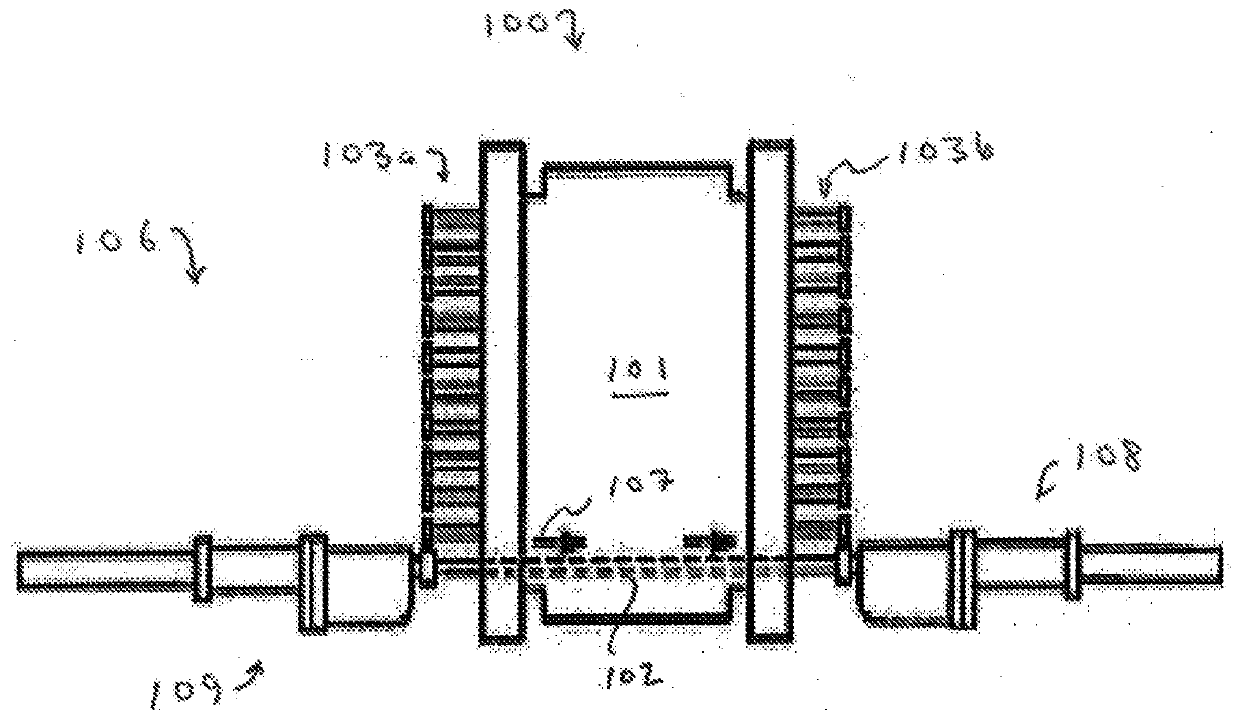

Heterogeneous Core Designs And Thorium Based Fuels For Heavy Water Reactors

ActiveUS20140211904A1Improve sustainabilityImprove fissile utilizationNuclear energy generationFast fission reactorsBurnupChannel types

A channel type heterogeneous reactor core for a heavy water reactor for burnup of thorium based fuel is provided. The heterogeneous reactor core comprises at least one seed fuel channel region comprising seed fuel channels for receiving seed fuel bundles of thorium based fuel; and at least one blanket fuel channel region comprising blanket fuel channels for receiving blanket fuel bundles of thorium based fuel; wherein the seed fuel bundles have a higher percentage content of fissile fuel than the blanket fuel bundles. The seed fuel channel region and the blanket fuel channel region may be set out in a checkerboard pattern or an annular pattern within the heterogeneous reactor core. Fuel bundles for the core are also provided.

Owner:ATOMIC ENERGY OF CANADA LIMITED

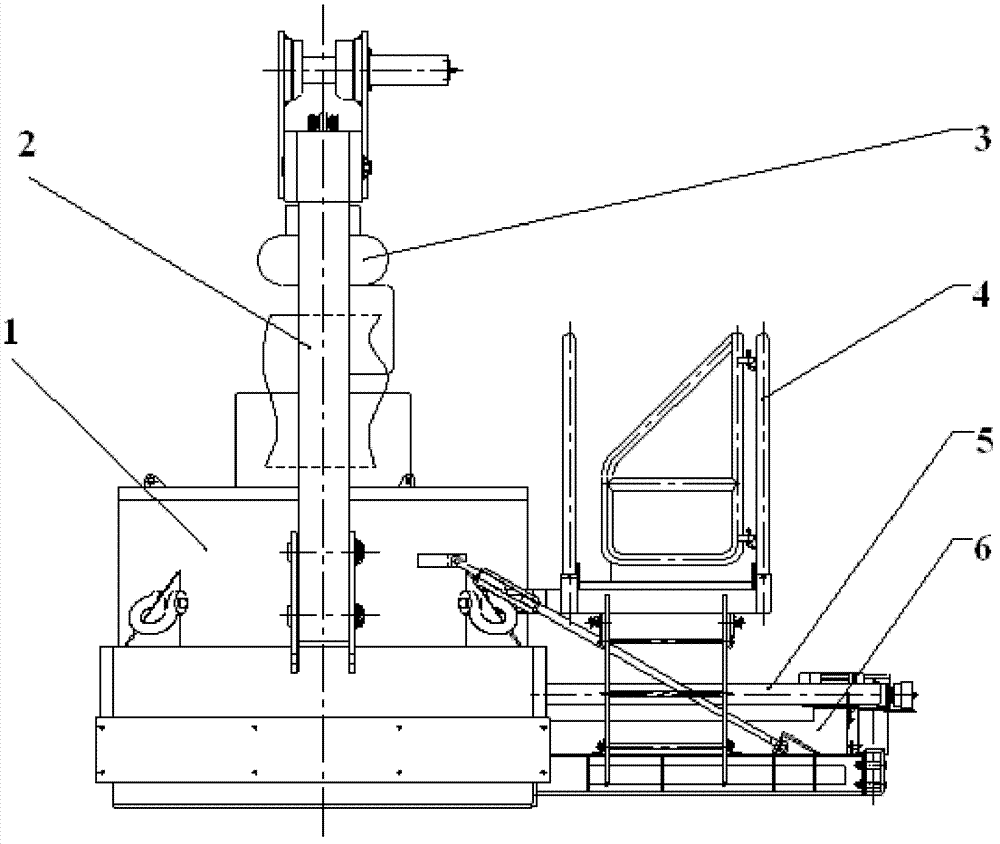

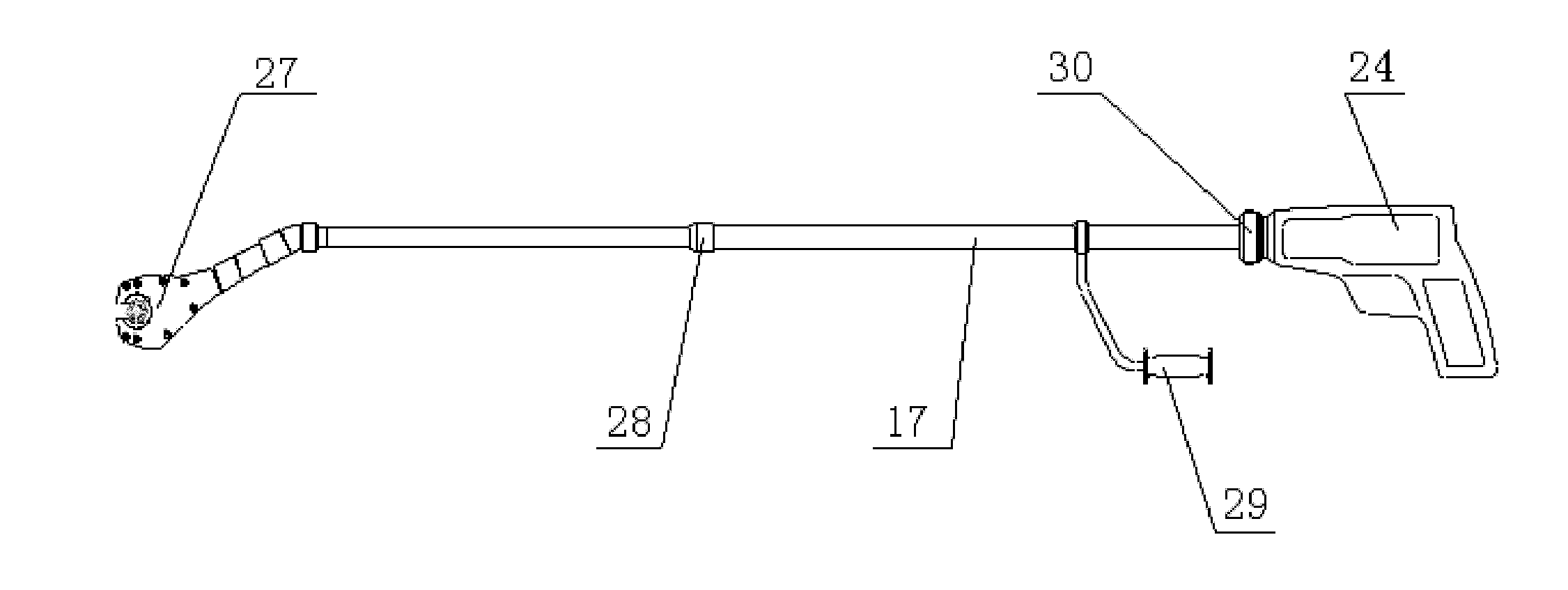

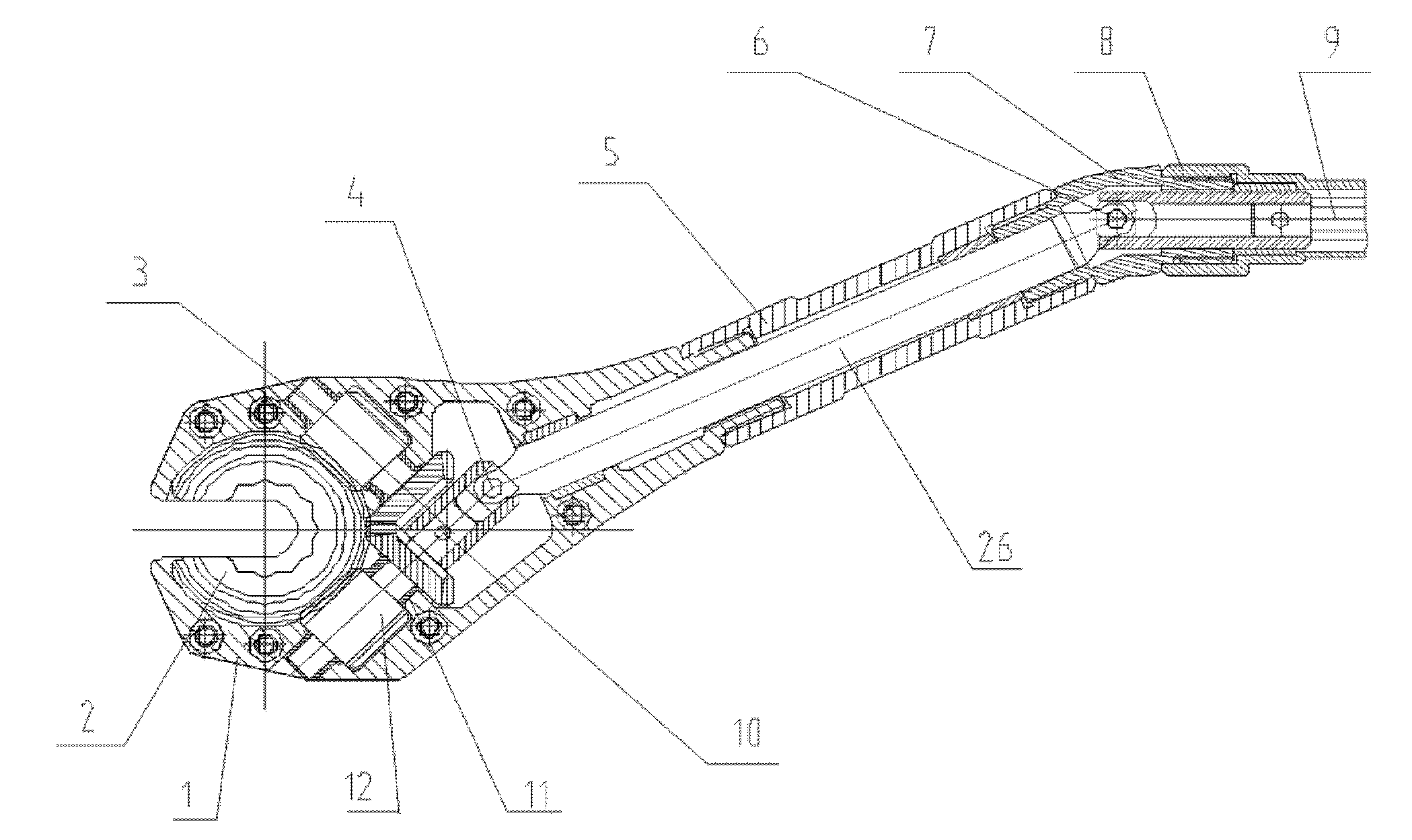

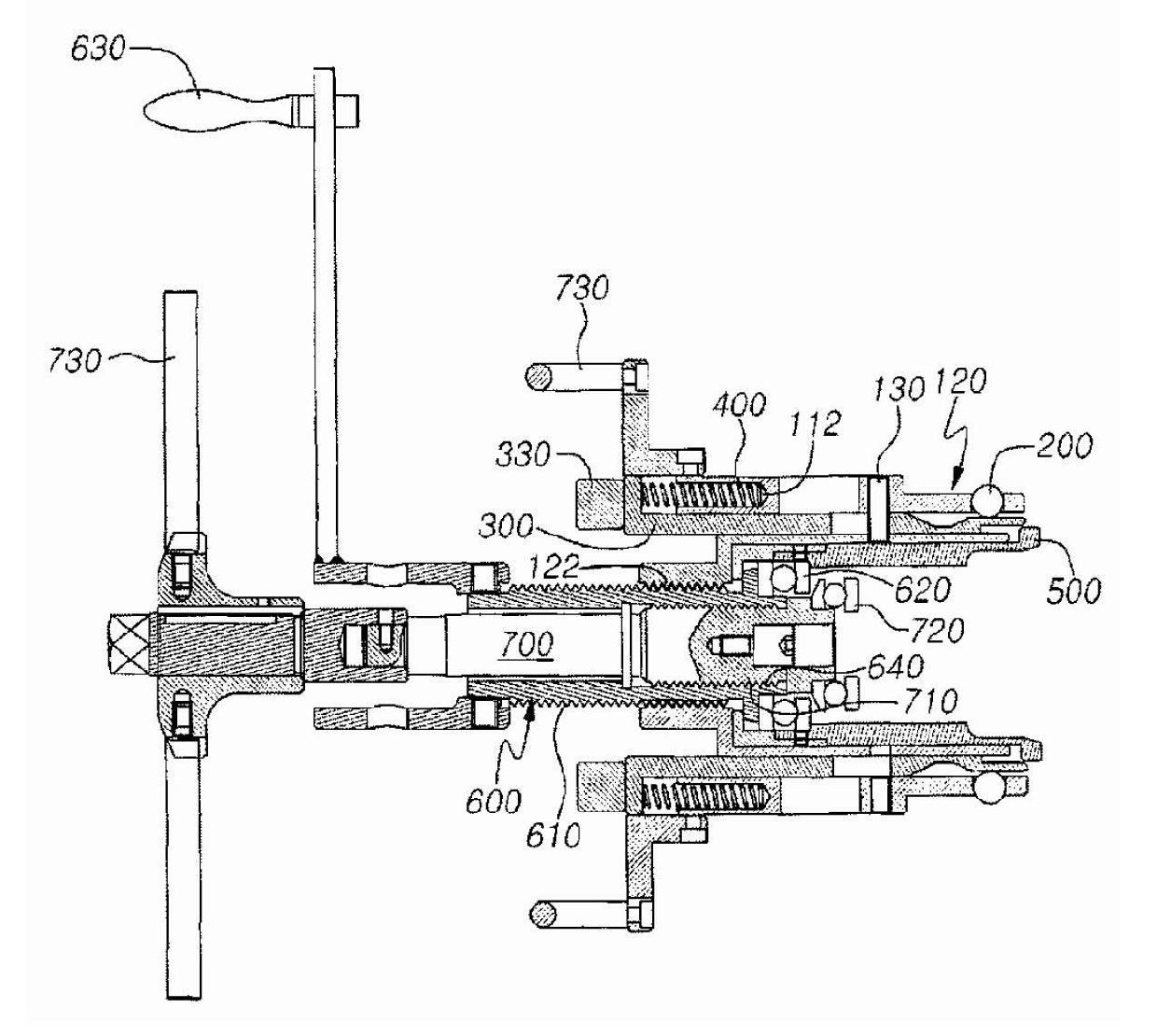

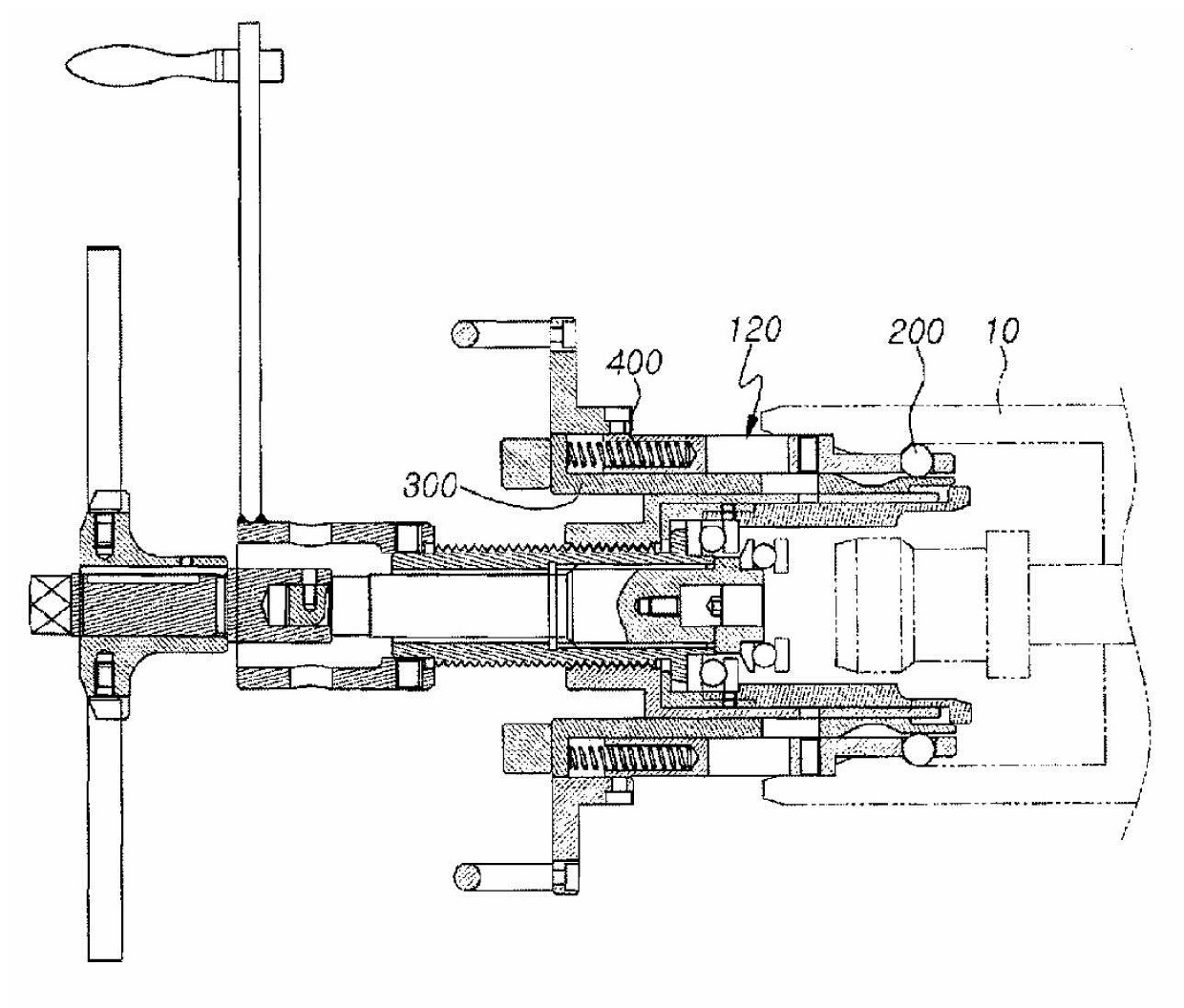

Wrench special for nuts of main heat transfer pipe support post of heavy water reactor

InactiveCN103170941AAchieve motorized continuous rotationReduce radiation doseSpannersWrenchesCouplingNuclear power

The invention relates to a wrench special for an upper nut and a lower nut of a main heat transfer pipe support post. The wrench is used for overhauling heavy water reactor nuclear power equipment. The wrench comprises a driving system and further comprises a rotary sleeve transmission system and a slide type pull rod device, wherein the rotary sleeve transmission system, the slide type pull rod device and the driving system are sequentially connected. The rotary sleeve transmission system comprises a tank body, a rotary worm gear sleeve, two worm bevel gear shafts, a first universal coupling section and a connection shaft, wherein a worm gear thread is arranged on the outer wall of the rotary worm gear sleeve, the two worm bevel gear shafts are arranged in the tank body, a bevel gear is arranged at one end of each worm bevel gear shaft, the bevel gears are meshed with the two worm bevel gear shaft, screw threads are arranged on the outer walls of the two worm bevel gear shafts, the screw threads are meshed with the worm gear thread, the end, where the bevel gear is arranged, of any one of the two worm bevel gear shafts is connected with the connection shaft through the first universal coupling section, and the connection is in clearance fit with the tank body. The wrench is reliable in running, convenient to operate and high in safety.

Owner:RES INST OF NUCLEAR POWER OPERATION +2

Heavy water reactor fuel canning graphite emulsion paint and preparation method thereof

ActiveCN102558986AAdjust granularityAdjust the particle size ratioEpoxy resin coatingsEmulsionWear resistant

The invention discloses a heavy water reactor fuel canning graphite emulsion paint and a preparation method thereof, and belongs to the technical field of preparation of paints. The paint consists of the following components in percentage by weight: 10-25 percent of graphite powder, 3-20 percent of low-temperature film former, 0.1-3 percent of dispersant, 0.1-2 percent of film forming auxiliary agent and 50-80 percent of mixed solvent. The graphite emulsion paint has the advantages of stable chemical property, uniform dispersion, no bubbling in coating, smooth coating and superior operability; and the coating calcined according to the construction requirements is compact and has high adhesion, superior wear-resistant performance and good lubrication.

Owner:TSINGHUA UNIV

Method for manufacturing catalyzer

InactiveCN101108341AImprove performanceSame exchange effectCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPolyvinyl alcoholPolymerization

The invention relates to a production method of a hybrogen to water (liquid) hybrogen isotope exchange catalyst, which is characterized in that: firstly, make polyvinyl alcohol aqueous solution as compound aqueous phase and toluol and other organic solvent as pore agent, under the catalyzing of ABIN initiator to realize mass polymerization of divinylbenzene to produce polymer porous resin ball, then add the polymer porous resin ball into chloroplatinic acid ethanol solution to soak according to certain proportion, after drying, restoring and cooling to produce lyophobic catalyst. The invention is characterized in that: the technics has good repeatability, high catalyst activity, strong anti-Beta irradiance, and wide application range, which is not only suitable for extracting pure tritium in light water containing tritium of light water reactor, but also suitable for extracting pure tritium in heavy water containing tritium of heavy water reactor, also used for extracting pure tritium in liquid radioactivity outflow (nuclear waste) of nuclear power reactor, and can be used to produce heavy water by the way of hybrogen to water (liquid) dual temperature exchanging method.

Owner:柯香文

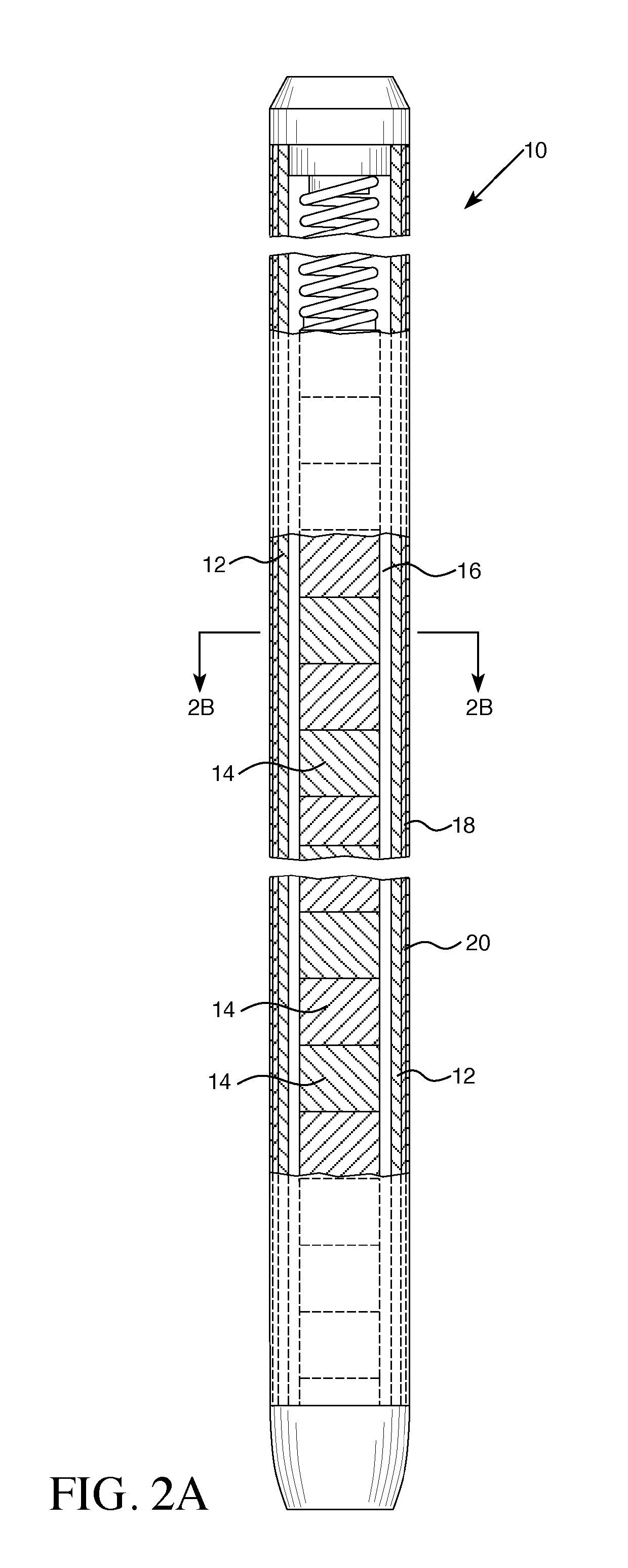

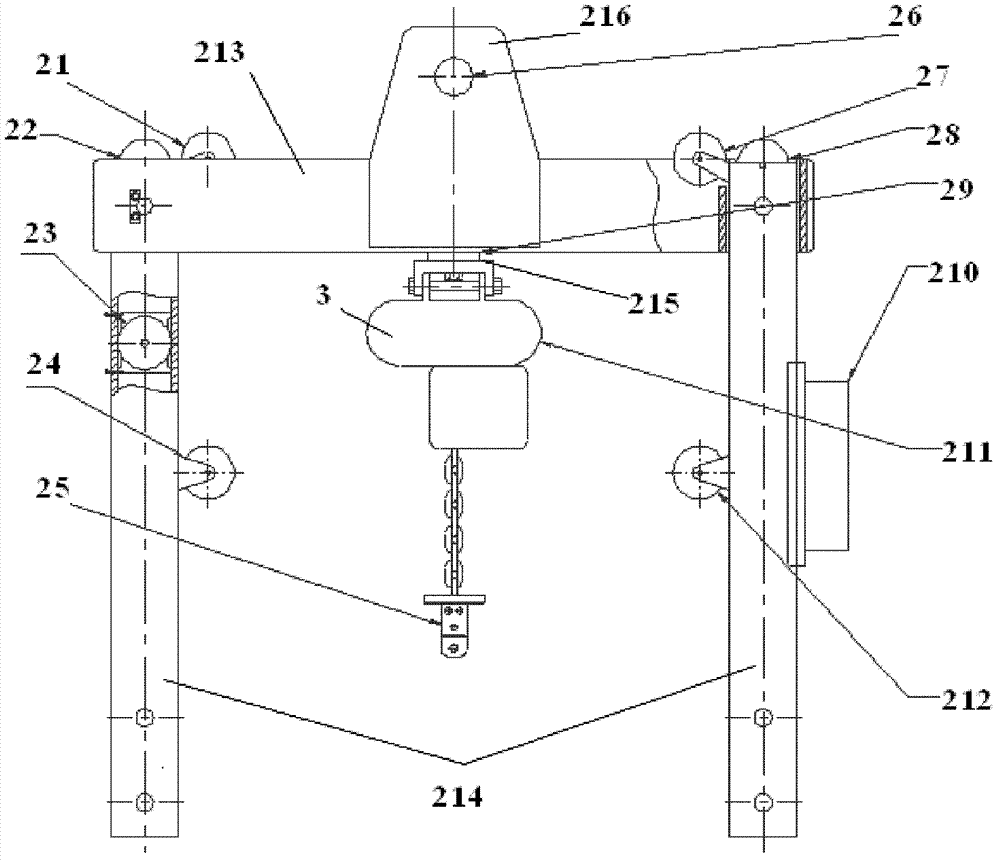

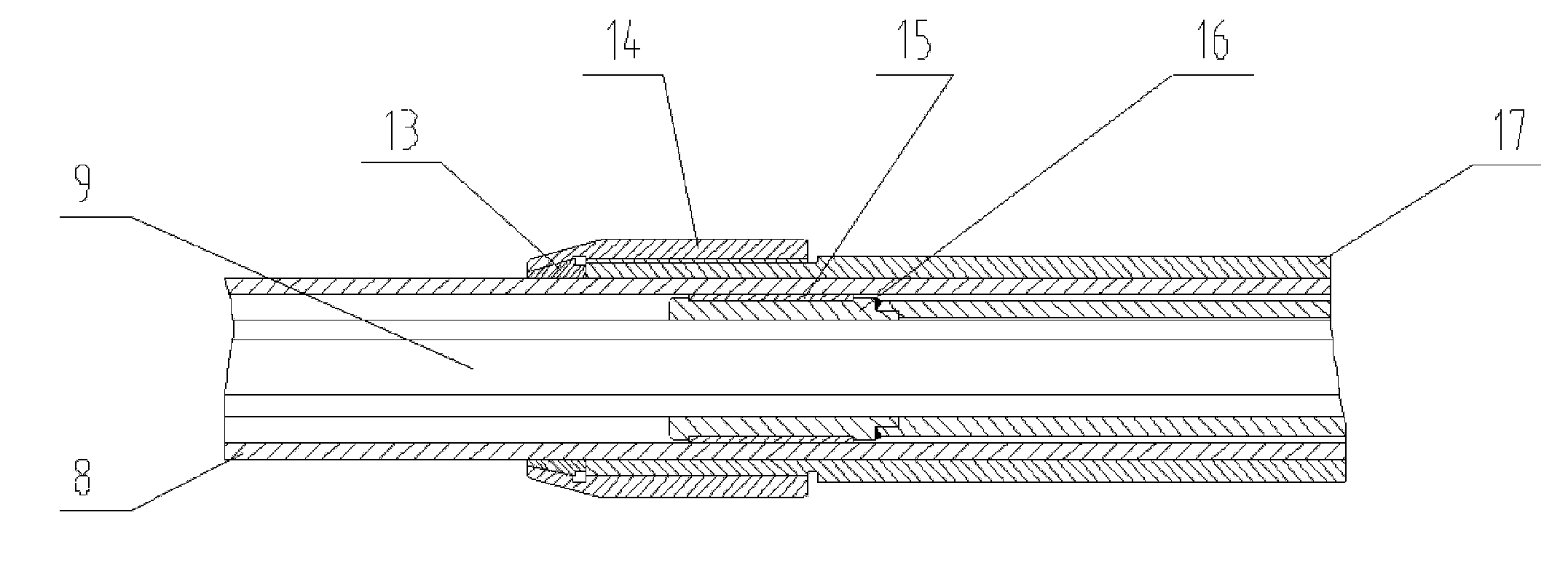

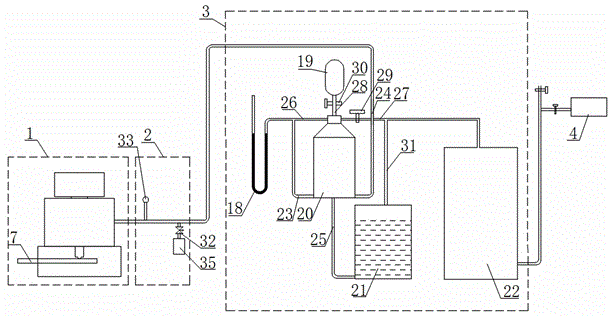

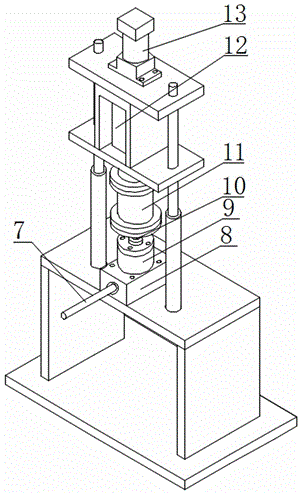

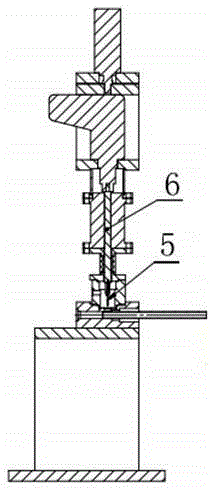

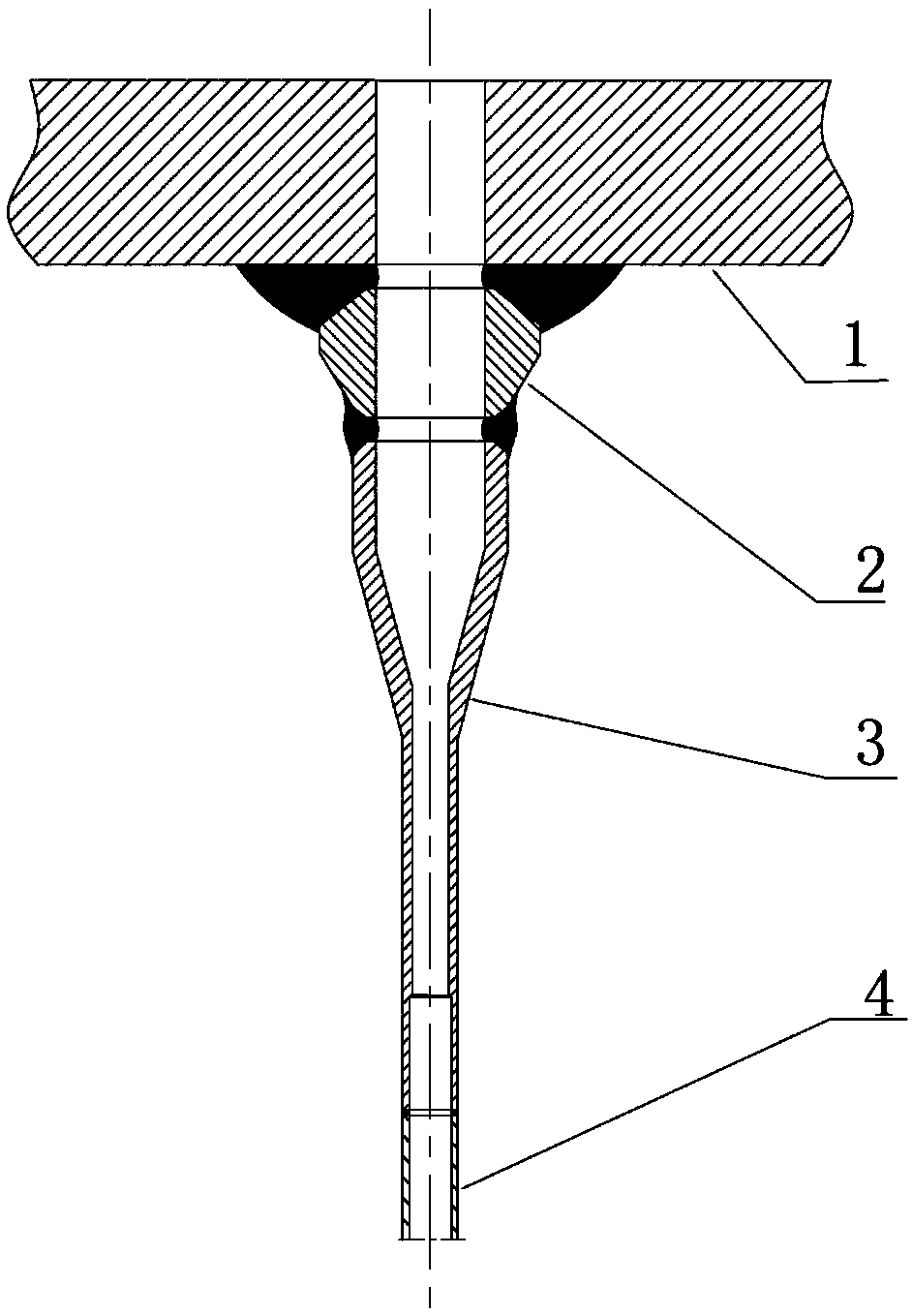

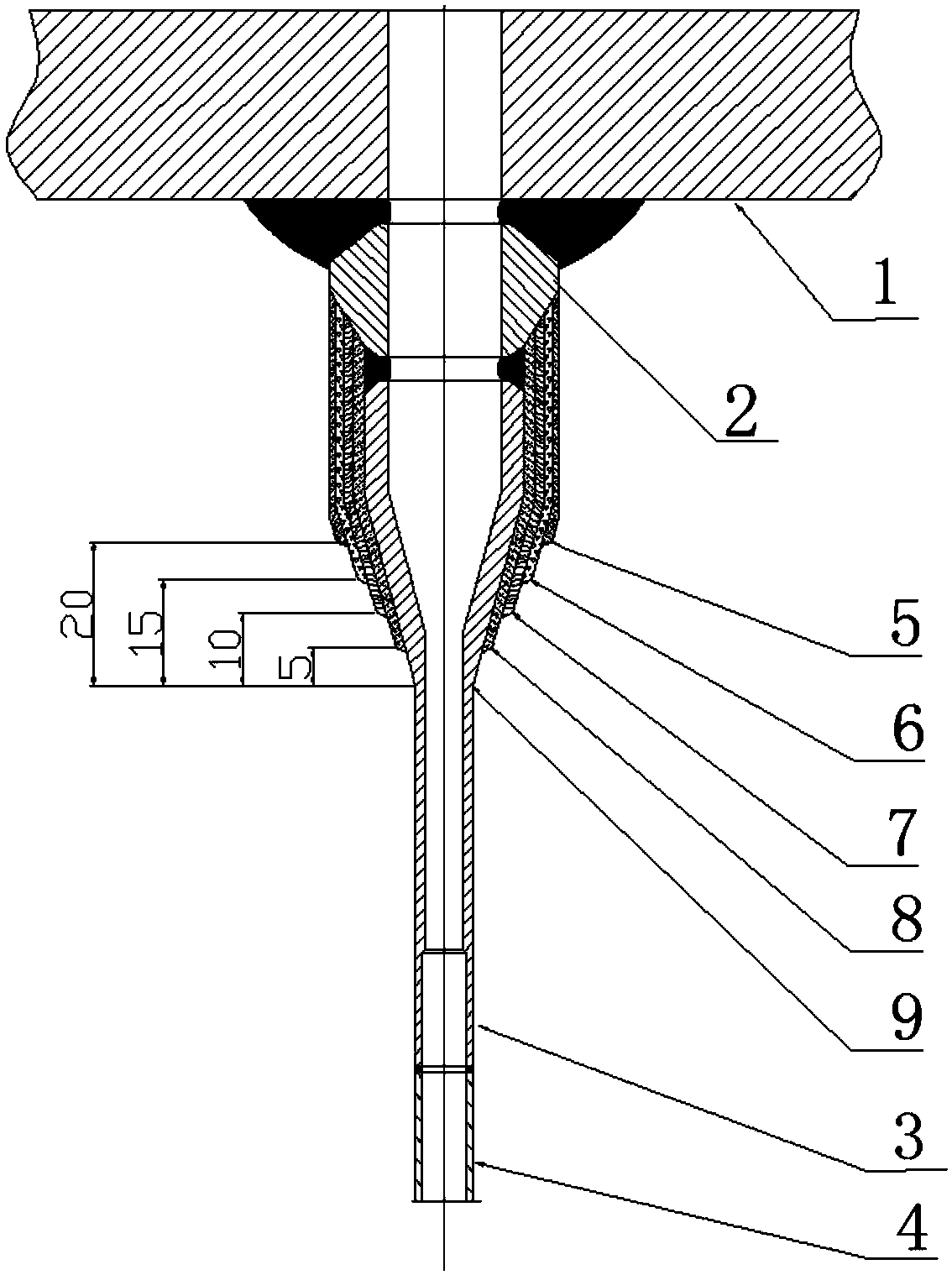

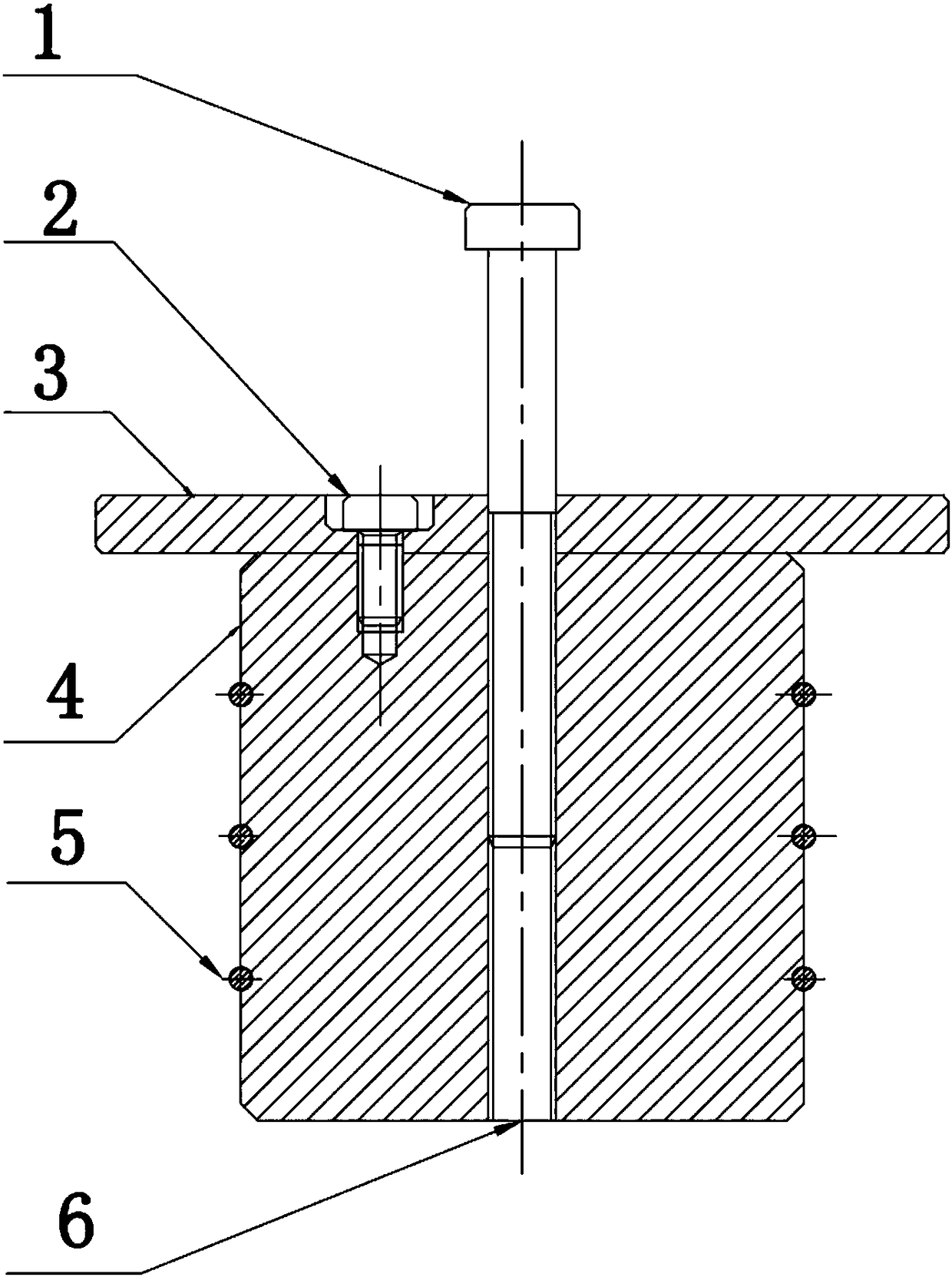

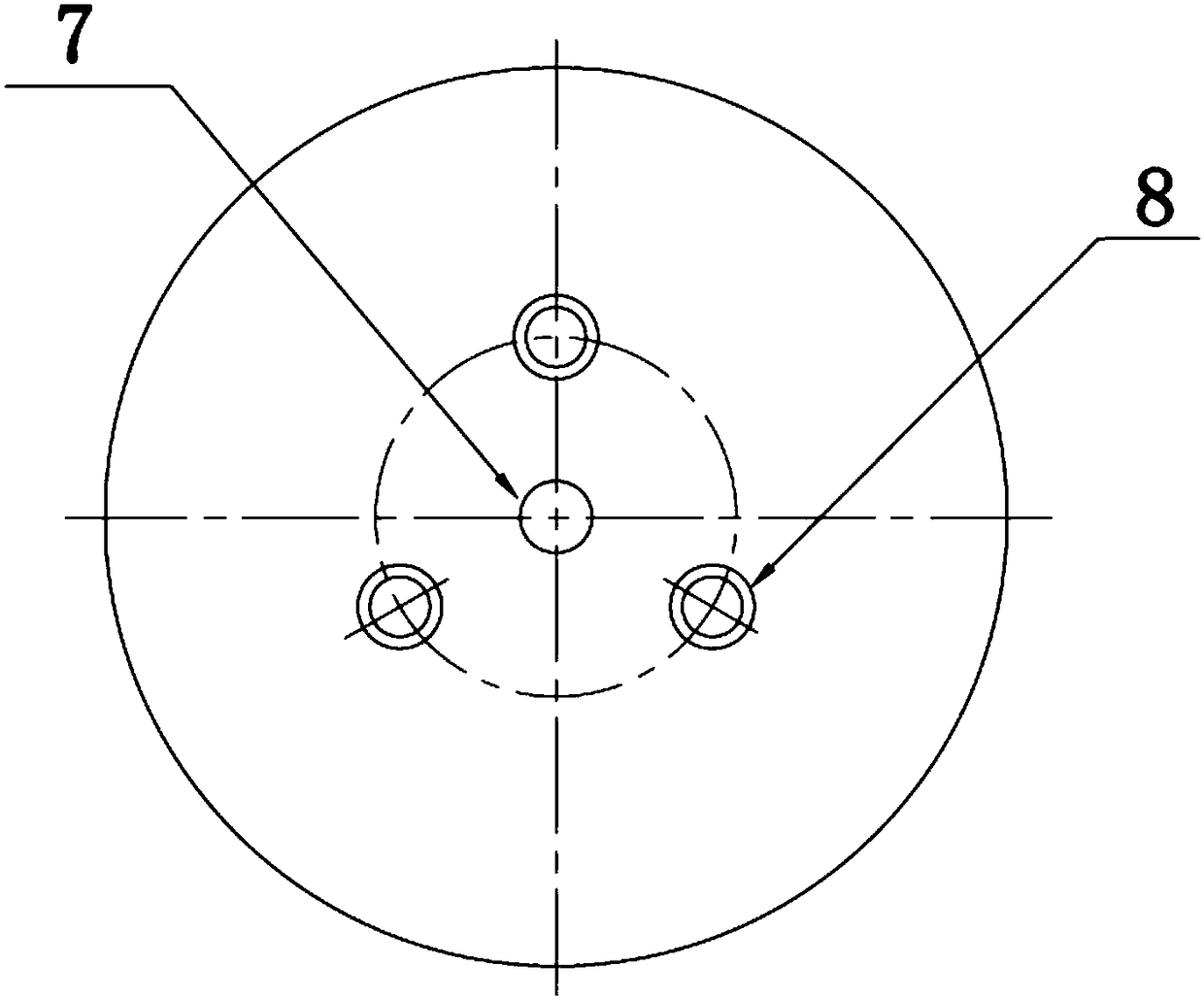

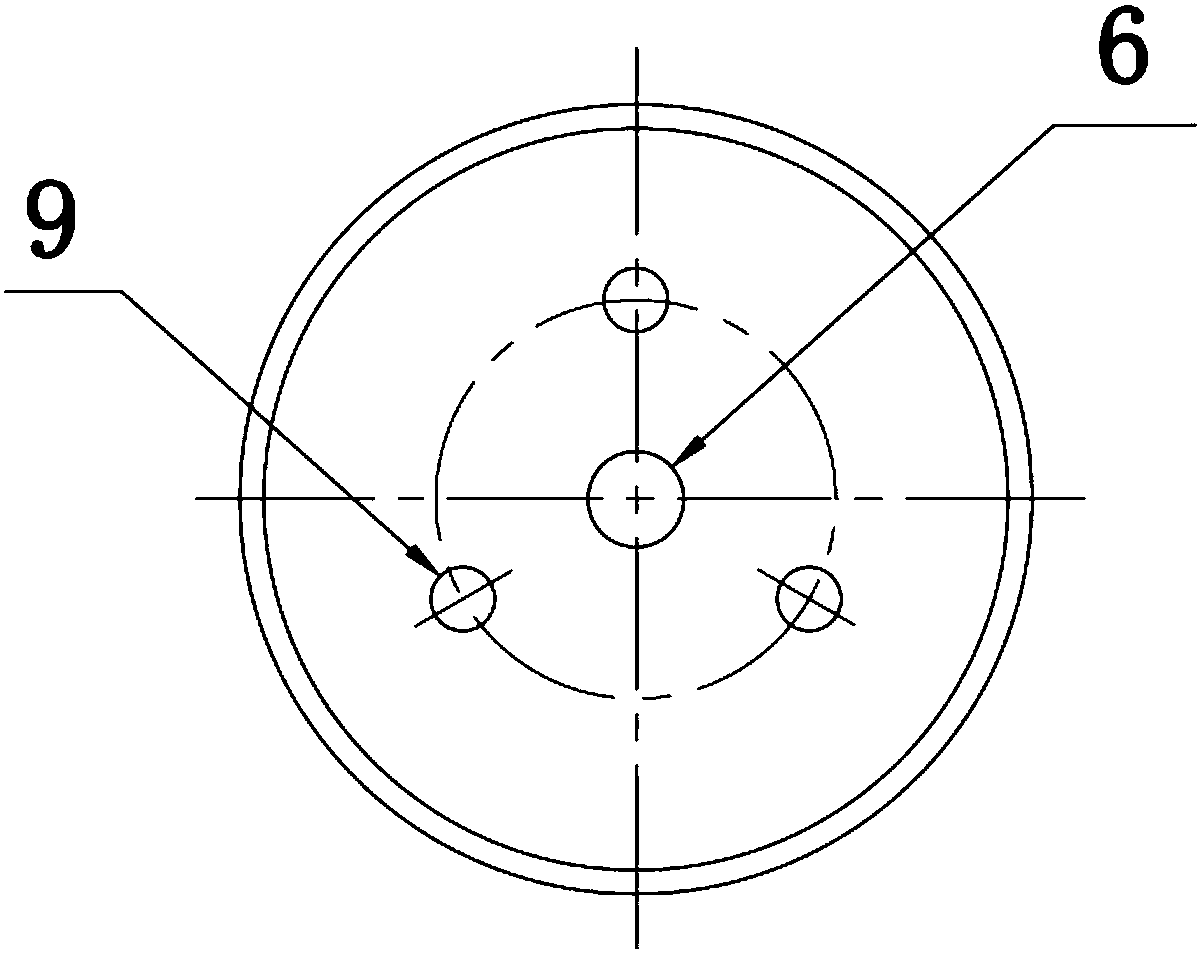

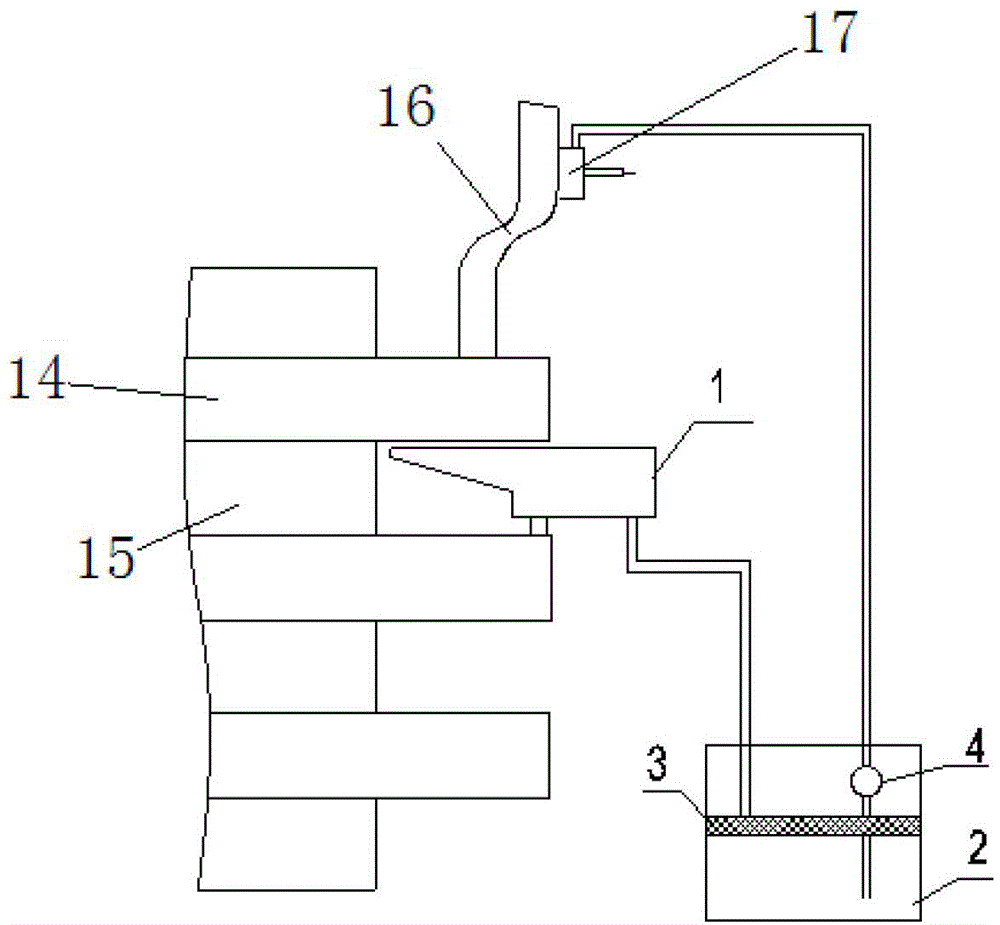

System and process for releasing and measuring fission gas of heavy-water reactor fuel elements

ActiveCN105427906AAchieve sealingAchieve releaseNuclear energy generationNuclear monitoringEngineeringGas release

The invention discloses a system for releasing and measuring fission gas of heavy-water reactor fuel elements. The system comprises a drilling device (1), a calibrating mechanism (2), a collecting device (3) and a vacuum unit (4). The drilling device (1) is used for drilling the heavy-water reactor fuel elements (7) and completely releasing the fission gas, the calibrating mechanism (2) is used for measuring the volumes of cavities inside the heavy-water reactor fuel elements (7), the collecting device (3) is used for pressurizing and collecting the fission gas released by the drilling device (1), and the vacuum unit (4) is used for vacuumizing the drilling device (1), the calibrating mechanism (2) or the collecting device (3). The invention further discloses a process for releasing and measuring the fission gas. The system and the process have the advantages that technologies for releasing and collecting the fission gas of the heavy-water reactor fuel elements are established, and accordingly the fission gas of the heavy-water reactor fuel elements can be released, collected and measured.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Fuel channel isotope irradiation at full operating power

A method of a method of irradiating a target material in a heavy water reactor for the production of an isotope, including the steps of providing a target comprised of a material suitable for producing the isotope by way of a neutron capture event, placing the target in a primary fluid side of the heavy water reactor, and irradiating the target.

Owner:BWXT ISOTOPE TECH GRP INC

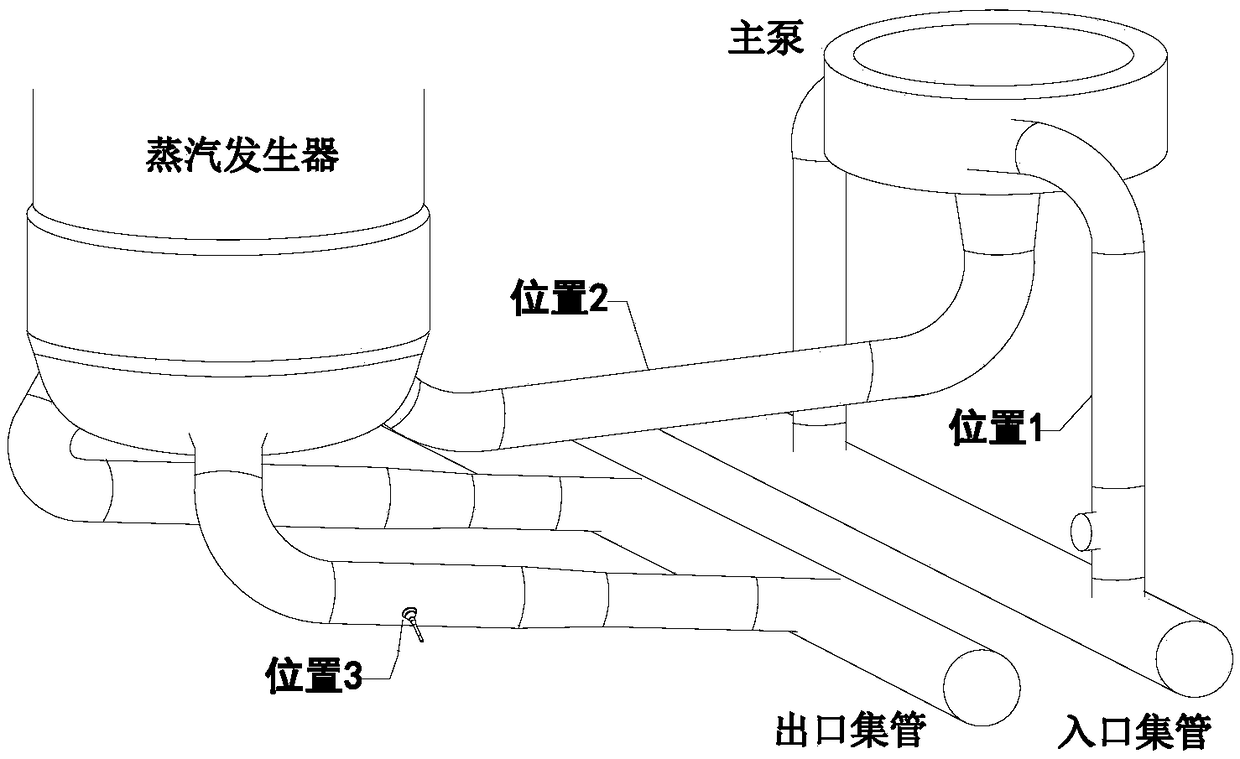

Heavy water reactor main pipeline branch pipe connector surfacing repairing structure

PendingCN108655604AGuarantee complete and reliableReduced stress corrosion susceptibilityArc welding apparatusWorkpiece edge portionsNuclear powerCarbon steel

The invention belongs to the technical field of nuclear power design and running, and particularly relates to a heavy water reactor main pipeline branch pipe connector surfacing repairing structure. The heavy water reactor main pipeline branch pipe connector surfacing repairing structure is characterized by comprising a main pipeline, a pipe base, an adapter and an instrument pipe and further comprising a surfacing layer cover face layer, a surfacing layer third layer, a surfacing layer second layer and a surfacing layer first layer; the upper end of the pipe base is connected to the lower endof the opening position, connected with a branch pipe, of the main pipeline, and the pipe base and the main pipeline are welded through argon arc welding; the upper end of the adapter is connected tothe lower end of the pipe base, and the adapter and the pipe base are welded through argon arc welding; the upper end of the instrument pipe is connected to the lower end of the adapter, and the instrument pipe and the adapter are subjected to all-position automatic welding; and surfacing welding is implemented to the outer surface of the connecting part of the pipe base and the adapter from theinterior to the exterior in the ring direction one by one, totally four layers are subjected to surfacing and are divided into the surfacing layer first layer, the surfacing layer second layer, the surfacing layer third layer and the surfacing layer cover face layer, and for each surfacing layer, welding is conducted to the reducing position of the adapter from the position of a carbon steel pipebase.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

Lead shielding block on end face of nuclear fuel channel in heavy water reactor nuclear power station and preparation method thereof

ActiveCN103943162AIncrease elasticityNo hard collisionsShieldingMetal layered productsNuclear powerRadiochemistry

The invention relates to a nuclear radiation protective supply and a preparation method of the nuclear radiation protective supply, in particular to a lead shielding block on the end face of a nuclear fuel channel in a heavy water reactor nuclear power station and a preparation method of the lead shielding block. The lead shielding block comprises multiple layers of overlying lead foil, wherein the lead foil is provided with locating holes, the fuel channel is sleeved with the lead shielding block through the locating holes, and silicone rubber layers are arranged on the outer side edges of the multiple layers of overlying lead foil and the inner wall faces of the locating holes. The preparation method of the lead shielding block comprises the steps of preparing the multiple layers of overlying lead foil, wrapping the multiple layers of overlying lead foil with silicone rubber, and conducting compression molding to obtain the lead shielding block. The lead shielding block does not damage the fuel channel and is light in self weight and easy to prepare, install and use.

Owner:SHENZHEN AIDUN RADIATION PROTECTION SAFETY EQUIP

Heavy water reactor nuclear power plant steam generator hand hole multifunctional foreign-matter-blockage preventive component

PendingCN108269625ASimple structureReduce weightNuclear energy generationNuclear monitoringForeign matterRubber ring

The invention relates to the technical field of nuclear power plant running and maintaining, in particular to a heavy water reactor nuclear power plant steam generator hand hole multifunctional foreign-matter-blockage preventive component which comprises a plug, a sealing face protection cover plate, an operation handle and a rubber ring. The plug is of a cylindrical structure integrally, size ofthe plug is matched with that of a steam generator hand hole, multiple grooves are formed in the outer circumferential wall of the plug from top to bottom, and the rubber ring is embedded in the grooves in a compressed manner; a balance air pressure through hole penetrating the plug and three threaded blind holes uniformly distributed around the balance air pressure through hole are formed in themiddle of a sealing face of the upper portion of the plug, an internal thread is formed in the balance air pressure through hole and used for being matched with an operation handle thread for penetrating operation. The component has functions of plugging a hand hole, resisting foreign matters and protecting a hand hole sealing face and is simple in structure, convenient to mount, reliable in operation, light in weight, convenient for carrying and transporting and capable of avoiding risks like foreign matter inhalation and sealing face scratching during maintenance operation.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

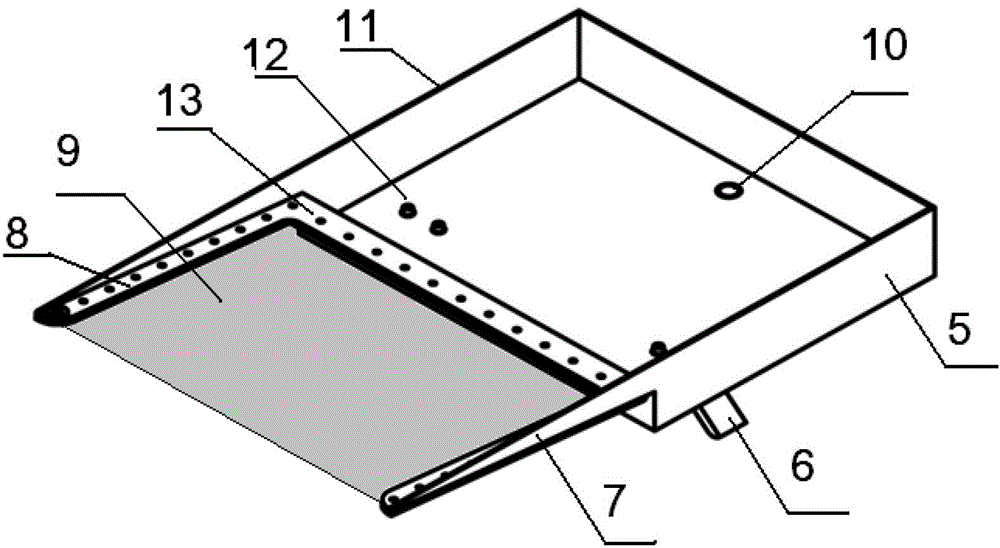

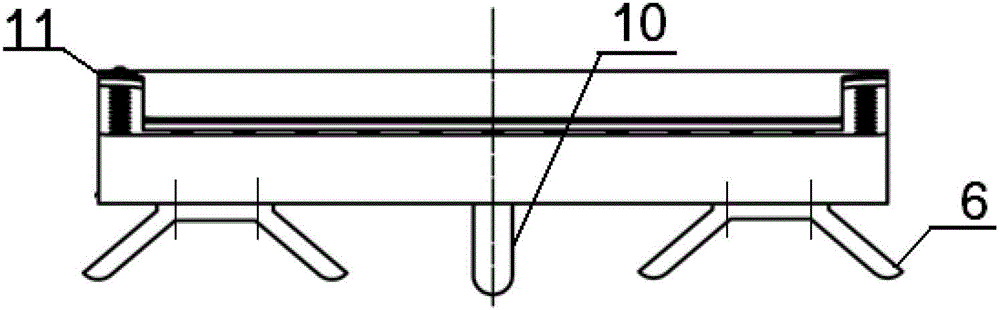

Recycling device of light water coupling agent for supersonic inspection on heat transfer branch pipe of heavy water reactor power station

InactiveCN104376885ALess panicReduce in quantityMaterial analysis using sonic/ultrasonic/infrasonic wavesNuclear energy generationPower stationCoupling

The invention belongs to the technical field of nuclear station in-service inspection, and specifically relates to a recycling device of a light water coupling agent for the supersonic inspection on a heat transfer branch pipe of a heavy water reaction power station. The device comprises a water receiving disc, a water tank, a filter core, and a water pump. The wedge-shaped water receiving disc is inserted into a gap between fuel channels and is connected to one end of a recycled water soft pipe, the other end of the recycled water soft pipe is arranged above the filter core, the filter core is arranged in the water tank, the lower end of a water supply soft pipe is arranged in the water tank, and the upper end of the water supply soft pipe goes through the filter core and is connected to a supersonic inspecting probe through the water pump. The provided device can recycle a light water coupling agent, which is used in the supersonic inspection on a heat transfer branch pipe of a heavy water reaction power station. The provided device can reduce the surface pollution in the job site, reduce the amount of wetted thermal insulation cotton, and relieve the panic of non-staff members on the on-site water, when they have no idea on the on-site situation.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

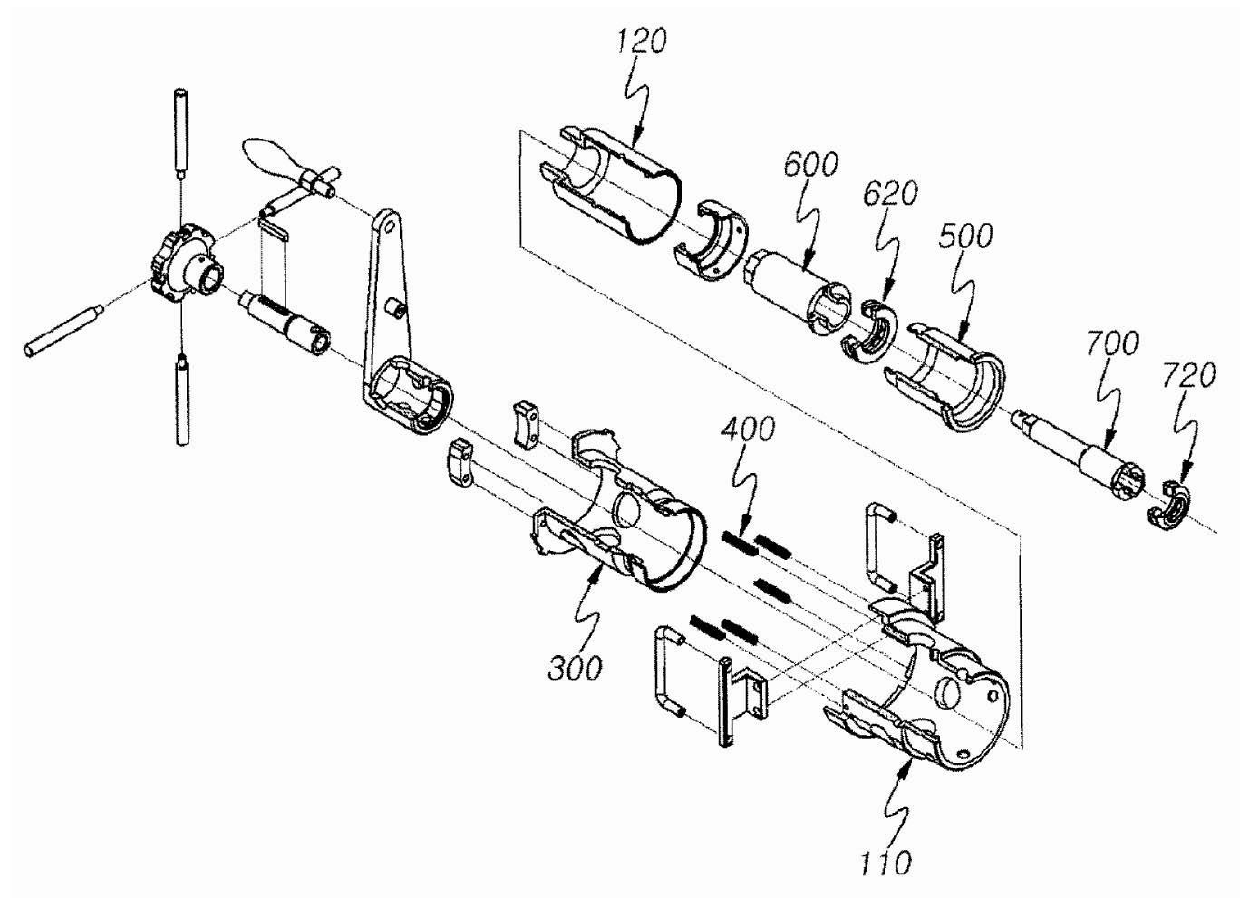

Plug removing device for heavy water reactor fuel system

ActiveCN102568634AEasy to install and removeQuick releaseNuclear energy generationRecycling and recovery technologiesEngineeringBung

The invention provides a plug removing device for a heavy water reactor fuel system. The removing device is arranged on a plug on a fuel element in the heavy water reactor fuel system. The plug comprises a locking ring rim and a pushing pipe which are formed along the internal circumference of the plug. The plug removing device comprises a clamping shell, positioning balls, a guide shaft bush, an elastic piece, a mortise lock pressing piece, a hollow main bar and a sub bar, wherein the clamping shell consists of an external shell and an internal shell; a plurality of ball pores are formed in the radial direction of the external shell, and the external shell is inserted into an internal diameter region of the plug; the internal shell is provided with a bar sleeve; the positioning balls are connected in the ball pores of the external shell and are locked on the locking ring rim so as to fix the clamping shell to the plug; the guide shaft bush is provided with a releasing slot which is formed to guide the positioning balls to release and is connected to guide the internal shell and the external shell to slide; the elastic piece is arranged between the guide shaft bush and the clamping shell and is used for recovering the released positioning balls so as to elastically lock the positioning balls; the mortise lock pressing piece is connected so as to slide into the internal diameter region of the internal shell and press the inner surface of the plug; the hollow main bar is screwed into a bar sleeve of the internal shell so as to make the mortise lock pressing piece slide; and the sub bar is connected to the internal diameter region of the main bar and presses the pushing pipe to remove the plug.

Owner:韩电KPS株式会社

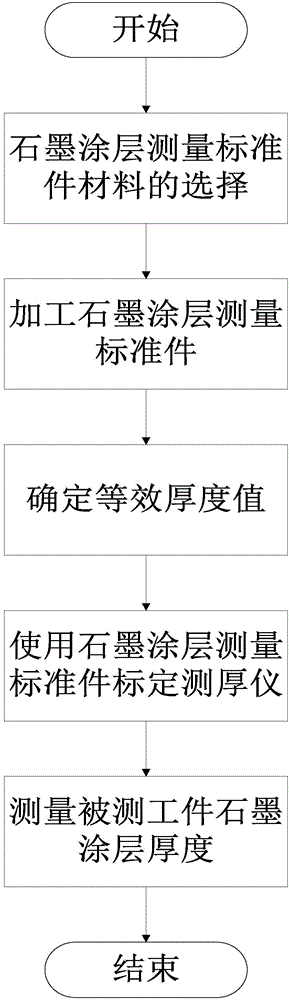

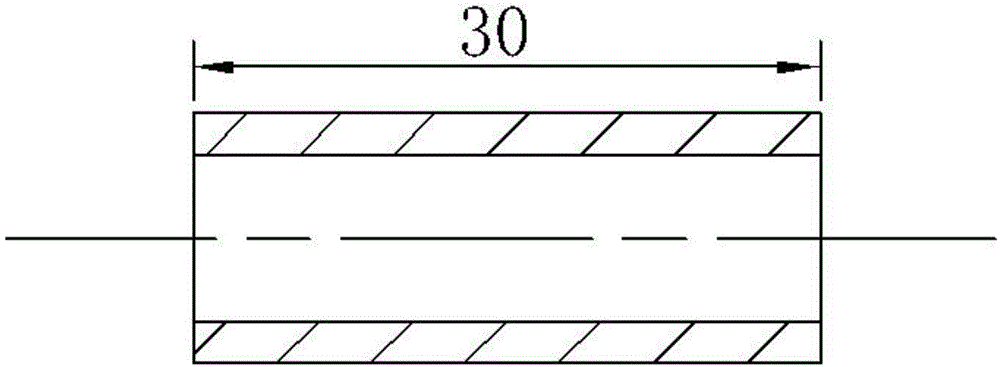

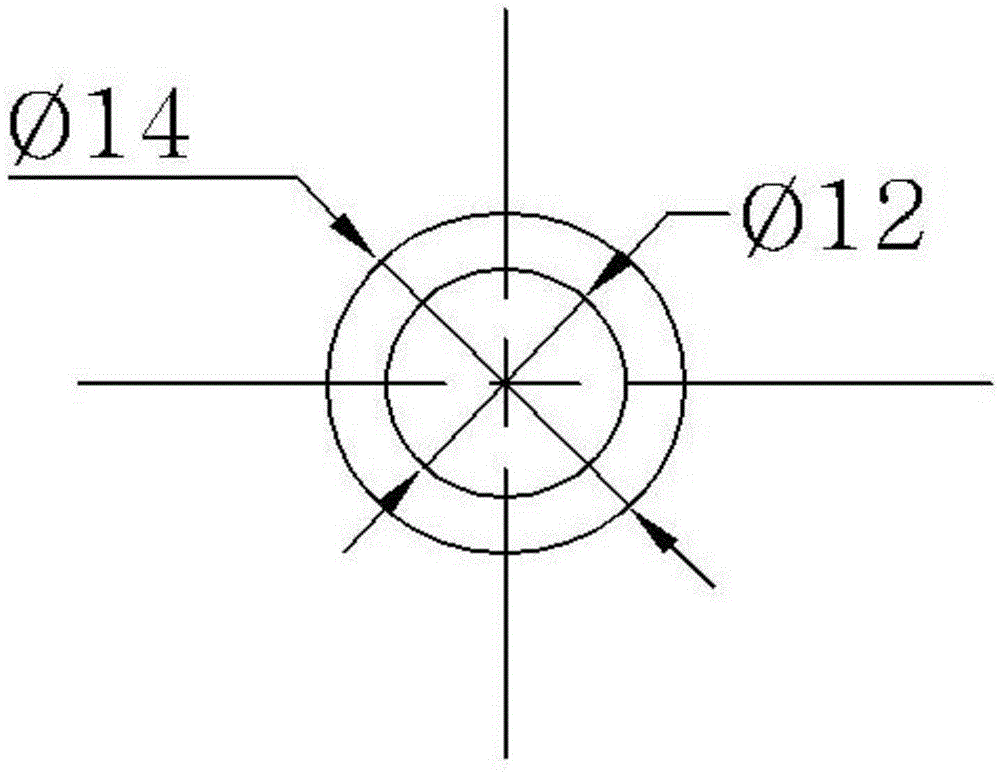

Graphite coating thickness measurement method

InactiveCN105806291AEasy to processImprove reliabilityMeasurement devicesManufacturing technologyGraphite

The present invention relates to the technical field of heavy water reactor nuclear fuel element manufacturing, particularly relates to a graphite coating thickness measurement method, and aims to solve the problem of an inaccurate measurement result caused by the easy abrasion of a coating by an existing graphite coating measurement method. The graphite coating thickness measurement method is characterized in that the method comprises the steps of selecting a graphite coating measurement standard element material, processing a graphite coating measurement standard element, determining an equivalent thickness value, calibrating a thickness measurement instrument by using the graphite coating measurement standard element, and measuring the thickness of the tested work piece graphite coating thickness. The graphite coating measurement tool of the invention has the advantages of simple processing, high reliability, little possibility of wear, and long-term repeated use. After an equivalent thickness value is determined, the tool can be reused for many times, the re-calibration of each measurement is not needed, and the cost of re-calibration is saved.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Target piece for producing C-14 isotope by heavy water reactor

PendingCN113140346ARealize industrial productionSolve the production capacitySpecific isotope recoveryConversion in nuclear reactorIsotopic labelingForeign technology

The invention aims to disclose a target piece for producing C-14 isotope by a heavy water reactor, the target piece comprises a connecting rod and an end plate, a target cylinder assembly or an absorption rod assembly is arranged around the connecting rod, and the target cylinder assembly or the absorption rod assembly is fixed at the upper end and the lower end of the arrangement position of the target cylinder assembly or the absorption rod assembly through the end plate. The connecting rod is connected with the upper positioning mechanism and is used for positioning the target piece; compared with the prior art, the target piece is placed in the reactor core of the heavy water reactor, and the C-14 isotope is generated by irradiation of thermal neutrons, so that the industrial production of the C-14 isotope can be realized, the production capacity of the C-14 can be improved, the foreign technical blockade can be broken, and the discourse right of the international isotope transaction market can be obtained; and the development of industries such as domestic biological medicine, environmental protection and isotope labeling detection is promoted, and the aim is fulfilled.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +2

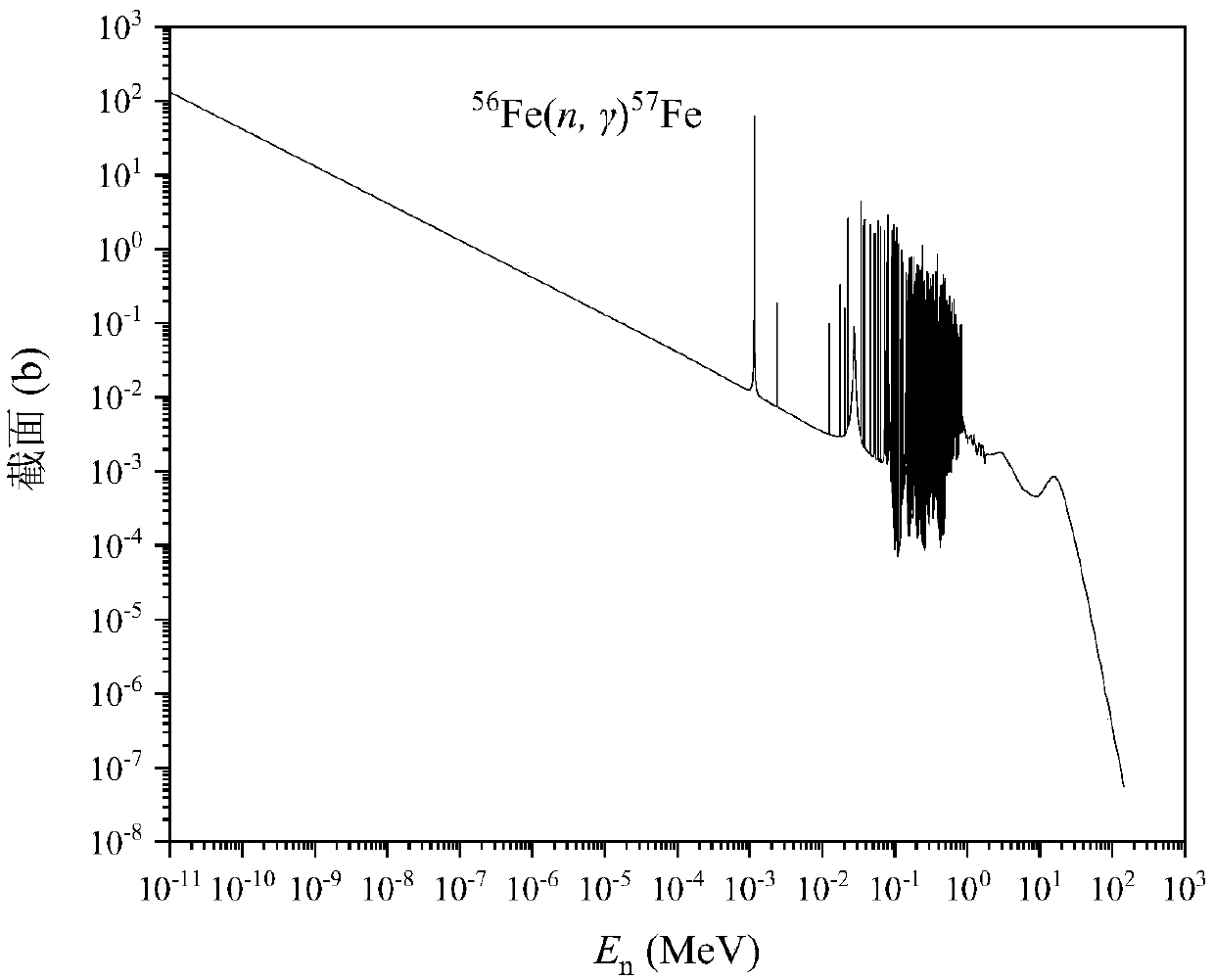

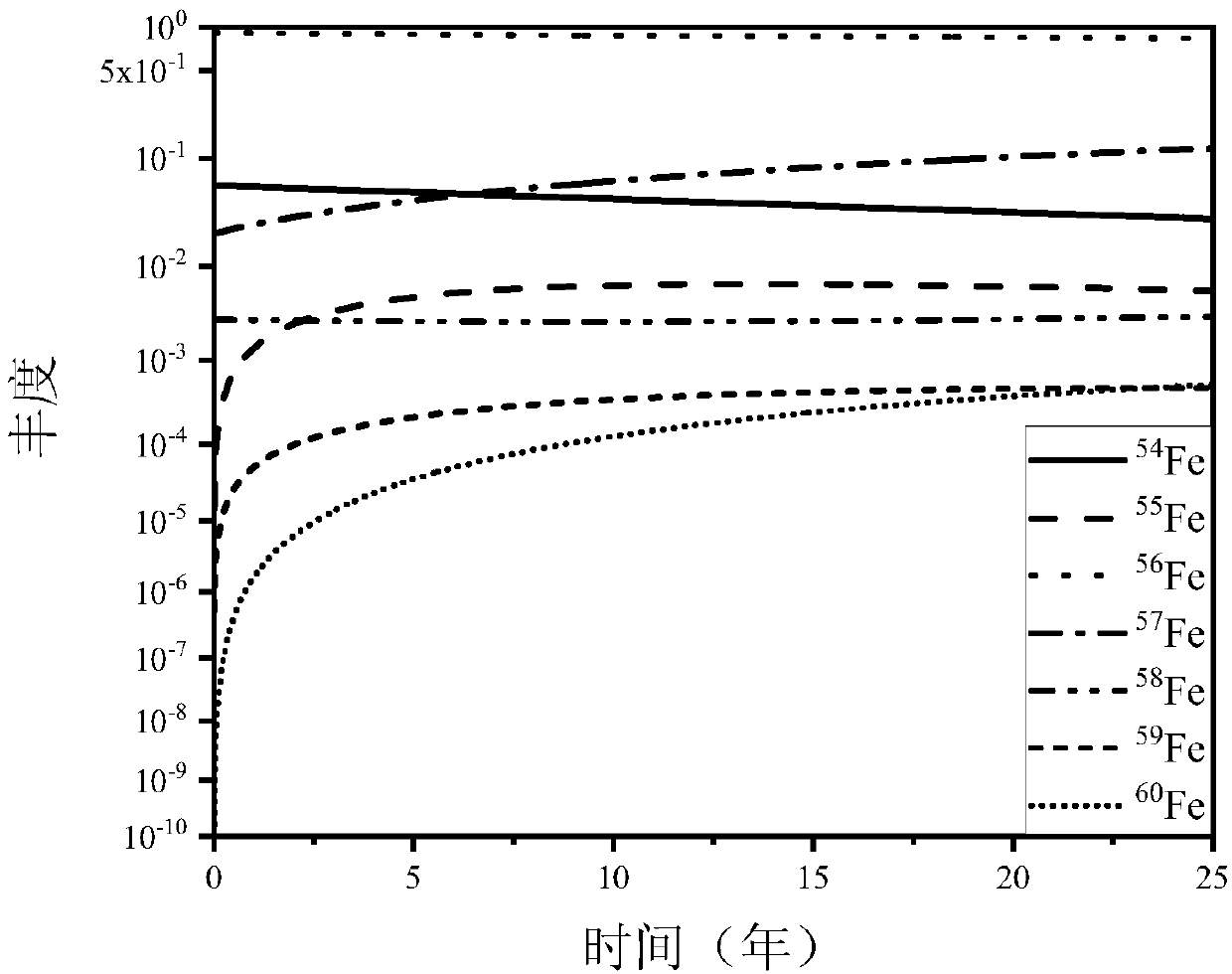

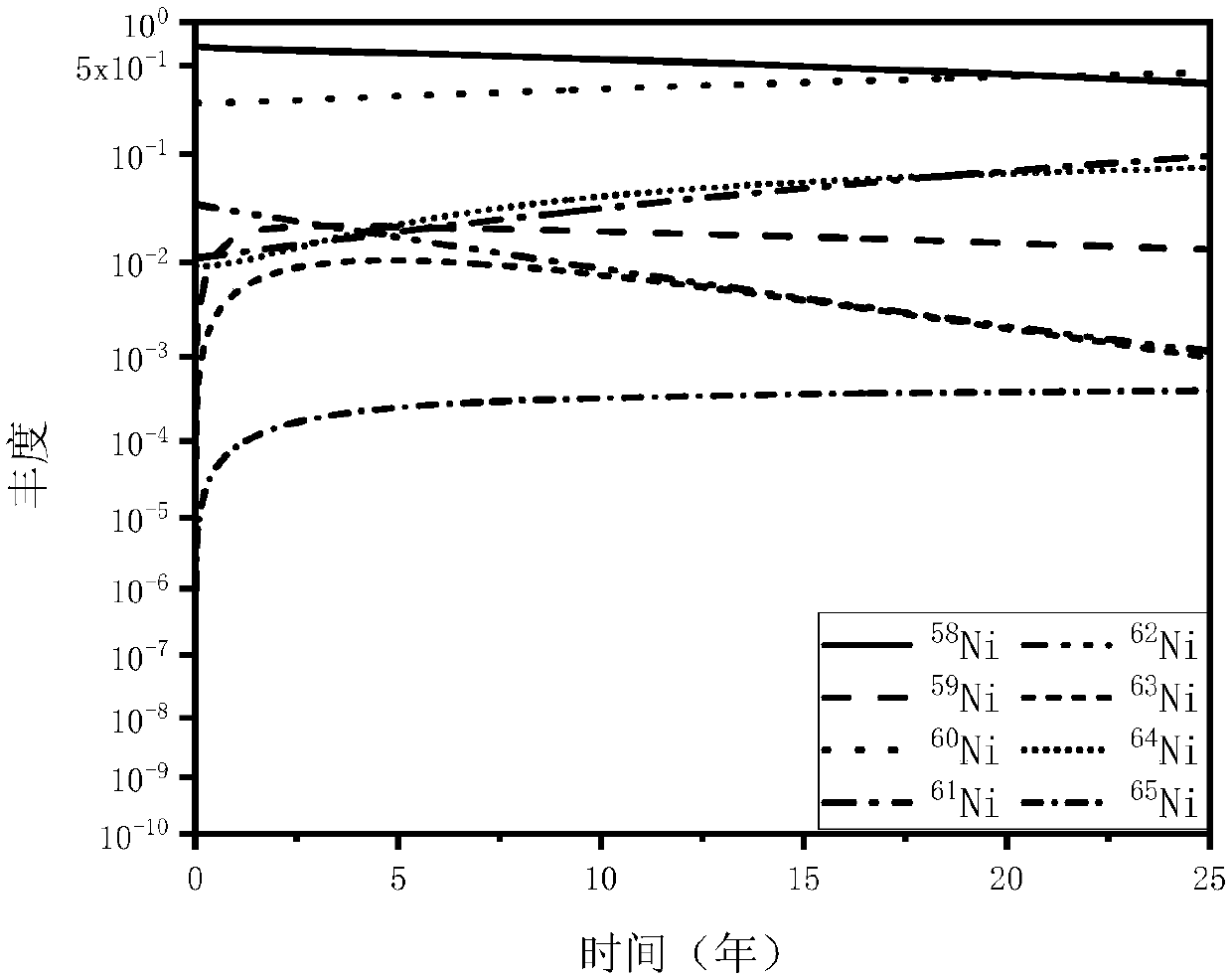

Method for estimating thermal neutron fluence of heavy water reactor

ActiveCN109659047AIntuitively reflect the radiation effectReflect the radiation effectNuclear energy generationNuclear monitoringNeutron irradiationIsotope

The invention discloses a method for estimating the thermal neutron fluence of a heavy water reactor. According to the method, the structural material of the core of a heavy water reactor is taken outafter neutron irradiation; then the isotope abundance of one or more elements is measured by a nuclear analyzer, because the nuclear material and neutrons (mainly thermal neutrons) carry out radiation capture reactions, the isotope abundances of all elements of the nuclear material change, and thus by measuring the isotope abundances, the thermal neutron fluence on the nuclear material can be estimated under a condition that the running time of the reactor is known. The provided method is simple, and the measurement of thermal neutron fluence is converted into measurement on isotope abundance.

Owner:PEKING UNIV

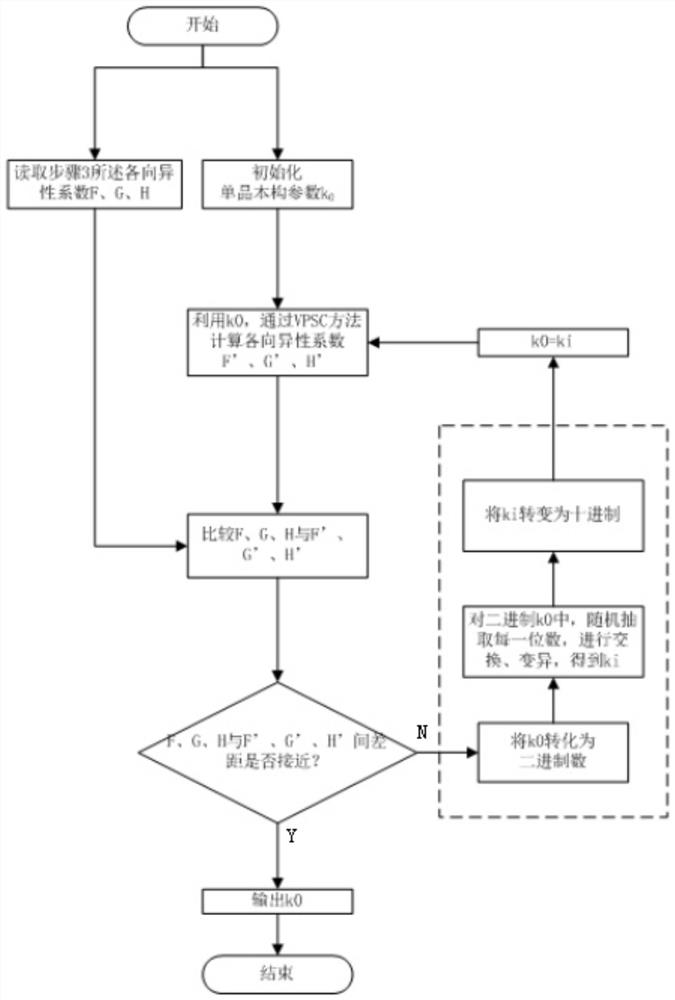

Method for obtaining constitutive parameters of zirconium alloy irradiation deformation single crystal

PendingCN112906275ASolve the difficulty of obtainingGeometric CADDesign optimisation/simulationGenetics algorithmsSingle crystal

The invention relates to the technical field of heavy water reactor material equipment design and evaluation, in particular to a method for obtaining zirconium alloy irradiation deformation single crystal constitutive parameters. The method comprises the following specific steps: collecting plastic deformation test or actual measurement parameters of zirconium alloy caused by irradiation deformation; simulating observed alloy deformation by adopting a finite element method or a finite volume method on the basis of a polycrystalline irradiation deformation constitutive structure under an irradiation condition; based on the simulation result, calculating the anisotropy coefficient of the irradiation plasticity of the polycrystal; and obtaining the apparent single crystal constitutive structure by utilizing the anisotropy coefficient and combining a genetic algorithm. Compared with the prior art, the method has the advantages that the problem that the constitutive parameters of the single crystal are difficult to obtain when the radiation deformation of the nuclear-grade zirconium alloy is predicted by utilizing a mesomechanical model can be well solved; the obtained apparent single crystal constitutive parameters can be used for obtaining irradiation deformation prediction of nuclear-grade zirconium alloy.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

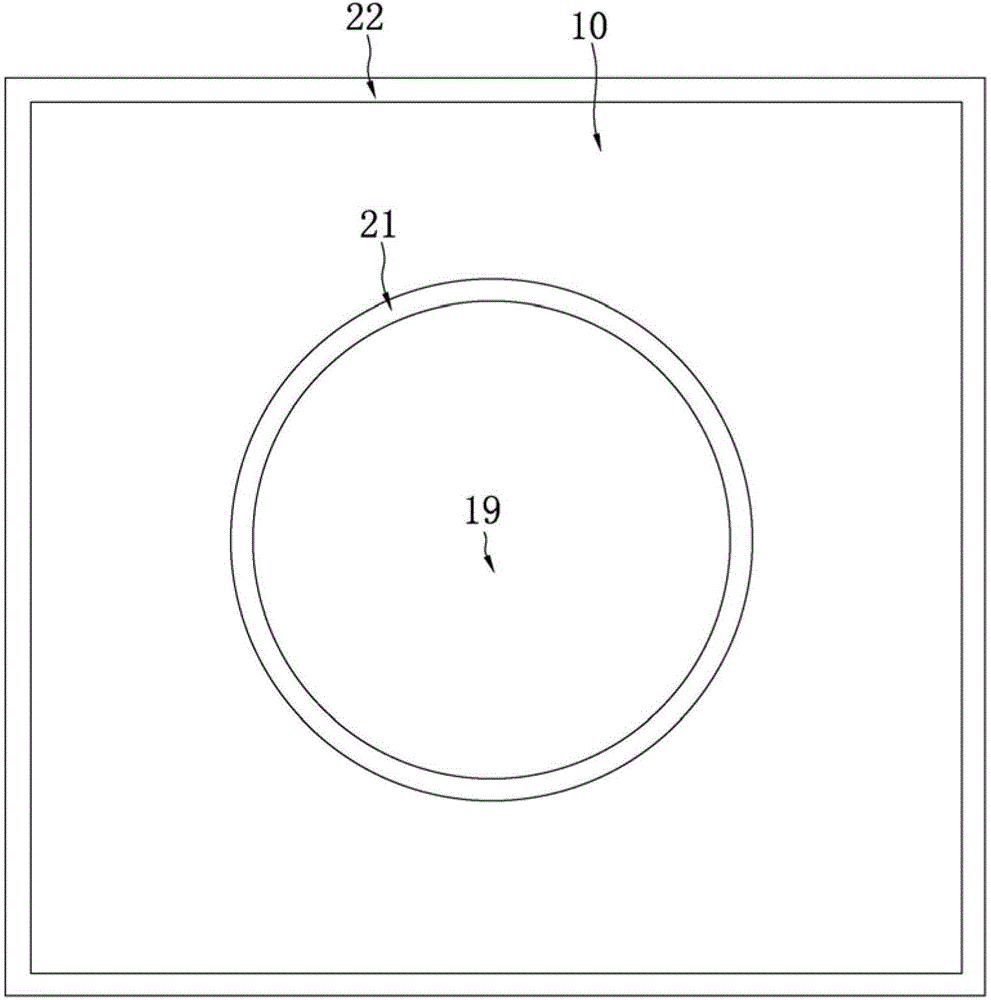

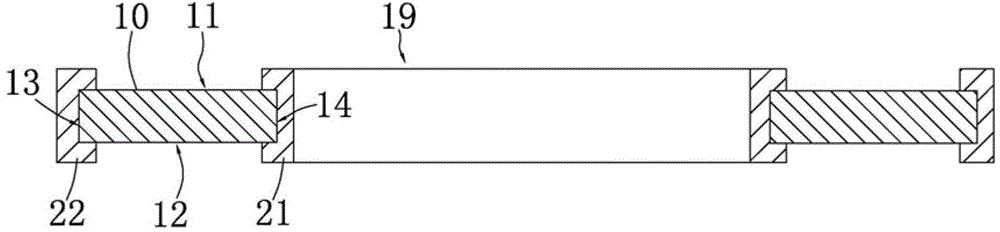

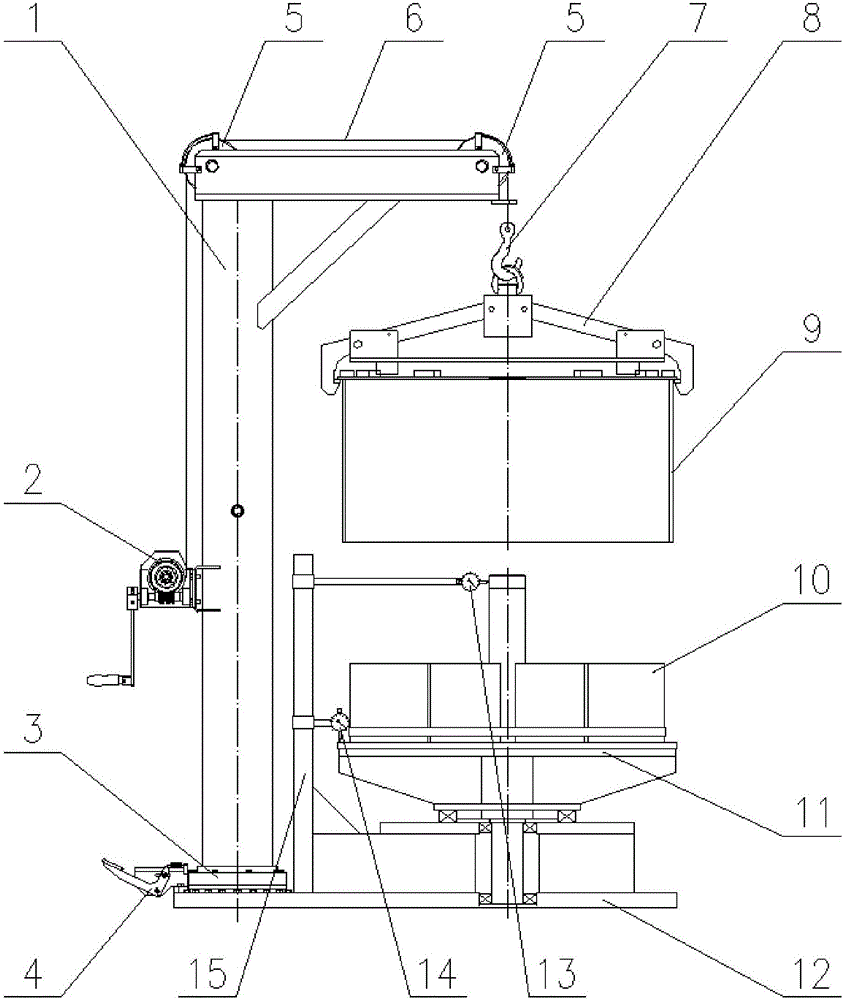

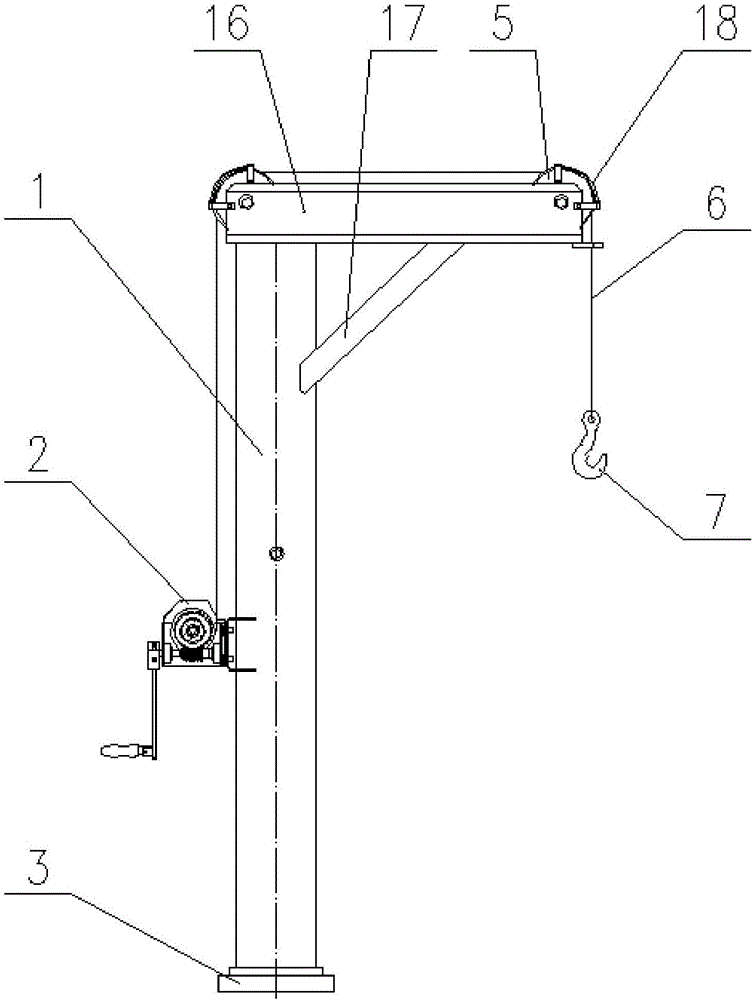

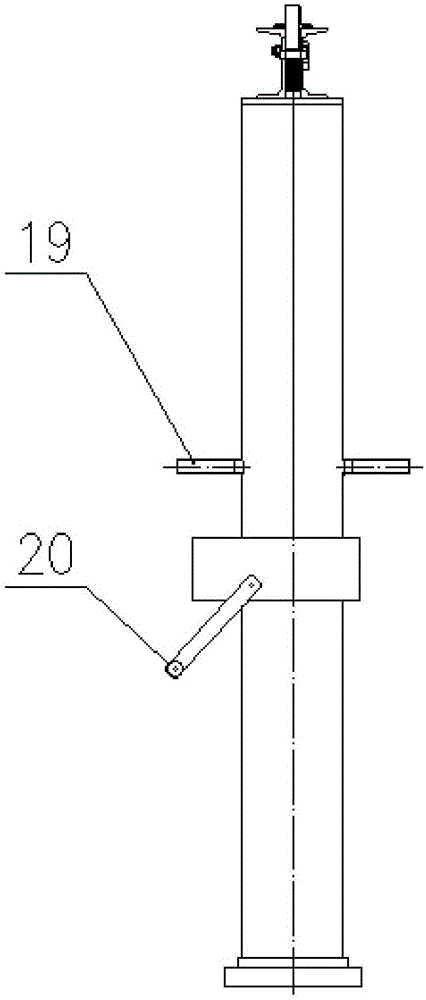

Heavy water reactor spent fuel basket testing inspection device

ActiveCN106705810ASatisfy IntegrityIntegrity guaranteedNuclear energy generationMechanical counters/curvatures measurementsNuclear powerDry storage

The invention belongs to the technical field of nuclear power station spent fuel dry storage, and particularly relates to a heavy water reactor spent fuel basket testing inspection device. The invention aims to develop a spent fuel basket testing inspection device, that is, a manufactured spent fuel basket is transferred to the testing inspection device, a dial indicator is erected after the inspection device is in place, the circularity, the coaxiality and the flatness of the fuel basket can be tested by rotating the fuel basket, and a cover of the fuel basket is opened to check whether the internal structure is completed or not. The characteristics lie in that the heavy water reactor spent fuel basket testing inspection device comprises a supporting and hanging bracket, a hand-cranking winding device, a supporting and hanging bracket supporting and locking device, a basket cover gripping apparatus, a rotating inspection platform, a base and a measuring and inspecting dial indicator device. The spent fuel basket testing inspection device disclosed by the invention is accurate in measured data, safe, reliable, convenient to operate and improved in work efficiency, can ensure subsequent relevant operations to be conducted normally before the fuel basket is loaded with spent fuel rod bundles, and ensures the integrity of fuel rod bundles and welding of upper and lower welding seams of the fuel basket to meet requirements of a welding technology.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com