Heavy water reactor spent fuel basket testing inspection device

A technology for inspecting devices and spent fuel, which is applied in the field of dry storage of spent fuel in nuclear power plants, and can solve problems such as drop, unit power reduction, shutdown and shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

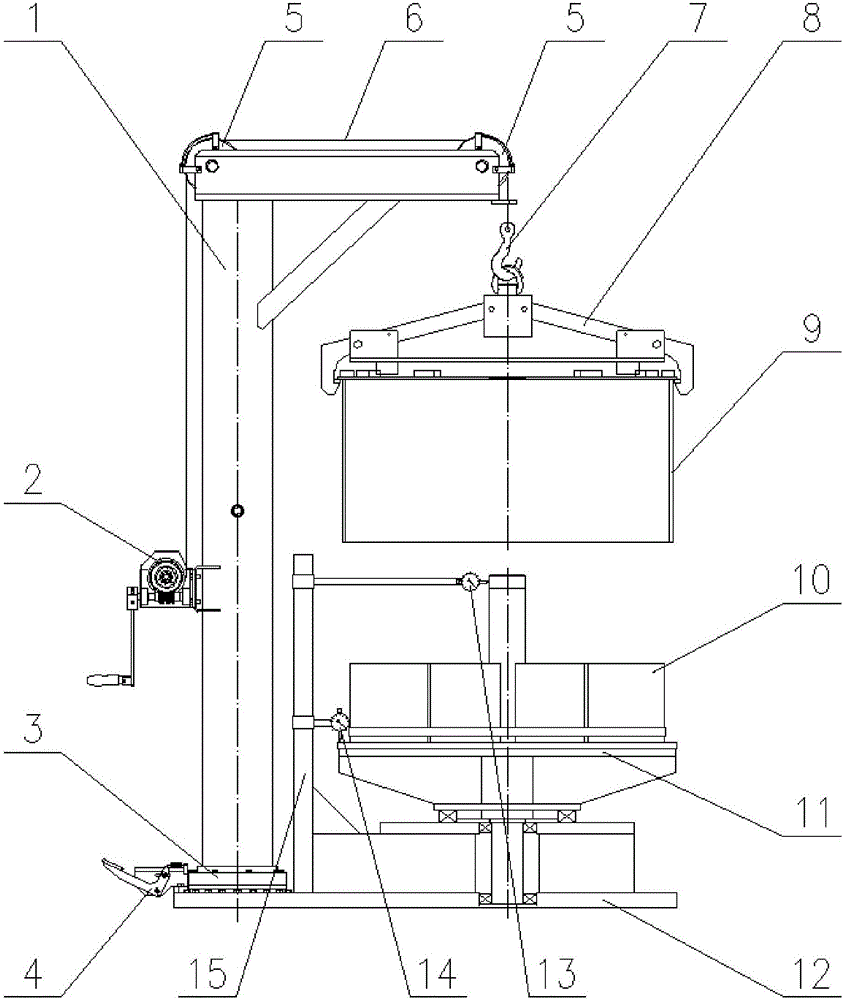

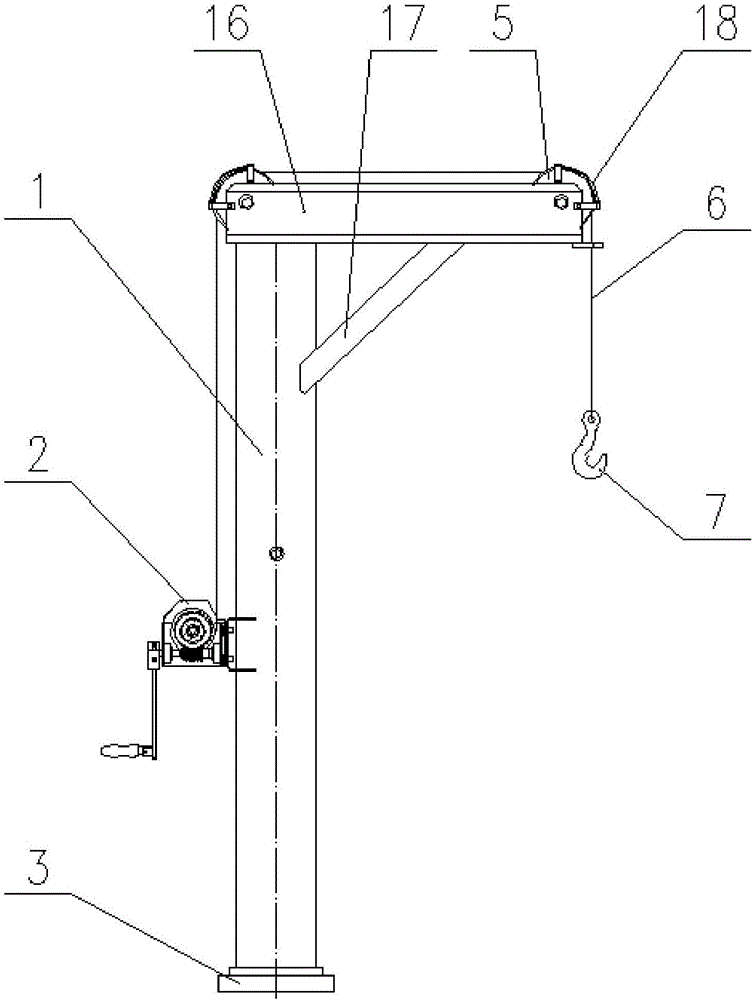

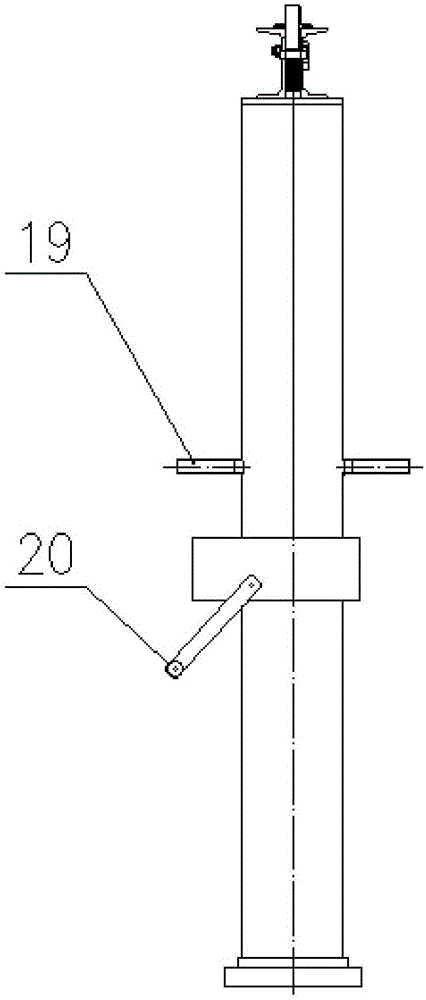

[0030] Such as figure 1 As shown, a heavy water reactor spent fuel basket test and inspection device includes a support hanger, a hand winch device 2, a support hanger support locking device 4, a basket cover gripper 8, a rotating inspection platform 11, a base 12 and a measurement inspection dial indicator device. Support hanger is fixed on the base 12. The hand hoisting device 2 and the hanger support locking device 4 are arranged on the hanger. The basket cover grabber 8 is suspended on the support hanger. The rotating inspection platform 11 and the measuring and checking dial indicator device are fixed on the base 12, located on one side of the support hanger, and also located under the basket cover grabber 8. The hanger and base 12 are used to provide structural support for the entire device. The hand winch 2 is used to lift the basket cover g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com