Zirconium based alloys having excellent creep resistance

a zirconium-based alloy and creep-resistant technology, applied in the field of zirconium-based alloy composites, can solve the problems of reaching the limit of use of conventional zircaloy-4 cladding tubes, zircaloy-4 cladding tubes are faced with difficulties in use, etc., and achieve excellent creep resistance, reducing creep deformation, and high stability and economic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example [UNK]

EXAMPLE 1˜13

Manufacturing Method of Zirconium Alloy

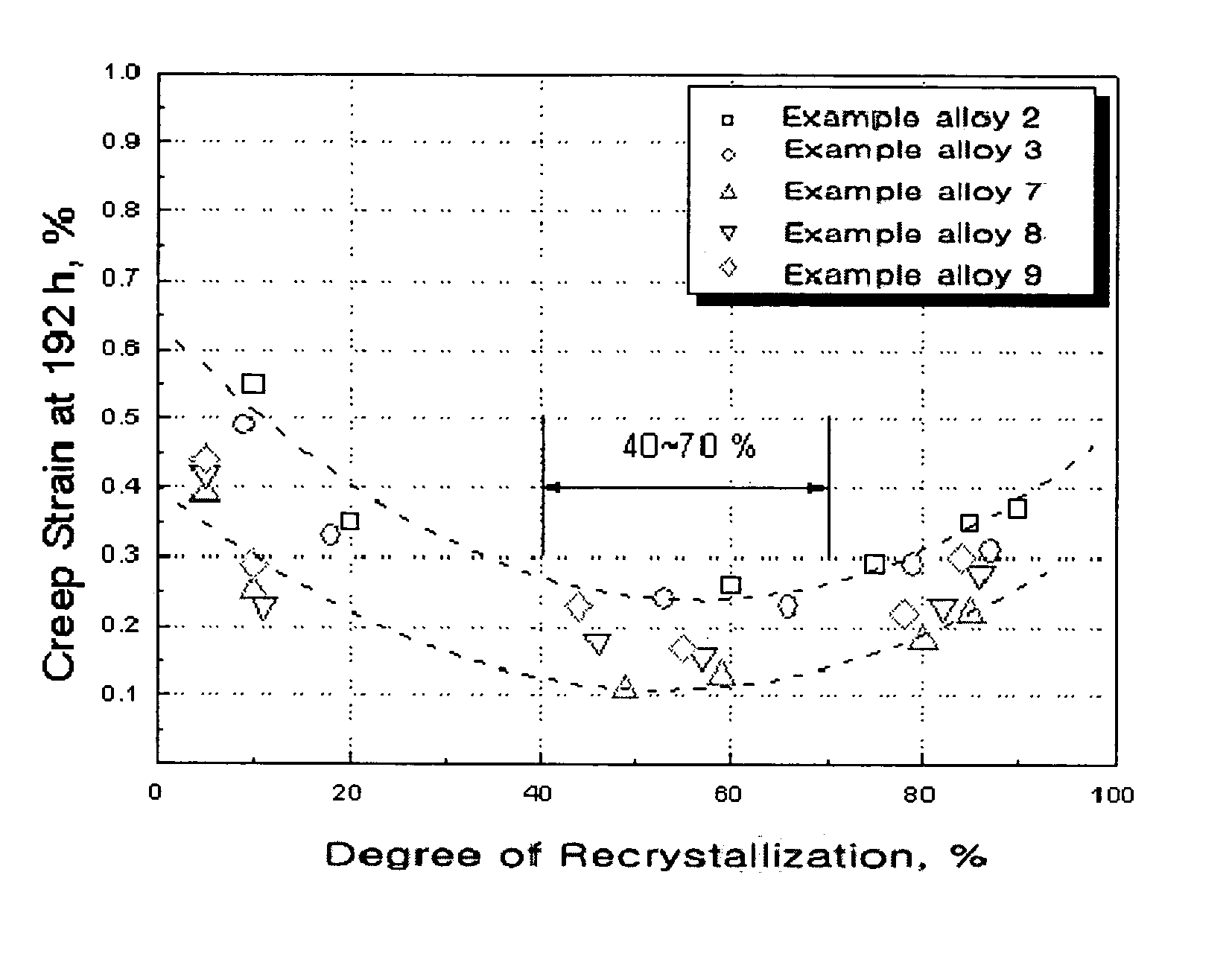

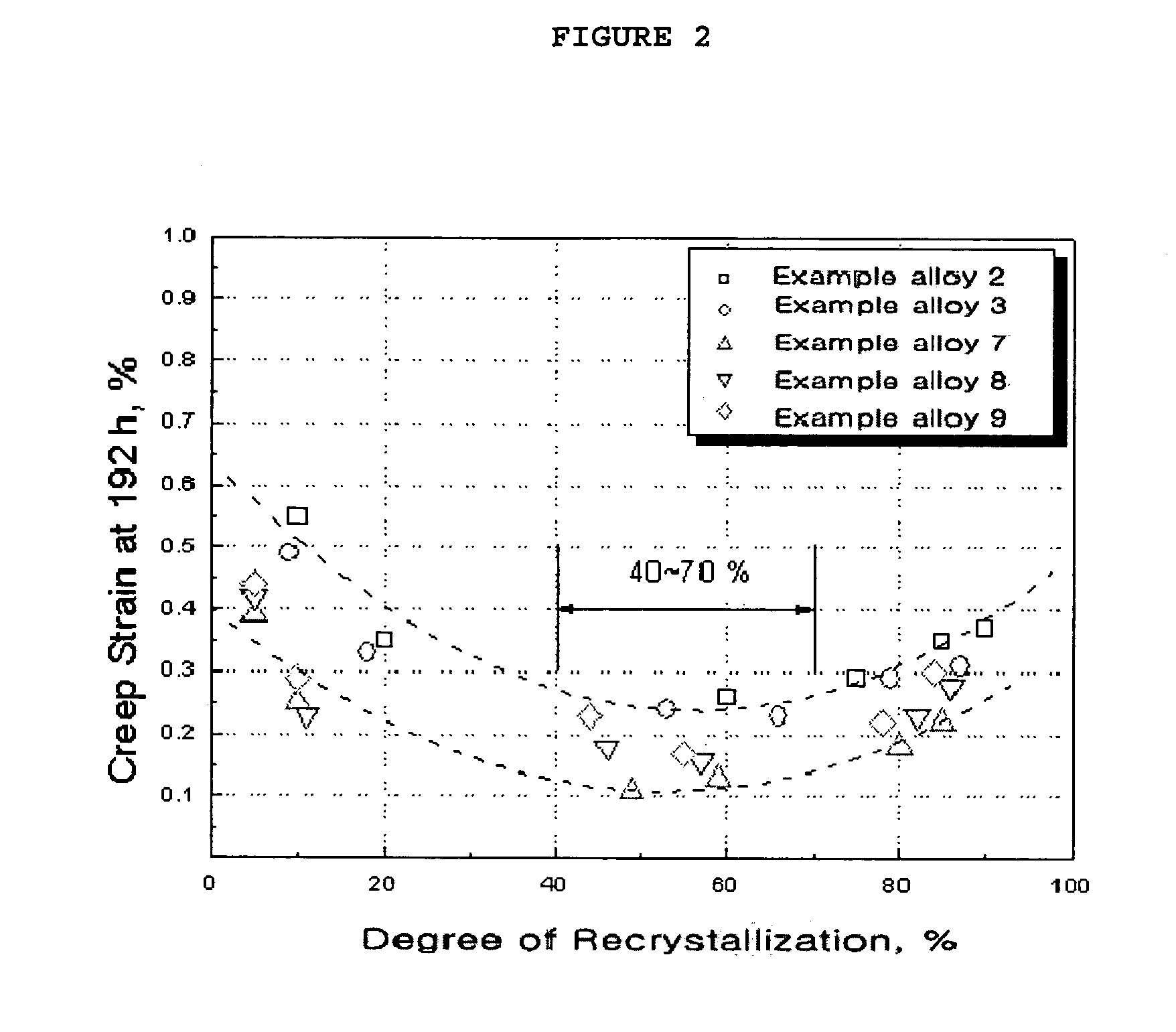

[0053] Four examples of alloy with niobium content from 0.8% to 1.8%: [0054] (1) Zr—0.8% Nb—0.07% Cu—0.14% O—0.008% C—0.008% Si—0.002% S; [0055] (2) Zr—1.1% Nb—0.07% Cu—0.14% O—0.008% C—0.008% Si—0.002% S; [0056] (3) Zr—1.5% Nb—0.07% Cu—0.14% O—0.008% C—0.008% Si—0.002% S; and [0057] (4) Zr—1.8% Nb—0.07% Cu—0.14% O—0.008% C—0.008% Si—0.002% S

[0058] Alloy of Zr—1.5% Nb—0.4% Sn: [0059] (5) Zr—1.5% Nb—0.4% Sn—0.14% O—0.008% C—0.008% Si—0.002% S

[0060] Four examples of alloy manufactured by adding one or more elements from Cu, Fe, and Cr to the above alloy containing Zr—1.5% Nb—0.4% Sn: [0061] (6) Zr—1.5% Nb—0.4% Sn—0.1% Cu—0.14% O—0.008% C—0.008% Si —0.002% S; [0062] (7) Zr—1.5% Nb—0.4% Sn—0.1% Fe—0.14% O—0.008% C—0.008% Si —0.002% S; [0063] (8) Zr—1.5% Nb—0.4% Sn—0.1% Cu—0.1% Fe—0.14% O—0.008% C—0.008% Si—0.002% S; and [0064] (9) Zr—1.5% Nb—0.4% Sn—0.2% Fe—0.1% Cr—0.14% O—0.008% C—0.008% Si—0.002% S

[0065] Four examples of alloy wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| creep resistance | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com