Recycling device of light water coupling agent for supersonic inspection on heat transfer branch pipe of heavy water reactor power station

An ultrasonic inspection and recovery device technology, which is applied in nuclear power generation, measurement devices, and material analysis using sound waves/ultrasonic waves/infrasonic waves. Effects of surface contamination, panic mitigation, and number reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

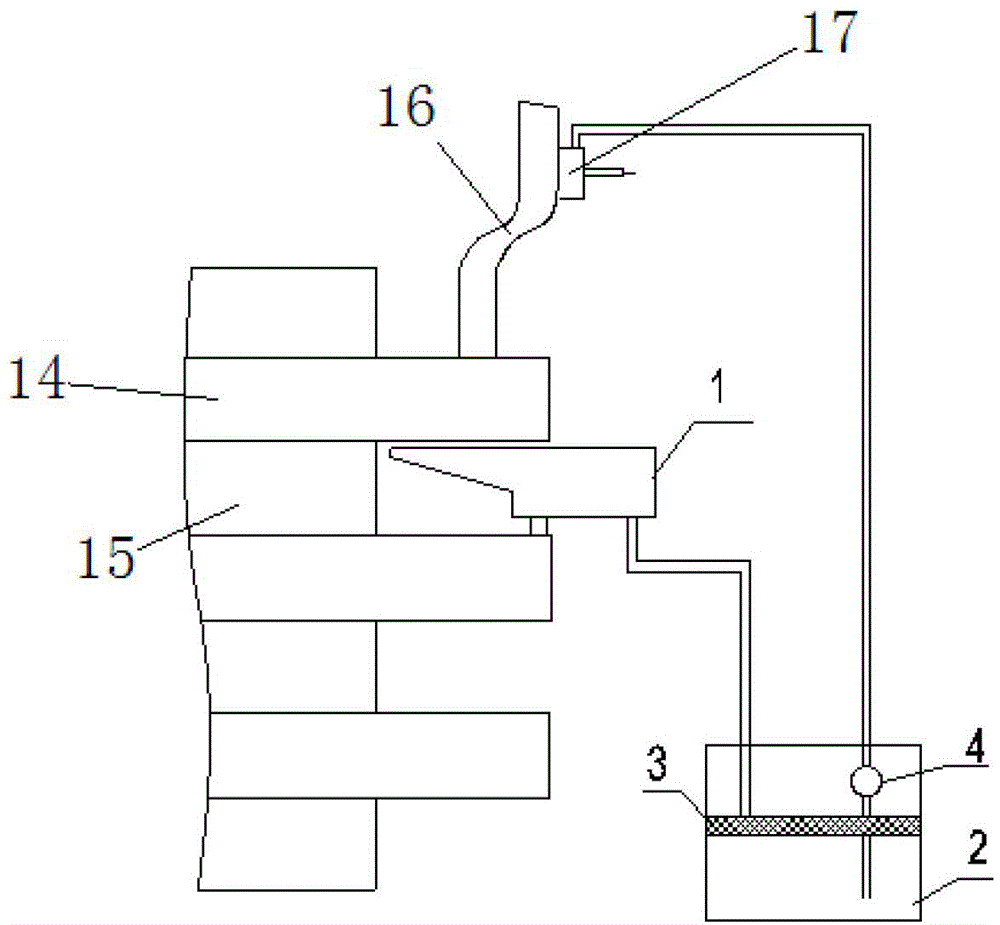

[0019] Such as figure 1 As shown, the light water couplant recovery device for ultrasonic inspection of the heat transfer branch pipes of the heavy water reactor nuclear power plant of the present invention includes a water receiving tray 1, a water tank 2, a filter element 3, and a water pump 4; , The water receiving tray 1 is connected to one end of the water recovery hose, the other end of the water recovery hose is located above the filter element 3, the filter element 3 is set in the water tank 2, the lower end of the water supply hose is located in the water tank, and the upper end passes through the filter element 3 through the water pump 4 and Ultrasonic inspection probe 17 is connected;

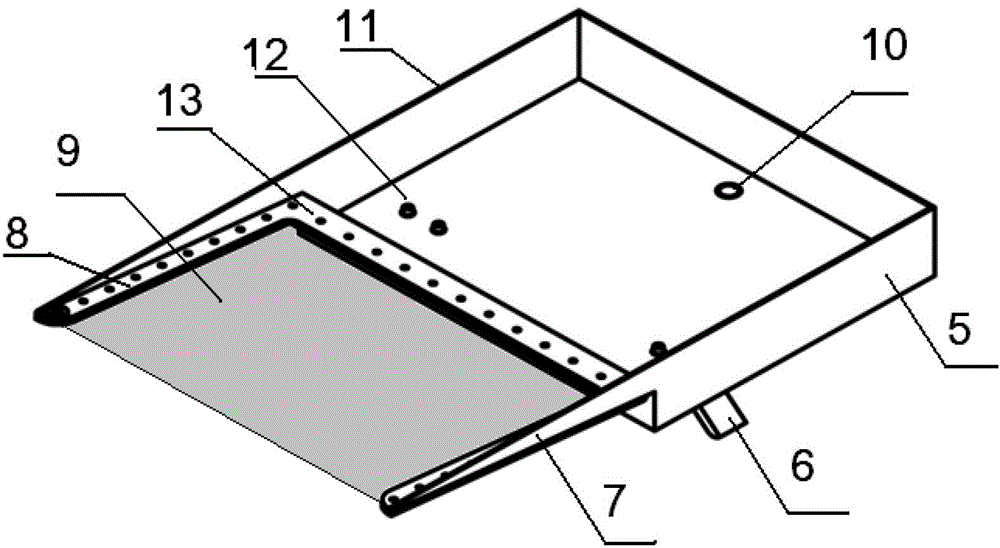

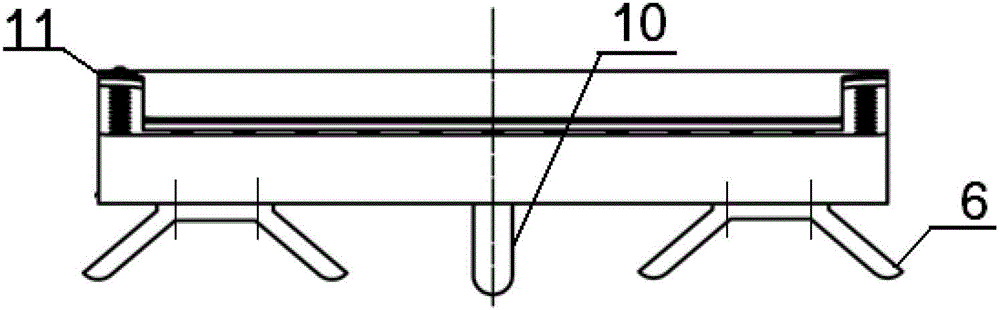

[0020] Such as Figure 2~3 As shown, the water receiving tray 1 includes a frame 5, a support 6, a front nozzle 7, a splint 8, an elastic rubber 9, a water receiving nozzle 10, and a rubber rubber 11. The front end of the wedge-shaped frame 5 is the front nozzle 7. The lower end of 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com