Analogue on-site regulating system for magnetic suspension bearing

A magnetic suspension bearing and on-site debugging technology, which is applied to bearing components, shafts, bearings, instruments, etc., can solve the problems of on-site debugging system for magnetic suspension bearings, damage to cost-effective mechanical equipment, and panic in the heart, so as to improve safety and reliability sex, reduce psychological stress and panic, and reduce risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

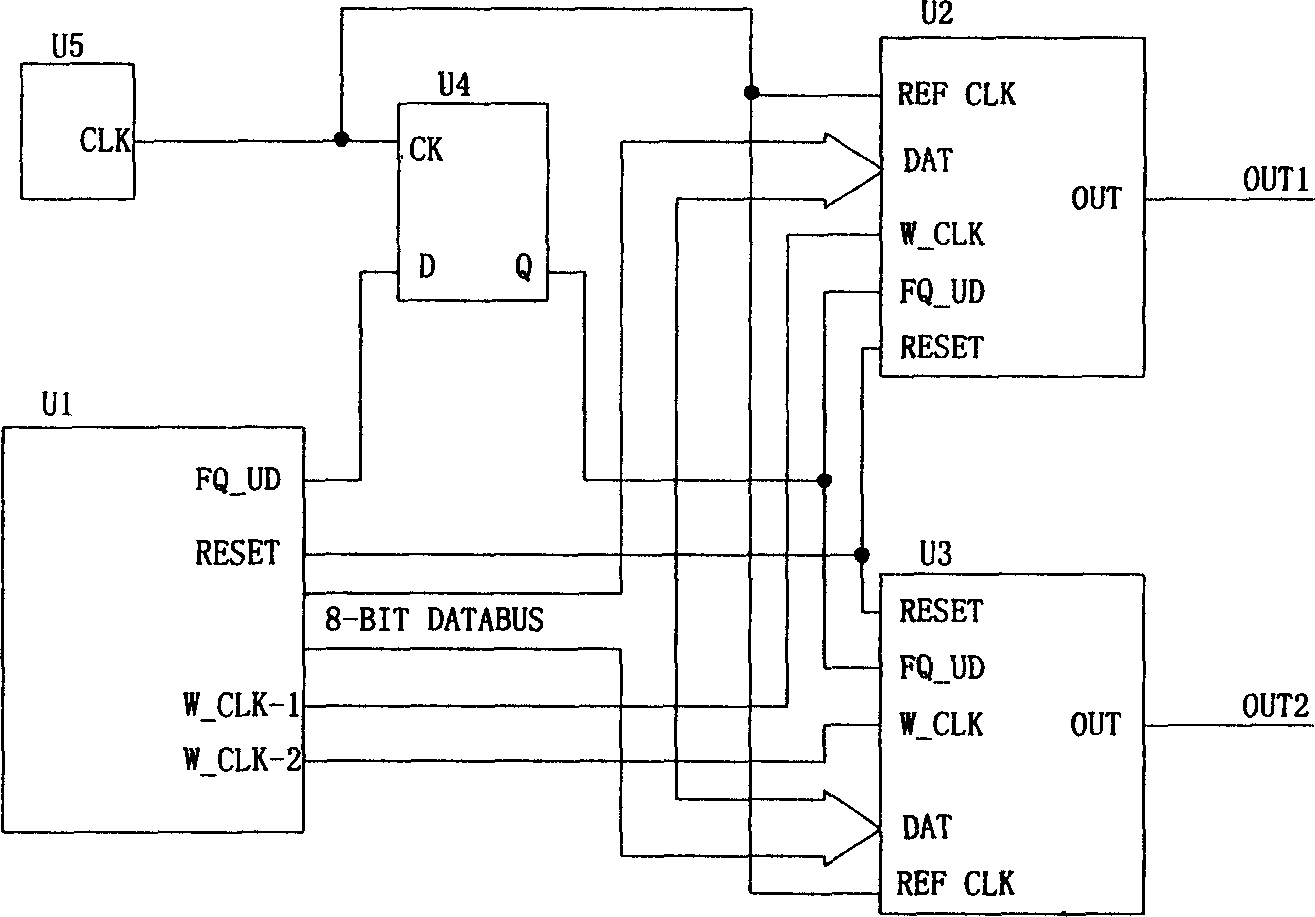

[0021] Such as figure 1 , figure 2 As shown, the magnetic suspension bearing simulation on-site debugging system includes a sine and cosine signal generation circuit, a sine signal processing circuit, a cosine signal processing circuit, a controller and a power amplifier, wherein the sine and cosine signal generation circuit includes a single-chip microcomputer U1 and a direct digital synthesis chip U2 , U3, bistable flip-flop U4 and crystal oscillator U5, the model of microcontroller U1 is P89C58, the model of bistable flip-flop U4 is 74HC74, the model of direct digital synthesis chips U2 and U3 is AD9851; the FQ_UD terminal of microcontroller U1 Connected to the D terminal of the bistable trigger U4, the Q terminal of the bistable trigger U4 is connected to the FQ_UD terminals of the direct digital synthesis chips U2 and U3 at the same time, and the RESET...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com