Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Gracilaria gracilis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

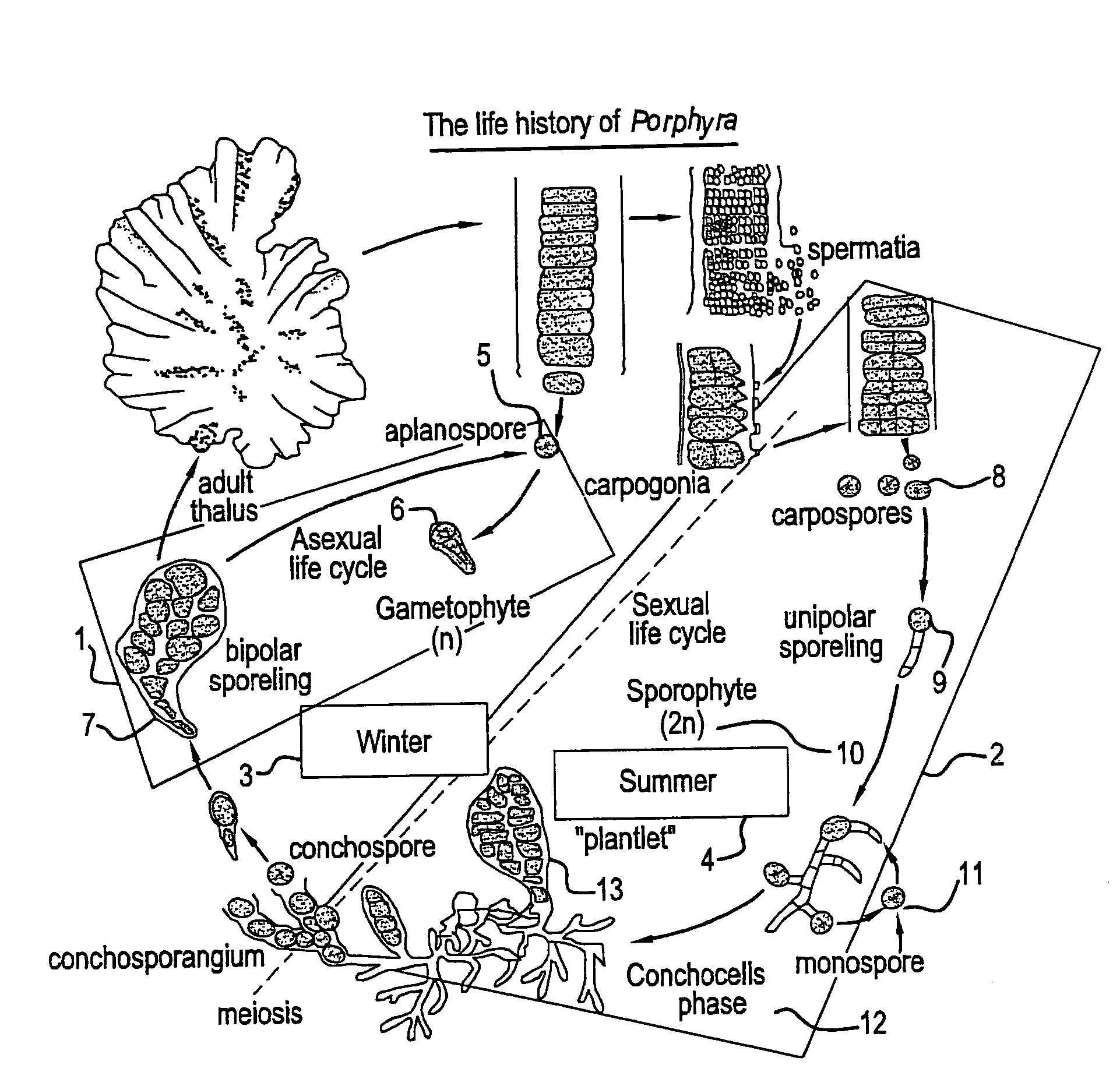

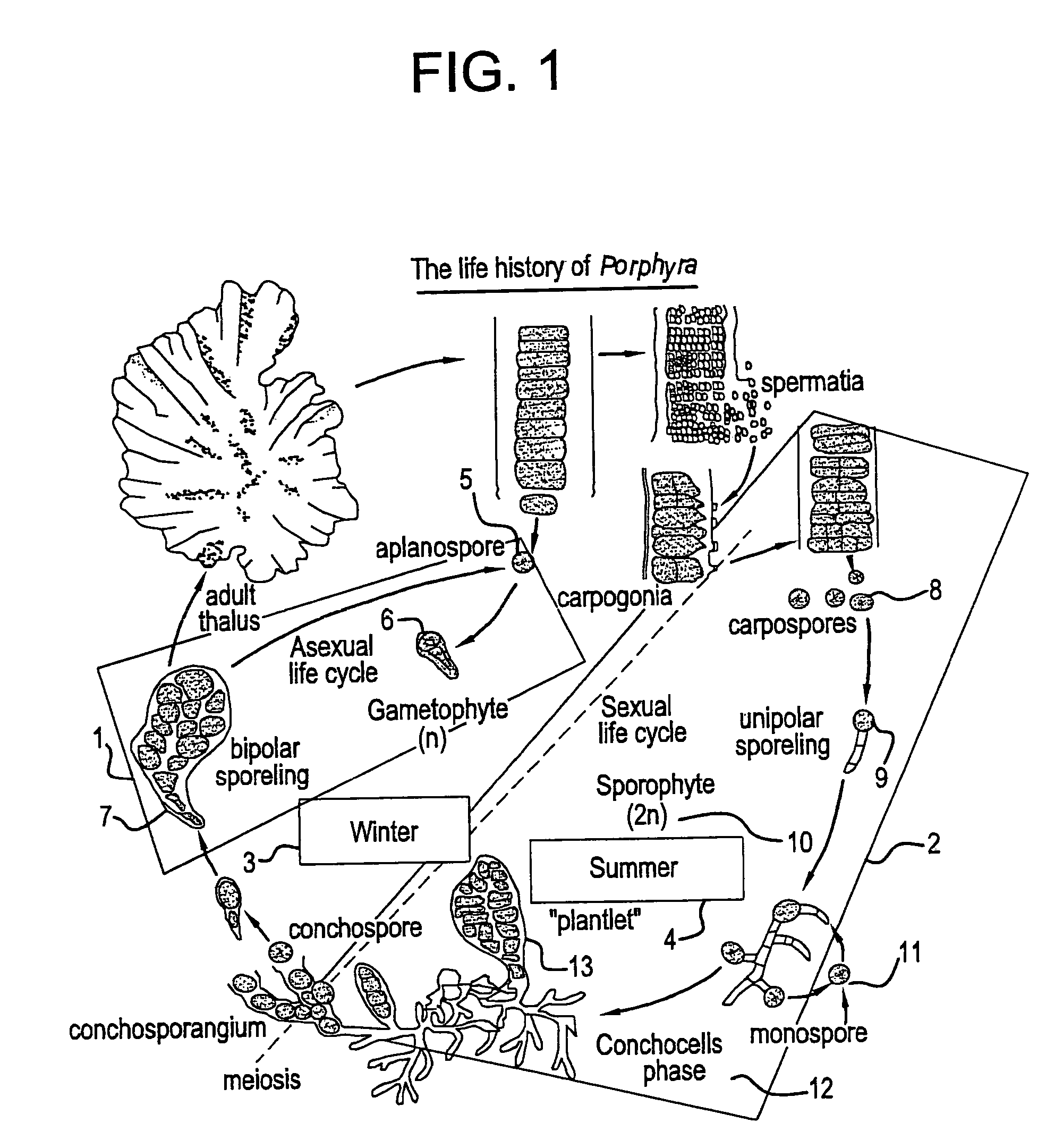

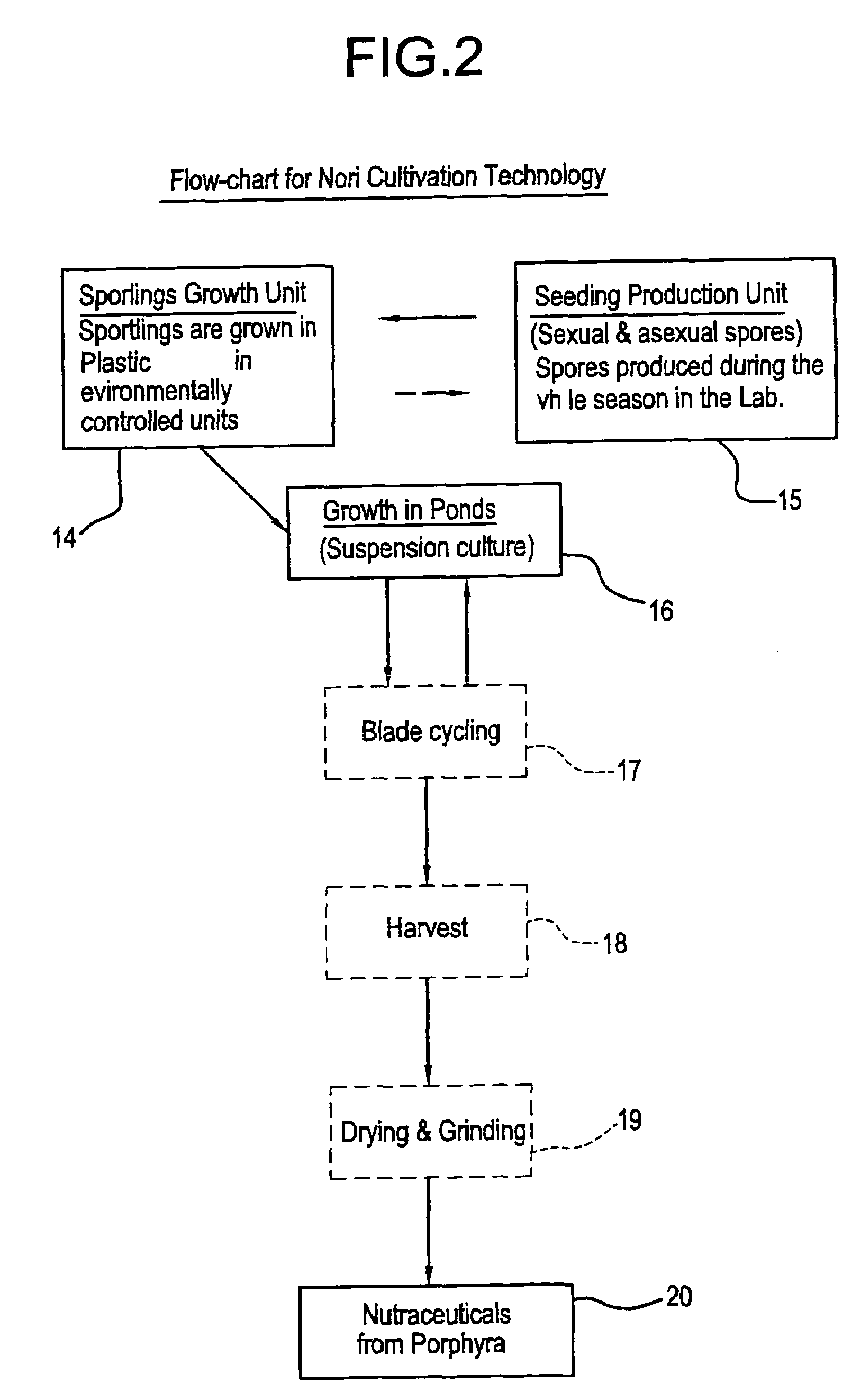

Technology for cultivation of Porphyra and other seaweeds in land-based sea water ponds

InactiveUS7484329B2Bioreactor/fermenter combinationsBiological substance pretreatmentsSporelingAscophyllum

Owner:SEAWEED BIO TECH

Method for extracting agar, fucoidin and protein from gracilaria as raw material by using enzyme process

ActiveCN103694374AHigh extraction rateHigh strengthPeptide preparation methodsBiotechnologyHydrolysate

The invention discloses a method for extracting agar, fucoidin and protein from gracilaria as a raw material by using an enzyme process. The method comprises the steps of: performing enzymolysis on the gracilaria by using a biological enzymolysis technology, separating protein from enzymatic hydrolysate by using an isoelectric precipitation technology after being concentrated, precipitating the solution after the protein is extracted through alcohol to separate the fucoidin, and performing procedures such as bleaching, glue boiling, freezing, thawing and dewatering on the enzymolysis residue to obtain a high-purity agar product. According to the method, the defect of a process of extracting the fucoidin by using a conventional alkaline process glue extracting and water extraction method is broken, the extraction separation of the agar, the fucoidin and the protein is realized in one step by adopting a biological enzymolysis method, and water saving, energy saving and emission reducing are greatly realized when the comprehensive utilization value of the gracilaria as the raw material is increased. The method accords with relevant national policies.

Owner:青岛福创环境科技有限公司

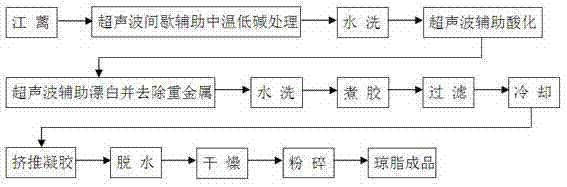

Ultrasound-assisted preparation method of high strength Gracilaria agar

The invention discloses an ultrasound-assisted preparation method of high strength Gracilaria agar. The method includes: taking Gracilaria as the raw material, conducting intermediate-temperature low-alkaline treatment under intermittent assistance of ultrasound, ultrasound-assisted acidification, ultrasound-assisted bleaching and heavy metal removal, carrying out gel boiling, filtering out impurities, performing cooling, extruding gel, conducting dehydration, drying, and smashing, and then passing the product through a 80-mesh sieve, thus obtaining the high strength Gracilaria agar. The invention adopts intermediate-temperature dilute alkaline treatment on Gracilaria, with NaOH assisted by ultrasound intermittently, so that the alkaline treatment time is shortened, and simultaneously gel loss can be substantially reduced. Ultrasound is employed to assist acidification of a mixed solution of HCl, H2SO4, and C2H2O4, so that the acid consumption is substantially reduced, and the action time is short. Ultrasound is adopted to assist a mixed solution of NaClO, H2O2, and EDTA-Na2 to realize efficient bleaching, and at the same time, heavy metals are removed from the raw material, so that product color and hygienic quality are guaranteed. The method provided in the invention makes use of ultrasound to assist preparation of Gracilaria agar having high strength, good color, and excellent security, and is of great significance in enhancing the technical level of agar preparation and improving product comprehensive quality.

Owner:FUJIAN PROVINCE LVQI FOOD COLLOID

Method for extracting agar from gracilaria with enzymatic method

The invention discloses a method for extracting agar from gracilaria with an enzymatic method. After gracilaria is soaked, cellulose and protease are added for enzymolysis, and gracilaria slag in enzymatic hydrolysate is filtered; after the gracilaria slag is subjected to bleaching, acidification and washing treatment, an appropriate amount of water is added, water is boiled to 95 DEG C for glue extraction, and enzyme activity is killed; a glue solution is filtered while hot, 95% ethyl alcohol with a volume of two to three times of that of the glue solution is added to the glue solution rapidly, precipitation is centrifuged or filtered, dehydration is performed twice with absolute ethyl alcohol, and drying is performed, so that an agar product is obtained. The main ingredient of agar in gracilaria is separated with a clean and efficient biological enzyme treatment technology, and the defects of a conventional alkali treatment technology are overcome; before glue extraction is performed on gracilaria, sodium hypochlorite is replaced with hydrogen peroxide for bleaching treatment, the bleaching effect is remarkable, and the problems of chloride ion residues and pollution caused by a sodium hypochlorite bleaching method are solved; and finally, agar is rapidly precipitated from the glue solution with a simple, convenient and feasible alcohol precipitation method, the production period is greatly shortened, and the cost is greatly reduced.

Owner:青岛福创环境科技有限公司

Algin for fodder

InactiveCN104757334AHigh value for feedHigh medicinal valueAnimal feeding stuffAnimal sciencePorphyra

The invention discloses algin for fodder. The algin comprises, by weight, 50-60 parts of kelp powder, 50-80 parts of gracilaria powder, 40-60 parts of nori powder, 0.5-3 parts of spiral seaweed powder, 5-10 parts of duckweed powder and 5-12 parts of undaria pinnatifida powder. The algin for the fodder can be added to any dry fodder powder directly to be evenly stirred, the iodine, calcium, phosphorus, magnesium, potassium, sodium and other active mineral elements are contained, various vitamins, sodium alginate, mannitol and the like are contained, the algin exists in a stateful mode and can be absorbed and utilized easily, the fodder efficiency can be improved effectively, and growth and development of animals are facilitated; the algin tastes special and salt and fishy, the color of the algin is like the color of the natural algae and wakes up the taste buds of aquaculture animals, and fierce feeding is aroused.

Owner:QUANZHOU QUANGANG KESHAN ALGA CO LTD

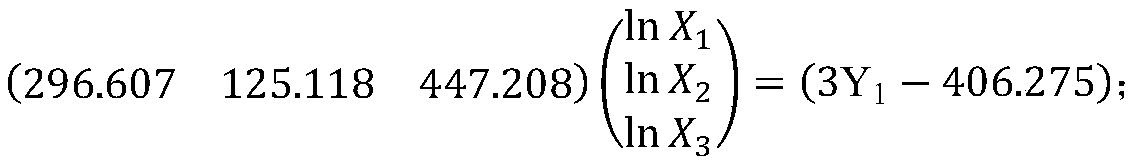

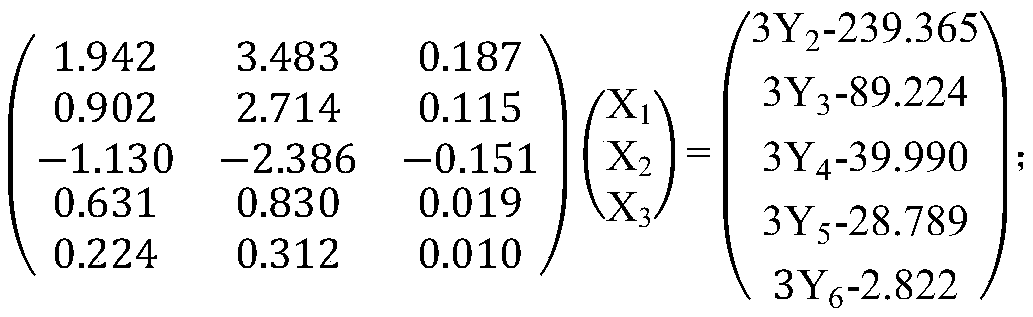

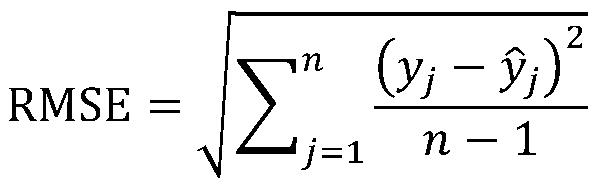

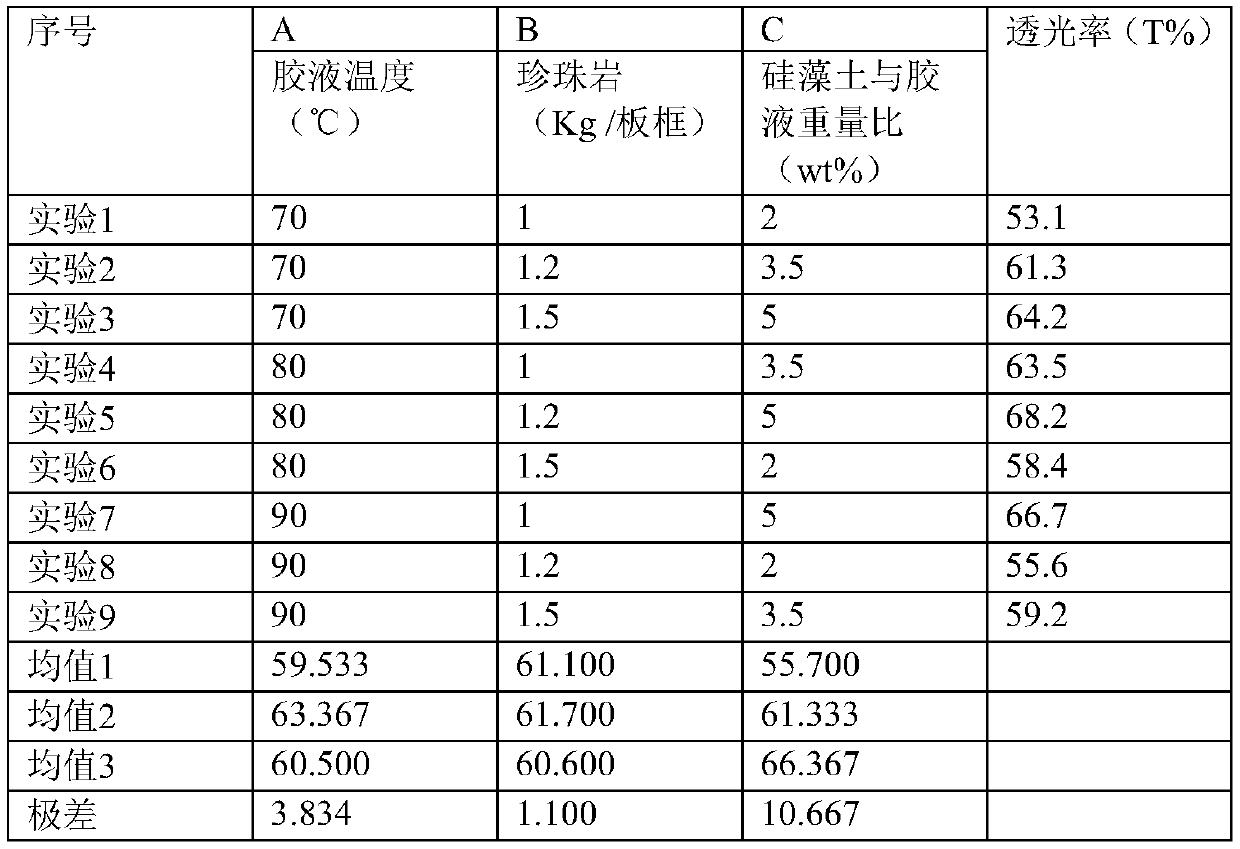

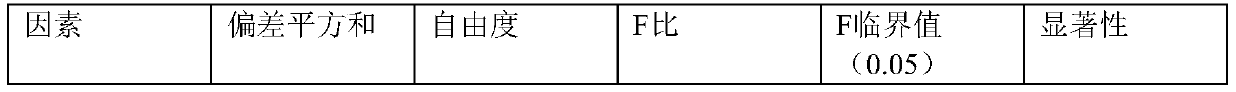

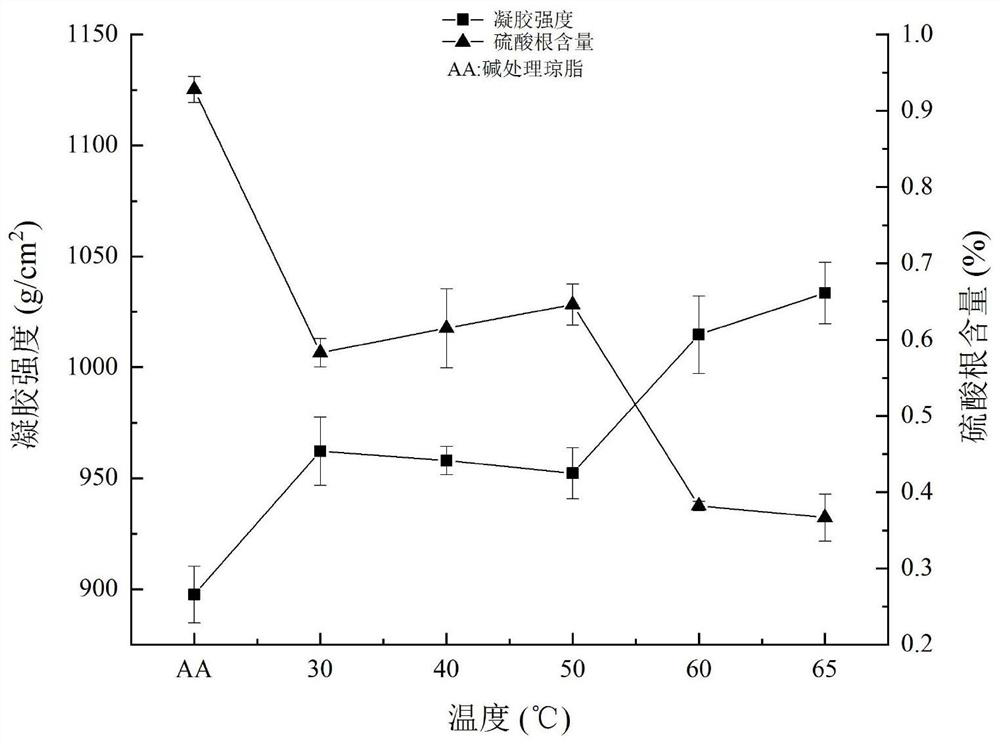

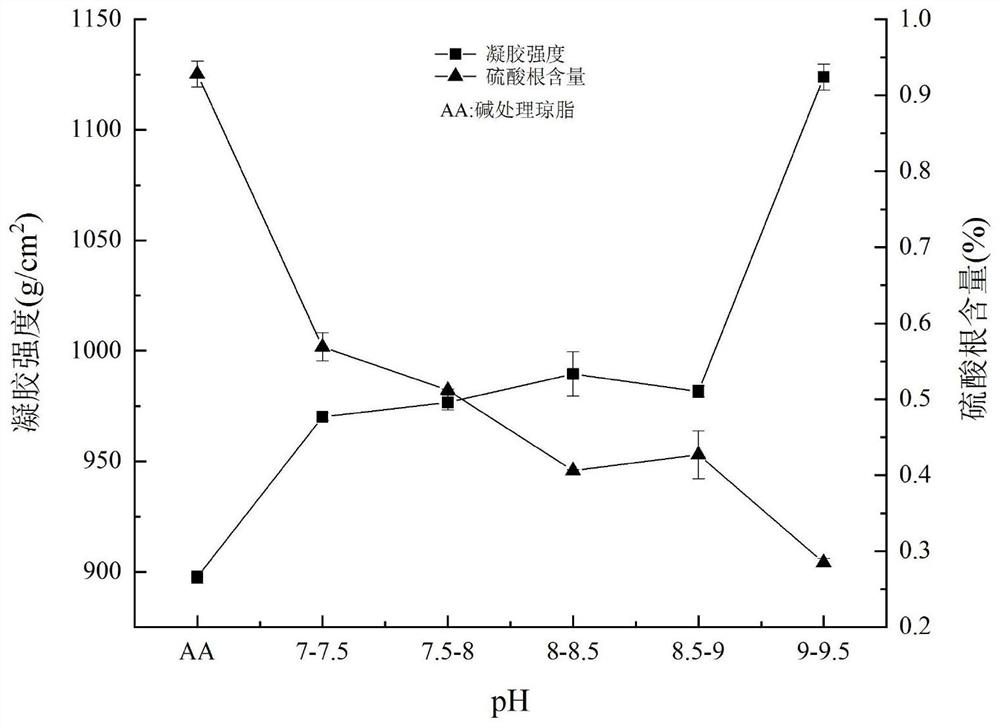

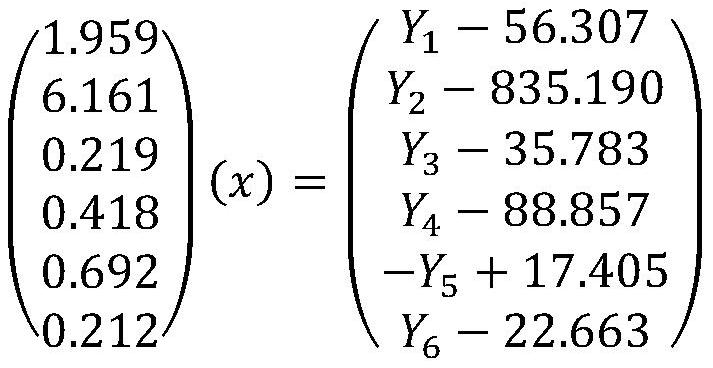

Gracilaria agar production method based on mathematical model

ActiveCN111499774AReduce alkali consumptionPromote sustainable developmentDesign optimisation/simulationSpecial data processing applicationsSulfate radicalsPhysical chemistry

The invention relates to a gracilaria agar production method based on a mathematical model. The gracilaria is subjected to alkali treatment; washing, acidifying and bleaching are carried out on the gracilaria subjected to alkali treatment; gel boiling is carried out on the gracilaria after washing, acidifying and bleaching to obtain gracilaria agar; the gel strength, transparency, 3, 6-anhydro content, sulfate radical content and gel yield of gracilaria agar are measured, the alkali consumption is calculated, a linear equation of experimental data is made, and the linear equation is convertedinto a matrix equation to construct a gracilaria agar quality influence factor kinetic model. According to the method, the alkali consumption and quality of the gracilaria agar under different alkalitreatment processes are calculated by establishing the model, and the method has important significance for the alkali treatment process required for producing the multi-index gracilaria agar and reducing the alkali consumption of the gracilaria agar.

Owner:JIMEI UNIV

Method for improving gracilaria agar gel strength

InactiveCN102863632AHigh strengthMeet the needs of domestic and foreign marketsFood preparationBiotechnologyMicroorganism

The invention relates to a method for improving gracilaria agar gel strength and belongs to the technical field of food production. The method aims to prepare high-strength agar by adding a microorganism enzyme namely transglutaminase into agar and specifically includes: dissolving agar powder in hot water to prepare 1.5% agar solution, boiling agar for a certain time until the agar is completely dissolved, adding transglutaminases of different concentrations within a certain temperature and pH range, stirring for reaction for a few minutes, standing at the room temperature to enable the surface to be solidified, placing at constant temperature for gelling for a few hours, and measuring the gel strength. The gel strength of the agar is evidently improved when addition amount of the transglutaminases is 0.01%-1.0% (g / g, relative to dry weight of agar powder). The method has the advantages that the agar is assuredly edible by using the biological method for improving gel strength, nontoxic, harmless and pollution-free, and the method is simple in operation and low in production cost.

Owner:GUANGDONG OCEAN UNIVERSITY

Preparation method of temperature-sensitive type gracilaria agar complex gel

InactiveCN105497908AIncrease profitSimple preparation stepsAerosol deliveryOintment deliveryGel preparationAlcohol ethyl

The invention relates to a preparation method of temperature-sensitive type gracilaria agar complex gel, and belongs to the technical field of gel preparation. The method includes the steps of preparing gracilaria agar from fresh gracilaria serving as the raw materials together with thrice sterile water under specific conditions, mixing gracilaria agar with ethyl alcohol and other substances to form a gracilaria agar ethanol solution, making the solution mixed with chloroacetic acid and other substances under specific conditions, and conducting filtering, concentrating and drying to obtain the gel. The method has the advantages that the medicine carrying capacity is strong, the slow-release time is long, and high stability is achieved; the medicine utilization rate is high and is improved by 10-15%, the preparation steps are simple, and cost is low.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

Method for extracting agar from gracilaria

ActiveCN110669153AReduce pollutionStrong process controllabilityOXALIC ACID DIHYDRATEGracilaria domingensis

The invention provides a method for extracting agar from gracilaria. The method comprises the following steps: 1) performing alkali treatment: placing and treating gracilaria plants free of impuritiesin an alkali solution, and removing the alkali solution after the treatment is finished; 2) crushing: crushing the gracilaria prepared in step 1) to obtain a crushed feed liquid; 3) heating for extracting agar: supplementing water to the feed liquid obtained in step 2), and performing heating for extracting agar; 4) carrying out deslagging treatment through plate-frame filtration; 5) carrying outdecolorizing treatment by adopting activated carbon; and 6) performing dehydrating and drying to obtain the agar. The gracilaria subjected to alkali treatment is mechanically crushed to form a colloidal solution, the colloidal solution subjected to heating, agar extraction, squeezing and filtration is subjected to decolorizing by using powdered activated carbon, and then undergoes freezing dehydration or squeezing dehydration and drying to obtain the agar product, so the product has a stable yield, a stable quality and a slightly yellow or white appearance. Hydrochloric acid, oxalic acid andthe like are not needed in the whole processing and production process, a chemical bleaching agent is not needed, the water consumption is only about 40% of that of a traditional method, and the generated wastewater amount is also greatly reduced.

Owner:GUANGDONG OCEAN UNIVERSITY

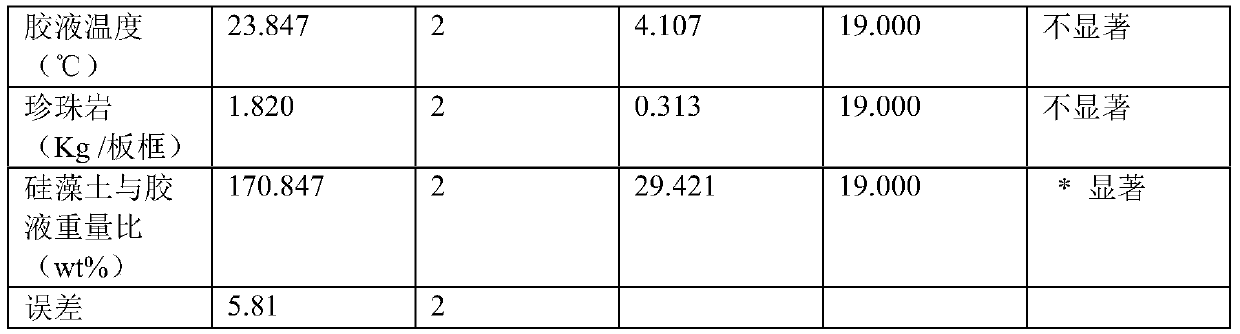

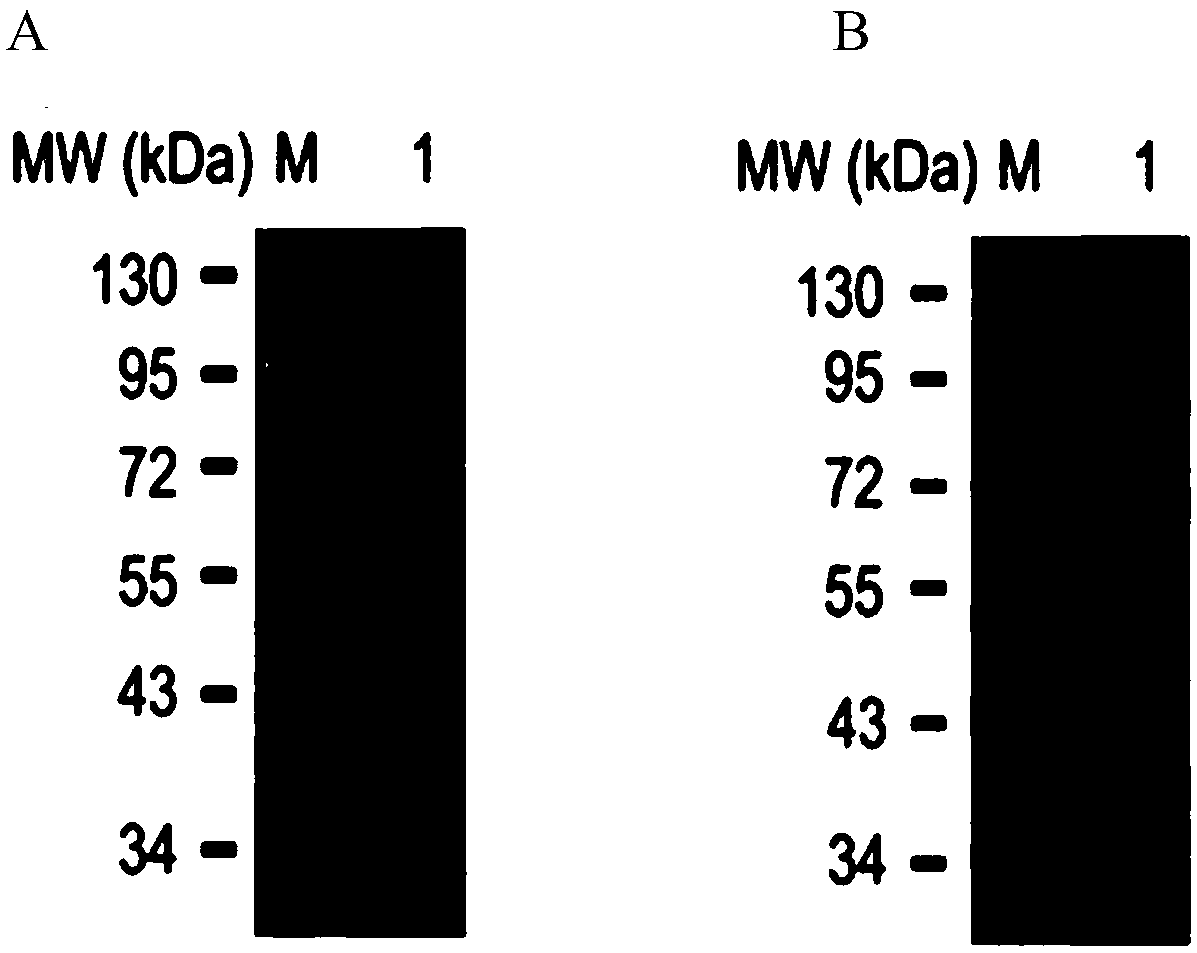

Gracilaria chouae uridine diphosphate (UDP)-glucose pyrophosphorylase (UGPase) gene

The invention relates to the field of genetic engineering technology, and particularly relates to a gracilaria chouae uridine diphosphate (UDP)-glucose pyrophosphorylase (UGPase) gene. The nucleotide sequence of the gene and the amino acid sequence of the coding protein are SEQ ID No.1 and SEQ ID No.2 respectively. According to the invention, the gene sequence is cloned through the gene cloning technology, and a prokaryotic expression vector is established; and enzyme activity detection on recombinant protein proves that the gene has the function of catalyzing UDP-glucose and pyrophosphoric acid to form glucose-1-phosphoric acid and UTP and belongs to a key enzyme coding gene of the synthesis path of agar-agar, starch, cellulose, trehalose, sucrose and the like. The gene has an important application value in increasing the content of economic components including algae agar-agar, starch, cellulose, trehalose, sucrose and the like.

Owner:OCEAN UNIV OF CHINA

Mixed culturing technology of gracilaria and epinephelinae

InactiveCN104642089AAvoid wastingReduce occupancyClimate change adaptationPisciculture and aquariaEutrophicationEnvironmental engineering

The invention discloses a mixed culturing method of gracilaria and epinephelinae. The method is characterized in that a pond culturing mode is adopted, a water inlet channel and a water outlet channel are formed in a pond, and cleaning, sterilizing and disinfecting need to be firstly carried out on a pond body; then seawater can be poured into the pond, and the water quality can be regulated to adapt to culturing; the depth of water in the pond is 0.3m-0.5m, and a pond-slope ratio is 1 / 5; the occupied culturing area of the gracilaria in the pond is more than 3 / 5, and the density for putting the epinephelinae is smaller than that of the epinepelinae which are independently cultured. According to the method disclosed by the invention, a high economic additional value and a high nutrient value of mixed culturing of the gracilaria and the epinephelinae are utilized; compared with the prior art, the mixed culturing technology has no need to apply a large amount of fertilizer to a water body, thus the pollution on the water body can be effectively avoided, substances of N and P in the water body can be effectively removed by the gracilaria in mixed culturing, the eutrophication of the water body can be effectively prevented, and higher ecological benefits can be obtained; meanwhile, the cost is low, the output is high, the economic benefit is good, and the method is a better source approach for supplementing the epinephelinae resource and broadening the gracilaria resource along the coast.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Natural macromolecular water absorbing material and preparation method thereof

The invention discloses a natural macromolecular water absorbing material and a preparation method thereof. Natural macromolecular gracilaria polysaccharides and sodium alginate are used as main raw materials; the natural macromolecular water absorbing material has great safety to people, particularly infants; the water absorbing multiples reach tens to hundreds of multiples of the self weight and the tensile strength is great; the natural macromolecular water absorbing material has a good water-retaining performance and the product can be naturally degraded.

Owner:FUZHOU UNIV

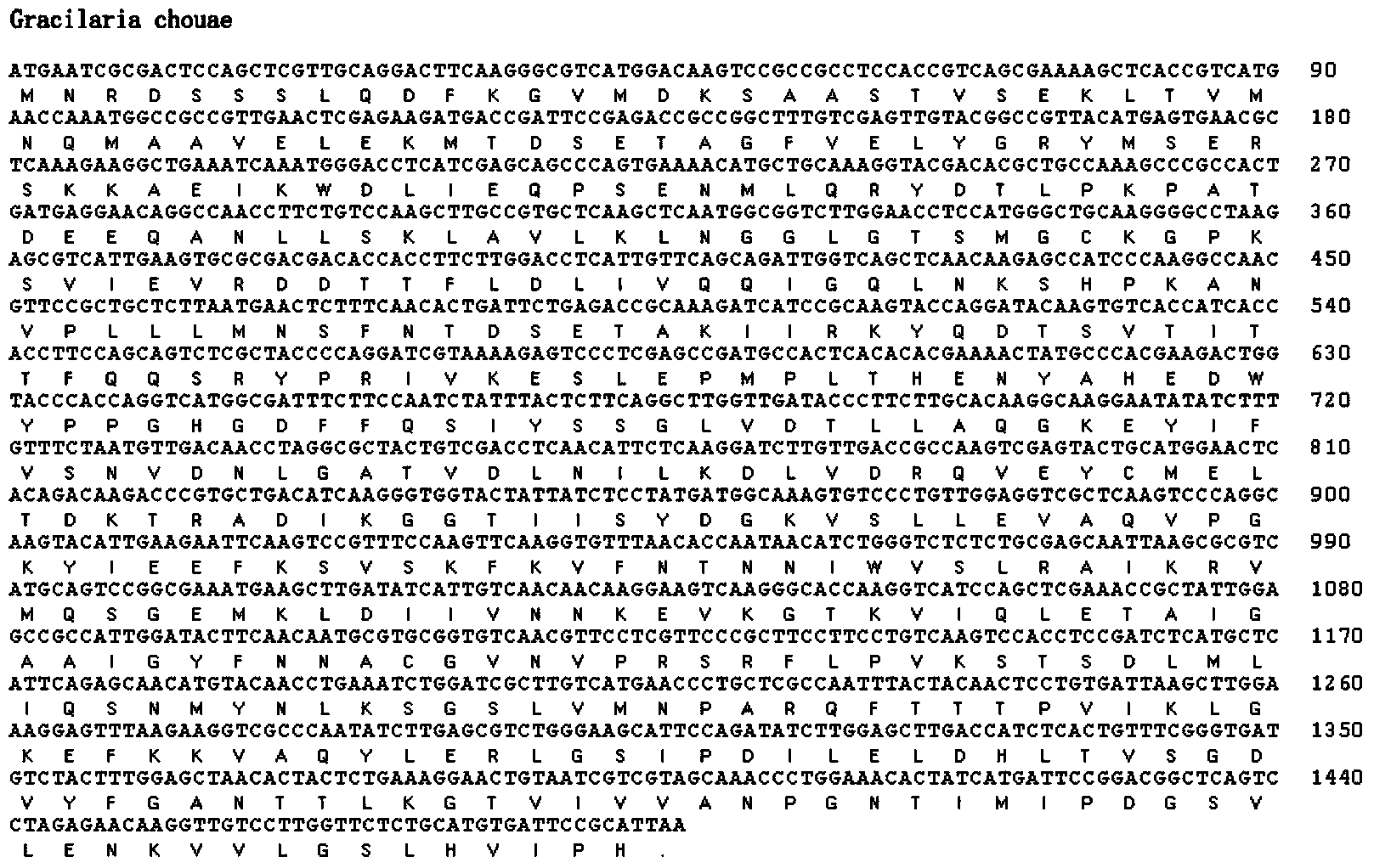

Production method of instant gracilaria convenience food

ActiveCN104351861AGreen stableImprove stability and securityFood dryingFood ingredient functionsIce waterPasteurization

The invention discloses a production method of instant gracilaria convenience food. The production method comprises processing steps as follows: gracilaria is placed in boiling water to be blanched for 1-2 min for fixation and enzyme deactivation, then after cooled by ice water, the gracilaria is placed in a flavoring liquid containing a color fixative and a protein cross-linking agent to be soaked for 3-12 h and is subjected to centrifugal dewatering, freeze thawing and secondary centrifugal dewatering, and moisture content of gracilaria is reduced to 70%-75%; and the obtained gracilaria is added with flavoring oil containing an antioxidant to be uniformly stirred and mixed, a weight ratio of the gracilaria to the flavoring oil is 1: (20-50), the mixture is subjected to vacuum packaging, sterilized at the temperature of 80-85 DEG C for 30-60s and cooled by ice water rapidly, and accordingly, the instant gracilaria convenience food is prepared. The processing technology is simple, and a product can be sterilized through pasteurization and can be stored at the normal temperature; and besides, the obtained instant gracilaria convenience food is free of remarkable fishy and astringent smell of algae, has bright green appearance and crisp and tender taste and can be accepted by most consumers.

Owner:JIMEI UNIV

Preparation method of agar gel solution

The invention discloses a preparation method of an agar gel solution. The method is characterized by comprising the following steps: acidifying gracilaria; rinsing to be neutral; adding water into therinsed gracilaria, and heating to melt the gracilaria into glue; adding Ca (OH) 2 and / or CaO to enable the glue solution to be alkaline, and continuously heating; introducing CO2 to react with Ca (OH) 2 so as to generate CaCO3; and filtering to obtain an agar gel solution. The method is green and environment-friendly, can be used for preparing agar with high gel strength and high yield, and has relatively high application value.

Owner:JIMEI UNIV

Haematococcus pluvialis culture medium, preparation method thereof and haematococcus pluvialis culture method

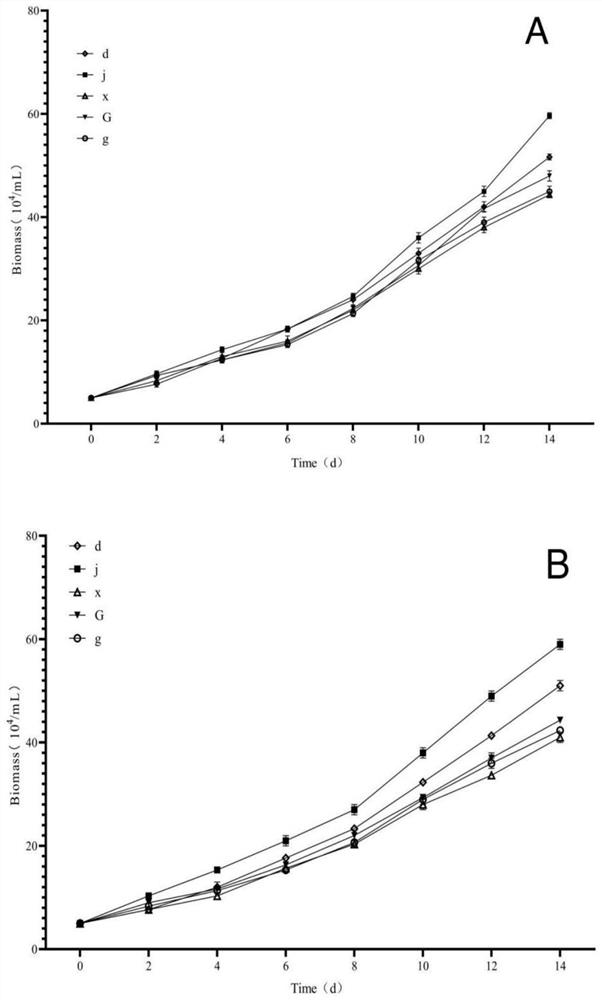

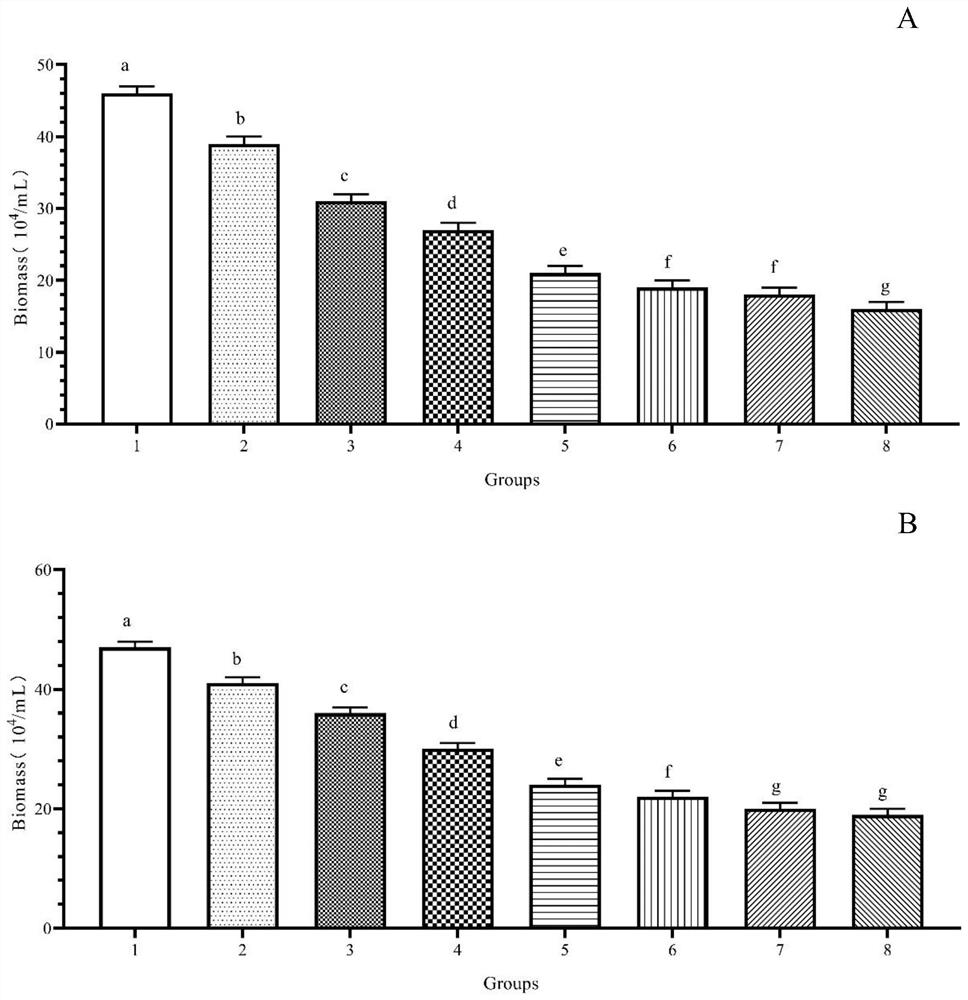

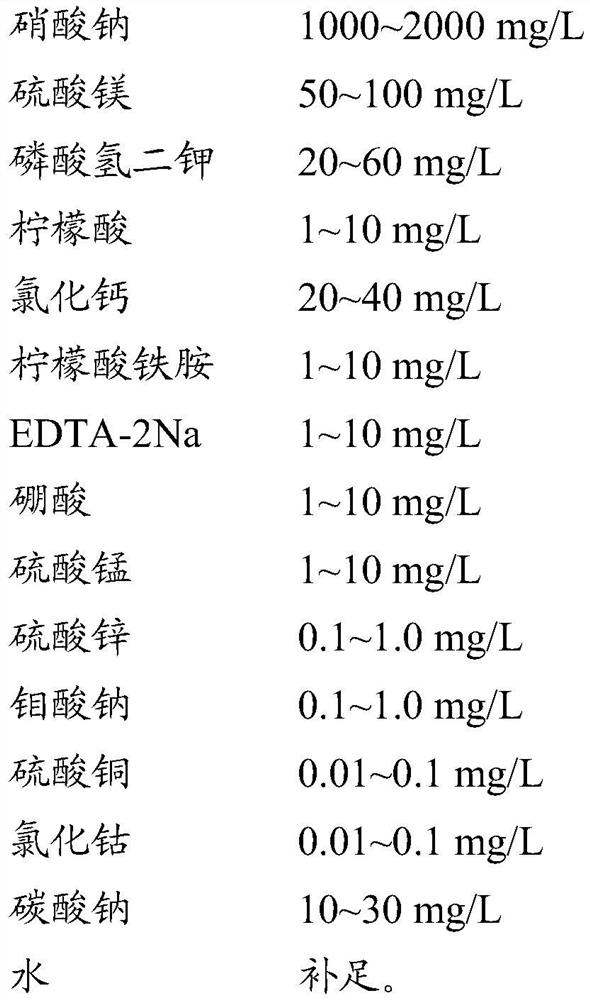

ActiveCN113462575AWidely distributedEasy to getUnicellular algaeMicroorganism based processesBiotechnologyMicrobiology

The invention relates to the technical field of biological culture for producing high-added-value products from microalgae, in particular to a haematococcus pluvialis culture medium, a preparation method thereof and a haematococcus pluvialis culture method. The haematococcus pluvialis culture medium comprises a basic culture medium, a gracilaria seaweed extract and lysine bacillus. According to the method, the gracilaria seaweed extract and the lysine bacillus are added in the haematococcus pluvialis culture process, so that the biomass of the haematococcus pluvialis and the yield of astaxanthin can be remarkably increased.

Owner:HAINAN UNIVERSITY

Protein of gracilaria chouae glucophosphomutase and encoding gene and application of protein

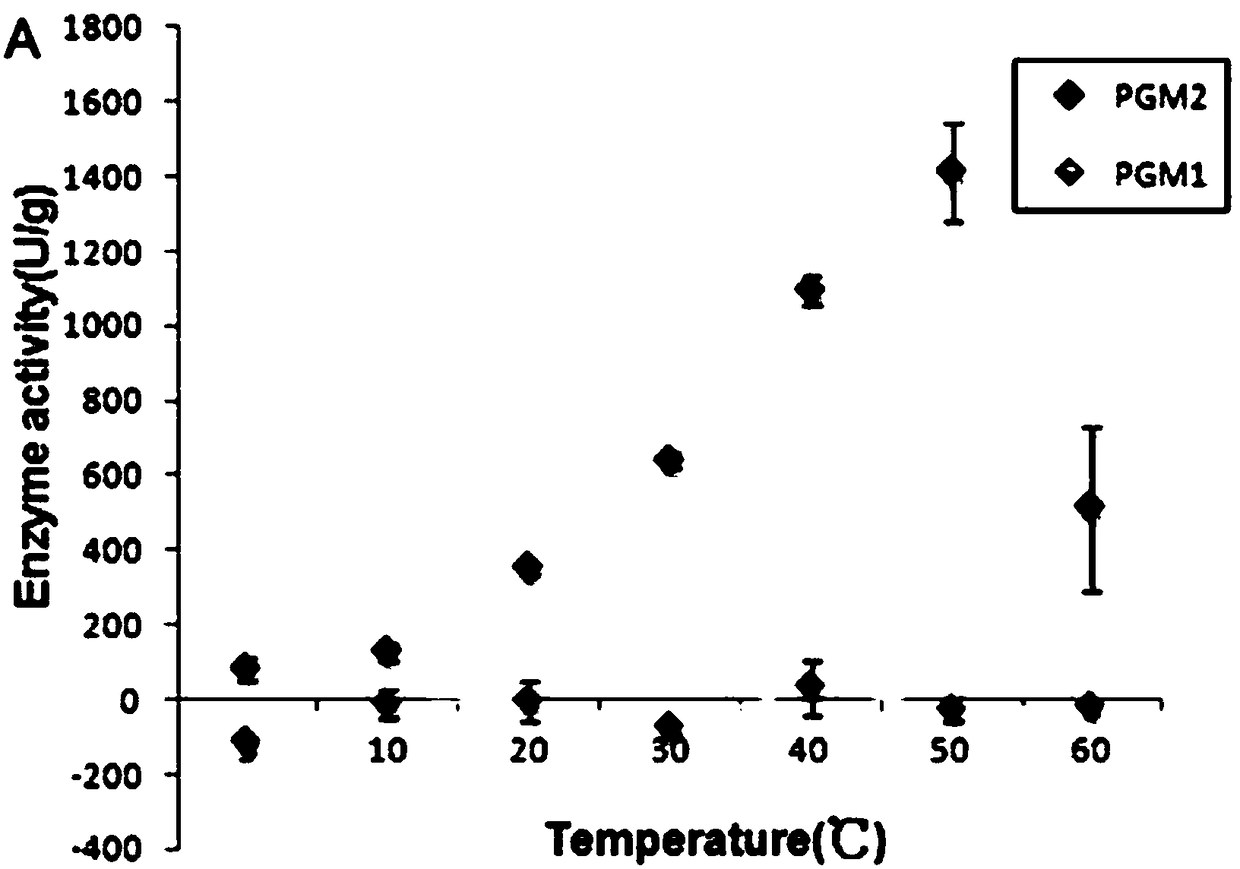

ActiveCN108374002AIncreased trehalose contentUnderstanding and Mastering Metabolic PathwaysTransferasesIsomerasesNucleotideGracilaria chouae

The invention discloses a protein of gracilaria chouae glucophosphomutase and an encoding gene and an application of the protein. The protein of the gracilaria chouae glucophosphomutase comprises a protein GchPGM1 and a protein GchPGM2, the amino acid sequence of the protein GchPGM is as shown in a sequence table SEQ ID NO.2, and the amino acid sequence of GchPGM2 is as shown in a sequence table SEQ ID NO. 4. The nucleotide sequence of the encoding gene GchPGM1 of the protein GchPGM1 of the gracilaria chouae glucophosphomutase is as shown in sequence table SEQ ID NO.1. The trehalose metabolicpathway, functions and effects of trehalose in aspects of system development, environmental adaptation and the like are further deeply known and mastered favorably; and the gene is used as a label toscreen or breed seaweed with high trehalose content, or genetic engineering seaweed with high trehalose content is constructed by over-expression of the gene.

Owner:OCEAN UNIV OF CHINA

Technology with high utilization rate for extracting agar from gracilaria seaweed

The invention discloses a technology with high utilization rate for extracting agar from gracilaria seaweed. Seaweed bodies are pretreated with a low-alkali high-temperature method, consumption of alkali is reduced, and product strength is improved; gel extraction is performed with a high-temperature pressurization method, and the gel output rate is effectively increased; the production cycle canbe shortened; a multi-stage vibrating screen filtration technology is developed, the seaweed with gel incompletely output is filtered and returned to secondary gel extraction, waste is reduced, and the gel extraction rate is increased; meanwhile, residues are modified and processed to form fertilizer and feed additives, so that the comprehensive utilization rate of raw materials is greatly increased.

Owner:FUJIAN GOLD SWALLOW OCEAN BIOTECH

Method for promoting growth of net cage apostichopus japonicus fry through macrophytic algae

InactiveCN113207764AIncrease growth rateImprove survival rateClimate change adaptationPisciculture and aquariaFisheryZoology

The invention discloses a method for promoting growth of net cage apostichopus japonicus fry through macrophytic algae. The method comprises the following steps: (1) putting macrophytic algae: when the average water temperature of a pond is higher than 16 DEG C, selecting gracilaria lichevoides which grows vigorously and is healthy in color, removing miscellaneous algae, and putting gracilaria lichevoides into a 3 m * 1.5 m * 0.8 m net cage according to the density of 200-800 g / m < 2 >; (2) putting apostichopus japonicus fry: selecting disease-free healthy apostichopus japonicus fry, and putting 1 kg of apostichopus japonicus fry with the specification of 2000 fry per kilogram into each net cage; (3) performing illumination and water control: using a sunshade net to control the illumination at 3000-12000 lx in the daytime; controlling the temperature of the seawater in the pond as 16-33 DEG C, and controlling the salinity of the seawater at 25-34; (4) performing feeding and daily management: feeding once a day, wherein the feeding amount accounts for 5% of the weight of apostichopus japonicus fry. According to the method, the growth rate and the survival rate of apostichopus japonicus are increased, the production cost is greatly reduced, the production of apostichopus japonicus fry is ensured, and the wide popularization can be realized.

Owner:山东省海洋资源与环境研究院

Shallow sea ecological culture method for kelp, gracilaria, haliotis discus hanai, strongylocentrotus intermedius and apostichopus japonicas

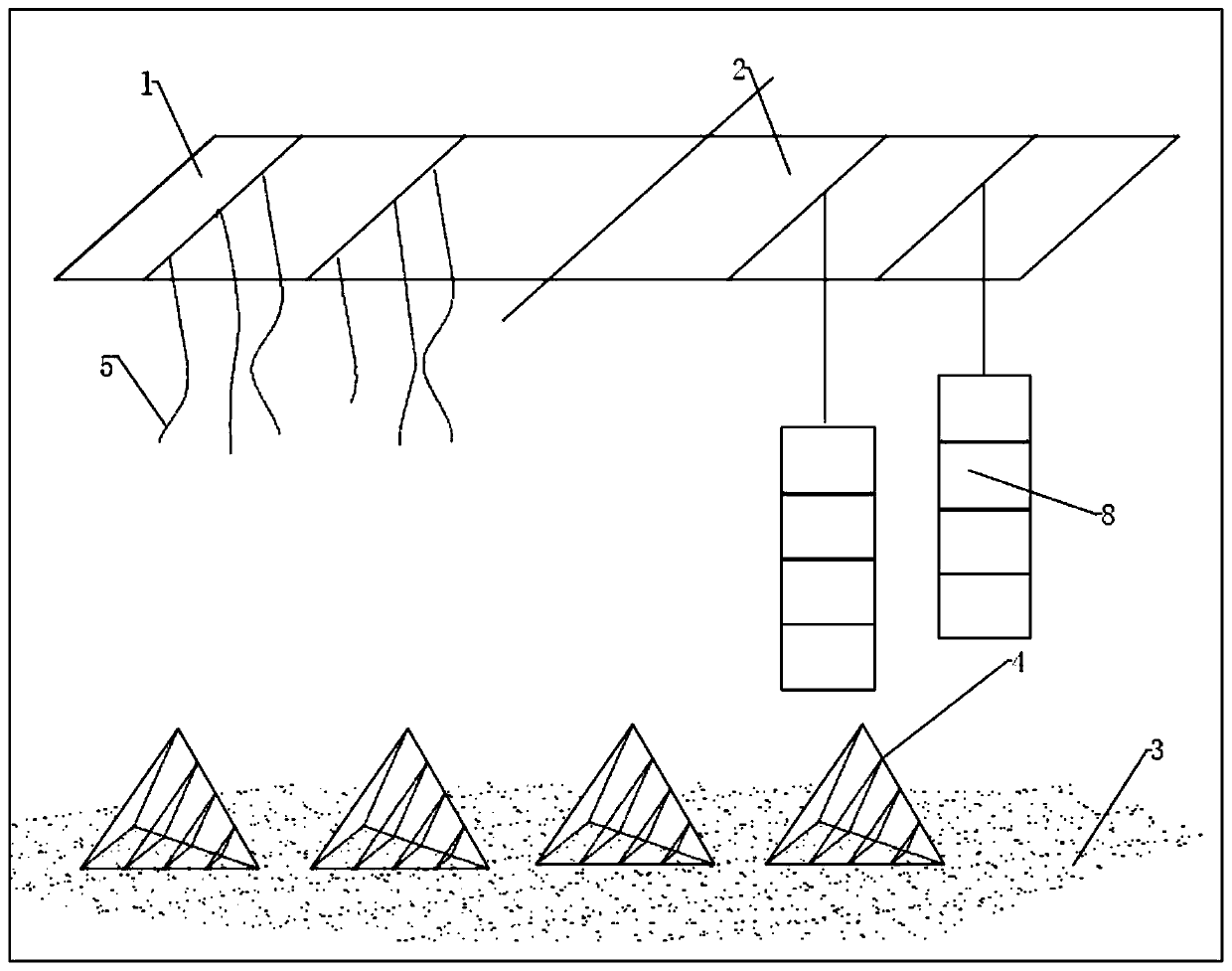

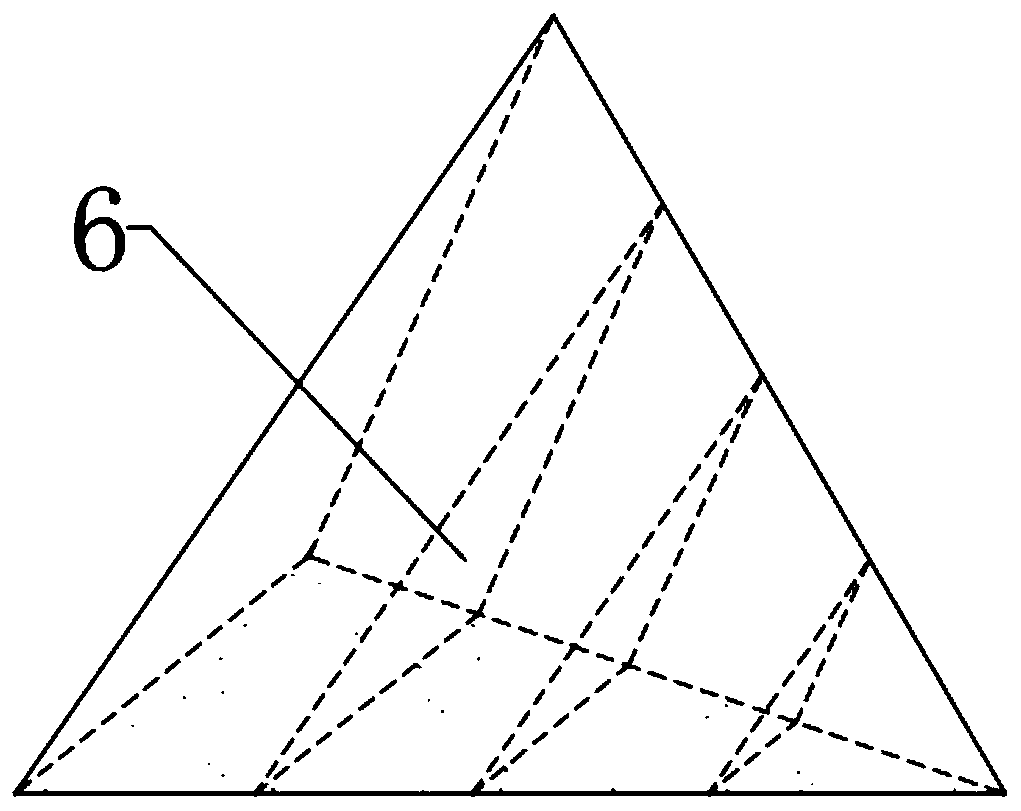

ActiveCN111387041AStable structureReasonable designClimate change adaptationPisciculture and aquariaHaliotis discusShallow sea

The present invention relates to the field of aquaculture, and particularly relates to a shallow sea ecological culture method for kelp, gracilaria, haliotis discus hanai, strongylocentrotus intermedius and apostichopus japonicus. The method comprises the specific steps of selecting a proper culture sea region; dividing the sea region into culture regions each with the area of 13 ha, wherein the two adjacent culture regions are an alga culture region and an abalone culture region respectively; and putting regular tetrahedron-shaped artificial fishing reefs at the bottoms of the alga culture region and the abalone culture region. The culture method effectively improves the system internal material and energy utilization efficiency, the annual production value per unit area is improved by 50% or above, the influence of culture production on the environment is effectively reduced, and ecological, efficient and low-carbon culture is realized.

Owner:WEIHAI OCEAN VOCATIONAL COLLEGE

Method for preparing agarose

The invention relates to a method for preparing agarose. The method comprises the following steps: cleaning gracilaria, and carrying out alkali treatment, acidification treatment, bleaching treatment,gelatin boiling, filtration, cooling and solidification to obtain colloid; dicing the colloid, and mixing the diced colloid with an ethanol solution to obtain a colloid block mixed solution; and heating the colloid block mixed solution, dropwise adding a glutaric anhydride ethanol solution for reaction, adjusting the pH value in the reaction process, filtering after the reaction is finished to obtain colloid blocks, and washing, dehydrating, drying and crushing the colloid blocks to obtain the agarose. According to the method, the content of sulfuric acid groups of agar can be remarkably reduced, the gel strength is improved, the electroendosmosis is remarkably reduced, the commercially available agarose index requirement is met, the reaction time is short, and the method is environmentally friendly.

Owner:SHANGHAI OPM BIOSCI CO LTD

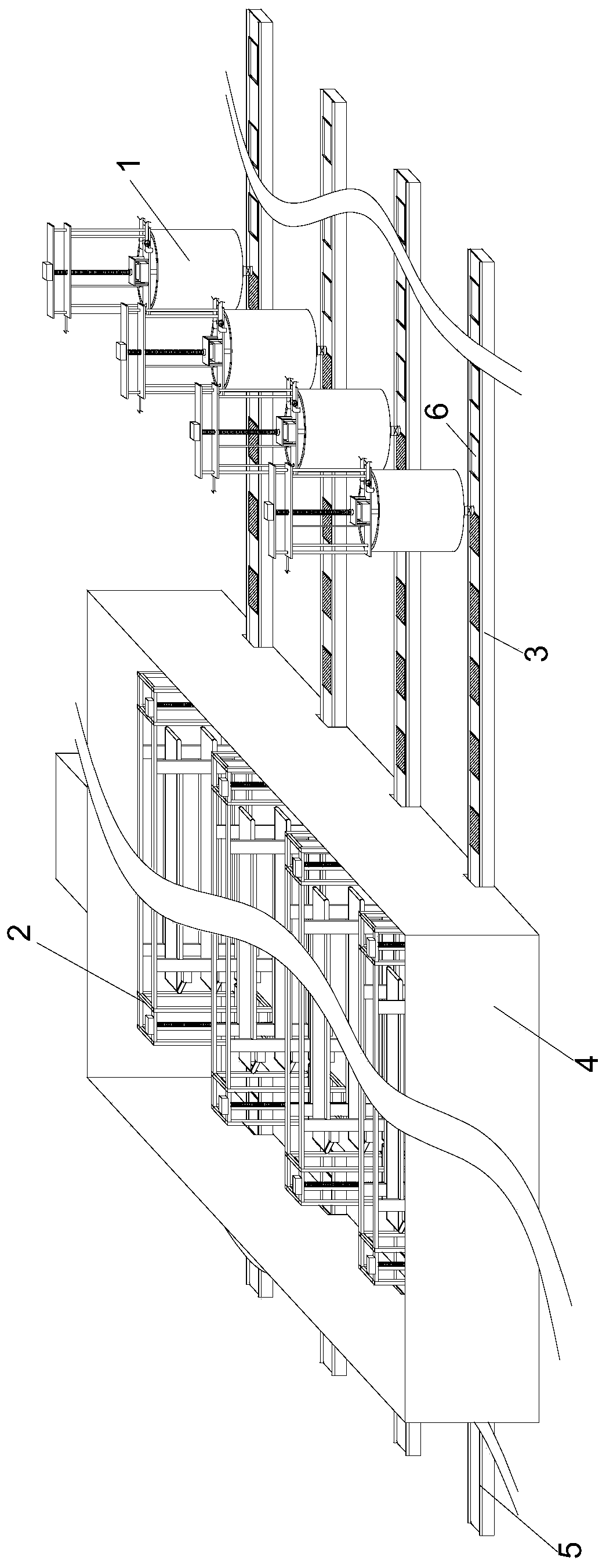

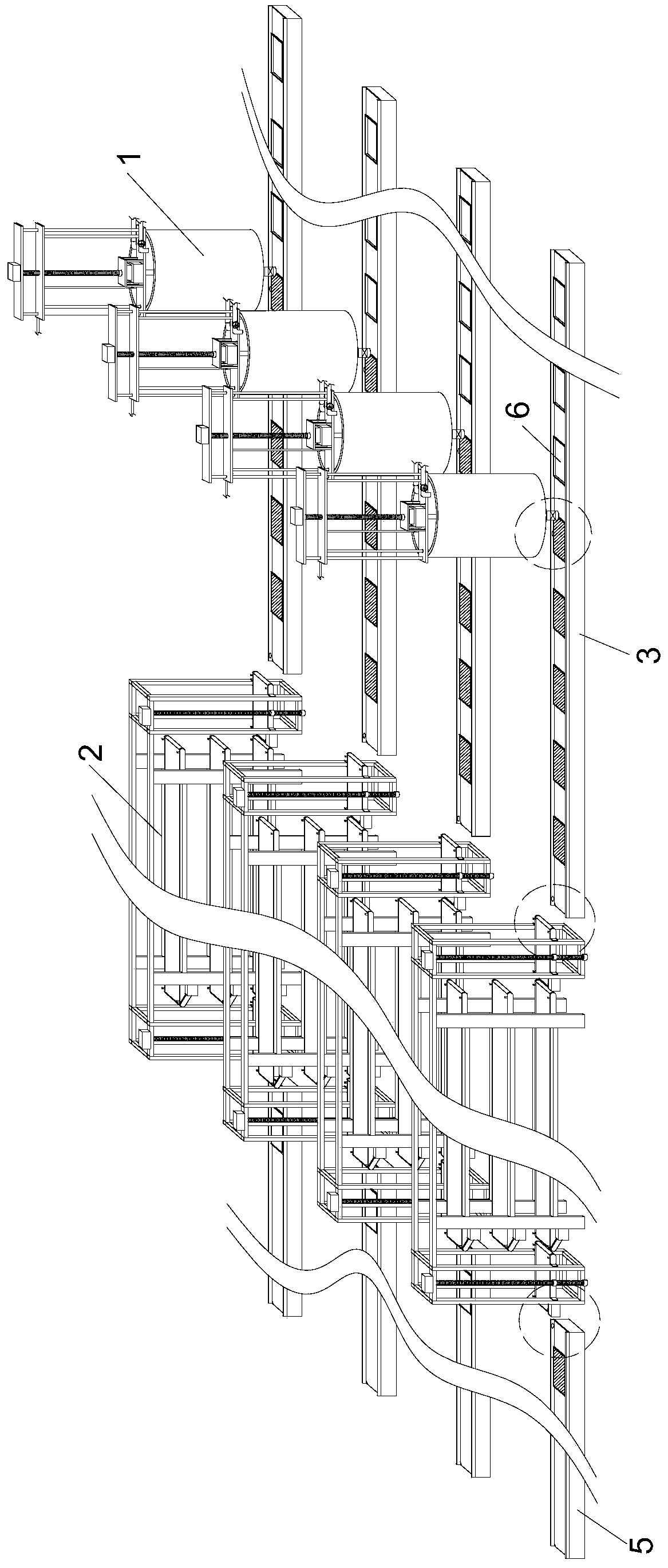

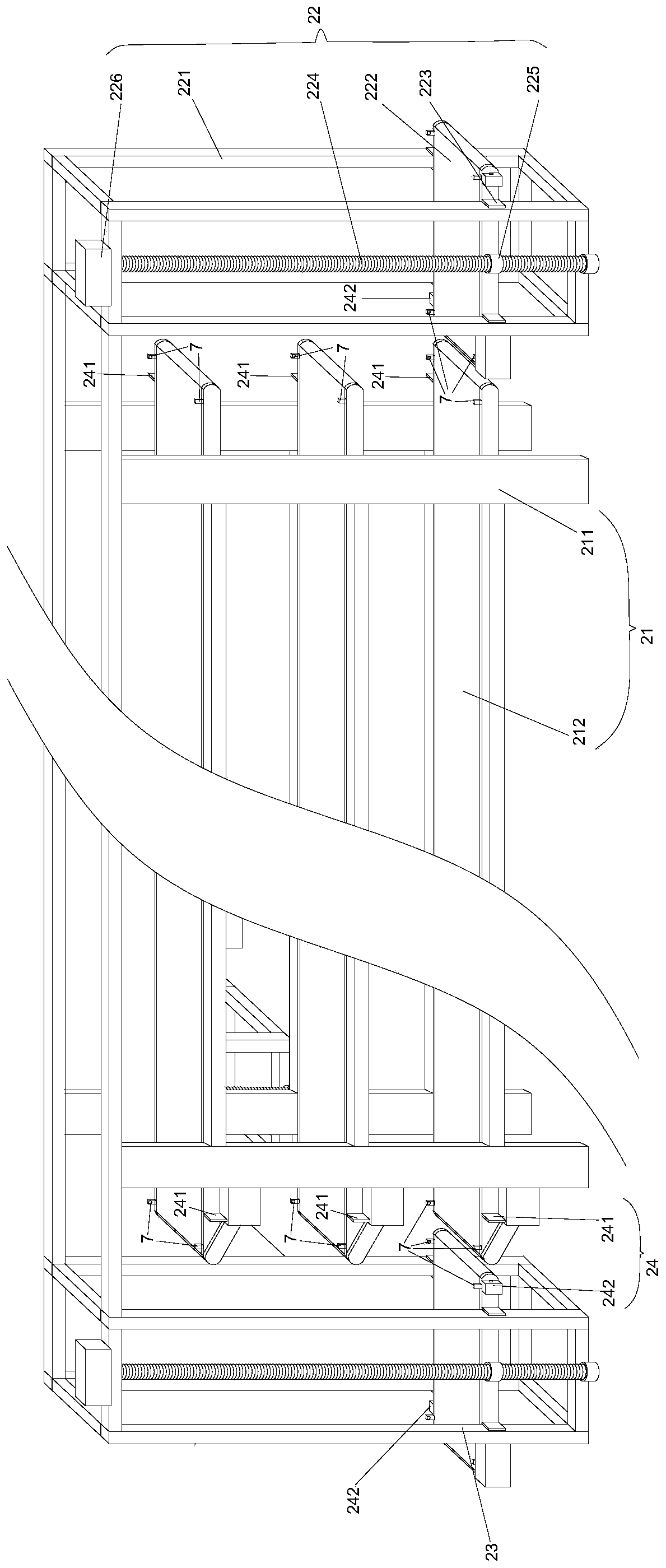

Automatic agar filling and cooling system

PendingCN110732292ASpeed up condensationIncrease productivityFusionEngineeringMechanical engineering

The invention relates to an automatic agar filling and cooling system. The system comprises a gracilaria gel boiling device, an agar condensing device, a to-be-condensed agar conveying belt and a gelframe, the middle section of the to-be-condensed agar conveying belt is arranged below a discharge hole of the gracilaria glue boiling device; the to-be-condensed agar conveying belt extends leftwardsand penetrates into a condensation chamber; the agar condensing device is installed in the condensation chamber and comprises an agar condensation conveying frame, a first lifting conveying frame anda second lifting conveying frame, the left end of the second lifting conveying frame is in butt joint with a condensed agar conveying belt, and the condensed agar conveying belt penetrates out of theleft side wall of the condensation chamber; the gracilaria gel boiing device comprises a cooking tank body, a stirring mechanism and a cooking mechanism, the gel boiling speed and the gel gelling speed are effectively increased, workers can be effectively prevented from being scalded by agar, and the production efficiency is greatly improved.

Owner:FUJIAN TIANYUAN XINGDA BIOTECHNOLOGY CO LTD

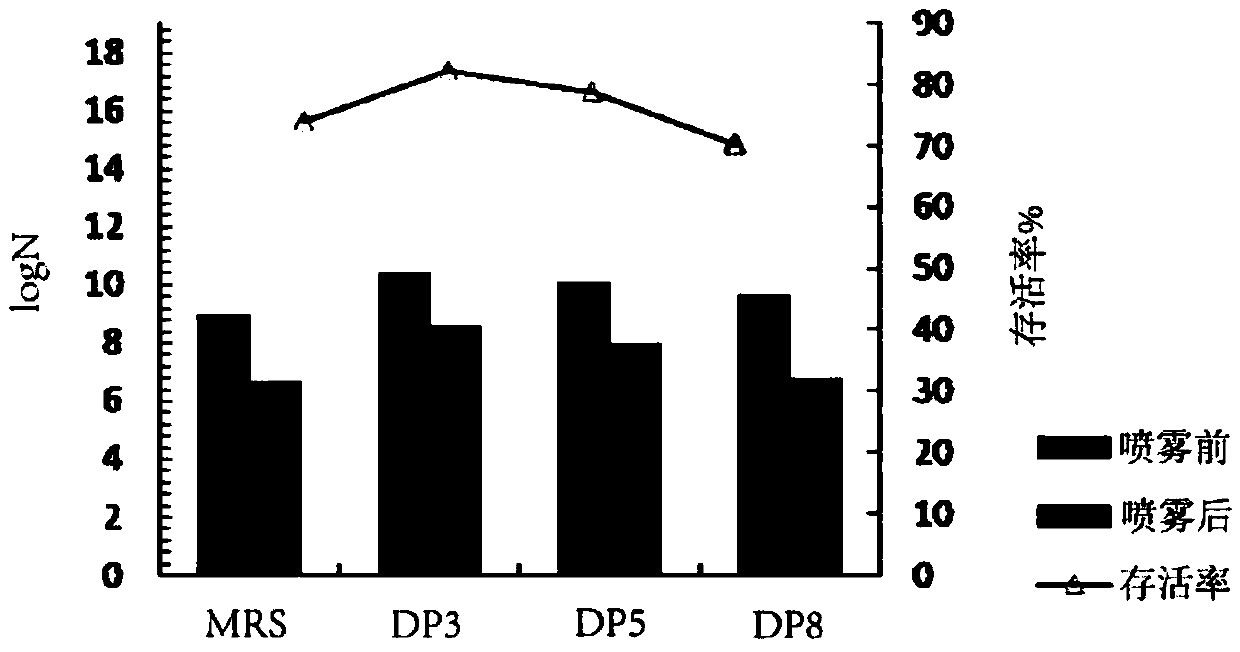

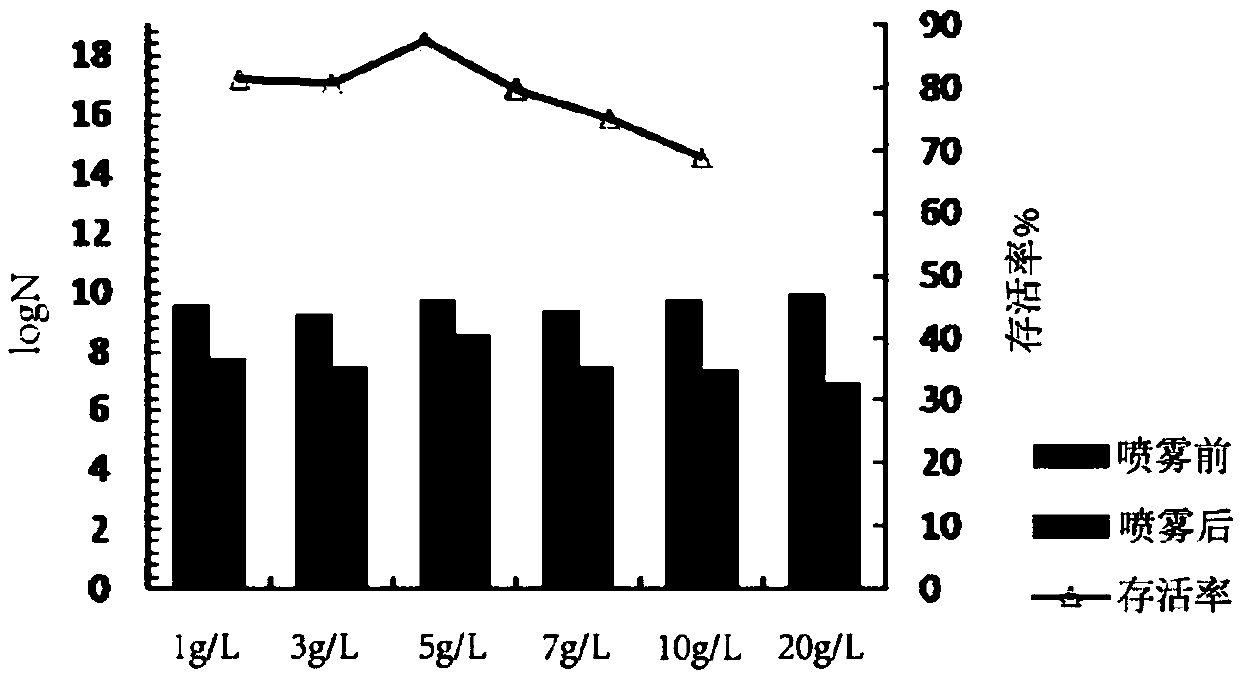

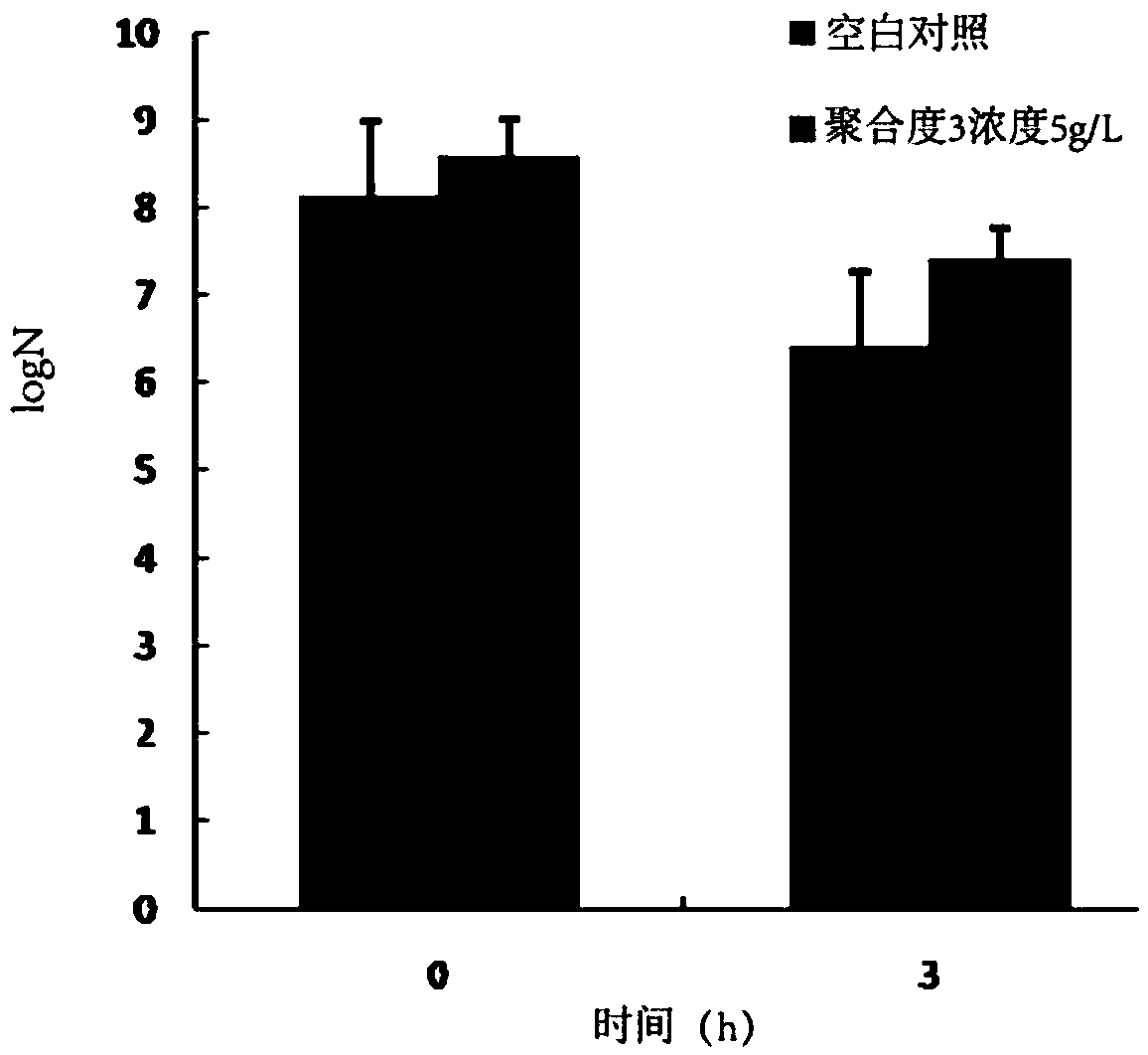

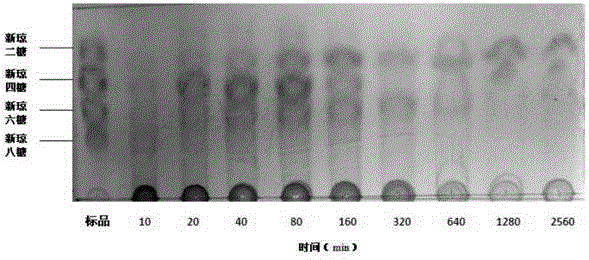

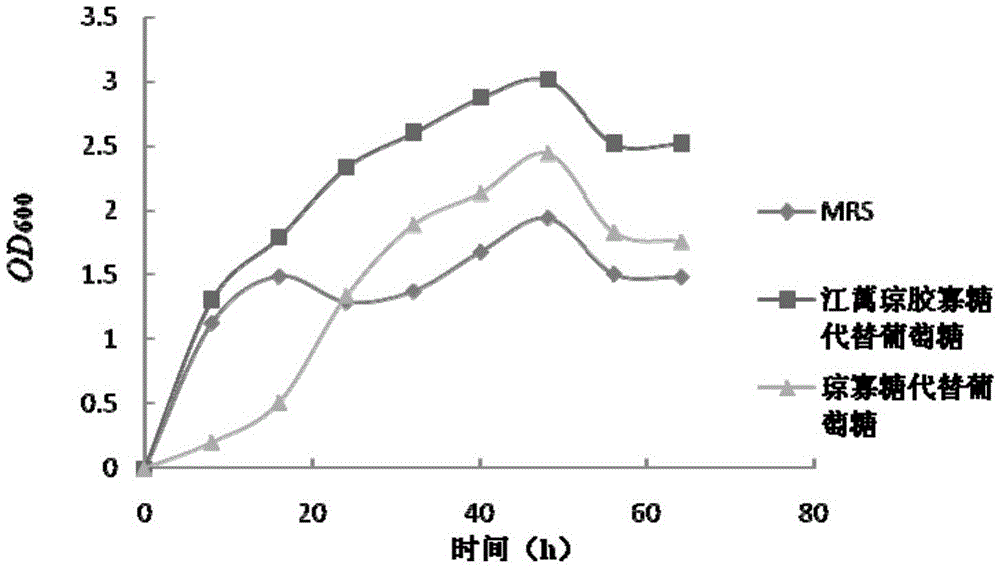

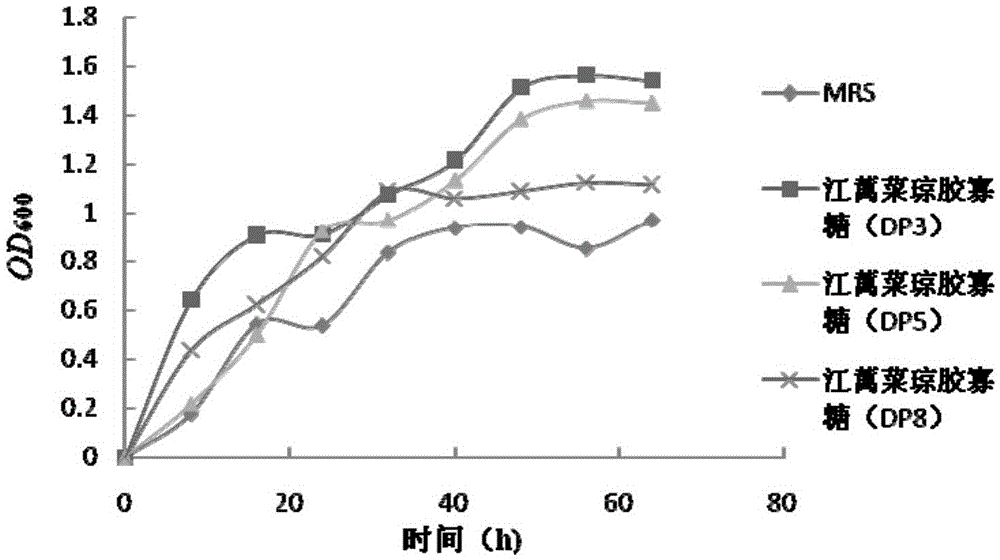

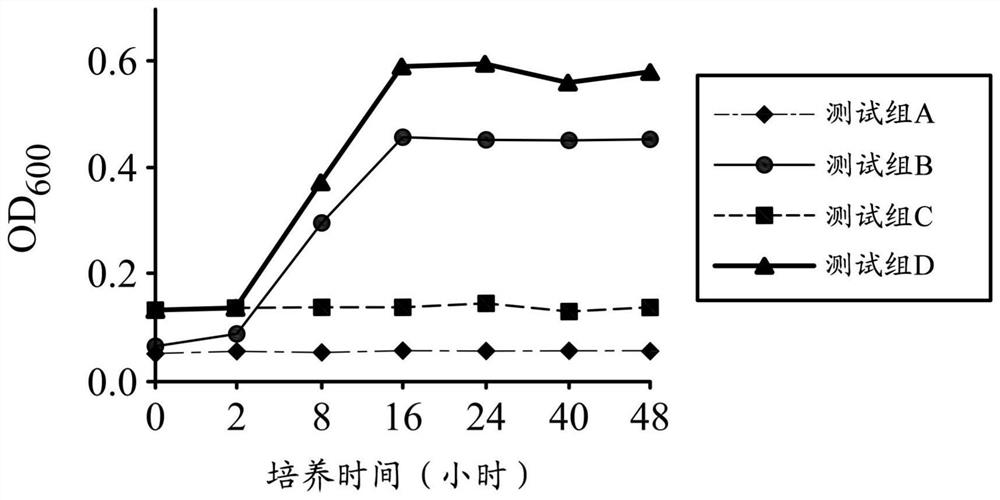

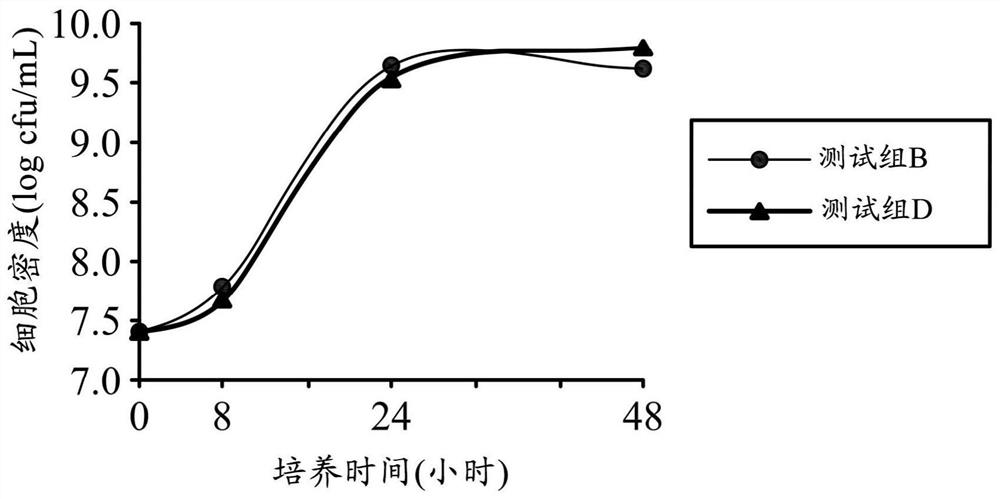

Preparation method and application of Gracilaria agar oligosaccharide promoting growth of Lactobacillus bulgaricus

InactiveCN105506032AHigh activityImprove protectionMicroorganism based processesMicroorganism preservationWater bathsFreeze-drying

The invention discloses a preparation method of Gracilaria agar oligosaccharide promoting growth of Lactobacillus bulgaricus. The preparation method includes following steps: step 1, removing impurities of Gracilaria: cleaning, removing impurities of Gracilaria, drying, and placing Gracilaria in water bath at 80 DEG C for heating for 2 h; step 2, sterilizing at high temperature: sterilizing at 121 DEG C for 20 min; step 3, squeezing glue: using filter cloth to wrap Gracilaria, squeezing, collecting a polysaccharide solution, cooling, drying, smashing into granules, and bagging the granules for standby use; step 4, performing enzymatic treatment: dissolving cooled coarse polysaccharide in water to prepare a polysaccharide solution of 5g / L in concentration, adding agarase for treatment, performing enzymolysis for 20-1280 min to prepare an oligosaccharide solution, wherein enzyme adding quantity is 15% and enzyme activity is 300 U / mL; step 5, drying: freeze-drying the oligosaccharide solution or vacuum-drying the same to form solid powder to obtain the agar oligosaccharide. The preparation method can be used for Lactobacillus fermentation enterprises and dairy product production enterprises to produce high-activity Lactobacillus products and high-storability dairy products.

Owner:FUJIAN PROVINCE LVQI FOOD COLLOID +1

Method for effectively reducing chlorine gas produced while bleaching gracilaria verrusosa with sodium hypochlorite

Owner:GUANGDONG OCEAN UNIVERSITY

Preparing method and application of gracilaria agaro-oligo saccharide for promoting streptococcus thermophilus growth

ActiveCN105624236AResolution cycleSolve the problem of low bacterial countBacteriaMicroorganism based processesWater bathsFreeze-drying

The invention discloses a preparing method of gracilaria agaro-oligo saccharide for promoting streptococcus thermophilus growth.The method comprises the steps of 1, preparation of agarase crude enzyme; 2, decontamination of gracilaria, wherein gracilaria is cleaned, decontaminated, dried and heated in a water bath which is 80 DEG C for 2 h; 3, heating and sterilization, wherein heated gracilaria is heated again to 121 DEG C and sterilized for 20 min; 4, latex squeezing, wherein latex squeezing is conducted while gracilaria is still hot, gracilaria is wrapped in a filter cloth and squeezed, and polysaccharide solution filtered out through latex squeezing is collected, cooled, dried and smashed into particles to be bagged to be used, so that gracilaria crude polysaccharide is obtained; 5, enzyme treatment, wherein the agarase crude enzyme is added for treatment to prepare oligosaccharide solution; 6, drying, wherein freeze drying or vacuum drying is conducted on the oligosaccharide solution to obtain solid powder, so that the agaro-oligo saccharide is obtained.The method can be used in lactobacillus fermentation enterprises and dairy product production enterprises to produce high-activity lactic acid bacteria products and high-storability dairy products.

Owner:FUJIAN PROVINCE LVQI FOOD COLLOID

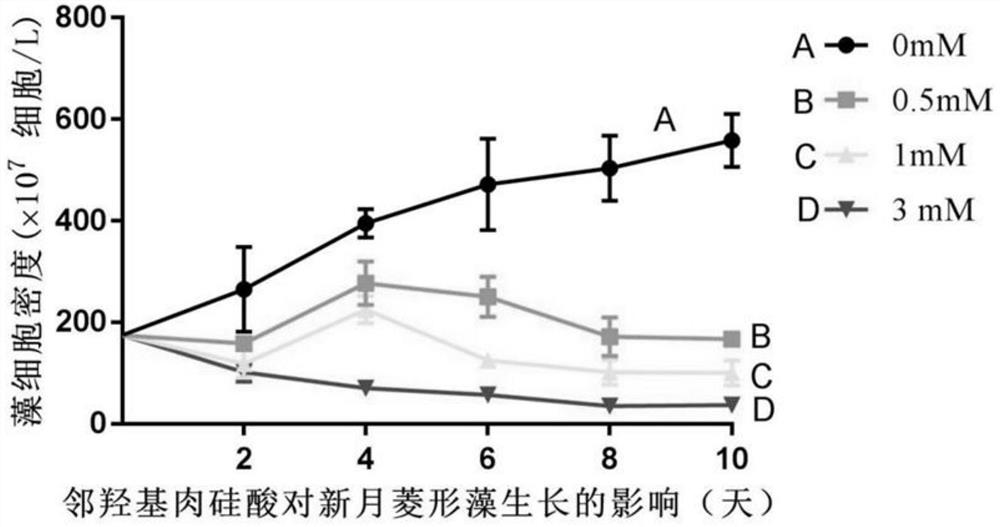

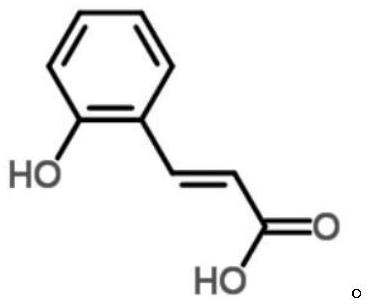

Application of o-hydroxycinnamic acid of in removal of harmful benthic diatom

PendingCN113994946AEfficient removalClear the economyBiocideClimate change adaptationOrtho-hydroxycinnamic acidSeaweed farming

The invention belongs to the technical field of seaweed cultivation, and particularly relates to an application of o-hydroxycinnamic acid in removal of harmful benthic diatom. The o-hydroxycinnamic acid is used as an algicide to remove the harmful benthic diatom, and the algicide-o-hydroxycinnamic acid used in the invention is an extract of gracilaria bailinae. Compared with a traditional diatom removal method, the application has the following remarkable advantages: (1) the diatom removal agent is easy to degrade in a natural environment and does not generate secondary pollution; (2) the effect is quick, the inhibition rate on adsorption type benthic diatom after 2 days, under the treatment of 3 mM / L o-hydroxycinnamic acid, exceeds 50%, operations are simple, and the manpower is saved; (2) the price is low and the acquisition is easy; therefore, the method for removing the harmful benthic diatom is an environment-friendly, efficient, and economical method of benthic diatom prevention and removal.

Owner:GUANGDONG OCEAN UNIVERSITY

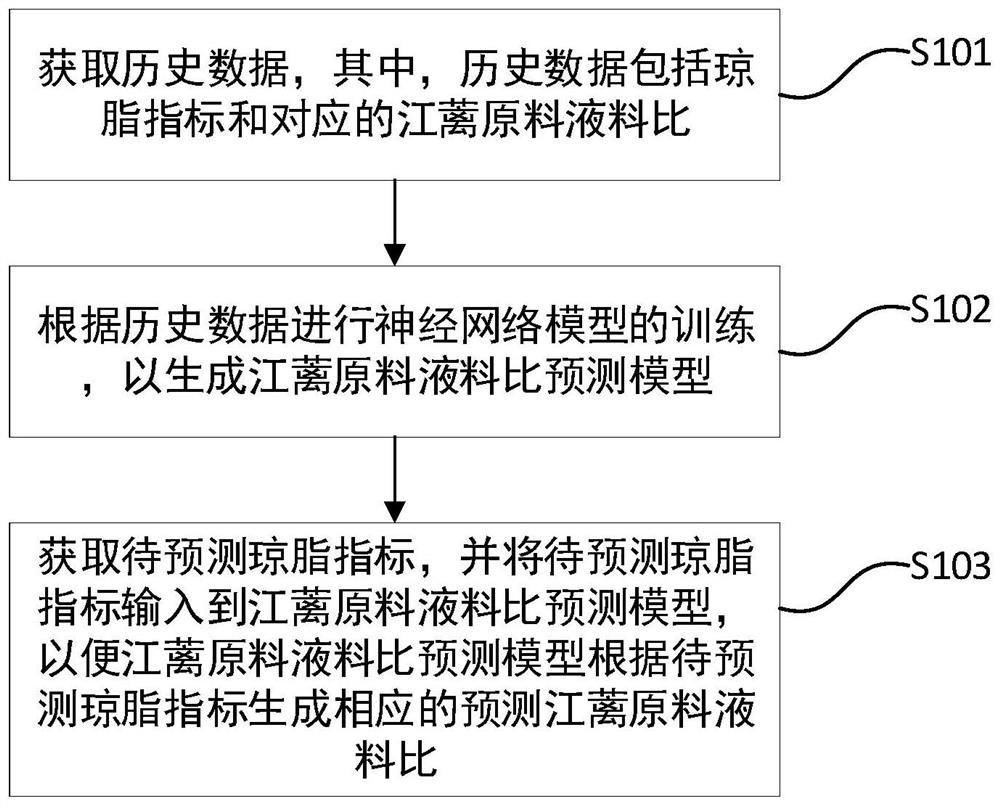

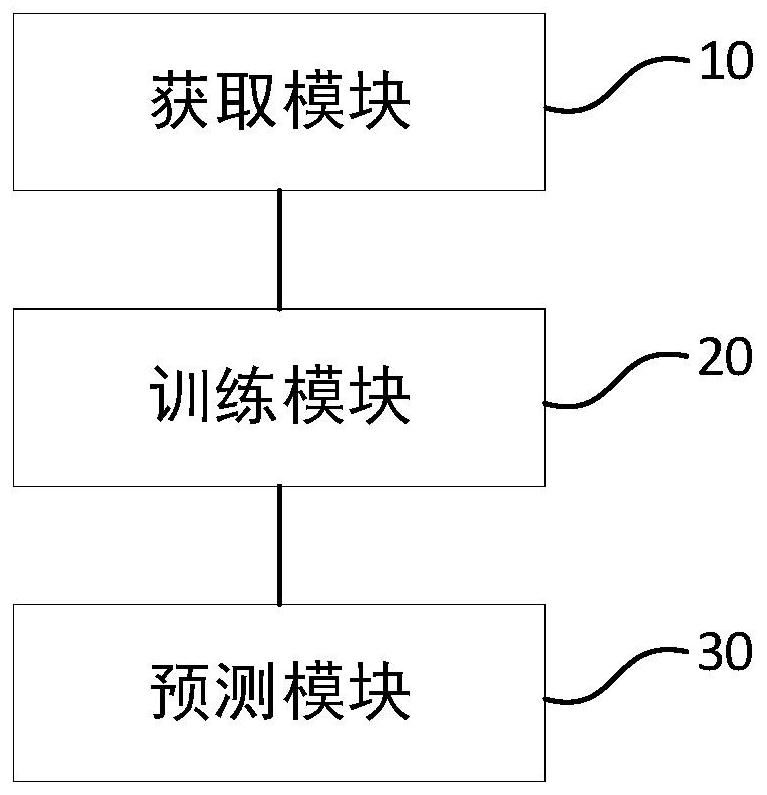

Gracilaria raw material liquid-to-material ratio prediction method and device based on neural network

PendingCN111723899AQuality assuranceReduce consumptionForecastingResourcesProcess engineeringNetwork model

The invention discloses a gracilaria raw material liquid-to-material ratio prediction method, medium, equipment and device based on a neural network, and the method comprises the steps: obtaining historical data which comprises an agar index and a corresponding gracilaria raw material liquid-to-material ratio; training a neural network model according to the historical data to generate a gracilaria raw material liquid-to-material ratio prediction model; acquiring a to-be-predicted agar index, and inputting the to-be-predicted agar index into the gracilaria raw material liquid-to-material ratioprediction model, so as to enable the gracilaria raw material liquid-to-material ratio prediction model to generate a corresponding predicted gracilaria raw material liquid-to-material ratio according to the to-be-predicted agar index. According to the method, the gracilaria raw material and liquid material ratio can be effectively predicted before production, so that the consumption of water resources is reduced while the agar quality is guaranteed.

Owner:JIMEI UNIV

A kind of industrialized polyculture method of Fangban Dongfeng snail, Yuzu sea cucumber and Gracilaria

ActiveCN107232102BInhibit deteriorationStrong selective feeding abilityClimate change adaptationPisciculture and aquariaPolycultureOrientia

The invention discloses an industrialization polyculture method of Babylonia areolata, holothuria leucospilota and gracilaria. The method comprises the following steps of (1) aquaculture water and bed-load activation before aquaculture, (2) stocking and feeding of fries and fingerling of the Babylonia areolata, and (3) environmental control. The method is an ecological breeding method, under the condition of land-based factory breeding, Babylonia areolata breeding is regarded as principle, the holothuria leucospilota is subjected to polyculture to improve the base material, the seaweed (gracilaria) is subjected to polyculture to improve the water quality, and thus the morbidity of the Babylonia areolata is lowered.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

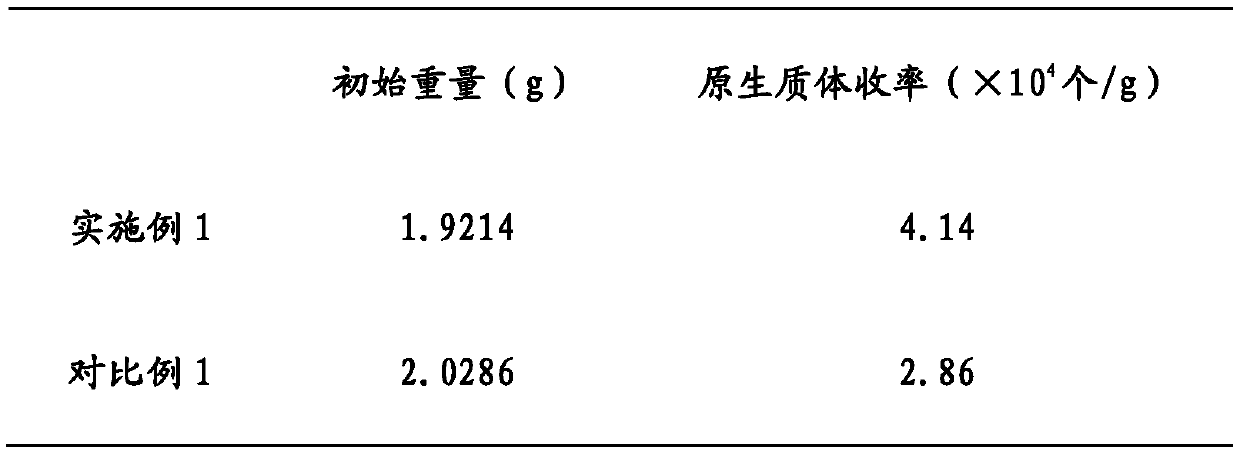

The preparation method of the protoplast of Gracilaria gracilaria in Chile

The invention relates to a method for preparing gracilaria chilensis protoplast and belongs to the field of algae cell engineering. The preparation method comprises the following steps: preparing a tissue enzyme solution, and performing enzymolysis on gracilaria chilensis tissues, wherein the step of preparing the tissue enzyme solution comprises the following steps: homogenizing with seawater in an amount of 1-10 times that of the volume of sea cucumber intestines at a temperature of 0 DEG C; extracting at a temperature of 4 DEG C for 4-18 hours, regulating the pH value of the extracting solution to be 7.0-8.0, freezing and centrifuging for 5 minutes, and taking the supernatant so as to obtain a sea cucumber enzyme solution; and mixing the sea cucumber enzyme solution, cellulase and seawater so as to obtain the tissue enzyme solution.

Owner:OCEAN UNIV OF CHINA

Gracilaria soaking and cooking system

PendingCN111939593AAvoid running back and forthLabor intensiveSolid solvent extractionFiltration circuitsEngineeringProcess engineering

The invention relates to a gracilaria soaking and cooking system, which comprises a production workshop, and a clean water tank, an alkali liquor tank, a plurality of soaking tanks and a plurality ofcooking tanks which are arranged in the production workshop, the clean water tank is connected with a clean water output pipe, the alkali liquor tank is connected with an alkali liquor output pipe, and the other end of the clean water output pipe is connected with each soaking tank; the other end of the alkali liquor output pipe is connected with each soaking pool, the bottom of each soaking poolis connected with a clear water return pipe, an alkali liquor return pipe and a gracilaria conveying pipe, the other end of each gracilaria conveying pipe is connected and introduced into the cookingpool, a first stirrer is mounted in each soaking pool, and a second stirrer is mounted in each cooking pool; a discharge switch is arranged at the joint of the gracilaria conveying pipe and the soaking pool, and a first valve and a second valve are arranged at the joint of the clear water return pipe and the alkali liquor return pipe respectively. By means of the system, alkali liquor and clear water can be recycled, soaked gracilaria is directly conveyed into the cooking pools, the cooking pools and the soaking pools are used at the same time, and the processing number can be increased.

Owner:FUJIAN TIANYUAN XINGDA BIOTECHNOLOGY CO LTD

Application and treatment of water extract or fermented product of Gracilariaceae plants and/or medicinal composition for alleviating neurological diseases or health food for alleviating neurological diseases

The present invention provides a kind of water extract of Gracilaceae plant or its fermented product for the preparation of medicine and / or health food for treating and / or alleviating neurological diseases, wherein the fermented product of the water extract of Gracilaceae plant is Lactic acid bacteria ferment.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com