Gracilaria agar production method based on mathematical model

A production method and technology of mathematical models, which are applied in CAD numerical modeling, electrical digital data processing, special data processing applications, etc., can solve the problems of time-consuming, labor-intensive, and high production costs, reduce alkali consumption, save production costs, and promote The effect of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

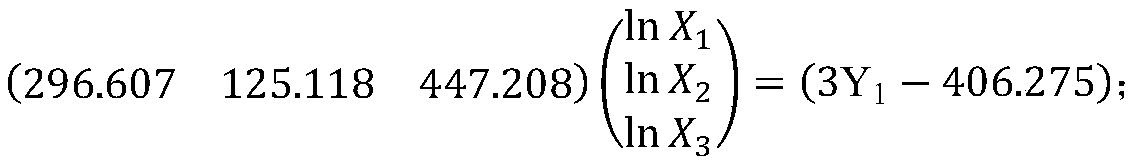

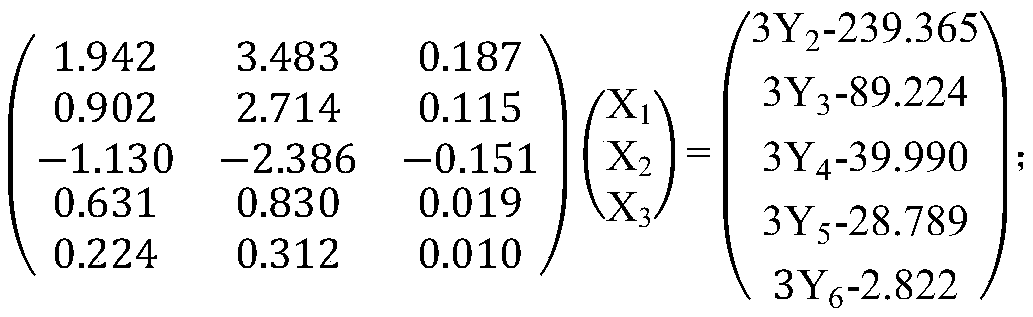

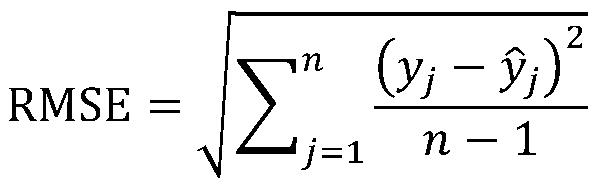

Method used

Image

Examples

Embodiment 1

[0026] A method for producing Gracilaria agar based on a mathematical model, comprising the following steps:

[0027] Alkali treatment: After the Gracilaria is rinsed, dry it in an oven at 60°C until it reaches constant weight, prepare 1500mL of NaOH solution with a mass fraction of 1% to 8%, add 100g of Gracilaria, and treat it at a constant temperature in a water bath at 50°C to 90°C for 0.5h~ 3.5 hours;

[0028] Washing, acidification and bleaching: add 100mL water to the alkali-treated Gracilaria to rinse the lye, soak in water for 30min, repeat four times, then add 0.65mL concentrated sulfuric acid, 0.96g oxalic acid and 0.192g EDTA-Na 2 Acidify for 0.5h, continue to add 1500mL of water to soak and wash until the pH is neutral, then add 1500mL of sodium hypochlorite solution with an effective chlorine mass fraction of 0.04%, mix evenly, stir and bleach for 0.5h, pour off the bleaching solution, add 1500mL of water to soak and wash until pH is neutral;

[0029] Gel cooki...

Embodiment 2

[0036] The transparency and the sulfate content of the agar produced under the same experimental alkali treatment process conditions are respectively substituted into the above-mentioned model of embodiment 1: (1) when the transparency is 90.1%, the above-mentioned model is substituted, and the relevant alkali treatment process can be obtained: the alkali treatment concentration is 4.7%, the alkali treatment time is 2.3h, the alkali treatment temperature is 73°C, and the alkali consumption of the production unit agar product is 1.77t; (2) when the sulfate radical content is 5.51%, substituting the above model, the relevant alkali treatment process can be obtained as: The alkali treatment concentration is 5.1%, the alkali treatment time is 2.2h, the alkali treatment temperature is 83°C, and the alkali consumption per unit of agar product produced is 1.83t.

[0037] Comparing the alkali consumption of the above two alkali treatment processes, the alkali consumption is the lowest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com