Preparing method and application of gracilaria agaro-oligo saccharide for promoting streptococcus thermophilus growth

A technology of Streptococcus thermophilus and agar oligosaccharide, which is applied in the field of food processing, can solve the problems of substandard quantity of probiotics in products, and achieve the effect of reducing heating time, reducing heat loss and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: A method for preparing Gracilaria agar oligosaccharide grown by Streptococcus thermophilus

[0030] A method for preparing Gracilaria agar oligosaccharide that promotes the growth of Streptococcus thermophilus, comprising the following steps:

[0031] Step 1. Preparation of agarase crude enzyme solution: inoculate the Streptococcus thermophilus strain (Vibriosp.NTi) in the agarase-producing liquid medium, activate the temperature at 25°C, cultivate at 180r / min for 12h, and inoculate with 2% The amount was transferred to the fermentation medium, the culture temperature was 25°C, and 180r / min was cultivated for 24h, the fermentation liquid was centrifuged at 8000r / min at 4°C for 30min, and the supernatant was taken to obtain the crude enzyme liquid of agarase. Agarase crude enzyme solution enzyme activity ≥ 200U / mL;

[0032] Step 2, removing impurities from Gracilaria: washing and removing impurities from Gracilaria, drying, adding water 30 times the weight of...

Embodiment 2

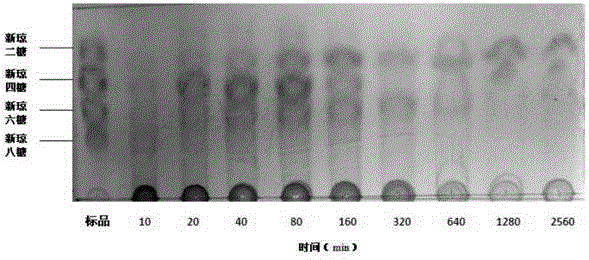

[0041] Embodiment 2: the technical process of preparing oligosaccharides with different degrees of polymerization

[0042] Utilize the crude enzyme liquid prepared by the fermentation of the agarase strain to add to the Gracilaria polysaccharide solution with 50mmol / LTris-HCl as buffer (pH7.0), the concentration of the Gracilaria agar polysaccharide solution is 5g / L, the crude enzyme liquid The added amount is 15%. Enzymatic products such as figure 1 shown. Qualitative test by thin-layer chromatography showed that the degree of polymerization of agar oligosaccharide was 8 when enzymatically hydrolyzing Gracilaria agarose polysaccharide for 20 minutes, 5 for 80 minutes, and 3 for 1280 minutes.

Embodiment 3

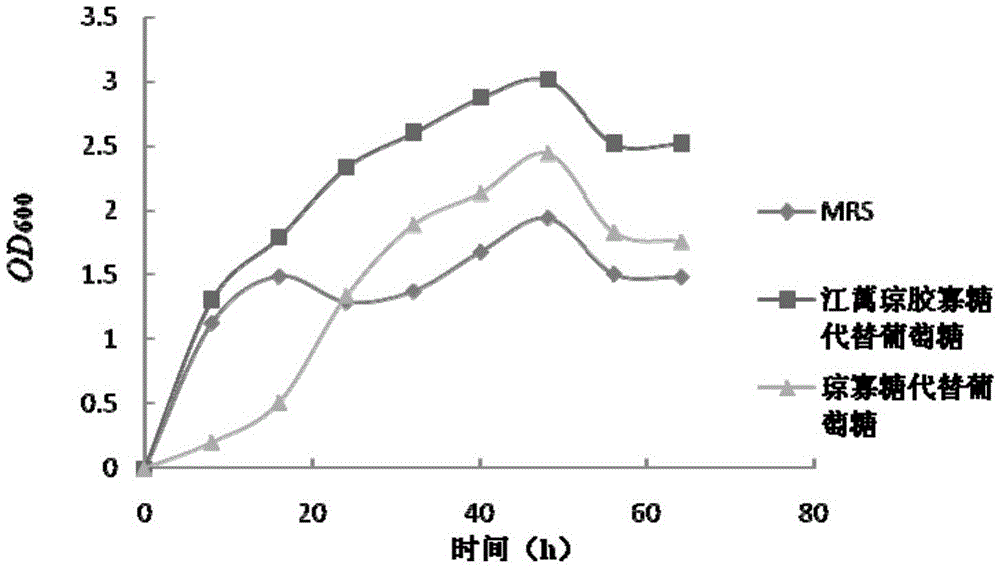

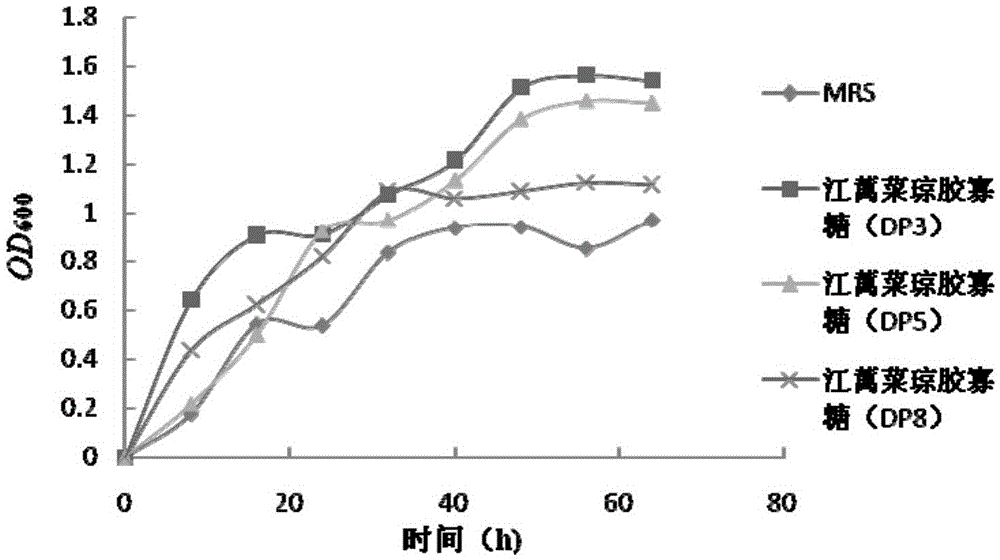

[0043] Embodiment 3: the technological process of different oligosaccharides promoting the growth method of Streptococcus thermophilus

[0044] Different oligosaccharides were prepared by using the above method for preparing oligosaccharides, and the culture medium was prepared. The culture medium of Streptococcus thermophilus and Gracilaria agar oligosaccharide were respectively prepared at the same concentration as the glucose medium and agar oligosaccharide in Streptococcus thermophilus. Replace the glucose medium in Streptococcus thermophilus with the same concentration. Streptococcus thermophilus OD 600 The bacterial solution with a value of 0.8, the inoculum size is 2%, the culture condition is under anaerobic environment, 42 ℃, static culture for 2-3 days, draw the growth curve of Streptococcus thermophilus, as figure 2 shown. The results showed that Gracilaria agar oligosaccharides had a better growth-promoting effect on Streptococcus thermophilus than agar oligosac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com