Preparation method and application of Gracilaria agar oligosaccharide promoting growth of Lactobacillus bulgaricus

A technology of agar oligosaccharides and lactobacilli, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, and the use of added compounds to stimulate growth, can solve the problem that the number of probiotics in the product does not meet the standard, and achieve reduced heating time, Less investment, better activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: A method for preparing Gracilaria agar oligosaccharide grown by Lactobacillus bulgaricus

[0033] Step 1. Remove impurities from Gracilaria: wash and remove impurities from Gracilaria until there is no sediment and the water sample is clear, dry, add water 30 times the weight of Gracilaria to fully swell Gracilaria, and then heat in a water bath at 80°C 2h;

[0034] Step 2, autoclaving: Carry out autoclave sterilization to the Gracilaria after heating treatment, kill microorganism, autoclave temperature is 121 ℃, sterilization time is 20min;

[0035] Step 3, extruding glue: Squeeze Gracilaria while it is hot, wrap Gracilaria with filter cloth, and use a press to squeeze the filter cloth containing Gracilaria, collect the polysaccharide solution filtered out by extrusion; put the collected polysaccharide The solution is cooled, dried, crushed into granules and bagged for later use, and stored in a cool and dry place to obtain the Gracilaria crude polysacchari...

Embodiment 2

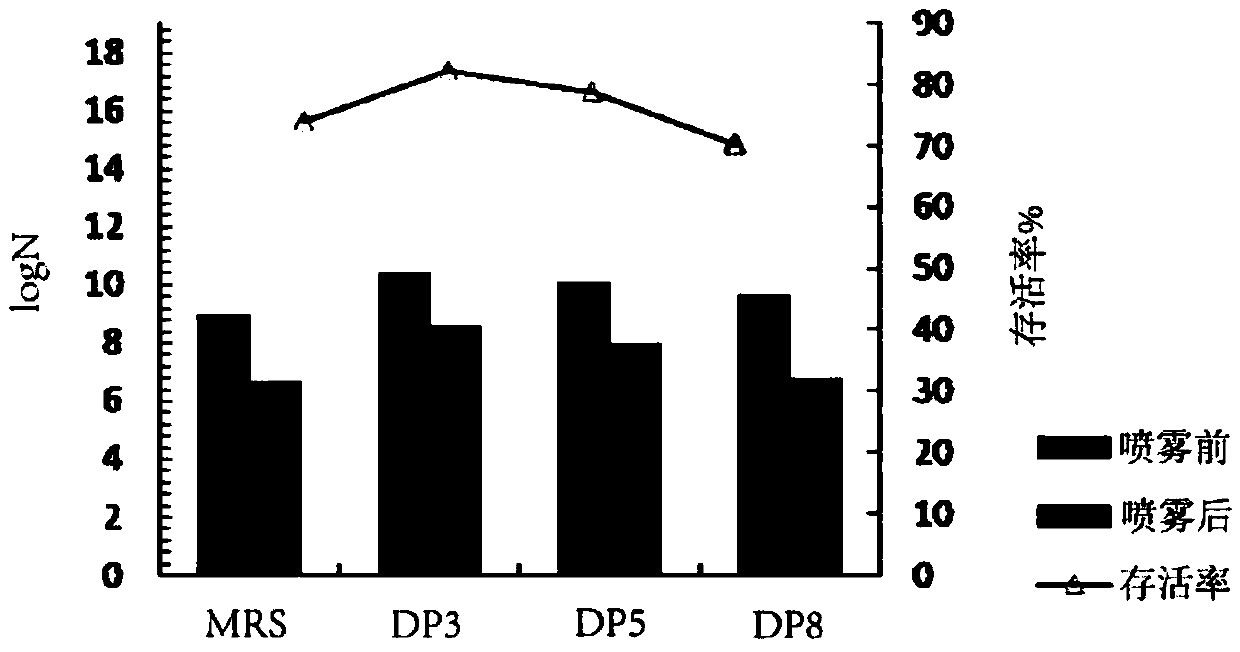

[0041] Example 2: Process flow for improving the viability of Lactobacillus bulgaricus under low temperature storage with agar oligosaccharides with different degrees of polymerization

[0042] Agar oligosaccharides with different degrees of polymerization were prepared using the above method for preparing oligosaccharides, and added to the fermented oligosaccharides to reach OD 600 In the MRS medium of Lactobacillus bulgaricus with a value of 0.8, agar oligosaccharides (DP3, DP5, DP8) with different degrees of polymerization at the same concentration were added to the medium, and the culture conditions were anaerobic environment, 4°C, standing After culturing, samples were taken every 3 days to observe the number of viable bacteria under a microscope, as shown in Table 1.

[0043] Table 1 Agar oligosaccharides with different degrees of polymerization improve the activity of Lactobacillus bulgaricus under low temperature storage

[0044]

[0045] The results showed that th...

Embodiment 3

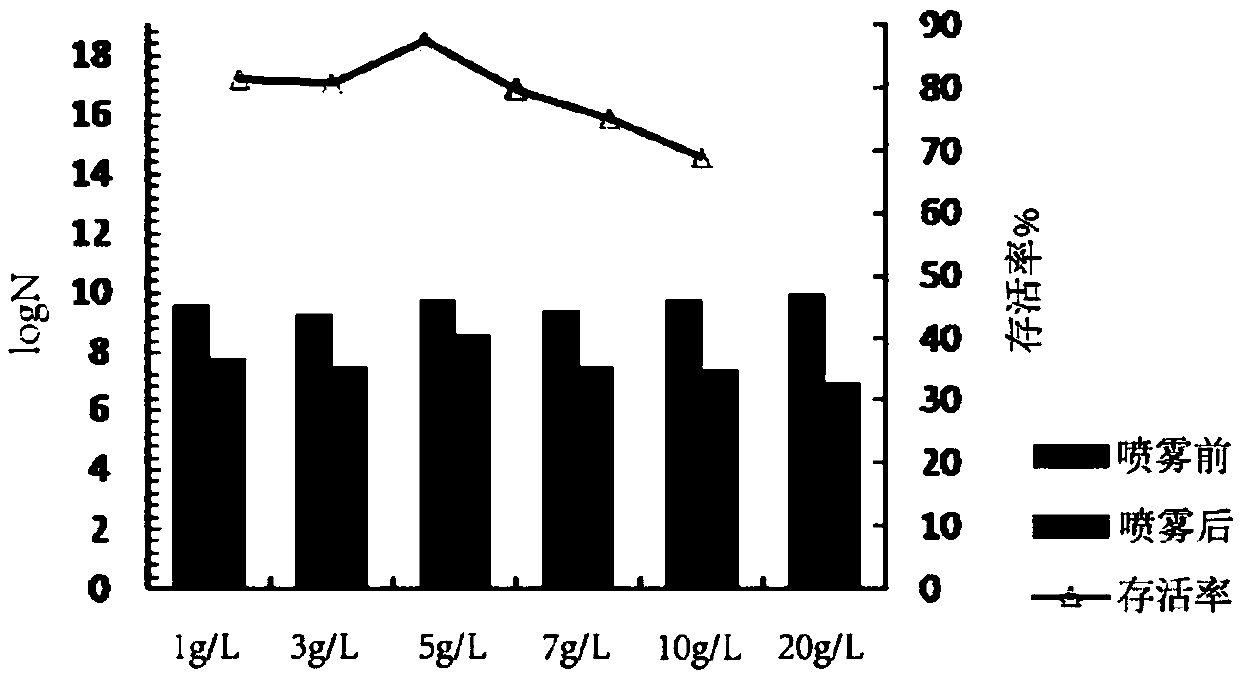

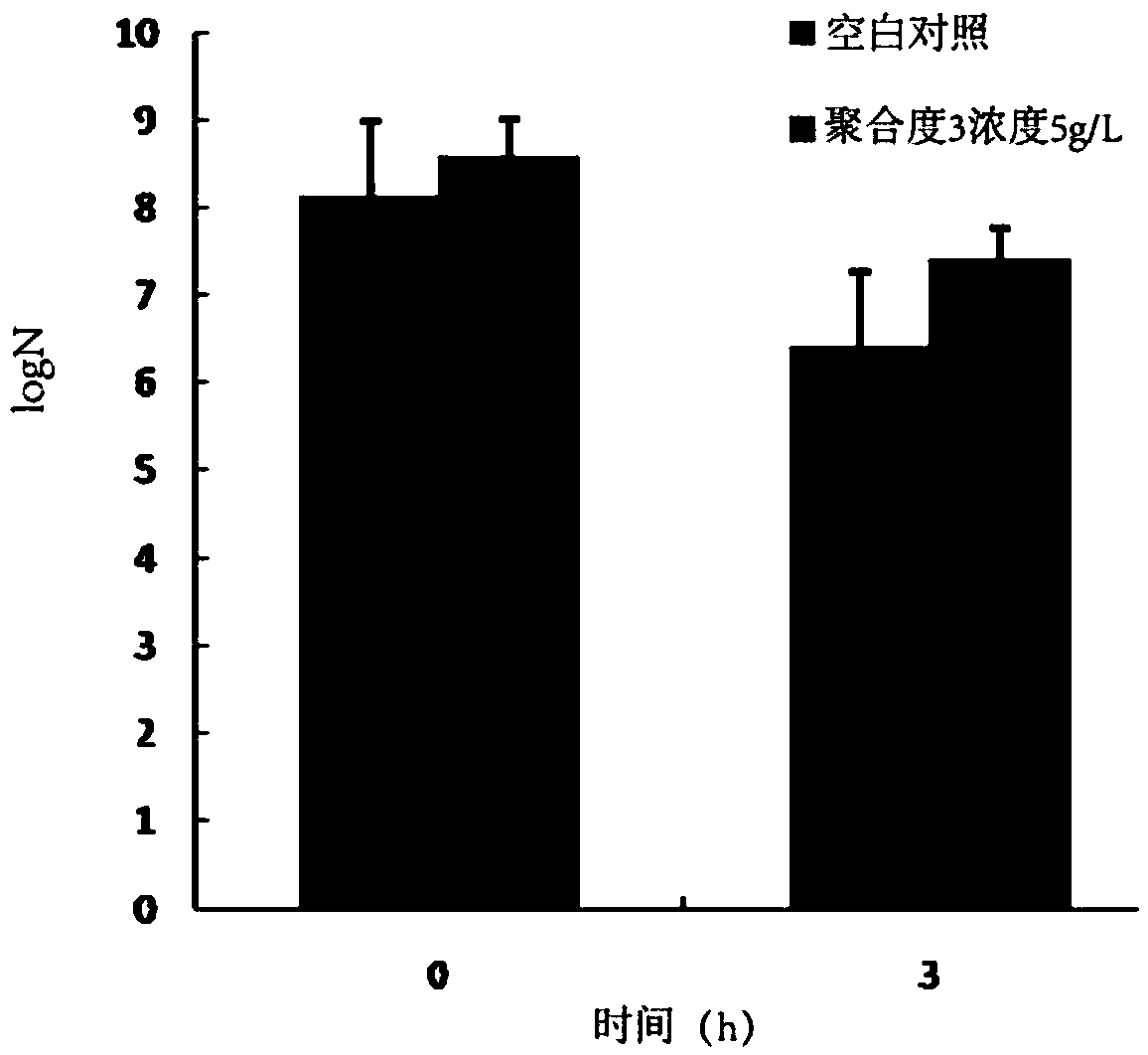

[0046] Example 3: Process flow for improving the activity of Lactobacillus bulgaricus under low temperature storage with different concentrations of Gracilaria agar oligosaccharides

[0047] Using the above method for preparing oligosaccharides, prepare different concentrations of agar oligosaccharides, and add them to the fermented oligosaccharides to reach OD 600In the MRS medium of Lactobacillus bulgaricus with a value of 1.2, different concentrations of agar oligosaccharides (1g / L, 3g / L, 5g / L, 7g / L, 10g / L) with a degree of polymerization of 3 were added to the medium In , the culture condition is an anaerobic environment, 4°C, static culture, sampling every 3 days to observe the number of viable bacteria under a microscope, as shown in Table 2.

[0048] Table 2 Different concentrations of Gracilaria agar oligosaccharides improve the activity of Lactobacillus bulgaricus under low temperature storage

[0049]

[0050]

[0051] The results showed that under the conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com