Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Electron-beam furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electron-beam furnace (EB furnace) is a type of vacuum furnace employing high-energy electron beam in vacuum as the means for delivery of heat to the material being melted. It is one of the electron-beam technologies.

Preparation method of tantalum 2.5 tungsten alloy

The invention provides a preparation method of a tantalum 2.5 tungsten alloy. The preparation method comprises the following steps: after preparing tantalum powder and tungsten powder in proportion, putting the powder into a drum mixer to be mixed for 24 hours; sieving the mixed powder with a 120-mesh sieve to obtain fine powder; pressing the fine powder into an alloy bar with a 500ton oil press; putting the alloy bar into a vacuum sintering furnace to be sintered to obtain a raw ingot blank; smelting the raw ingot blank at least twice with a vacuum electron beam furnace to prepare an alloy ingot blank; putting the alloy ingot blank into a high frequency furnace to be heated to 1400 DEG C, then taking out the alloy ingot blank and forging the alloy ingot blank for many times, thus obtaining a finished product of ingot blank. The preparation method has the beneficial effects that through full mixing of tantalum powder and tungsten powder and many times of smelting, the problem of nonuniformity of ingot blank tissues is solved and the problems that the blanks easily fall off and become brittle are improved.

Owner:陕西世纪创优金属材料有限公司

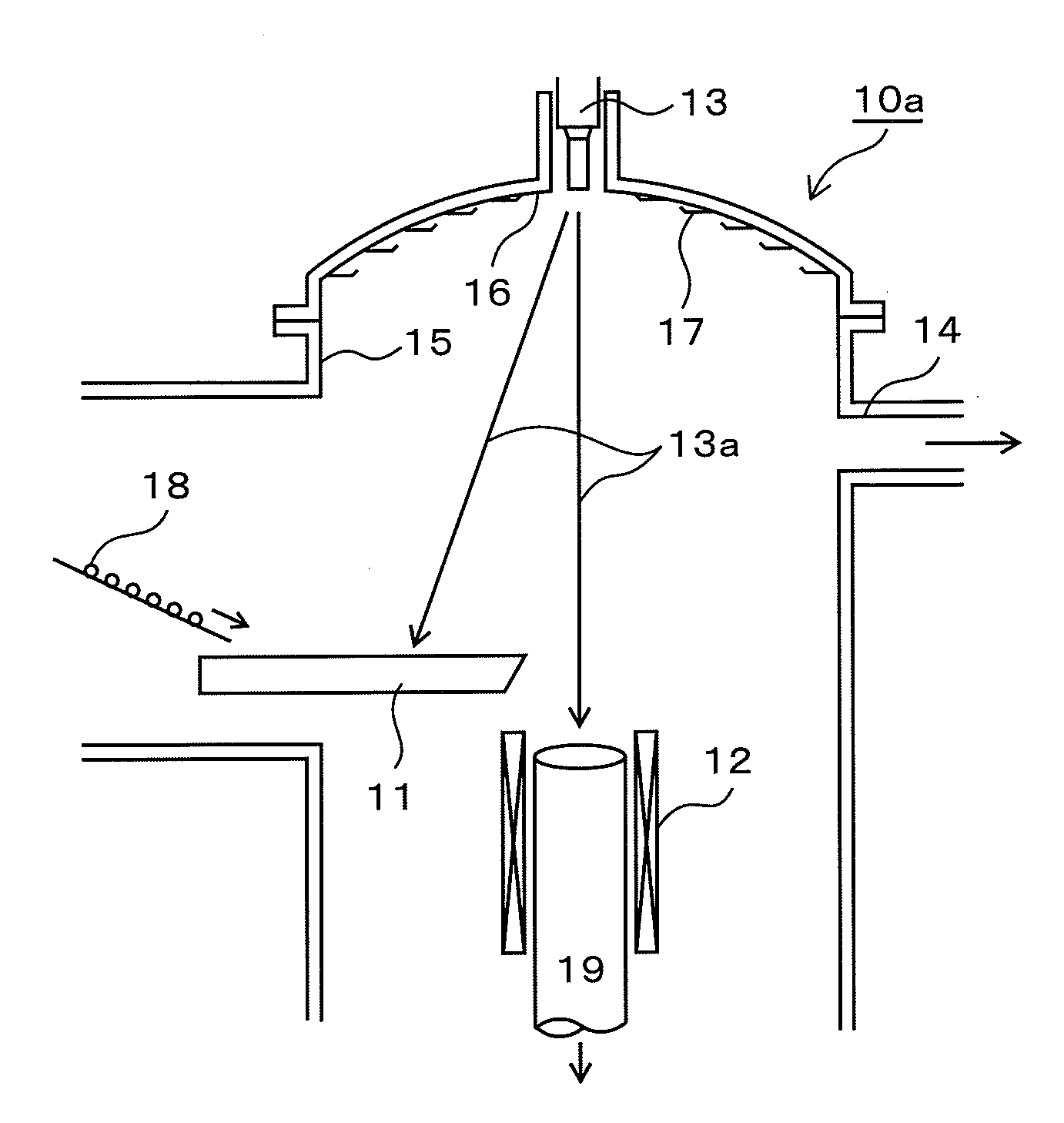

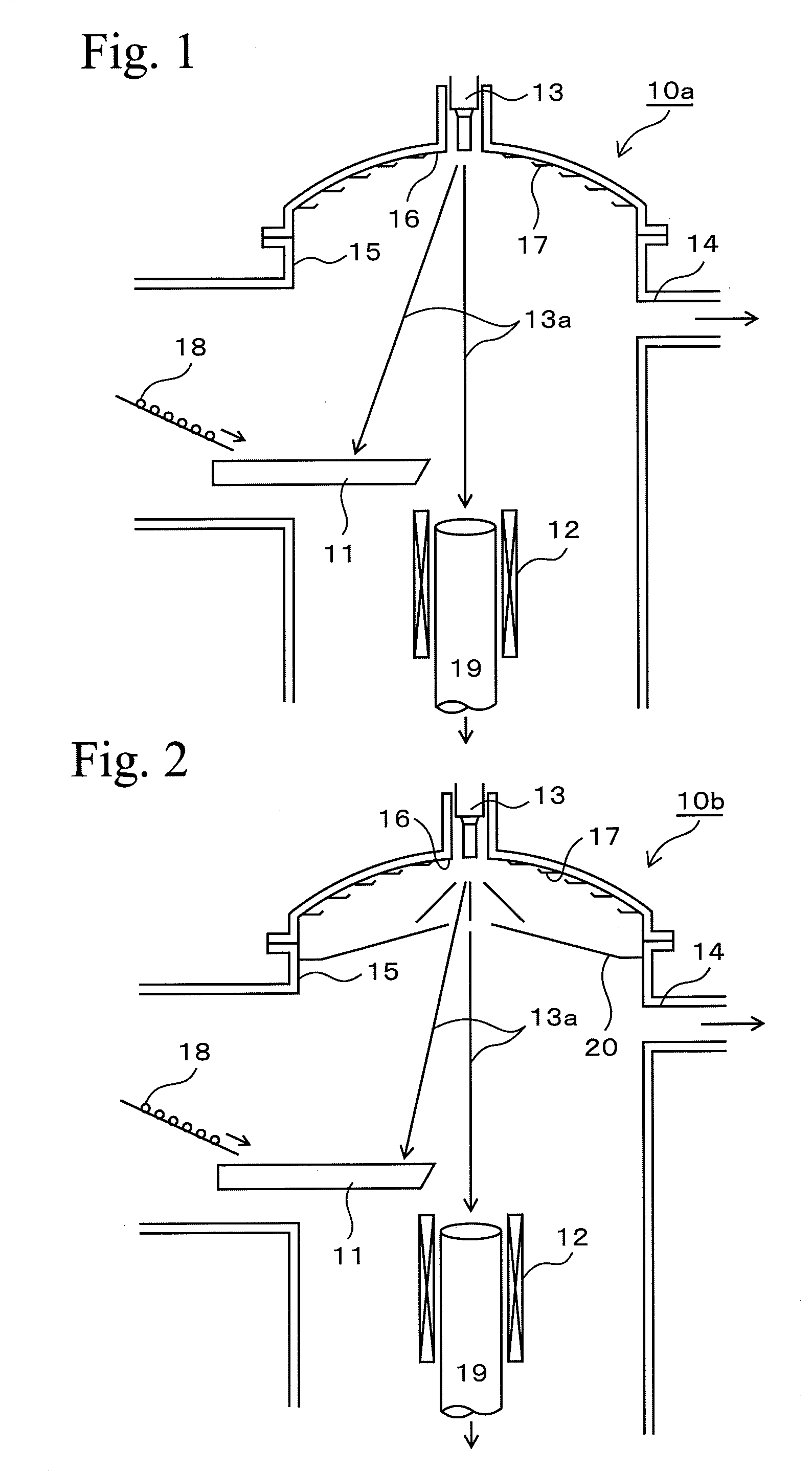

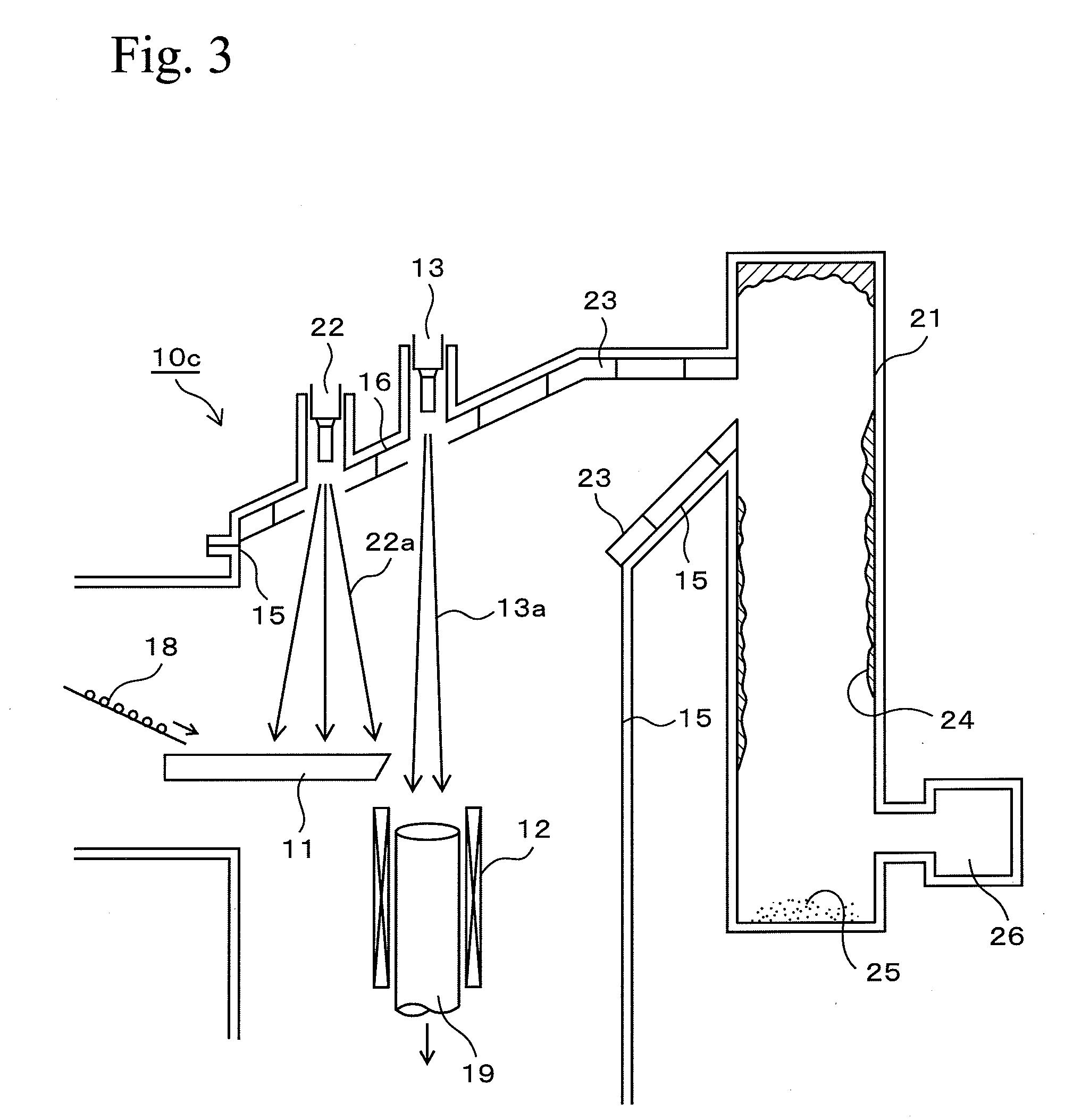

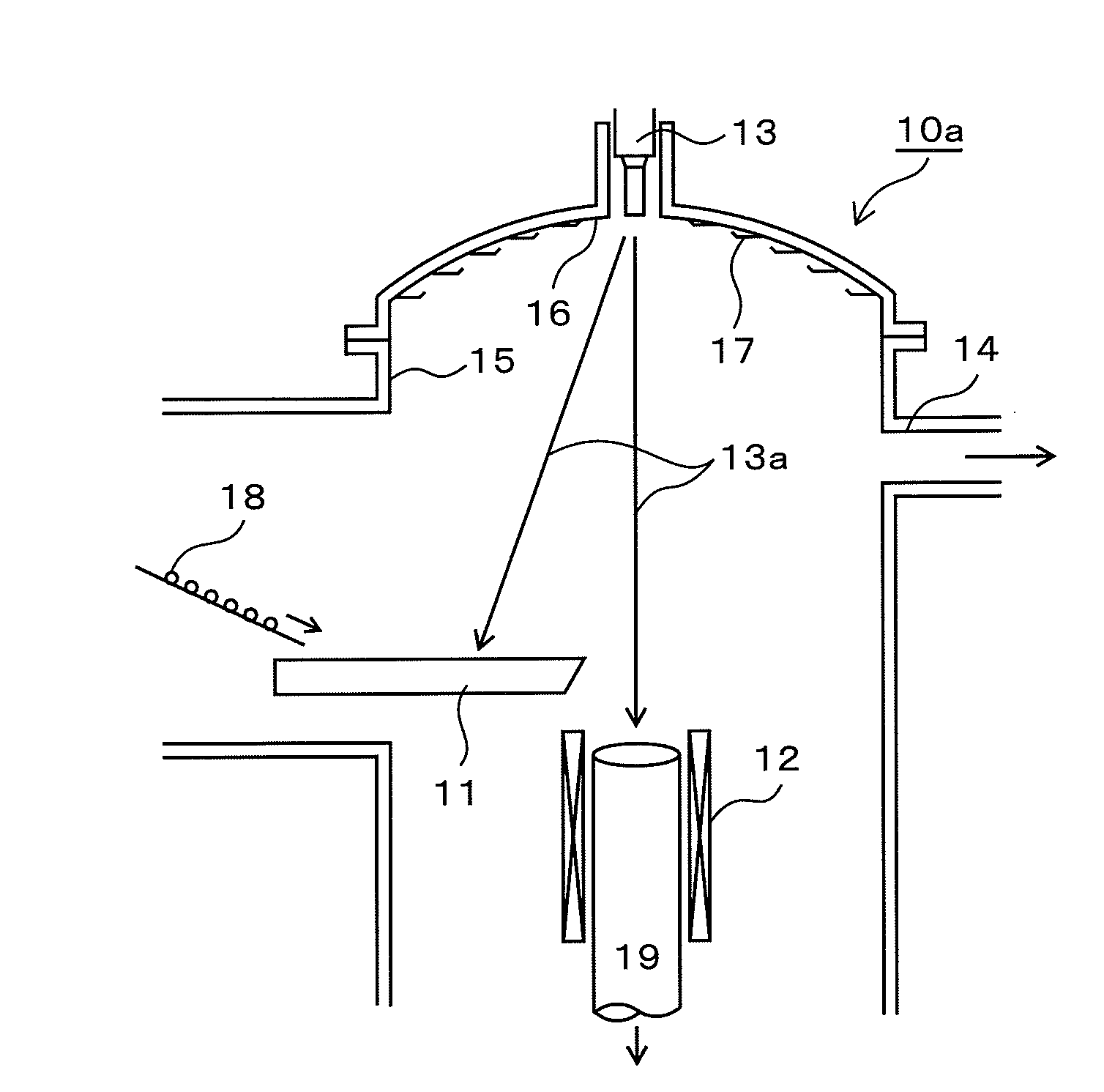

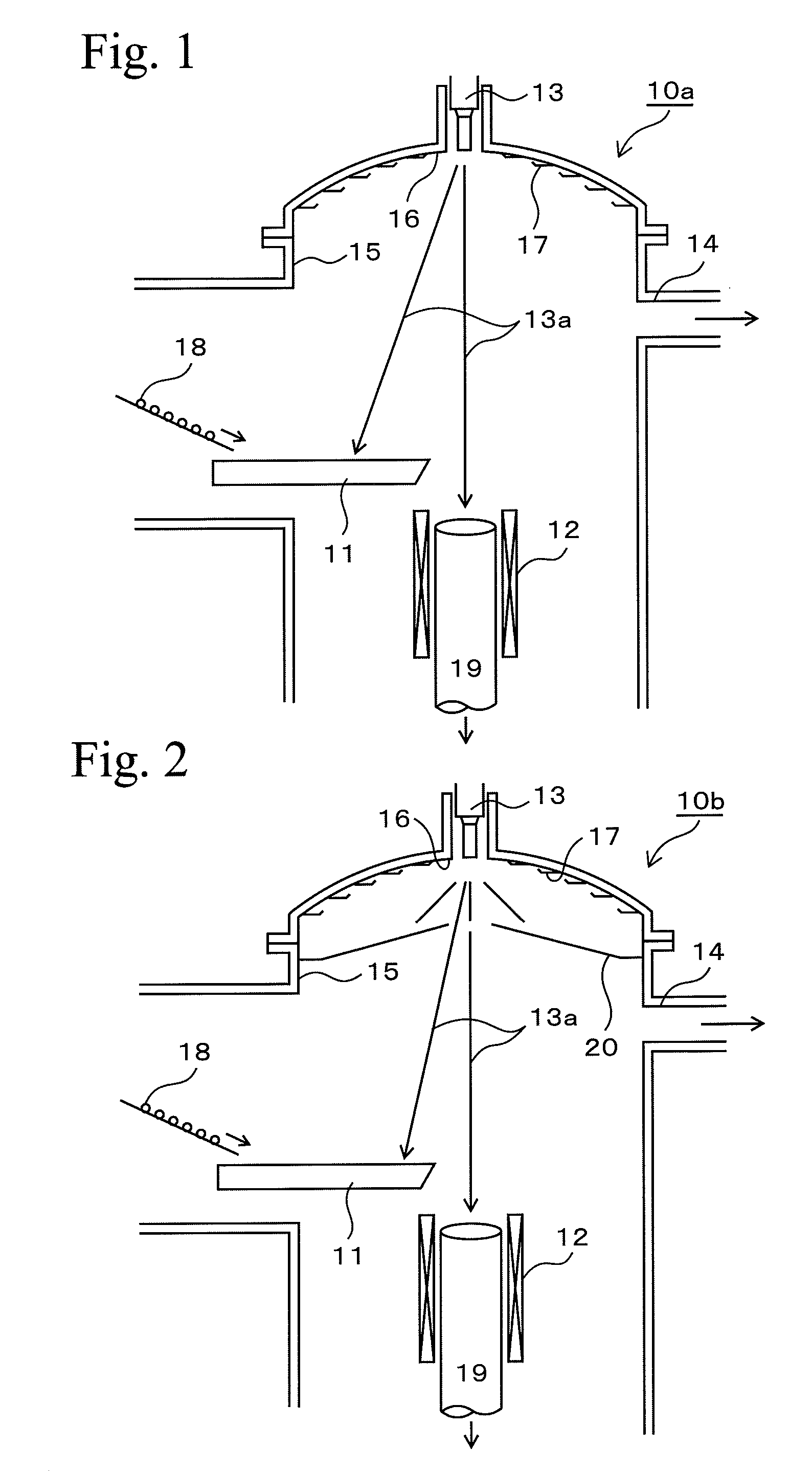

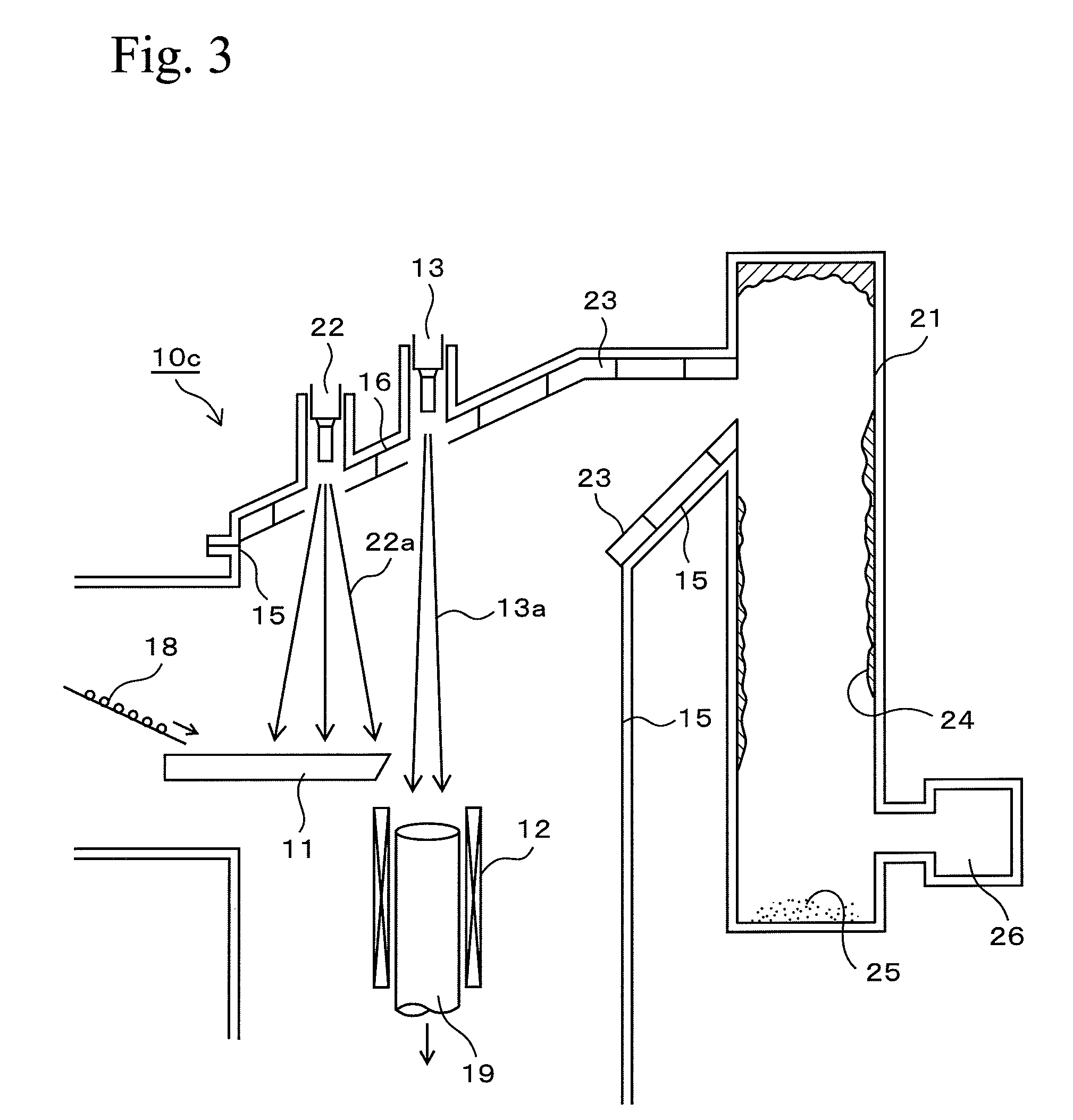

Apparatus For Melting Metal By Electron Beams And Process For Producing High-Melting Metal Ingot Using This Apparatus

ActiveUS20080105400A1Additional contamination of impurityReduce frequencyProcess efficiency improvementHearthElectron

The present invention provides an electron-beam furnace and a melting method that, in producing an ingot by melting a metal with an electron beam, can suppress the contamination of new impurities in the ingot production, are less likely to again result in inclusion of once evaporated impurities from a molten metal pool within a hearth or a mold, and can be improved in utilization rate. The electron-beam furnace for melting a refractory metal includes a feeder unit for raw materials, a melting unit for raw materials, which is connected to the feeder unit for raw materials and, at the same time, is defined by a furnace wall and a ceiling wall, and includes at least a hearth, a water-cooled mold, and an electron gun, and an evacuation unit for exhaust gas connected to the melting unit for raw materials. In this electron beam furnace, at least one of the furnace wall and the ceiling wall is lined with titanium or stainless steel, and in addition, plural fin-shaped members formed of titanium or stainless steel are provided at the ceiling wall. A lining, which can be attached and detached, is provided on the inner face of the electron beam furnace.

Owner:TOHO TITANIUM CO LTD

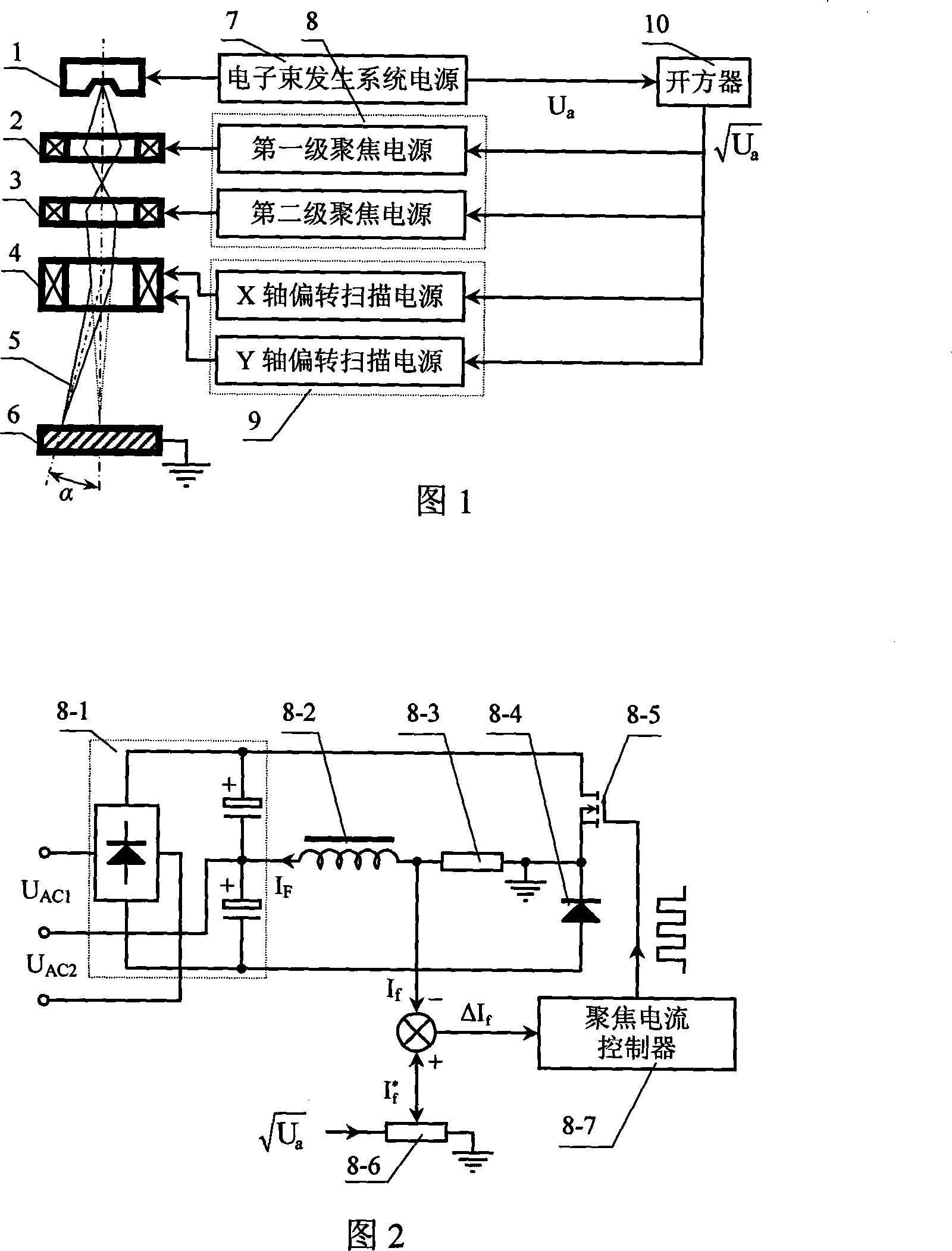

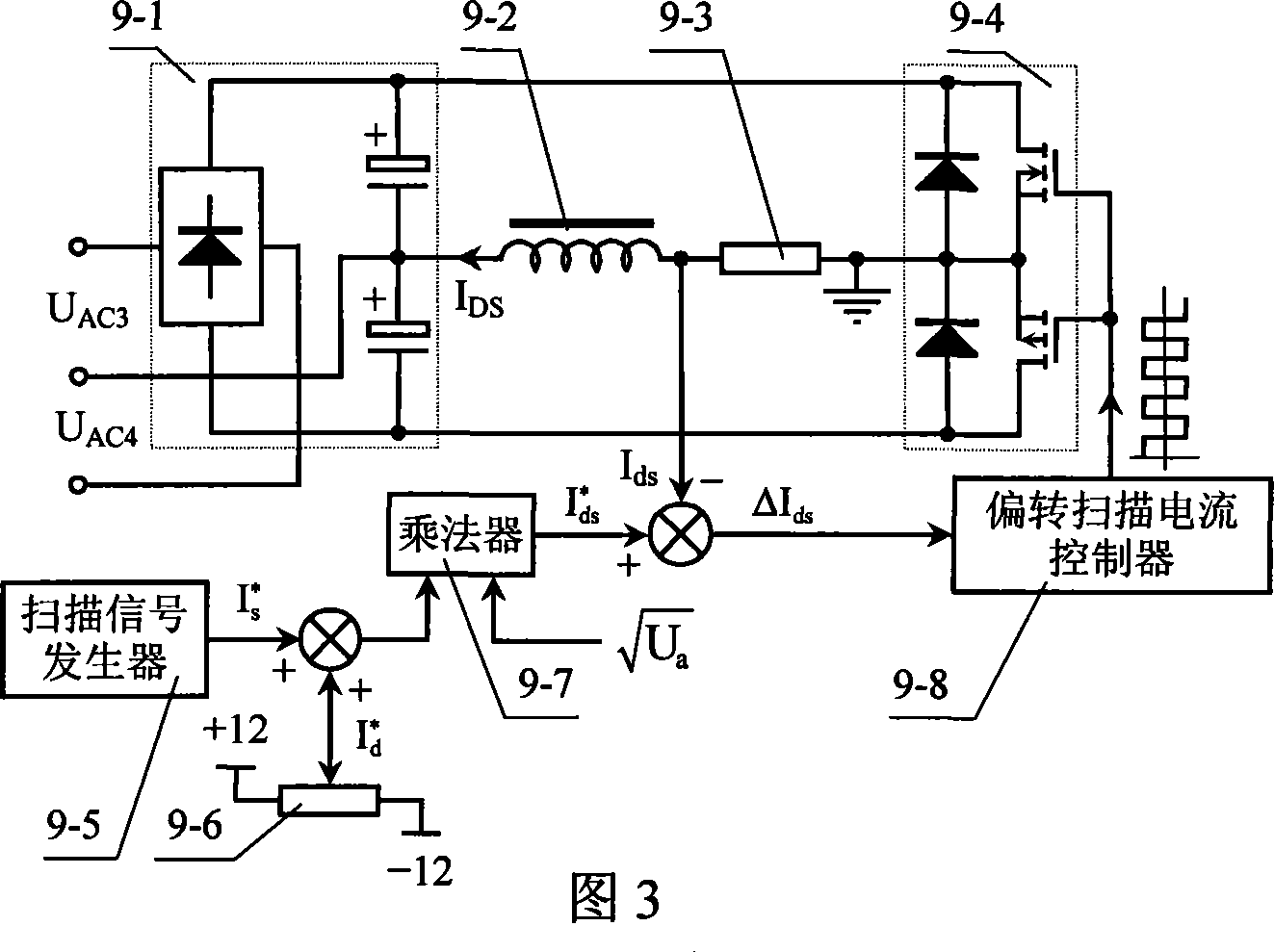

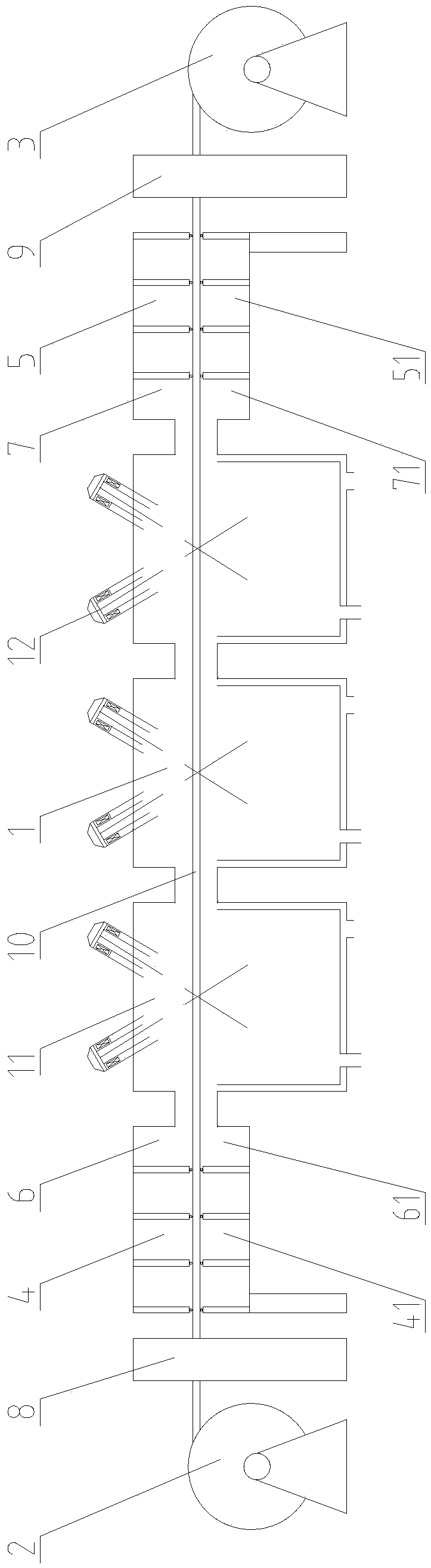

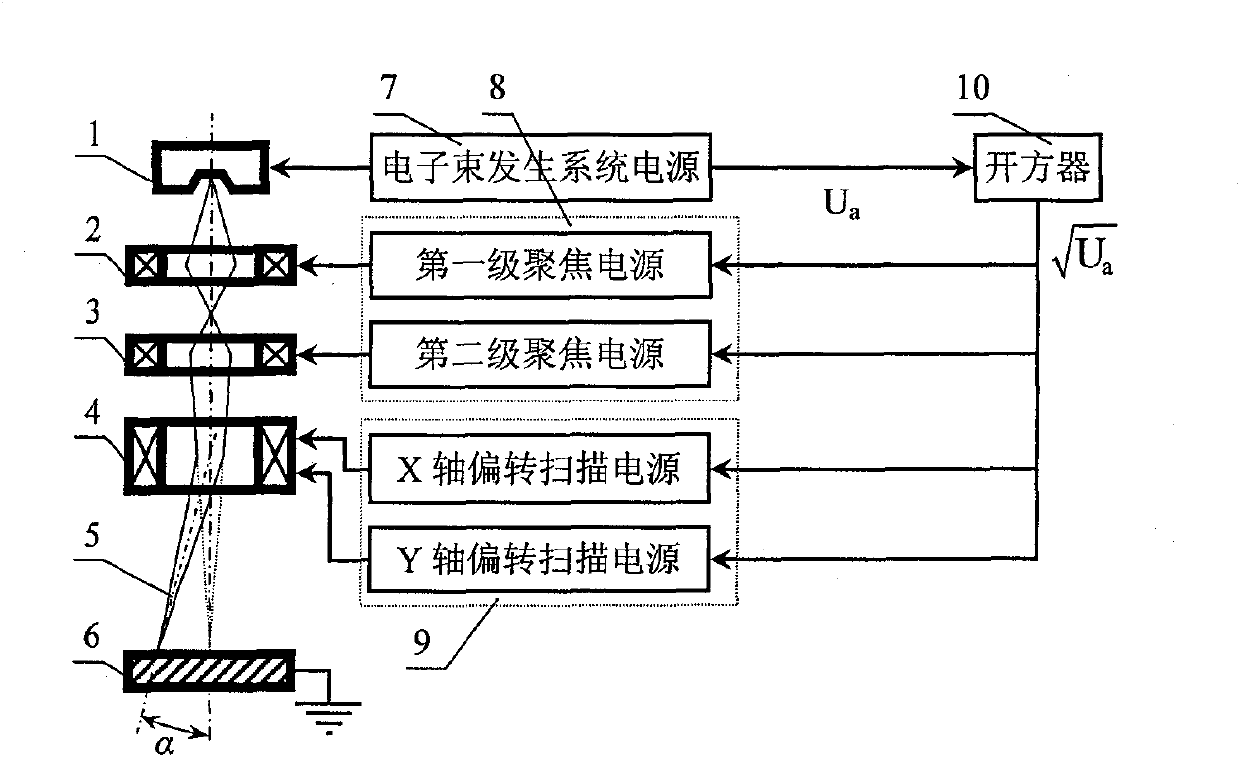

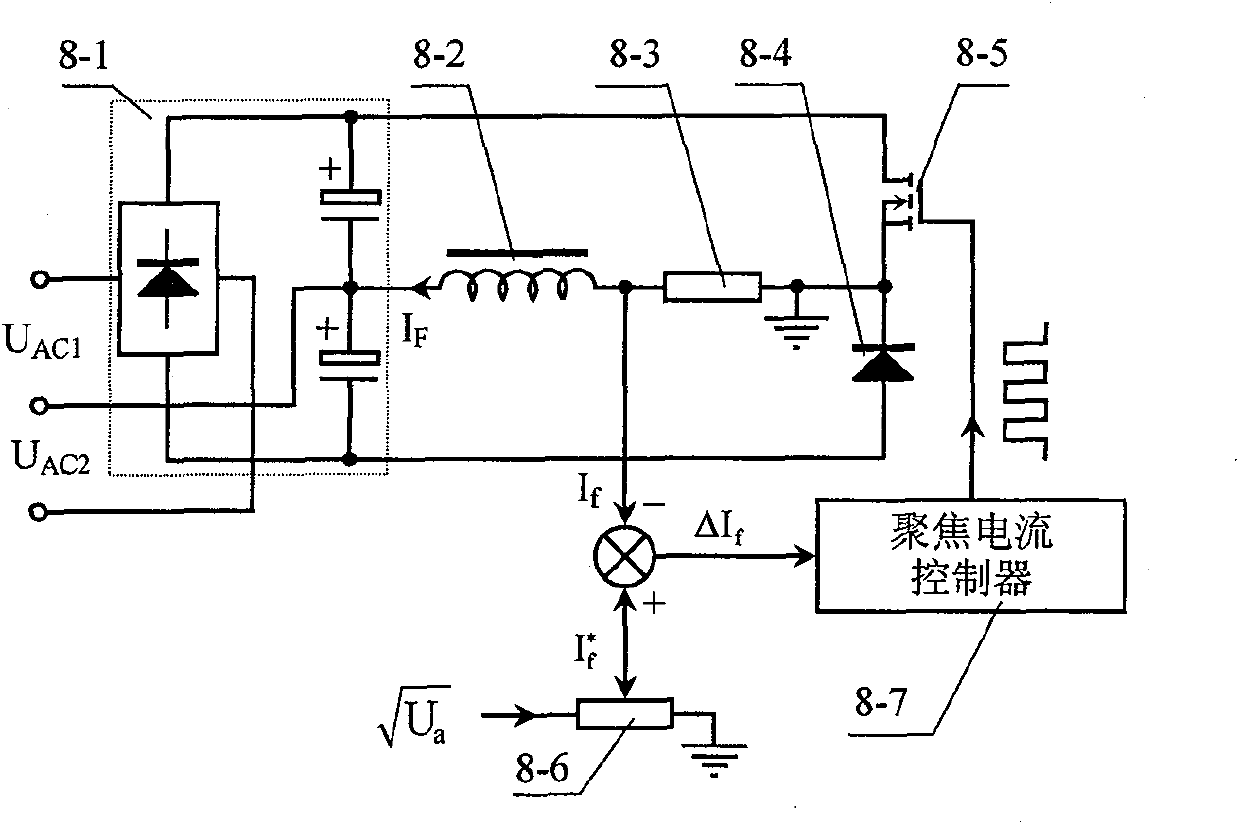

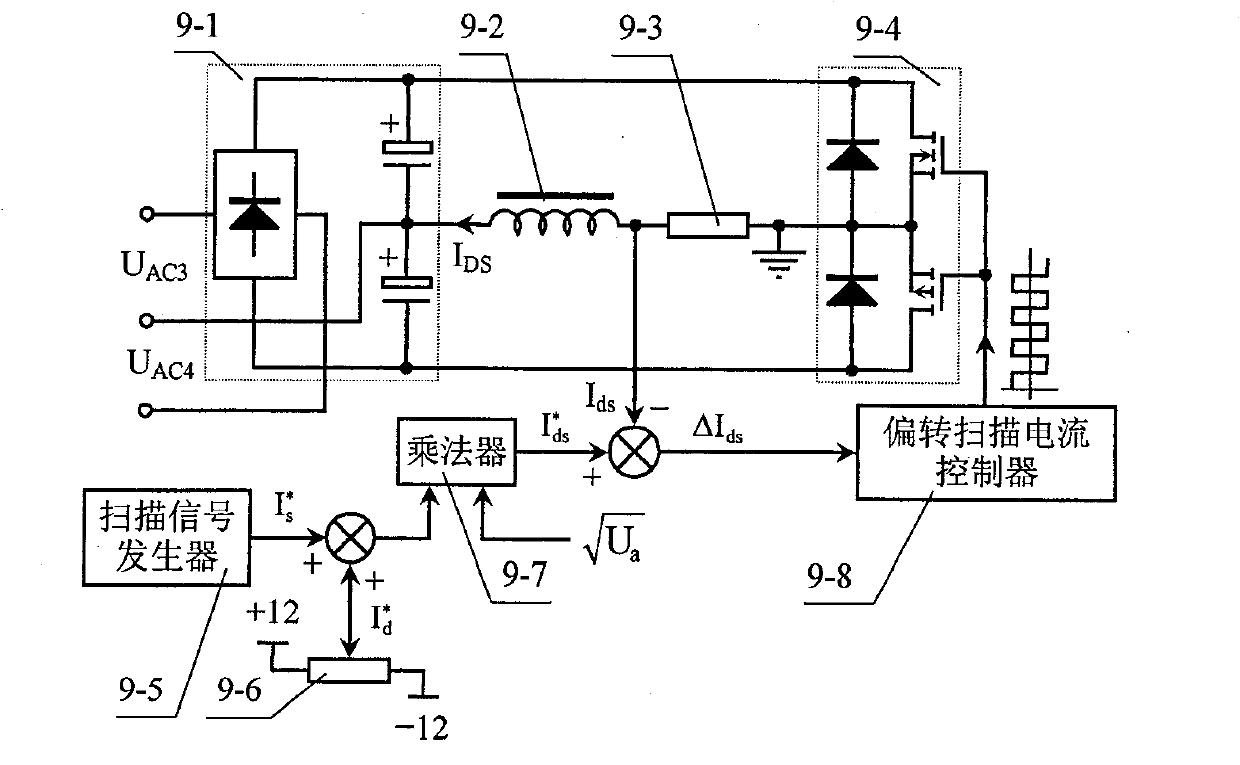

Power control Method and power device in electronic optical circuit system of electronic bundle impact furnace

InactiveCN101237727AAvoid damageFast dynamic follow performance indicatorsElectric discharge heatingIncreasing energy efficiencyHysteresis bandControl signal

The invention discloses a method for controlling a power supply of an electron-optical circuit system of an electron beam furnace and a power supply device. The method takes the extraction value of an acceleration voltage sampling signal of a power supply of an electron beam generating system as a control signal for a focusing and deflection scanning power supply and the amplitude of a focusing and deflection scanning current changes linearly according to the control signal, which ensures that the operation parameter of the electron-optical circuit system is free from the influence of the fluctuation of the acceleration voltage. The power supply device has the acceleration voltage sampling signal connected with a square root extractor first and then connected to a focusing and deflection scanning power supply control circuit, and adopts a hysteresis-band current tracking pulse modulation controller to maintain a small up and down oscillation amplitude of a working current based on an expected value. An extraction value signal of the acceleration voltage sampling signal is used to control a focusing current, and a general control signal which is the produce of a deflection scanning integrated signal and the extraction value of the acceleration voltage sampling signal is used to control deflection scanning current, so the focusing and deflection scanning region of the electron beam is not influenced by the acceleration voltage, and in event of failure, the change of the focusing and deflection scanning region of the electron beam is controlled in a permitted range.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Apparatus for melting metal by electron beams and process for producing high-melting metal ingot using this apparatus

ActiveUS7757748B2Improve usabilityShorten maintenance timeProcess efficiency improvementHearthElectron

The present invention provides an electron-beam furnace and a melting method that, in producing an ingot by melting a metal with an electron beam, can suppress the contamination of new impurities in the ingot production, are less likely to again result in inclusion of once evaporated impurities from a molten metal pool within a hearth or a mold, and can be improved in utilization rate. The electron-beam furnace for melting a refractory metal includes a feeder unit for raw materials, a melting unit for raw materials, which is connected to the feeder unit for raw materials and, at the same time, is defined by a furnace wall and a ceiling wall, and includes at least a hearth, a water-cooled mold, and an electron gun, and an evacuation unit for exhaust gas connected to the melting unit for raw materials. In this electron beam furnace, at least one of the furnace wall and the ceiling wall is lined with titanium or stainless steel, and in addition, plural fin-shaped members formed of titanium or stainless steel are provided at the ceiling wall. A lining, which can be attached and detached, is provided on the inner face of the electron beam furnace.

Owner:TOHO TITANIUM CO LTD

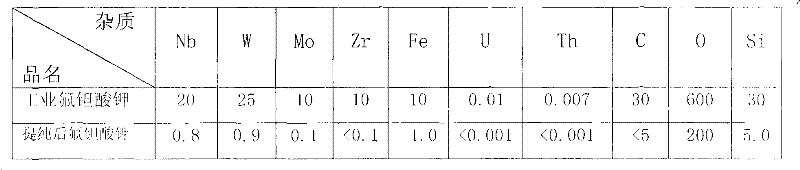

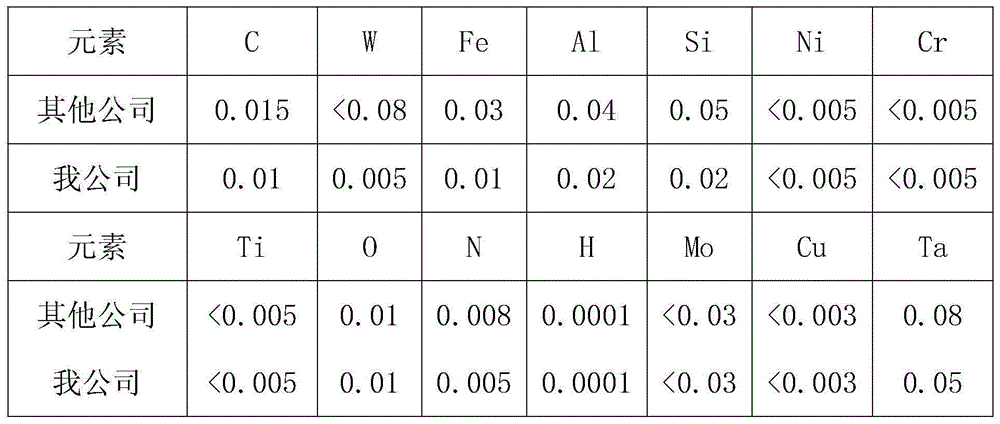

Preparation method of target-grade ultrahigh-purity tantalum metal

The invention provides a preparation method of target-grade ultrahigh-purity tantalum metal. In the method, a recrystallization process is added in tantalum wet-process metallurgy, thereby effectively reducing the contents of high-melting-point metal impurities and radioactive elements. The preparation method comprises: industrial K2TaF7 is put in a pure diluted HF solution, the concentration of crystalline HF is controlled, the temperature of crystalline HF is controlled to 80-90 DEG C, and potassium salt is excessive by 5-10%; after naturally cooling to 35-45 DEG C, cooling water is introduced to cool to room temperature; filtration is carried out while washing with a solution having PH 9 and absolute ethyl alcohol, thus high-melting-point metals, transition metals and impurities such as uranium, thorium, carbon, oxygen and the like are effectively removed; and then in tantalum pyrometallurgy, Si is effectively removed, and the pollution of Fe, Ni and Cr is prevented; and low-melting-point metals of less than 3000 DEG C are further removed in tantalum refining, thereby effectively reducing the contents of C, N and O. By using the preparation method provided by the invention, therefining frequency of an electron beam furnace is saved, and production cost is reduced.

Owner:稀美资源(广东)有限公司

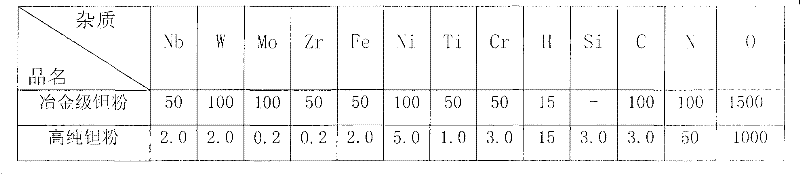

Method for preparing high-purity nickel ingot

The invention discloses a method for preparing high-purity nickel ingot, relating to a method for preparing high-purity nickel ingot by high-purity nickel plate, which is obtained by electrolyzing method through an electron-beam furnace and corresponding electron beam melting technique. The method is characterized in that in the preparing process, electrolytic nickel with purity higher than 99.999% is taken as raw material; and electron beam melting is adopted after surface cleaning to obtain high-purity nickel ingot. The method of the invention uses electron beam as a heat producer with rapid melting speed, thereby improving melting efficiency. The melting process is carried out in vacuum where the process is free of external air pollution, therefore, air impurity removing effect is good. High-purity nickel ingots of various specifications, ranging from Phi80 millimetres to Phi300 millimetres, can be prepared by replacing pots, thereby simplifying complex process, reducing production cost and saving energy. Therefore, the method for realizes diversity of products, optimizes physical property, and raises product quality so as to completely meet operation requirements of various downstream customers.

Owner:JINCHUAN GROUP LIMITED

Preparation method of tantalum 10 tungsten alloy

InactiveCN103555981AUneven solutionImprove the problem of easy falling offIngotElectron-beam furnace

The invention provides a preparation method of a tantalum 10 tungsten alloy. The preparation method comprises the following steps: after preparing tantalum powder and tungsten powder in proportion, filling the powder into a drum mixer to be fully mixed and screening the powder to obtain fine powder; pressing the fine powder into an alloy bar with a 500ton oil press; putting the alloy bar into a vacuum sintering furnace to be sintered to obtain a raw ingot blank; smelting the raw ingot blank at least twice with a vacuum electron beam furnace to prepare an alloy ingot blank; putting the alloy ingot blank into a high frequency furnace to be heated to 1400 DEG C, then taking out the alloy ingot blank and forging the alloy ingot blank for many times, thus obtaining a finished product of ingot blank. The preparation method has the beneficial effects that through full mixing of tantalum powder and tungsten powder and many times of smelting, the problem of nonuniformity of ingot blank tissues is solved and the problems that the blanks easily fall off and become brittle are improved.

Owner:宝鸡市众邦稀有金属材料有限公司

High-Zr content Nb alloy and melt casting manufacturing method thereof

The invention discloses a high-Zr content Nb alloy and a melt casting manufacturing method thereof. The high-Zr content Nb alloy contains 5 to 12wt% of Zr. The melt casting manufacturing method comprises the following steps of 1, processing an Nb metal into Nb plates, Nb strips or Nb rods, and processing an active Zr metal into Zr rods or Zr plates, 2, mixing the Nb plates, the Nb strips or the Nb rods and the Zr rods or the Zr plates according to a principle of excess of Zr, wherein an excess ratio of Zr is controlled in a range of 15 to 19%, 3, carrying out primary melting of an electrode in an electron beam furnace and carrying out melt casting to obtain a primary alloy ingot, 4, carrying out expanding electron beam melting of the primary alloy ingot, and 5, carrying out arc-melting by the electron beam melted secondary ingot obtained by the step 4 and simultaneously, fully mixing the melt components by electromagnetic stirring to realize alloy homogenization.

Owner:NINGXIA ORIENT TANTALUM IND

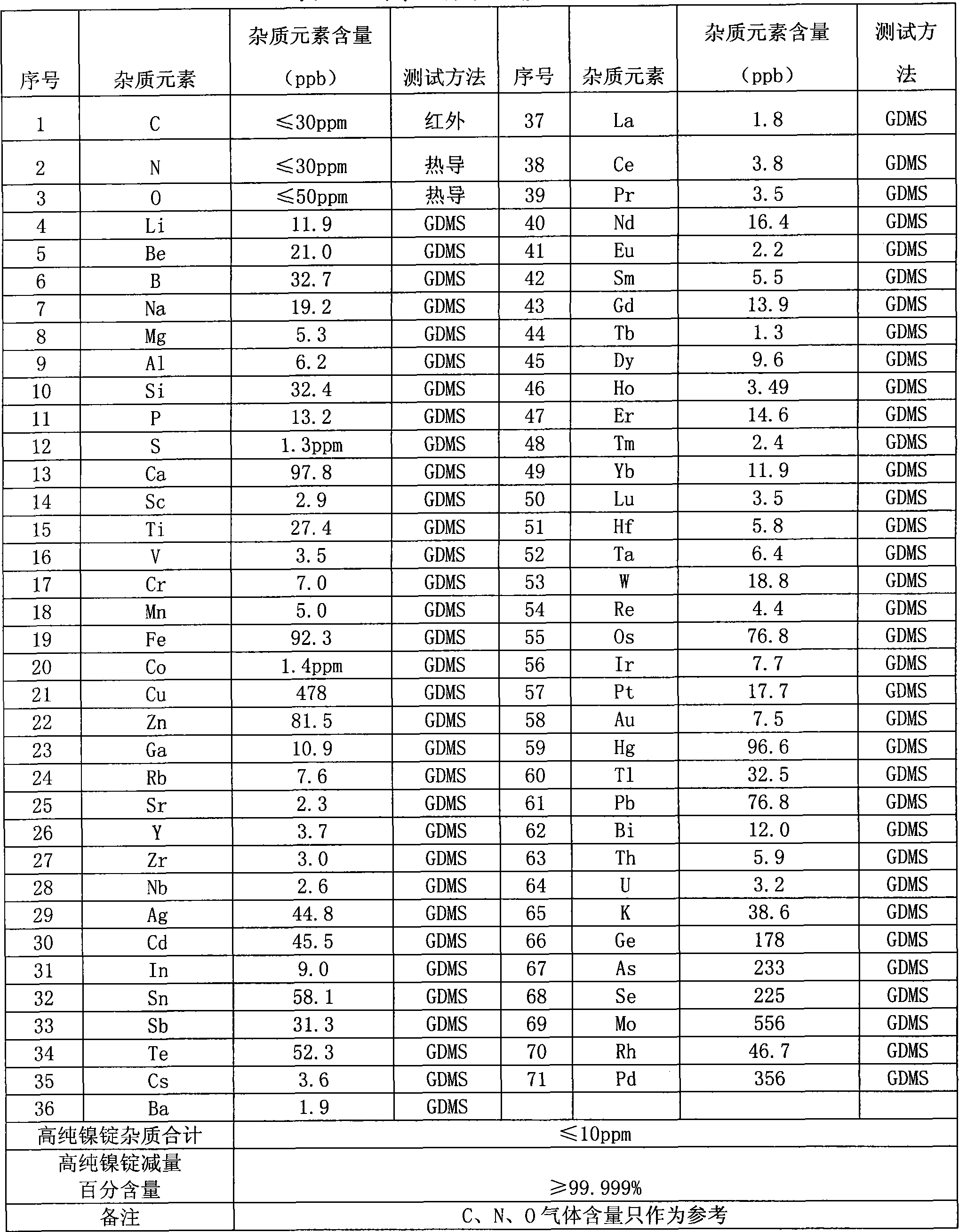

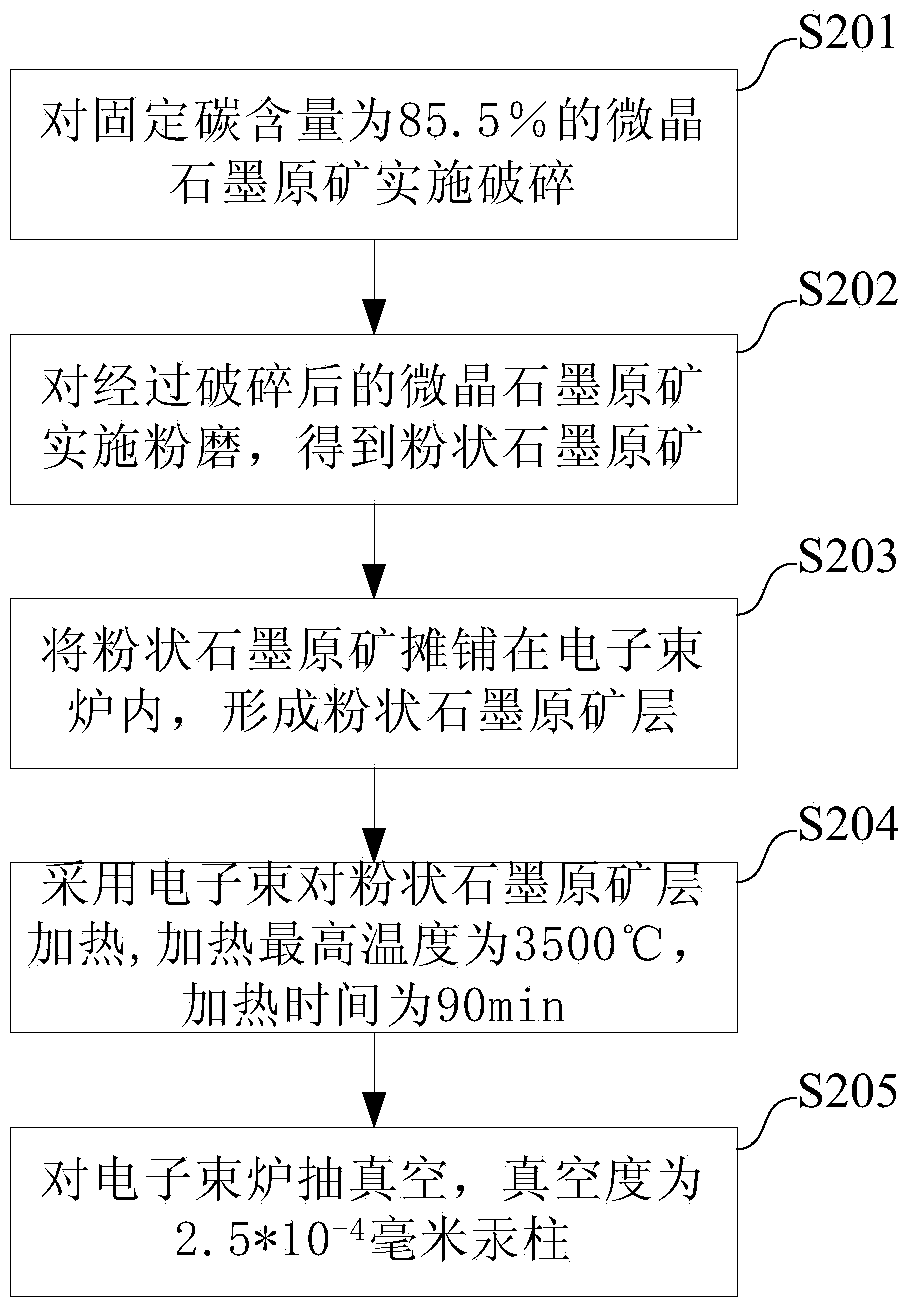

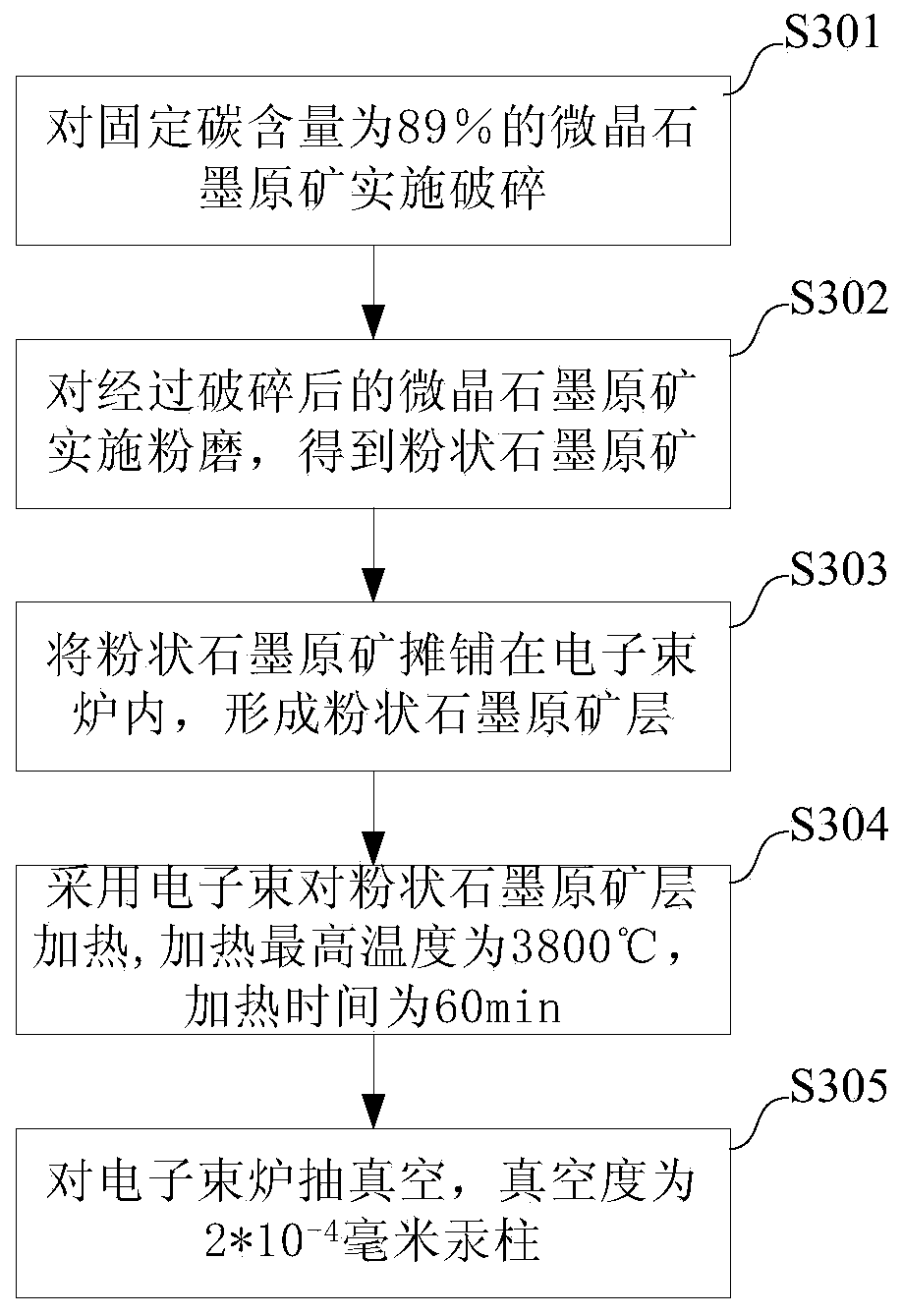

Purification method for graphite

InactiveCN104016334AEfficient purificationHigh purityCarbon compoundsHeating timePurification methods

The invention belongs to the technical field of substance purification. A disclosed graphite purification method comprises the following steps: successively performing crushing and grinding on microcrystalline graphite raw ore with the fixed carbon content of 82%-95% by weight, so as to obtain powdered graphite raw ore; paving the powdered graphite raw ore in an electron beam furnace to form a powdered graphite raw-ore layer; and using an electronic beam to gradually heat the powdered graphite raw-ore layer with the single-time heating area not more than the focusing area of the electronic beam, and vacuumizing the electronic beam furnace, and controlling the vacuum degree of the electronic beam furnace to be less than 1*10<-4> mmHg, the single-time heating time to be 30 min-120 min and the highest heating temperature to be 3500 DEG C-4500 DEG C. The purity of graphite obtained by employing the provided graphite purification method reaches 99.99%, and the graphite purification method helps to solve the problems that a present high-temperature purification method for graphite is relatively large in energy consumption and relatively high in cost.

Owner:付毅 +2

Preparation technique of high-purity nickel ingot for semiconductor target

InactiveCN106399721ALow purityControlled Evaporation RemovalTemperature controlMaterials preparation

The invention provides a preparation technique of a high-purity nickel ingot low in impurity element content, namely a preparation technique of a high-purity nickel ingot for a semiconductor target. The preparation technique comprises the main steps that material preparation, charging and repeated smelting are conducted, specifically, an electron beam furnace is used for smelting, warming smelting starts to be conducted when the vacuum degree of a hearth is maintained to 1.0*10<2> Pa or below in the smelting process, the smelting temperature is controlled to 2130 DEG C or over, the smelting speed is controlled to 20.1 kg / h or below, and an electrolysis nickel board is fully molten; and the nickel ingot formed after smelting is cooled in the hearth for 6-12 h and then discharged out of the furnace. According to the preparation technique of the high-purity nickel ingot for the semiconductor target, parameters including the smelting speed, the smelting temperature, the smelting time and the like are selected according to the quantity of materials, electron beams are controlled to be distributed accurately in the smelting process, and thus the purity of metal and volatilizing removal of impurities can be controlled to the maximum extent; and high-purity metallic nickel is free of pores and inclusions and suitable for subsequent processing and using of the target.

Owner:宝鸡一众有色金属材料有限公司

Vacuum electron beam welding method of NbTi/Cu superconduction composite sheath

Owner:西部超导材料科技股份有限公司

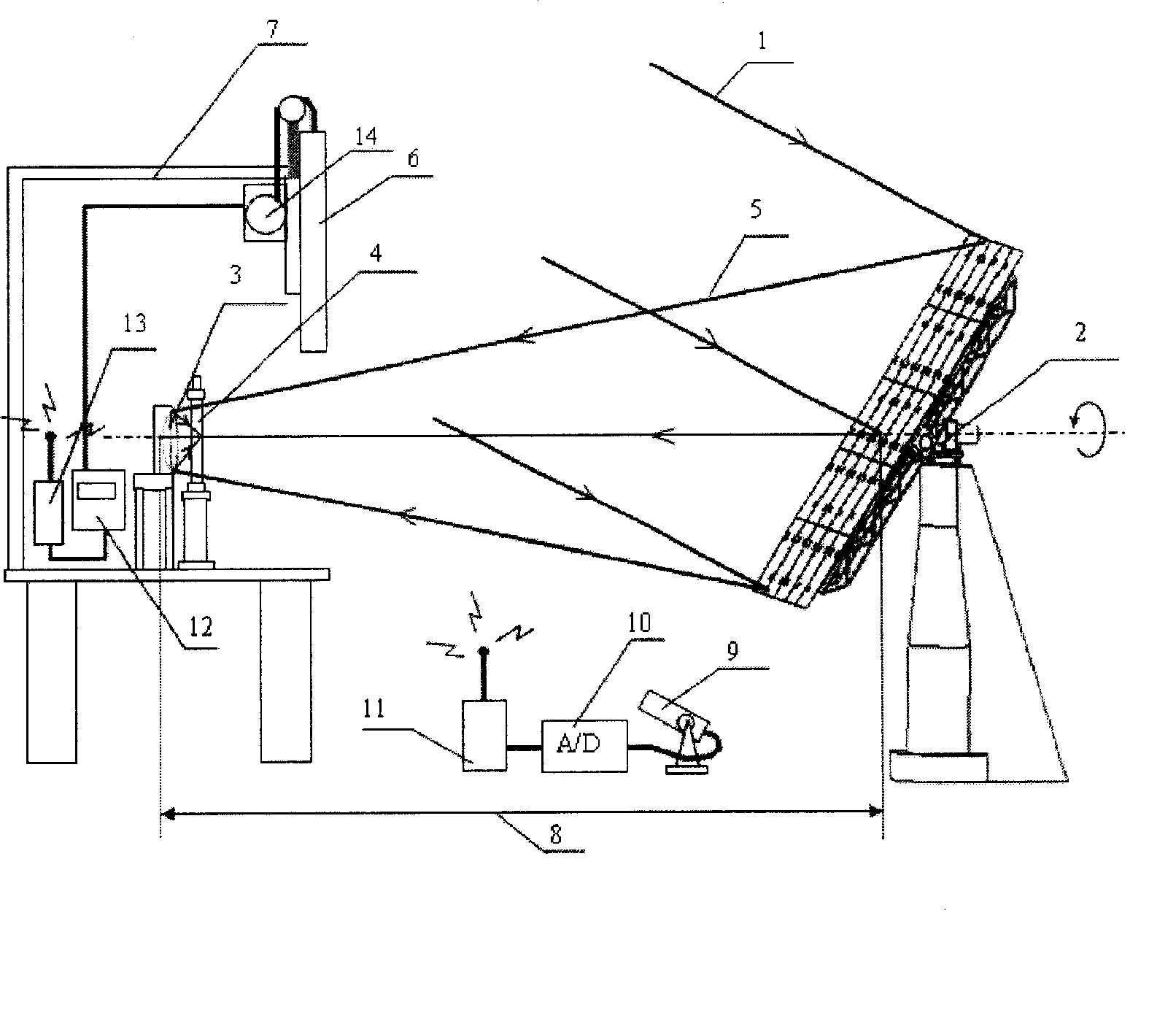

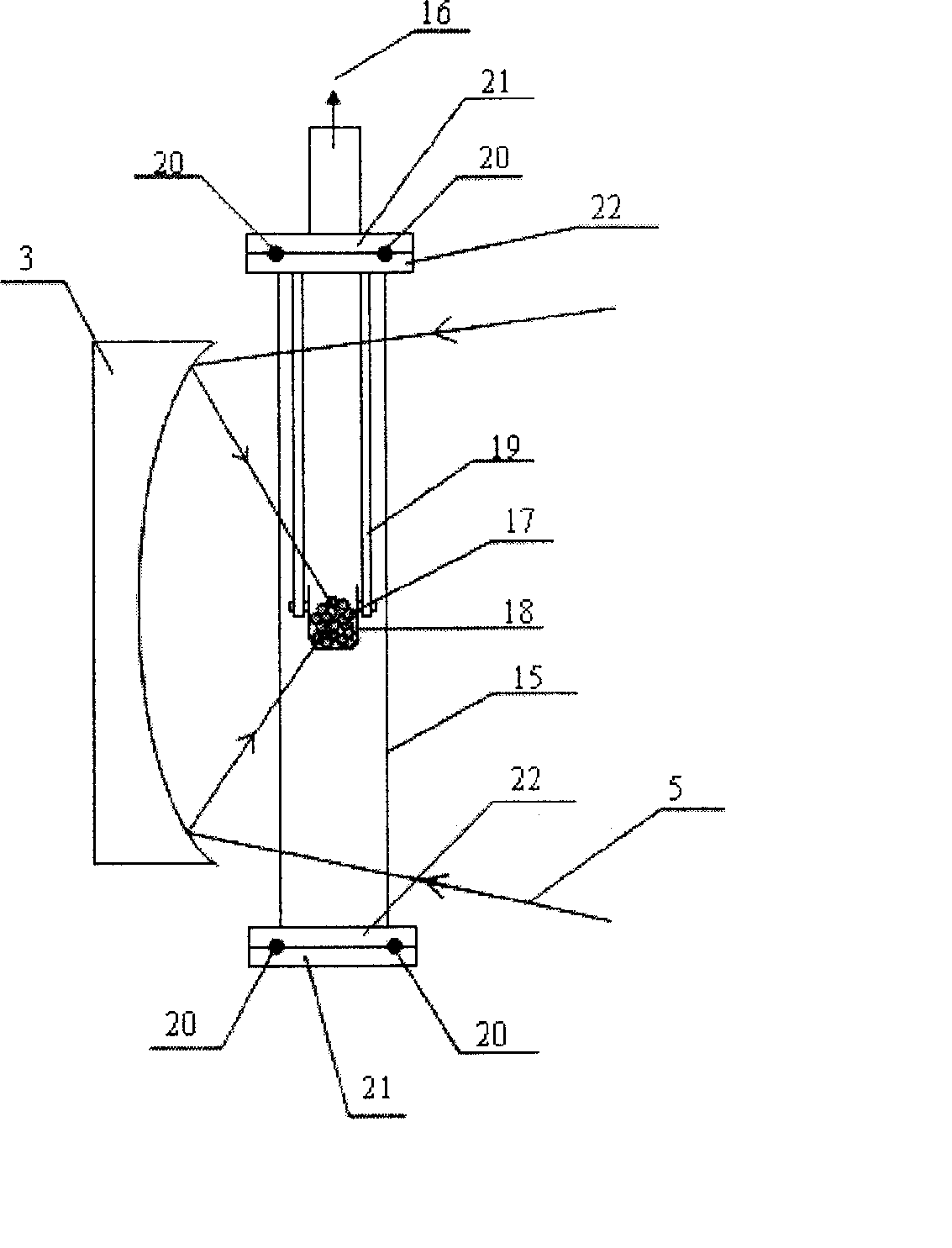

Method for vacuum prification of material by self-rotation elevation tracked solar furnace

InactiveCN100460320CEliminates the risk of damaging containersShort time intervalSolar heat devicesFurnace typesEngineeringElectron-beam furnace

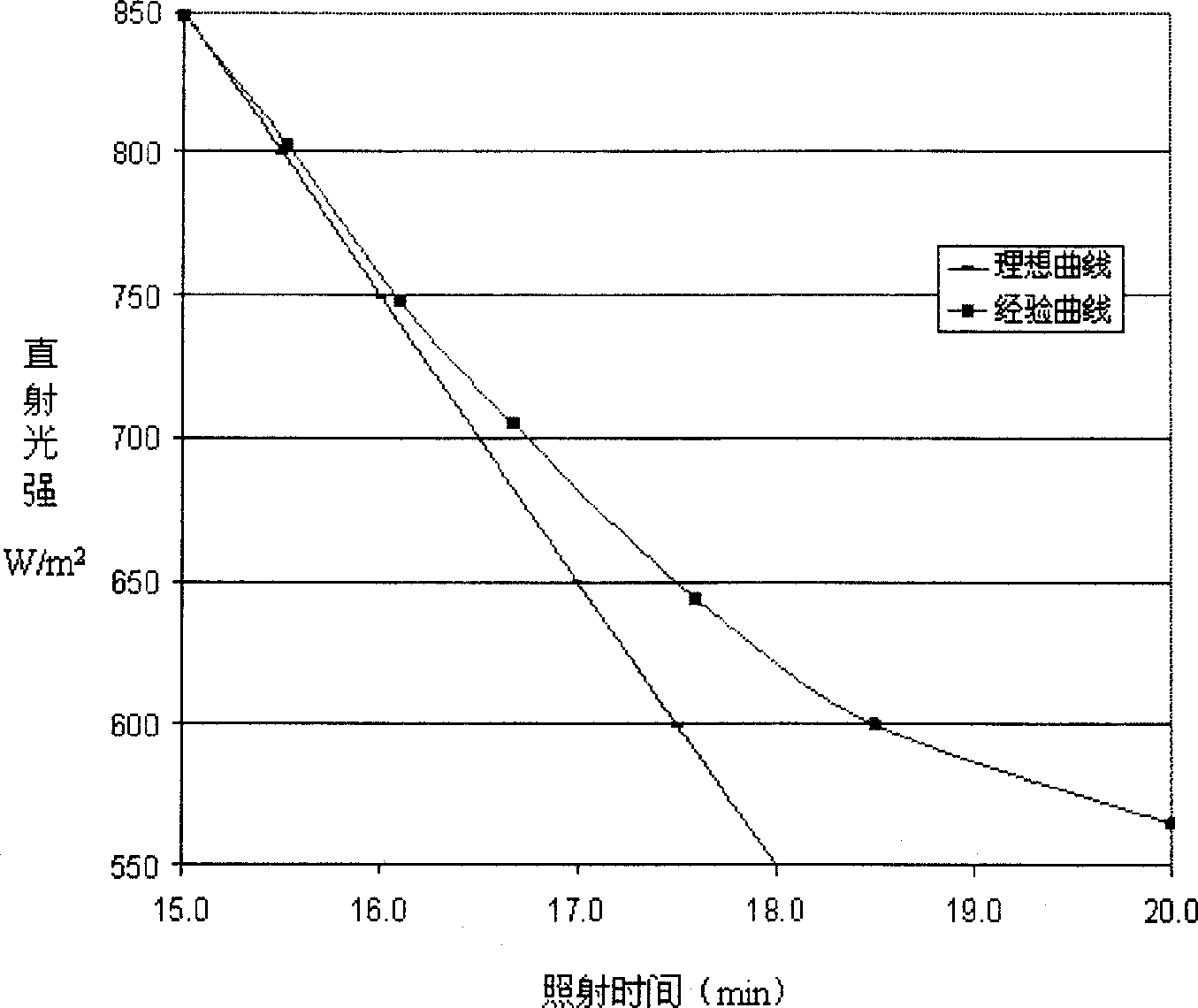

This inventive process contains steps of: heating the raw material in crucible under vacuum condition by the irradiation from solar energy stove utilizing elevation angle tracing mode and matrix turning aberration correction method. After the content is heated and liquefied, the irradiation is contained to the content being heated up to boiled condition. Thorough agitation is proceeded to make the impurities being volatiled off in that vacuum condition. After a certain irradiation duration, the purity of the content reaches the target. Under the conditions of direct light intensity being more than 550 w / square meter, and the quantity of the content being less than 150 g, the typical irradiation duration is 15-20 min. the accurate irradiation duration for this inventive method can be obtained by searching the curved of light intensity curve. The raw materials being subject to this purification are: silicon, titanium, calcium, aluminium and the like. This invented method has many advantages than that of prior art method.

Owner:丰宁满族自治县应天光电技术有限公司

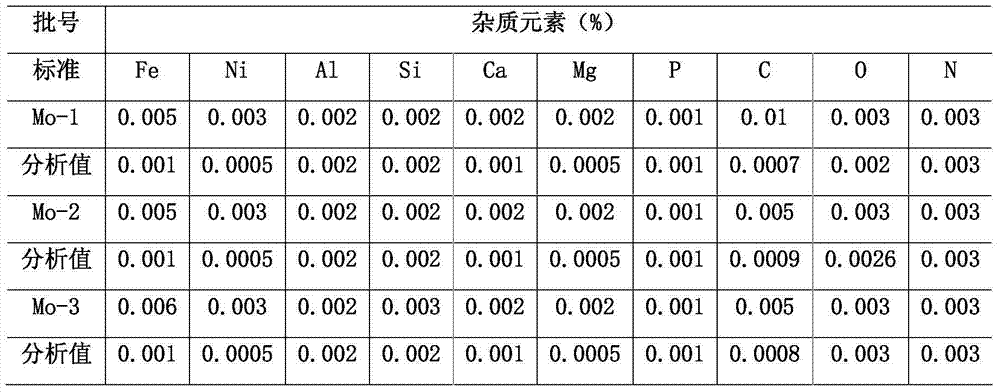

Pure niobium purification process

The invention relates to a pure niobium purification process including the steps of material preparation, material mixing, reduction furnace cleaning, reducing, discharging, crushing, screening, vacuum electron beam furnace cleaning, charging, primary smelting with a vacuum electron beam furnace, primary cooling, secondary smelting with the vacuum electron beam furnace, secondary cooling, discharging, sampling analysis and finished product obtaining. The process is rigorous in steps, the purification efficiency is high, and the purification purity is high.

Owner:江苏圣亚有色金属材料有限公司

High-purity titanium ingot purification method

InactiveCN109266863AFully meltedLow elemental contentProcess efficiency improvementPurification methodsTitanium

Owner:宝鸡市华烨钛镍金属有限公司

Method for smelting and purifying backing material of monocrystalline pot by electron beams

InactiveCN107010629AEfficient removalImprove life expectancySilicon compoundsCrucibleMetal impurities

The invention relates to a method for smelting and purifying backing material of a monocrystalline pot by electron beams. The method comprises the following steps of respectively charging the backing material of the monocrystalline pot into a material bin, a smelting crucible, a material delivery cart and five condensing crucibles; after material charging is completed, sucking vacuum out of an electron beam furnace, and preheating three electron guns when the vacuum degree is smaller than 0.5Pa; enabling the power of each of the three electron guns to continue to maintain for 250kW, and smelting silicon material; closing two electron guns which radiate to the smelting crucibles, pouring out the silicon liquid, and maintaining the power of the electronic gun radiating the condensing crucible to 250kW after the pouring is finished; finally, enabling the electron guns to maintain for 10min at the power of 250kW, 2min at the power of 200kW, 3min at the power of 150kW, 5min at the power of 120kW, 7min at the power of 100kW, 10min at the power of 80kW, 15min at the power of 50kW, 20min at the power of 30kW, and 25min at the power of 20kW, and condensing the electron beams at the power of 0kW. The method has the advantages that the metal impurities can be effectively removed, the removal rate reaches 98% or above, and the minority carrier lifetime in the produced polycrystalline cast ingot can be effectively prolonged; the condition is mild, and the operation is easy.

Owner:DALIAN UNIV OF TECH QINGDAO NEW ENERGY MATERIALS TECH RES INST CO LTD

Continuous vacuum electron beam coating method

InactiveCN109295417ALarge coating thicknessLow costVacuum evaporation coatingSputtering coatingWinding machineElectron

The invention discloses a continuous vacuum electron beam coating method and belongs to the technical field of coating. The invention aims to provide a method of coating a thick film with low cost, nopollution, high efficiency and high quality. The method comprises the following steps: putting a coated metal in a continuous vacuum electron beam coating device, wherein a substrate material operates in an electron beam furnace through an uncoiler and a winding machine; heating the substrate material to 400-1200 DEG C; and setting the electron beam power to be not smaller than 20 KW and controlling the vacuum degree of the working chamber of the electron beam furnace at 10-10<-3>Pa to coat, and cooling the coated film to be not higher than 300 DEG C to obtain the coated composite material. The method can be used for obtaining corrosion-resistant coated composite material which is large in coated thickness and has the characteristics of being low in cost, pollution-free, high in speed andhigh in efficiency.

Owner:PANZHIHUA UNIV +1

Production technology of metal molybdenum

The invention relates to a production technology of metal molybdenum. The production technology is characterized by comprising the following steps: firstly, an aluminium powder and a calcium fluoride powder are added into a molybdenum oxide powder; the materials are fully mixed and the mixed materials are sent into a reaction vessel; the reaction vessel is vacuumized; by a heating mode, an exothermic agent is ignited to carry out an aluminothermic reduction reaction so as to obtain a primary alloy; and finally, the primary alloy is melted and purified to obtain high-purity metal molybdenum. According to the production technology of metal molybdenum, molybdenum oxide, the aluminium powder and calcium fluoride are used as raw materials; by an aluminothermic reduction method, the primary molybdenum aluminium alloy is produced; and the alloy is purified by a vacuum electron beam furnace; and metal molybdenum is prepared by characteristics of large differences between molybdenum and aluminium melting points and different metallic vapour pressures of molybdenum and aluminium. By the technology, production costs of metal molybdenum are greatly reduced. The metal molybdenum produced by the technology has characteristics of low cost, short production cycle, high yield and the like.

Owner:NINGXIA ORIENT TANTALUM IND

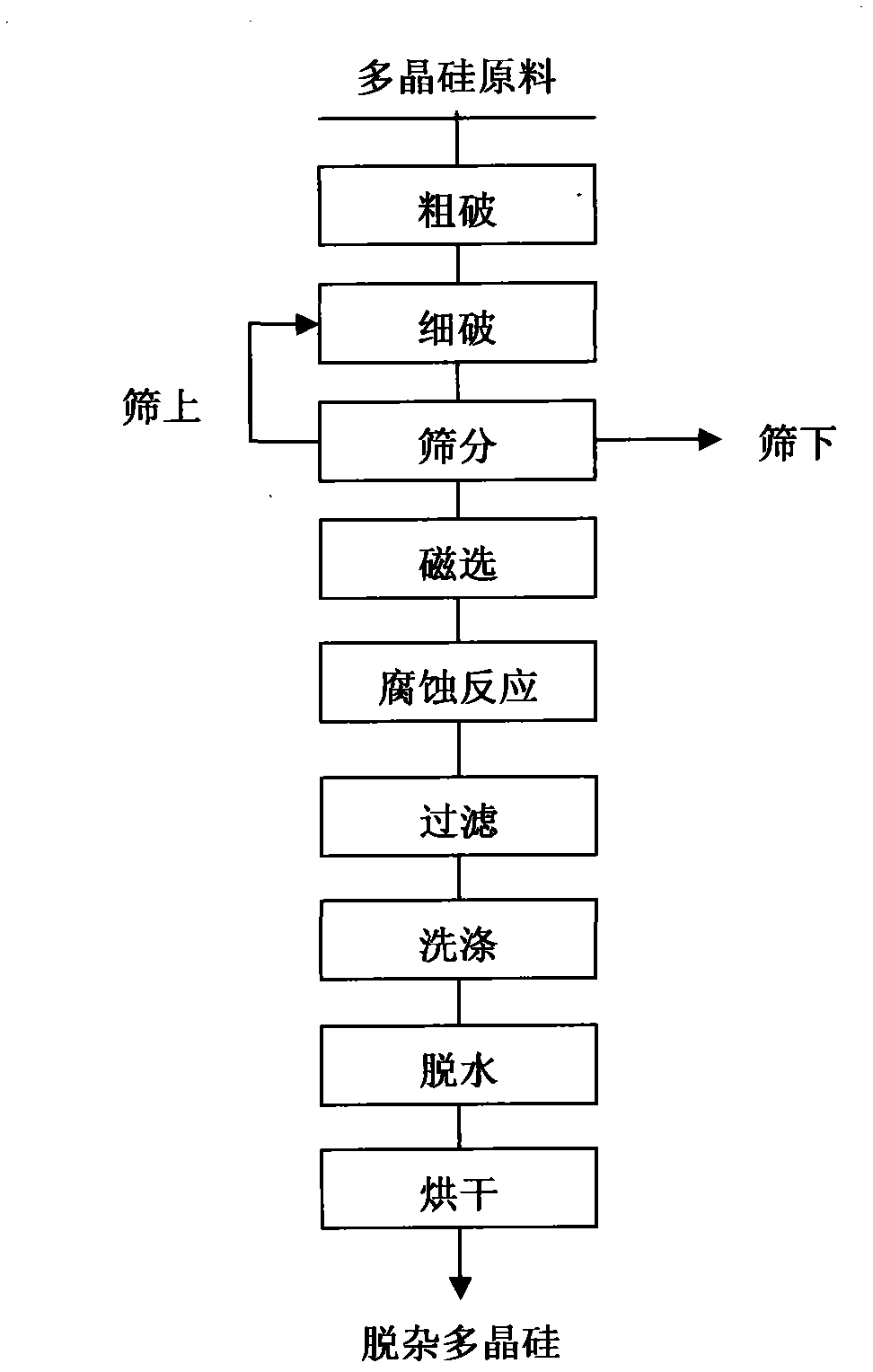

Method for removing impurities on surface of metal silicon

InactiveCN102001663ALess investmentReduce energy consumptionSilicon compoundsIngot castingPhysical metallurgy

The invention discloses a method for removing the impurities on the surface of polysilicon by using a composite corrosive and a magnetic separation method, belonging to the field of physical metallurgy. The method comprises the steps of: coarsely breaking, finely breaking, screening and magnetically separating the metal silicon raw material; putting in a container with stirring function, adding the corrosive; heating and stirring; recycling the filtrate; and washing, dehydrating and drying a filter cake to obtain impurity-removed polysilicon which can be used as furnace burden for other pyrometallurgical purification such as ingot casting purification and electron beam furnace purification and the like. By adopting a wet metallurgical method, the production cost for the impurity removal of pyrometallurgical equipment is greatly reduced, therefore, the method is a novel polysilicon wet metallurgical impurity removing method which can be industrially implemented on a large scale and has the characteristics of simple structure, low investment and low energy consumption. The metal impurities in the raw polysilicon are reduced from thousands of ppmw to below 200 ppmw without any selection and pre-purification. The method abandons the defects such as large power consumption and large equipment investment of the pyrometallurgical method, and a feasible novel way which can be industrially implemented on a large scale and has the characteristics of simple structure, low investment and low energy consumption is provided.

Owner:云南乾元光能产业有限公司

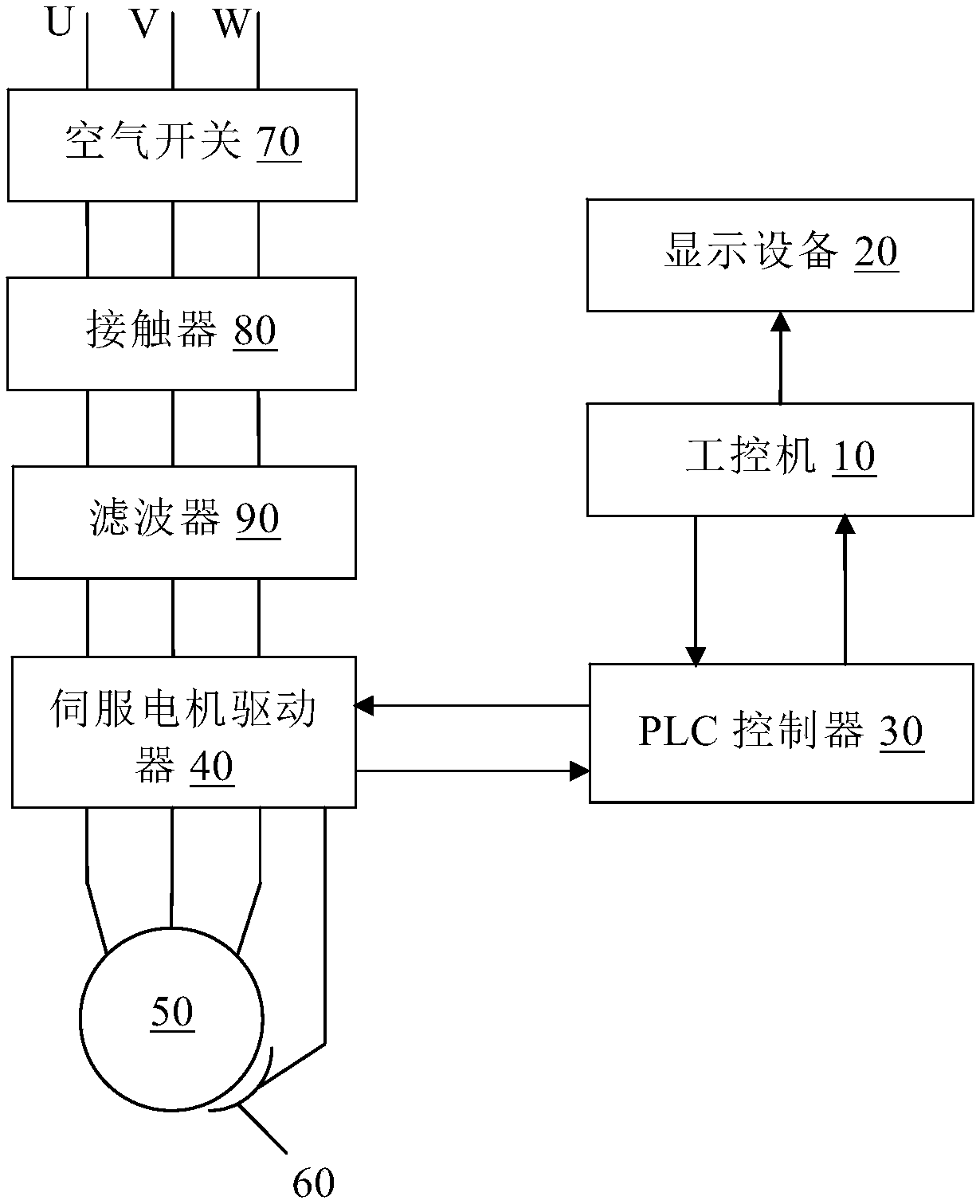

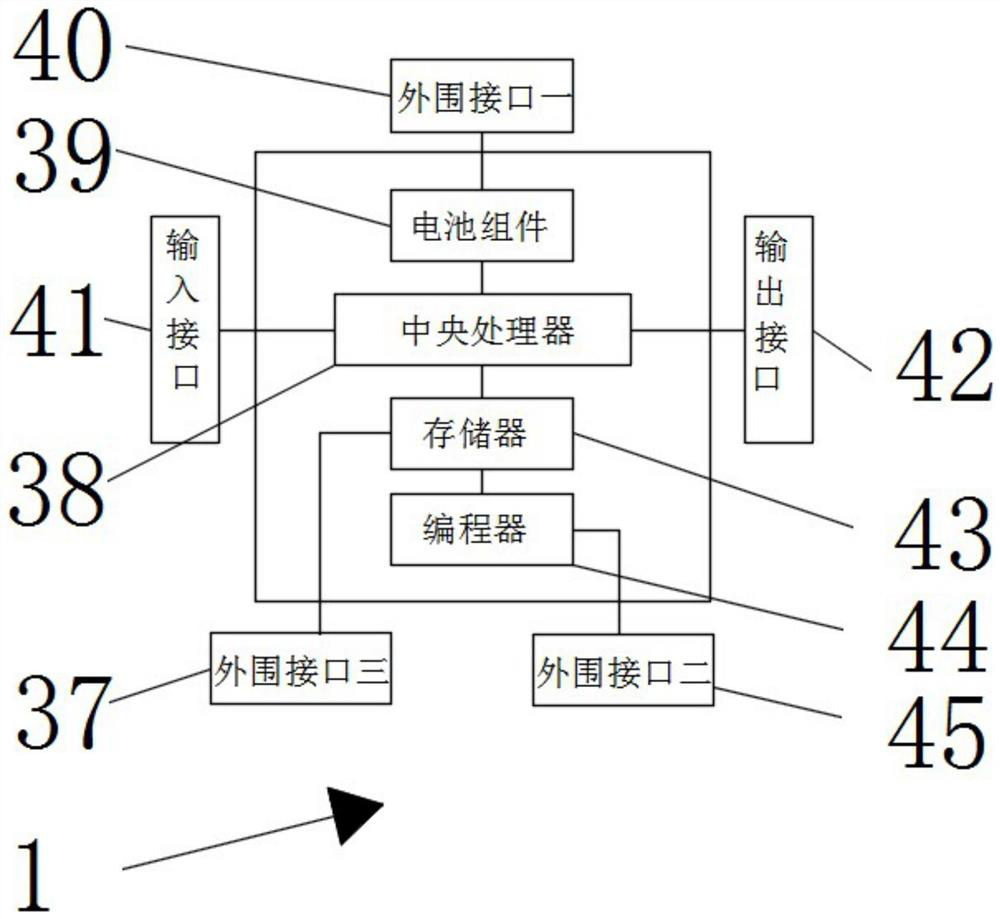

Automatic ingoting control system for vacuum electron beam furnace and control method of automatic ingoting control system

The invention discloses an automatic ingoting control system for a vacuum electron beam furnace and a control method of the automatic ingoting control system. The automatic ingoting control system includes an industrial control computer, a PLC, a servo motor actuator and an ingot pulling motor, wherein the industrial control computer is connected with the PLC through an industrial ethernet bus, the servo control communication port of the PLC is connected with the communication port of the servo motor actuator through the industrial ethernet bus, the motor power supply input port of the servo motor actuator is connected with a three-phase power grid through a filter, a contactor and an air switch, the servo motor actuator drives the ingot pulling motor, the data transfer port of a high-speed encoder mounted on the ingot pulling motor is connected with the feedback signal receiving port of the servo motor actuator, and an ingot rod is connected with an output shaft of the ingot pulling motor through a bearing. According to the automatic ingoting control system, automatic control is achieved in the entire process, manual interference is not needed, smoothness of the outer surface of an ingot metal after ingoting is guaranteed, the rate of finished products is high, the production efficiency is high, and the service life of a crucible is greatly prolonged.

Owner:GRIMAT ENG INST CO LTD

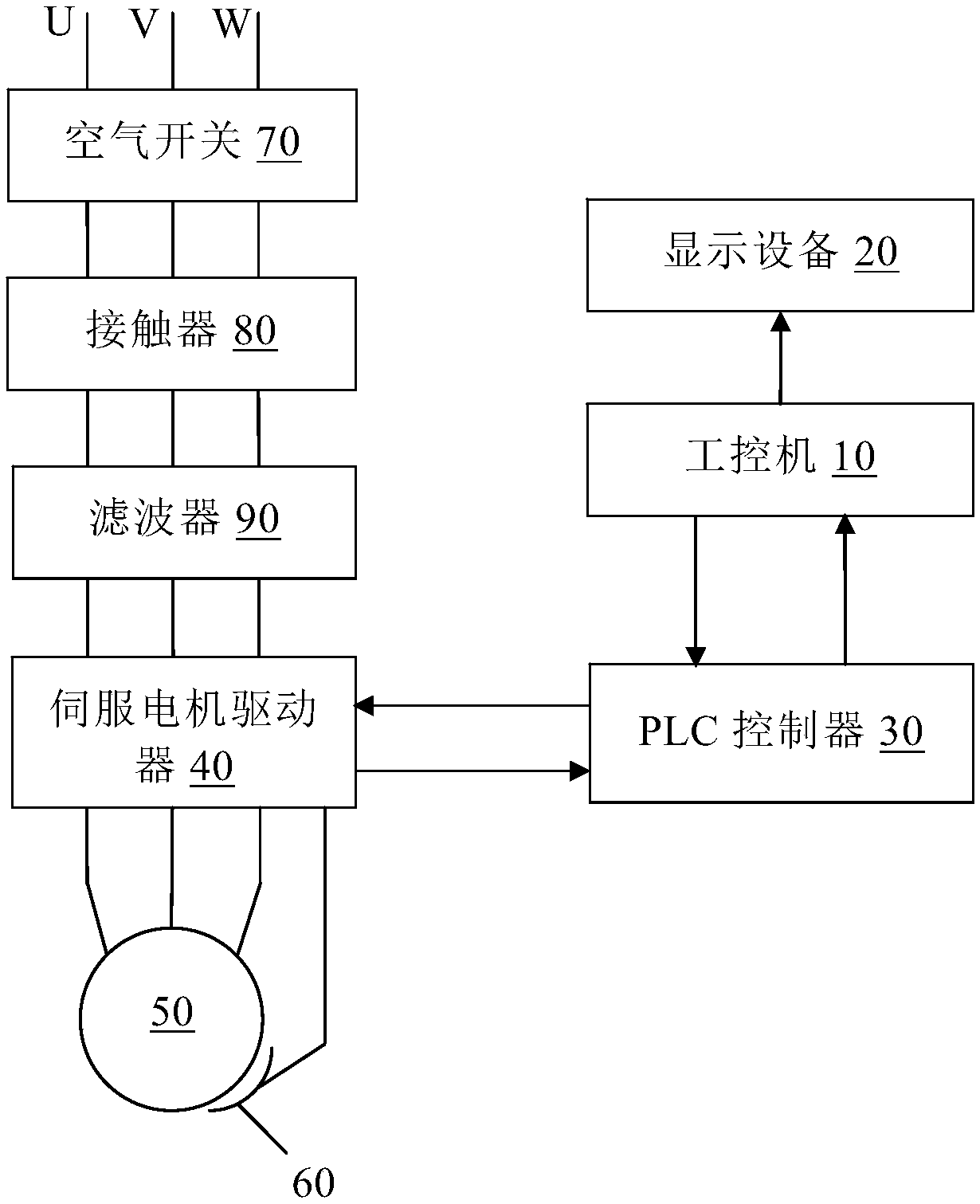

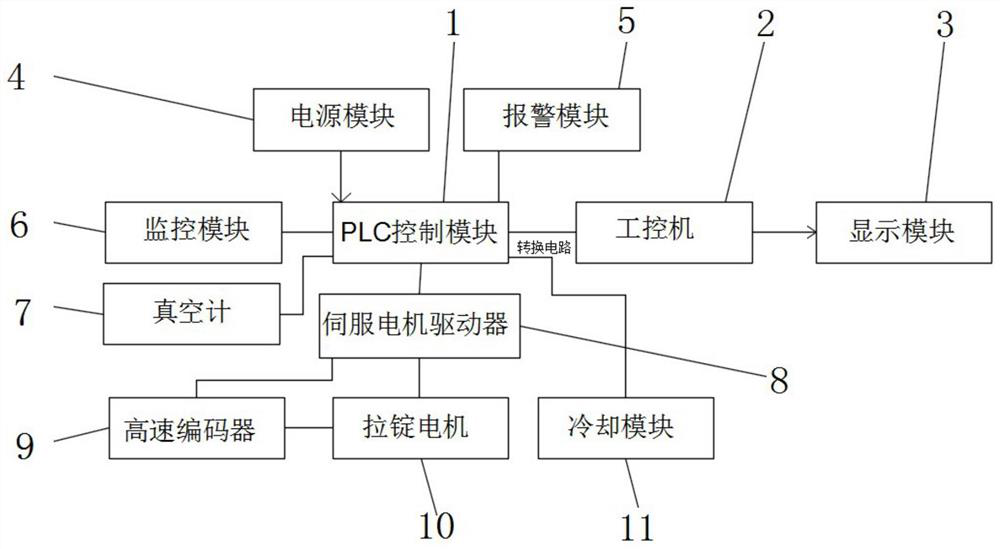

Automatic ingot casting control system for vacuum electron beam furnace

InactiveCN112024836AGuarantee personal safetyImprove processing efficiencyCooling/ventillation arrangementControl systemIngot casting

The invention discloses an automatic ingot casting control system for a vacuum electron beam furnace. The system comprises a PLC control module, an industrial personal computer, a display module, a power supply module, an alarm module, a monitoring module, a vacuum gauge, a servo motor driver, a high-speed encoder, an ingot pulling motor and a cooling module. The PLC control module is electricallyconnected with the power module, the alarm module, the monitoring module, the vacuum gauge, the servo motor driver and the cooling module. The PLC control module is electrically connected with the display module through the industrial personal computer, and the servo motor driver is electrically connected with the ingot pulling motor through the high-speed encoder. The cooling module is matched with the ingot pulling motor. The system has the advantages that the influence of high temperature on the ingot pulling motor can be reduced, the ingot pulling motor can be kept in a normal working state, field electronic instruments can be monitored, the state of electronic devices can be known conveniently, and the system can be maintained conveniently in time.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

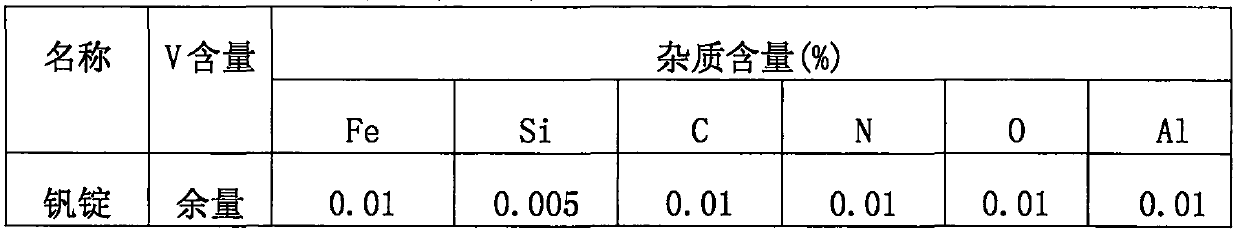

Method for producing high-purity metal vanadium ingot by three-step approach

The embodiment of the invention provides a method for producing a high-purity metal vanadium ingot through a three-step approach. According to the method, high-purity vanadium pentoxide and high-purity aluminum powder are used as raw materials; a vanadium-aluminum alloy containing about 90% of vanadium is produced by a vacuum aluminothermic method and argon protection; a horizontal electron beam smelting furnace is used for smelting to form a metal vanadium plate by adopting, and some impurities which are easy to remove are removed, such as aluminum, iron and chromium; an electron beam ingot furnace is used for continuous smelting to form a metal vanadium column ingot, and the impurities such as aluminum, iron, chromium and the like and difficult-to-remove impurities (silicon) are furtherremoved. According to the method provided by the invention, an electron beam ingot furnace smelting step is added after a horizontal electron beam furnace smelting step; after the metal vanadium plateis melt in an electron beam ingot furnace, and is dripped into an ingot casting crucible; the impurity elements sink or float upwards in the column ingot due to different specific gravities of the impurity elements and the metal vanadium, and finally the upper end and the lower end of the metal vanadium column ingot are removed so as to obtain the high-purity metal vanadium ingot of which the silicon content is less than 0.004% and the vanadium content is increased to 99.9% or above.

Owner:CNMC NINGXIA ORIENT GRP

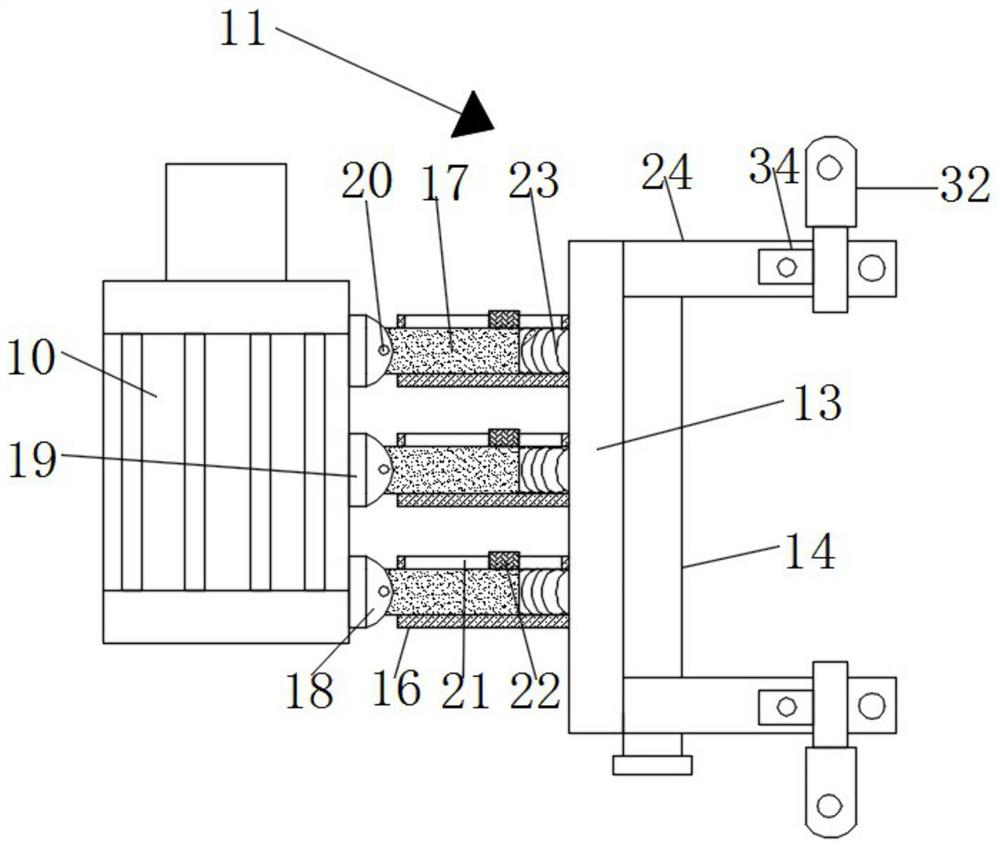

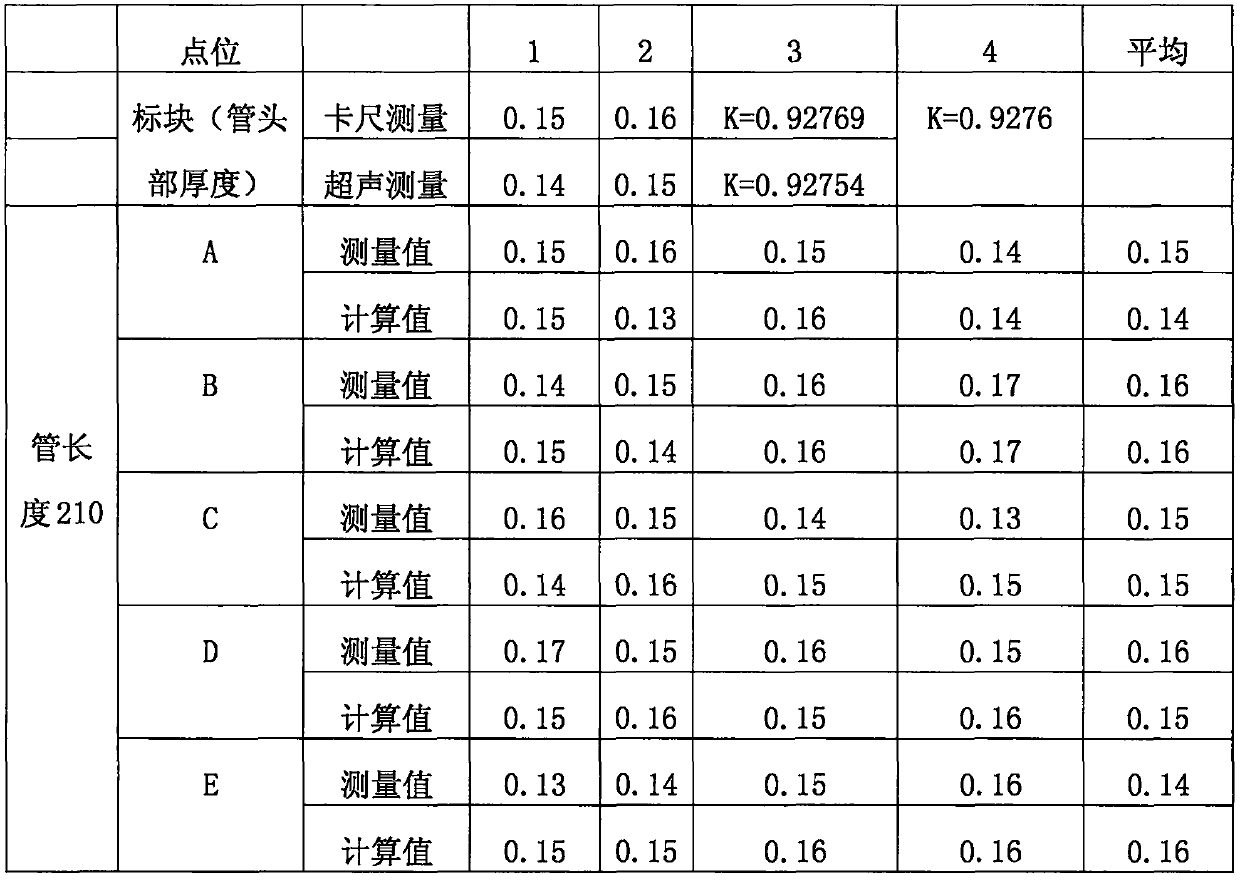

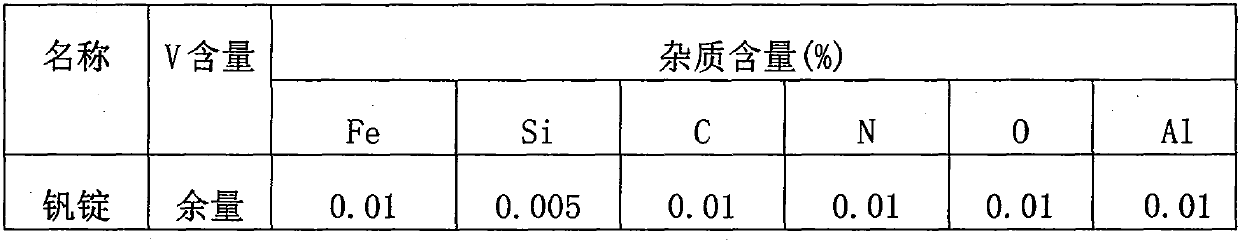

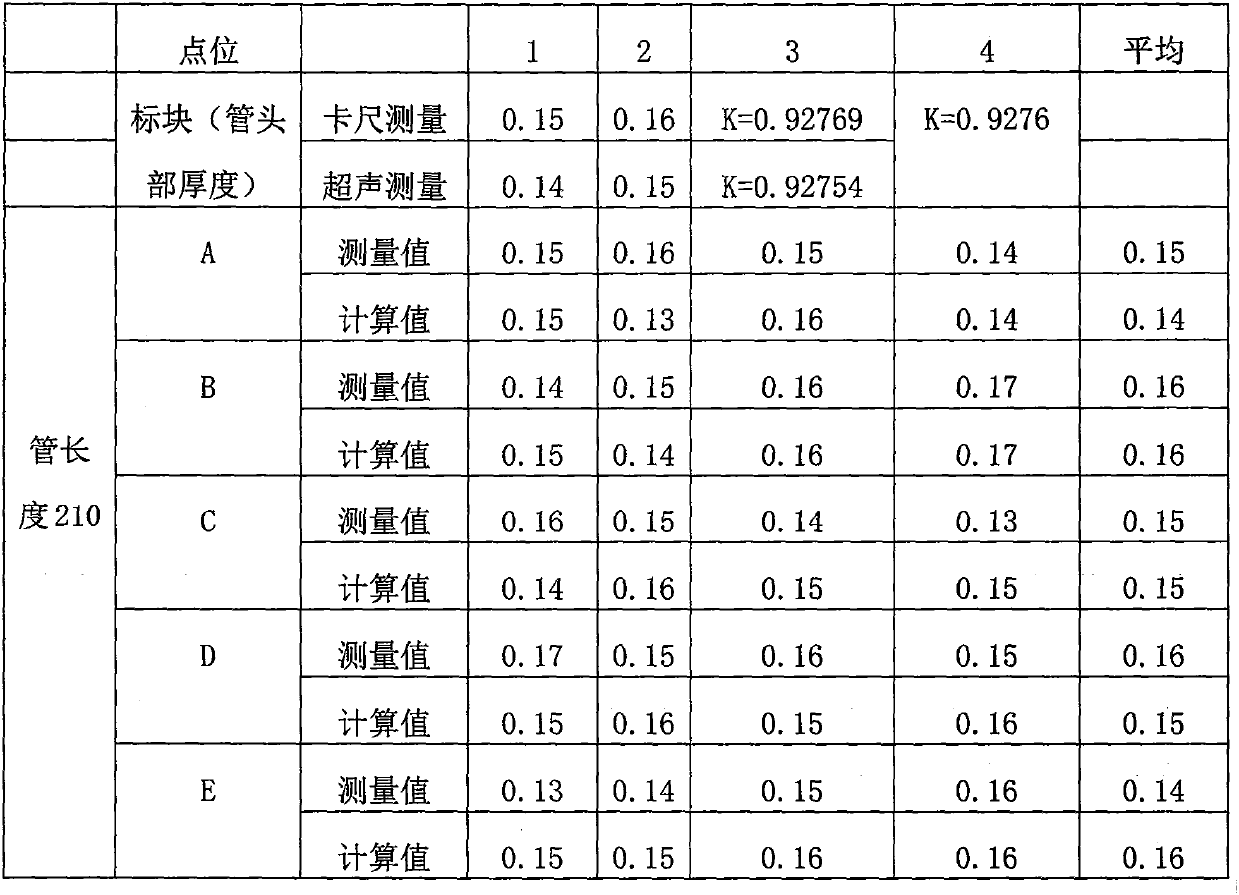

Manufacturing process of ultra-thin-wall vanadium pipe for preparing high purity hydrogen

ActiveCN107891251AReduce the cost of hydrogen productionHigh hydrogen permeabilityNonferrous metalIngot

The invention belongs to the field of nonferrous metal machining, and particularly relates to a manufacturing process of an ultra-thin-wall vanadium pipe for preparing high purity hydrogen. The manufacturing process mainly comprises the steps of vanadium ingot purification, vanadium ingot forging, heat treatment and pipe blank making, pipe rolling and intermediate annealing, vanadium pipe cleaning, specific cutting and inspection storage. An electron beam furnace is used for refining a high-purity metal vanadium ingot casing multiple times, wherein the ingot casing can be directly rolled and machined, then, the ingot casing can be further rolled into the thin-wall vanadium pipe with the diameter being 6 mm, the vanadium pipe wall thickness is 0.15+ / -0.01 mm, and the purity is larger than or equal to 99.95%; the manner that an existing expensive palladium and alloy ultra-thin-wall pipe is used for hydrogen production is replaced, the hydrogen production cost is lower, the hydrogen penetration is higher, the infinite selectivity for hydrogen is achieved, and the higher application prospect is achieved.

Owner:BAOJI BOXIN METAL MATERIALS

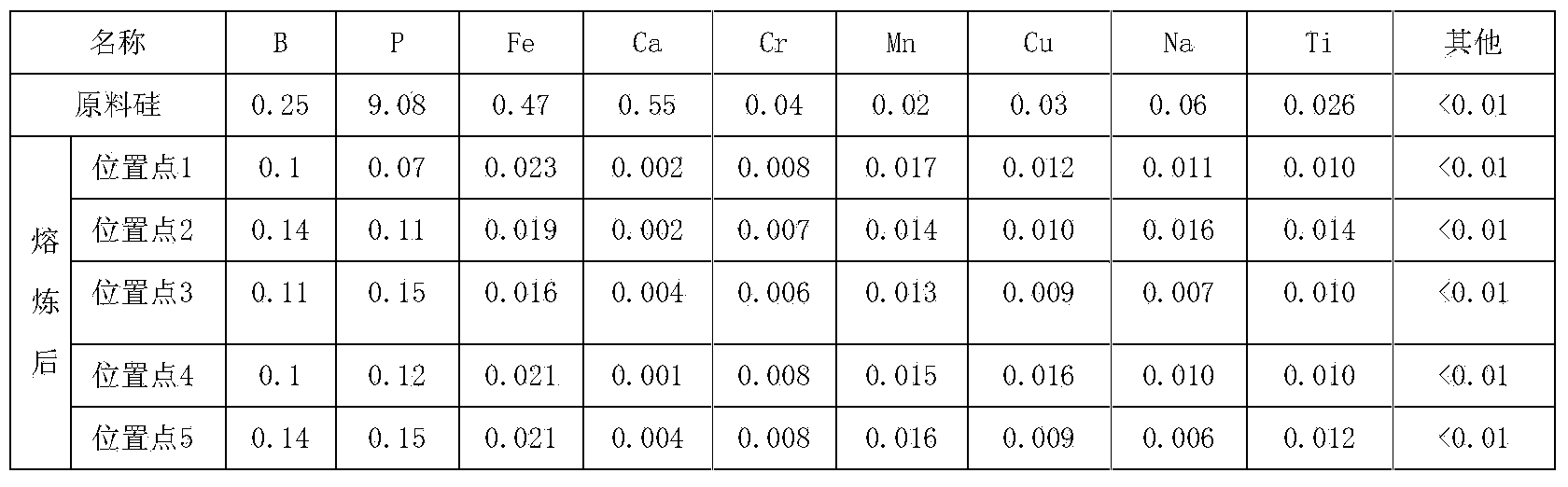

Method for removing boron and metal impurities for polysilicon melting in electron-beam furnace

ActiveCN103588208AUnique methodAchieve removalSilicon compoundsMetal impuritiesTemperature resistance

The invention relates to a method for removing boron and metal impurities for polysilicon purification, in particular to a method for removing boron and metal impurities for polysilicon melting in an electron-beam furnace. The method is characterized in that silicon briquettes as the raw materials firstly are subjected to acid pickling and washing, and are then placed in a high-temperature resistance furnace for high-temperature oxygenation pre-processing; the processed silicon materials are fed into a three-gun electron-beam furnace for melting; after the melting, the silicon ingots are taken out after the temperature is reduced to the room temperature; the skins and bottom layers are removed, the loose layer, where metal impurities are concentrated, of the core at the upper end of each silicon ingot is gently knocked off through a hard alloy hammer, and then solar polysilicon is obtained. The method provided by the invention is unique; through the adoption of the method, not only are phosphorus and metals such as calcium and sodium are removed, but also has very remarkable effects for removing boron and iron, copper and other metal impurities; the method has the advantages of high impurity removal efficiency, large yield and remarkable economic effects.

Owner:宁夏宁电光伏材料有限公司

Preparation method of tantalum 2.5 tungsten alloy

The invention provides a preparation method of a tantalum 2.5 tungsten alloy. The preparation method comprises the following steps: after preparing tantalum powder and tungsten powder in proportion, putting the powder into a drum mixer to be mixed for 24 hours; sieving the mixed powder with a 120-mesh sieve to obtain fine powder; pressing the fine powder into an alloy bar with a 500ton oil press; putting the alloy bar into a vacuum sintering furnace to be sintered to obtain a raw ingot blank; smelting the raw ingot blank at least twice with a vacuum electron beam furnace to prepare an alloy ingot blank; putting the alloy ingot blank into a high frequency furnace to be heated to 1400 DEG C, then taking out the alloy ingot blank and forging the alloy ingot blank for many times, thus obtaining a finished product of ingot blank. The preparation method has the beneficial effects that through full mixing of tantalum powder and tungsten powder and many times of smelting, the problem of nonuniformity of ingot blank tissues is solved and the problems that the blanks easily fall off and become brittle are improved.

Owner:陕西世纪创优金属材料有限公司

Ti-W-Nb intermediate alloy and preparation method thereof

ActiveCN113881871AMeet the needs of smelting preparationImproves ingredient uniformityTitanium metalNiobium

The invention relates to a Ti-W-Nb intermediate alloy and a preparation method thereof. The Ti-W-Nb intermediate alloy comprises the following chemical components of, in percentage by weight, 20-30% of Nb, 20-30% of W and the balance Ti. The intermediate alloy is prepared through smelting by adopting an electron beam furnace, raw materials comprise sponge titanium, Ti-Nb intermediate alloy, pure W powder and the like, the melting point of the titanium-tungsten-niobium intermediate alloy is far lower than that of a tungsten metal simple substance, the intermediate alloy prepared by adopting the method is used for smelting preparation of the W-containing titanium alloy and titanium intermetallic compounds, the uniformity and stability of alloy components can be effectively improved, and the defects of segregation, inclusion and the like of refractory metal elements are reduced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Cold bed electron beam smelting method for high-purity nickel ingot

The invention discloses a cold bed electron beam smelting method for a high-purity nickel ingot. The method comprises the following steps: S1, selecting a high-purity electrolytic nickel plate as a raw material, polishing, cleaning with a cleaning solution, drying, recording the weight, sequentially loading into a bin of an electron beam furnace, fixing, and vacuumizing the electron beam furnace; S2, preheating an electron gun, increasing power, starting a pushing mechanism after the electron gun is stabilized, sequentially pushing the high-purity electrolytic nickel plate fixed in the bin in the step S1 into a cold bed for complete melting to form nickel melt, keeping the nickel melt staying on the cold bed for 24 minutes, and after the nickel melt is fully deflated, enabling the nickel melt to flow into an ingot casting crucible to prepare a nickel ingot; and S3, switching off the electron gun and the vacuum system sequentially, opening the electron beam furnace, and taking the nickel ingot prepared in the step S2 out. According to the method, the problem of internal defects of the nickel ingot in the smelting process is solved, and the product percent of pass and the production efficiency are improved.

Owner:宁波创润新材料有限公司

Power device in electronic optical path system of electronic bundle impact furnace

InactiveCN100584132CAvoid damageFast dynamic follow performance indicatorsElectric discharge heatingIncreasing energy efficiencyControl signalHysteresis band

The invention discloses a method for controlling a power supply of an electron-optical circuit system of an electron beam furnace and a power supply device. The method takes the extraction value of an acceleration voltage sampling signal of a power supply of an electron beam generating system as a control signal for a focusing and deflection scanning power supply and the amplitude of a focusing and deflection scanning current changes linearly according to the control signal, which ensures that the operation parameter of the electron-optical circuit system is free from the influence of the fluctuation of the acceleration voltage. The power supply device has the acceleration voltage sampling signal connected with a square root extractor first and then connected to a focusing and deflection scanning power supply control circuit, and adopts a hysteresis-band current tracking pulse modulation controller to maintain a small up and down oscillation amplitude of a working current based on an expected value. An extraction value signal of the acceleration voltage sampling signal is used to control a focusing current, and a general control signal which is the produce of a deflection scanning integrated signal and the extraction value of the acceleration voltage sampling signal is used to control deflection scanning current, so the focusing and deflection scanning region of the electron beam is not influenced by the acceleration voltage, and in event of failure, the change of the focusing and deflection scanning region of the electron beam is controlled in a permitted range.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A manufacturing process for preparing ultra-thin-walled vanadium tubes for high-purity hydrogen

ActiveCN107891251BReduce the cost of hydrogen productionImprove hydrogen permeabilityNonferrous metalIngot

The invention belongs to the field of nonferrous metal machining, and particularly relates to a manufacturing process of an ultra-thin-wall vanadium pipe for preparing high purity hydrogen. The manufacturing process mainly comprises the steps of vanadium ingot purification, vanadium ingot forging, heat treatment and pipe blank making, pipe rolling and intermediate annealing, vanadium pipe cleaning, specific cutting and inspection storage. An electron beam furnace is used for refining a high-purity metal vanadium ingot casing multiple times, wherein the ingot casing can be directly rolled and machined, then, the ingot casing can be further rolled into the thin-wall vanadium pipe with the diameter being 6 mm, the vanadium pipe wall thickness is 0.15+ / -0.01 mm, and the purity is larger than or equal to 99.95%; the manner that an existing expensive palladium and alloy ultra-thin-wall pipe is used for hydrogen production is replaced, the hydrogen production cost is lower, the hydrogen penetration is higher, the infinite selectivity for hydrogen is achieved, and the higher application prospect is achieved.

Owner:BAOJI BOXIN METAL MATERIALS

Electron beam furnace mounting and construction method

The invention relates to an electron beam furnace mounting and construction method. The method comprises the following steps: S1, carrying out construction preparation: in a ground floor, based on a smelting room, determining a longitudinal center line and a transverse center line and then respectively throwing in the longitudinal and transverse center lines in each of elevation layers; S2, mounting a ingot-pulling system; S3, mounting foundation columns of the smelting room as well as a first steel structure platform from bottom to top; S4, mounting the smelting room; S5, mounting a gas collecting room and a diffusion pump of the gas collecting room; S6, mounting a main charger; S7, installing a second steel structure platform from bottom to top; S8, mounting a rotary charger; S9, mounting a lid trolley; and S10, mounting a vacuum system. The method considers in an overall manner and weakens disciplinary partitionment, and optimizes the mounting sequences of equipment according to different elevations, different systems and the like. In addition, a positioning reference point is thrown in the ground of + / -0.000m, and a mounting reference line is arranged in each of the elevation platform layer, so that reference can be aligned for relatively high multilayered equipment.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Method for preparing titanium ingot from high-oxygen titanium recovery material

ActiveCN110484737AIncrease profitIncrease the addition ratioProcess efficiency improvementHydrogen atmosphereDehydrogenation

The invention relates to a method for preparing a titanium ingot from a high-oxygen titanium recovery material and belongs to the technical field of preparation of a titanium cast ingot. The method for preparing the titanium ingot from the high-oxygen titanium recovery material comprises the following steps: A, performing heating reaction on the high-oxygen titanium recovery material in hydrogen atmosphere for 5 to 30 minutes and cooling to obtain a hydrogenated titanium block, wherein the reaction temperature is 470 to 550 DEG C and the pressure intensity of the hydrogen atmosphere is 0.2 to1 MPa; and B, crushing the hydrogenated titanium block, mixing with a titanium material, smelting in an electron beam cold bed smelting furnace and cooling to obtain the titanium ingot, wherein the mass ratio of the high-oxygen titanium recovery material to the titanium material is 1:(1-4). According to the method of the invention, the adding ratio of high-oxygen titanium is high and the utilization rate of titanium scrap is slightly high. Titanium hydride obtained through preparation is directly mixed with sponge titanium, heating, and dehydrogenation and smelting are conducted integrally bythe electron beam furnace, so cost is low.

Owner:PANZHIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com