Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Avoid internal defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot top casting process for phi 784-mm 7xxx-series superhard aluminum alloy round bar

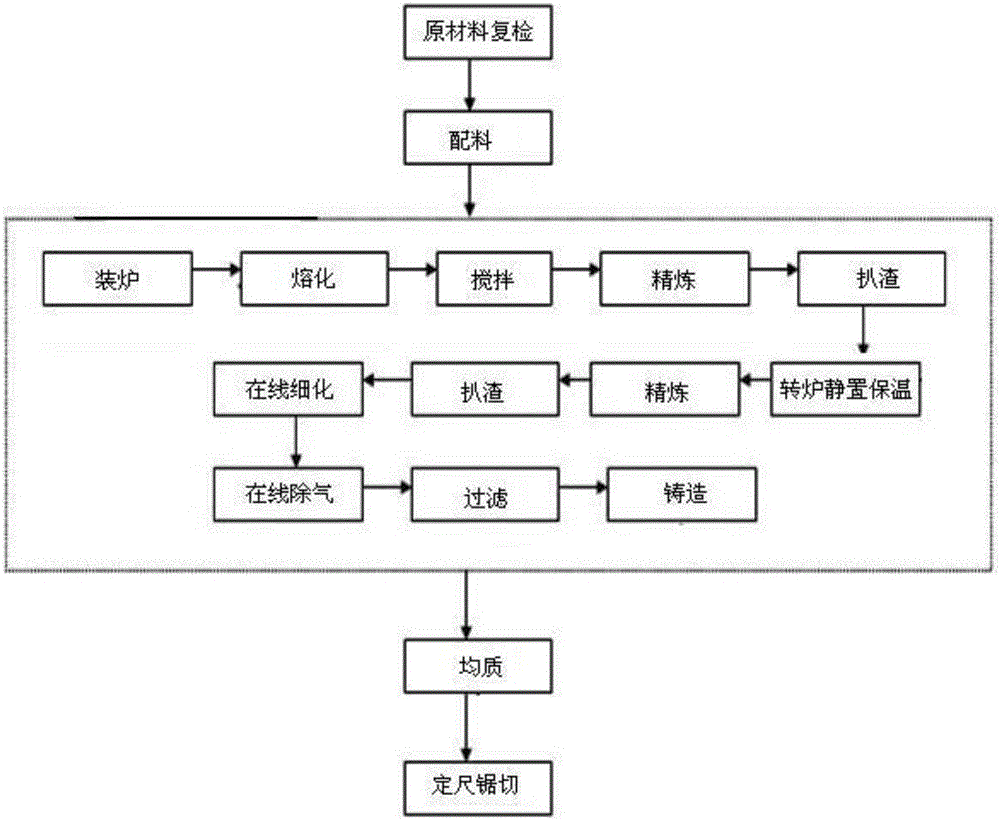

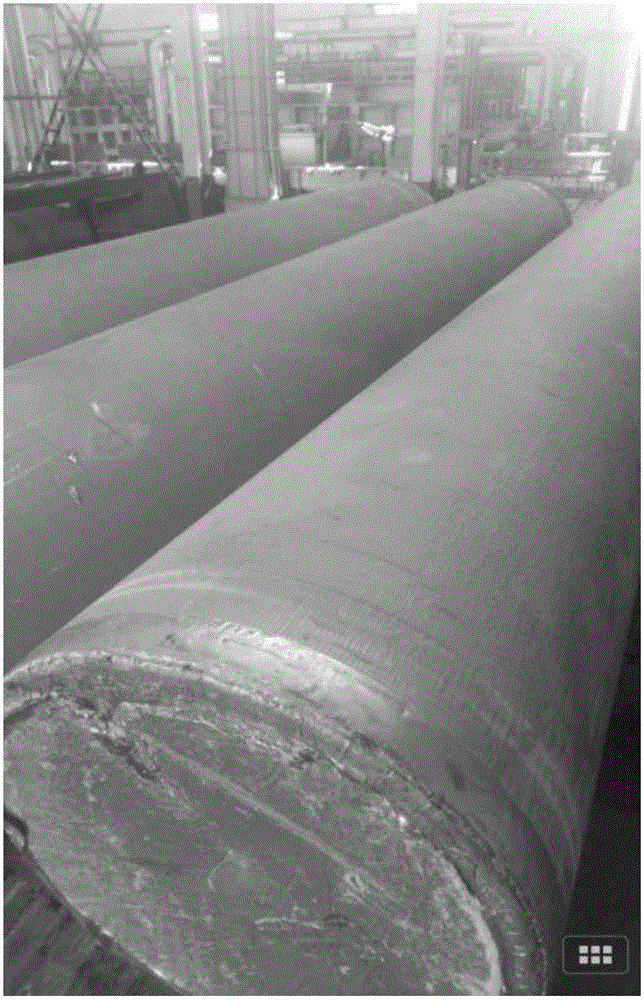

The invention discloses a hot top casting process for a phi 784-mm 7xxx-series superhard aluminum alloy round bar. The aluminum alloy round bar is composed of, by mass, 0.25% of Si, 0.4% of Fe, 1.55-1.65% of Cu, 0.25% of Mn, 2.55-2.65% of Mg, 0.19-0.25% of Cr, 5.6-5.7% of Zn, 0.15% of Ti, 0.03% of Zr and the balance Al. The manufacturing process comprises the steps of a, material preparation; b, smelting; c, stirring; d, refining; e, slagging-off; f, heat preservation and standing; g, online thinning; h, online degassing; i, filtration; j, casting; k, homogenizing. Through the process, the defects, such as cracks, component segregation, bright grains, thick grains and loose pores, which often appear when a direct condensation casting technology is adopted for large-diameter superhard aluminum alloy are overcome, and by the adoption of hot top casting, the defects of surface segregation tumors, thick coarse-grain layers and the like are overcome.

Owner:CHINA ZHONGWANG

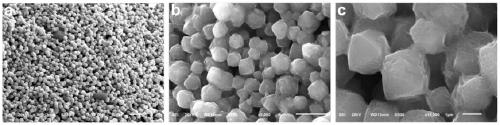

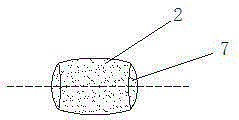

Alloyed powder for directly printing metal parts in 3D (three-dimensional) manner and preparation method of alloyed powder

ActiveCN104668553ANo lossPrevent solidificationTransportation and packagingMetal-working apparatusStructural deformationMicrosphere

The invention provides alloyed powder for directly printing metal parts in a 3D (three-dimensional) manner. The alloyed powder is characterized in that nanometer aluminum is adhered to the surface of oxide of iron through a layer of thin tin powder to form iron-base alloy microspheres, the grain size of the microspheres is 2-10 micrometers, the sphericity is greater than 95%, and the alloyed powder comprises the following materials in part by weight: 60-70 parts of iron oxide, 30-40 parts of nanometer aluminum and 0.1-0.5 part of tin powder. The alloyed powder can be directly used for printing the metal parts in the 3D manner. When the alloyed powder is used for directly printing the metal parts in the 3D manner, the iron oxide is gradually reduced through aluminum, structure deformation caused by direct fusion molding of metal, cooling crystallization is uniform, the strength of a molded piece is improved by formed aluminum oxide, the porosity of products is reduced, and the compactness is high. The alloyed powder can be used for directly printing the high-precision metal parts which have complication shapes.

Owner:康硕(河南)智能制造有限公司

Method for preparing integrated molecular sieve blocks on basis of 3D printing technology

PendingCN109160800AHigh mechanical strengthHigh porosityAdditive manufacturing apparatusMolecular sieve catalystsFiberMolecular sieve

The invention discloses a method for preparing integrated molecular blocks on basis of a 3D printing technology, and belongs to the field of molecular sieve type adsorbent or catalyst processing. Themethod comprises the following steps of: (1) uniformly mixing a molecular sieve body with an inorganic binder, an inorganic fiber, an organic shaping auxiliary, a pore forming agent and water so as toconfigure a pasty mixture; (2) carrying out ultrasonic treatment on the pasty mixture; (3) designing a printing program; (4) printing molecular sieve blocks by utilizing a 3D printer; and (5) carrying out low-temperature aging shaping and high-temperature roasting. According to the method, the 3D printing technology is applied to intelligent preparation of molecular sieve type bodies for the time, so that the method has the advantages of being simple to operate, low in cost and high in material utilization rate; and the molecular sieve blocks have the advantages of being wear-resistant, highin mechanical strength, developed in pores, uniform in micropore-mesopore-macropore grade pore structure, small in pressure reduction and high in mass transfer rate, and is suitable for processing various molecular sieve adsorbents and catalysts.

Owner:JILIN UNIV

Ship tail shaft bracket electric arc wire fusing 3D printing manufacturing method and product thereof

ActiveCN108971699AUniform and dense tissueLow costArc welding apparatusManufacturing technologyMachining

The invention belongs to the technical field of ship tail shaft bracket manufacturing technologies, and discloses a ship tail shaft bracket electric arc wire fusing 3D printing manufacturing method. The method comprises the steps that (1) a corresponding three-dimensional model is built for a tail shaft bracket and is divided into three partitions corresponding to a tail shaft hub, a transverse arm and a supporting arm; (2) according to the different partitions, printing paths are planned and designed based on different principles, and a tail shaft hub printing path with all layers in ring shapes, a transverse arm printing path with all layers in rectangle shapes and a supporting arm printing path with all layers in rectangle shapes are obtained; and (3) according to the obtained differentmanufacturing paths, the electric arc wire fusing 3D printing manufacturing technology is adopted for conducting corresponding molding machining. The invention further discloses a corresponding shiptail shaft bracket product. By means of the method and the product, the problems that in the traditional ship tail shaft bracket manufacturing process, a die model is difficult, and the molding pieceperformance is poor are solved, and a new method and thinking are provided for manufacturing the tail shaft bracket.

Owner:HUAZHONG UNIV OF SCI & TECH

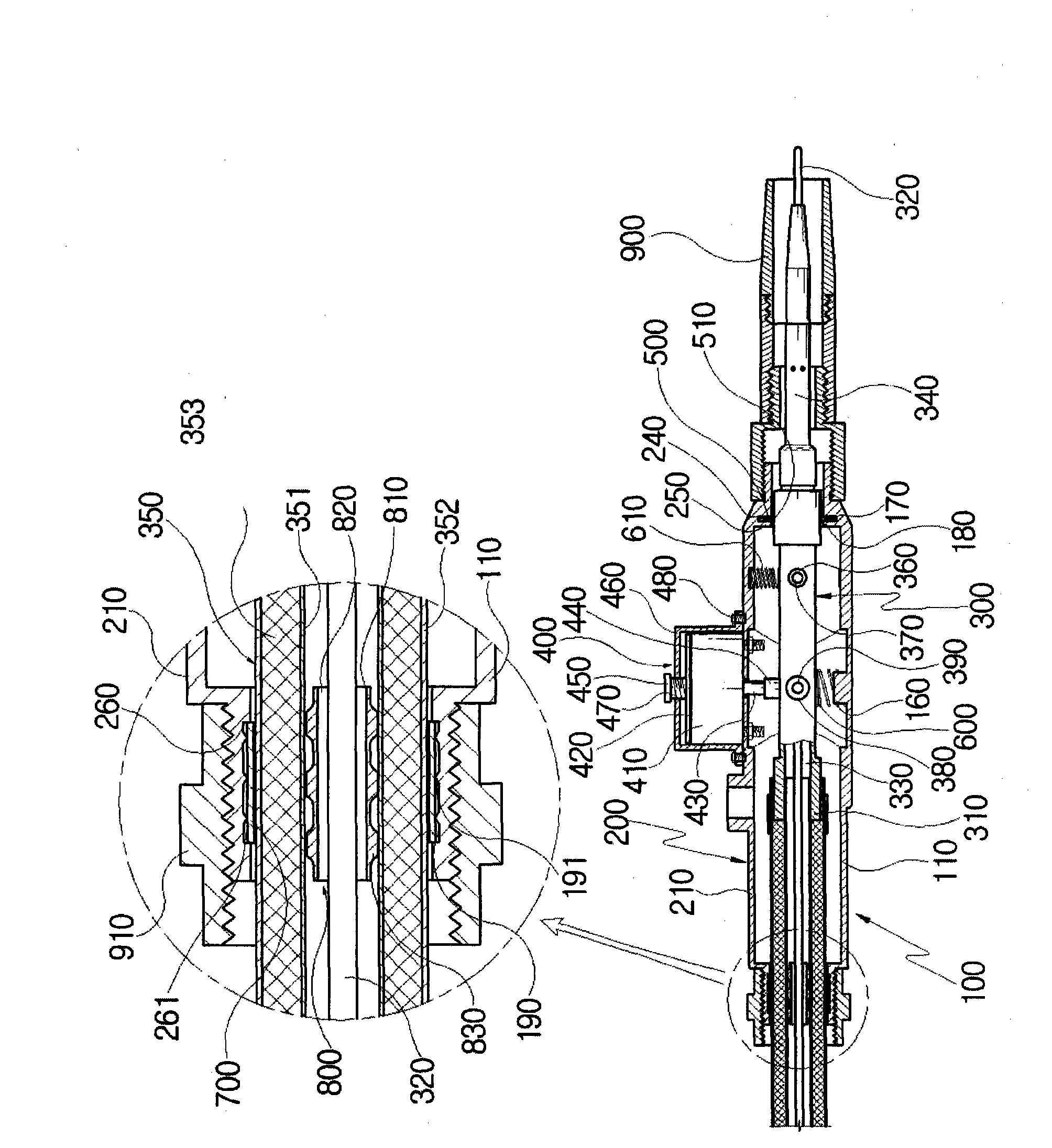

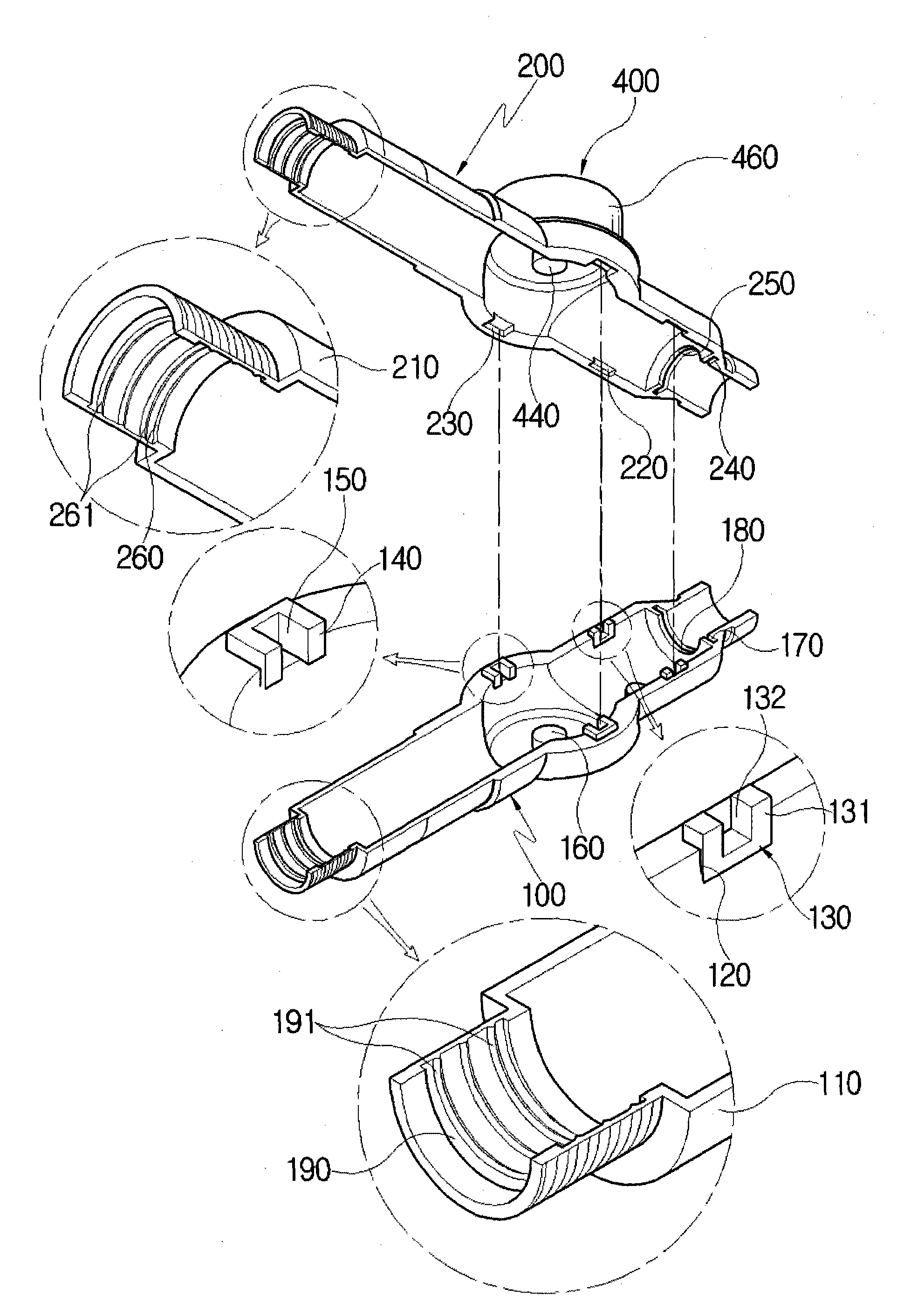

Weaving torch device for auto wellding

InactiveCN101821050APrevent left/right movementBest weld beadWelding/cutting auxillary devicesElectrode supporting devicesReciprocating motionTorch

The present invention relates a weaving torch device for auto welding that can maintain necessary molten metal for desired welding such as welding by a person and provide the best welding beads, by locking a hinge pin and a conveying pin, which are provided to both sides of a weaving torch of a torch device connected to a welding machine, to a locking protrusion and a locking step of a hinge support member of a lower case in order to prevent left / right conveying while the weaving torch is automatically reciprocated up / down by operation of an electromagnet and a conveying spring.

Owner:SM T&D

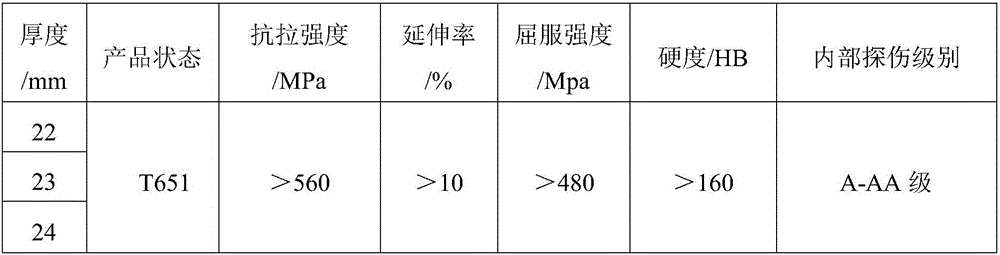

Aluminum alloy thick plate for high-strength mold and production method thereof

ActiveCN106435305AReduce hydrogen contentAvoid internal defectsFurnace typesHeat treatment furnacesSlagQuenching

The invention discloses an aluminum alloy thick plate for a high-strength mold and a production method thereof. The aluminum alloy thick plate has the following chemical elements in percentage by mass: Si not more than 0.25%, Fe not more than 0.45%, 1.5-1.8% of Cu, Mn not more than 0.25%, 2.4-2.8% of Mg, 0.19-0.25% of Cr, 5.3-5.8% of Zn, 0.02-0.03% of Ti, and the balance of Al. Firstly, raw materials are put in a smelting furnace for smelting, and are put in a refining furnace for refining; obtained molten aluminum is stood, refined and cast; and an obtained ingot performs surface milling, thermalization, hot rough rolling, quenching, stretching and aging in sequence to obtain the aluminum alloy thick plate for the high-strength mold. The aluminum alloy thick plate for the mold with high strength and flatness, no hole and slag in the internal and higher ductility and yield strength is prepared.

Owner:河南泰鸿新材料有限公司

Supercritical-fluid-based 3D electrodeposition machining device and method

ActiveCN104480505AGood miscibilityImprove electric field distributionCellsAdditive manufacturing apparatusMachine partsChemical plating

The invention provides a supercritical-fluid-based 3D electrodeposition machining device and method. The device comprises a carbon dioxide gas bottle, a high-pressure pump, a digital controller, a reactor, a moving anode assembly, a moving cathode assembly, a direct-current power supply and a cathode matrix serving as a machined part, wherein the reactor is internally provided with a mechanical stirrer; the moving anode assembly comprises a Z-directional linear motor, a driving lead screw, an anode connecting rod and a moving anode; the moving cathode assembly comprises an X-directional linear motor, a Y-directional linear motor, a guide rail, a moving block and a fixture; and when the supercritical-fluid-based 3D electrodeposition machining device is used, the moving anode and the cathode matrix are respectively and electrically connected with the anode and cathode of the direct-current power supply. The machining method mainly comprises the steps of carrying out chemical plating treatment on the cathode matrix in advance; mounting the cathode matrix; preparing a supercritical fluid; carrying out electrodeposition machining and after-treatment and the like. By using the supercritical-fluid-based 3D electrodeposition machining device and method, the electrodeposition speed can be effectively increased, the deposition quality can be improved, a complex and precise metal part can be prepared through electrodeposition in a three-dimensional space, and the application field of an electrodeposition technology is widened.

Owner:JIANGSU UNIV OF TECH

Optical fiber image inverter rotary torsion processing technology

InactiveCN101702044ASolve heating uniformityReduced Uniformity RequirementsBundled fibre light guideManufacturing technologyDrive shaft

The invention belongs to the technical field of manufacture of optical fiber image transmission devices, in particular to an optical fiber image inverter rotary torsion processing technology. The invention solves the problem of poor optical fiber image inverter quality brought by a simple torsion method of the optical fiber image inverter in the prior art. The technology comprises the following steps of: driving both ends of an optical fiber composite rod blank in a horizontal state to generate synchronous rotation; meanwhile, heating a optical fiber composite rod to a certain temperature and then starting to apply resistance on a driven shaft to enable the driven shaft to gradually form a certain angle difference with a driving shaft; when the difference reaches 180 DEG C, controlling the rotation speed of the driven shaft to be consistent to the rotating speed of the driving shaft so that the two shafts realize the synchronous rotation; when cooling the optical fiber composite rod blank to plate taking temperature during torsion, shutting down and taking a plate to obtain an image transmission device of which both end surfaces are differed by 180 DEG C. Compared with the prior art, by using the technical scheme, the quality and the torsion qualification rate of the optical fiber image inverter can be improved.

Owner:山西长城微光器材股份有限公司

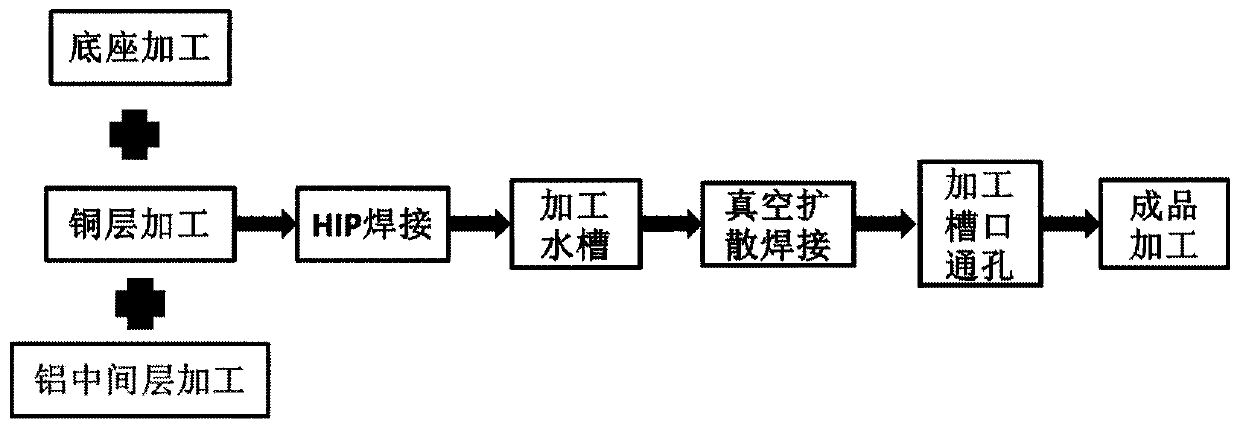

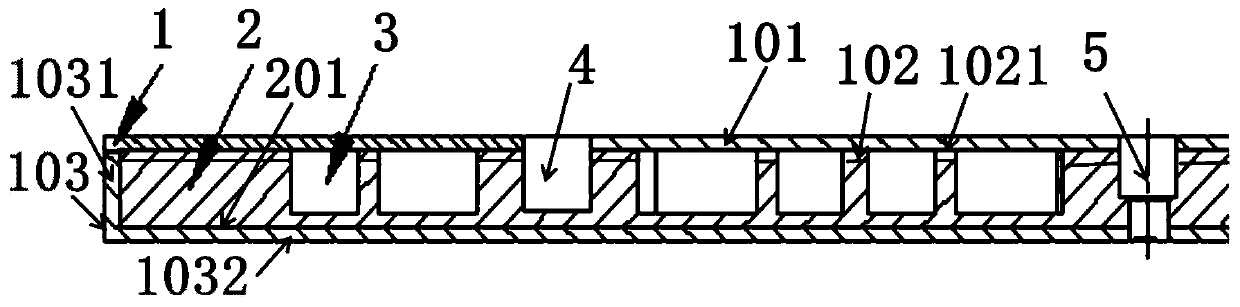

Composite cooling water disc and manufacturing method and application thereof

ActiveCN110911316ASolve the problem of low heat transfer coefficientWon't leakSemiconductor/solid-state device manufacturingMetallurgySemiconductor

The invention provides a composite cooling water disc. The problem that an existing cooling water disc is low in heat transfer coefficient is solved by arranging the aluminum shell and the copper layer wrapped in the aluminum shell, copper is completely wrapped in the aluminum shell, it can be guaranteed that copper metal cannot leak out. The composite cooling water disc is applied to the field ofsemiconductors, and the stability of chip manufacturing can be guaranteed. The invention further provides a manufacturing method of the cooling water disc. Firstly, a copper layer is welded in an aluminum shell through hot isostatic pressing to obtain a welded assembly. After the assembly is machined out of the water tank, the assembly and the upper aluminum layer are combined and subjected to vacuum diffusion welding to obtain the cooling water disc, the copper layer is completely wrapped in the aluminum shell, the water tank cannot be blocked, and the manufactured cooling water disc is highin cooling efficiency and has high industrial application value.

Owner:宁波江丰芯创科技有限公司

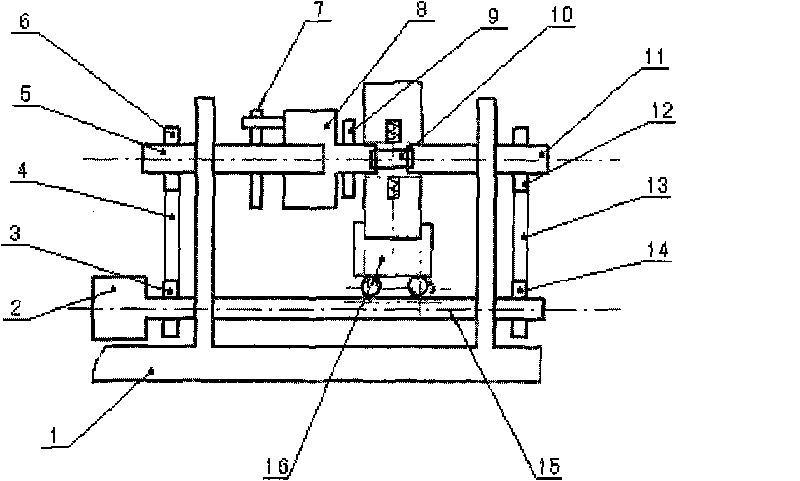

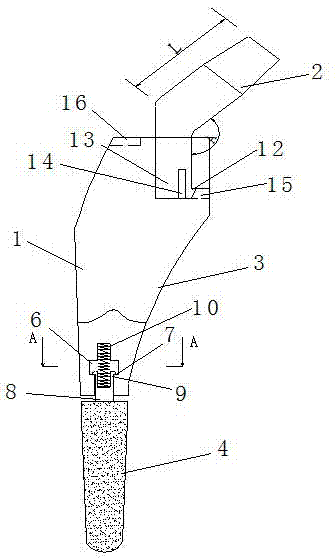

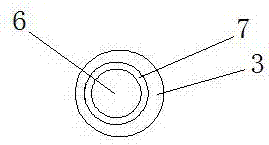

Three-dimensional lifting and pulling forming device

InactiveCN108465803AControl speedControl angular velocityMolten metal pouring equipmentsFiberThree dimensional shape

The invention discloses a three-dimensional lifting and pulling forming device. The three-dimensional lifting and pulling forming device comprises two triangular supporting frames. According to each triangular supporting frame, a triangle is formed through three sectional materials, and connecting angle components are arranged between the sectional materials. Each connecting angle component is provided with a belt wheel and a motor. Polished rods are arranged between every two adjacent connecting angle components. A belt is arranged between every two belt wheels of the connecting angle components. The polished rods are provided with tackle bases. The tackle bases are fixed to the belts. A material bucket is arranged at the center positions of the triangular supporting frames. A motion synthesizer is arranged above the material bucket. A guide-in bar is arranged at the lower portion of the motion synthesizer. Carbon fiber pipes are arranged between each tackle base and the motion synthesizer. Compared with the prior art, in the work process, the guide-in bar goes deep into the raw material fusion forming material bucket; according to the requirement, the temperature of the raw materials attached to the guide-in bar is accurately controlled to be at the phase change point; and meanwhile, the speed and the angular speed of the guide-in bar are accurately controlled for slow lifting and pulling, and accordingly the specific three-dimension shape is formed.

Owner:SOUTHEAST UNIV

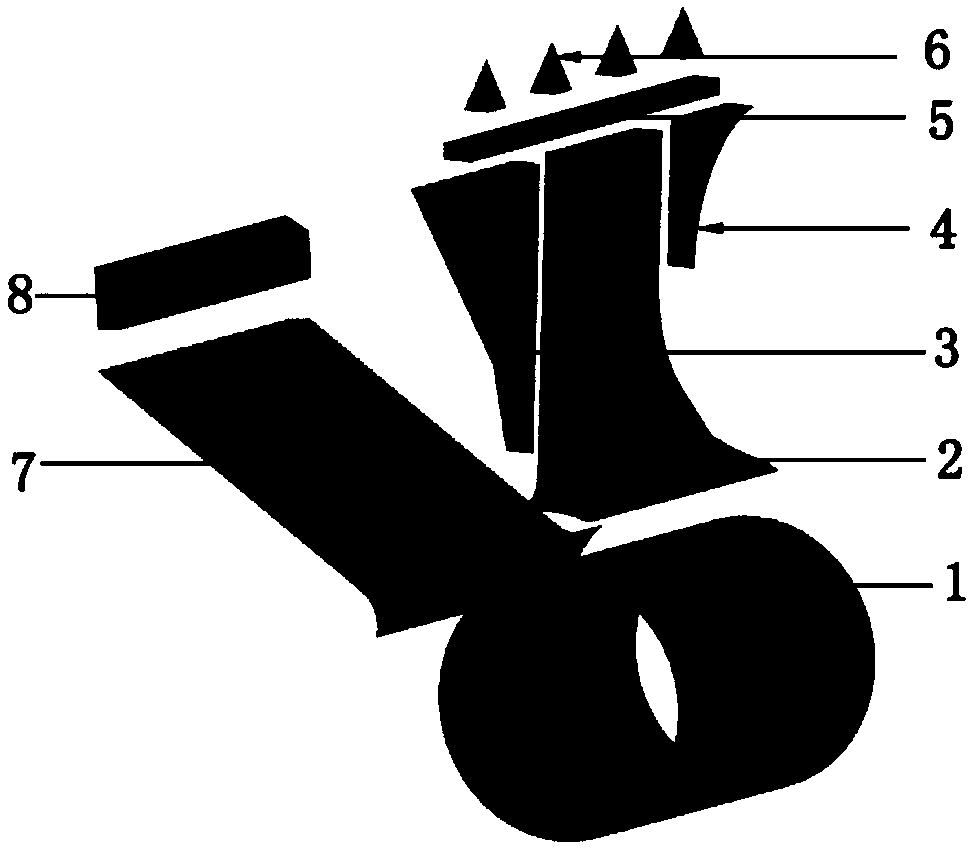

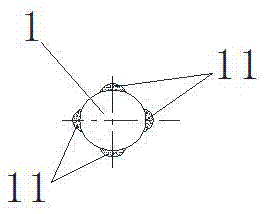

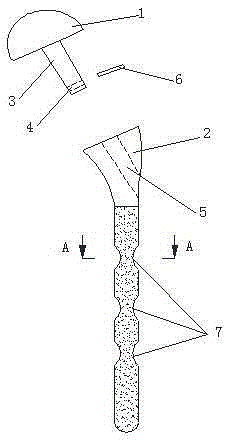

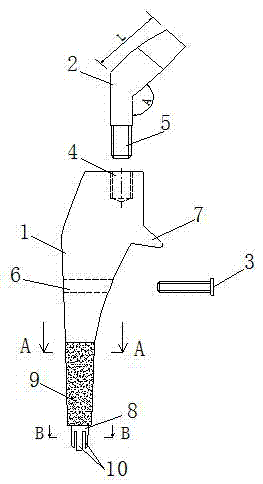

Hip joint replacement prosthesis

ActiveCN106913398AAvoid waste of failurePrevents sinking and spinningJoint implantsTissue regenerationFemoral stemFemoral neck

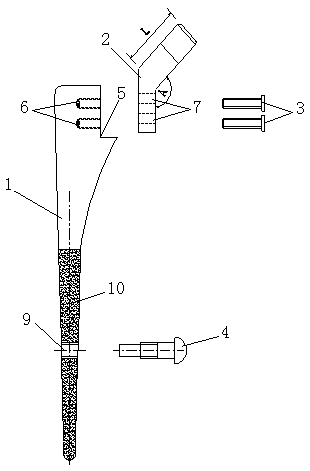

The invention relates to a hip joint replacement prosthesis. The hip joint replacement prosthesis comprises a femoral stem (1) and a femoral neck (2). The hip joint replacement prosthesis is characterized in that the tail end of the lower part of the femoral neck (2) is formed by two parts, one part is an elastic barb (4) and the other part is a cylindrical object (5), and an interval gap (6) is arranged between the elastic barb (4) and the cylindrical object (5). The head of the femoral stem (1) is internally provided with an L-shaped hole (7). The lower part of the femoral neck (2) is plugged in the L-shaped hole (7), and the elastic barb (4) is hooked and clamped in a horizontal hole (9) of the L-shaped hole (7). The surface of the lower part of the femoral stem (1) is attached with raised edges (11) made of a hierarchical porous material. The hip joint replacement prosthesis is reasonable in structure design, and has relatively high connection stability and biocompatibility after being implanted.

Owner:CHONGQING RUNZE PHARM CO LTD

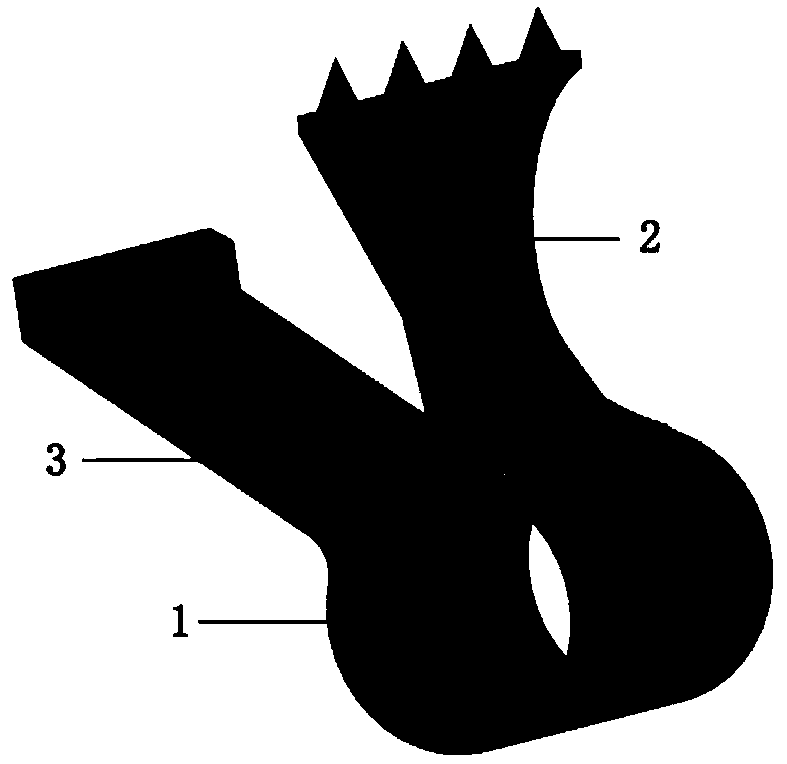

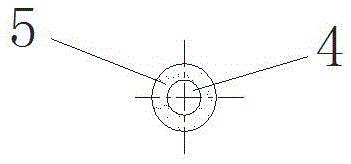

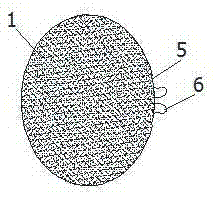

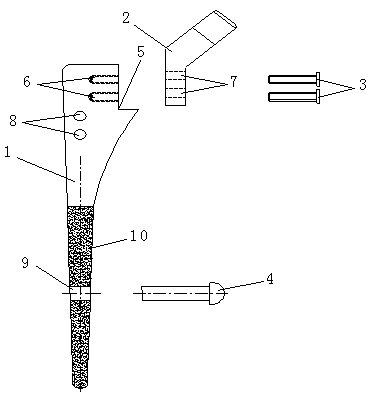

Artificial shoulder joint prosthesis

InactiveCN106880424AMeet a variety of functional needsLose weightJoint implantsShoulder jointsBiocompatibility TestingShoulder joint prosthesis

The invention relates to an artificial shoulder joint prosthesis. The artificial shoulder joint prosthesis comprises a humeral head (1) and a humeral handle (2), and is characterized in that a round hole (3) is arranged at the upper part of the humeral handle (2), wherein the lower handle body of the humeral handle (2) is composed of a body (4) and a coating layer (5) arranged at the outer layer of the body (4), and the coating layer (5) is made of a multi-level-hole material; through holes (6) are arranged in the handle body. The artificial shoulder joint prosthesis is reasonable in structural design, the selected materials are suitable and controllable and are uniform in height, after being implanted into the human body, the artificial shoulder joint prosthesis is high in connection stability and biocompatibility, and thus the postoperative quick recovery is facilitated.

Owner:CHONGQING RUNZE PHARM CO LTD

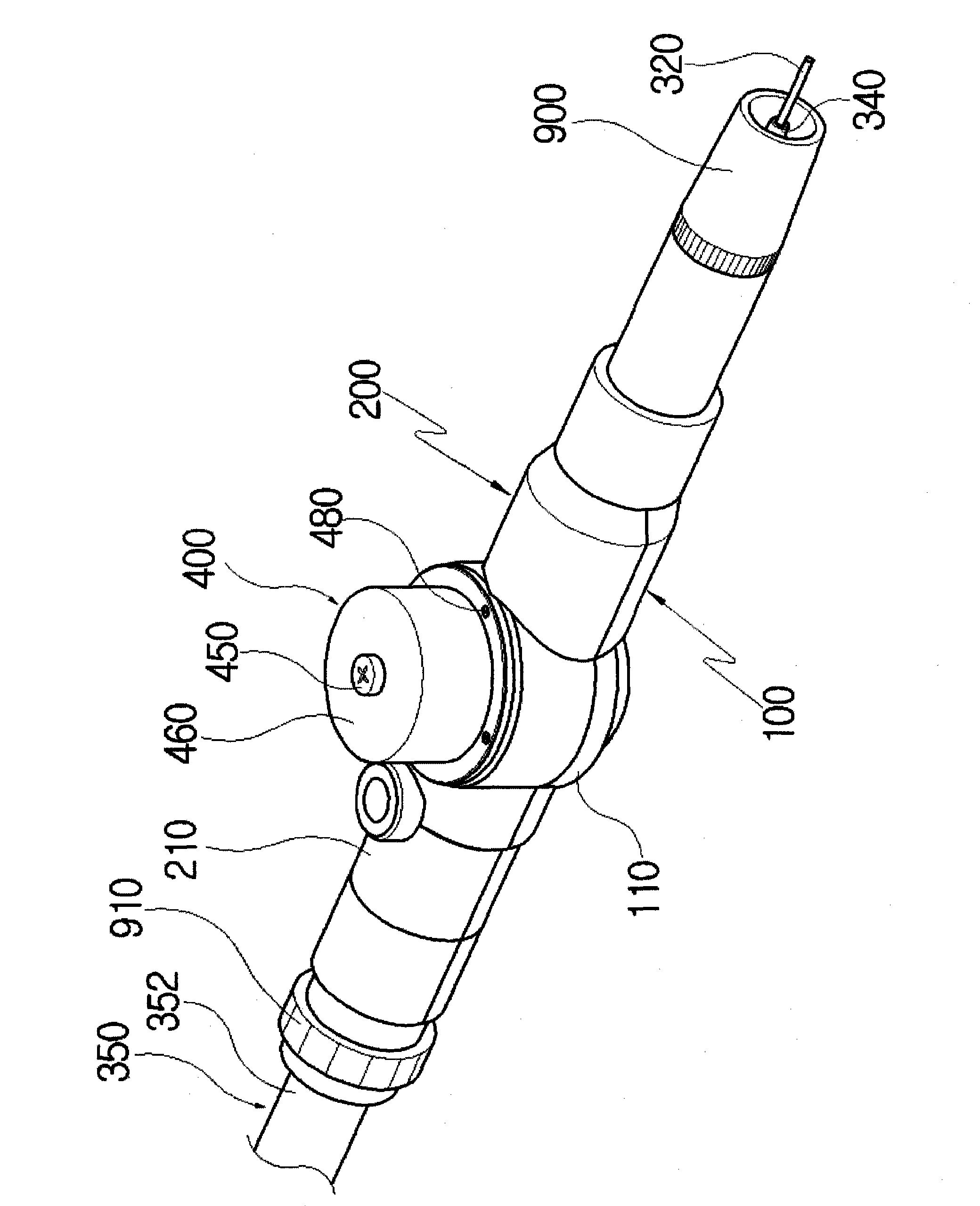

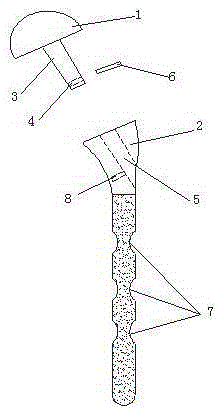

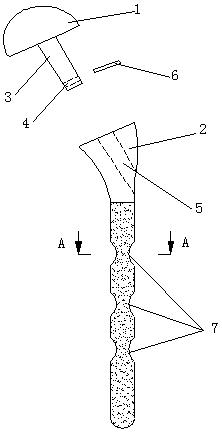

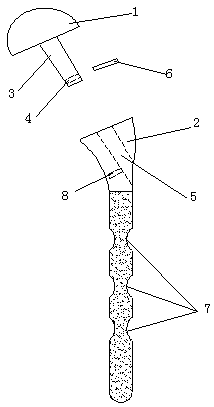

Buffer hip joint

ActiveCN106913399APrevent disengagementAvoid waste of failureJoint implantsFemoral headsFemoral stemBiocompatibility Testing

The invention relates to a buffer hip joint. The hip joint comprises a femoral stem (1) and a femoral neck (2). The hip joint is characterized in that the femoral stem (1) is divided in two parts of a near end (3) and a far end (4). The heat of the near end (3) is internally provided with an L-shaped hole (5). The lower part of the femoral neck (2) is plugged in the L-shaped hole (5). The lower part of the near end (3) is provided with an inner hole (6), and the inner hole (6) is internally provided with a step surface (7). The far end (4) is made of a hierarchical porous material. The head of the far end (4) is added with a connecting rod (8). The end of the connecting rod (8) is provided with an elastic barb (9). The connecting rod (8) is plugged in the inner hole (6), and the elastic barb (9) is hooked and clamped in the step surface (7) of the inner hole (6). The inner hole (6) is longer than the connecting rod (8). The hip joint is reasonable in structural design, and connection stability and biocompatibility are relatively high, and post-surgery healing effect is better and faster.

Owner:CHONGQING RUNZE PHARM CO LTD

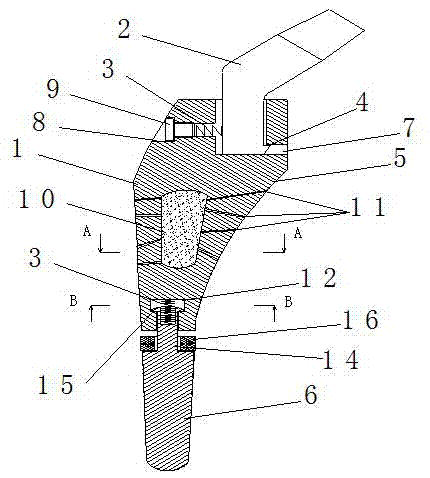

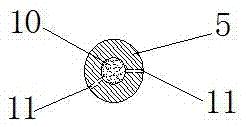

Biological type hip joint

ActiveCN106913395ARealize mutual connection and fixationAvoid failureJoint implantsFemoral headsCoxal jointFemoral stem

The invention relates to a biological type hip joint. The hip joint comprises a femoral stem (1) and a femoral neck (2). The hip joint is characterized in that the lower part of the femoral neck (2) is provided with a barb (4), the upper part of the femoral stem (1) is provided with an L-shaped hole (7), and an installing hole (8) communicated with a longitudinal hole in the L-shaped hole (7). The lower part of the femoral neck (2) is inserted into the L-shaped hole (7). The barb (4) is hooked and clamped in a horizontal hole in the L-shaped hole (7). The installing hole (8) is internally provided with a spring (3). One end of the spring (3) is abutted against the lower part of the femoral neck (2), and the outer side of the other end is provided with a screw rod (9) which is connected in the installing hole (8). The femoral stem (1) is provided with a filling interlayer (10) which passes through two sides of a stem body, and a hole (11) passing through the stem body and communicated with the filling interlayer (10). The filling interlayer (10) is made of a hierarchical porous material. The hip joint has relatively high connection stability and biocompatibility, and post-surgery healing effect is better.

Owner:CHONGQING RUNZE PHARM CO LTD

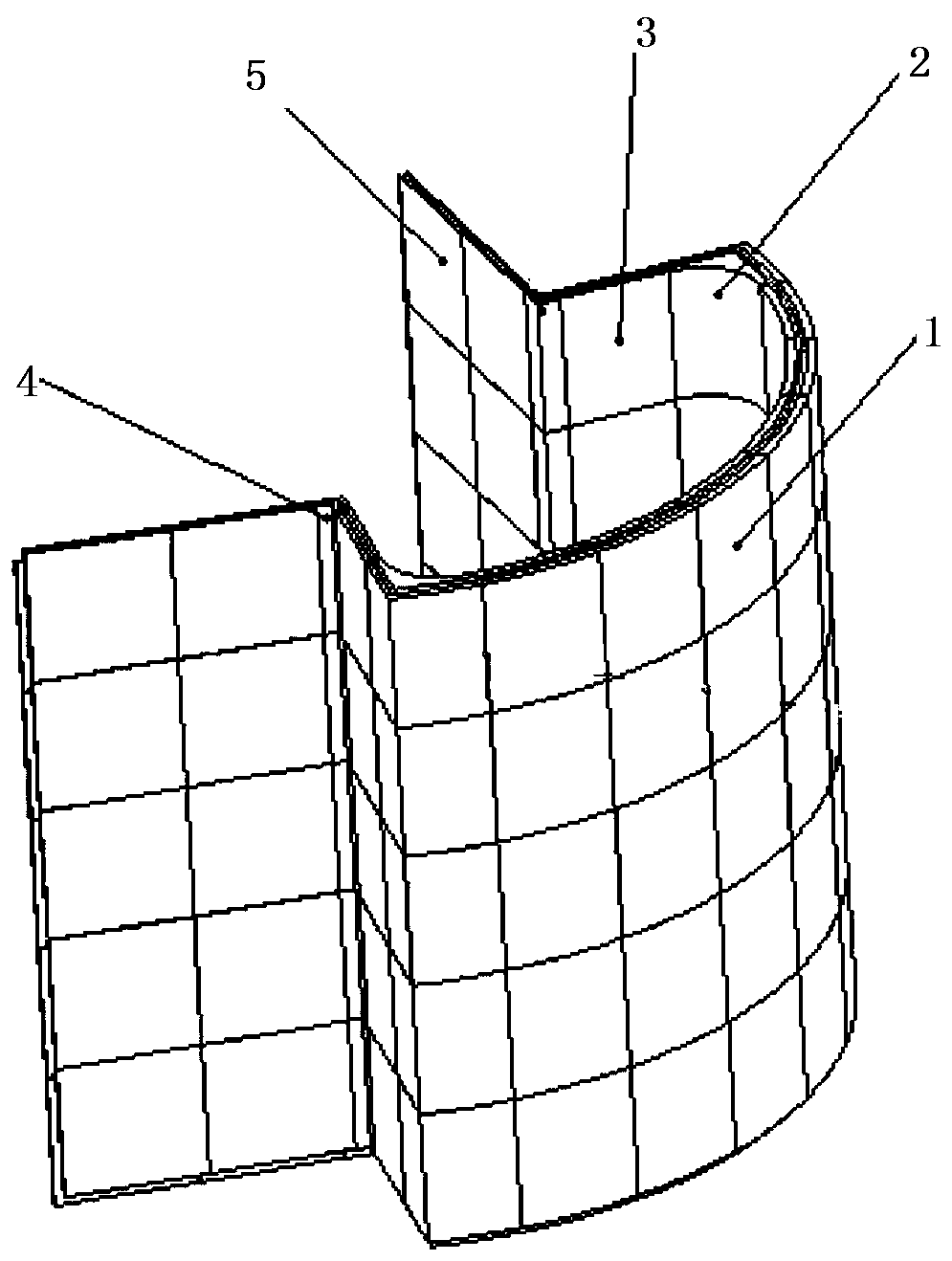

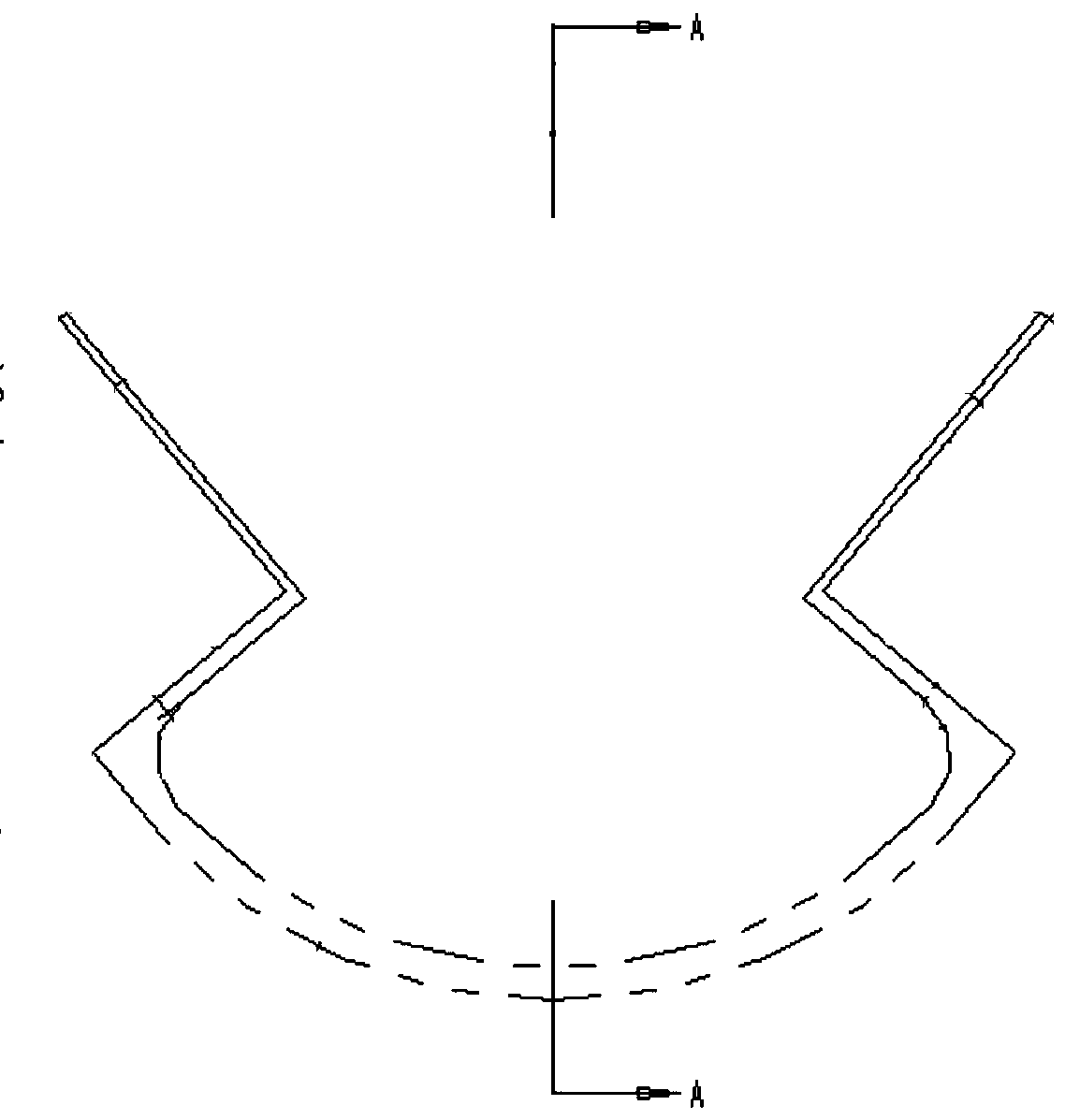

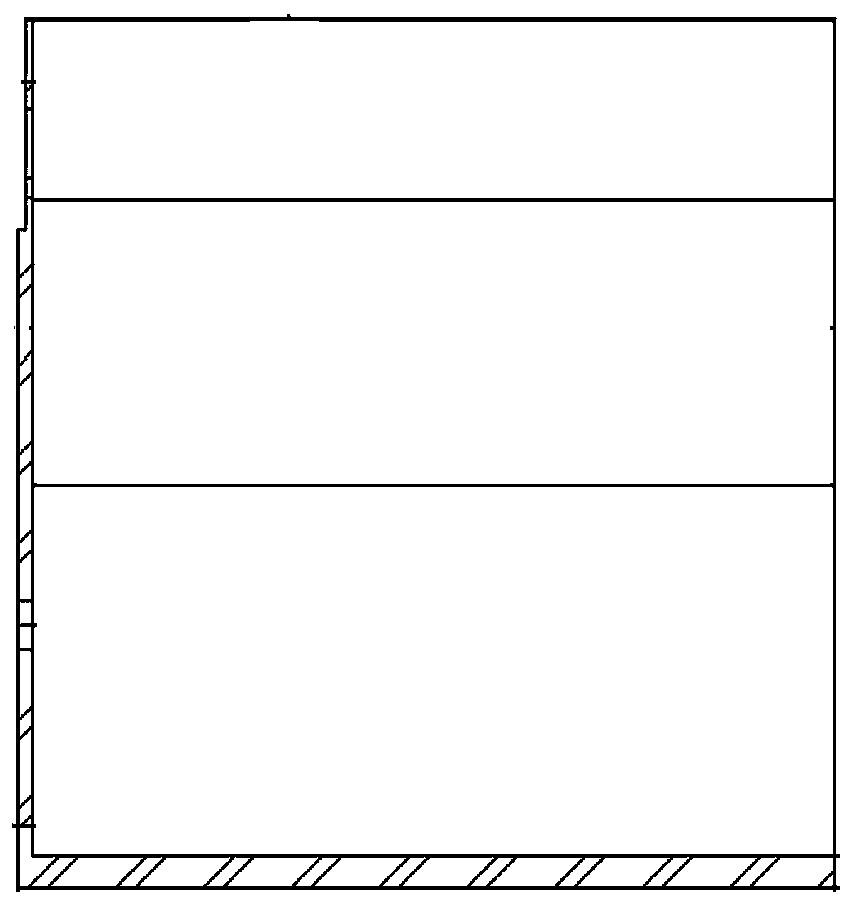

Combined insulating layer and manufacturing method thereof

ActiveCN108915896AGuaranteed compactnessShorten production timeRocket engine plantsAdhesiveSemi automatic

The invention discloses a combined heat insulating layer and a manufacturing method thereof, wherein the combined heat insulating layer comprises a plurality of spliced insulating layer units, whereinthe heat insulating layer units are spliced by using tongues and grooves, and an adhesive layer coats on the tongues and grooves; the heat insulating layer unit comprises a flat plate unit, an arc-shaped plate unit and a switching unit for connecting the insulating layer units with different thicknesses. The invention also relates to a manufacturing method of the combined heat insulating layer, which comprises the following steps of: firstly, forming a heat insulating layer unit by using a mould, coating the spliced part of the obtained heat insulating layer unit with adhesive, and finally assembling and curing at normal temperature to obtain the combined heat insulating layer. Compared with the prior art, the method greatly saves the manufacturing time, ensures the compactness of the inner part of the heat insulating layer by molding, and avoids internal defects caused by manual sticking, such as gas clamping, debonding, material shortage and the like, the structural integrity and reliability thereof are improved, and the conversion from manual to semi-automatic can be achieved.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

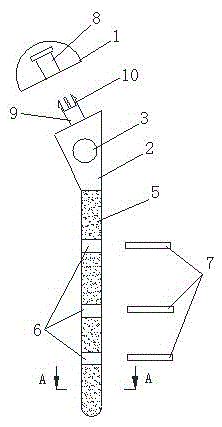

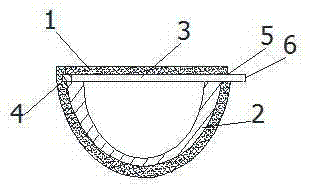

Shoulder joint prosthesis

ActiveCN106880422AMeet a variety of functional needsMeet functional requirementsJoint implantsShoulder jointsShoulder joint prosthesisBiocompatibility Testing

The invention relates to a shoulder joint prosthesis. The shoulder joint prosthesis comprises a humeral head (1) and a humeral stem (2). The shoulder joint prosthesis is characterized in that the humeral head (1) is of a hemispherical structure, and an inserting rod (3) is fixed to the end face of the humeral head; a through hole (4) is formed in the inserting hole (3); an inserting hole (5), which goes through in an oblique direction, is formed in the head part of the humeral stem (2); the inserting rod (3) is inserted into the inserting hole (5), and the part, where the through hole (4) is formed, of the inserting rod (3) extends out of the inserting hole (5); a nail (6) is matched in the through hole (4); a stem body of the humeral stem (2) is made from a multi-stage porous material; and arc-shaped grooves (7) are formed in the stem body. The shoulder joint prosthesis provided by the invention is simple and convenient in structural design, relatively high in overall connectivity and biocompatibility and is conducive to rapid recovery after operations.

Owner:CHONGQING RUNZE PHARM CO LTD

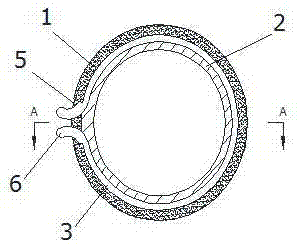

Bionic acetabular prosthesis

InactiveCN106923938AAvoid displacementPrevent looseningJoint implantsAcetabular cupsProsthesisBiocompatibility Testing

The invention relates to a bionic acetabular prosthesis. The bionic acetabular prosthesis comprises an acetabular cup (1) and a liner (2), and is characterized in that a clamping groove (4) is arranged in the inner surface of the rim of the acetabular cup (1), a spring clamping ring (3) is increased in the clamping groove (4), the liner (2) is placed in the acetabular cup (1), and the rim of the liner (2) pushes against the lower surface of the spring clamping ring (3); and the acetabular cup (1) is made of a hierarchical porous material. The bionic acetabular prosthesis is stable in structural connection and convenient to mount, and has relatively high biocompatibility.

Owner:CHONGQING RUNZE PHARM CO LTD

a shoulder prosthesis

ActiveCN106880422BMeet a variety of functional needsMeet functional requirementsJoint implantsShoulder jointsBiocompatibility TestingShoulder joint prosthesis

The invention relates to a shoulder joint prosthesis. The shoulder joint prosthesis comprises a humeral head (1) and a humeral stem (2). The shoulder joint prosthesis is characterized in that the humeral head (1) is of a hemispherical structure, and an inserting rod (3) is fixed to the end face of the humeral head; a through hole (4) is formed in the inserting hole (3); an inserting hole (5), which goes through in an oblique direction, is formed in the head part of the humeral stem (2); the inserting rod (3) is inserted into the inserting hole (5), and the part, where the through hole (4) is formed, of the inserting rod (3) extends out of the inserting hole (5); a nail (6) is matched in the through hole (4); a stem body of the humeral stem (2) is made from a multi-stage porous material; and arc-shaped grooves (7) are formed in the stem body. The shoulder joint prosthesis provided by the invention is simple and convenient in structural design, relatively high in overall connectivity and biocompatibility and is conducive to rapid recovery after operations.

Owner:CHONGQING RUNZE PHARM CO LTD

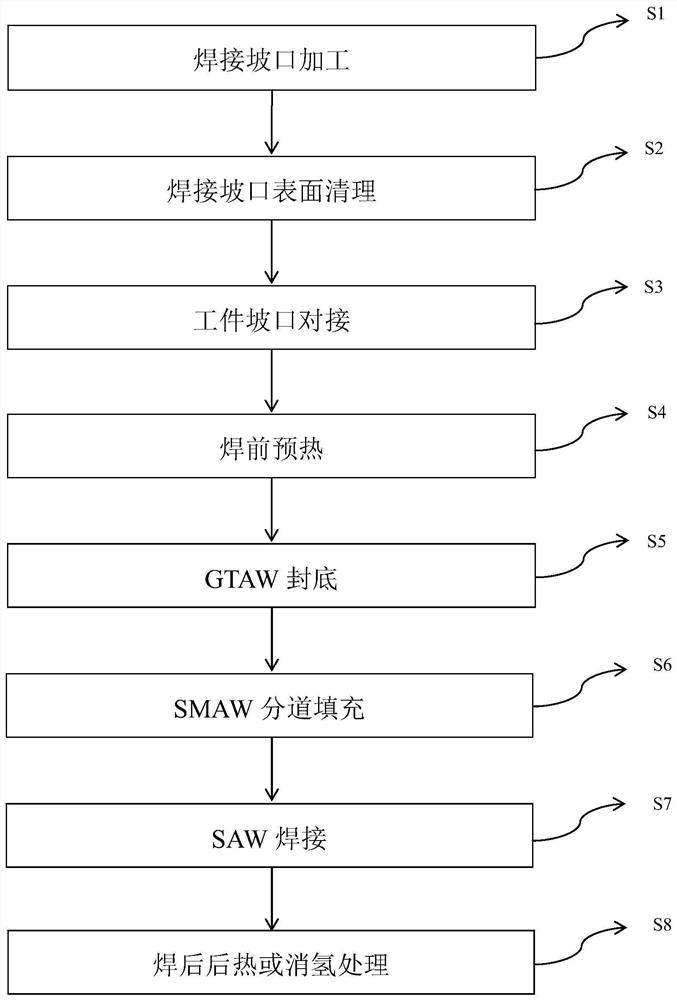

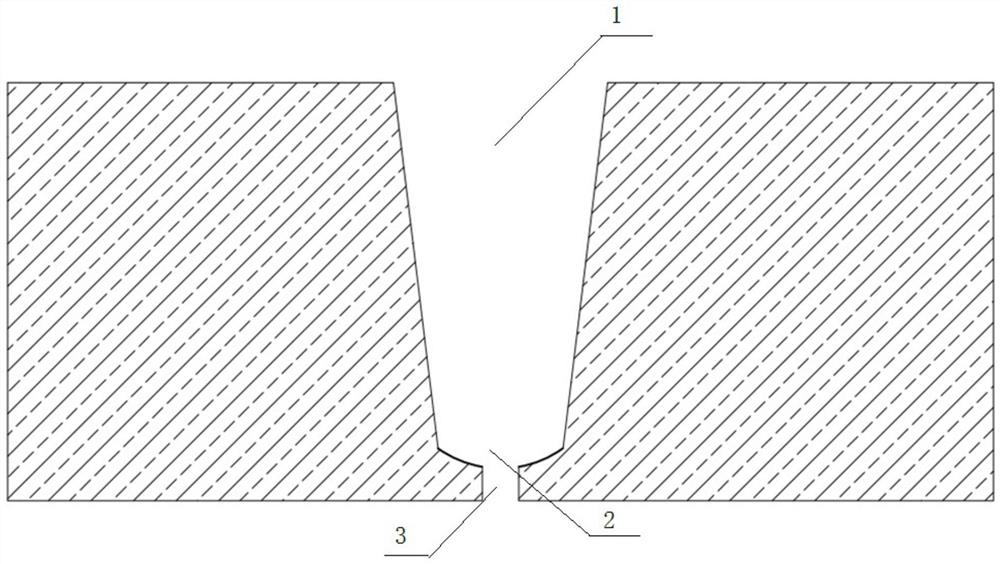

Girth welding process for thick-wall header and pipeline on power station boiler

ActiveCN113600971AImprove quality and efficiencyImprove welding efficiencyArc welding apparatusButt weldingPower station

The invention relates to a girth welding process, in particular to the girth welding process for a thick-wall header and a pipeline on a power station boiler. The girth welding process aims to solve the problems that the existing submerged arc welding is easy to break down when being used for welding the power station boiler header and pipeline with the diameter phi of 219 mm and the wall thickness of 20mm-55 mm, and the girth welding cannot be accurately and quickly finished by an automatic submerged arc welding method. According to the girth welding process, a series of problems existing in the girth welding process of a traditional power station boiler header and pipeline with the specification of phi 219 * 20mm-55 mm are solved through the eight procedures of welding groove machining, welding groove surface cleaning, workpiece groove butt joint, preheating before welding, argon arc welding bottom sealing, manual electric arc welding filling thickening, submerged arc welding and post-heating or hydrogen elimination treatment after welding, and the welding quality and the welding efficiency are improved. The girth welding process is mainly used for welding the thick-wall header and the pipeline on the power station boiler.

Owner:哈尔滨红光锅炉总厂有限责任公司

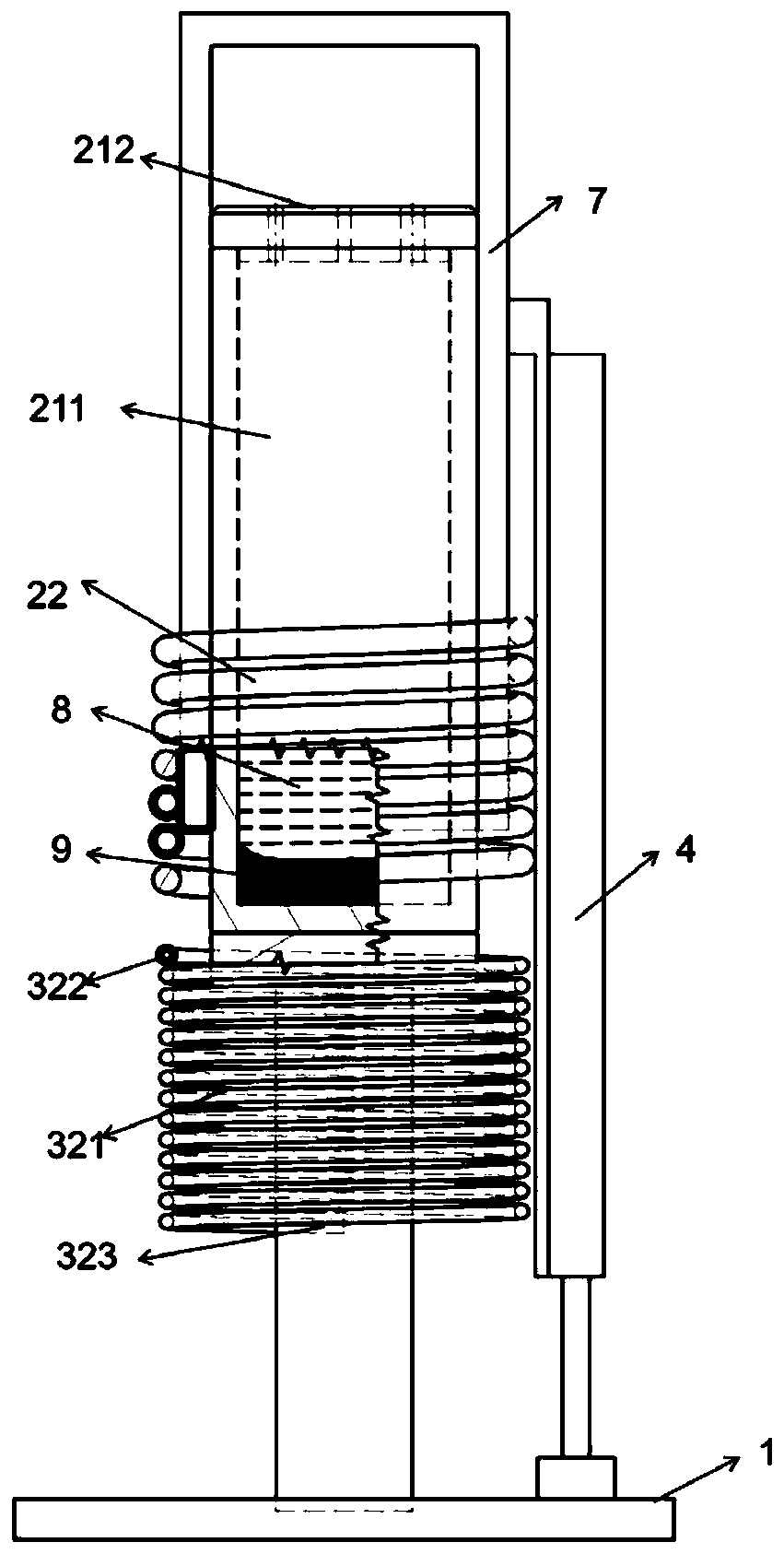

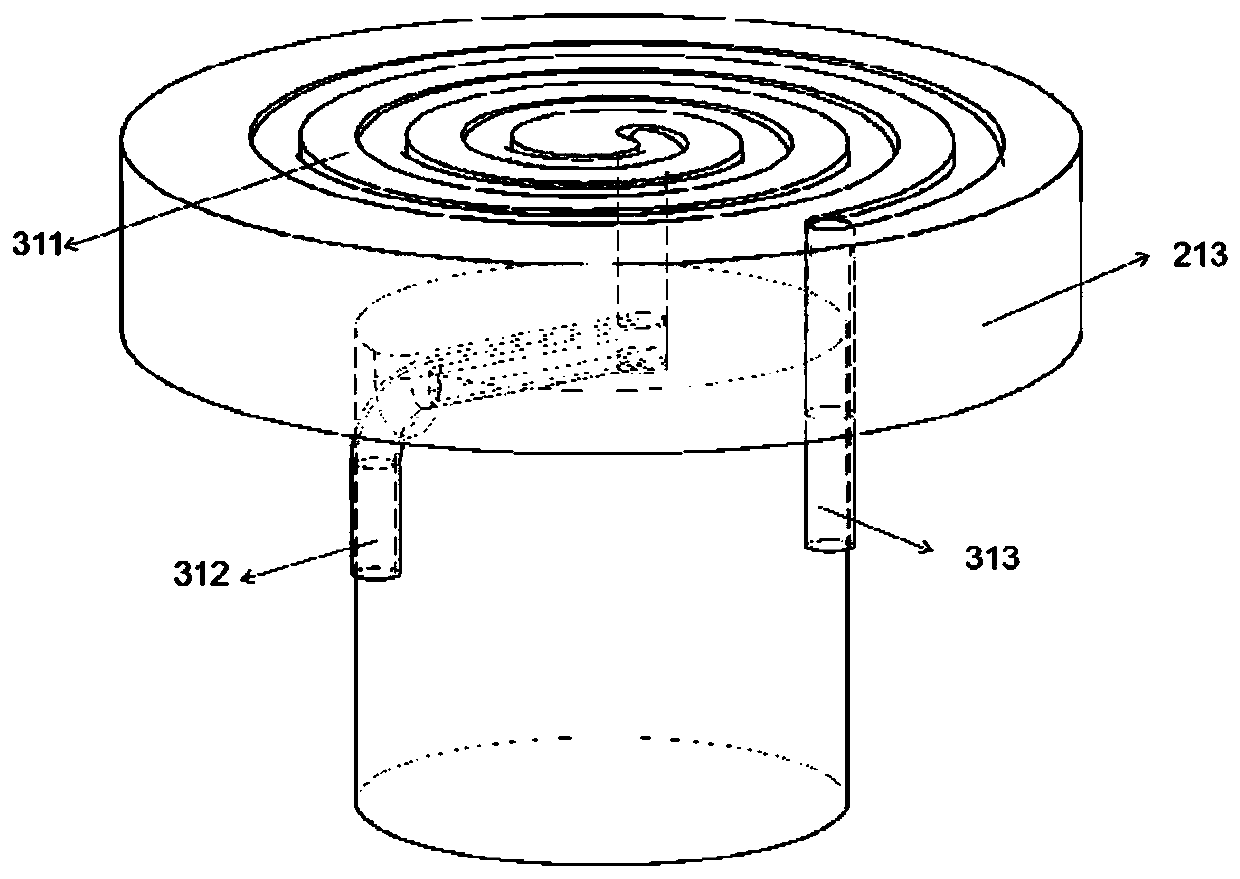

Production device and method of large oxygen-free copper ingot applied to target material

ActiveCN110629180AReduce defectsGuaranteed DensityVacuum evaporation coatingSputtering coatingHigh densityIntermediate frequency

The invention provides a production device for a large high-purity and high-density oxygen-free copper ingot applied to a target material. The device comprises a lifting mechanism, wherein in the production process of the oxygen-free copper ingot, after raw copper is melted, a lifting mechanism can drive an intermediate frequency coil, an insulating layer and an air cooling assembly to move upwards to realize directional solidification of copper liquid from bottom to top. In the solidification process of the copper liquid, as the cooling mechanism is located below a crucible assembly and the air cooling assembly moves slowly and evenly from bottom to top, the copper liquid starts to solidify from the bottom of a crucible, solid copper is located at the bottom of the crucible, uncooled liquid copper is located at the upper part, coexistence of solid and liquid is achieved, and liquid copper exists on the surface of the solid copper or the copper being solidified all the time; when defects such as holes are produced in the solid copper at the bottom, liquid copper at the upper part can be used for replenishment in time, and thus, the effect of feeding is achieved, internal defects ofthe copper ingot are reduced, density of the copper ingot is improved, and the obtained oxygen-free copper ingot has high purity, high density, large size and small defects.

Owner:河北冠靶科技有限公司

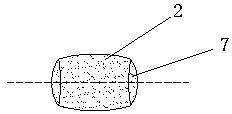

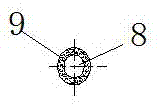

Simple hip joint

ActiveCN106913397APrevent disengagementAdapt to individual needsJoint implantsFemoral headsCoxal jointFemoral stem

The invention relates to a simple hip joint. The hip joint comprises a femoral stem (1) and a femoral neck (2). The hip joint is characterized in that the upper end face of the head of the femoral stem (1) is provided with an installing hole (4), and the tail end of the lower part of the femoral neck (2) is directly cooperated with the installing hole (4). The lower part of the femoral stem (1) is formed by a stem body (8) and an annular jacket layer (9) which is attached on the outer surface of the stem body (8). The annular jacket layer (9) is made of a hierarchical porous material. The tail end of the stem body on the lower part of the femoral stem (1) extends out of the annular jacket layer (9), and the tail end of the stem body is provided with a discontinuous annular workpiece (10) which is coaxial with the femoral stem (1). The hip joint is simple in structural design, and has relatively high biocompatibility, and connection is stable after implantation, and post-surgery healing effect is better and faster.

Owner:CHONGQING RUNZE PHARM CO LTD

a hip prosthesis

ActiveCN106880419BMeet a variety of functional needsMeet functional requirementsJoint implantsFemoral headsBiocompatibility TestingFemoral stem

The invention relates to a hip prosthesis. The hip prosthesis comprises a femoral stem (1) and a femoral neck (2). The hip prosthesis is characterized by further comprising connecting nails (3) and a fastening inserting rod (4), wherein an L-shaped cross section (5) is arranged on the head part of the femoral stem (1), and threaded holes (6) are formed in the longitudinal surface of the L-shaped cross section (5); through holes (7) are formed in the lower side of the femoral neck (2); the connecting nails (3) run through the through holes (7) and are in matched connection to the threaded holes (6); a hole (9) is formed in a stem body of the femoral stem (1); the fastening inserting rod (4) is matched in the hole (9); and a stem body lower part (10) of the femoral stem (1) is made from a multi-stage porous material. The hip prosthesis provided by the invention is simple and convenient in design and is relatively high in overall connectivity, connecting stability and biocompatibility; and the hip prosthesis can facilitate the efficient implementation of an implanting operation.

Owner:CHONGQING RUNZE PHARM CO LTD

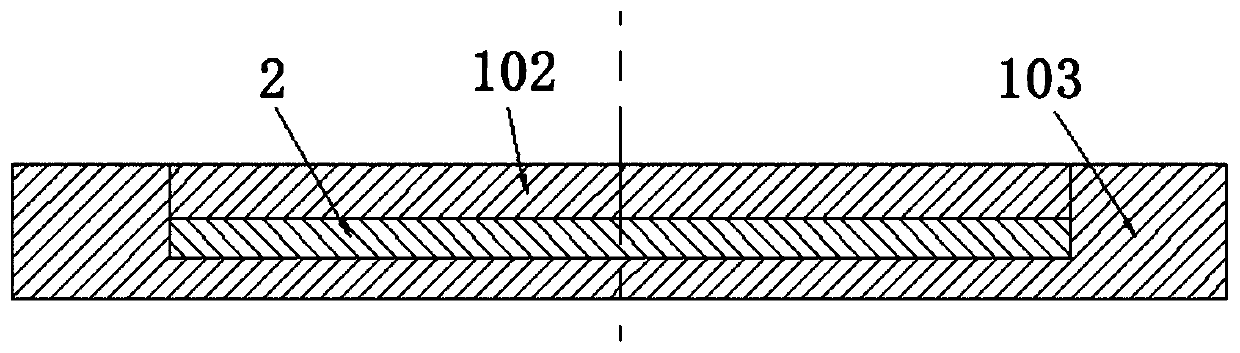

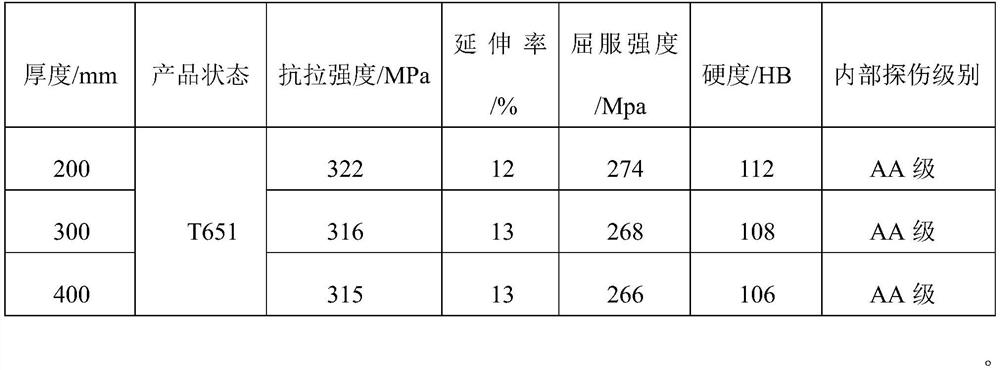

Super-thick aluminum alloy quenched plate and preparation method thereof

The invention discloses a super-thick aluminum alloy quenched plate and a preparation method thereof. The aluminum alloy quenched plate comprises the following alloy elements in percentage by mass: less than or equal to 0.25% of Si, less than or equal to 0.3% of Fe, 0.23-0.28% of Cu, less than or equal to 0.1% of Mn, 1.0-1.15% of Mg, 0.19-0.23% of Cr, less than or equal to 0.01% of Zn, 0.02-0.03% of Ti and the balance of Al. Raw materials of an aluminum ingot, Al-Cu75, a pure magnesium ingot, Al-Cr75, a Zn alloy ingot and 5Ti-1B are sequentially subjected to smelting, refining, casting, head sawing, surface milling, soaking treatment, hot rolling, quenching and aging treatment procedures, and the super-thick aluminum alloy quenched plate is prepared. The obtained product has good tensile strength, yield strength, hardness and ductility, and therefore the high strength, high hardness, impact resistance and other performance of the aluminum alloy super-thick plate are effectively improved.

Owner:河南泰鸿新材料有限公司

3D printing method of low melting point metal fused deposition based on continuous fiber pulling

ActiveCN106041087BHigh resolutionHigh precisionAdditive manufacturing apparatusImage resolutionLiquid metal

The low melting point metal fused deposition 3D printing method based on continuous fiber traction uses continuous fiber filaments as the traction line for liquid metal extrusion deposition, so that the liquid metal is attached to the continuous fiber filaments and continuously extruded following the continuous fiber filaments, avoiding metal The formation of large droplets greatly improves the printing resolution; at the same time, during the deposition and solidification process, the continuous fiber filaments can bind the diffusion of liquid metal, thereby improving the precision of the parts, avoiding excessive structural defects, and improving the printing quality to a certain extent. The mechanical properties and functionality of parts, thus promoting the development and application of metal 3D printing technology.

Owner:XI AN JIAOTONG UNIV

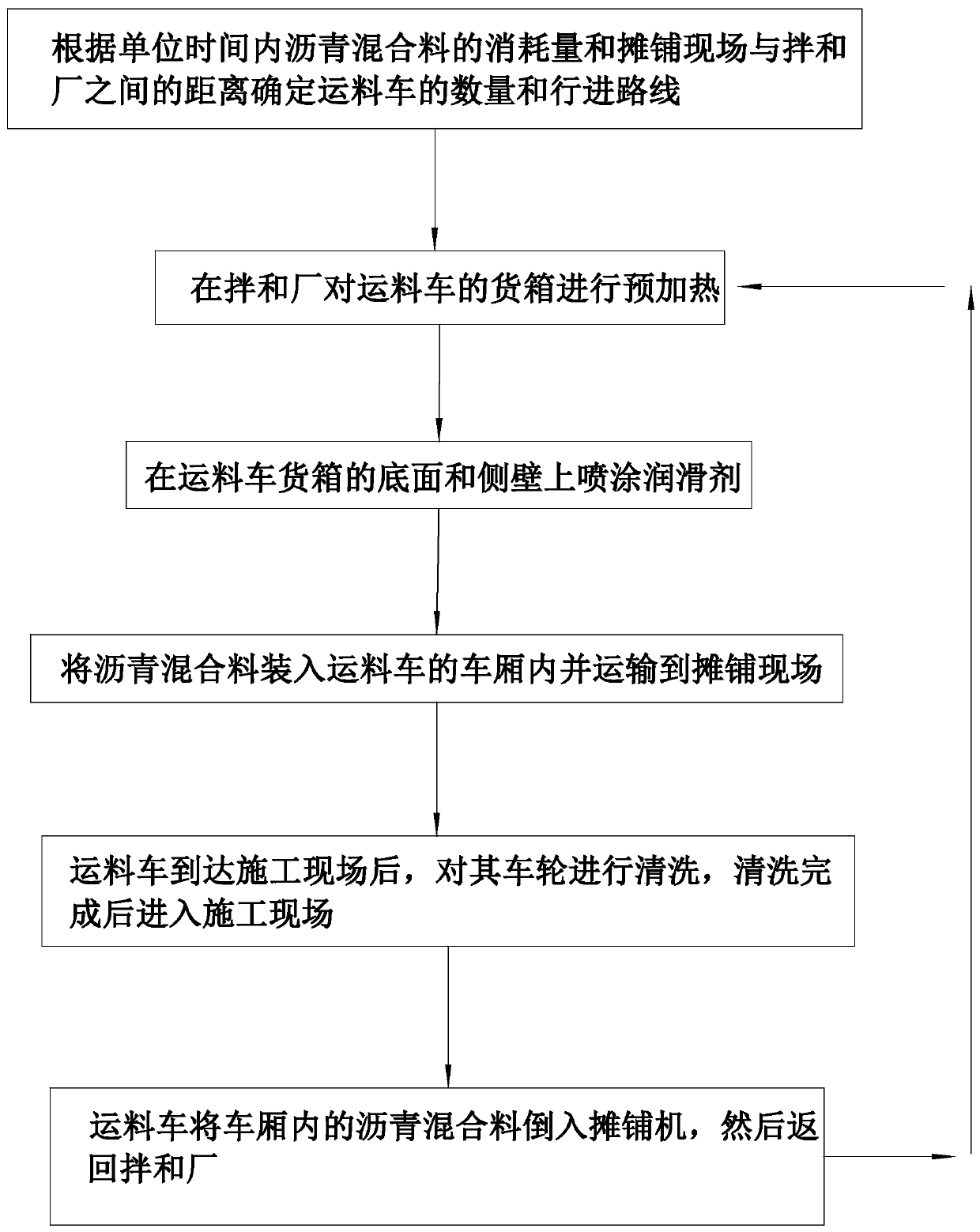

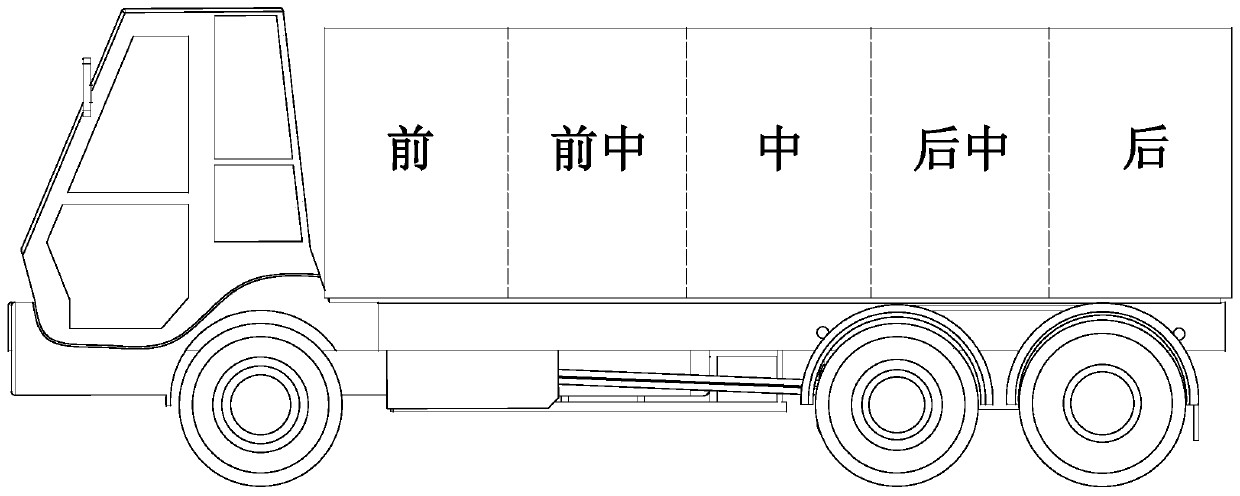

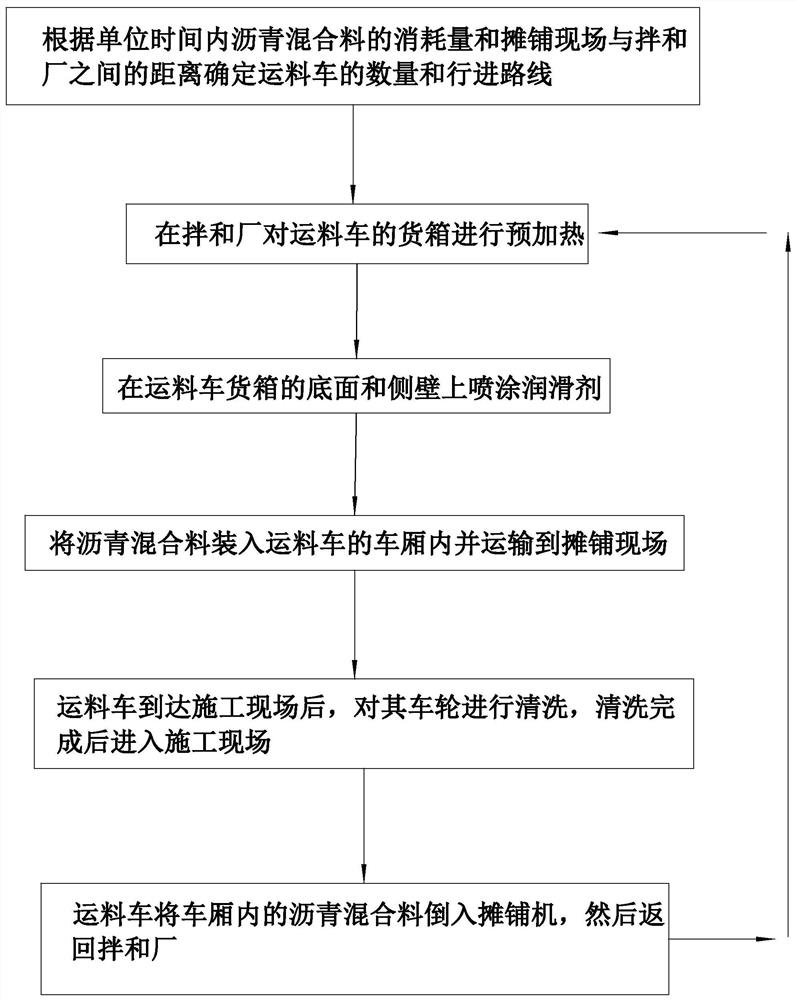

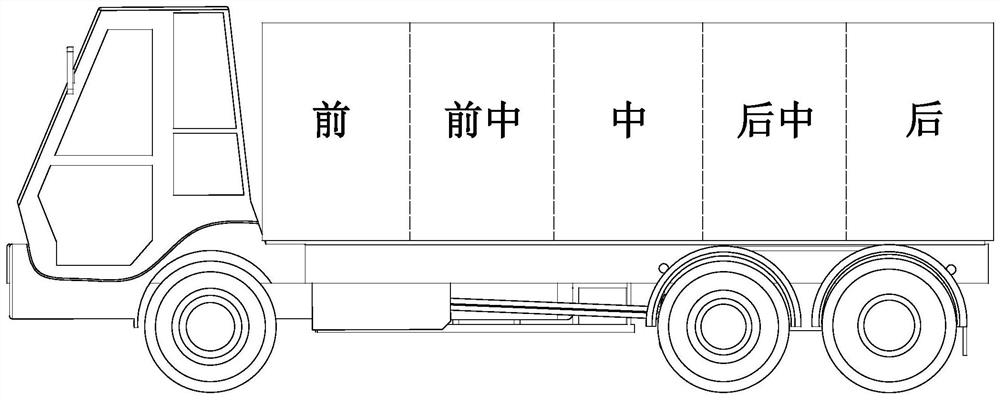

Asphalt mixture transportation method for expressway

The invention discloses an asphalt mixture transportation method for an expressway. The asphalt mixture transportation method comprises the steps that the number of material transportation vehicles iscalculated, an advance route is determined, the material transportation vehicles are preheated, lubricant is sprayed, vehicles are loaded, heat preservation is conducted, transportation is conducted,and cleaning is conducted, the number of the material transportation vehicles is determined according to production capacity, transport time, consumption and the like of a mixing plant, safety reserve vehicles are increased, and occurrence of material stopping of paving is avoided. Material transportation vehicle pre-heating, lubricant spraying, heat preservation and other measures can minimize probability of segregation of an asphalt mixture, and the effects of improving the quality of asphalt pavement, prolonging the service life of the pavement, and lowering the cost of later maintenance are realized.

Owner:河北交规院瑞志交通技术咨询有限公司

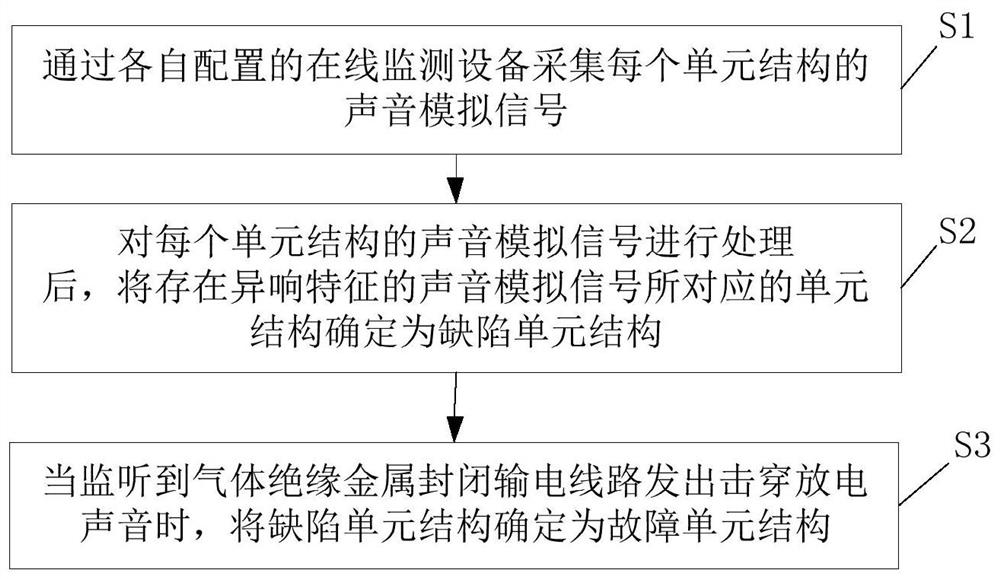

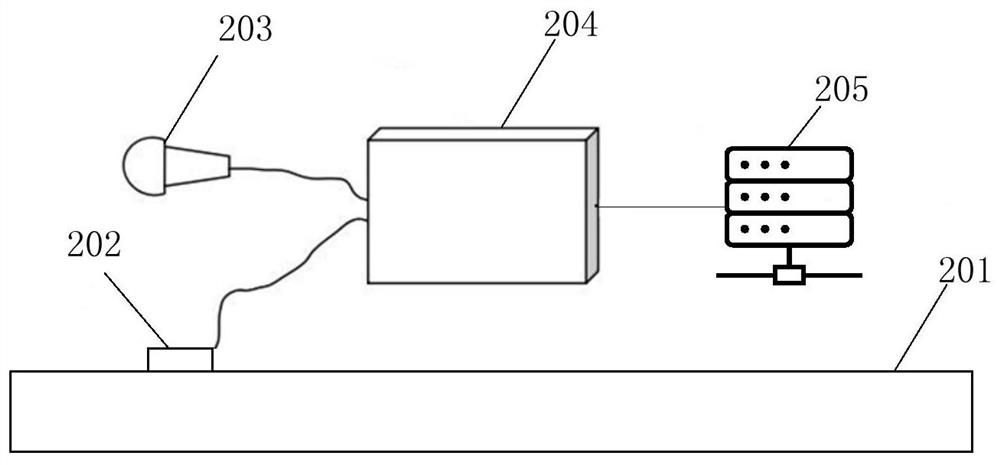

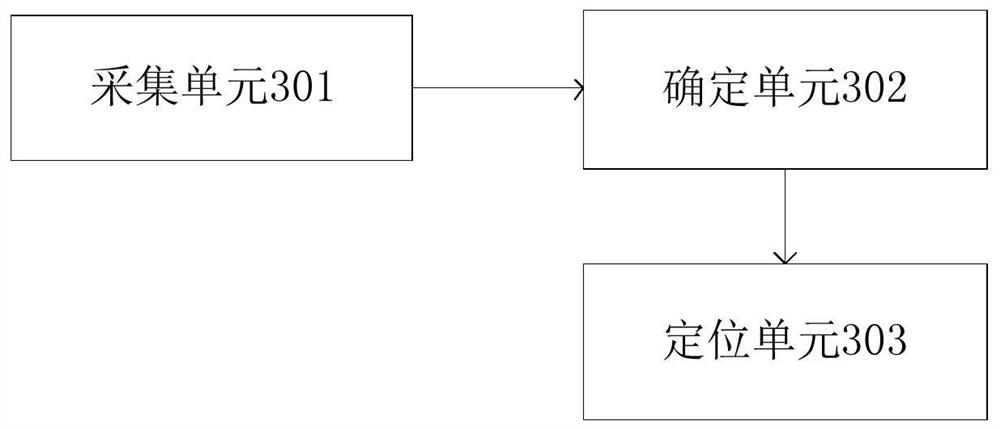

Fault positioning method and device for gas-insulated metal-enclosed power transmission line

ActiveCN112578230AQuick fixAccurately determineFault location by conductor typesTesting using acoustic measurementsAnalog signalMechanical engineering

The invention discloses a fault positioning method and device for a gas-insulated metal-enclosed power transmission line. The fault positioning method comprises the steps of monitoring each unit structure of the gas-insulated metal-enclosed power transmission line in real time through online monitoring equipment, capturing a sound analog signal with an abnormal sound feature, and determining a defect unit structure with an abnormal sound. According to the fault positioning method and the device, the internal defects are prevented from being further developed, and when the gas-insulated metal-enclosed power transmission line is broken down, the broken-down fault unit structure is quickly and accurately determined according to the defect unit structure, so that the fault is more sensitivelypositioned.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

Colored pencil lead with high flexural strength and preparation method thereof

The invention discloses a colored pencil lead with high flexural strength and a preparation method thereof, and belongs to the technical field of pencil lead manufacturing. The preparation method comprises the following steps: dissolving and stirring 25-30 parts by mass of cellulose nitrate in a reaction kettle by using a solvent, adding 25-30 parts by mass of whiskers, 15-20 parts by mass of a lubricant, 5-10 parts by mass of wax and 13-17 parts by mass of toner, uniformly stirring, immediately adding 1-3 parts by mass of a dispersant, stirring for a period of time, adding 1-3 parts by mass of a plasticizer, continuously stirring, removing most of the solvent, and carrying out roller milling, rod beating, core extrusion, straightening, drying and end cutting to obtain a finished product. And the colored pencil lead with excellent performance is obtained. The colored pencil lead prepared by the method has the characteristics of high flexural strength, good coloring degree, high writing lubricity and the like, and multi-specification large-scale production can be realized without purchasing new equipment in the preparation process.

Owner:SHAANXI UNIV OF SCI & TECH

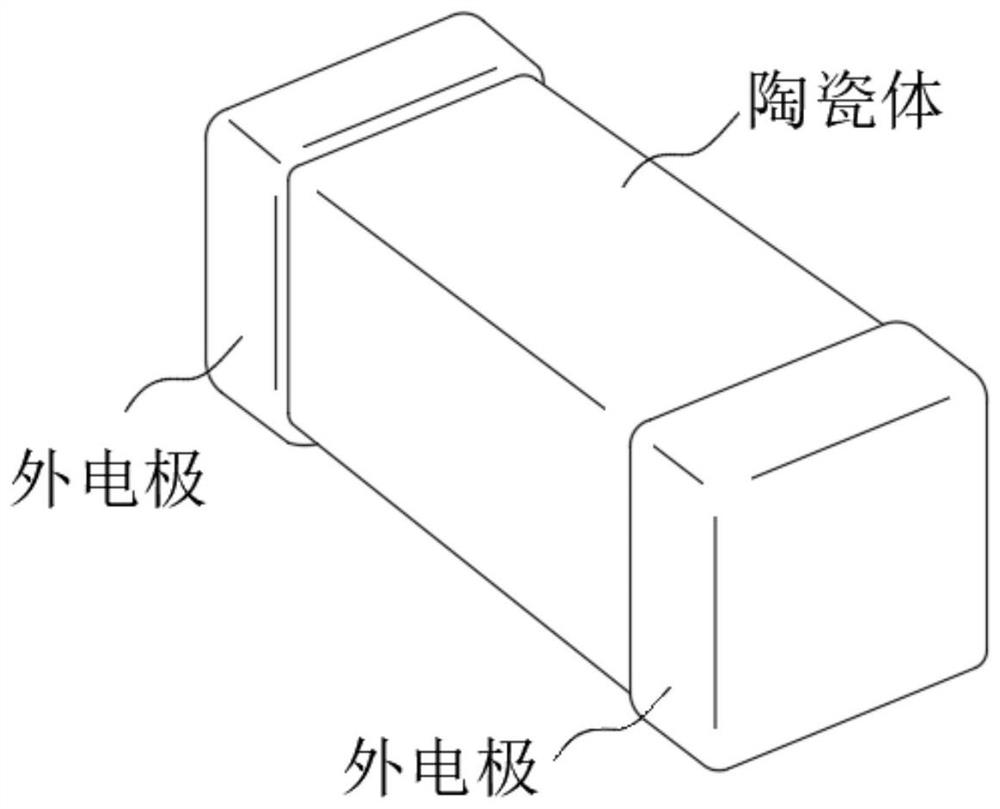

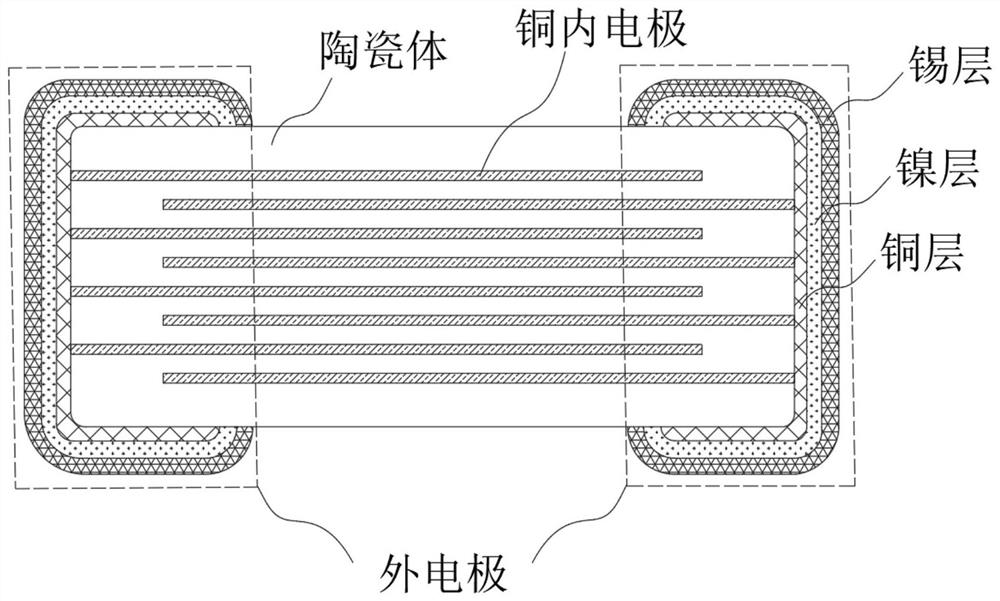

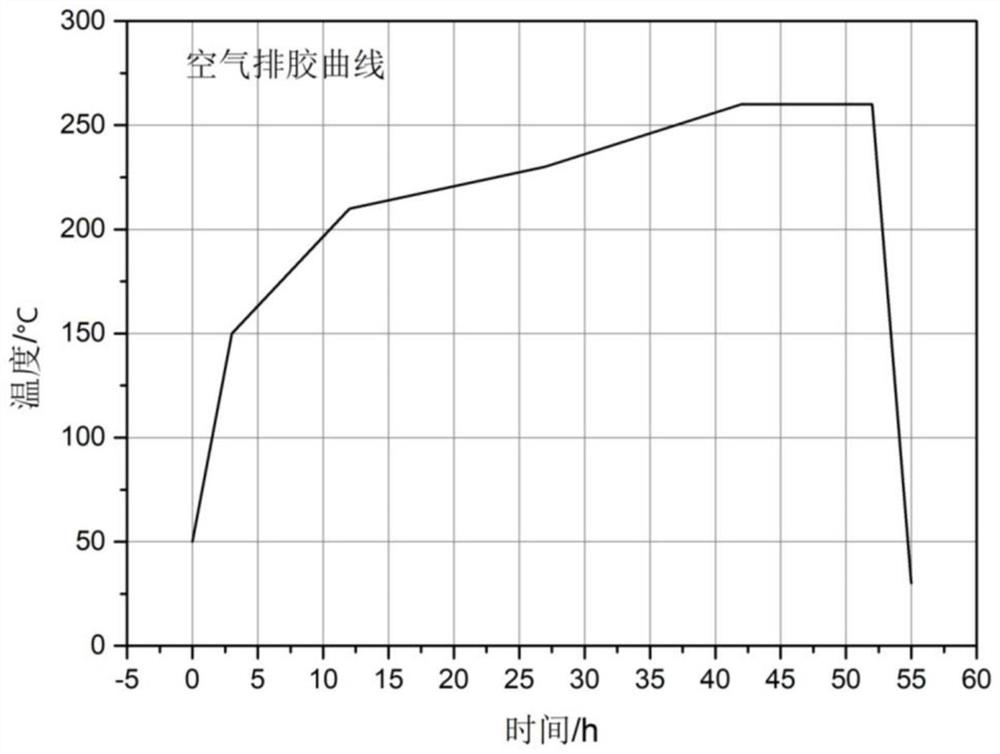

Preparation method of radio frequency chip type multilayer ceramic capacitor

InactiveCN111933451ASolve the problem of high lossAvoid internal defectsFixed capacitor electrodesFixed capacitor dielectricDielectricCeramic capacitor

The invention discloses a preparation method of a radio frequency chip type multilayer ceramic capacitor. The preparation method comprises the following steps: S1, carrying out tape casting on high-frequency ceramic slurry to form a ceramic medium; S2, printing copper electrode slurry on the ceramic medium to prepare a laminated body; S3, removing glue from a ceramic medium film in air at the temperature of 450 DEG C or below, grinding the ceramic dielectric film into powder, and sintering the powder to obtain film powder; S4, discharging glue from the laminated body, scattering a layer of uniform film powder to the bottom and the surface of the laminated body during glue discharging, and the glue discharging mode being air glue discharging or nitrogen glue discharging; S5, sequentially sintering and chamfering the laminated body to obtain the radio frequency ceramic chip; and S6, coating the two ends of the radio frequency ceramic chip with Cu external electrode slurry, then burning the end, and carrying out electroplating to manufacture an external electrode, thereby obtaining the radio frequency chip type multilayer ceramic capacitor. According to the invention, the problem thatan existing nickel electrode sheet type multilayer ceramic capacitor cannot meet the performance requirement of working at a higher frequency is solved, and the problem that the cost is high becausethe silver / palladium sheet type multilayer ceramic capacitor adopts noble metal materials as the inner electrode and the end electrode is solved.

Owner:四川华瓷科技有限公司

The method of sic/graphene oxide composite modified epoxy resin

ActiveCN108659467BGuaranteed nanoscale dispersionAvoid reunionHeat-exchange elementsEpoxyPolymer science

The invention relates to a method for preparing SiC / graphene oxide composite modified epoxy resin. The method specifically comprises the following processes: adding nano SiC and a silane coupling agent into an aqueous graphene oxide dispersion for ultrasonic treatment; then replacing moisture in a system with an epoxy active diluent; mixing an obtained mixture with epoxy resin and a processing aid; and curing and molding to obtain an SiC / graphene oxide modified epoxy resin composite. After treatment, SiC and graphene oxide achieves nanoscale uniform dispersion in an epoxy resin matrix and forms a heat conducting network; and since SiC and graphene oxide have relatively high heat conductivity, the two fillers are collocated to significantly improve the heat conductivity of the epoxy resin.

Owner:WUHAN UNIV OF TECH

A method of transporting asphalt mixture for expressways

The invention discloses a method for transporting asphalt mixture for expressway, which comprises the steps of counting the number of transport vehicles, determining the traveling route, preheating the transport vehicles, spraying lubricant, loading, heat preservation, transportation, cleaning and the like. The number of transport vehicles is determined according to the production capacity, transportation time and consumption of the mixing plant, and additional safety reserve vehicles can avoid paving material breakage. Measures such as preheating of the transport vehicle, spraying lubricant and heat preservation can minimize the probability of segregation of the asphalt mixture, improve the quality of the asphalt mixture, improve the quality of the asphalt pavement, prolong the service life of the pavement and reduce the maintenance cost in the later period effect.

Owner:河北交规院瑞志交通技术咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com