Girth welding process for thick-wall header and pipeline on power station boiler

A technology for power station boilers and circumferential seam welding, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as breakdown, and achieve the effect of reducing internal stress, avoiding internal defects, and reducing physical harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

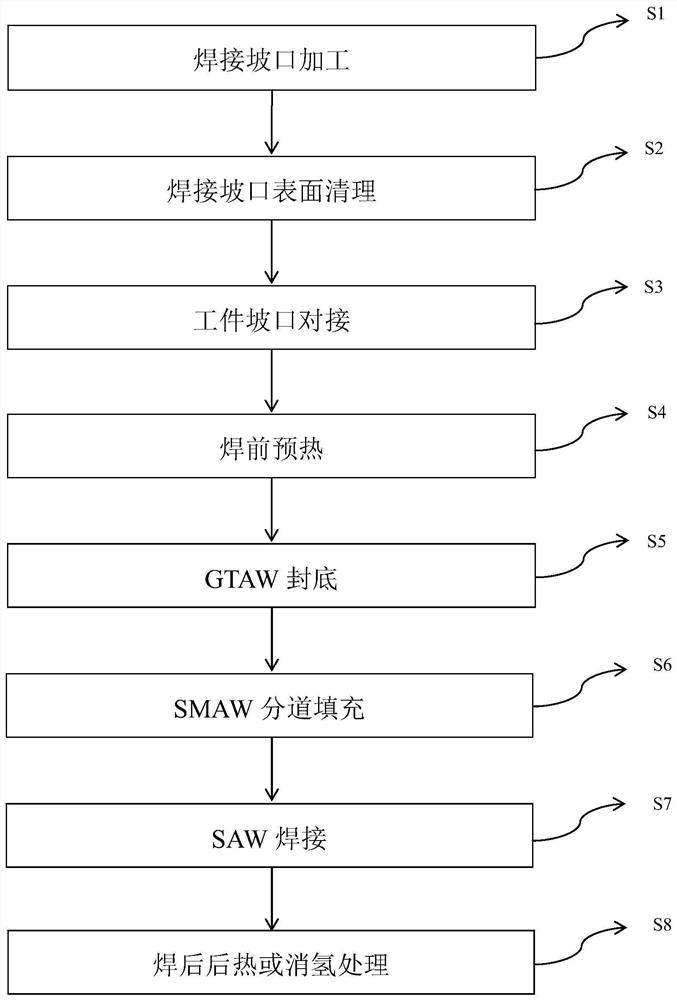

[0054] Embodiment 1: Taking a pipe whose parent material is 12Cr1MoVG, whose specification is 219 mm in diameter, and whose pipe wall thickness is 45 mm as an example, the girth welding process of the invention will be described in detail, and the process flow is as follows:

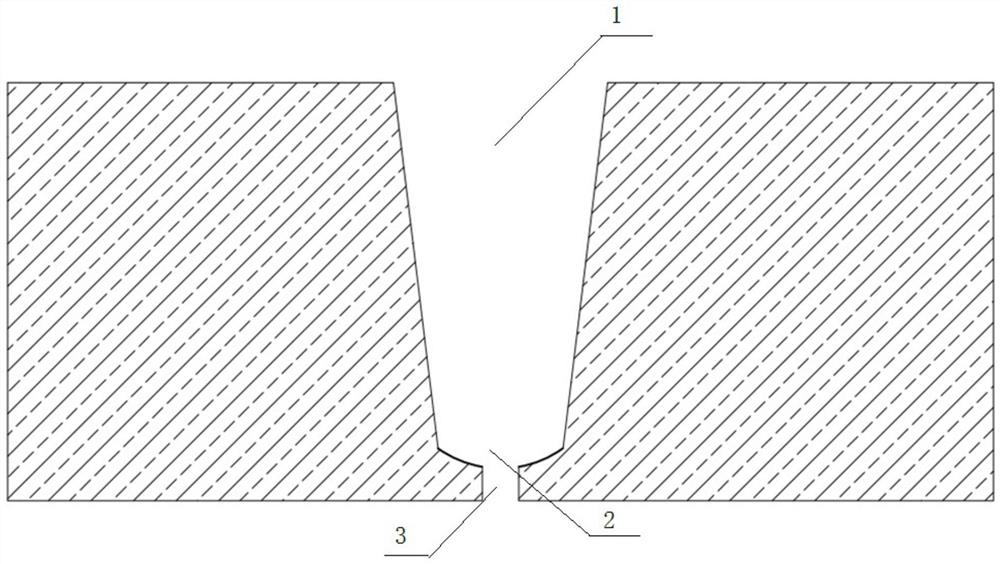

[0055] S1. Welding groove treatment: UV groove processing is performed on the opposite end faces of the two pipes to be welded. The slope of the processed V-shaped groove is 10°, and the arc-shaped slope of the U-shaped groove is The radius of the face is 5mm, and the height of the vertical face of the blunt edge is 2.5mm;

[0056] S2. Cleaning of the surface of the welding groove: use a grinder and a wire brush to remove residual dirt such as rust on the surface of the welding groove and the area extending 20mm to both sides of the welding groove, and use flame heating to clean the welding groove Dry the oil and moisture on the surface;

[0057] S3. Workpiece groove butt joint: Align the two workpieces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com