Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

299 results about "Down-the-hole drill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A down-the-hole drill, usually called DTH by most professionals, is basically a mini jackhammer screwed on the bottom of a drill string. The fast hammer action breaks hard rock into small flakes and dust and is blown clear by the air exhaust from the DTH hammer. The DTH hammer is one of the fastest ways to drill hard rock. Now smaller portable drillcat drilling rigs with DTH hammers can drill as fast as much larger truck rigs with this newer technology. The system is thought to have been invented independently by Stenuick Frères in Belgium and Ingersoll Rand in the USA in the mid-1950s.

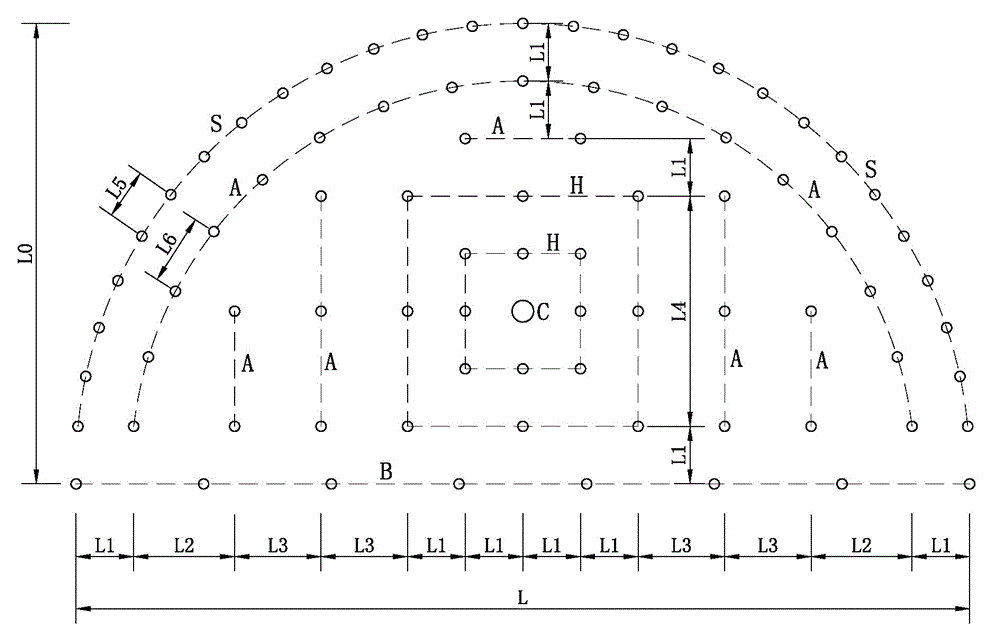

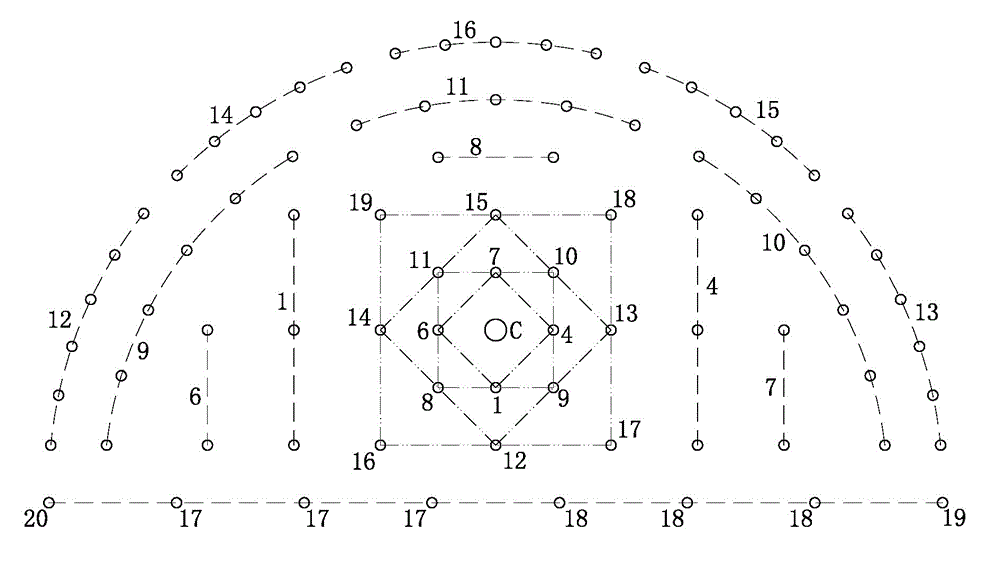

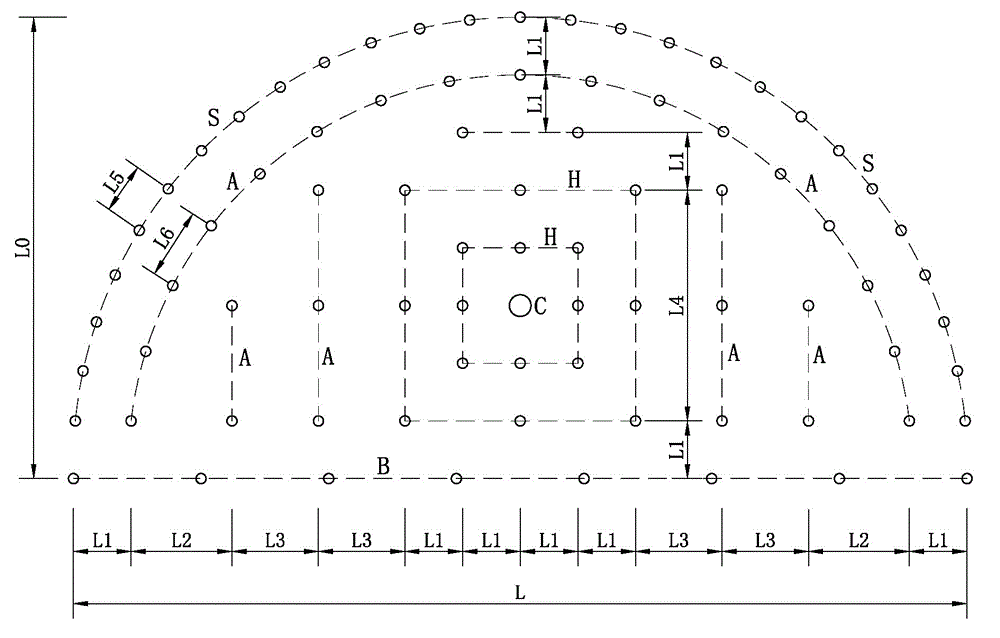

Hollow-hole rhombic parallel cut blasting damping method

InactiveCN102914226AReduce blasting vibration velocityReduce the impactBlastingDetonatorUnderground tunnel

The invention relates to a hollow-hole rhombic parallel cut blasting damping method. Blasting tunneling is performed on the tunnel face of an underground tunnel. The construction method comprises using a down-the-hole drill to drill a hollow hole with the diameter of 90mm to 180mm at the position of the middle of the tunnel face of the tunnel; using a hammerdrill to drill a plurality of blast holes, enabling the blast holes to comprise cut holes, auxiliary holes, periphery holes and base plate holes which are expanded around the hollow hole; filling explosives and detonators, using stemming to seal the blast holes, adopting rock emulsion explosives, and using ordinary millisecond nonel detonators or high-precison millisecond nonel detonators; and detonating the explosives according to blast hole arranging orders and detonator delay time. The hollow-hole rhombic parallel cut blasting damping method has the advantages that when an urban subway underneath passes buildings at a close range in a granite stratum and old resident houses, the blast vibration speed can be effectively controlled, influences of blast vibration on the buildings and life of residents are reduced, and compared with a traditional wedge cut blasting scheme, the hollow-hole rhombic parallel cut blasting damping method enables the maximum blasting vibration speed to be reduced by 50%.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

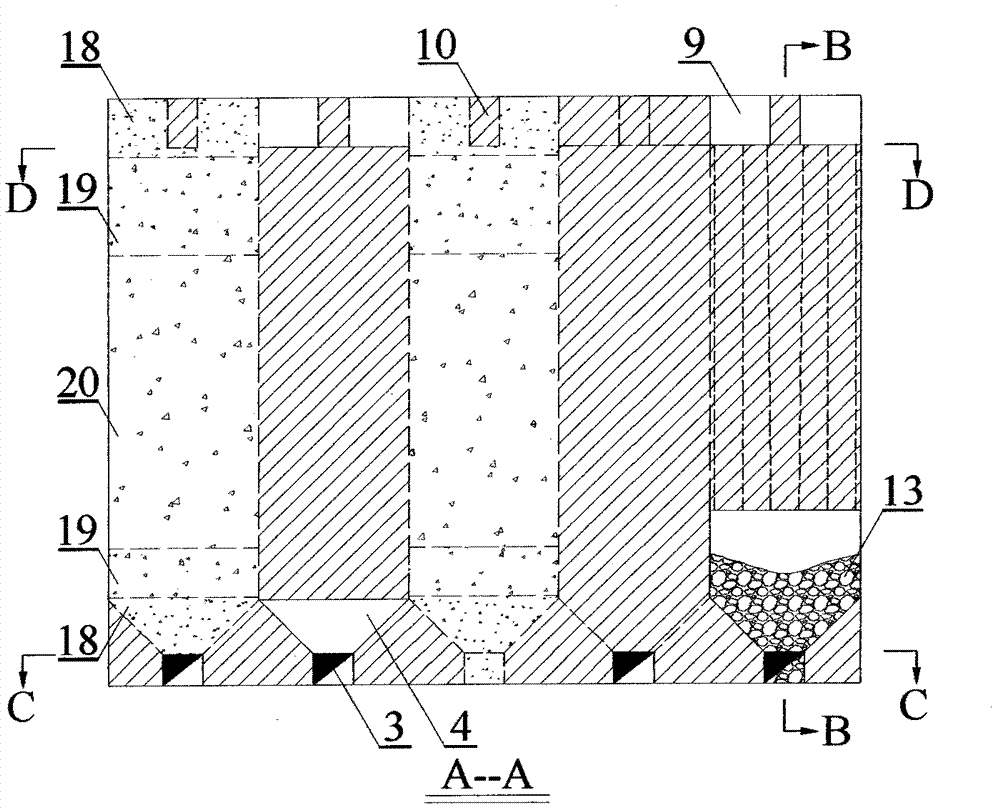

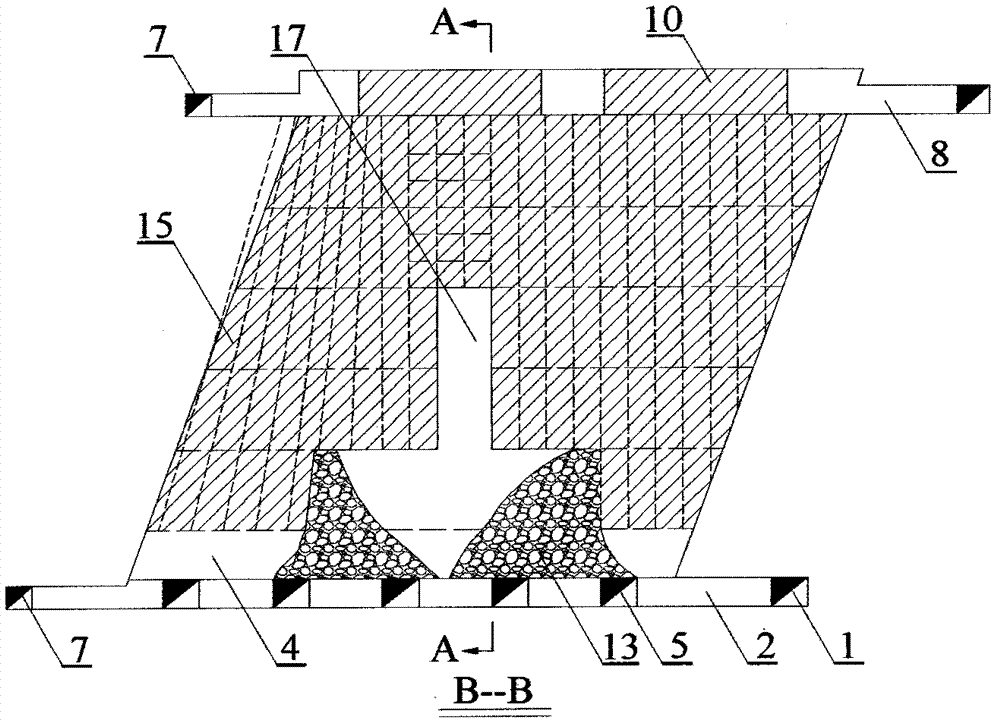

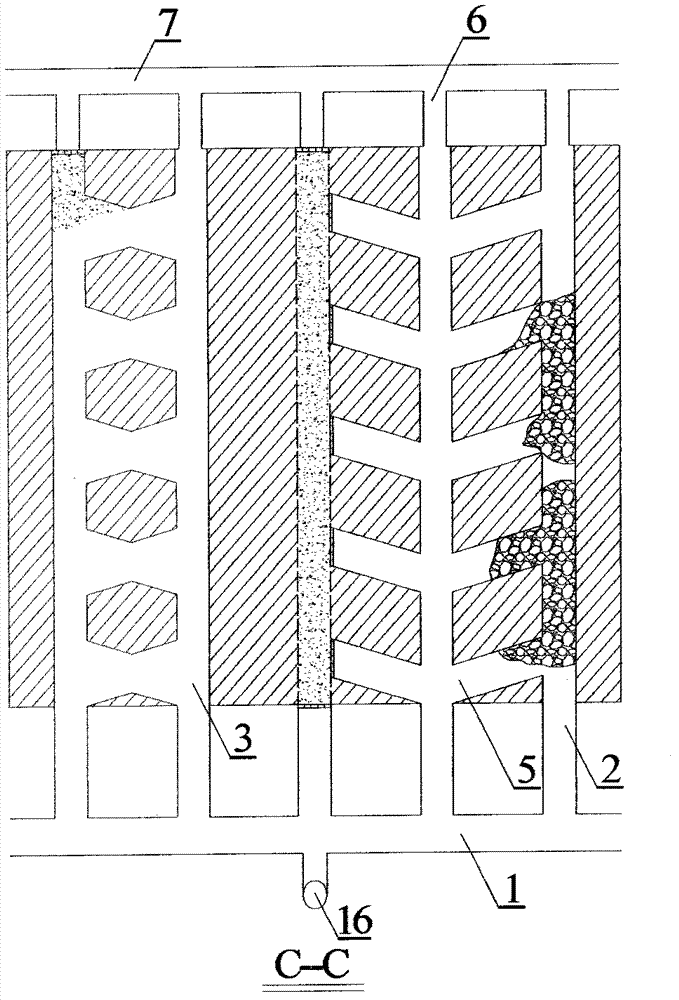

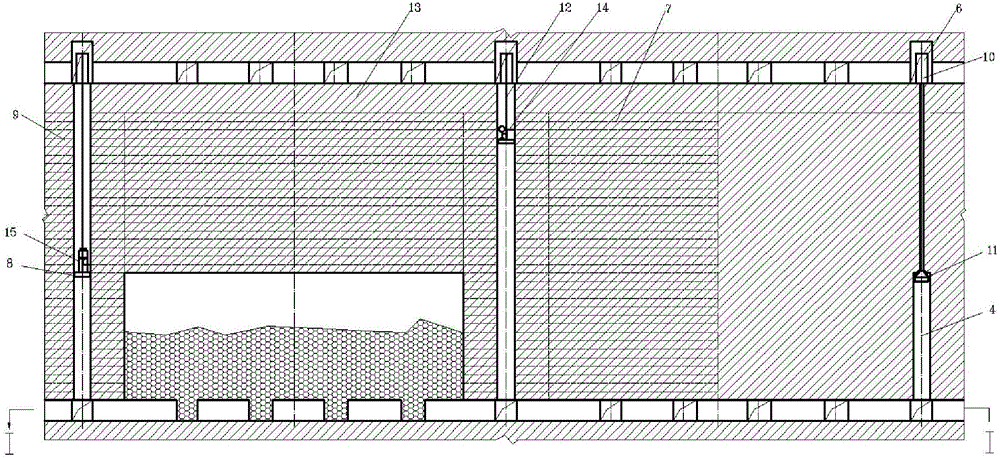

Room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method

InactiveCN102953732AImprove mining safetyGood for stope stabilityUnderground miningSurface miningRoom and pillar miningSingle stage

The invention discloses a room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method for a steeply-inclined medium-thick orebody and gently-inclined and inclined extremely-thick orebodies with steady surrounding rocks at upper and lower panels. The method is characterized in that: an orebody is divided into panels, then the panels are divided into continuous single-stage stoping units, and mining is carried out by using a stoping sequence of stoping one unit every other unit, i.e., mining a room at first and a pillar next; when mining a room, a V-shaped trench bottom structure is employed, a longhole drilling chamber is arranged at the upper part of stope, bar-shaped pillars are left to support the top plate of the chamber, a down-the-hole drill is used for drilling rocks, an explosion mode of light section VCR method underholing inverted-step-like lateral caving with a common emulsion explosive is employed, access roads towards the room for ore removal are arranged in the pillars, and cemented roof-contact filling is employed; and during stoping of the pillars, access roads for ore removal are dug towards the pillars in cemented bodies in the room, a stoping manner for the pillars is identical to that for the room, and non-cemented filling with tailings and waste is employed. The method provided by the invention has the advantages of high security, a low production cutting ratio, great production capacity, low operation cost and small loss and dilution of resources.

Owner:彭康

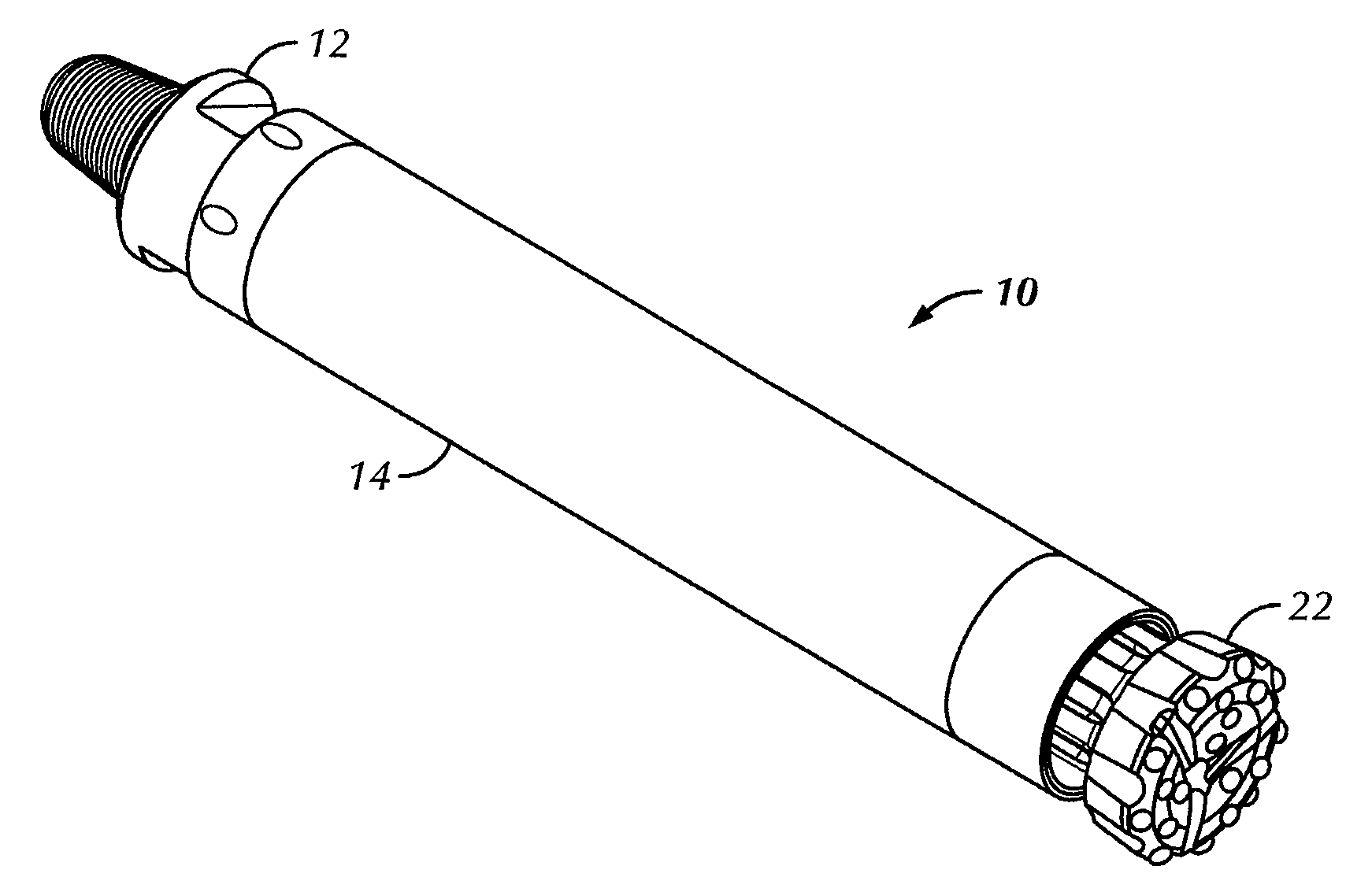

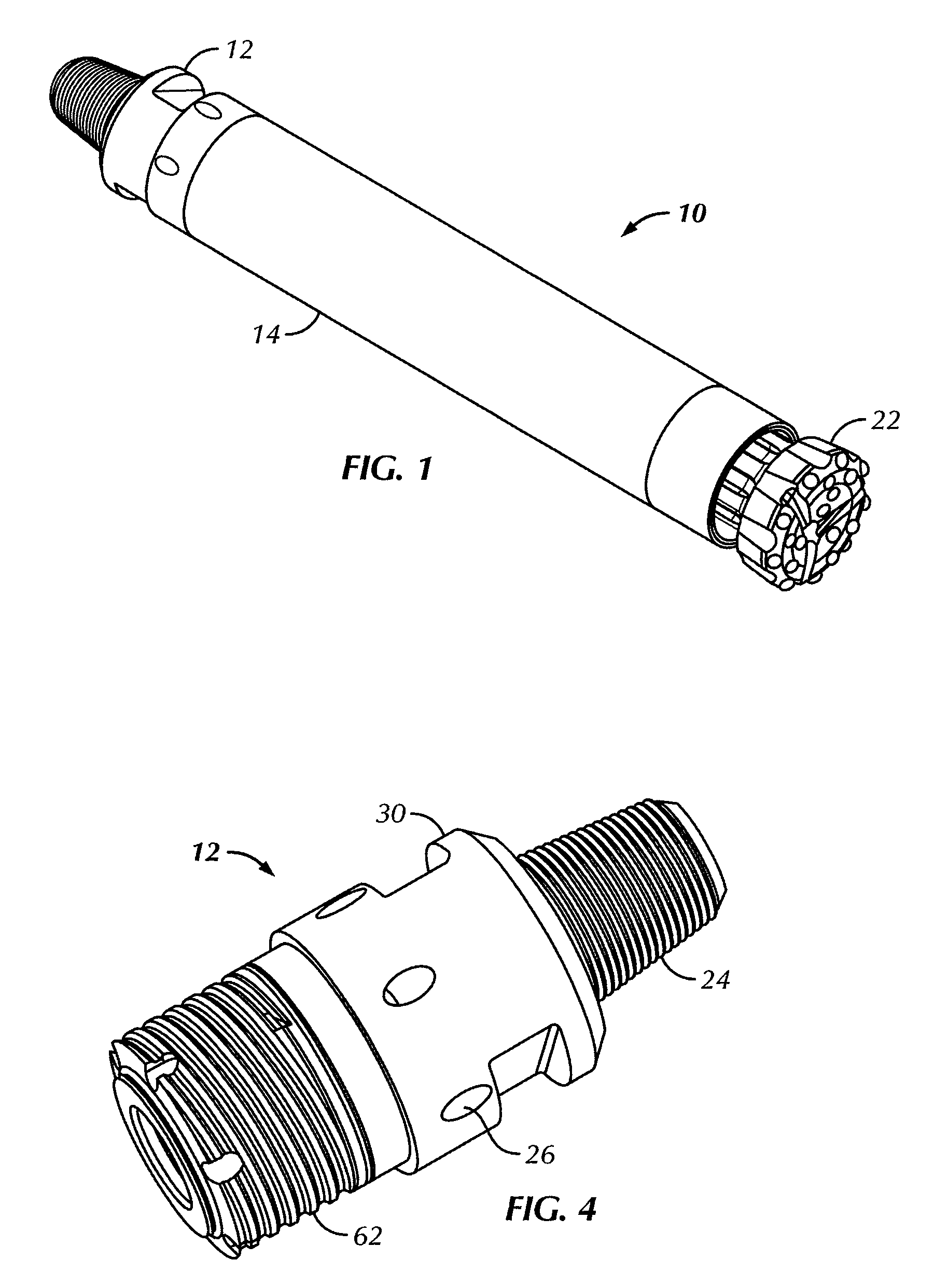

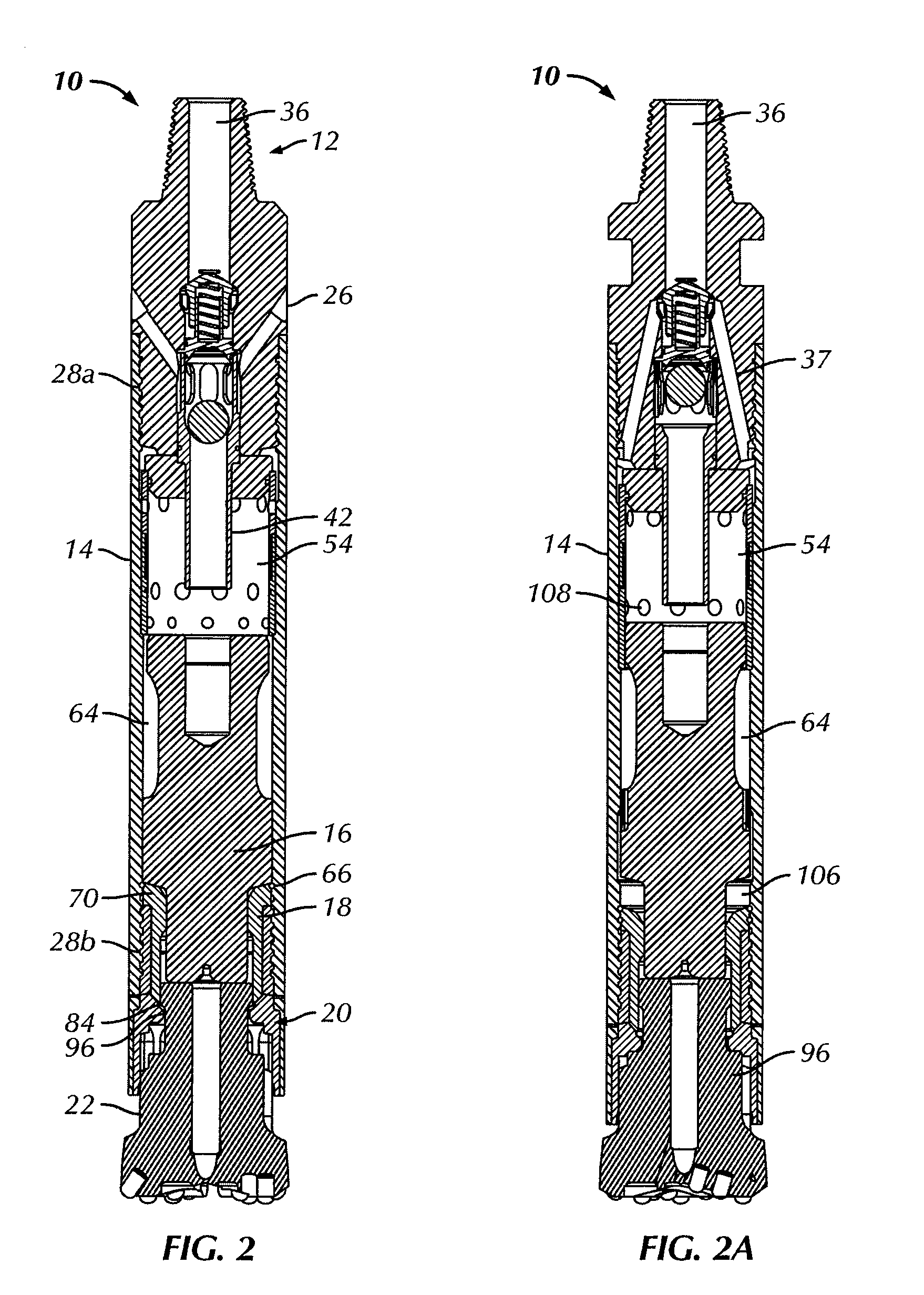

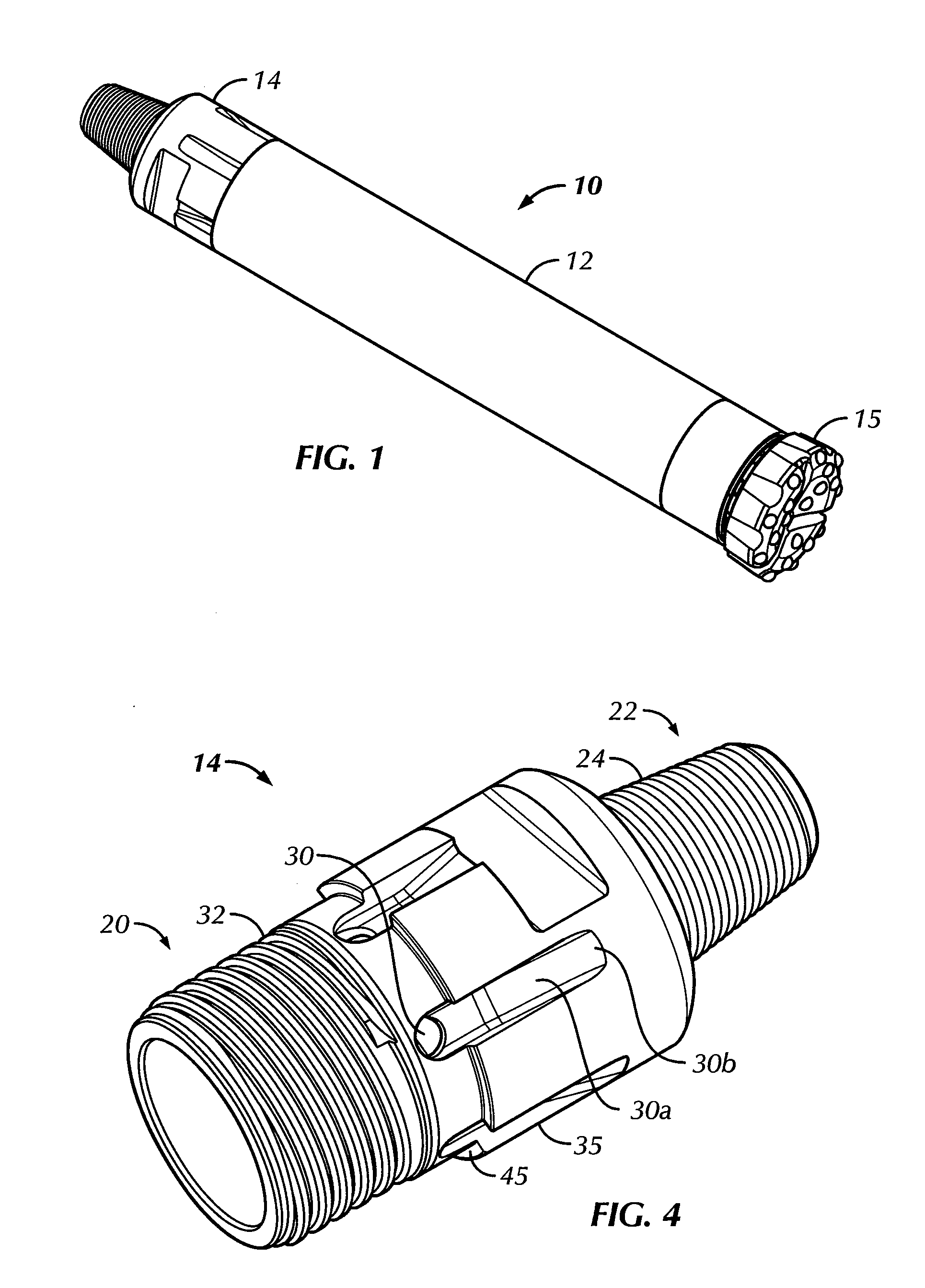

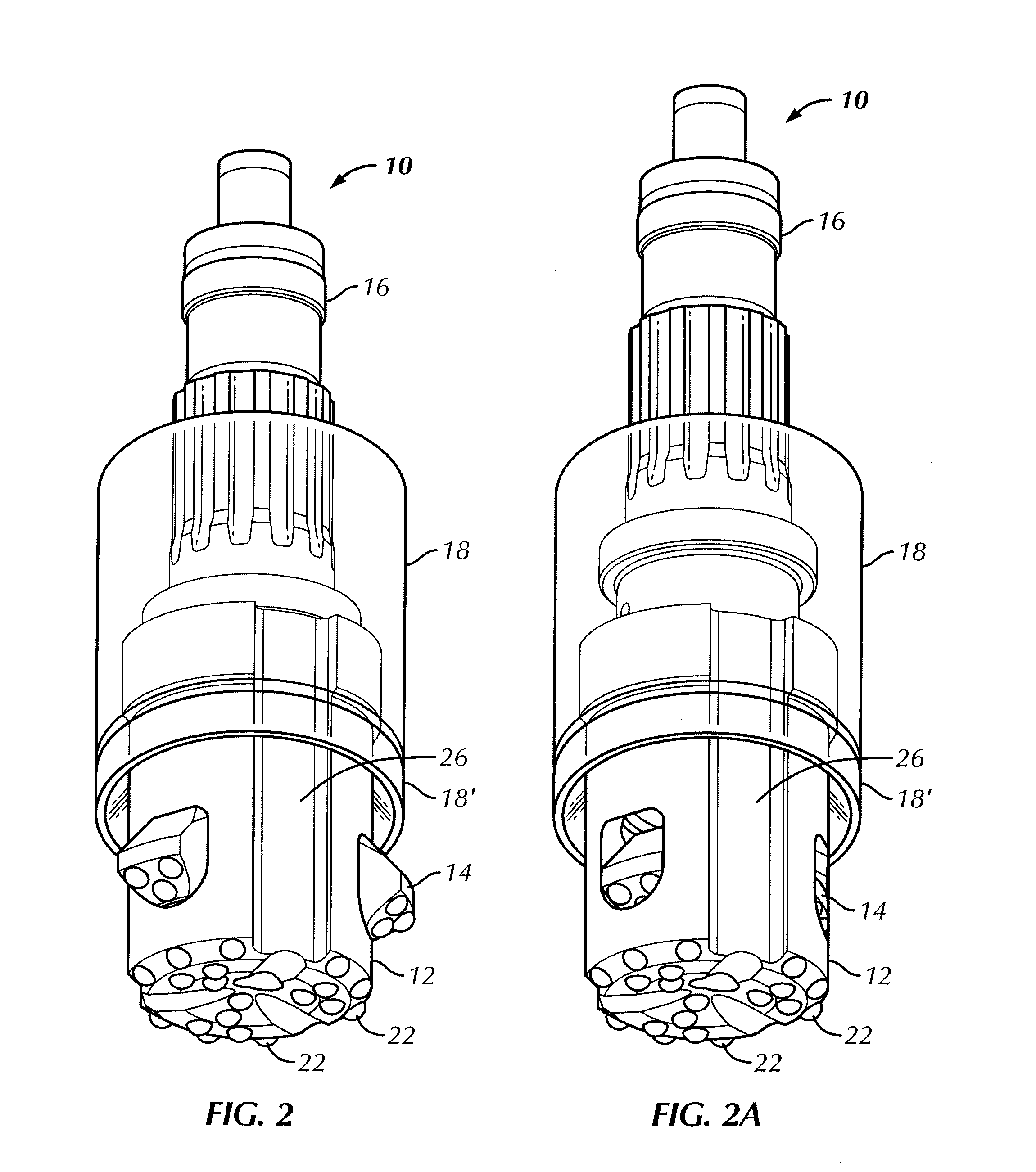

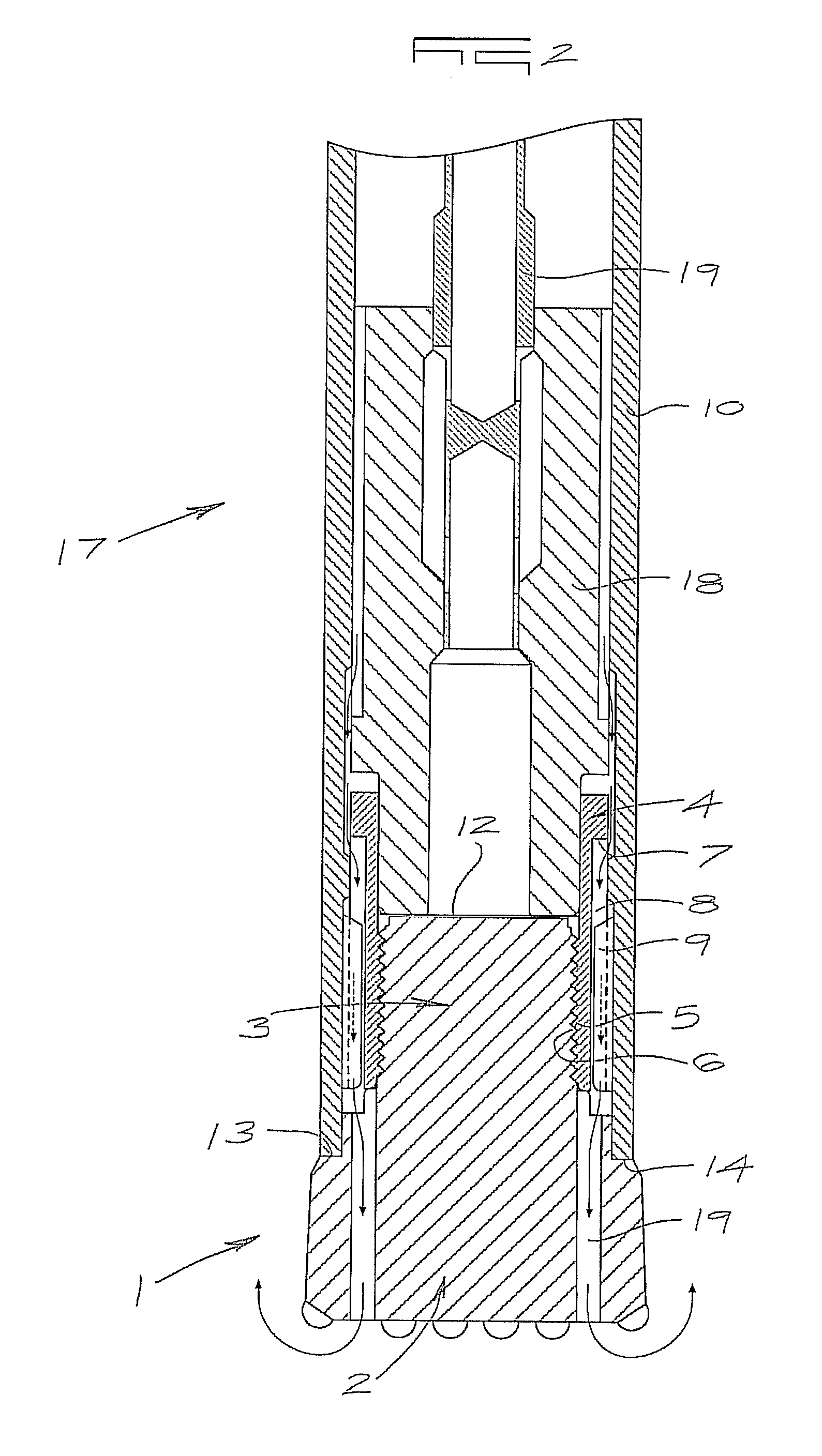

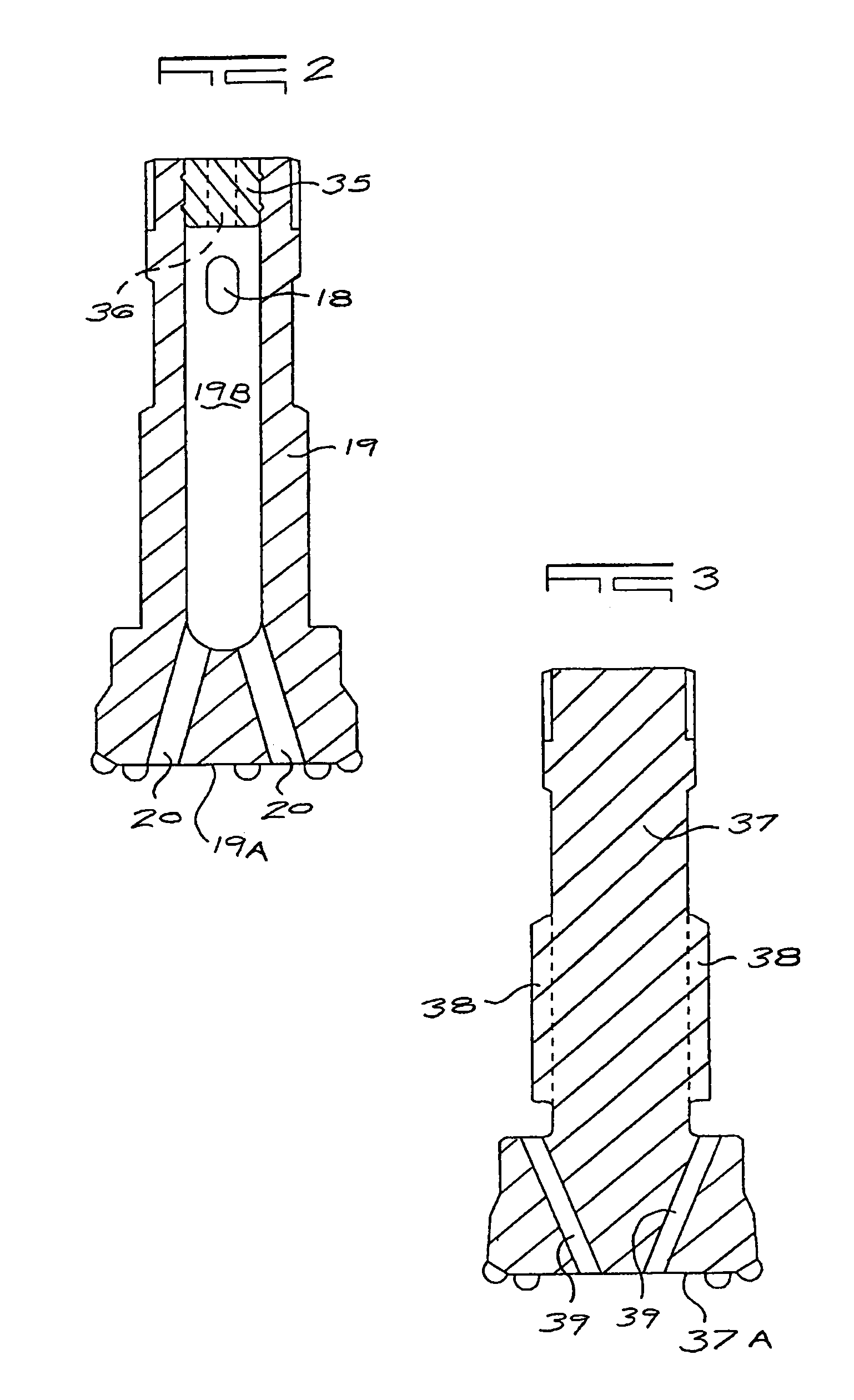

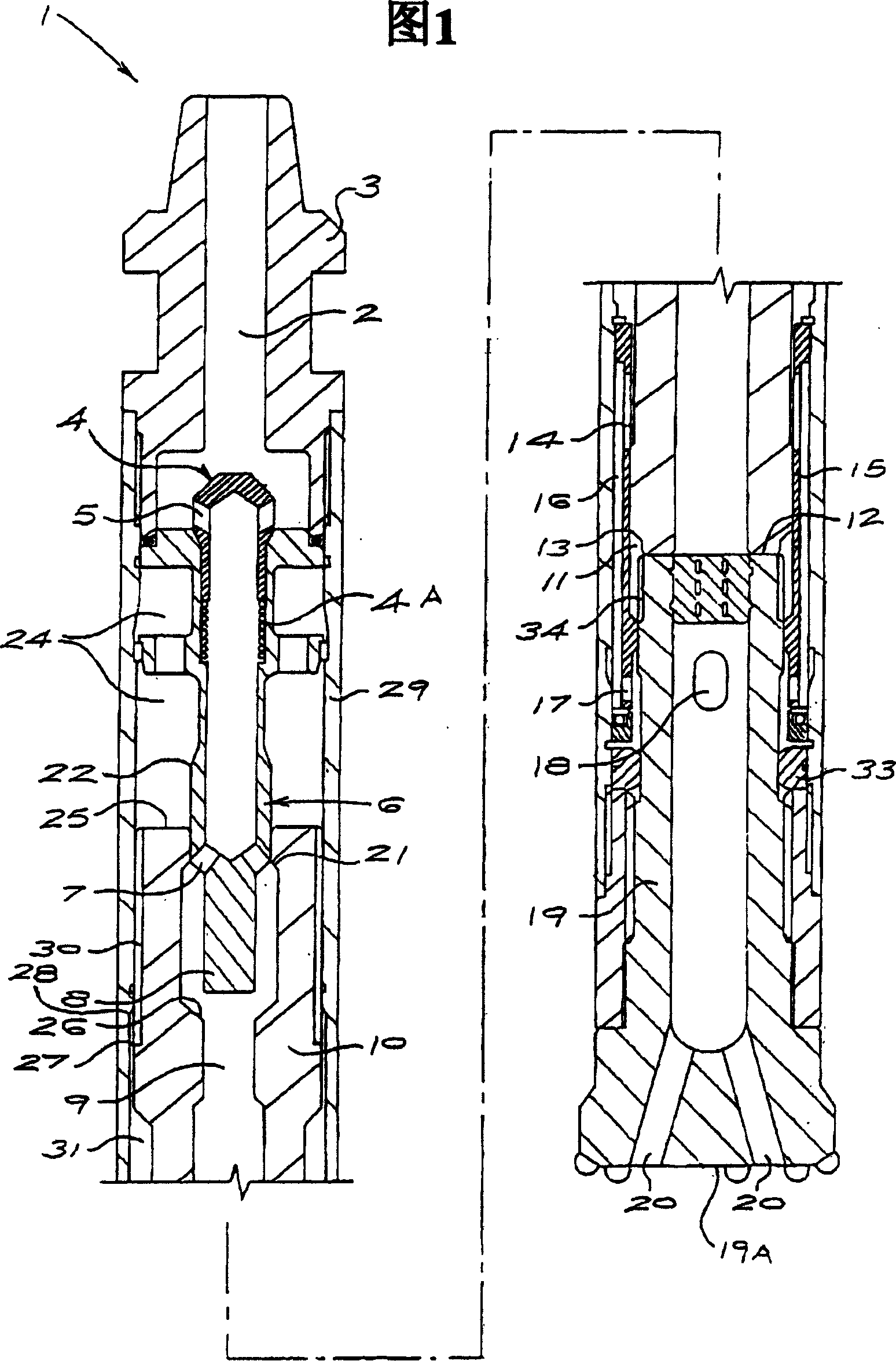

Down-the-hole drill hammer having a reverse exhaust system and segmented chuck assembly

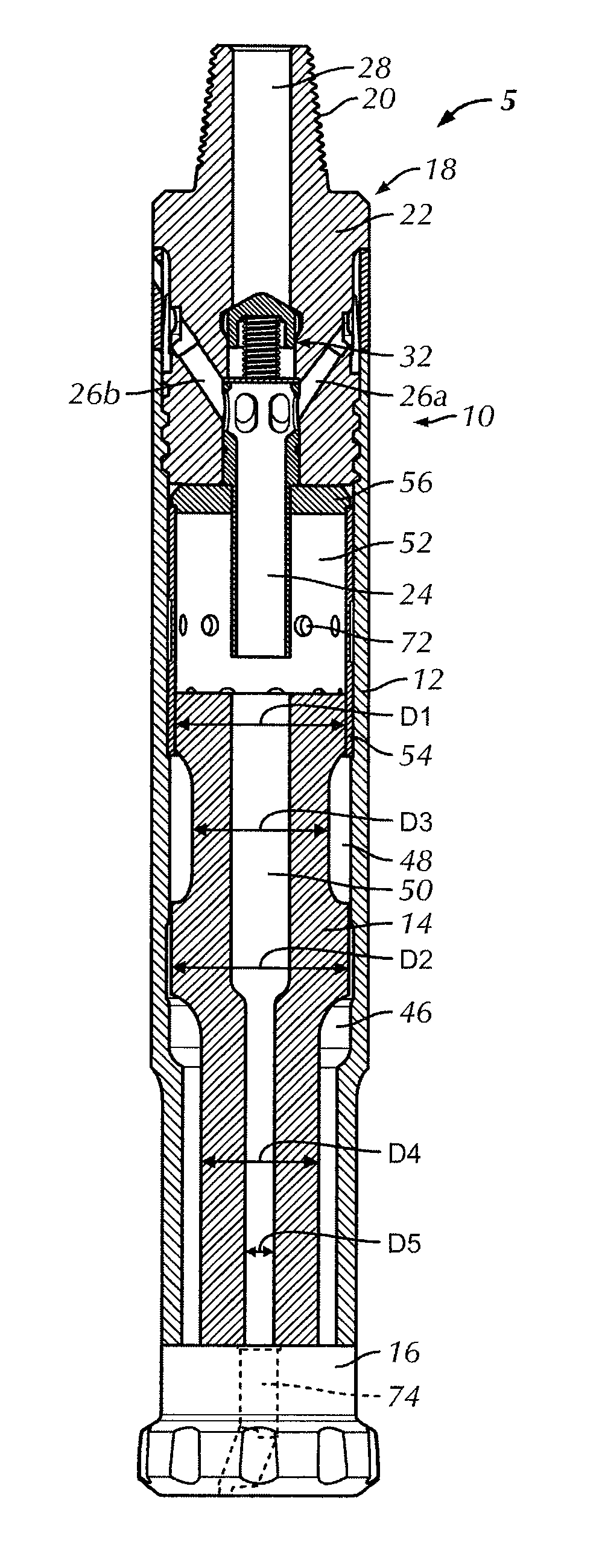

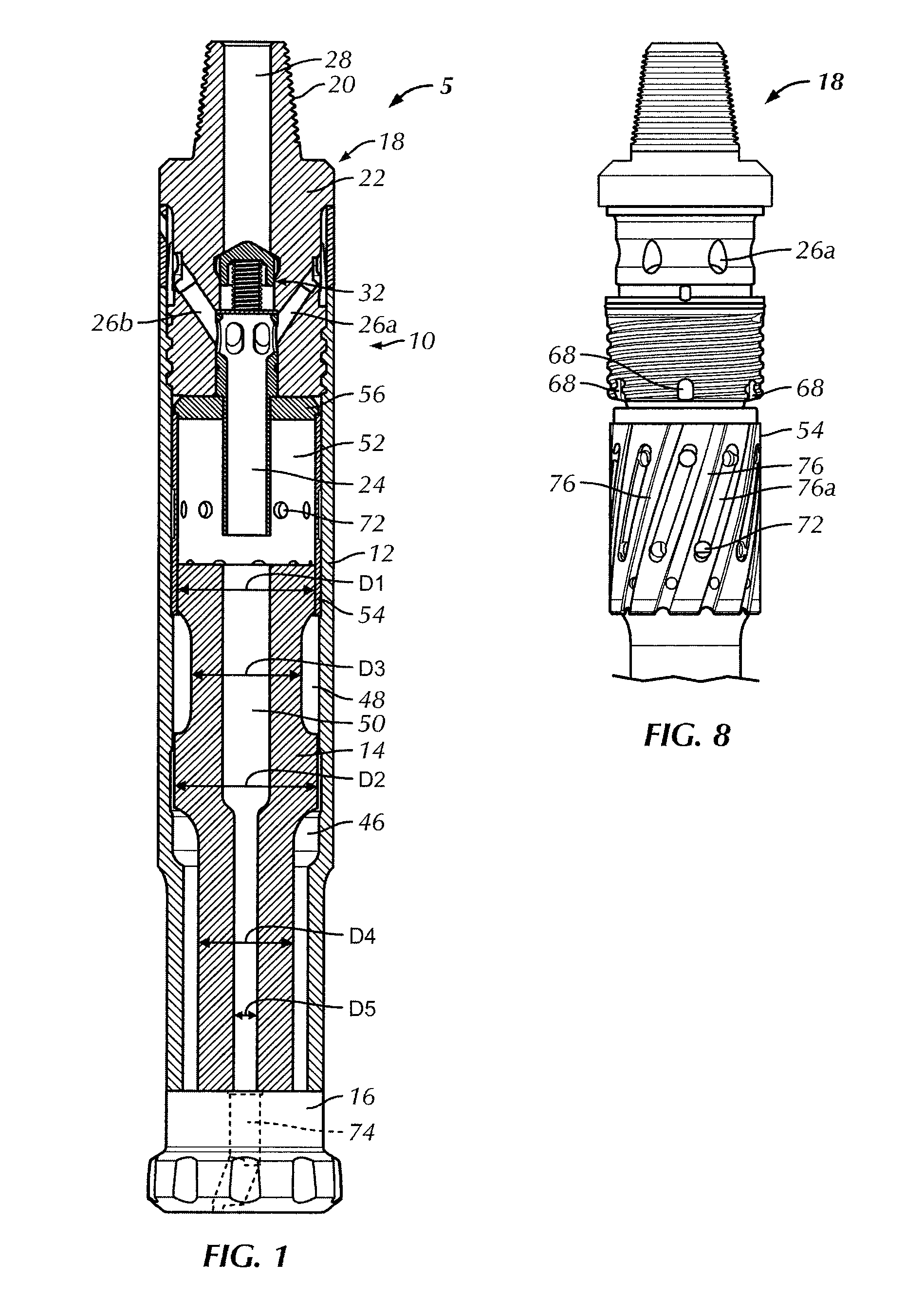

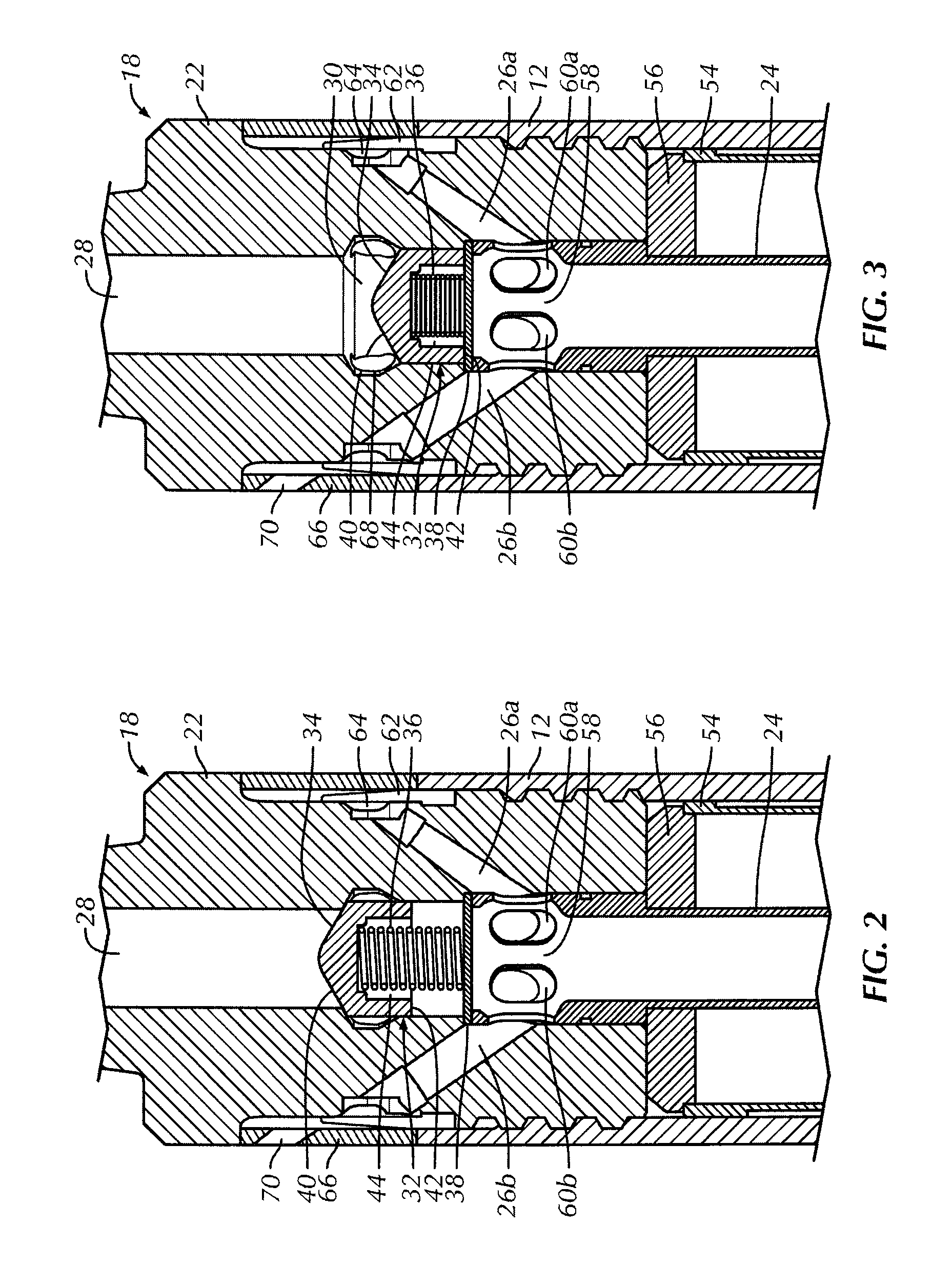

A down-the-hole drill hammer is provided that includes a housing, a solid core piston mounted within the housing, a seal located between the solid core piston and the housing, and a backhead configured to exhaust working fluid volumes about a proximal end of the DHD hammer. The backhead includes a check valve assembly having a plug seal that can be moved to a closed seal position by gravity. A DHD hammer having a segmented chuck assembly is also provided. The segmented chuck assembly includes a plurality of chuck segments forming a cylindrical chuck assembly.

Owner:CENTER ROCK INC

Down-the-Hole Drill Hammer Having a Sliding Exhaust Check Valve

A down-the-hole drill hammer having a housing, a backhead and a tubular sliding check valve assembly that includes a distal end, a threaded male proximal end, a supply inlet and an exhaust port. The exhaust port communicates between an interior of the backhead and an exterior of the backhead. The tubular sliding check valve assembly includes a distributor, a sliding valve, and a biasing member. The distributor has a central opening extending through the distributor, an aperture extending through the distributor, and an exhaust gallery. The sliding valve is slidable along the central opening. The biasing member biases the sliding valve to a closed position.

Owner:CENTER ROCK INC

Heat treatment method for down-the-hole drill bit of high-wind pressure drilling tool, and drill bit

ActiveCN102703911AImprove toughness and plasticityHigh surface hardnessSolid state diffusion coatingFurnace typesNumerical controlHardness

The invention relates to a heat treatment method for a down-the-hole drill bit of a high-wind pressure drilling tool. The method comprises the following steps: heating the original down-the-hole drill bit to 750-850 DEG C for forging and beating, forming and die forging, conducting air cooling after heating at 900-950 DEG C for four hours to five hours, conducting furnace cooling to be lower than 200 DEG C after heating at 650-700 DEG C for four hours to five hours, carrying out numerical control machining according to size requirement, conducting carburization treatment at 900-950 DEG C, then conducting high-temperature tempering to the carburization treatment, machining, and conducting isothermal quenching at 850-900 DEG C. The invention further relates to a down-the-hole drill bit of the high-wind pressure drilling tool, which is manufactured by the heat treatment method. The down-the-hole drill bit is subjected to mechanical treatment after being heated and cooled for many times, so that the toughness and plasticity of the down-the-hole drill bit can be greatly improved, the surface hardness and compression stress of the down-the-hole drill bit can also be enhanced, and the fatigue resistance strength and the wear resistance of threads can be improved.

Owner:CHANGSHA HEIJINGANG IND CO LTD

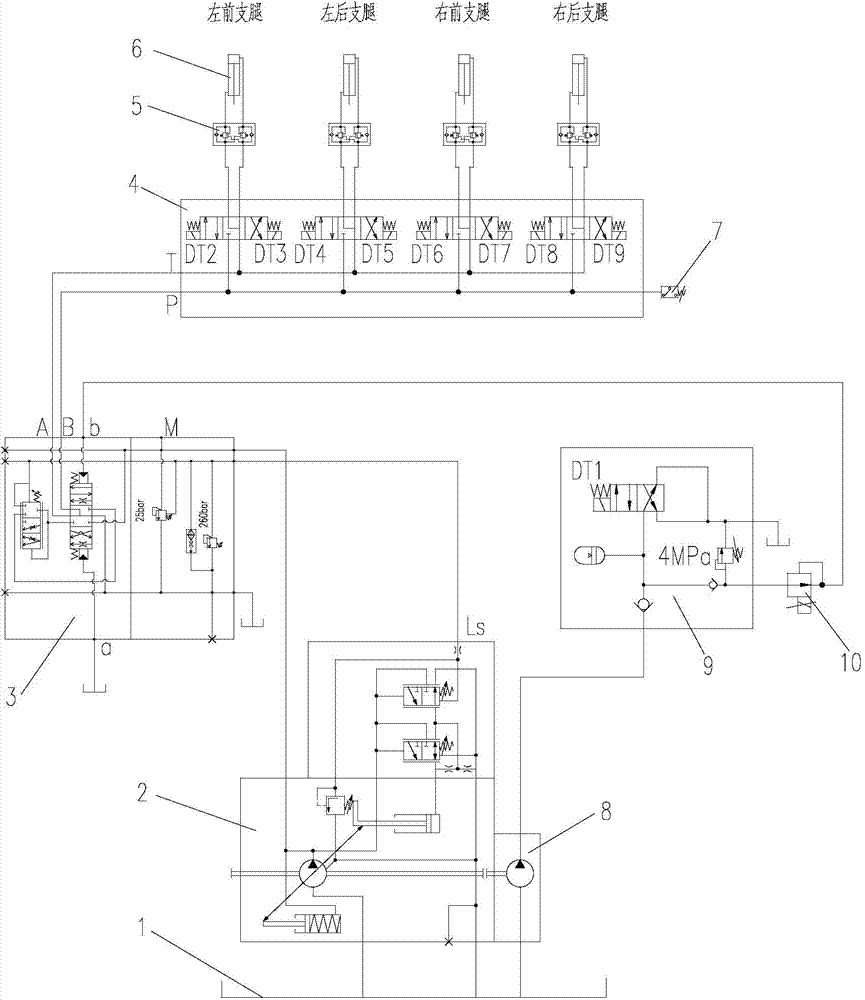

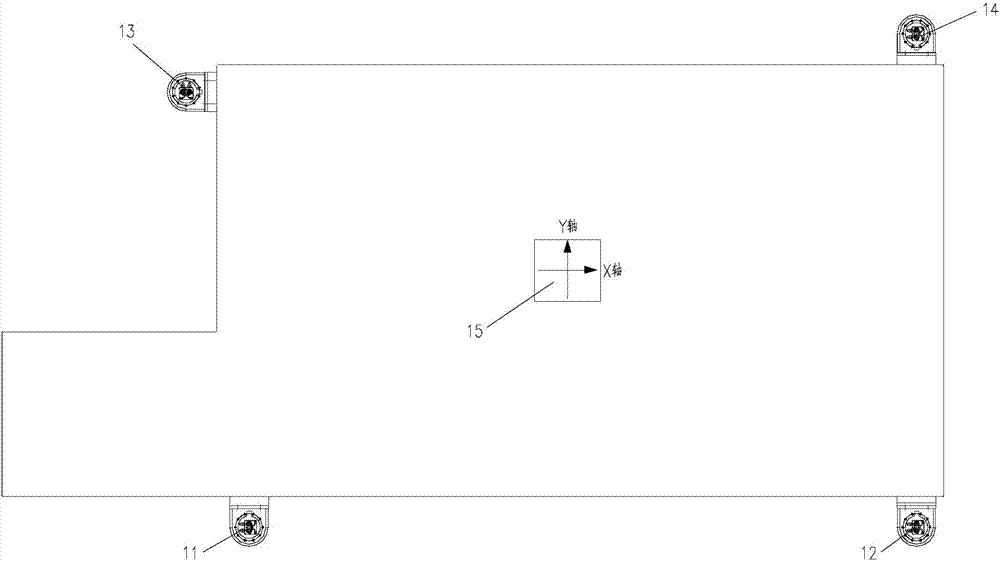

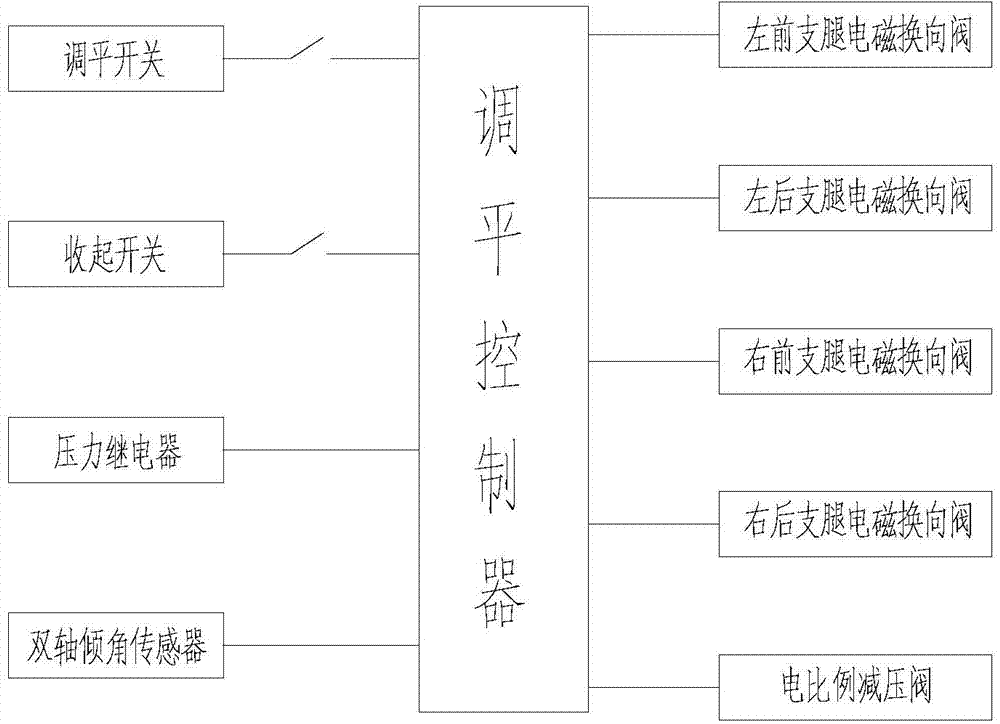

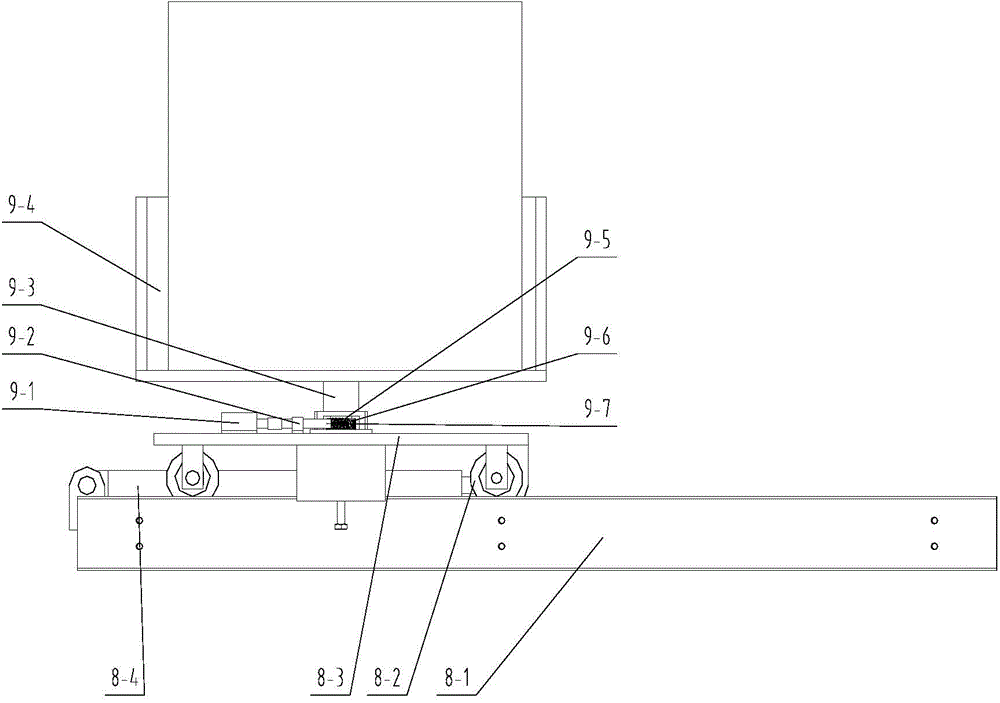

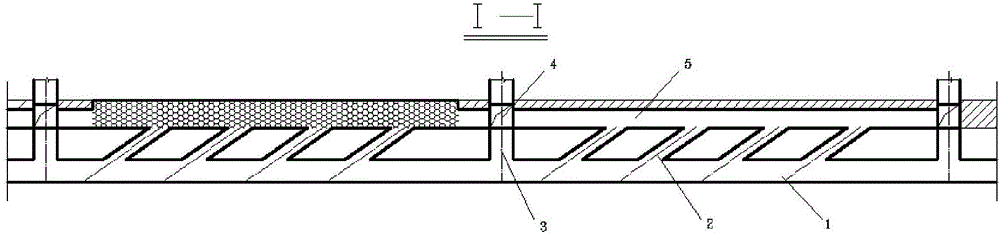

Automatic quick leveling hydraulic control circuit of down-the-hole drill and control method thereof

ActiveCN103939405AReduce outlet pressureDecrease the opening of the proportional directional valve to reduce the outlet pressureServomotor componentsDerricks/mastsLoad sensingFuel tank

The invention discloses an automatic quick leveling hydraulic control circuit of a down-the-hole drill and a control method of the automatic quick leveling hydraulic control circuit. The automatic quick leveling hydraulic control circuit comprises support oil cylinders, support balance valves, a magnetic exchange valve bank, a hydraulic control proportional directional valve, a load sensing variable displacement pump and a hydraulic oil tank. Magnetic exchange valves corresponding to the support oil cylinders in quantity are arranged in the magnetic exchange valve bank. Rod cavities and rodless cavities of the support oil cylinders are connected with oil ports of the magnetic exchange valves through the support balance valves. Oil inlets and oil outlets of the magnetic exchange valves are connected in parallel to serve as an oil port P and an oil port T of the magnetic exchange valve bank. An oil port A and an oil port B of the hydraulic control proportional directional valve are communicated with the oil port T and the oil port P of the magnetic exchange valve bank respectively. A pressure relay is communicated with an oil inlet of the magnetic exchange valve bank. A pilot oil pump is connected with a pilot control valve block. A control port of the pilot control valve block is communicated with a pilot cavity b of the hydraulic control proportional directional valve through an electric proportional pressure reducing valve. A pressure feedback port Ls of the load sensing variable displacement pump is communicated with the hydraulic control proportional directional valve. The load sensing variable displacement pump is connected with the hydraulic oil tank. According to the automatic quick leveling hydraulic control circuit of the down-the-hole drill and the control method of the automatic quick leveling hydraulic control circuit, a working platform of the drill can be quickly, accurately and stably leveled, so that operation difficulty is lowered, auxiliary operation time is shortened, and comprehensive drilling efficiency is enhanced.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

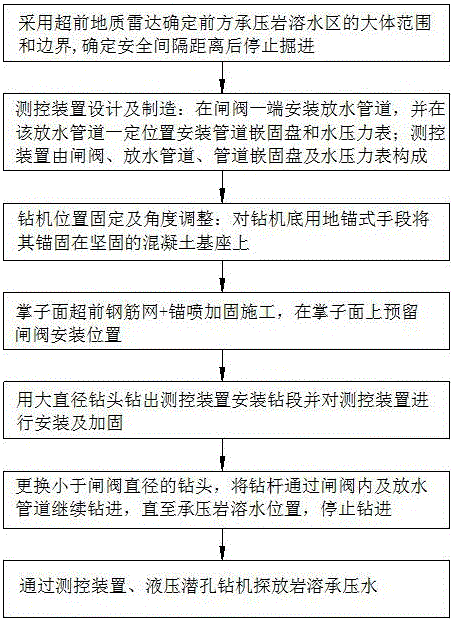

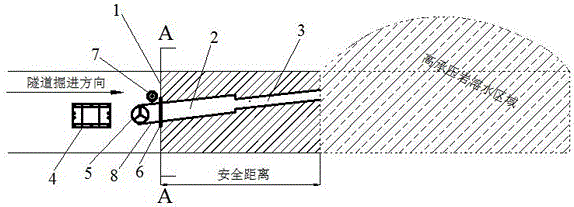

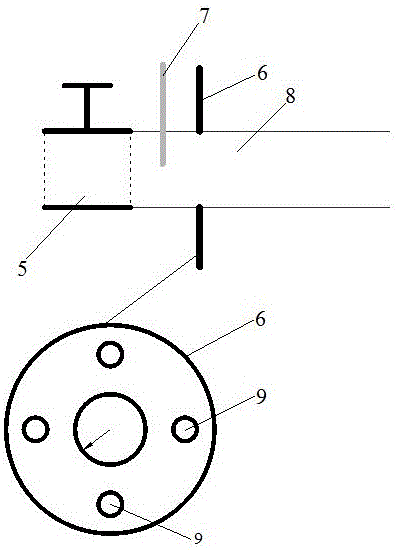

Exploration and draining method for pressure-bearing karstic water in tunneling process

InactiveCN105840235AControl excavation deformationImprove securityUnderground chambersFoundation engineeringHydrologyRebar

The invention discloses an exploration and draining method for pressure-bearing karstic water in a tunneling process. The method comprises the steps that a high-pressure-bearing water karstic area is searched for through advanced geological prediction, the karstic area is locked, the boundary range is determined, a tunnel face is closed, and a drilling tool exits; a measuring and control device is designed and manufactured; the position of a hydraulic down-the-hole drill is determined, the angle is adjusted, and a base of the hydraulic down-the-hole drill is reinforced through a ground anchor; the tunnel face is reinforced through a reinforcing mesh in an anchoring and shotcreting mode in advance; a large-diameter drill bit drills out an installation section of the measuring and control device, and the measuring and control device is installed and reinforced; a drill bit with the diameter smaller than the diameter of a brake valve is replaced, and a drill rod passes in the brake valve and a draining pipe to continue to carry out drilling; after a drill bit of the hydraulic down-the-hole drill reaches the pressure-bearing karstic water position, drilling is stopped, and the drilling tool exits; the high-pressure-bearing karstic water is explored and drained through the measuring and control device and the hydraulic down-the-hole drill; the operation is repeatedly carried out till all water is explored and drained. The problems that surrounding rock unstability is caused by high-pressure-bearing karstic water bursting and mud bursting phenomena in the drilling machine tunneling process, and geological disasters are caused are solved.

Owner:HUNAN UNIV

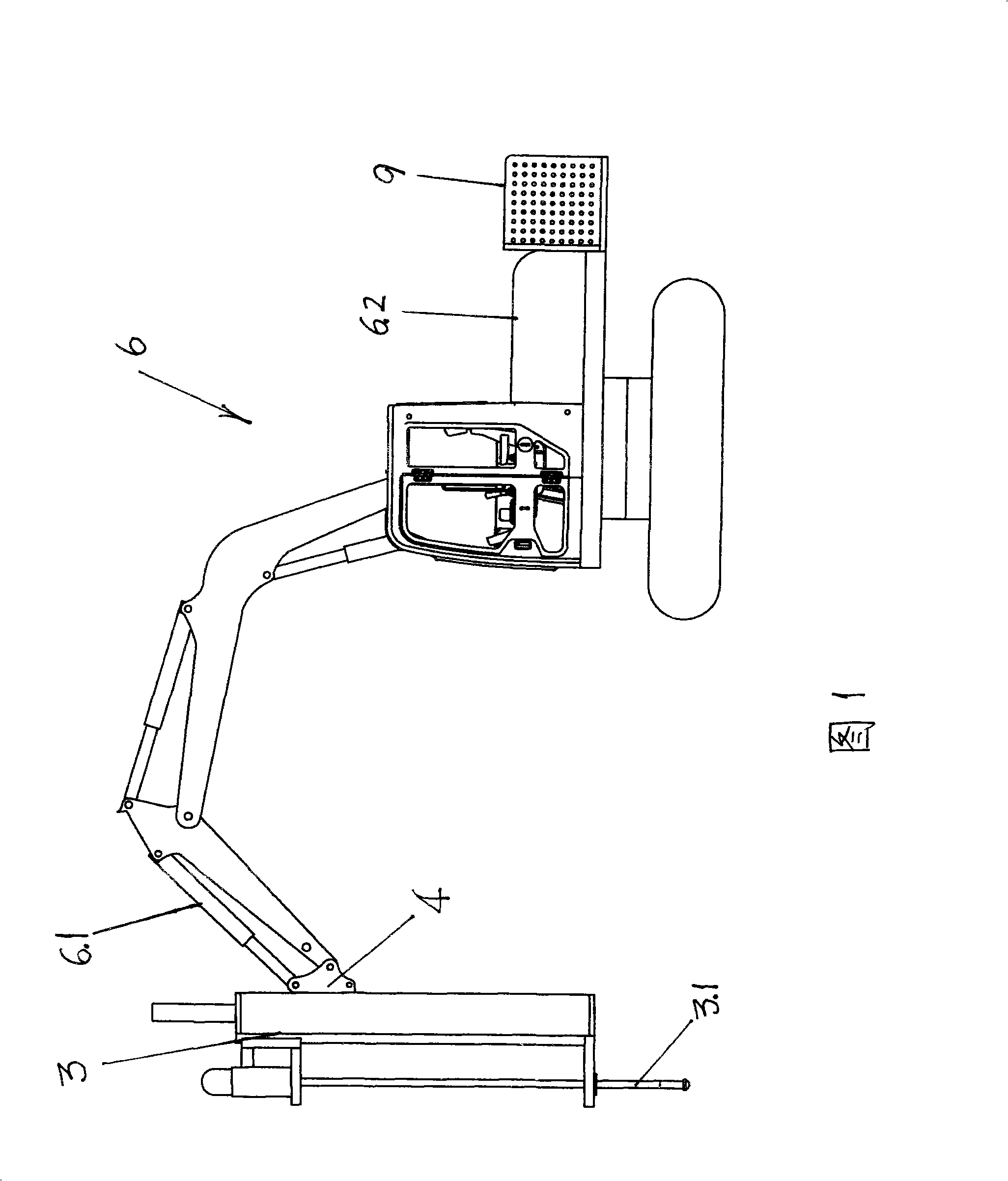

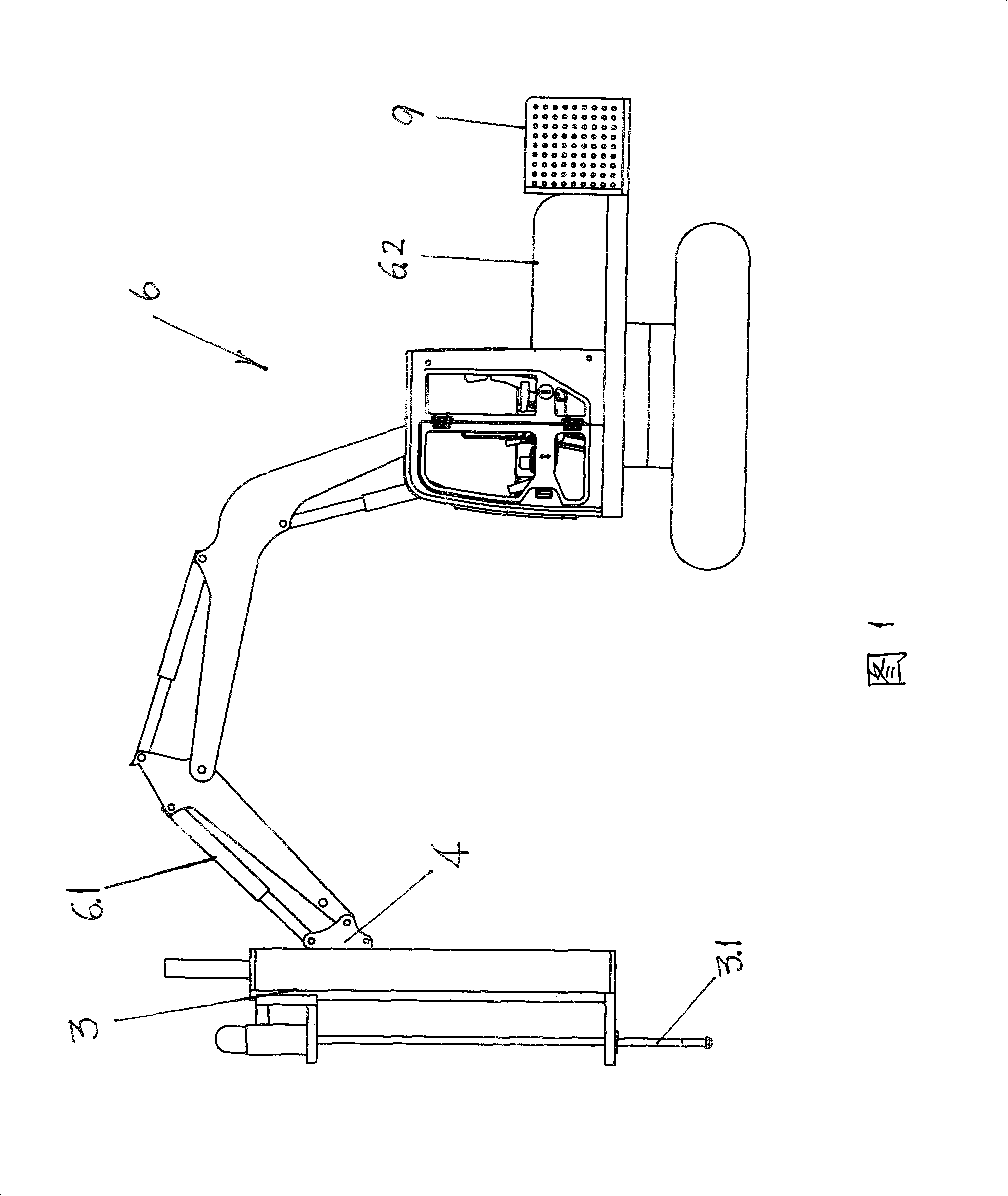

Combination type multifunctional engineering equipment

InactiveCN101319509ALow costImprove work efficiencyReciprocating drilling machinesMechanical machines/dredgersHydraulic motorSlag

The invention provides combined multi-functional engineering equipment, which aims to solve the technical problem that: at present, the completion of a tunneling operation task needs a plurality of engineering machines such as a bulldozer, a hydraulic down hole drill, a frozen-clay drill, an excavating machine and so on, synchronously arrive at the scene and synchronously work, but sometimes the operation efficiency is extremely low when the engineering machines synchronously arrive at the scene due to smaller operation surface. The combined multi-functional engineering equipment has the key points that: a base body of the excavating machine, a bucket of the excavating machine, a bit of a down hole drill, a drill rod of the frozen-clay drill and a hydraulic hammer are arranged on a small arm of the excavating machine through connecting pieces, the equipment is also provided with a hydraulic output oil circuit which provides power for the bit of the down hole drill, the drill rod of the frozen-clay drill and the hydraulic hammer, wherein, a drill rod of the bit of the down hole drill is provided with a second-stage propulsion oil cylinder, an air compressor is arranged on the back of a hydraulic system of the excavating machine, a motor of the air compressor is substituted by a hydraulic motor, and a pneumatic output tube of the air compressor is connected with a slag blowing wind pipe of the down hole drill. The use of the combined multi-functional engineering equipment is to implement multi-functional engineering operations.

Owner:SHENYANG MILITARY DISTRICT HEADQUARTERS ENG SCI RES DESIGNING INST

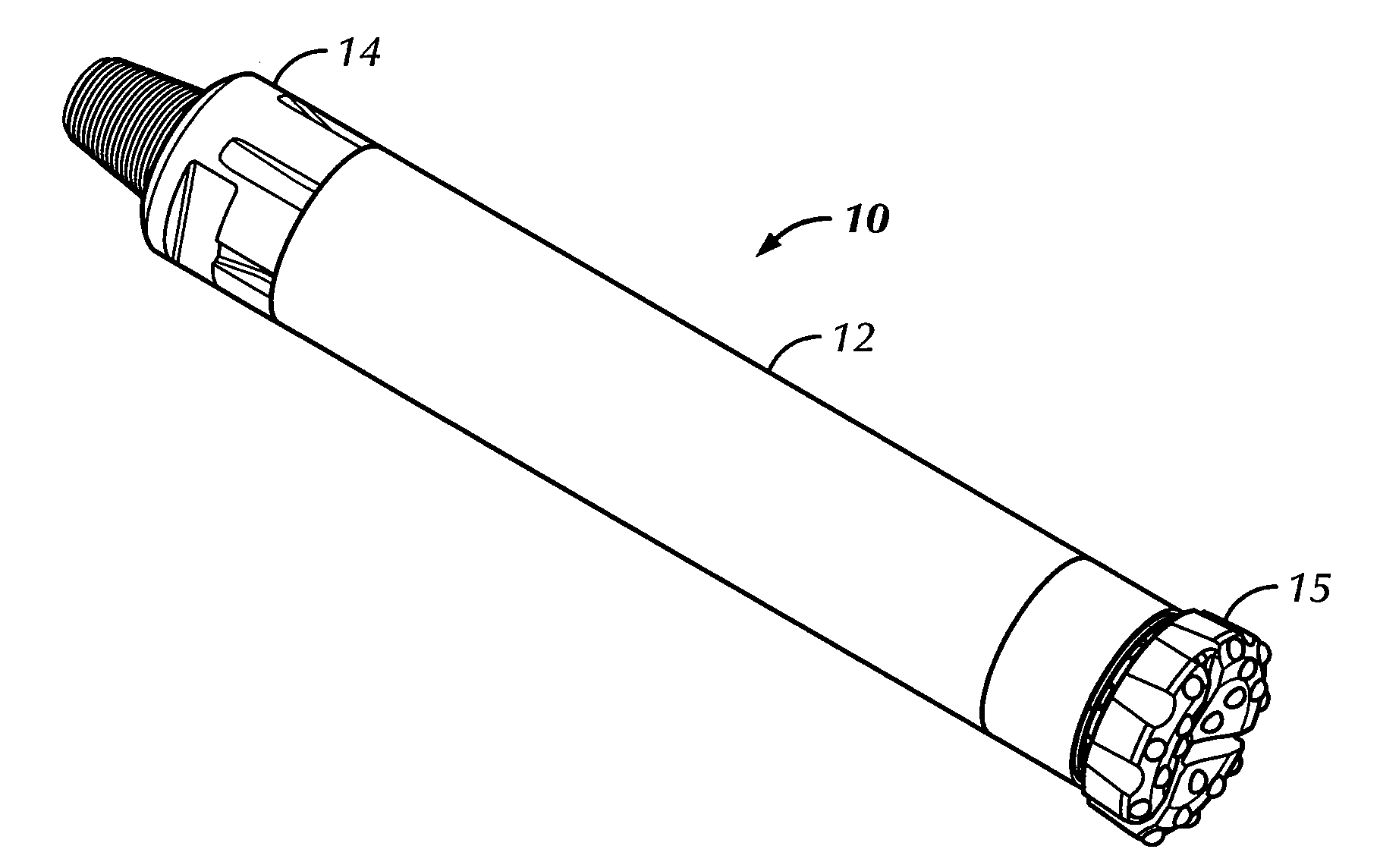

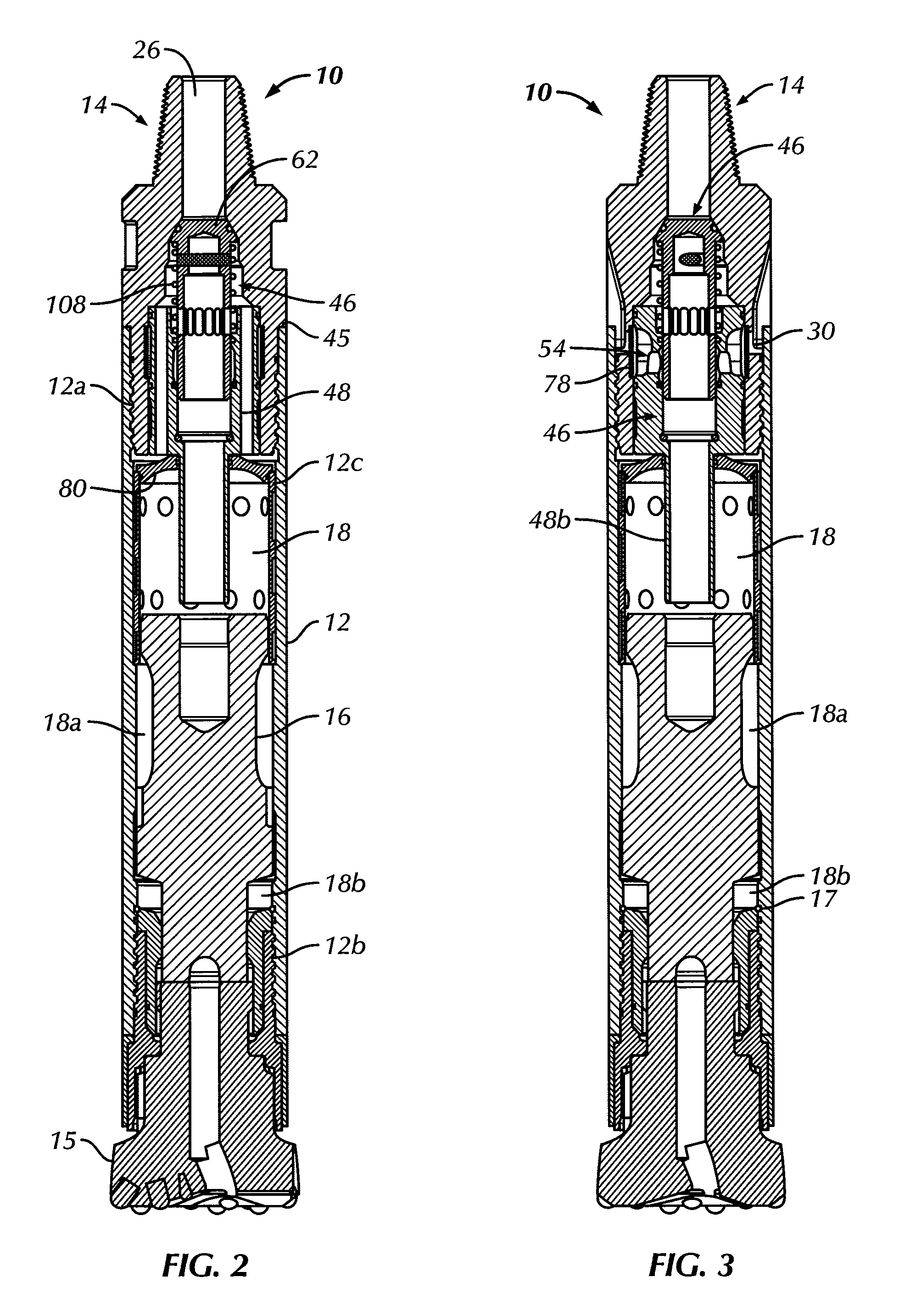

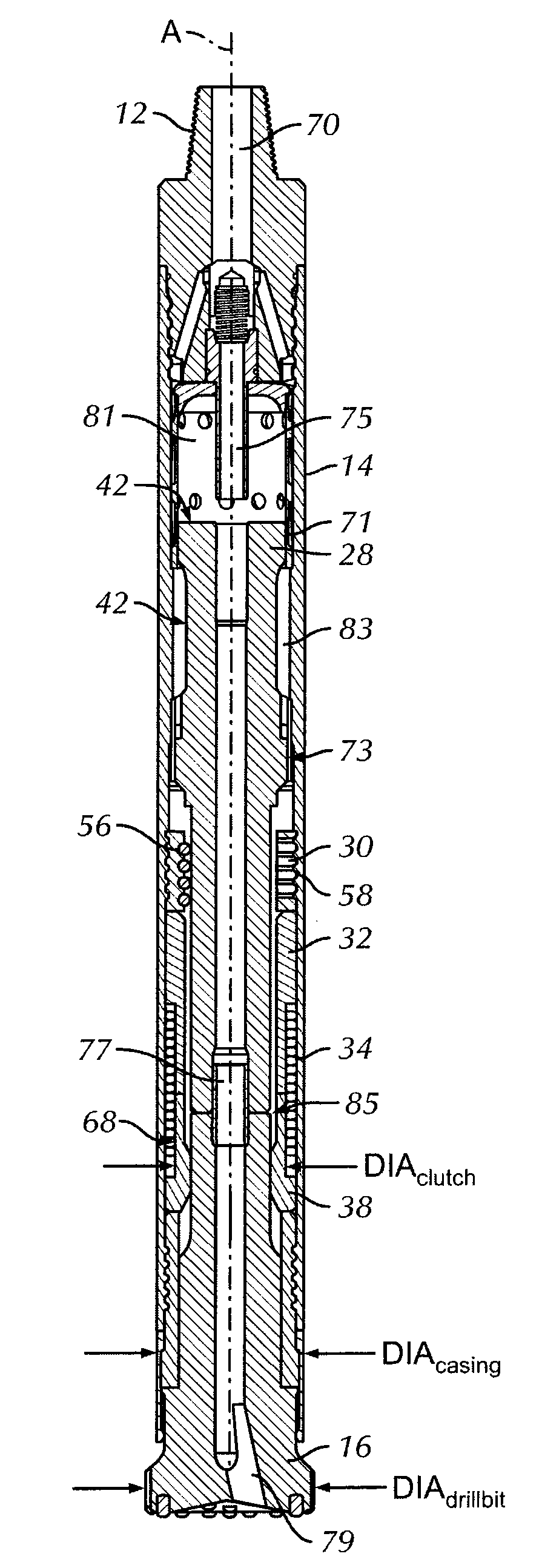

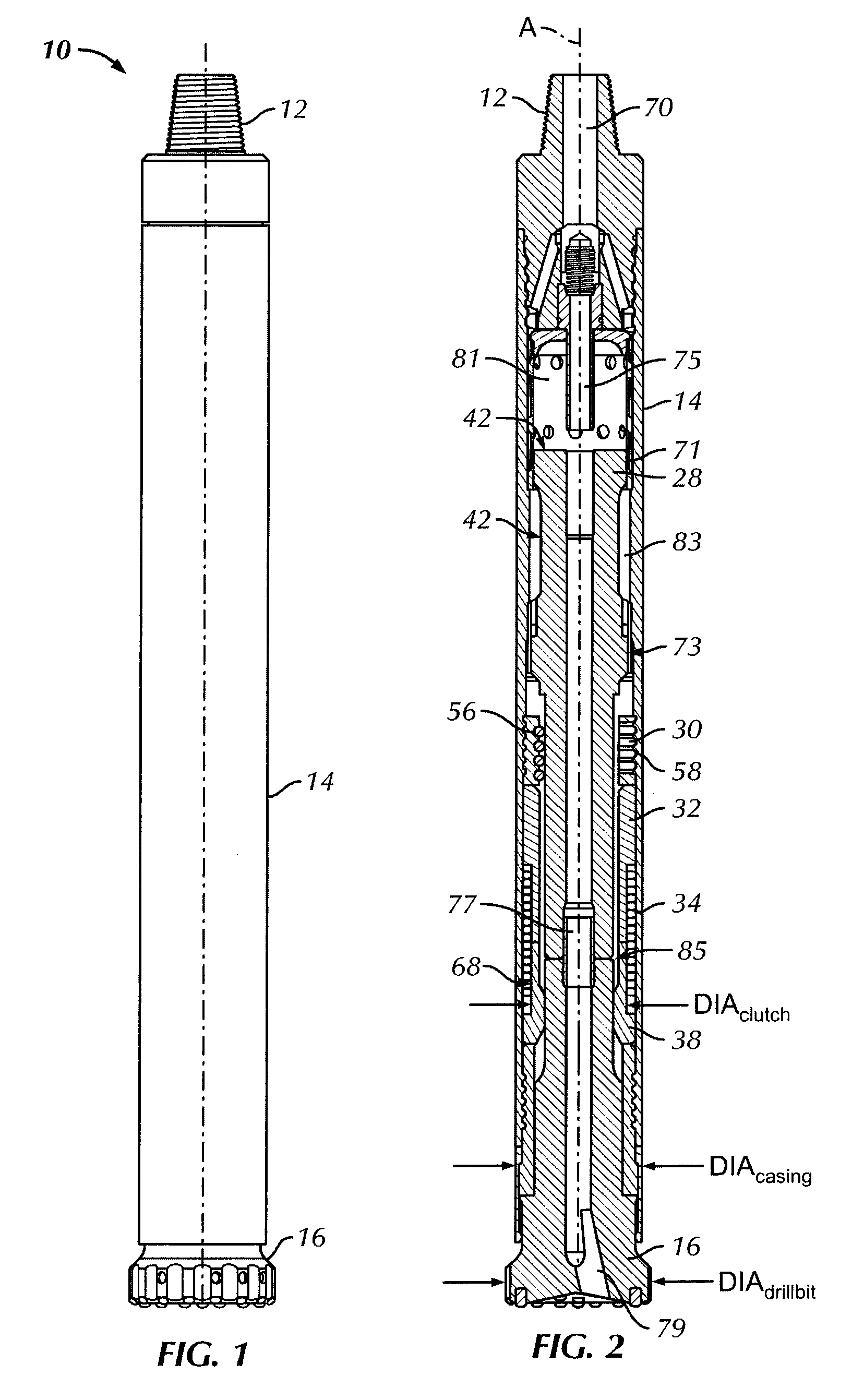

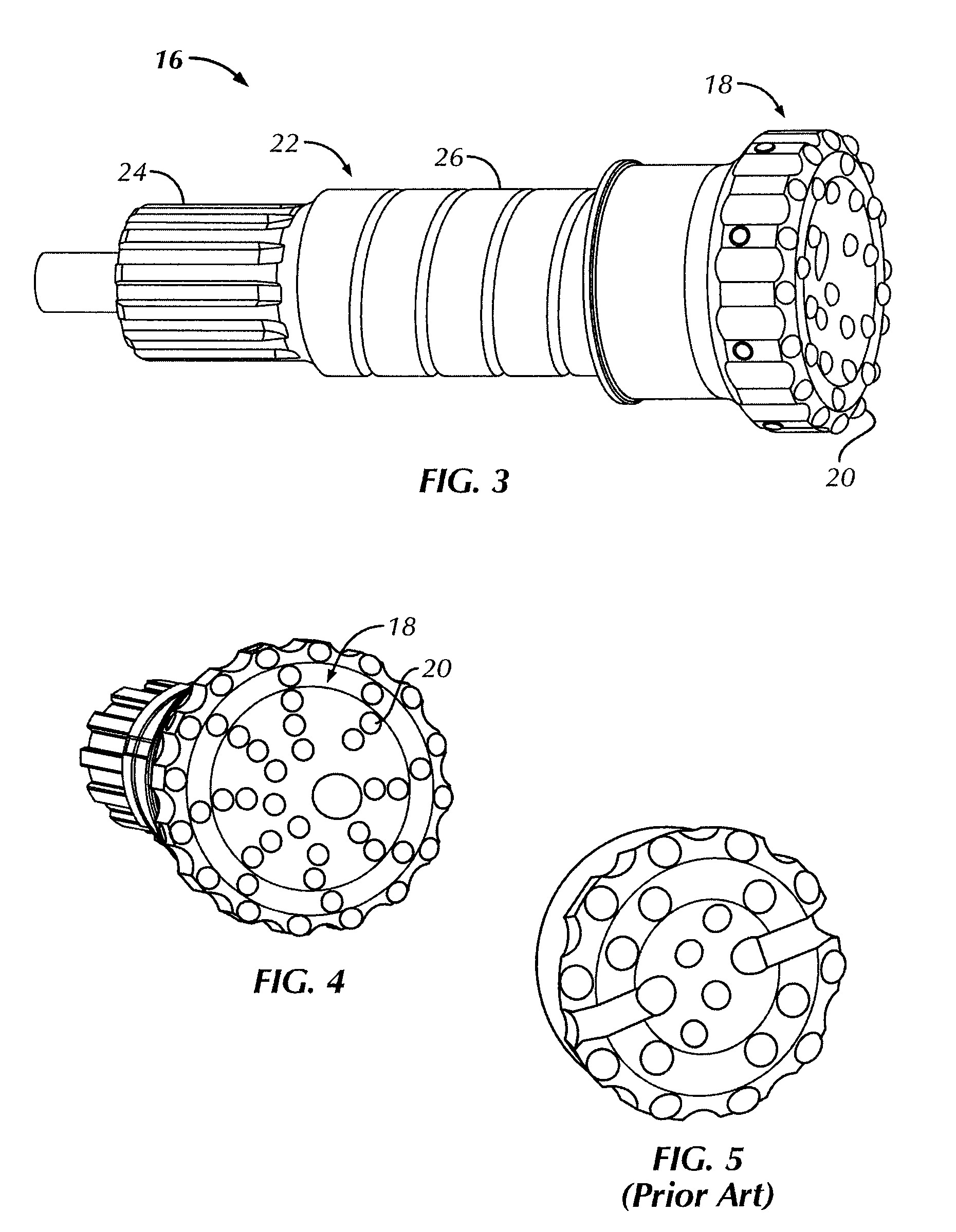

Self-Indexing Down-The-Hole Drill

A down-the-hole drill (DHD) hammer having a casing, a drill bit proximate a distal end of the casing, a piston mounted within the casing and a self-indexing drive transmission is provided. The piston includes a plurality of helical and axial splines. The drive transmission includes a driver sleeve, a driven sleeve and a wrap spring clutch assembly. The driver sleeve and driven sleeve are housed within the casing and circumscribes the piston. The driver sleeve includes a plurality of openings for receiving a plurality of bearings. The driver sleeve bearings are configured to operatively engage the helical splines on the piston. The wrap spring clutch assembly includes a wrap spring circumscribing the driver sleeve and driven sleeve. The driven sleeve operatively engages the drill bit to rotationally index the drill bit.

Owner:CENTER ROCK INC

Down-the-hole drill hammer having an extendable drill bit assembly

ActiveUS20110240373A1Cost-effective and reliable under reaming operationSimple and reliable processDrill bitsBorehole drivesPetroleum engineeringDrill hole

A down-the-hole drill hammer assembly includes a casing, a drill stem, a drilling lug segment and a pilot drill bit is provided. The drill stem is housed within the casing and includes an abutment surface. The drilling lug segment is slidably engaged with a distal end of the drill stem and movable between an initial configuration and an extended configuration. The drilling lug segment includes a proximal end engageable with the abutment surface of the drilling lug segment. The drill stem is movable between first and second positions within the pilot drill bit. In moving to the second position, the drill stem slidingly engages the drilling lug segment and moves the drilling lug segment to the extended configuration.

Owner:CENTER ROCK INC

Primary blasting well forming method for middle guide well

InactiveCN108374661AVarious construction methodsHigh security riskBlastingShaft sinkingDetonatorSludge

The invention relates to the field of tunnel engineering, and discloses a primary blasting well forming method for a middle guide well. The method includes the steps: (1) performing measuring and positioning to determine the wellhead position of a vertical well; (2) mechanically digging a wellhead of the vertical well; (3) reversely digging the bottom of the vertical well upwards; (4) according toa blasting design lofting blast hole position of the middle guide well: performing lofting to form 2m*2m middle guide well position of the vertical well by the aid of a total-station instrument, andlabeling the position of the blast hole position; (5) completely drilling a blast hole by a down-the-hole drill once; (6) plugging the bottom of the blast hole; (7) filling the blast hole with explosive; (8) plugging an upper opening of the blast hole with blast sludge after the blast hole is plugged by the explosive; (9) line connecting and explosion initiating, connecting starting detonators inthe blast holes in a clustering manner, and performing differential initiation of non-electric millisecond detonators. The method has the advantages that construction safety is improved, potential safety hazards are reduced, and life safety of construction staff is guaranteed.

Owner:浙江省隧道工程集团有限公司

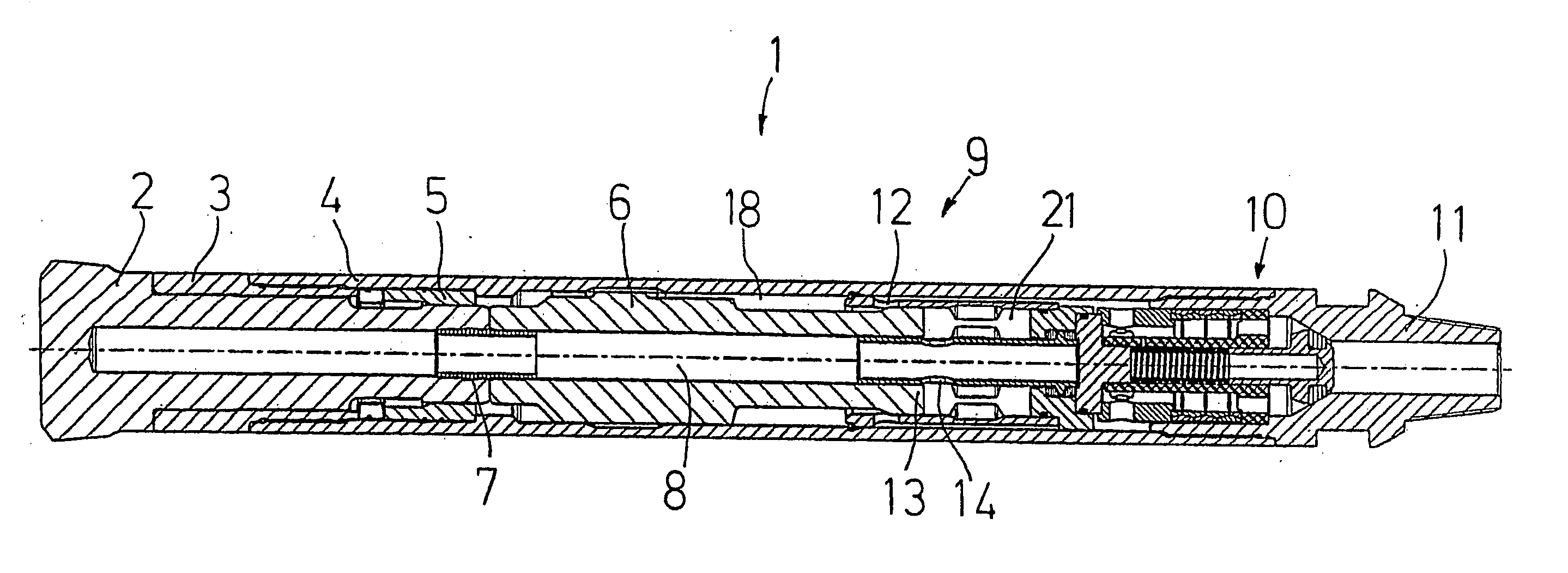

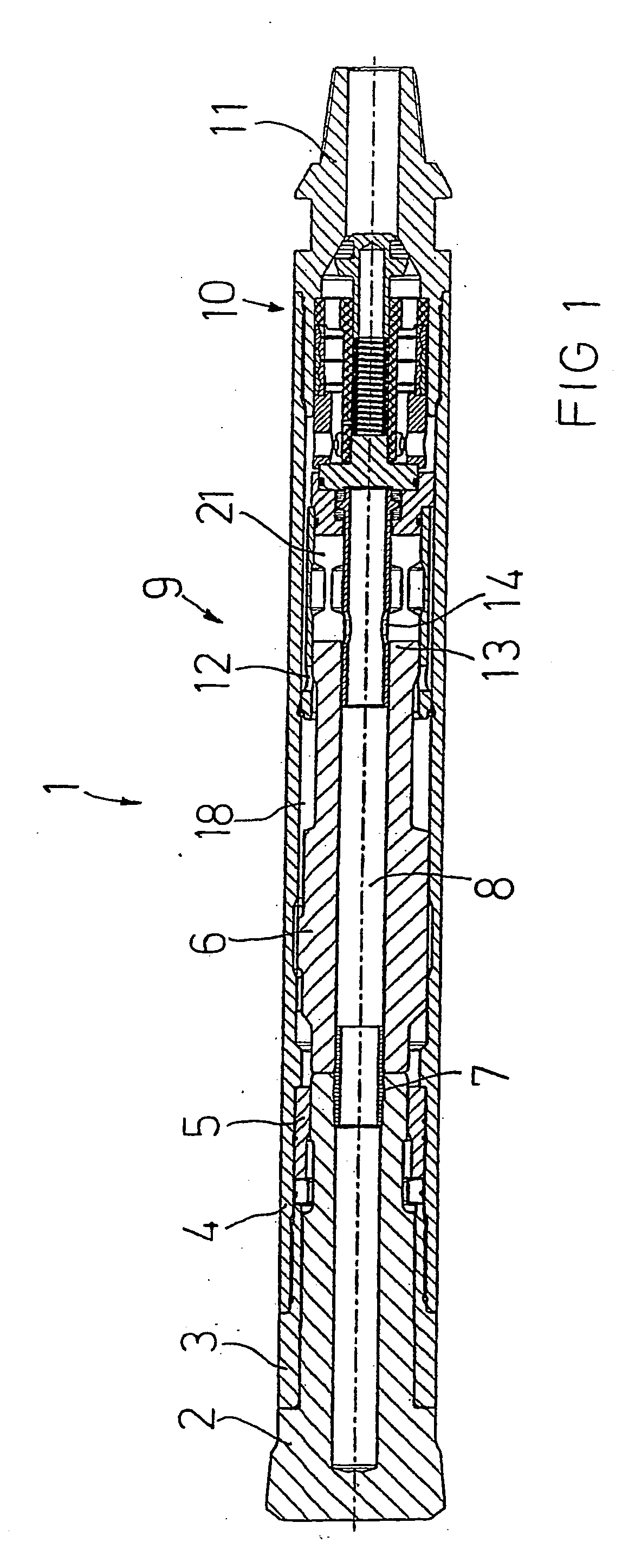

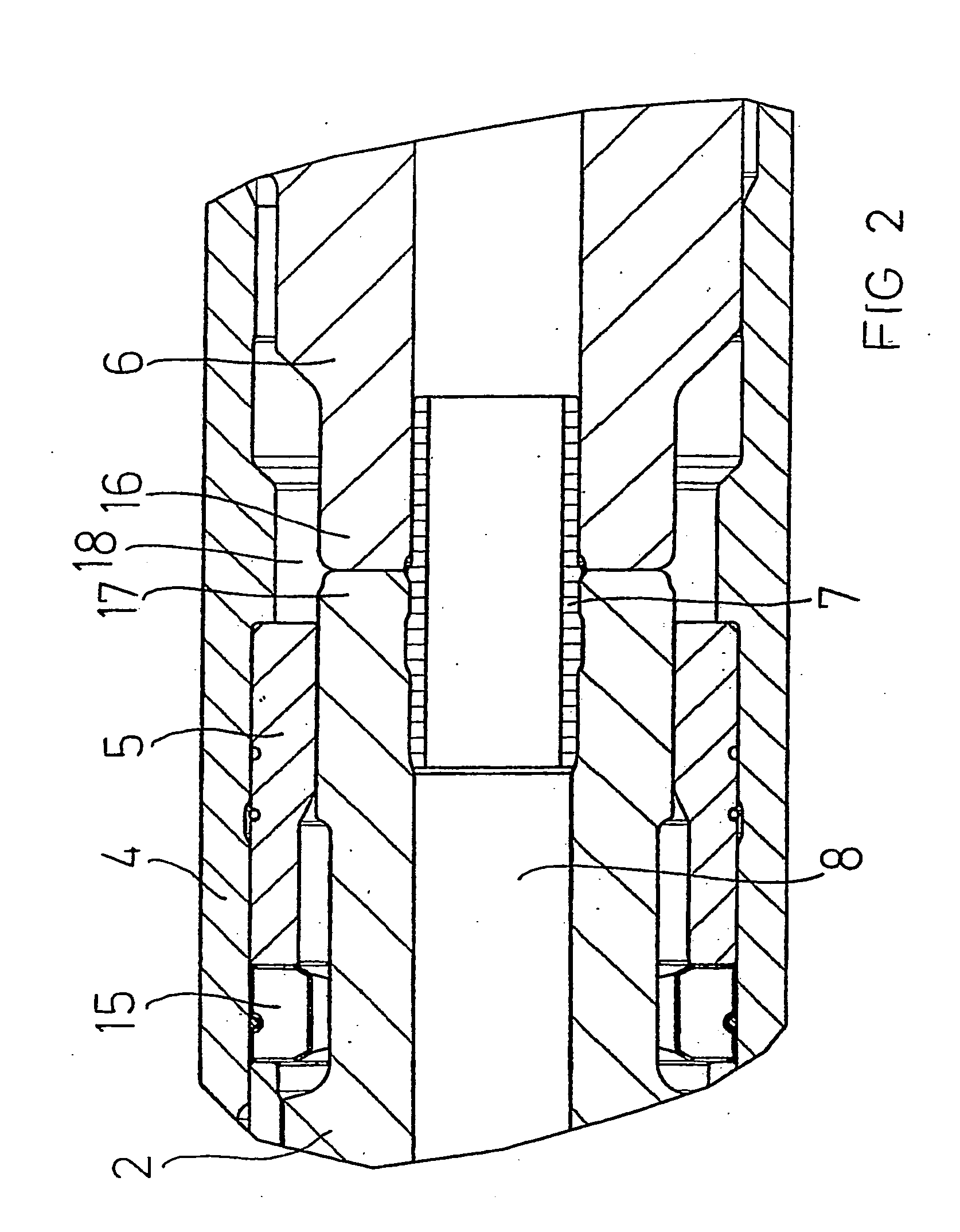

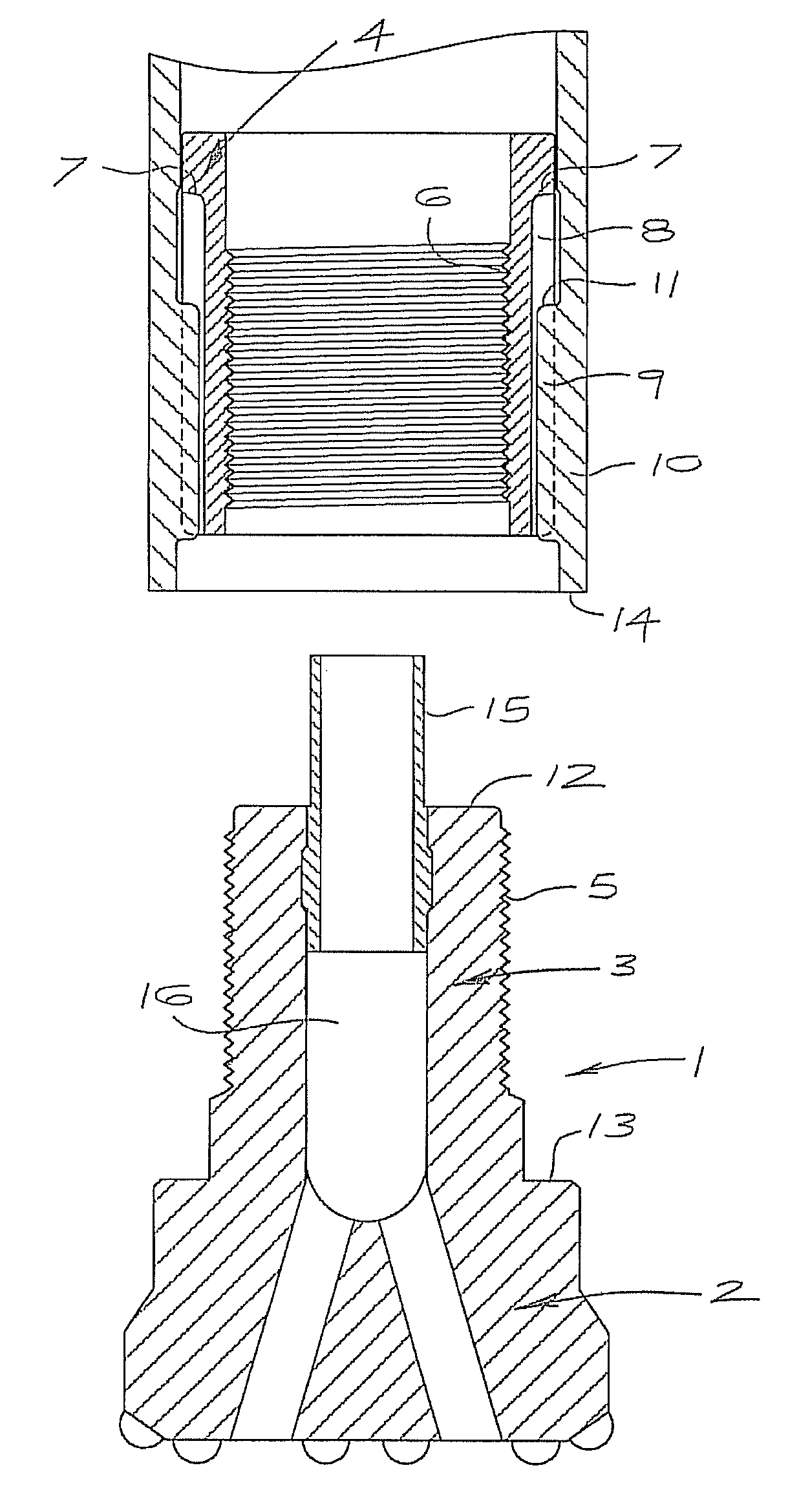

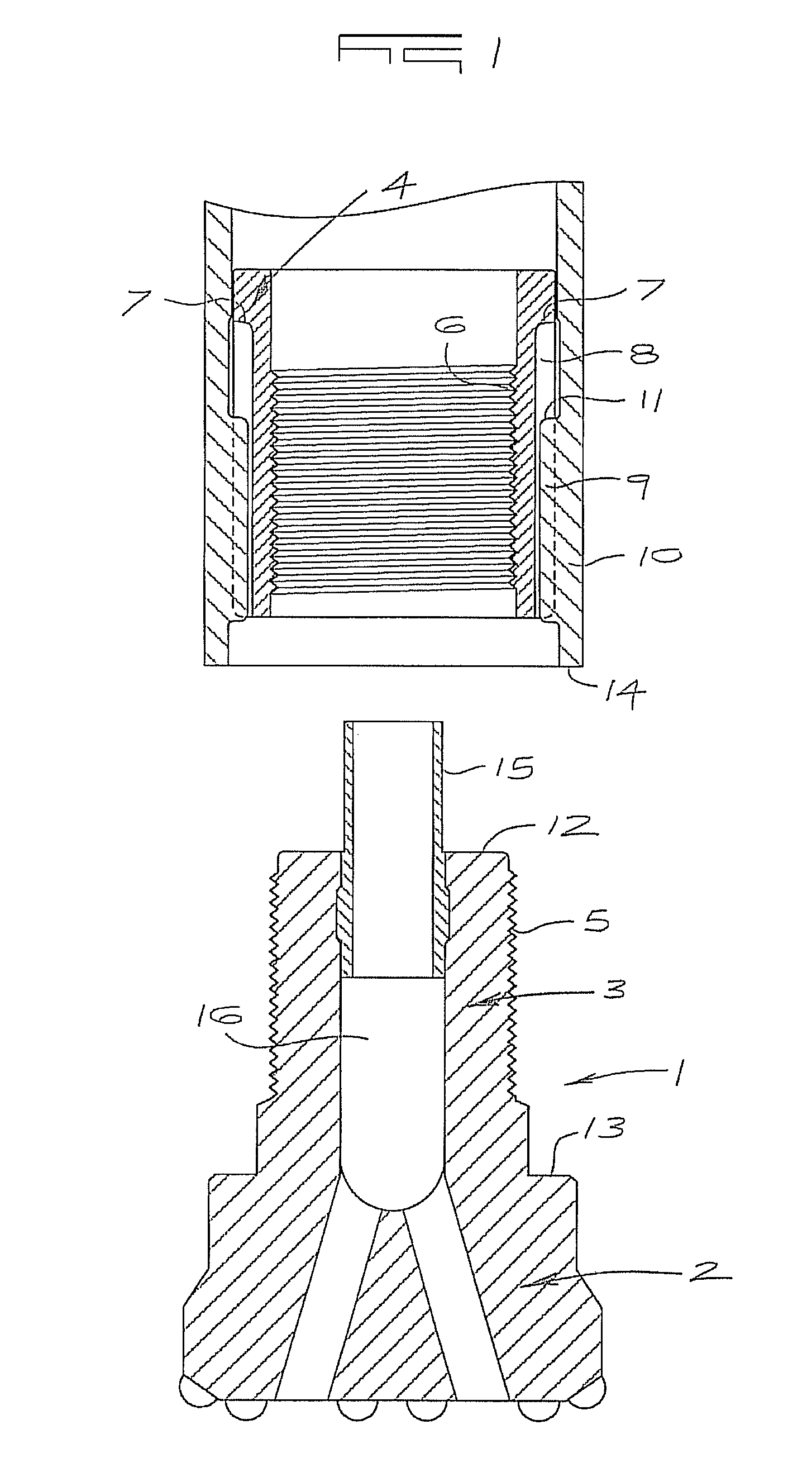

Compressed air percussive mechanism for a down hole hammer and down hole hammer

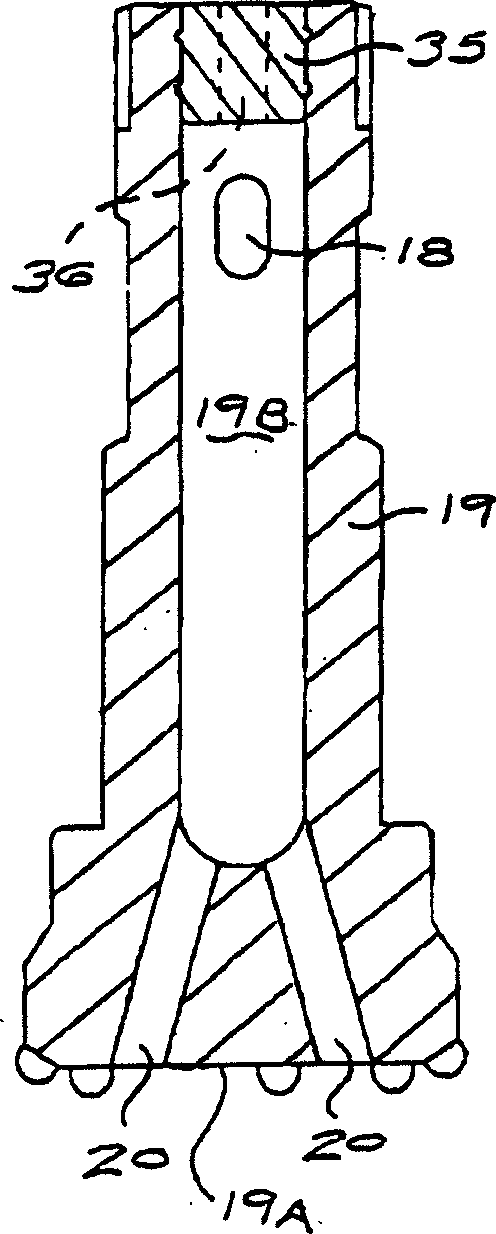

Pressure-air driven percussion device for a down-the-hole drill (1) with a hammer-piston (86) which is axially reciprocally movable in a hammer-piston chamber (18) through a driving device (9), said hammer-piston (6) in operation acting with a hammer-end (16) against an upper end (17) of a drill bit (2) which is positioned inside a chuck (3), wherein an air-cushion for reducing percussive power is arranged to be formed at the hammer-end of the hammer-piston in positions where the drill bit (2) has been moved passed a predetermined distance in the percussion direction. The drill bit (2) is sealingly slidingly supported in a drill bit bushing (5), and the hammer-end (16) of the hammer-piston (6) is formed so that it sealingly cooperates with the drill bit bushing (5) in said positions in order to form said air-cushion (19). The invention also concerns a down-the-hole drill (1).

Owner:EPIROC DRILLING TOOLS AB

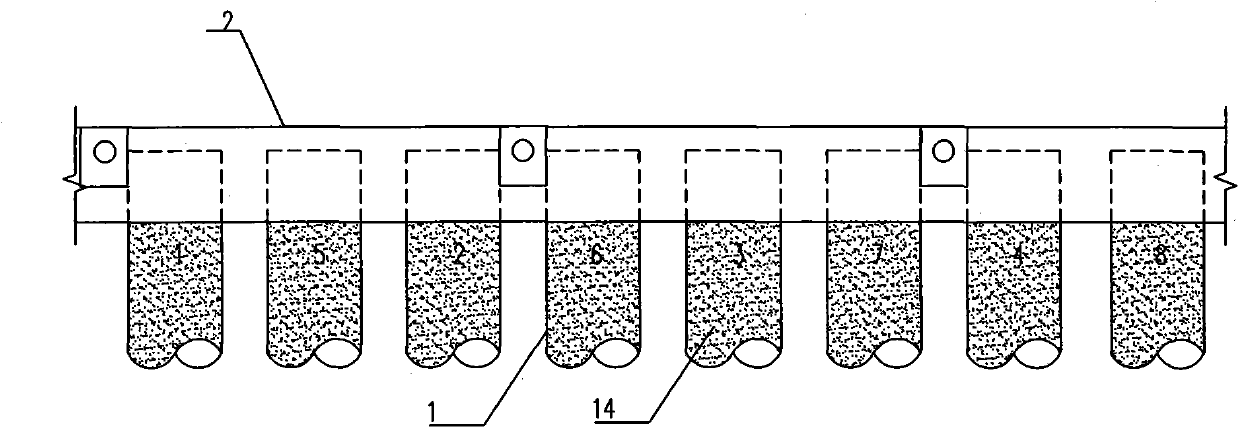

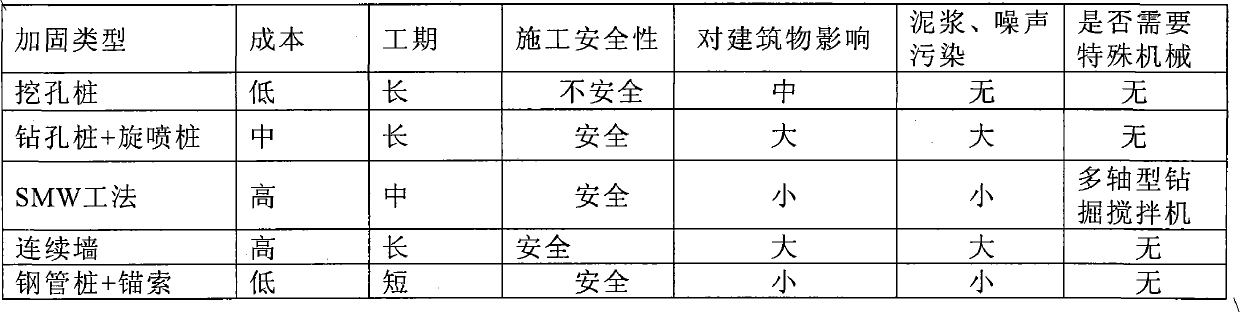

Method for protecting and reinforcing anchor rope of steel pipe pile

InactiveCN101906780AReduce the impactReduce pollutionExcavationsBulkheads/pilesArchitectural engineeringSteel bar

The invention relates to a method for protecting and reinforcing an anchor rope of a steel pipe pile. The method comprises the following steps of: inserting the steel pipe pile, wherein the steel pipe pile is a steel pipe of which the diameter is between 400 and 600 millimeters; accurately positioning the steel pipe and inserting the steel pipe into a formation until the steel pipe reaches a designed position; constructing a top beam on the top of the steel pipe pile, erecting a formwork, binding a reinforcing steel bar and pouring concrete on the top of the steel pipe pile and connecting the top of the steel pipe pile into a whole to form the top beam; and constructing the anchor rope on the top of the steel pipe pile, forming holes through the top beam by using a down-the-hole drill, drilling holes and constructing the anchor rope. The problem of the reinforcement and protection of a building before foundation pit construction is solved, and the safety of the building can be ensured effectively. The method has the characteristics of short construction time, safety, low cost, a small amount of environmental pollution and no need for special construction machinery.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

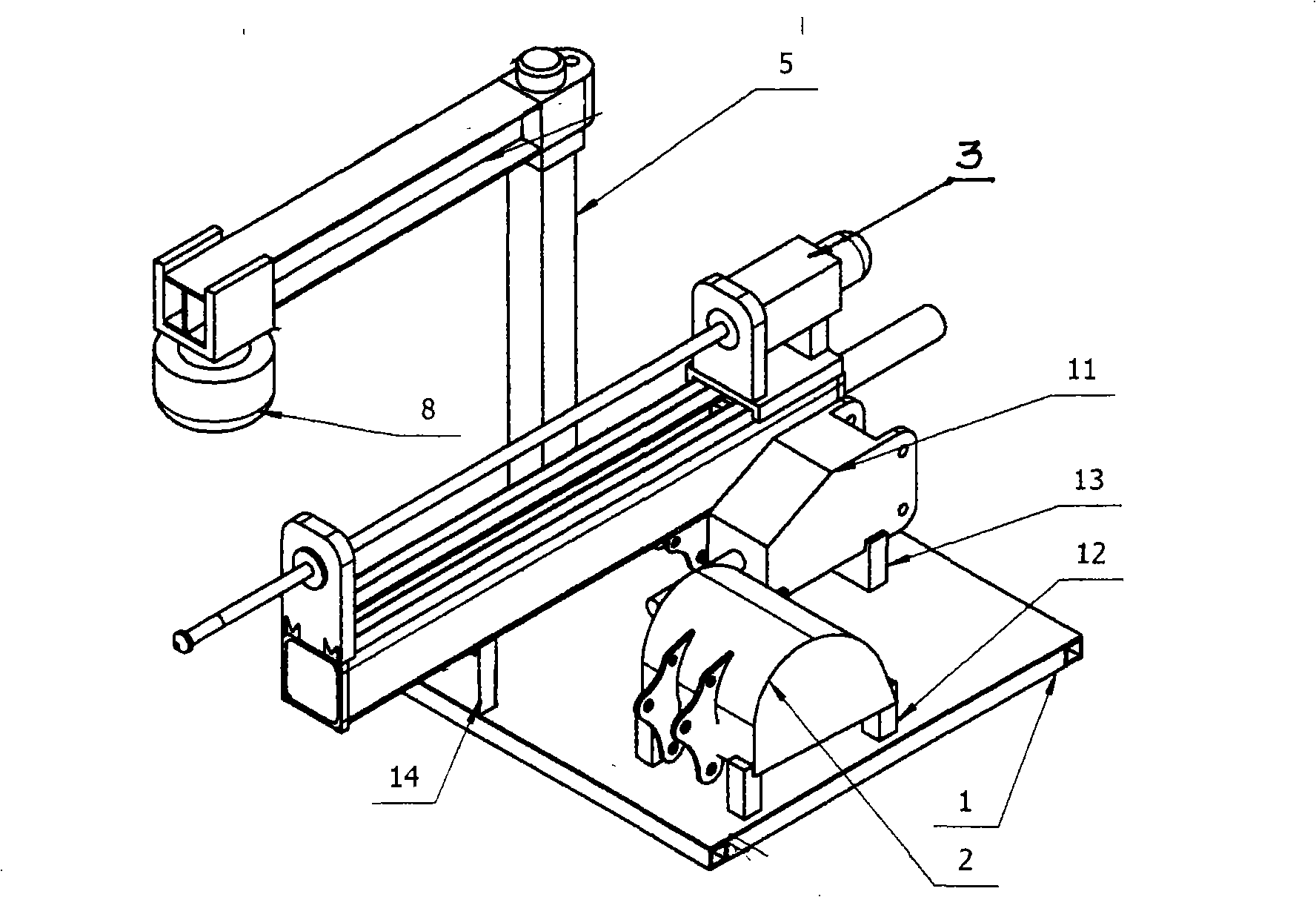

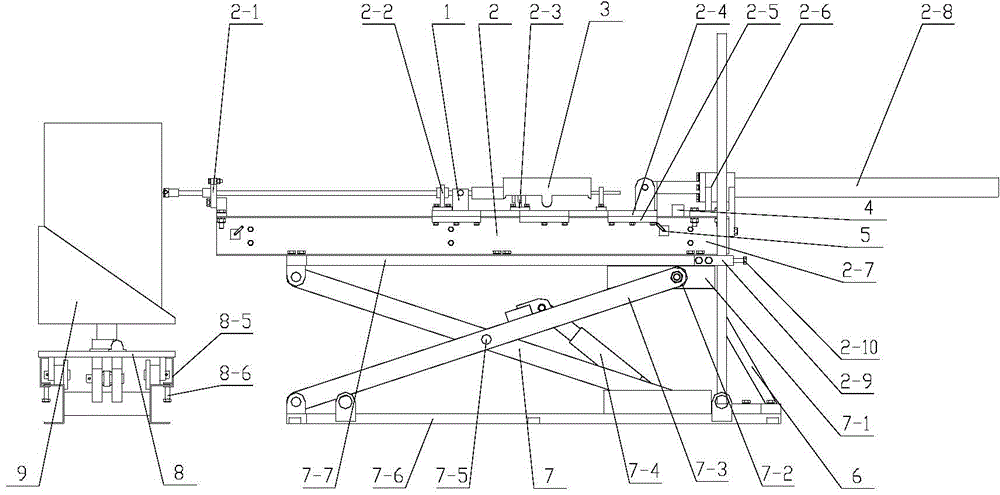

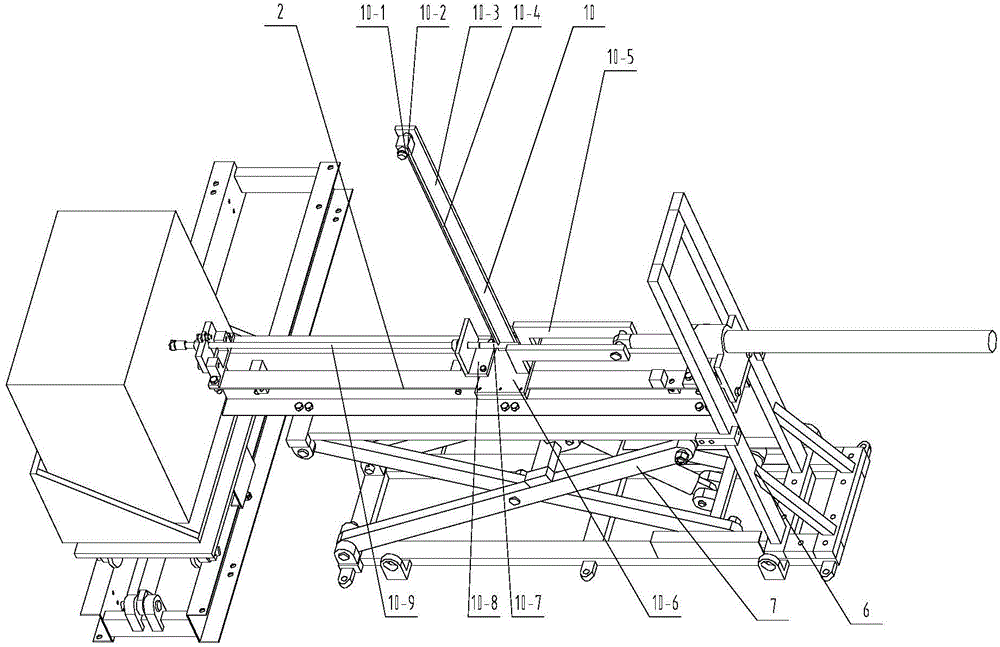

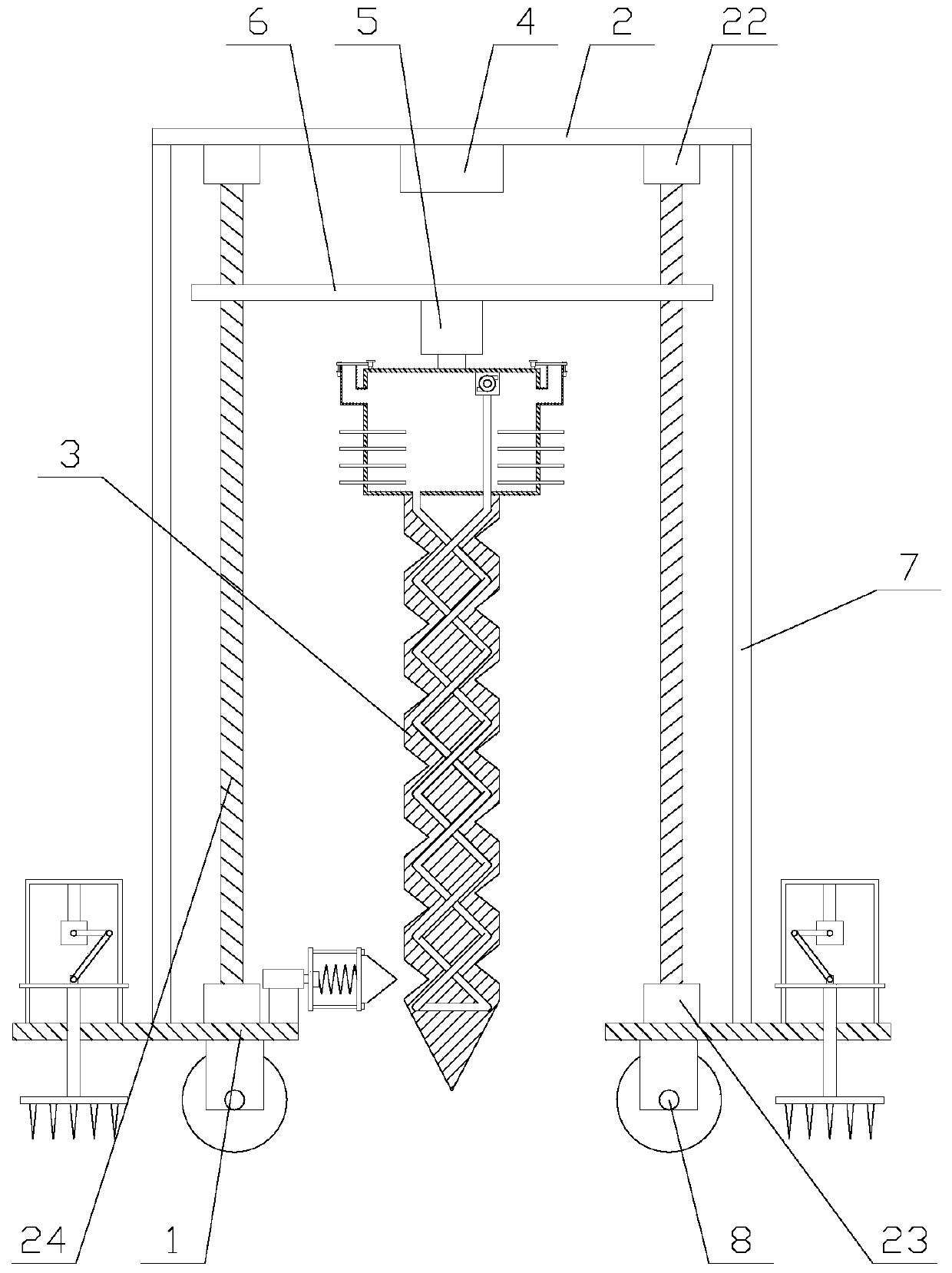

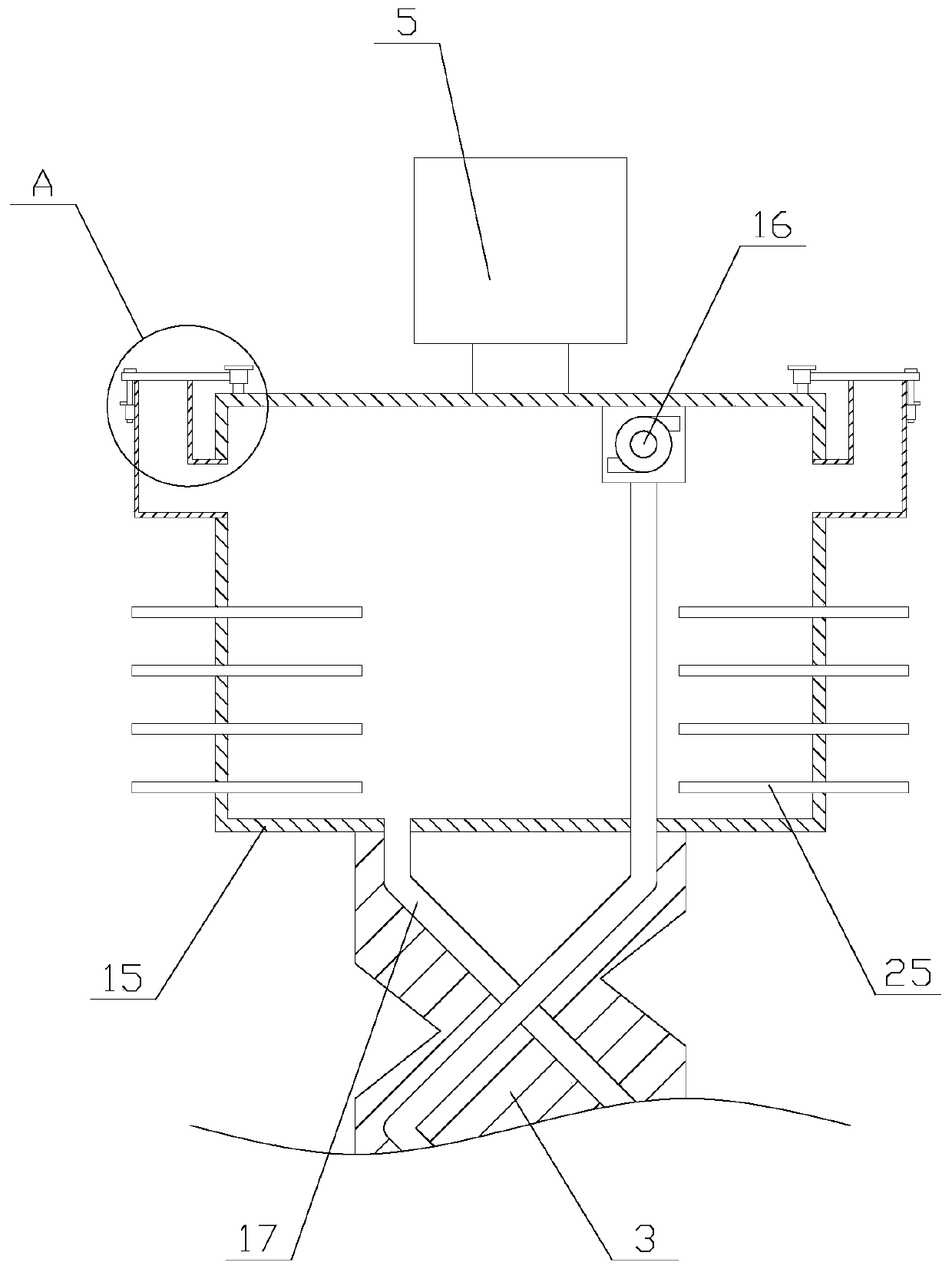

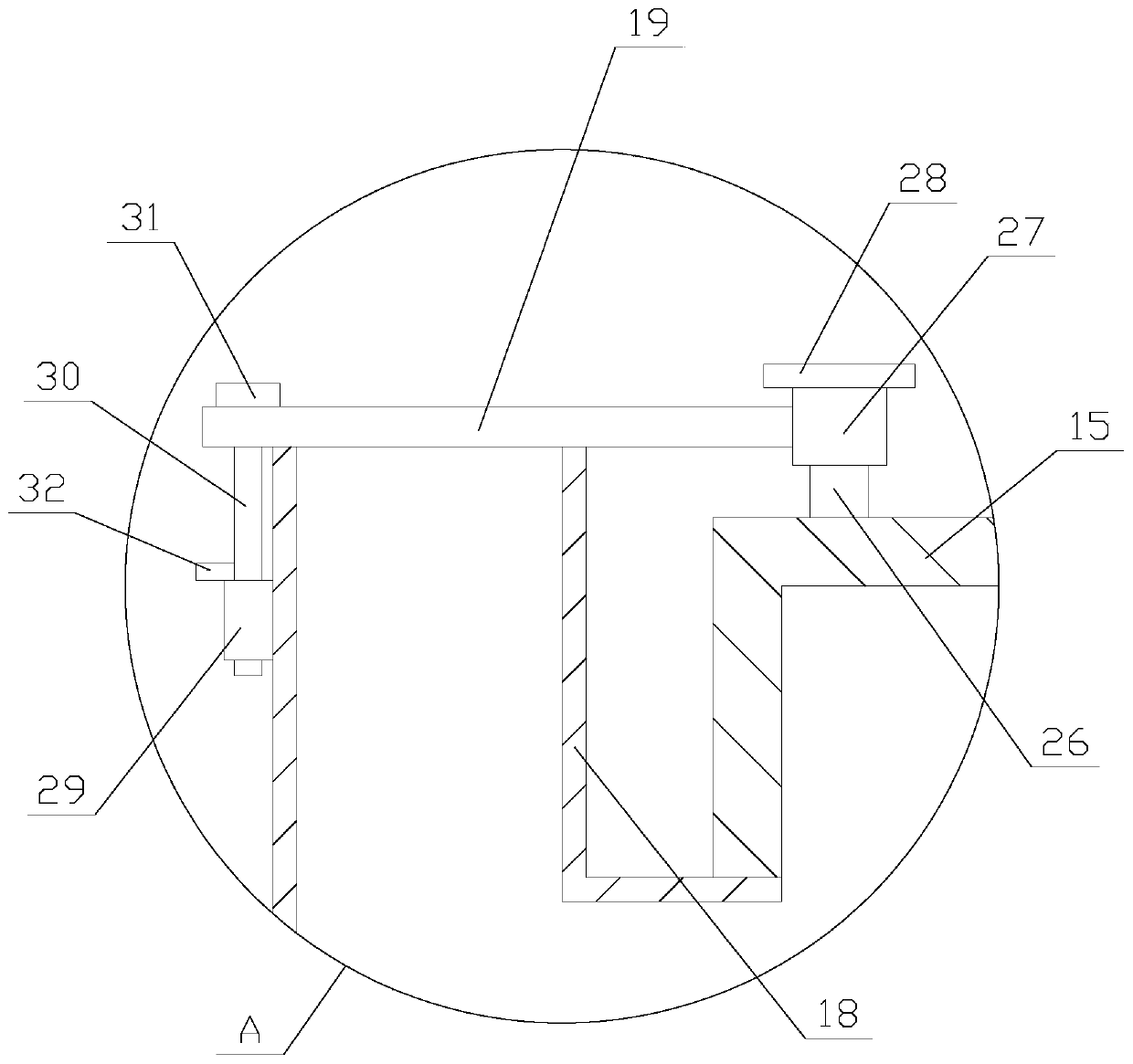

Comprehensive rock impacting breaking test stand

InactiveCN104634673AAchieve horizontal movementRealize layoutMaterial strength using single impulsive forceMaterial strength using repeated/pulsating forcesChanging equipmentSingle impact

The invention discloses a comprehensive rock impacting breaking test stand which comprises a rotating speed sensor, a propelling part, a rock drill, a displacement sensor, a travel switch, a rear support, a lifting table, a thrust rack, a rotating rack and a pendulum bob part. Optional height adjustment in the operating range, horizontal movement of rock and change of the included angle between a tool and the rock can be realized, holes in large rock at different regular positions are formed, the empty hole effect of the rock is researched, the research of rock breaking by combining impacting and rock breaking methods in other forms is realized by virtue of rapid replacement equipment, and the research of rock impacting breaking under single impact and continuous impact conditions is realized. The comprehensive rock impacting breaking test stand disclosed by the invention can serve as both research equipment in a lab and performance detection equipment in factories of rock drills, hydraulic hammers, down-the-hole drills and the like.

Owner:CHINA UNIV OF MINING & TECH

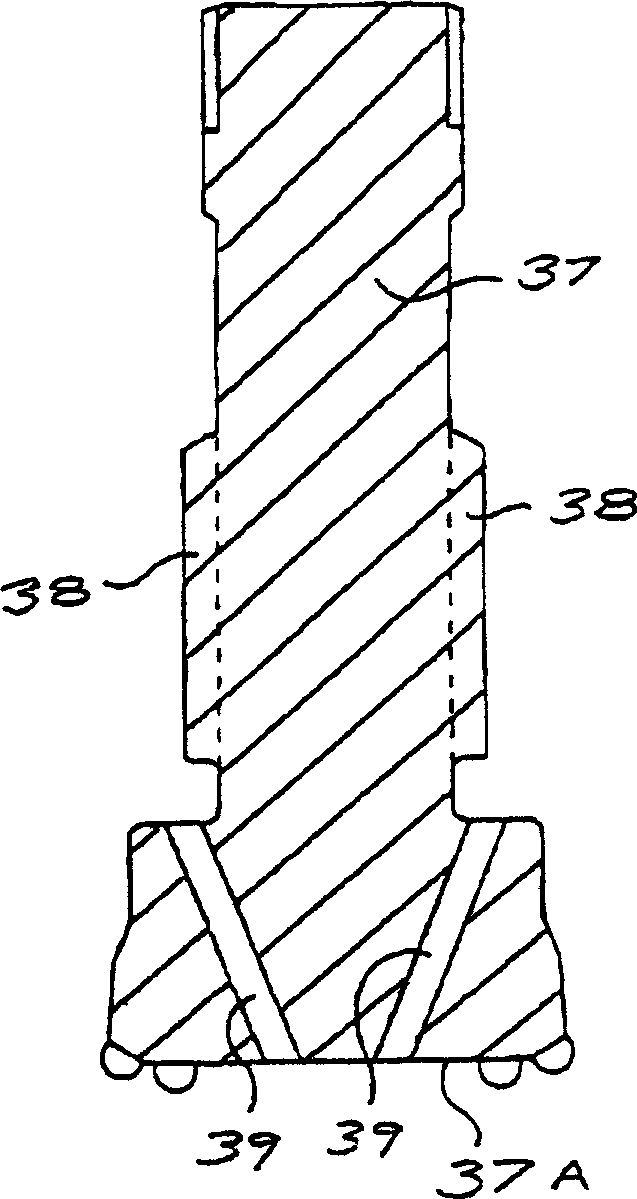

Improved drill bit

The invention provides a drill bit for a down-the-hole drill hammer. The bit has a head at its forward end with a shank extending from the head. The shank is screw threaded along its length. A reciprocating chuck is provided as a sleeve with internal screw threads corresponding to those of the shank. The shank is releasably secured in the chuck with the rear end of the shank providing a striking face. An arrangement of external splines on the chuck, and a retaining shoulder at its rear end, provide for the required guided movement of the chuck within a drill hammer wear sleeve. The bit is simple to machine with screw threads replacing the usual splines and other structural features ordinarily required on this component. These features are instead provided on the chuck and in the wear sleeve.

Owner:GIEN BERNARD LIONEL

Medium-length hole raise mining subsequent filling method

ActiveCN106223956AFast well formationImprove ergonomicsUnderground miningSurface miningCut and fillEngineering

The invention discloses a medium-length hole raise mining subsequent filling method. Ore blocks are arranged in the ore body direction, and divided into stages in the vertical height. The two ends of the ore blocks are provided with mining preparation raises. The bottoms of the ore blocks are provided with a flat bottom ore removal structure. The upper portions of the ore blocks are provided with a raise boring machine chamber. A raise boring machine is adopted for drilling mining preparation raises; a raise boring machine lifting system is adopted for lifting and drilling rock and exploding a working platform, a down-the-hole drill drills horizontal parallel or annular medium-length hole blast holes from the two sides of the raise, and concentrated rock drilling, split blasting, concentrated ore removal and subsequent filling are carried out. The method is mainly applicable to heavy pitch thin and medium thickness ore bodies, the problems of a shrinkage method, a sublevel open stop mining method or a cut-and-fill mining method are solved, and the method has the advantages that the mining and cutting work amount is small, the stope mechanical operation degree is high, production efficiency is high, production capacity is large, workers do not need to enter a stope for work, and safety conditions are good.

Owner:GUANGXI UNIV

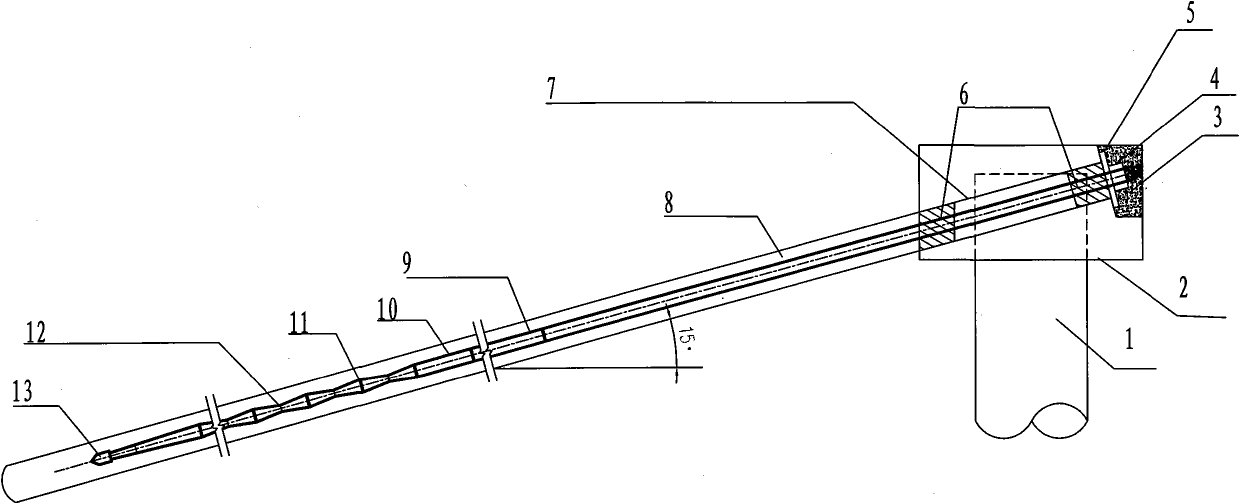

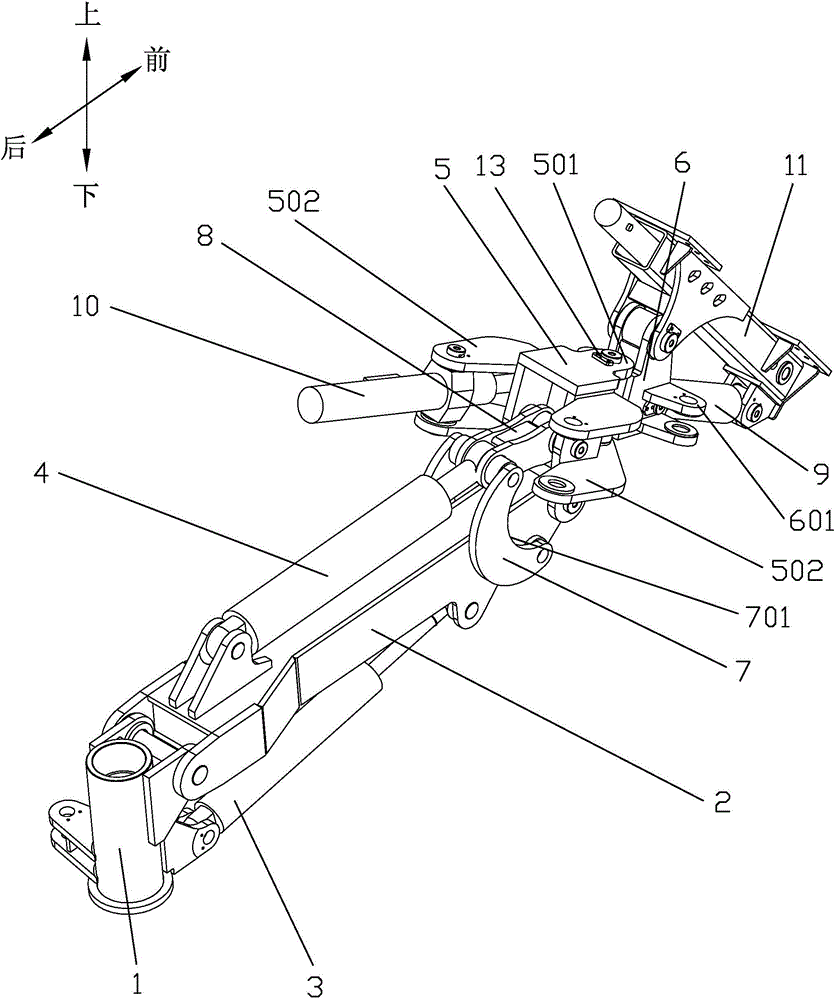

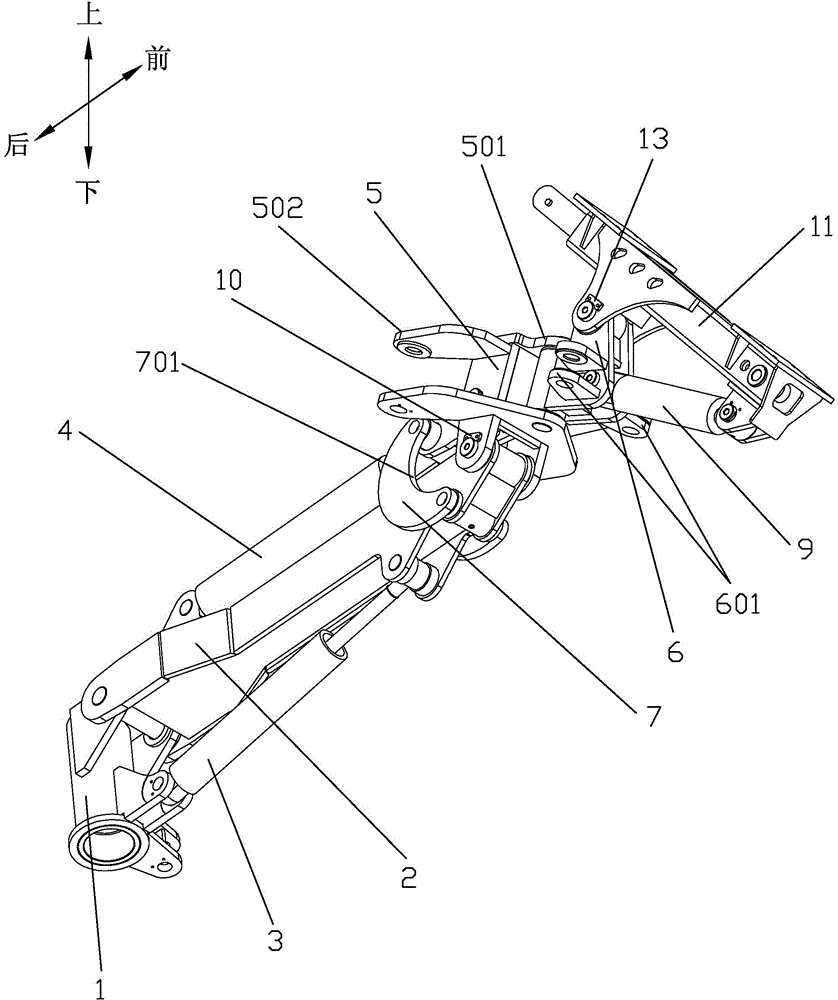

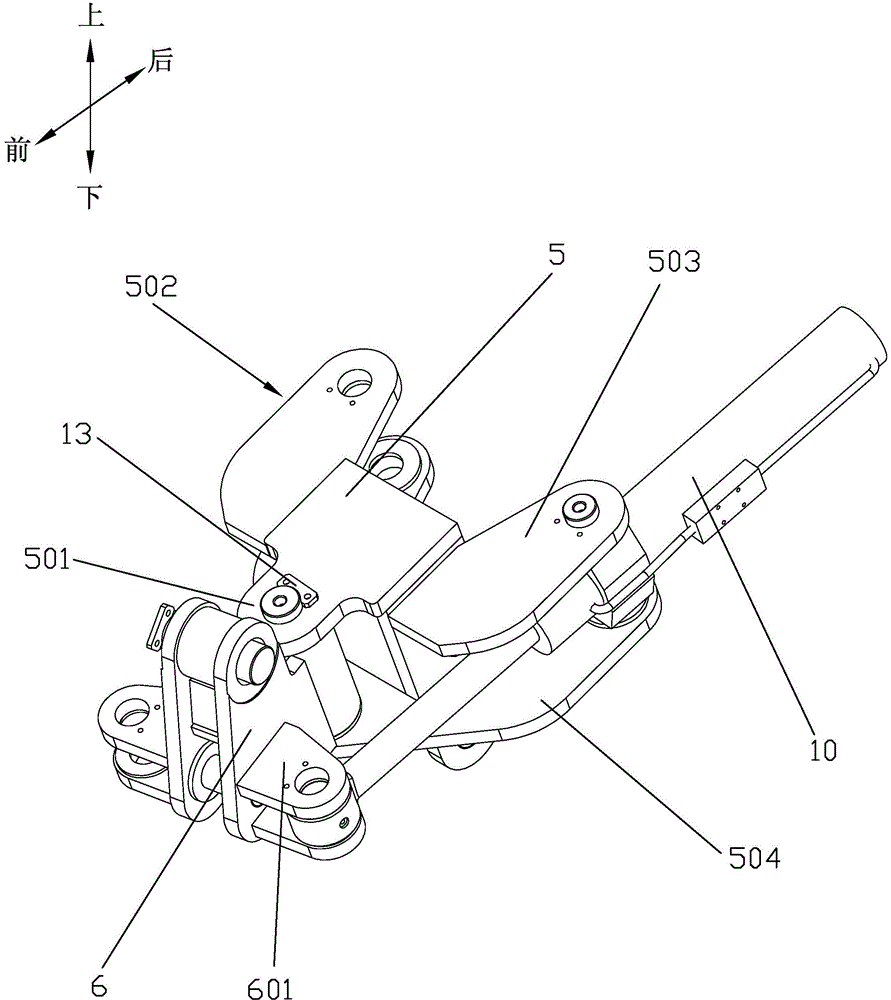

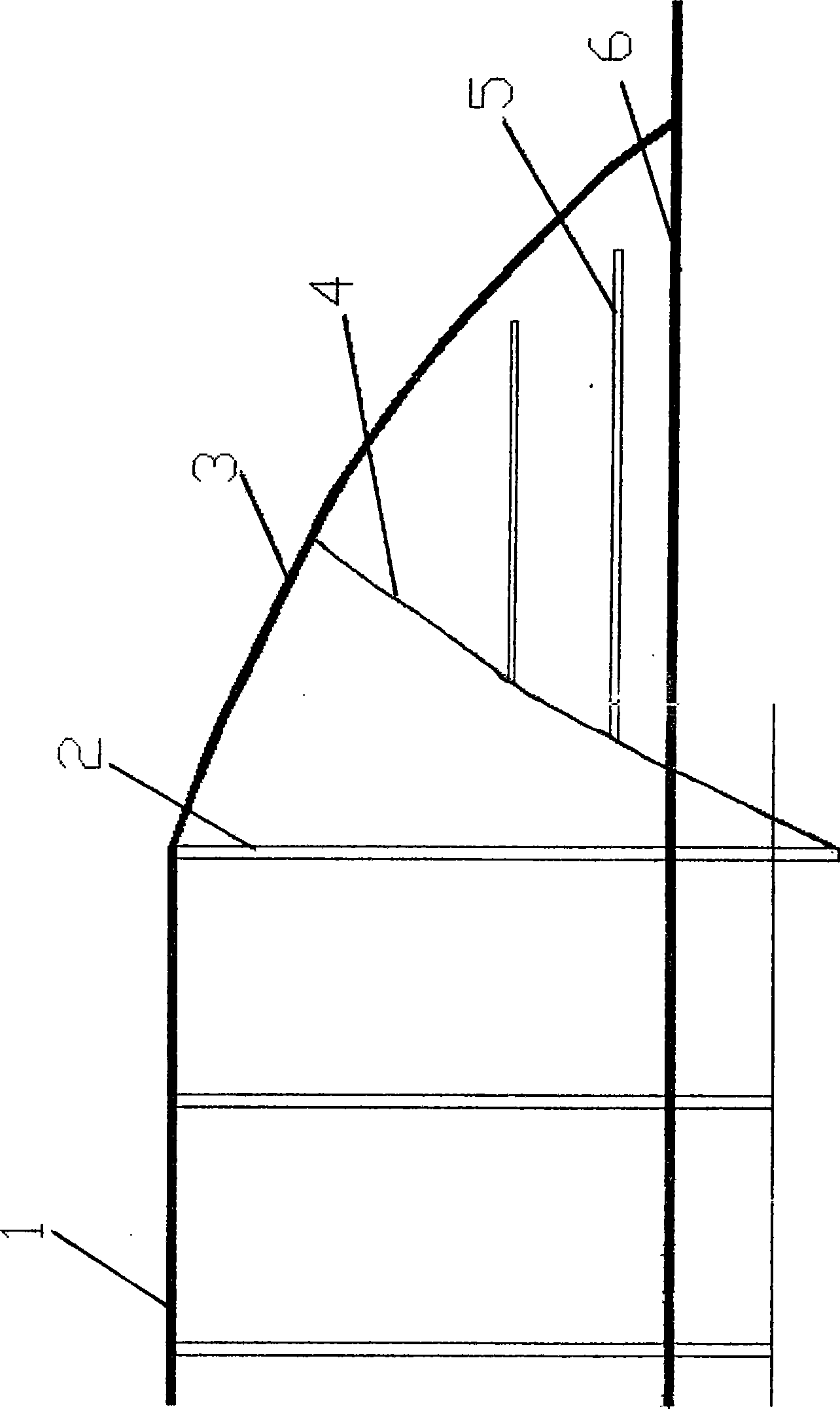

Wide-angle pitching and swinging down-the-hole drill

InactiveCN104653102AIncrease pitch angleIncrease the pitching speedDerricks/mastsBorehole drivesPetroleum engineeringDown-the-hole drill

The invention discloses a wide-angle pitching and swinging down-the-hole drill, which comprises a main arm and a connecting seat, wherein the main arm is hinged to an upper oil cylinder and a bending plate; a core bar of the upper oil cylinder, the bending plate and a connecting rod are hinged in a coaxial manner; the other end of the connecting rod is hinged to the middle part of a connecting base; the action of the upper oil cylinder is driven by pushing the connecting seat to pitch and rotate by the bending plate and the connecting rod; the front end of the connecting seat is provided with a convex plate, the convex plate is hinged to a swing seat in horizontal swing; a compensation bracket for installing a drill bit is connected with the swing seat; the side of the convex plate of the connecting seat is provided with a first wing plate; the swing seat is provided with a second wing plate which is on the same side of the first wing plate; the first wing plate is provided with a swing oil cylinder in a hinging manner; a core bar of the swing oil cylinder is hinged to the second wing plate; and the swing oil cylinder acts to drive the swing seat to horizontally swing. The pitch angle and the rotational speed of a down-the-hole drill are increased by the bending plate and the connecting rod; and the swing seat is capable of driving a crossbeam and the drill bit to swing over 180 degrees through parts such as the swing oil cylinder and the swing seat.

Owner:广东孔山重工机械有限公司

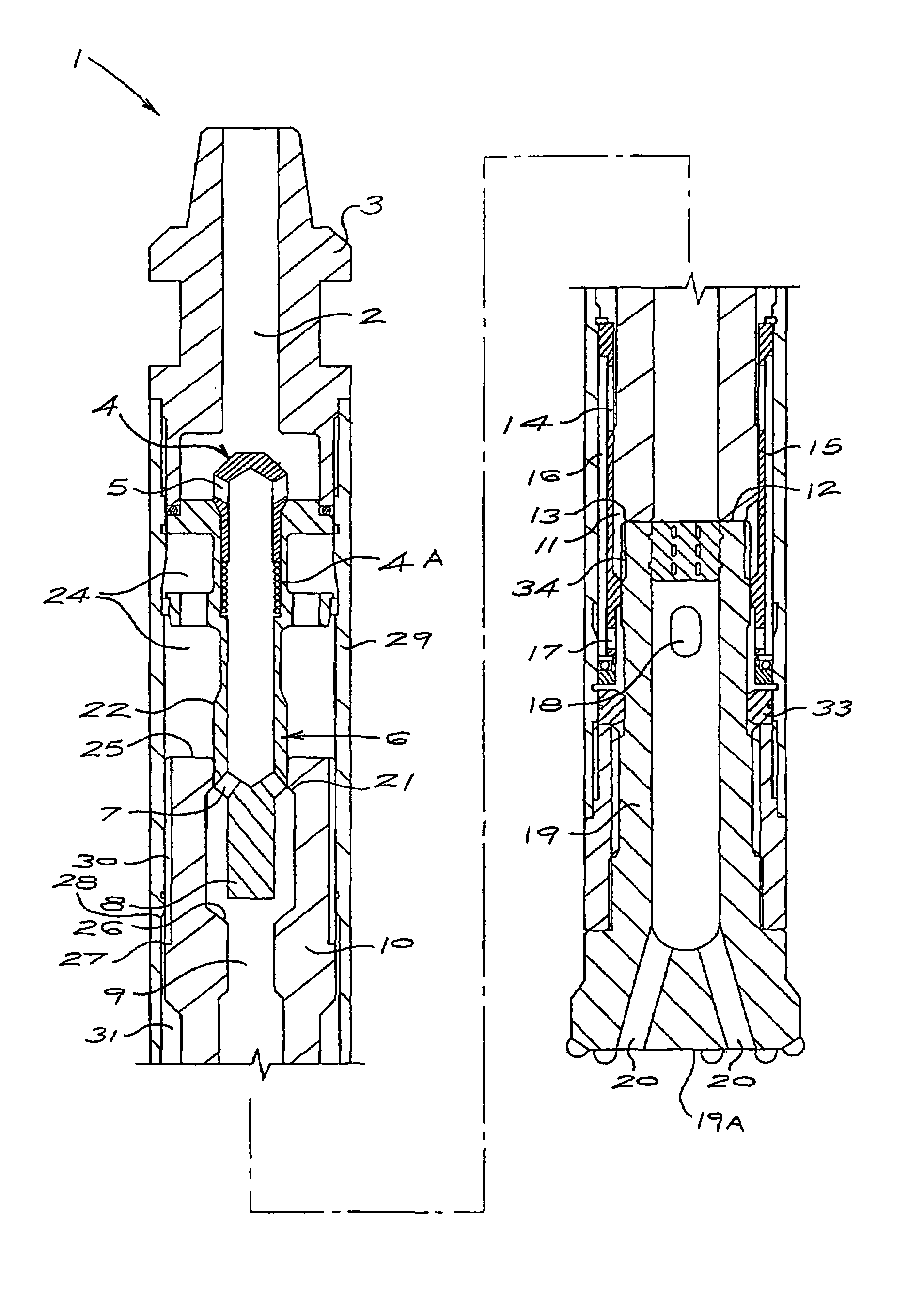

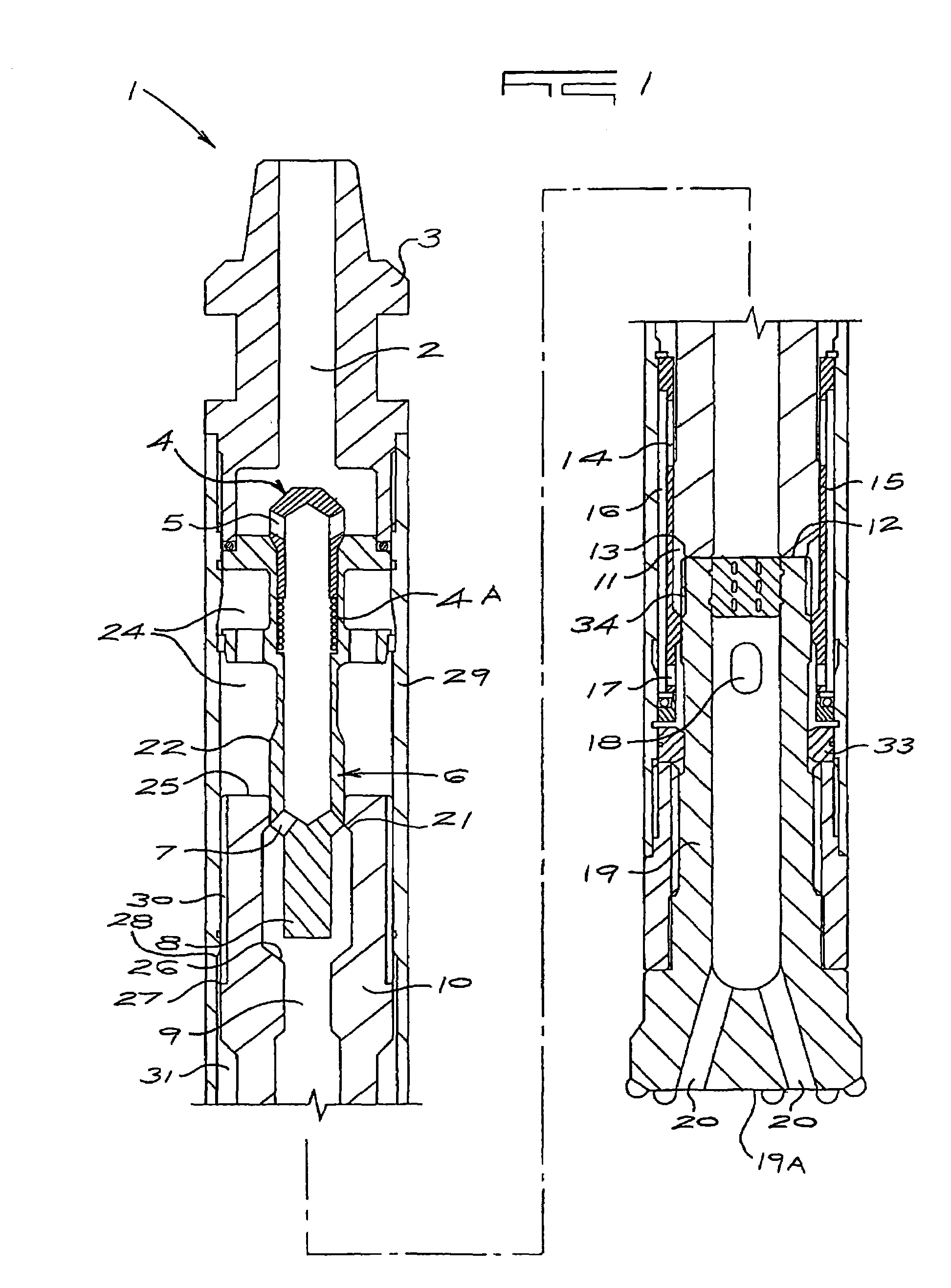

Pressurized fluid flow system having multiple work chambers for a down-the-hole drill hammer and normal and reverse circulation hammers thereof

A pressurized fluid flow system for a down the hole drill hammer has a plurality of chambers that exert work, namely one or more auxiliary drive and lifting chambers besides two main chambers located at opposite ends of the piston, the auxiliary chambers each formed around respective waists on the piston and externally delimited by respective cylinders which are arranged longitudinally in series. Two or more internal chambers filled with the pressurized fluid are defined by recesses in the inner surfaces of the piston for supplying said fluid to the work chambers, controlled in a cooperative way by the piston and a control tube coaxially arranged within a central bore of the piston. One or more discharge chambers are formed in between the outer casing and the cylinders for emptying the work chambers through discharge ports in the cylinders. Reverse and normal circulation drill hammers are provided having this system.

Owner:DRILLCO TOOLS

Down-the-hole drill assembly

The invention provides a down-the-hole drill assembly having exhaust passages from upper and lower chambers past the inner end of a bit and through the body of the bit to exit through the bit face. The construction of the assembly and bit obviates a foot valve tube from the head of the bit and the disadvantages associated with this component.

Owner:GIEN BERNARD LIONEL

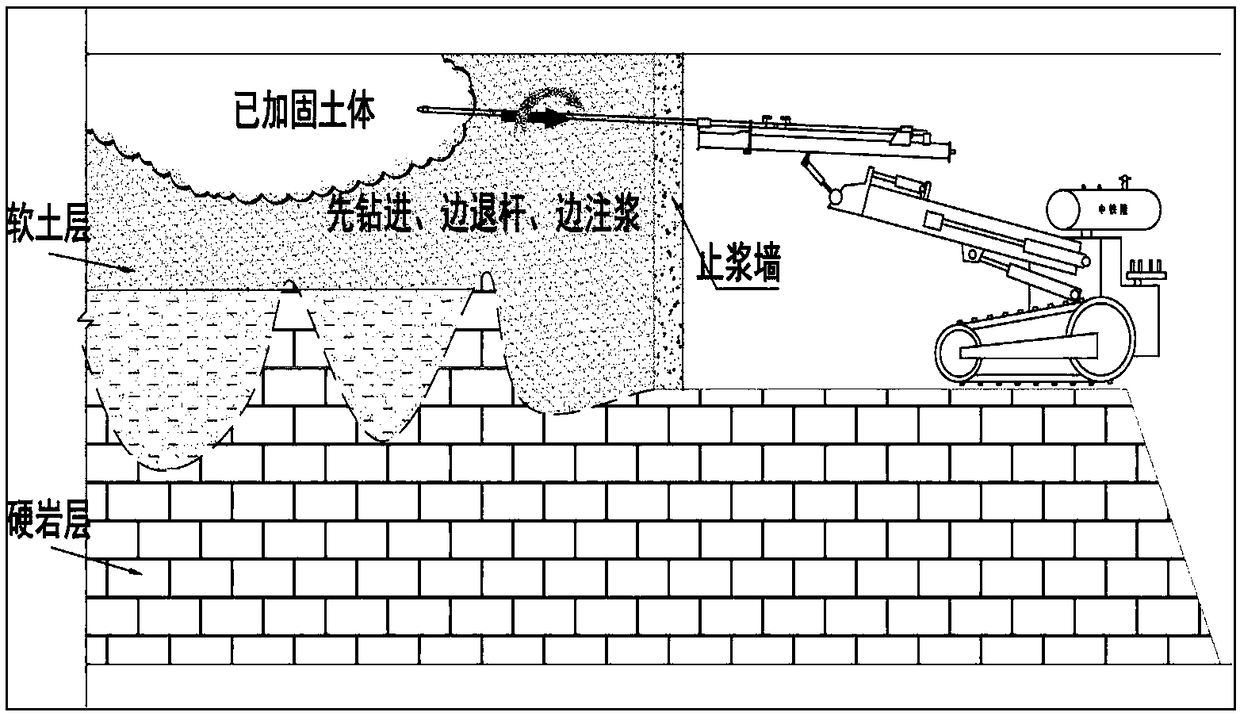

Construction method for undercrossing of urban shallow tunnel through soft-flow plastic red clay layer

ActiveCN108252719AEasy to reinforceSolve the problem of difficult groutingUnderground chambersTunnel liningRebarGrout

The invention discloses a construction method for undercrossing of an urban shallow tunnel through a soft-flow plastic red clay layer. The construction method comprises the following steps that 1, a simple grout-preventing wall is built, concrete is sprayed through a reinforcing mesh, and meanwhile annular implemented anchor bars are preliminarily erected on a tunnel face and connected with the reinforcing mesh into a whole; and 2, retrograde grouting is conducted, specifically, a down-the-hole drill drills in the tunnel face to drill forwards till the preset depth is reached, grouting work isconducted through a hollow drill rod, meanwhile the drill rod rotates and retreats, and the grouting pressure is controlled to be 0.5-1 Mpa. According to the construction method, low-pressure grouting processing operation of the soft-flow plastic red clay layer can be effectively achieved, the construction safety and urban pipe network road safety are guaranteed, and the construction schedule isaccelerated.

Owner:RANKEN RAILWAY CONSTR GROUP

Submerged hole driller component element

The invention provides a down-the-hole drill assembly having exhaust passages from upper and lower chambers past the inner end of a bit and through the body of the bit to exit through the bit face. The construction of the assembly and bit obviates a foot valve tube from the head of the bit and the disadvantages associated with this component.

Owner:莱昂内尔·吉安·伯纳德

Construction method for entering shallow-buried multi-arch tunnel under water-rich geological conditions

InactiveUS20220106879A1High practicabilityNovel conceptUnderground chambersTunnel liningSoil massMarking out

A construction method for a shallow-buried multi-arch tunnel under water-rich geological conditions includes the following steps: cleaning a grouting ground surface; marking a grouting reinforcement scope; performing survey setting-out; drawing a cross-section diagram to scale; calculating out coordinates and angles of anchor points that need to be set; marking drilling positions; nailing small wooden piles at the drilling positions for identifying; determining a setting depth of the anchor rods according to ground elevation; drilling holes, cleaning bottom of hole, grouting, performing construction preparation, performing long pipe shed construction at the entrance after an earth-rock of a tunnel entrance and an open cut tunnel is excavated to flush with a springing line of the tunnel. A down-the-hole drill is used for drilling in construction. Long pipe shed grouting is designed based on solidifying a soil mass in limited scope around a consolidation pipe shed.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

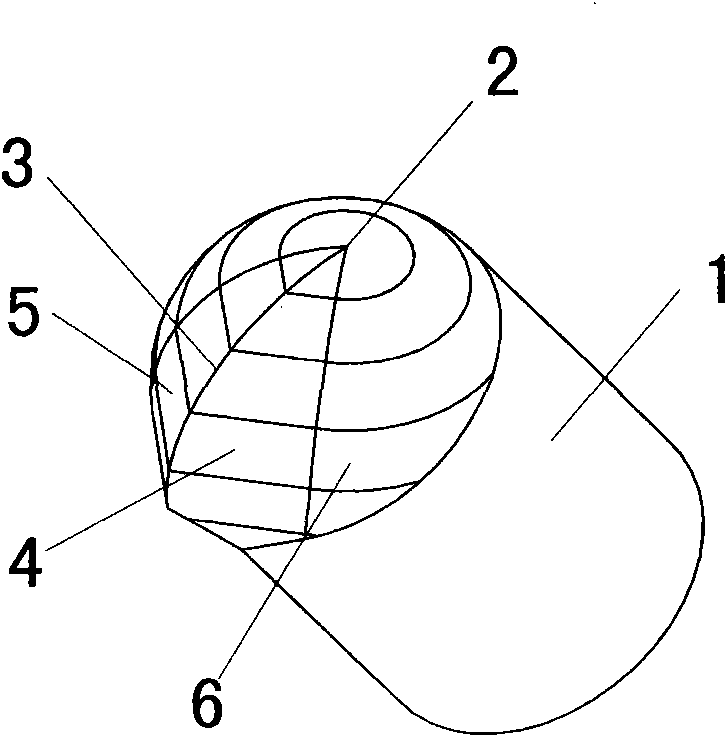

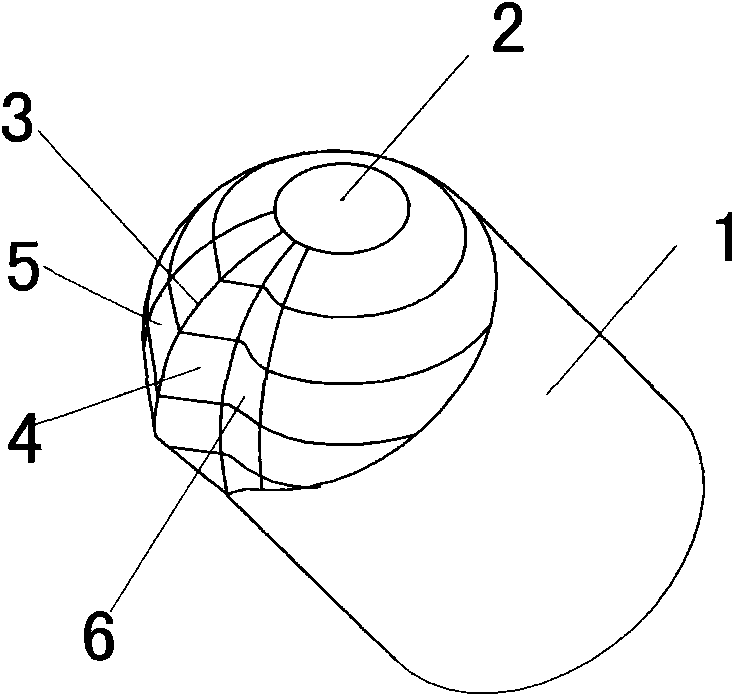

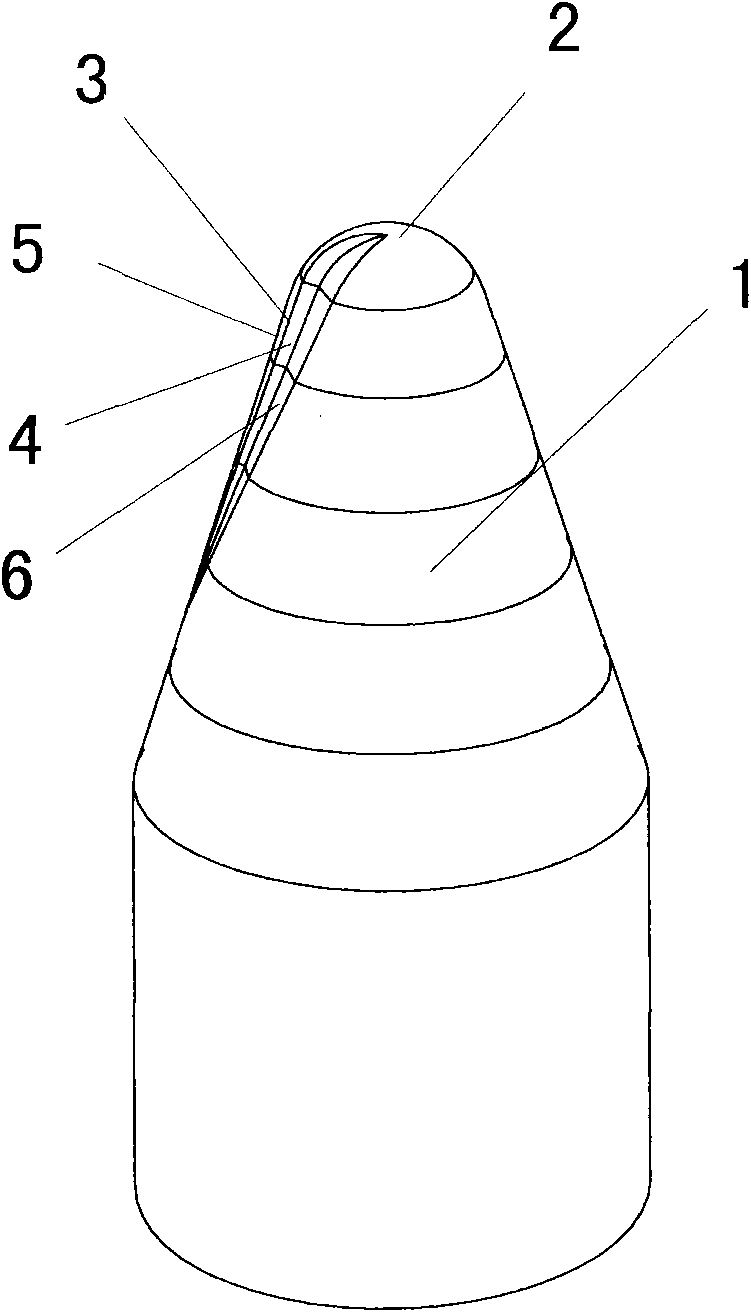

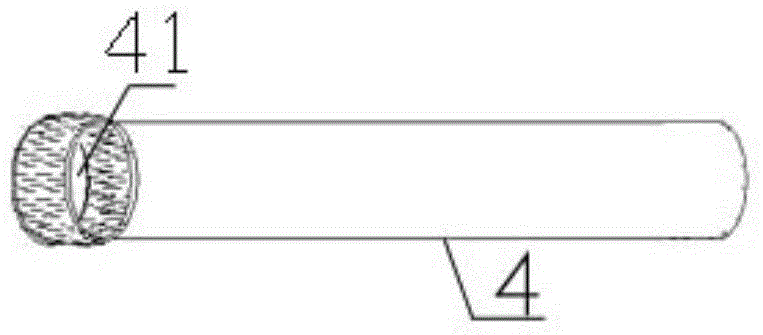

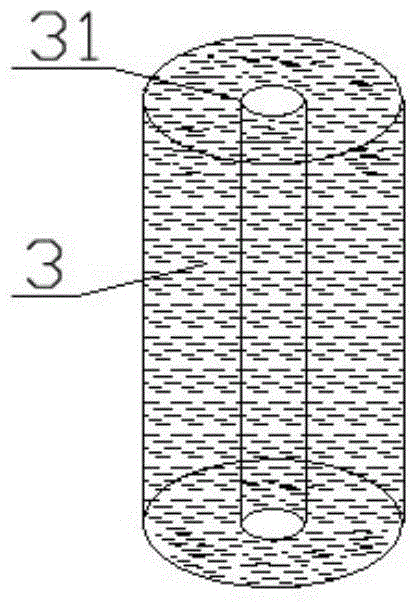

Stud gear with cutting edge and drill thereof

InactiveCN102168526ASolution to short lifeGuaranteed impact strengthDrill bitsDrilling rodsEngineeringPetroleum

The invention discloses a stud gear with a cutting edge and a drill thereof, and is suitable for manufacturing a stud gear with a cutting edge and the drill of the stud gear which are used for drilling operations for getting water, mining minerals, petroleum and natural gas, geological drilling operation and the like, as well as rock drilling operations of various civil constructions, wherein the stud gear and the drill thereof can be a roller bit working in a rolling manner, a hole bit and or stud gear bore bit working in a spinning manner. The stud gear comprises a cutting edge which is additional arranged at the side part, the original rotation body structure of the stud gear head is basically maintained, so that the original impact resistance strength is maintained. After the drill disclosed by the invention is adopted, the shortage that the spherical face of the traditional stud gear is easy to wear when used for scraping rocks is basically overcome.

Owner:李荟敏

Efficient, safe and environment-friendly post-water-injection type static blasting method and water injection device using same

The invention relates to the field of static blasting, in particular to an efficient, safe and environment-friendly post-water-injection type static blasting method and a water injection device using the method. The method comprises the steps that a plurality of holes are drilled at designed intervals in the working face in the air of a place needing static blasting; a water injection tube is inserted into each hole, one end of each water injection tube is close to the bottom of the corresponding hole, and the other end of each water injection tube extends out of the corresponding hole opening; the holes are filled with expanding agents and rapid solidification mixed materials so that the hole openings can be sealed, and gaps are reserved between the insertion ends of air outlet tubes and the interfaces of the expanding agents; after the hole openings are sealed after solidification, water is injected into the holes. Because the technology of drilling a large hole array on the working face with a down-the-hole drill, the technology of tubular expanding agent filling and the post-water-injection technology are adopted, the static blasting method is applicable to rock excavation construction beside tall urban buildings, railways in operation, expressways and high-voltage steel pylons, and the purposes that high-work-amount rock excavation and concrete removal static blasting construction is safe and environment-friendly, and is carried out without shakes or flying stones or sounds or dust are achieved.

Owner:HUNAN MUYU INTELLIGENT TECH CO LTD

Rim angle excavation method by blasting for natural side hill

ActiveCN101424503ASolve the technical problems of blastingEfficient recyclingBlastingOpen-pit miningHigh density

A method for blasting natural hillside corner belongs to the field of opencast iron ore mining and is designed aiming at the problem that a drilling machine is unable to punch, so that the formed irregular triangular sloping surfaces can not be treated when the slight pitch natural hillside is mined in an opencast way. Vertical holes are drilled at the juncture of the natural hillside and production steps, the pitch-row is reduced by 2-3 m compared with the normal operation, and the hole depth is deepen by 2-5 m compared with the normal operation. The bottom of the deep hole is provided with explosive having high density and power, and the blasting energy is utilized to blast the part close to the steps. After cleaning up, a down-the-hole drill is used for drilling 2-3 lines of horizontal holes on the crushing surface after being blasted, wherein the pitch-row is 1-2 m, and the hole depth is 6-11 m; the hillside corner is blasted by adopting the simultaneous blasting technology. The method has the characteristics of thorough blasting treatment, effective ore recovery and the like, and can be applied to the corner blasting of various slight pitch hillside surface mines.

Owner:ANSTEEL GRP MINING CO LTD

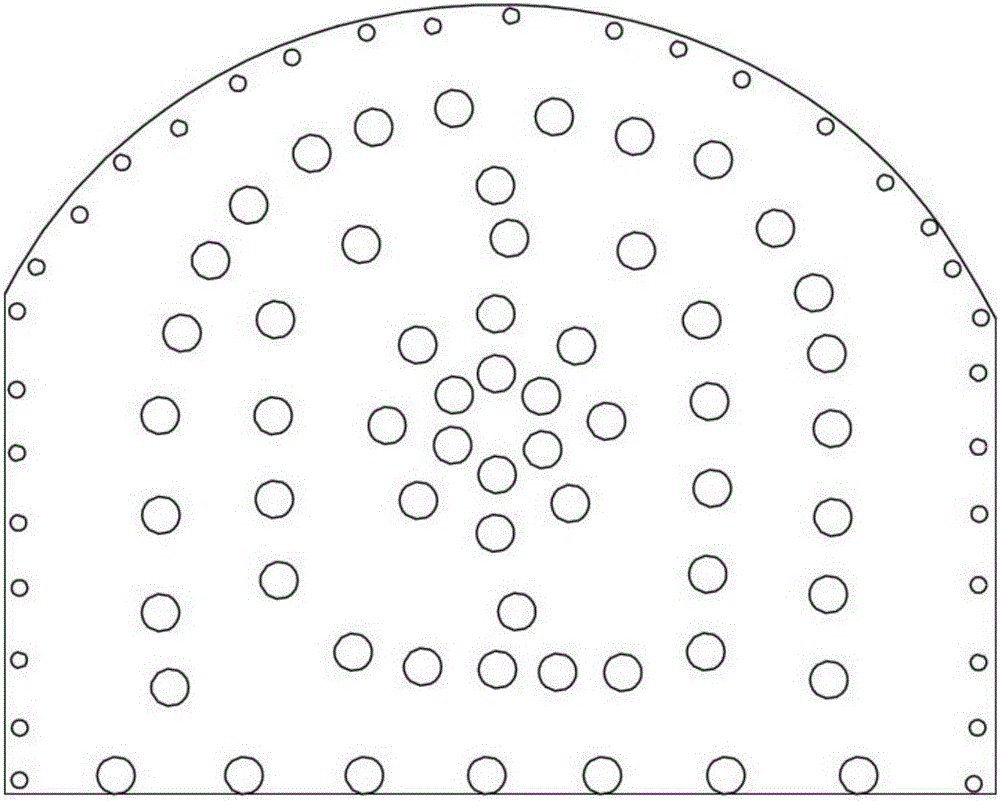

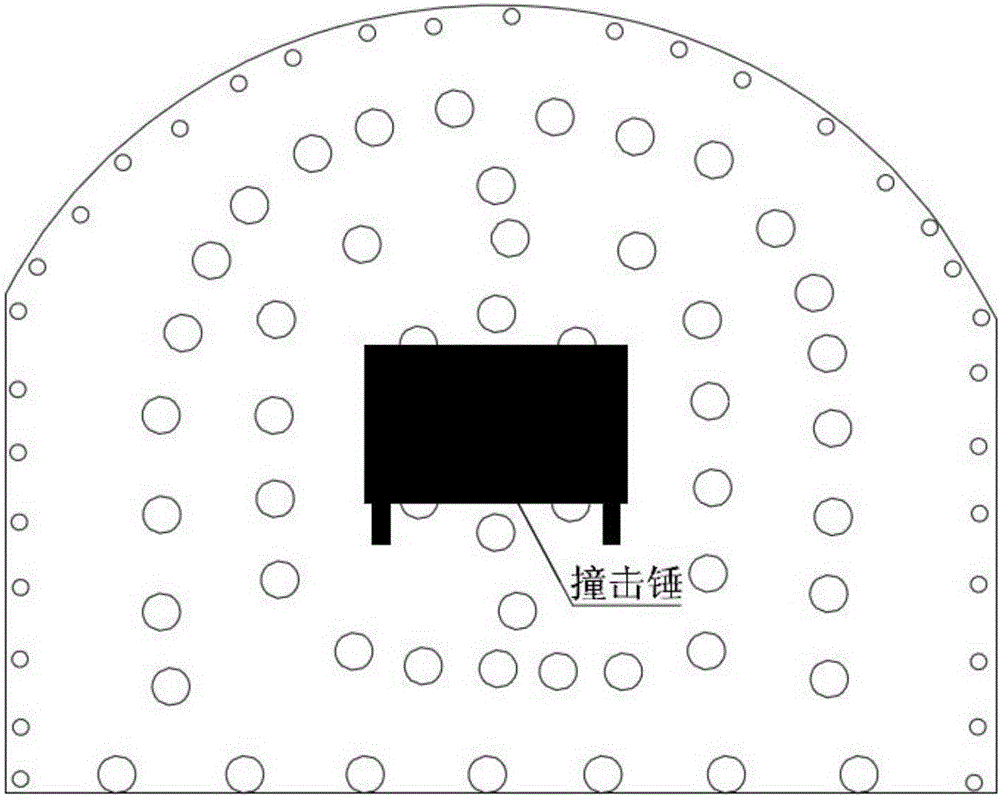

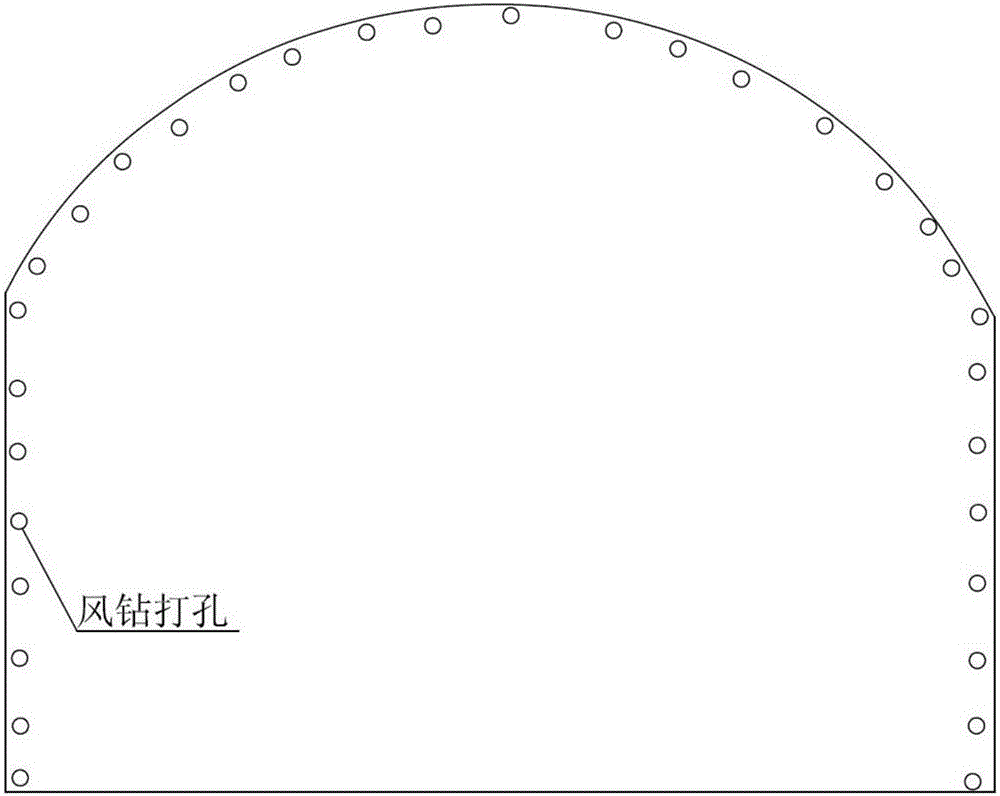

Blasting vibration limited rock tunnel excavation method

The invention discloses a blasting vibration limited rock tunnel excavation method. The method comprises the following steps: S1: drilling quincuncial holes similar to honeycomb briquette in the circumferential inner circle of a tunnel with a down-the-hole drill, and then impacting the quincuncial holes with an impact hammer to smash the quincuncial hole wall rock, thereby completing cyclic excavation of the inner circle rock of the tunnel; and S2: adopting air drill punching and splitting blasting for the circumferential rock of the tunnel to complete rock tunnel excavation. The rock tunnel excavation method disclosed by the invention can carry out efficient tunnel excavation to the maximum under the condition that a large tunnel boring machine is not used, and the method considers the problems of economy and efficiency in short length rock tunnel construction near a high-speed railway or crossing or near a blasting vibration limited new building.

Owner:NINGBO COMM PLANNING INST CO LTD +1

Down-the-hole drill reverse exhaust system

A DHD hammer that can exhaust working air volumes partially through a proximal end of the DHD hammer's actuator assembly includes a drive chamber, a return chamber, and a backhead that includes exhaust ports. Working air volumes from the drive chamber are exhausted through the backhead while working air volumes from the drive chamber are exhausted primarily through a drill bit.

Owner:CENTER ROCK INC

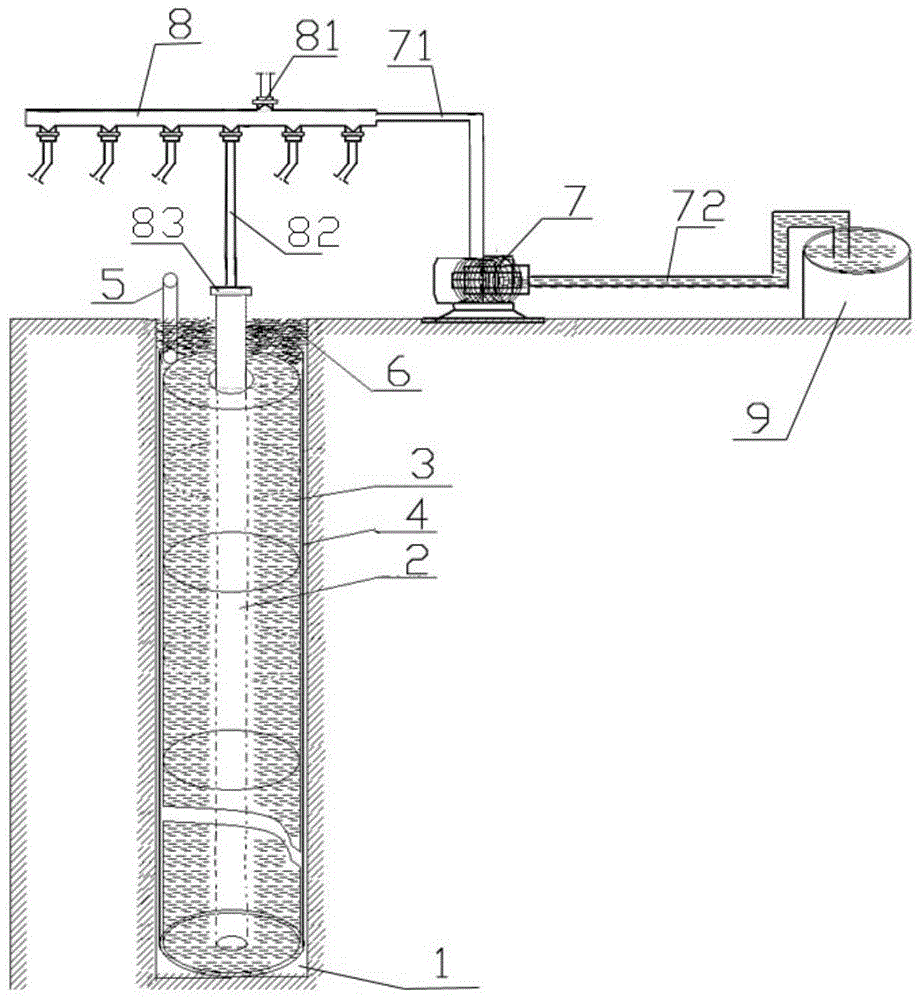

Down-the-hole drill with cooling function and for mining exploration

ActiveCN110284831AEasy coolingExtended service lifeEarth drilling toolsDrilling rodsWater flowCooling pipe

The invention relates to a down-the-hole drill with a cooling function and for mining exploration. The down-the-hole drill comprises a base, a top plate, a drill pipe, a processor, a first motor, a cooling mechanism, a lifting plate, a cleaning mechanism, two supporting plates and a plurality of rollers. The cleaning mechanism comprises a cylinder, a moving plate, a pressure sensor, a spring, a flat plate, a cleaning block and two limiting units. The cooling mechanism comprises a water tank, a water pump, a cooling pipe and two water injection components, and the water injection components comprise water injection pipes, sealing plates, fixing units and rotating units. The down-the-hole drill with the cooling function and for mining exploration enables circulating flowing water to flow through a cooling pipe through the cooling mechanism, the heat of the drill pipe is continuously absorbed, the cooling process of the drill pipe is convenient, and the service life of the drill pipe is prolonged; and moreover, the cleaning mechanism is used for extending a cleaning block into a spiral concave groove of the drill pipe which moves upwards, soil in the spiral concave groove is extruded, the cleaning of the drill pipe is realized, and the practicability of the device is improved.

Owner:江门市新会区泰盛石场有限公司

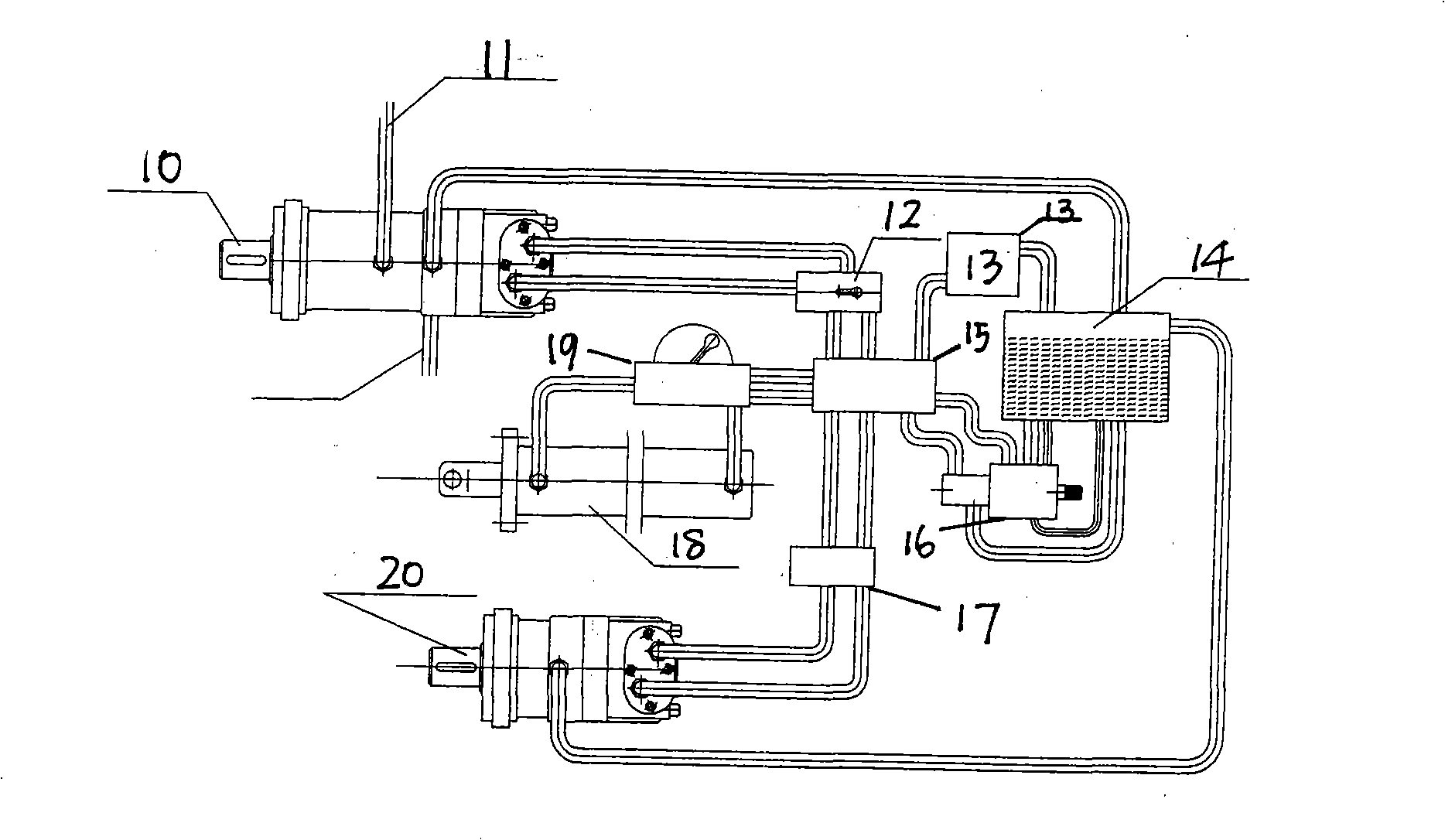

Hydraulic shock vibration system in multifunctional engineering equipment

InactiveCN101319508ALow costImprove work efficiencyReciprocating drilling machinesMechanical machines/dredgersHydraulic motorGas compressor

The invention provides a hydraulic shock vibration system in multi-functional engineering equipment, which aims to solve the technical problem that: engineering equipment that a base body of an excavating machine is assembled with other work heads is integrated with excavation, rock drilling, frozen-clay drilling and crushing functions, which can reduce the cost for engineering machinery and also greatly improve the operation efficiency at the same time; but a bit of a down hole drill needs pneumatic power, the down hole drill has pneumatic impact; however, the excavating machine can only provide hydraulic powder, which becomes a bottleneck for restricting the equipment. The hydraulic shock vibration system has the key points that: the system is provided with the base body of the excavating machine; the system is characterized in that: a guide rod of the bit of the down hole drill is provided with a multi-stage propulsion oil cylinder, an air compressor is arranged on the back of a hydraulic system of the excavating machine, a motor of the air compressor is substituted by a hydraulic motor, and a pneumatic output tube of the air compressor is connected with a slag blowing wind pipe of the down hole drill. The use of the hydraulic shock vibration system is to implement multi-functional engineering operations.

Owner:SHENYANG MILITARY DISTRICT HEADQUARTERS ENG SCI RES DESIGNING INST

Up and down hole combined cutting-well-free slot broaching method

ActiveCN111441774AReduce clamping effectSufficient space for blasting compensationUnderground miningBlastingRock cuttingEngineering

The invention provides an up and down hole combined cutting-well-free slot broaching method. The method comprises the steps that inclined down holes are constructed in corresponding positions of an upper layering rock chiseling roadway and a lower layering cutting transverse roadway through a down-the-hole drill, after the down holes are arranged and constructed, a lower ore roof falling zone andthe lower layering cutting transverse roadway serve as blasting free faces, and blasting is carried out to obtain a first blasting space; up slot broaching holes are mounted and constructed in the lower layering cutting transverse roadway, first blasting space formed through down hole blasting and the lower layering cutting transverse roadway serve as free faces, and segmented blasting is carriedout to form a complete cutting vertical slot. The down holes and up holes are combined to carry out slot broaching, the up holes take the blasting space formed by the down holes as the free faces, segmented blasting is carried out, the process is simple and reliable, and the method is safe and economic. The method is suitable for breaking ores, construction of a cutting well is not needed, high danger and cost of construction of the cutting well in fractured ore rock can be reduced, and giant application prospects can be achieved.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com