Blasting vibration limited rock tunnel excavation method

A technology of tunnel excavation and blasting vibration, which is applied in blasting, tunneling, earthwork drilling and mining, etc. It can solve the problems of high excavation cost, inability to dig hard rock, low hydraulic splitting efficiency of light tunnel boring machines, etc., and achieve high efficiency The effect of tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

[0035] In this embodiment, the excavation and support methods of the rock tunnel are as follows:

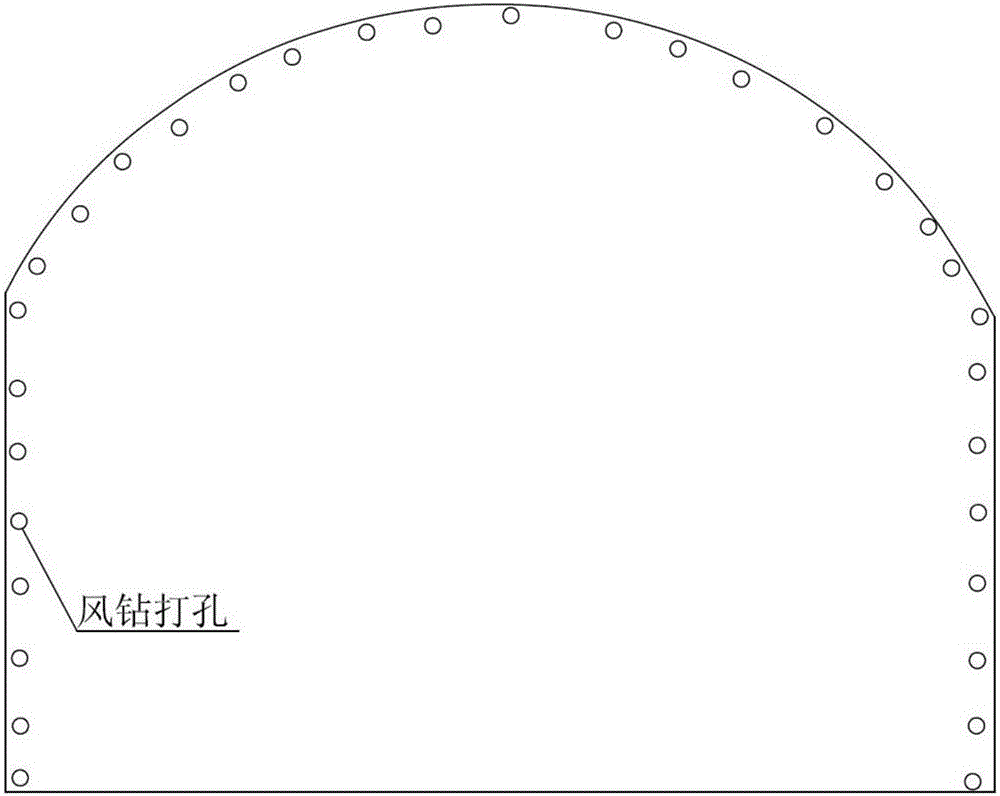

[0036] (1) Mechanically excavate the road cutting at the entrance of the hole and take preliminary protection and drainage measures;

[0037] (2) Do a good job of opening support or pre-support structure;

[0038] (3) According to the formulas (1.1), (1.2), (1.3), adjust the wall thickness of the plum blossom hole and the thickness of the splitting layer until it is suitable.

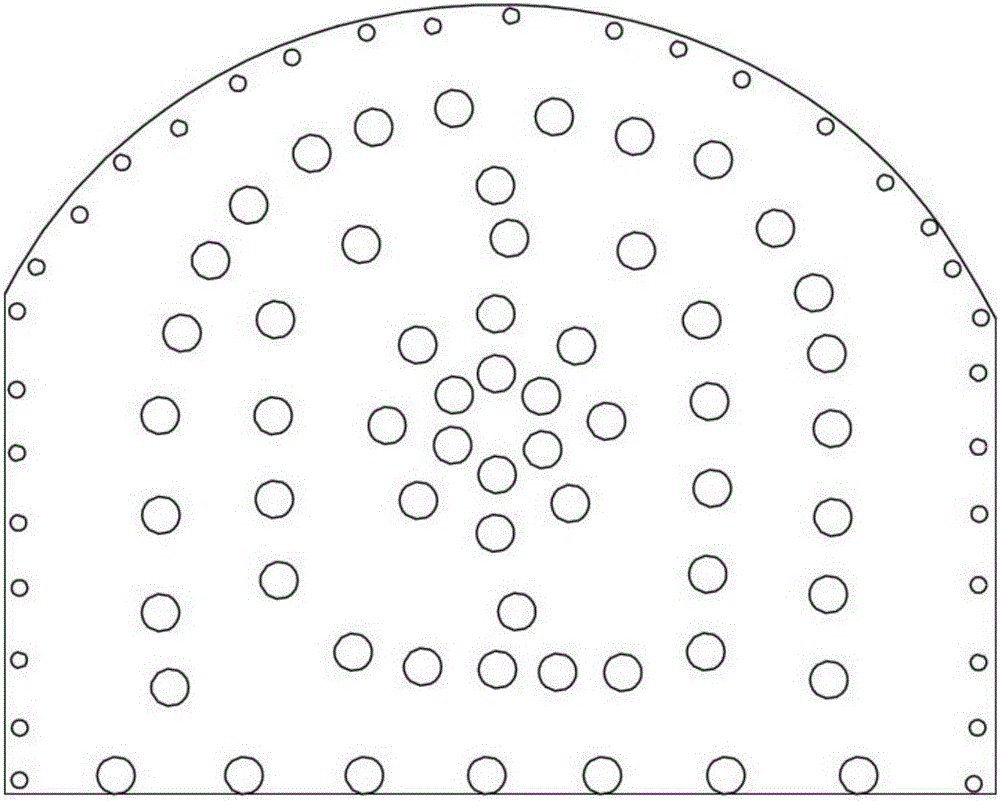

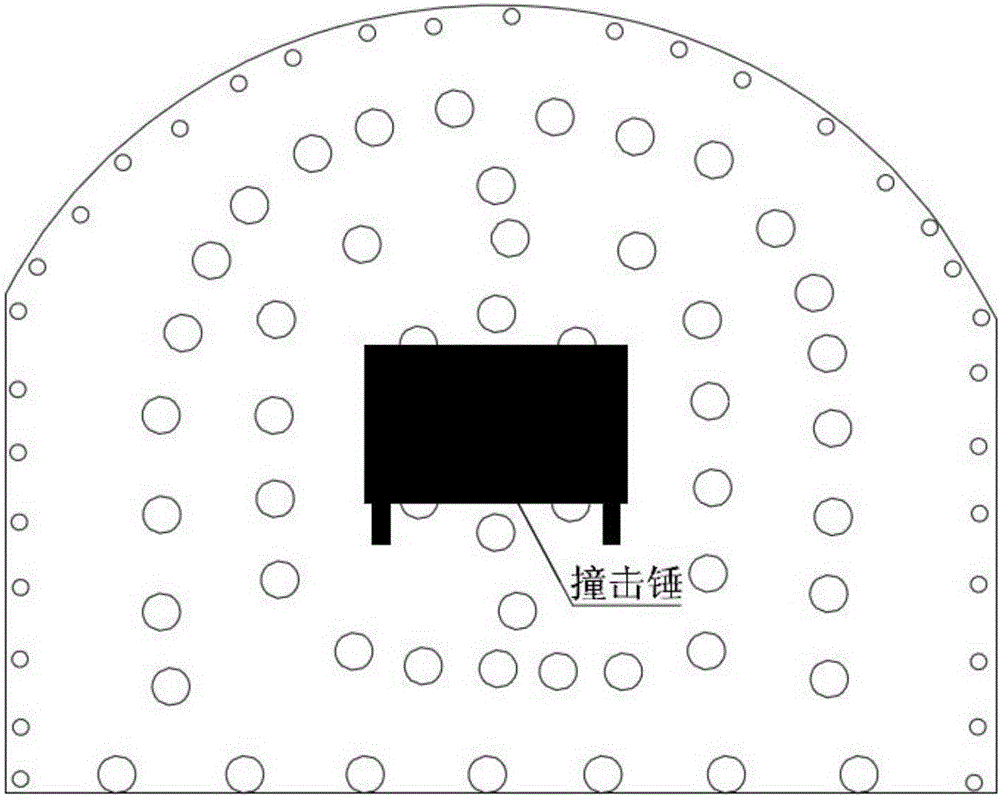

[0039] The density of the plum blossom-shaped hole and the determination method of the impact energy of the impact hammer are as follows:

[0040] S101: Determine the impact energy E of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com