Super-large-diameter deep shaft simple shield device and shielding method

A super-diameter, vertical shaft technology, applied in vertical shaft equipment, well sinking, earthwork drilling, etc., can solve the problems of increased auxiliary operation time, complex geological conditions, backward support measures, etc., to improve operation efficiency and construction speed, reduce The danger of landslides, the effect of efficient excavation and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions, and advantages of the implementation of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings in the embodiments of the present invention. In the drawings, the same or similar reference numerals indicate the same or similar elements or elements with the same or similar functions. The embodiments of the present invention will be described in detail below in conjunction with the drawings.

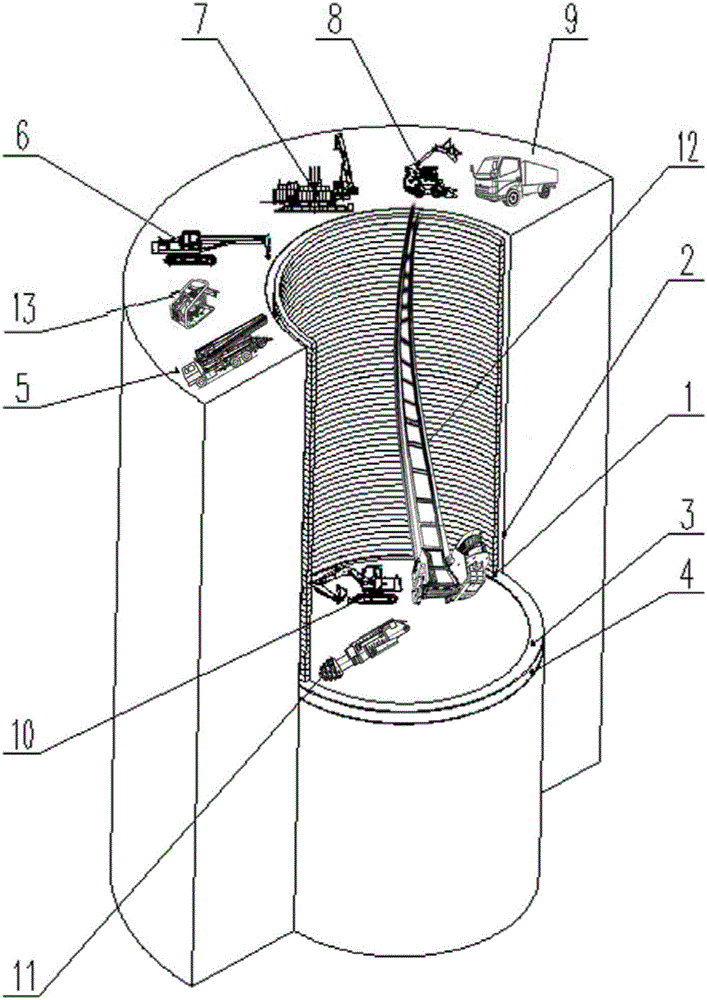

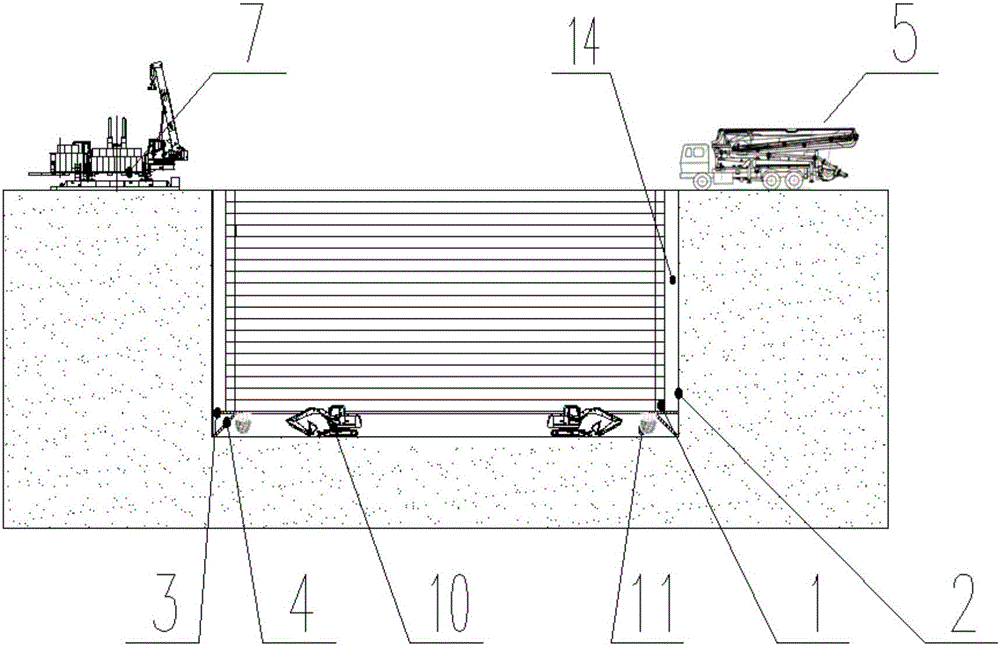

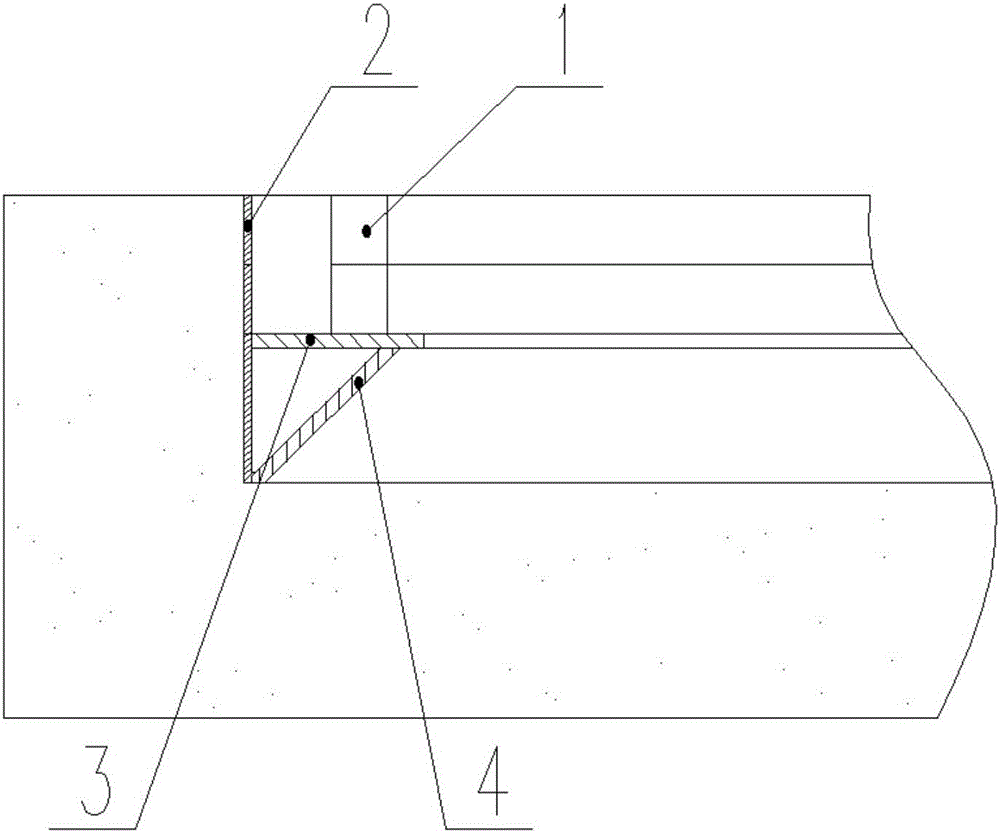

[0026] figure 1 , figure 2 , image 3 A simple shield device for a super large-diameter deep shaft is shown, including concrete segment 1; steel ring shaft wall 2; trustee segment seat 3; soil cutting segment 4; concrete pump truck 5; crane 6; segment pressing machine 7; loading Machine 8; slag truck 9; excavator 10; tunneling cutting head 11; slag conveying device 12; welding machine 13. The steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com