Medium-soft rock cutterhead and cantilever tunneling machine with same

A cutter head and soft rock technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve the problems of low cutting efficiency of cutter heads, improve cutting strength and rock entry efficiency, improve driving efficiency, facilitate disassembly and assembly and The effect of position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

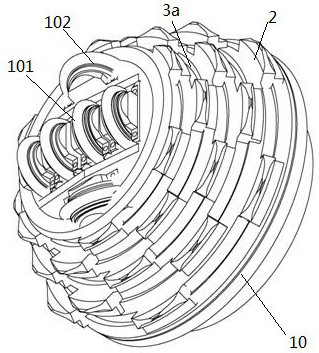

[0026] Example 2, such as image 3 As shown, a kind of medium soft rock cutter head, in order to improve the overall excavation efficiency of the cutter head, a spiral cutter groove 3a can also be provided on the tapered side plate 5, and the wedge-toothed cutter 2 is evenly arranged in the spiral cutter groove 3a. The plane where the edge of the wedge-tooth cutter 2 is located is perpendicular to the tapered side plate 5 to ensure its excavation efficiency. The knife seat part 201 matches the spiral knife groove 3a, and the connecting part 203 is detachably connected with the spiral knife groove 3a. The connecting part 203 is connected with the outer groove wall of the annular sipe 3 or the spiral sipe 3 a through fastening bolts. Similarly, the outer groove wall of the spiral knife groove 3a is provided with a positioning screw hole, and the connecting part is connected with different positioning screw holes to realize the adjustment of the position of the wedge-toothed kni...

Embodiment 3

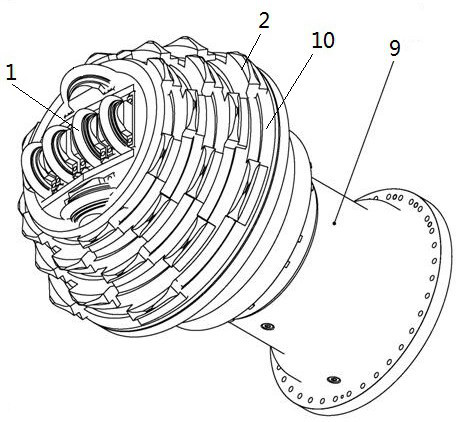

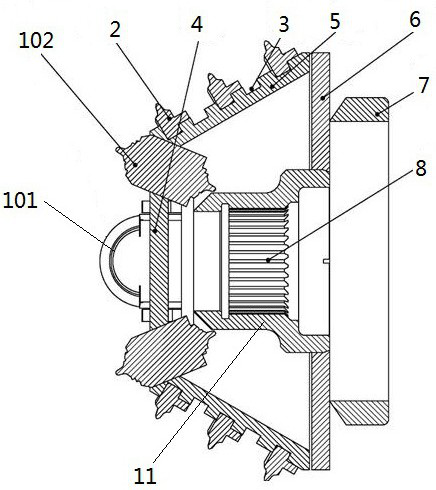

[0029] Embodiment 3: as Figure 4 , 5 A cantilever roadheader is shown, which includes the medium-soft rock cutterhead described in Embodiment 2. A cutting arm is provided on the cantilever roadheader, and the cutting arm is connected to the medium-soft rock cutterhead. Under the action of the cutting arm, the medium-soft rock cutter head can carry out swing and axial excavation. When the rock is being broken, mainly the disc-shaped hob installed on the front panel of the cutter head squeezes the rock that cuts the face and peels the rock off the face. Free cross-section rock breaking: mainly the wedge-toothed cutter installed on the conical panel of the cutterhead cuts and breaks the rock. Flexible and efficient rock breaking, improving tunneling efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com