Submerged hole driller component element

A technology for down-the-hole drilling and components, which is used in drill bits, earth-moving drilling, drilling equipment, etc., can solve the problems of restricting the air discharge of the hammer drill, reducing the performance of the hammer drill, and breaking the bottom valve tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

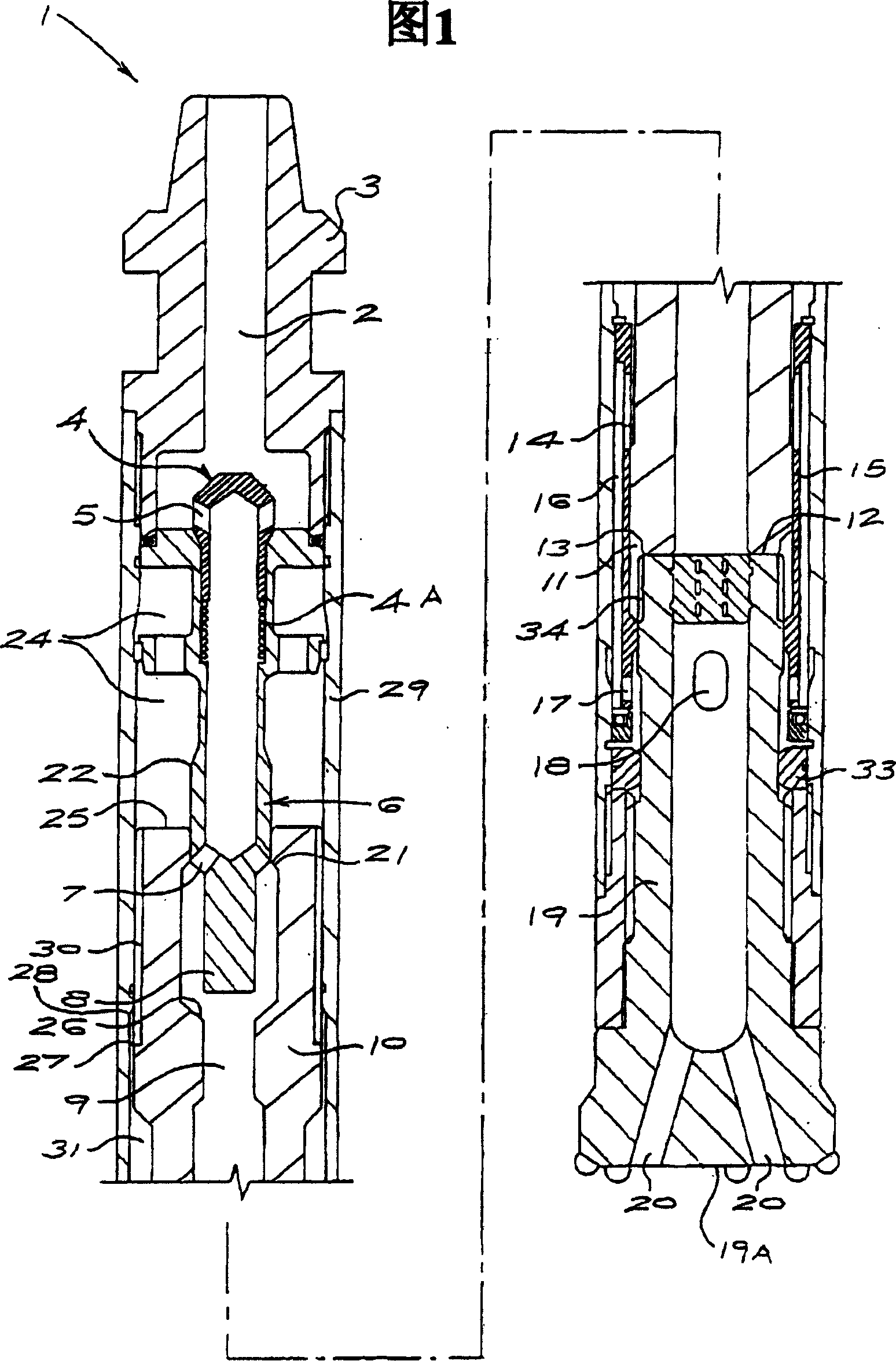

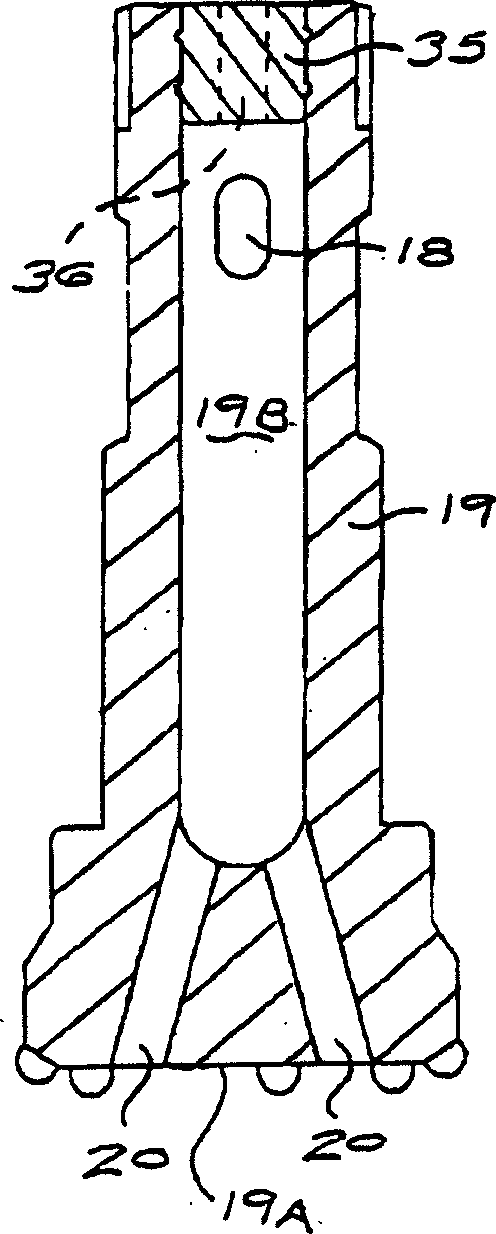

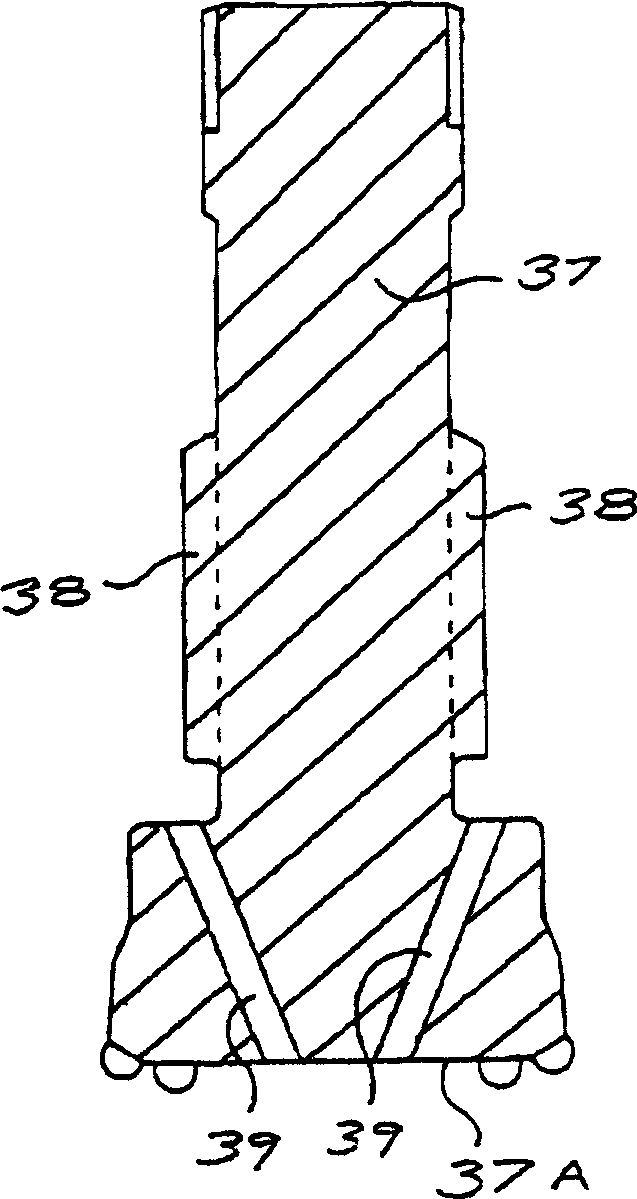

[0017] A down-the-hole hammer drill as shown in the figure comprises a drill assembly (1) according to the invention. The assembly (1) provides lifted air to the lower chamber (11) below the piston (10) through the bore (9) of the piston (10), and through the outside of the piston (10) and through at least the outside of the drill bit (19) body Part of the exhaust. Then, the exhausted air is directed through the opening (18) to the inside of the bit facet (19A), simply because it facilitates the thorough blowing of the cuttings from the underside of the bit facet (19A). Since the compressed air flows directly into the lower chamber (11) through the hole (9) of the piston (10) without deflection and makes the piston (10) reciprocate faster, thereby releasing more energy to the drill bit (19), so Hammer drills are very effective.

[0018] In this embodiment of the invention, the drill bit (19) has an opening (18) extending transversely through the wall of the drill bit (19) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com