Efficient, safe and environment-friendly post-water-injection type static blasting method and water injection device using same

A static blasting, safety and environmental protection technology, applied in blasting and other directions, can solve problems such as hydration reaction heating and vaporization, eye injury, punching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

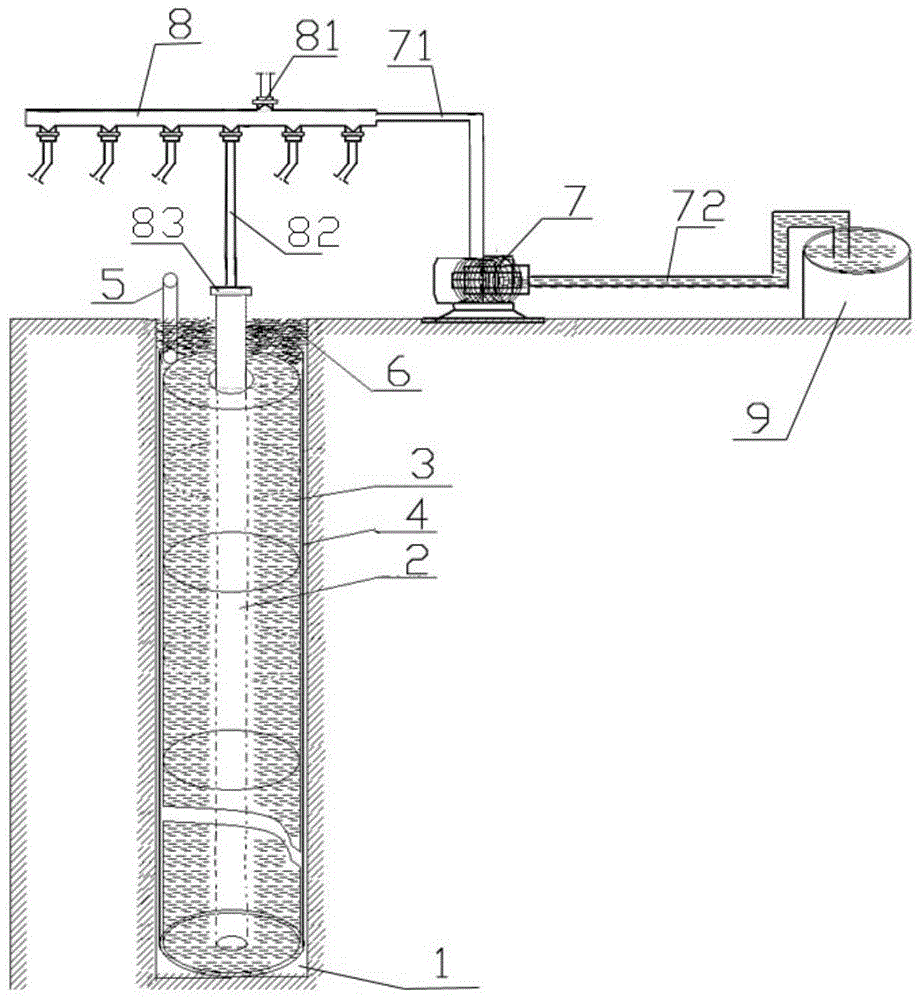

[0023] Combine below figure 1 , figure 2 with image 3 The present invention is further described in detail:

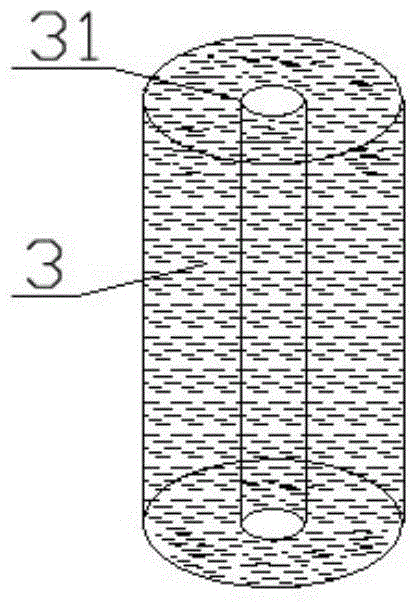

[0024] In the process of implementation, according to the actual geological conditions on site and the conditions of the working face, if there is an empty working face, design and calculate the row spacing and row spacing of drilling holes, and then drill hole 1. The hole depth should be shorter than that of water injection pipe 2. About 300mm, when the holes are drilled to a certain number of rows, the expansion agent 3 can be filled.

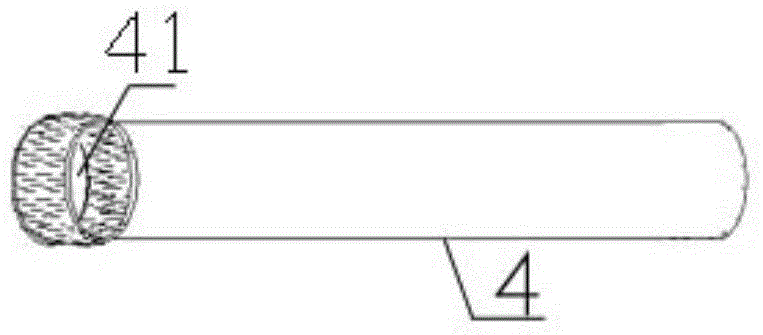

[0025] Generally, before filling the expansion agent, several leak-proof socket sleeves 4 are axially inserted into each hole. Cause the seepage water in the crack to flow into the hole, causing the expansion agent to expand prematurely; (2) Prevent the expansion agent from being fully hydrated due to water leakage in geological fractures. In the implementation process, among the two adjacent upper and lower leak-proof socket sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com