Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Architrave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In Classical architecture an architrave (/ˈɑːrkɪtreɪv/; from Italian: architrave "chief beam", also called an epistyle; from Greek ἐπίστυλον epistylon "door frame") is the lintel or beam that rests on the capitals of the columns.

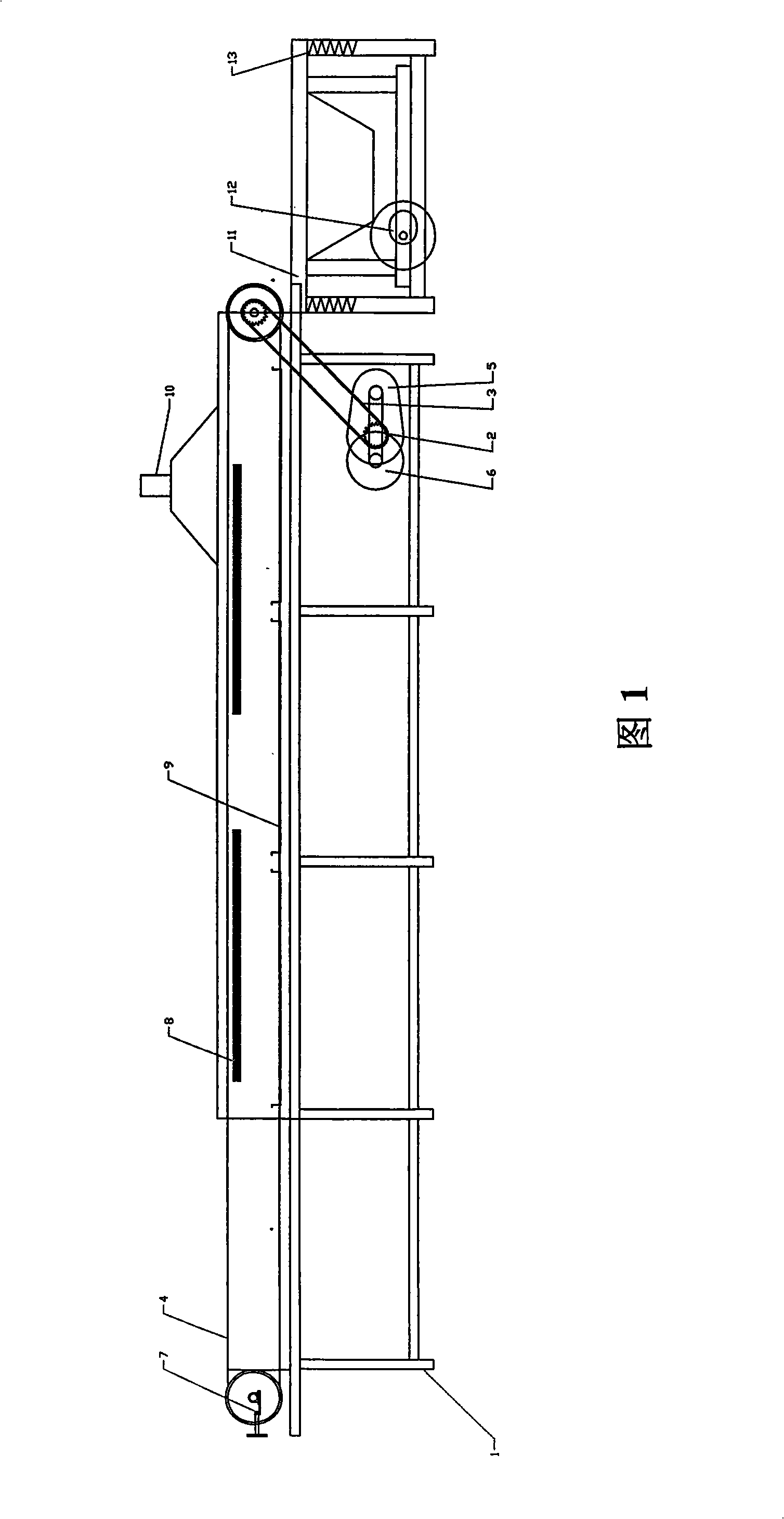

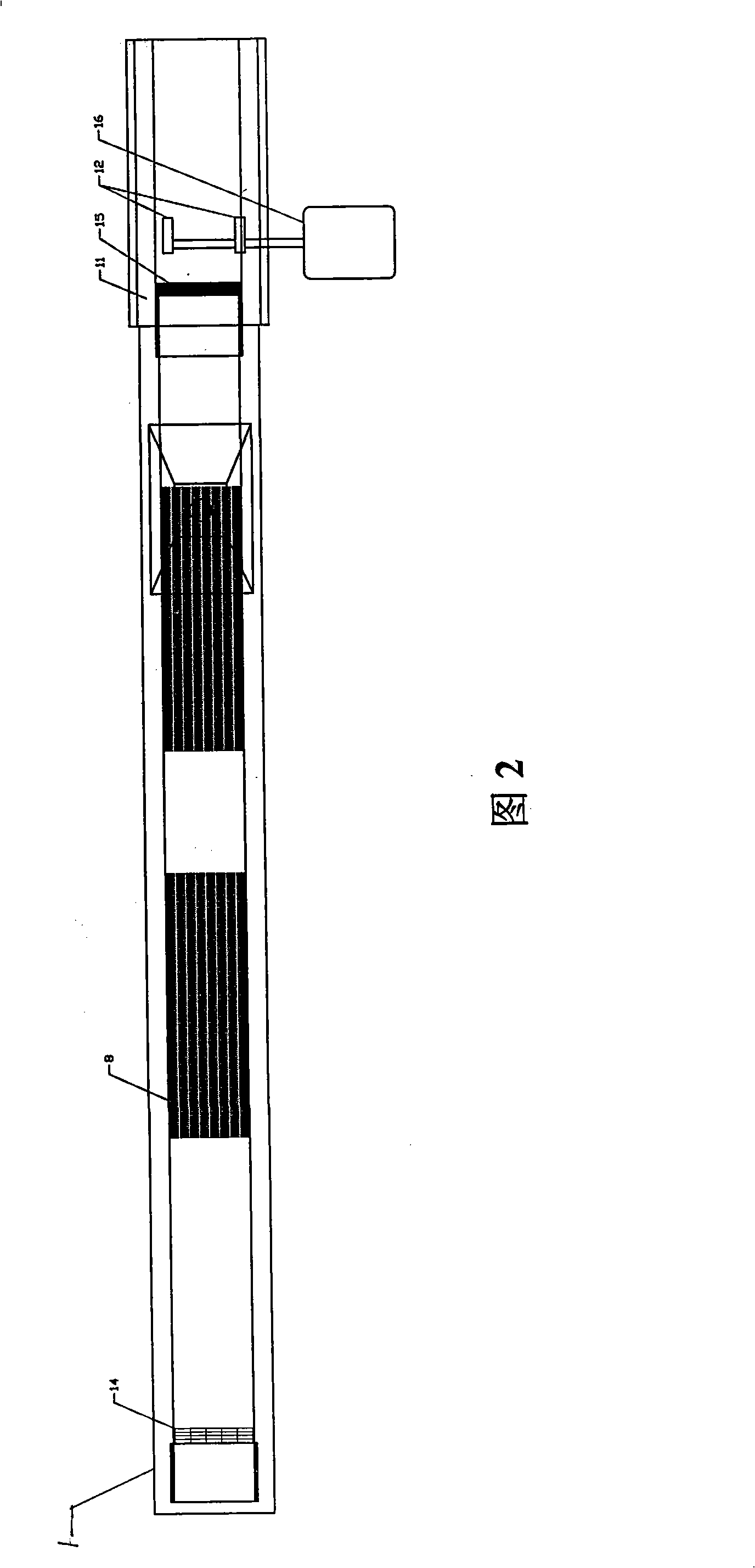

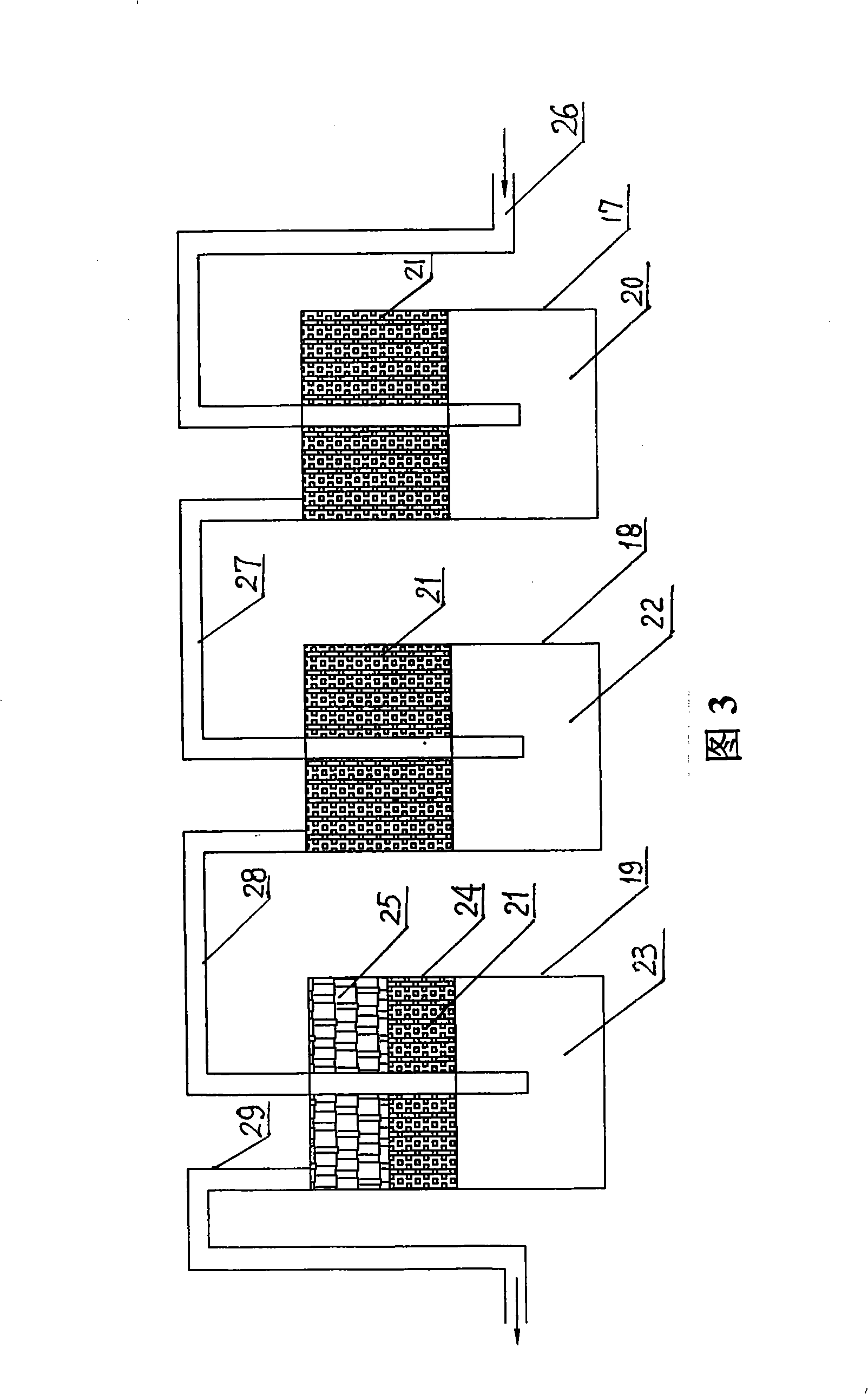

Method and apparatus for separating component pins and soldering tin of circuit board

InactiveCN101327541ACollect completelyFree from pollutionSolid waste disposalSoldering apparatusEngineeringSoldering

The invention discloses a disengaging method of architrave and mischzinn of a circuit board element and a device thereof. A metallic mesh-shaped conveyor belt is mounted on the frame; a heating device is installed below the conveyor belt; a circuit board is fed in from the front end of the conveyor belt and is transferred by the conveyor belt to the position above the heating device for continuous heating, and during the process, some of the architrave and the circuit board are disengaged automatically and fall into a receiving basin below the conveyor belt; at the same time, harmful gases produced in the heating process are exhausted by an exhaust pipe and are discharged into the air after the deodorization treatment; a vibration device and a recovery device are installed and connected to the position below a rear roller of the conveyor belt; a vibrating grid vibrates at high frequency, and the molten mischzinn and the architrave on the circuit board fall off with the function of the vibration and fall into a recovery container. The heating method of the invention is capable of completely removing and recovering the tin and the mischzinn, the method is simple, practical and efficient, and effectively protects the air from contamination, thereby the method is environment friendly.

Owner:HUNAN VARY TECH

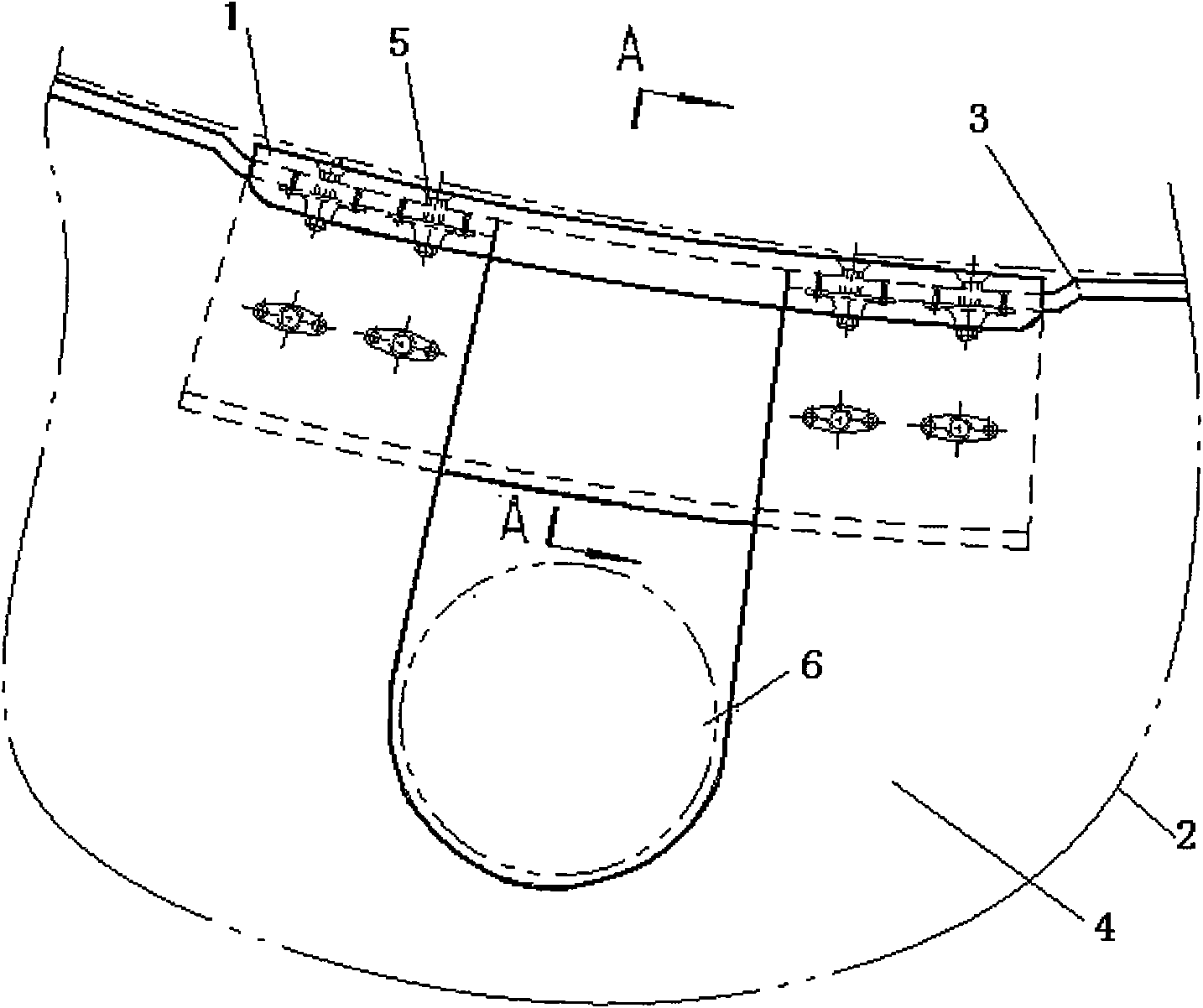

Civil aircraft fuselage bottom structure based on impact strength tests

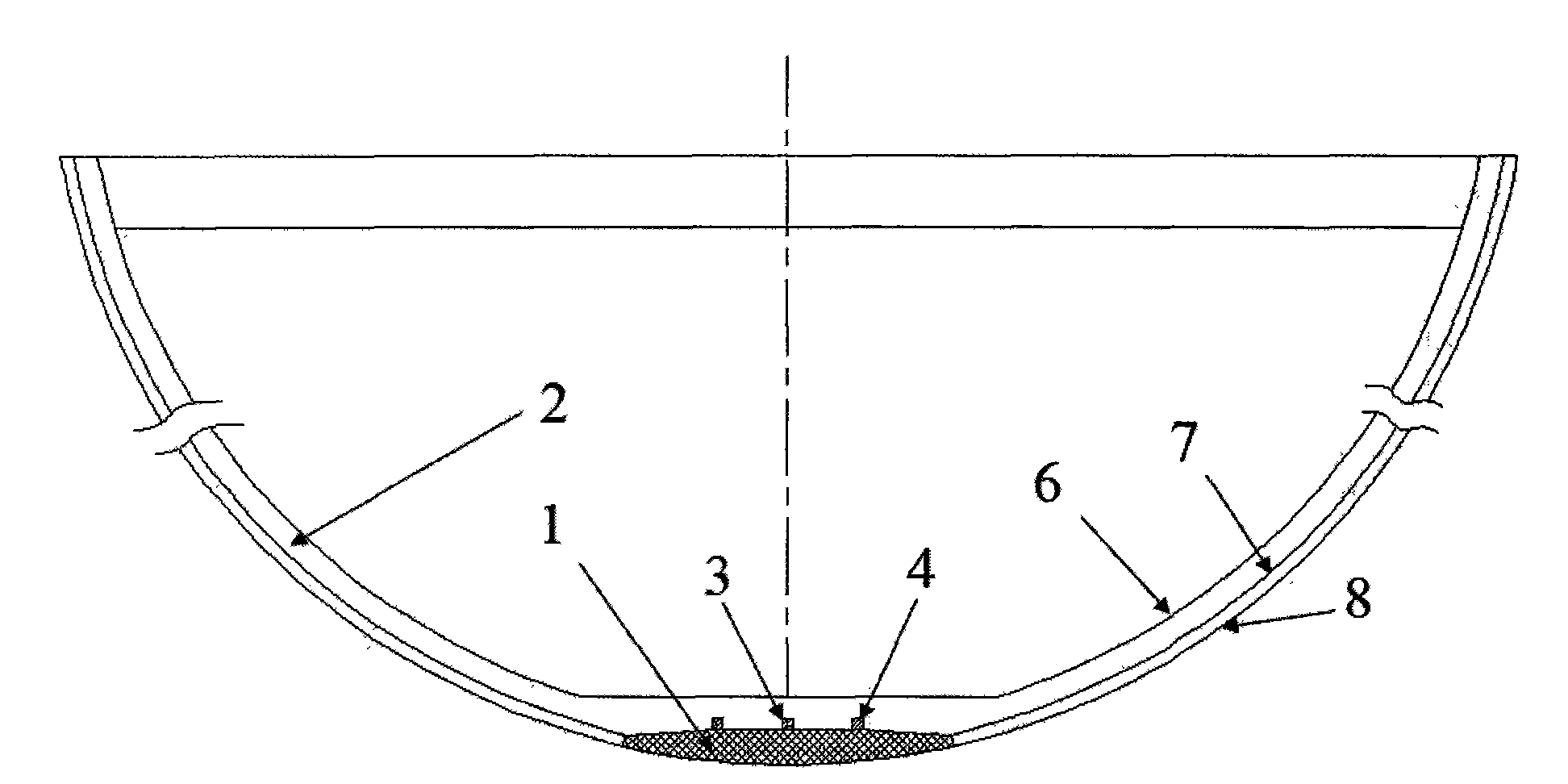

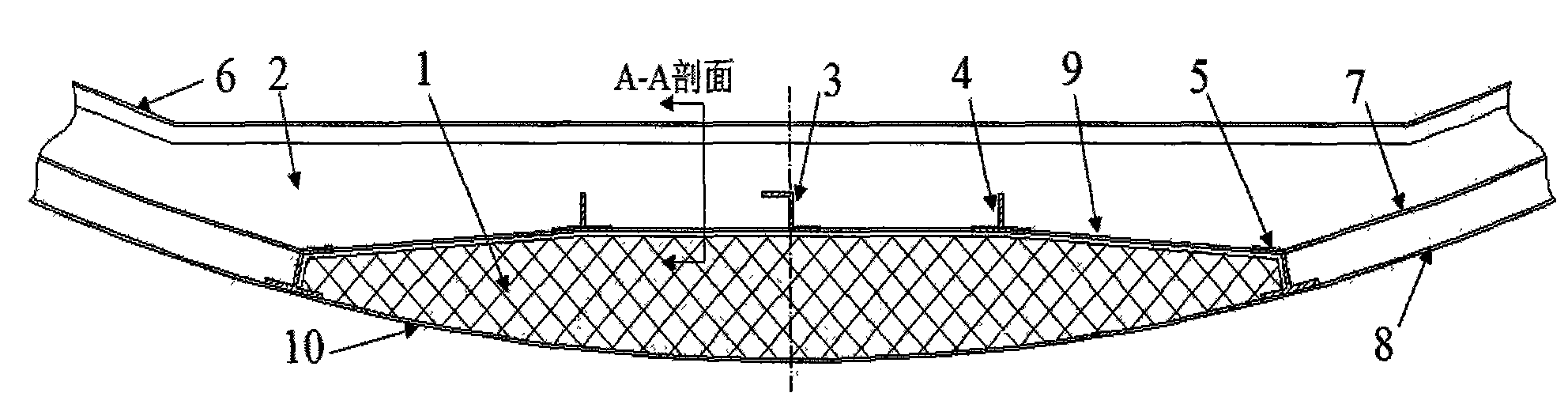

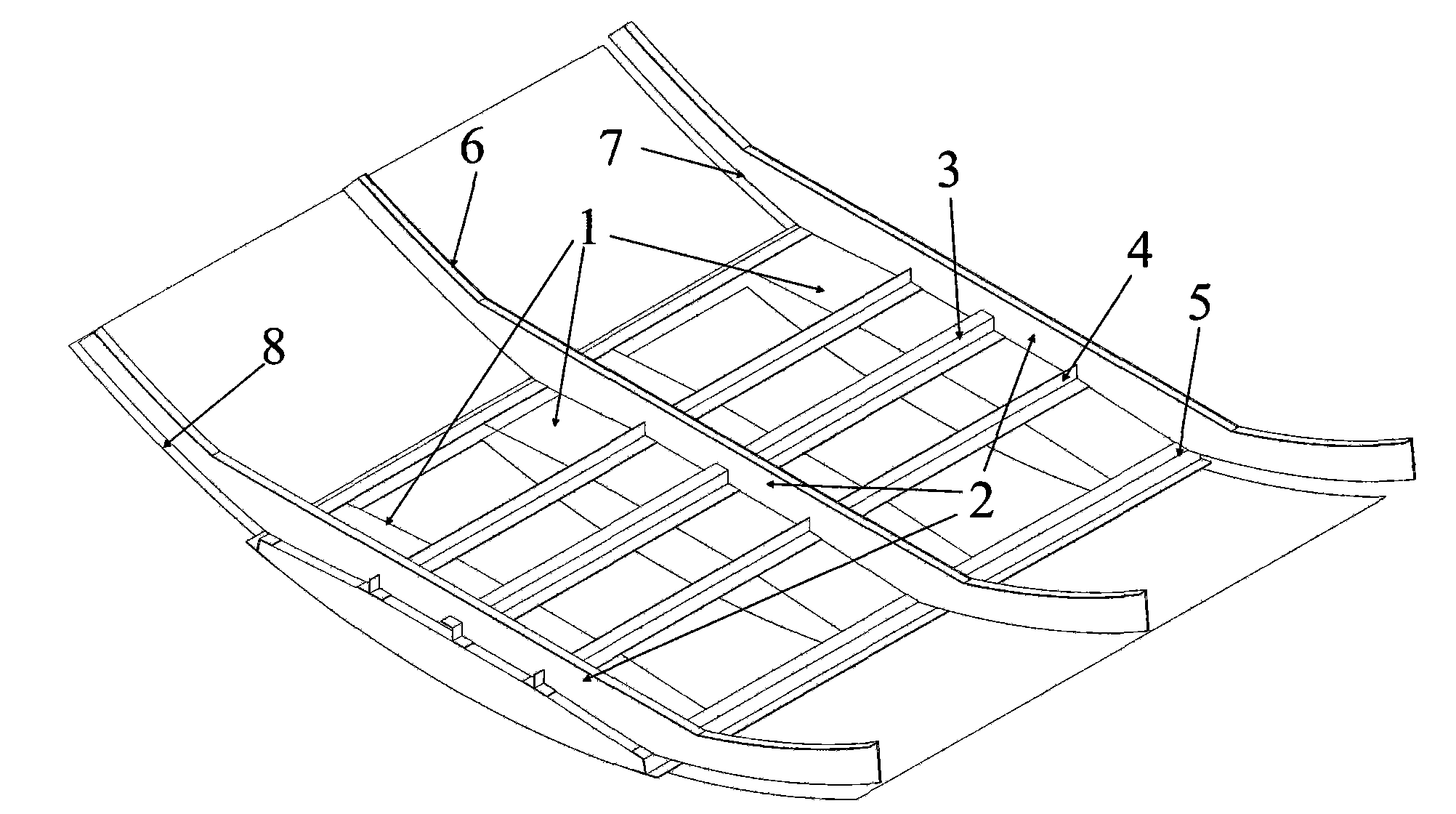

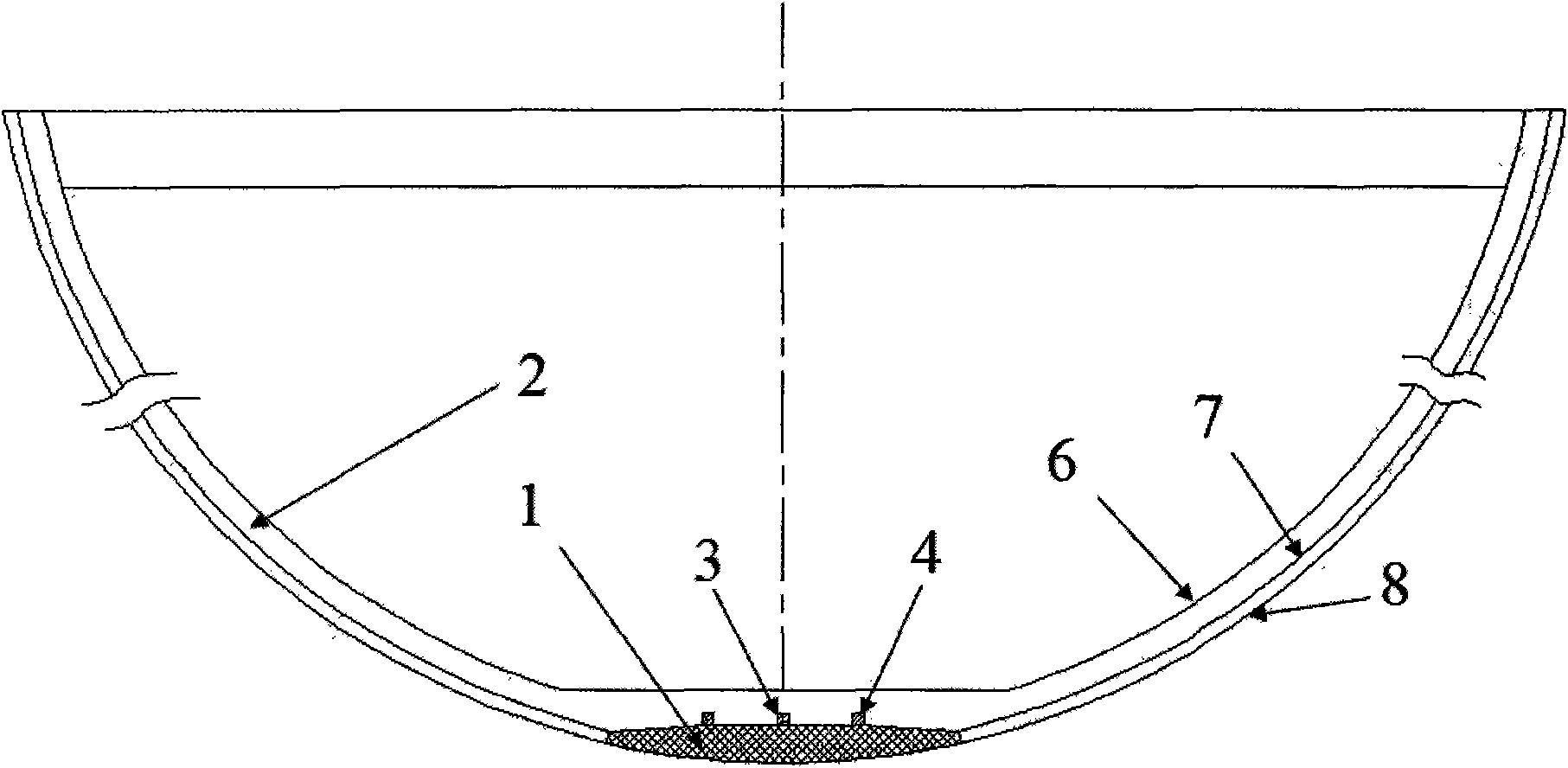

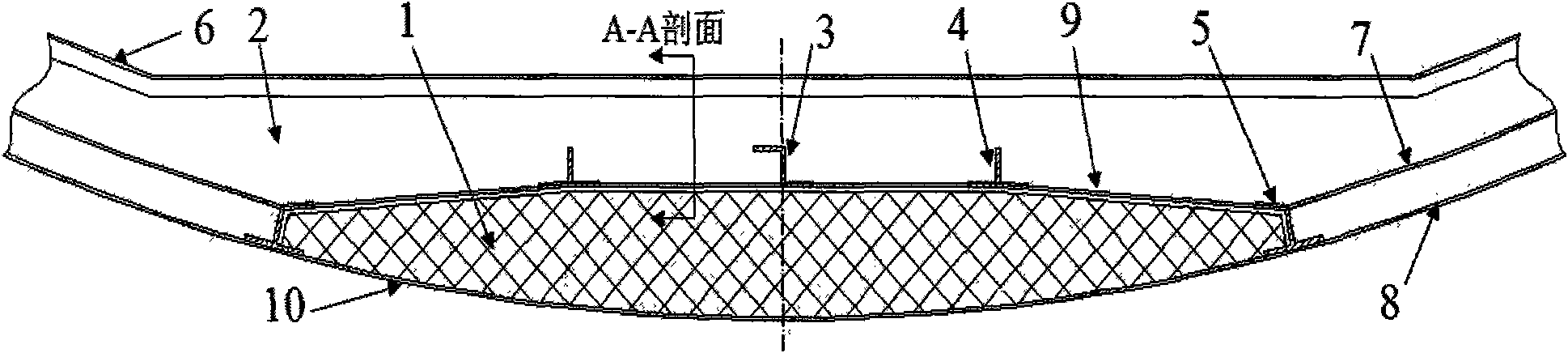

The invention discloses a civil aircraft fuselage bottom structure considering impact strength, comprising bulkheads, outer panel skin, long purlins and foam; on the foundation of arc-shaped fuselage bulkheads, the contour of the fuselage remains unchanged, upper architraves and lower architraves of the bulkheads are hoisted upwards, the arc shape of the bulkhead bottom is changed to the flatbottom shape, the lower part of each bulkhead is symmetrically provided with a piece of foam, the ends at the two sides of the foam are provided with non-closed-angle-shaped structures in certain height, the lower part of the foam is supported by ventral outer panel skin, the top and sides of the foam adopt the outer panel skin for supporting, the two sides and the top of the foam are provided with long purlin structures which have the function of longitudinal reinforcement. The fuselage bottom foam structure of the invention can greatly improve the crash resistance of the fuselage structure, the new structure consisting of the outer panel skin and the foam contributes to bearing distributed load, as a result, the fuselage bottom structure of the invention not only has good crash resistance against ground crash but also has good crash resistance against water surface impact accidents.

Owner:BEIHANG UNIV

Punching bag support apparatus

Owner:SAGALL JASON

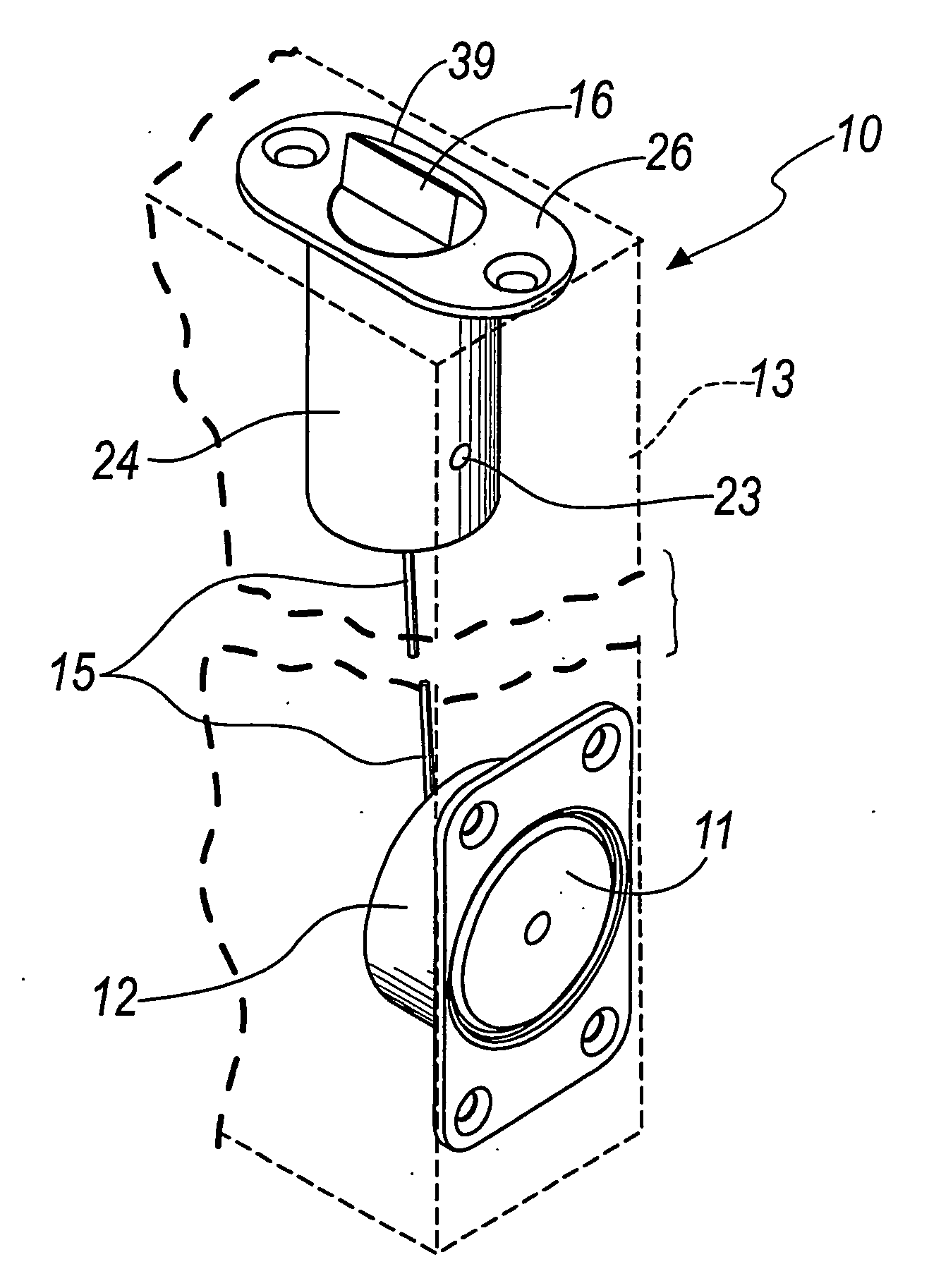

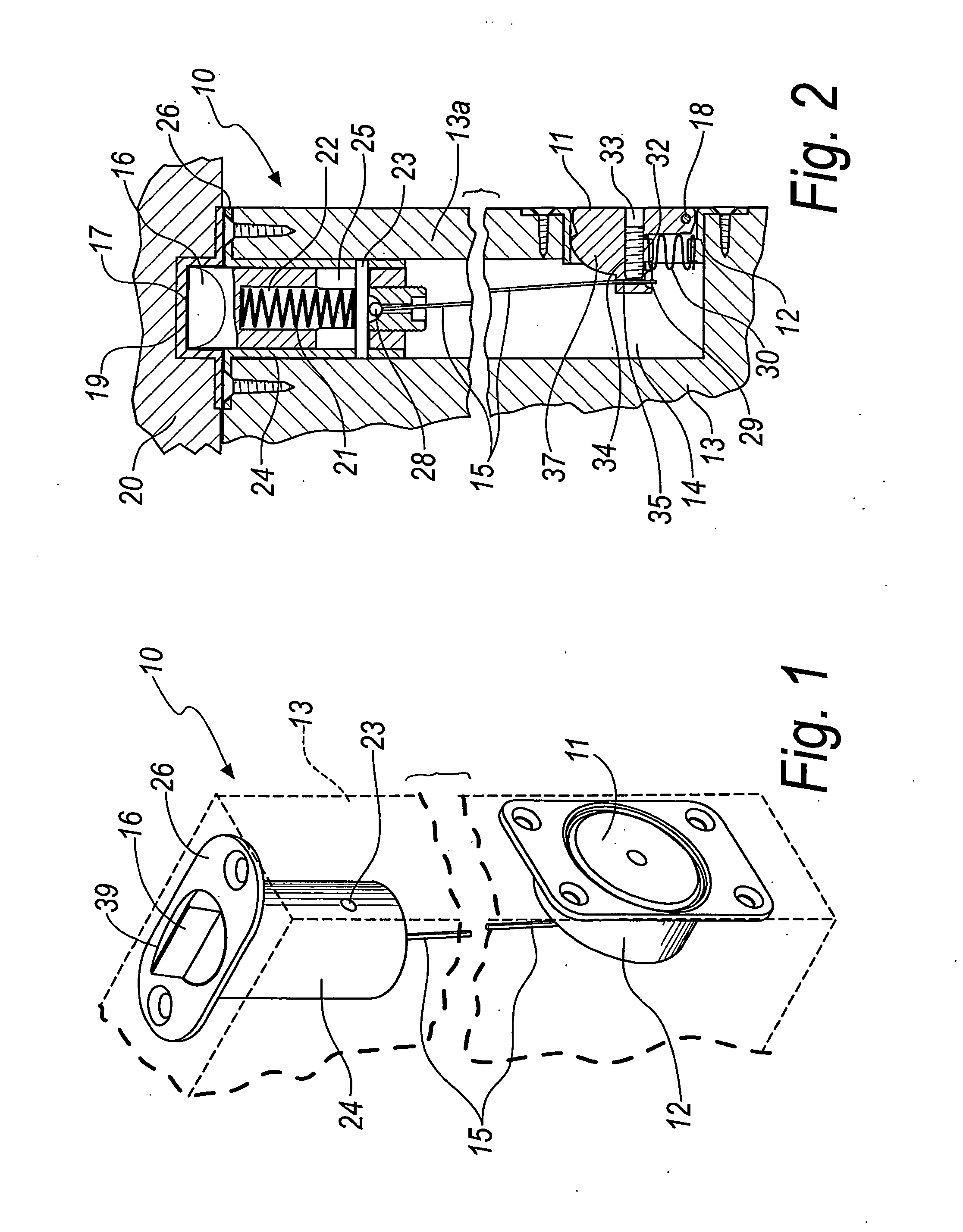

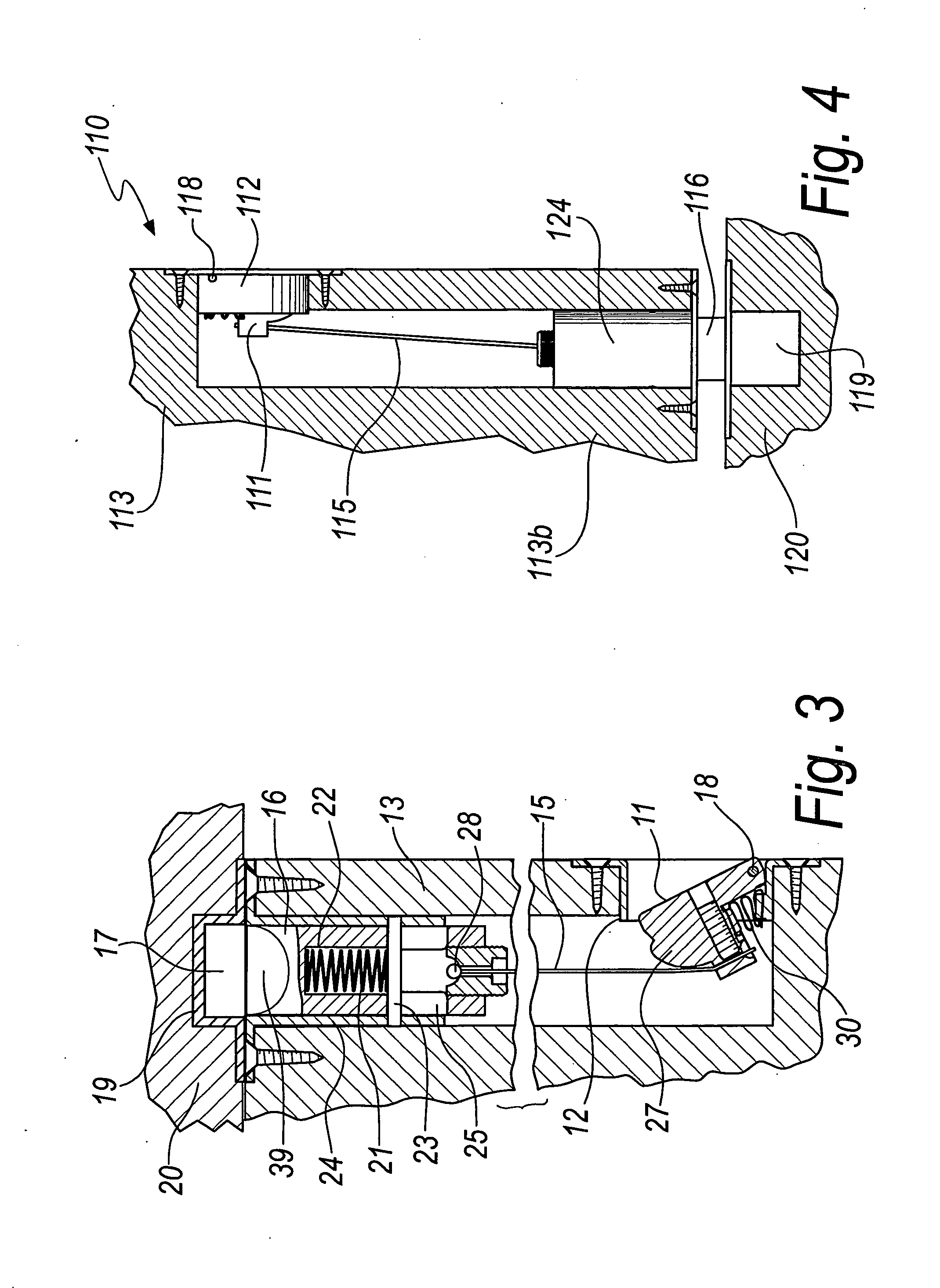

Device for locking second leaves in the closed configuration

InactiveUS20120074714A1Easy to operateEasy to installWing handlesWing fastenersMechanical engineeringArchitrave

Device for locking second leaves, for example of a door with two leaves, in the closed configuration, comprising a recessed button, which is pivoted to a corresponding accommodation body recessed in the side of a second leaf, and which is designed to be pushed in rotation, causing, by means of a transmission element, the retraction, towards the inside of the second leaf, of a latch that is normally pushed vertically towards the architrave or upper cross-member or towards the floor, in engagement in a corresponding seat for locking the second leaf.

Owner:RIGO SANDRA

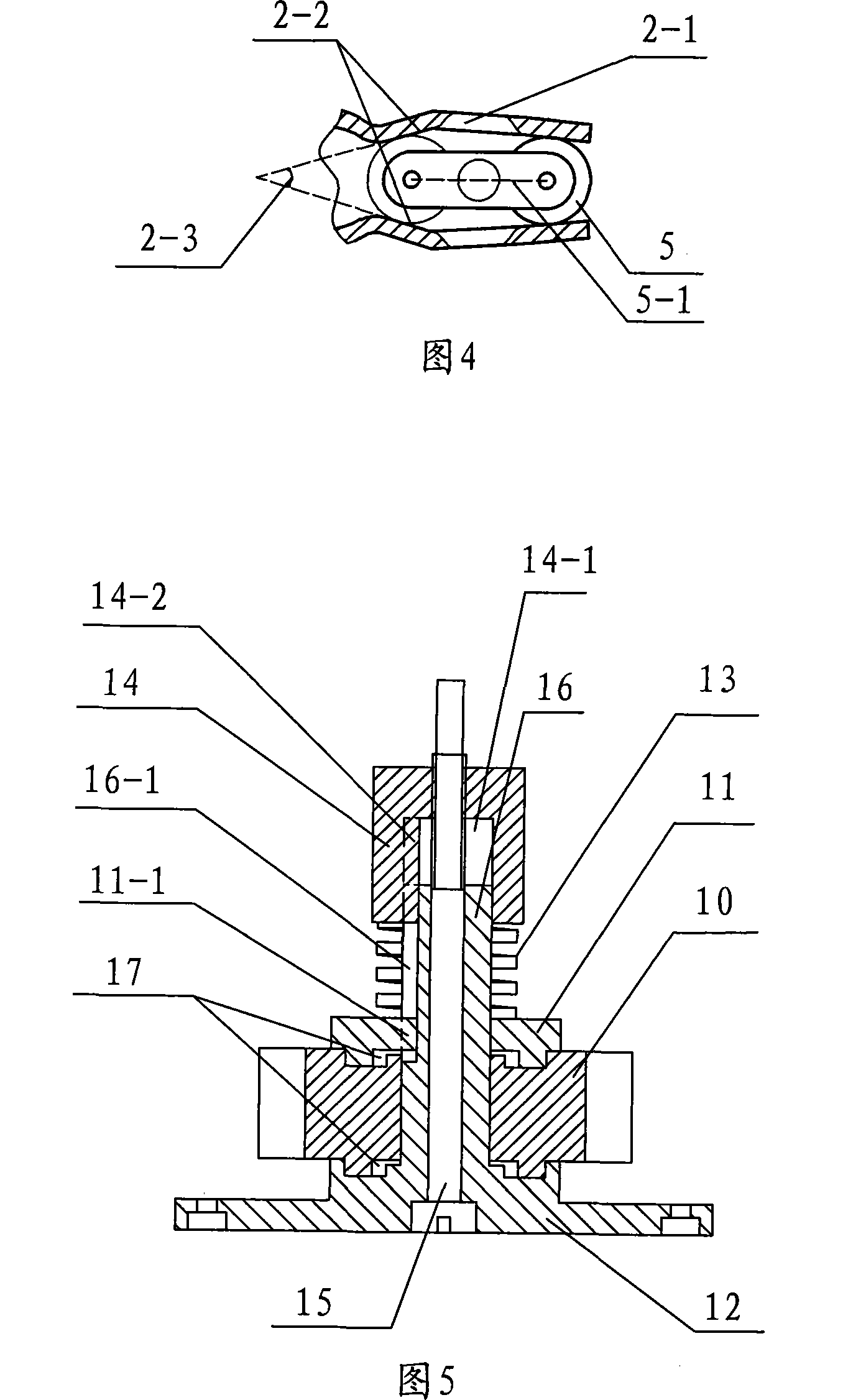

Reinforcing repairing structure for ancient building eave column and single-architrave node

The invention relates to a reinforcing repairing structure for an ancient building eave column and a single-architrave node. The structure comprises a wood filling and a single architrave riveted into the eave column, wherein a dovetail mortise opening and a straight tenon mortise opening which are communicated are formed in one side of the eave column; the single architrave consists of a single architrave body and a gyrus frontalis shoulder part; the a hook head lap tenon A is chiseled on the single architrave body; a hook head lap tenon B in mortise joint with the hook head lap tenon A is chiseled on the gyrus frontalis shoulder part; a dovetail joint is arranged at the other end of the gyrus frontalis shoulder part and is riveted into a dovetail mortise opening; a straight tenon riveted into the straight tenon mortise opening is formed in one end of the wood filling; a mortise opening A penetrating through the single architrave body and the gyrus frontalis shoulder part is formed; an insertion tenon A is riveted into the mortise opening A; a mortise opening B penetrating through the eave column and the straight tenon is formed; an insertion tenon B is riveted into the mortise opening B. On the basis of not changing the raw materials and the construction process, the integral stability, the anti-twisting and anti-shearing performance and the anti-seismic performance of the ancient building eave column and the single-architrave node can be greatly improved; the damage probability of the single architrave due to the tenon pulling can be reduced; the repair times can be reduced.

Owner:LUOYANG INST OF SCI & TECH

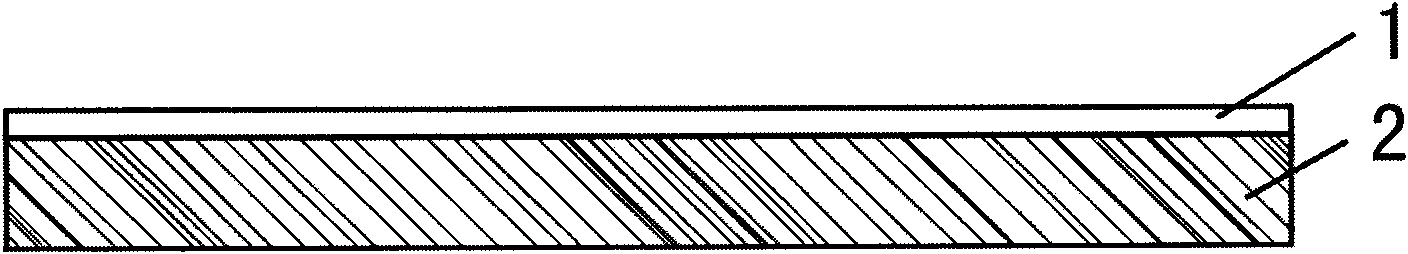

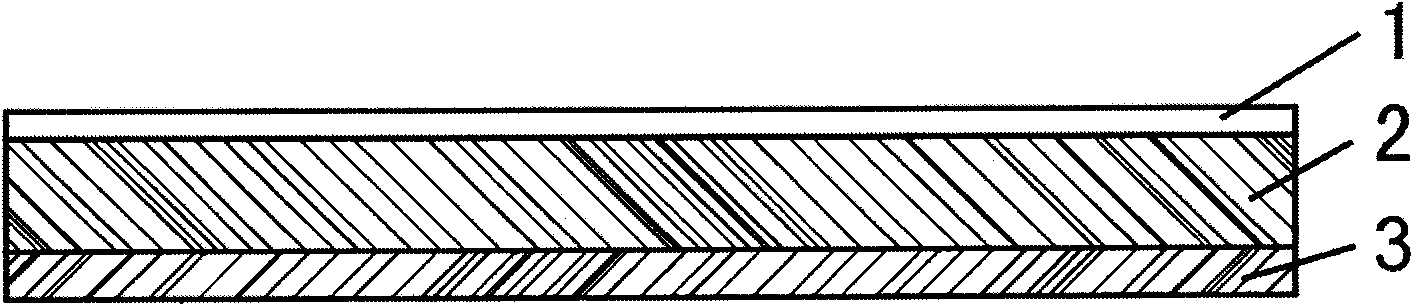

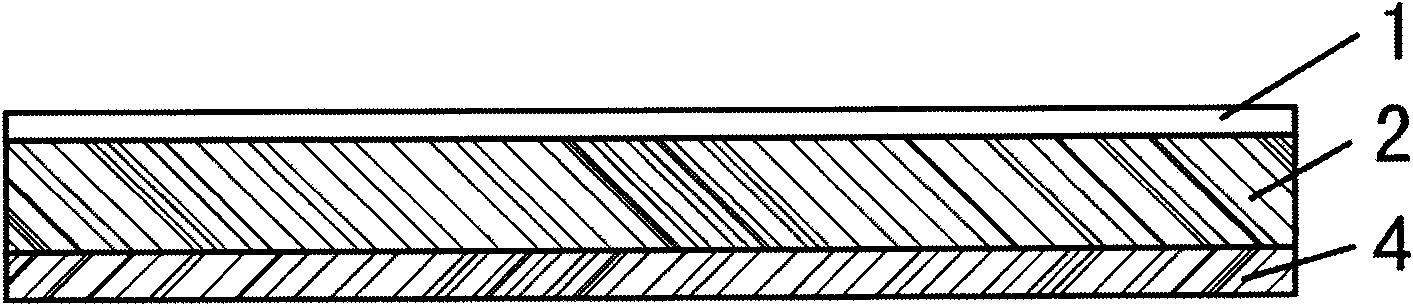

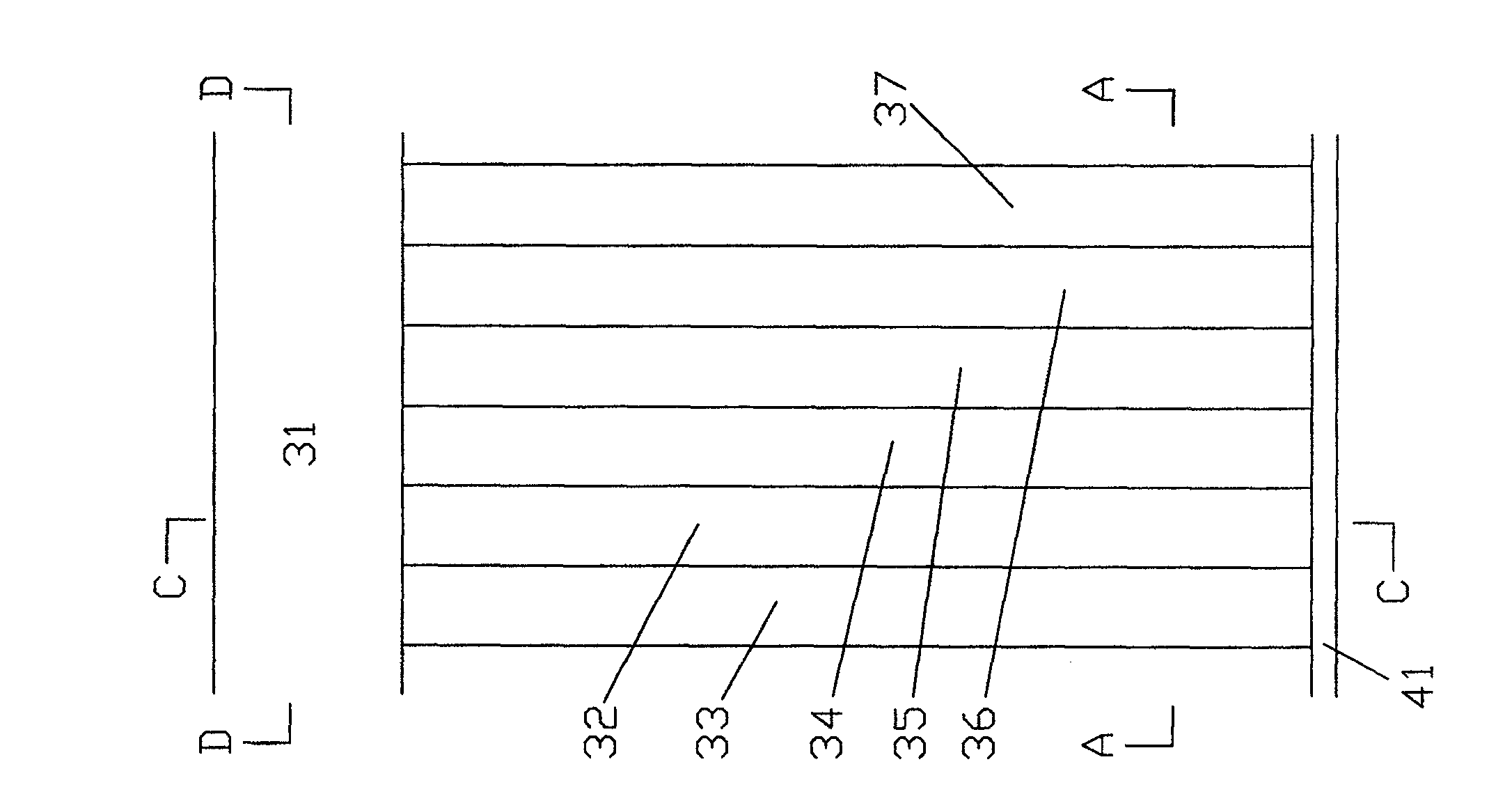

Flexible thermosetting resin impregnated paper high-pressure laminated plate

InactiveCN101954768AImprove waterproof performanceImprove flame retardant performanceSynthetic resin layered productsPaper/cardboard layered productsVegetable fibersEngineering

The invention discloses a flexible thermosetting resin impregnated paper high-pressure laminated plate, which comprises an impregnated bond paper decoration layer (1) and a non-woven fabric layer (2), wherein the impregnated bond paper decoration layer (1) and the non-woven fabric layer (2) form a thin high-pressure laminated plate through interlayer composition. The impregnated bond paper decoration layer (1) is an artificial board surface decoration material prepared by drying special paper impregnated by an initial polycondensate or prepolymer of synthetic resin; and the non-woven fabric layer (2) is a vegetable fiber non-woven fabric layer or a chemical fiber non-woven fabric layer. The flexible thermosetting resin impregnated paper high-pressure laminated plate has the advantages of high water resistance and flame retardation, good chamfer bending performance, good environmental protection performance, convenience of the product without surface post-treatment after coating, high decorative property, smoothness, no need of paint, easy maintenance, simple production technology, short hot-pressing time, energy conservation, high efficiency, wide application to coating door sleeves and architraves and direct use for decorative finish of door sheets and cupboards.

Owner:庄启程 +2

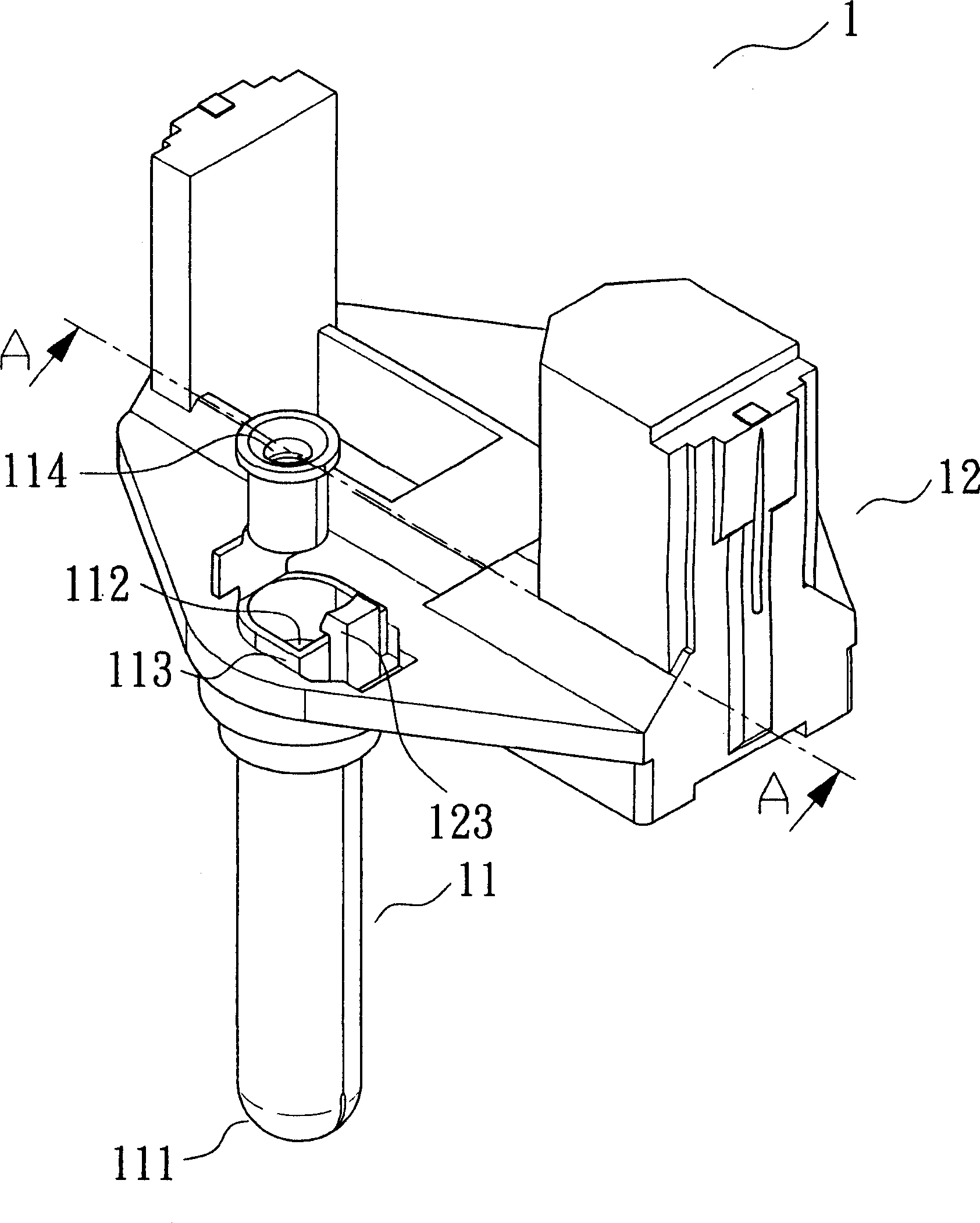

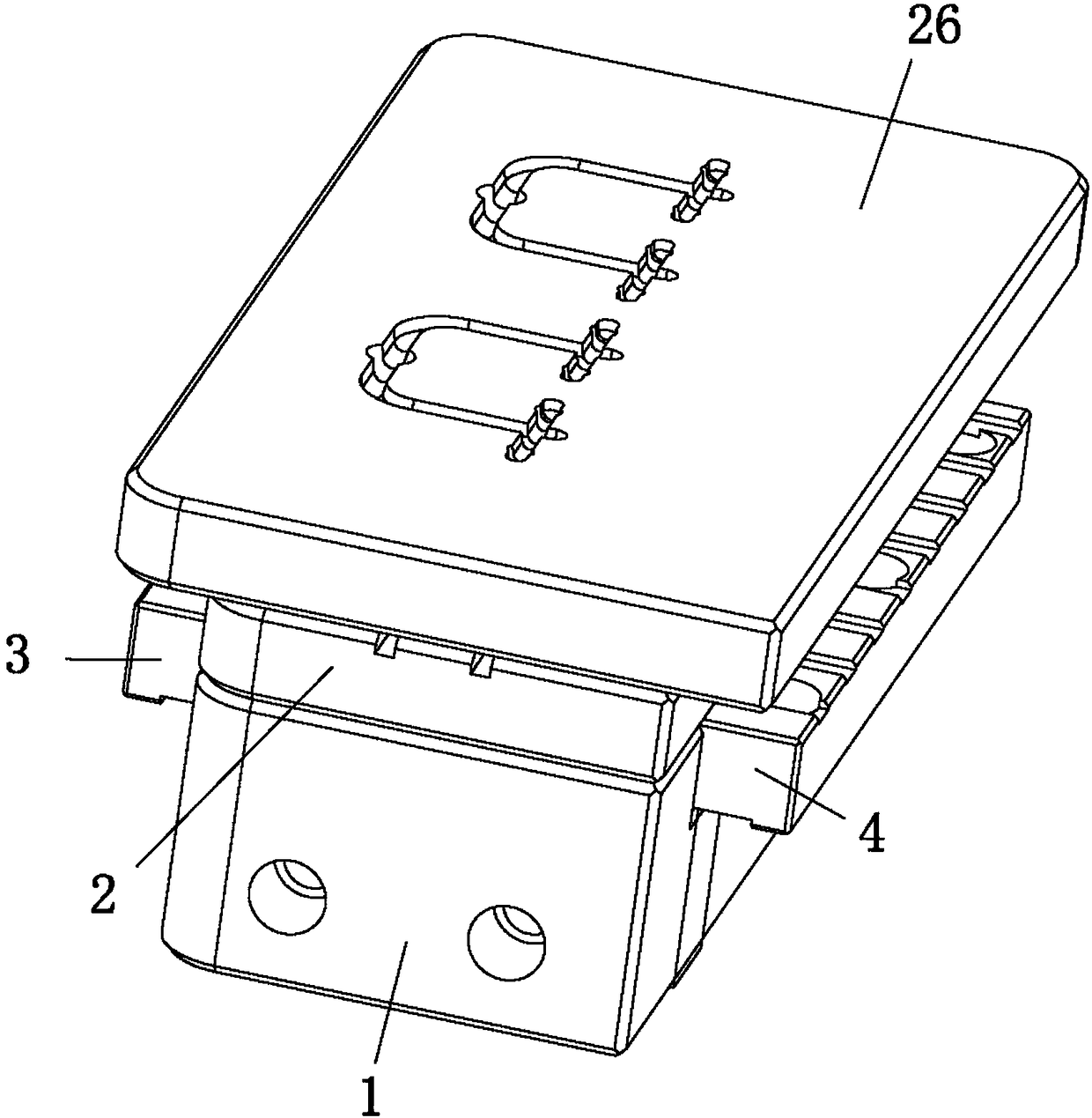

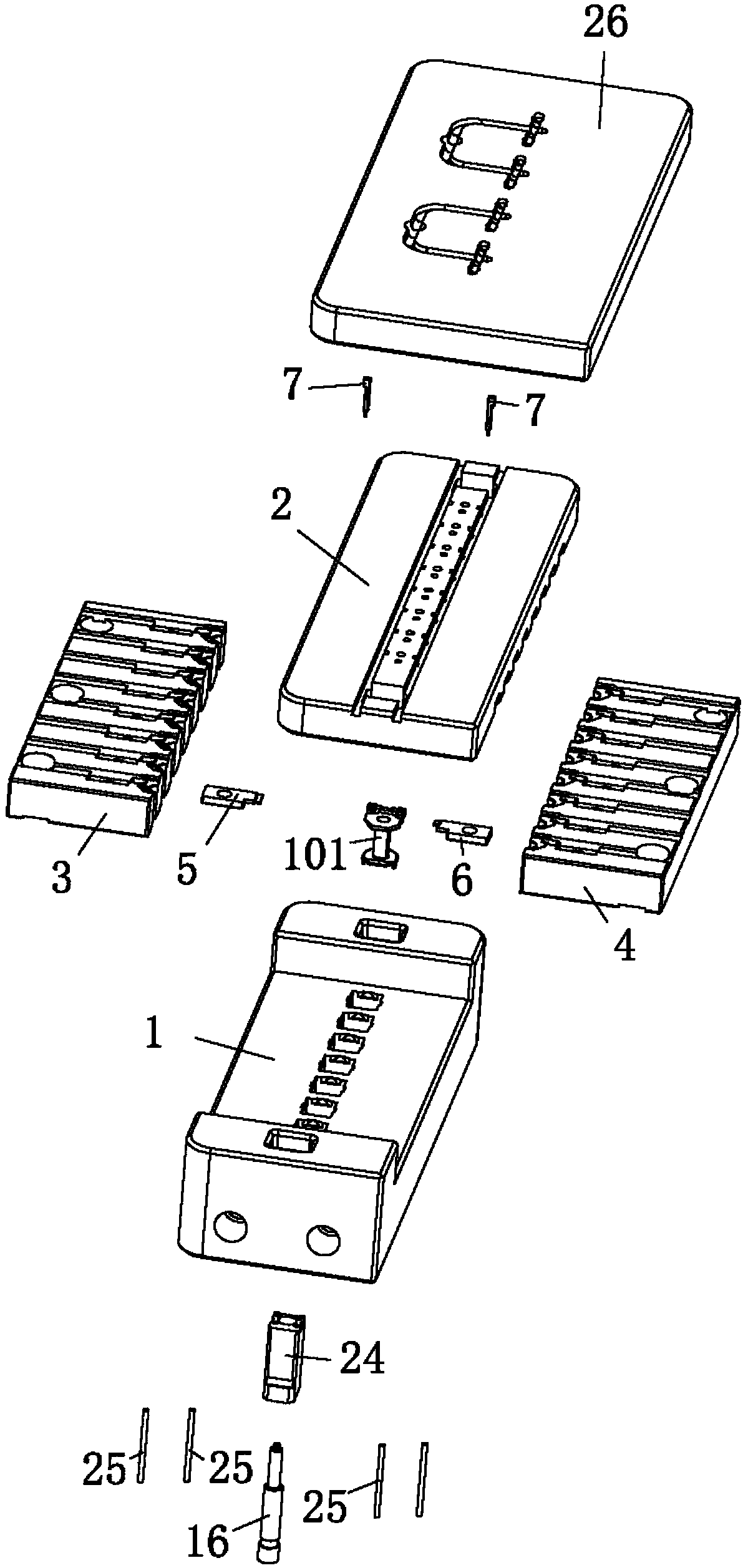

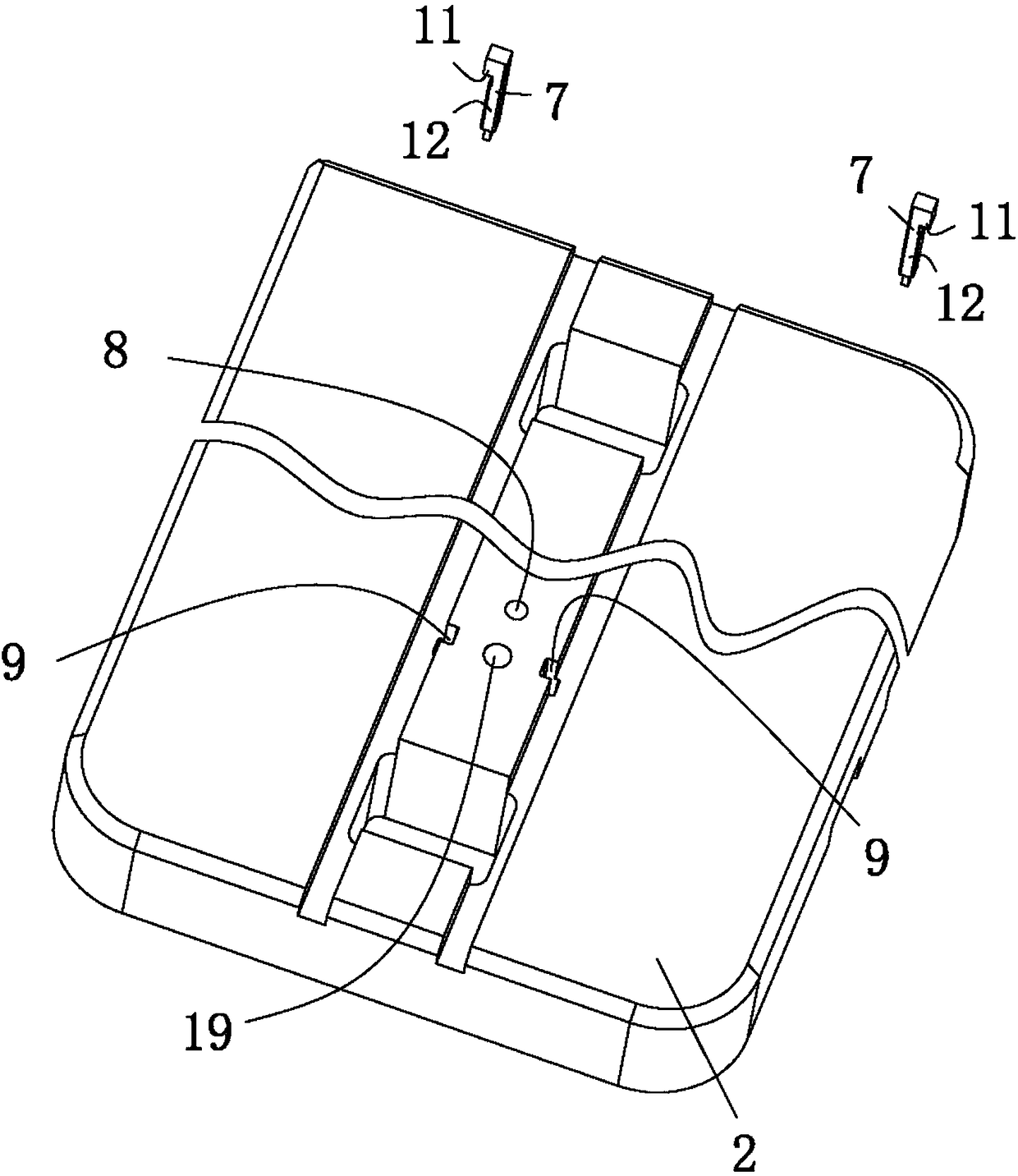

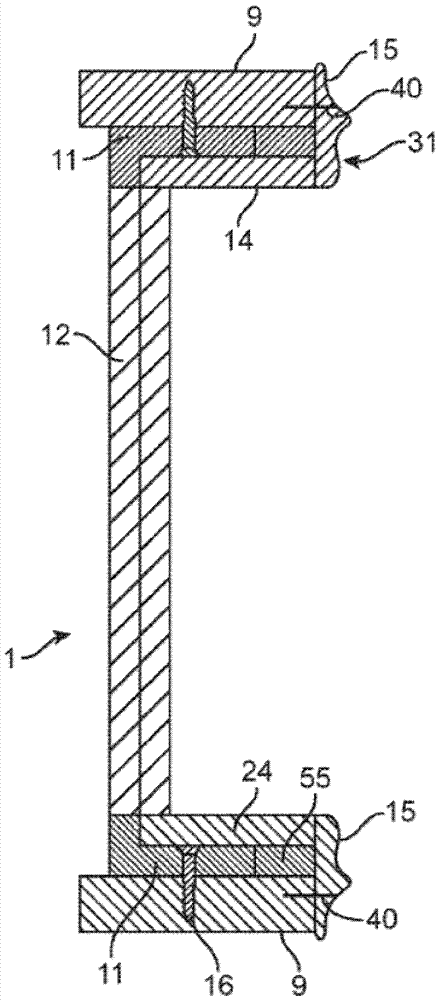

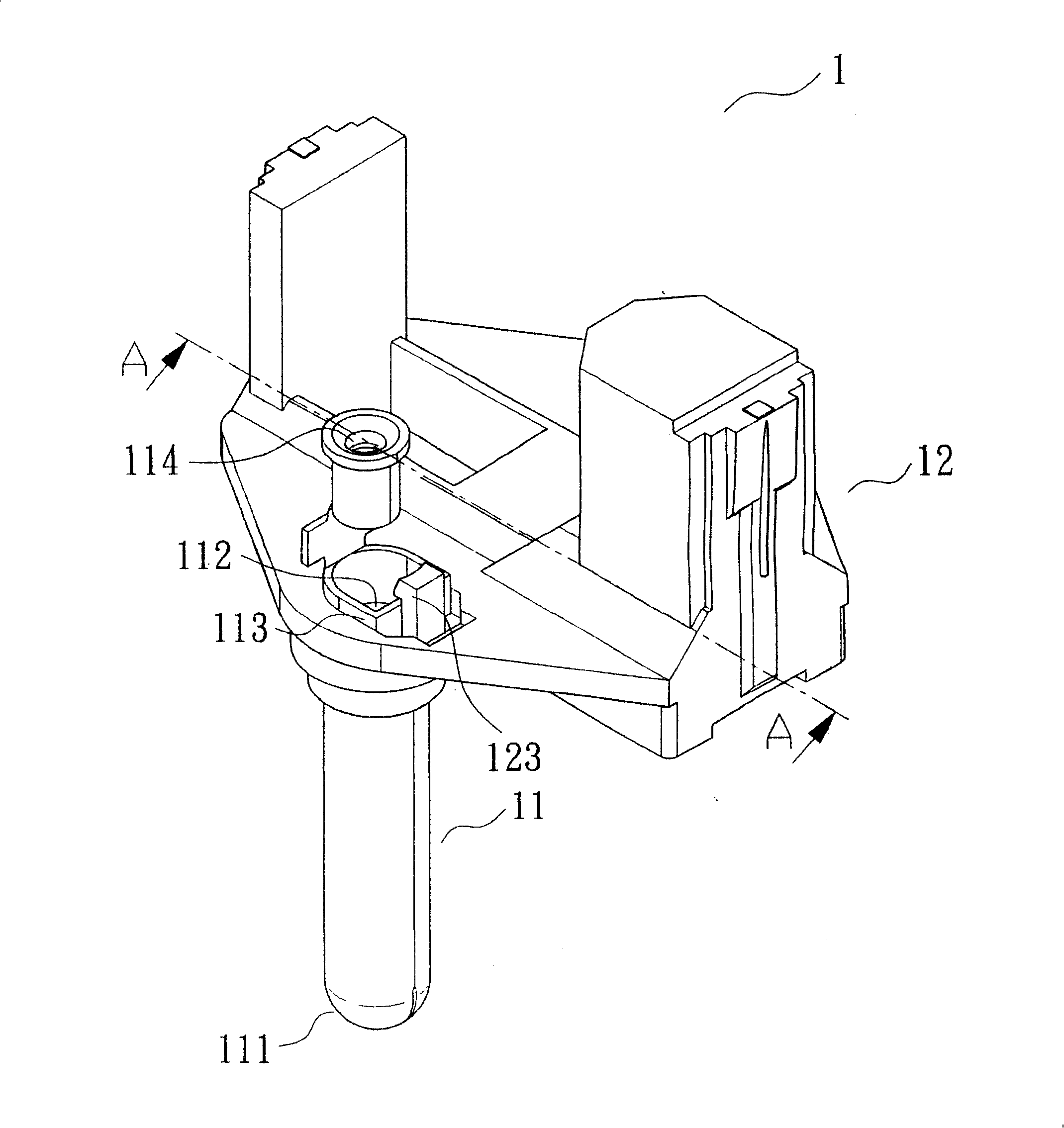

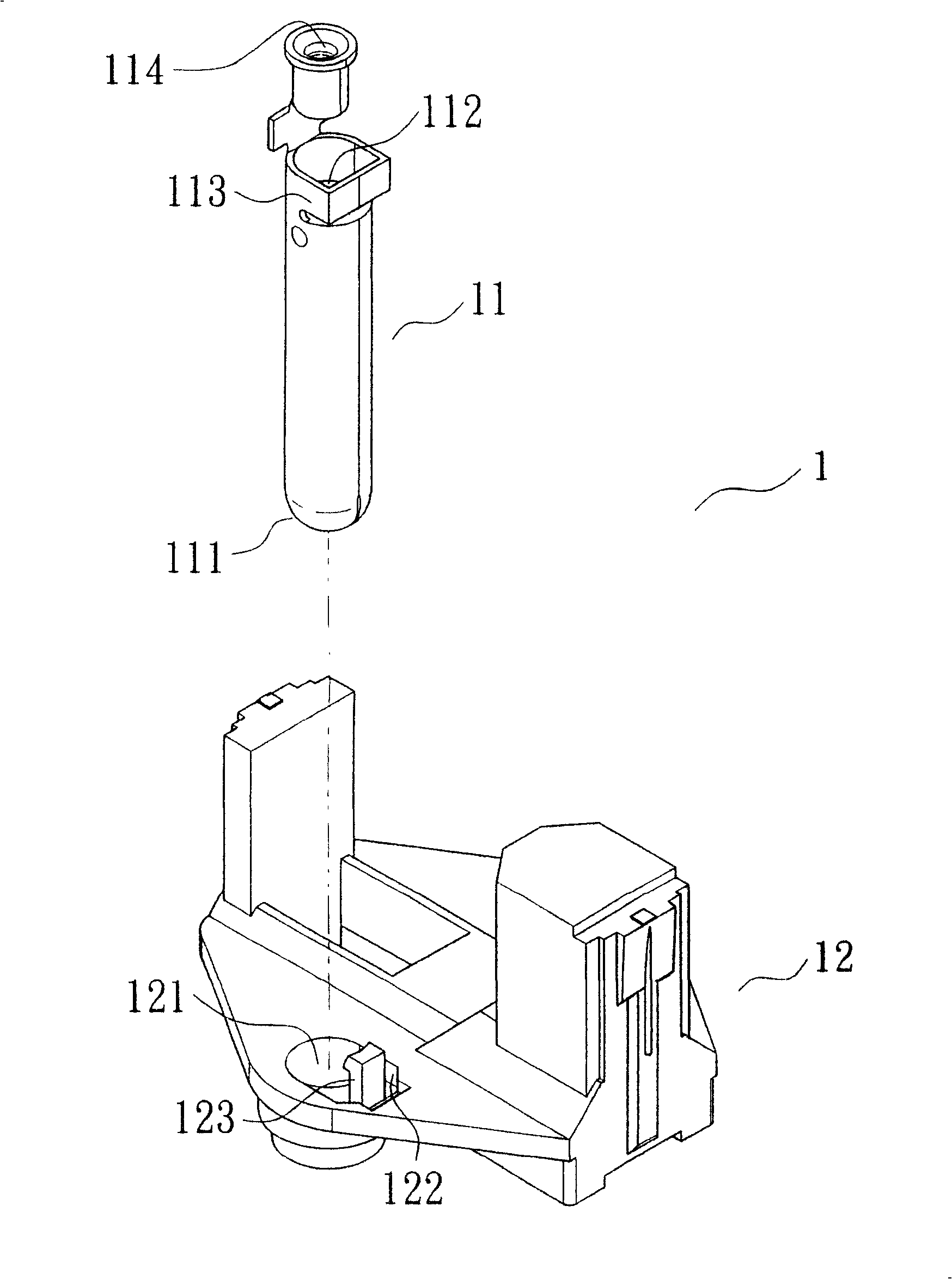

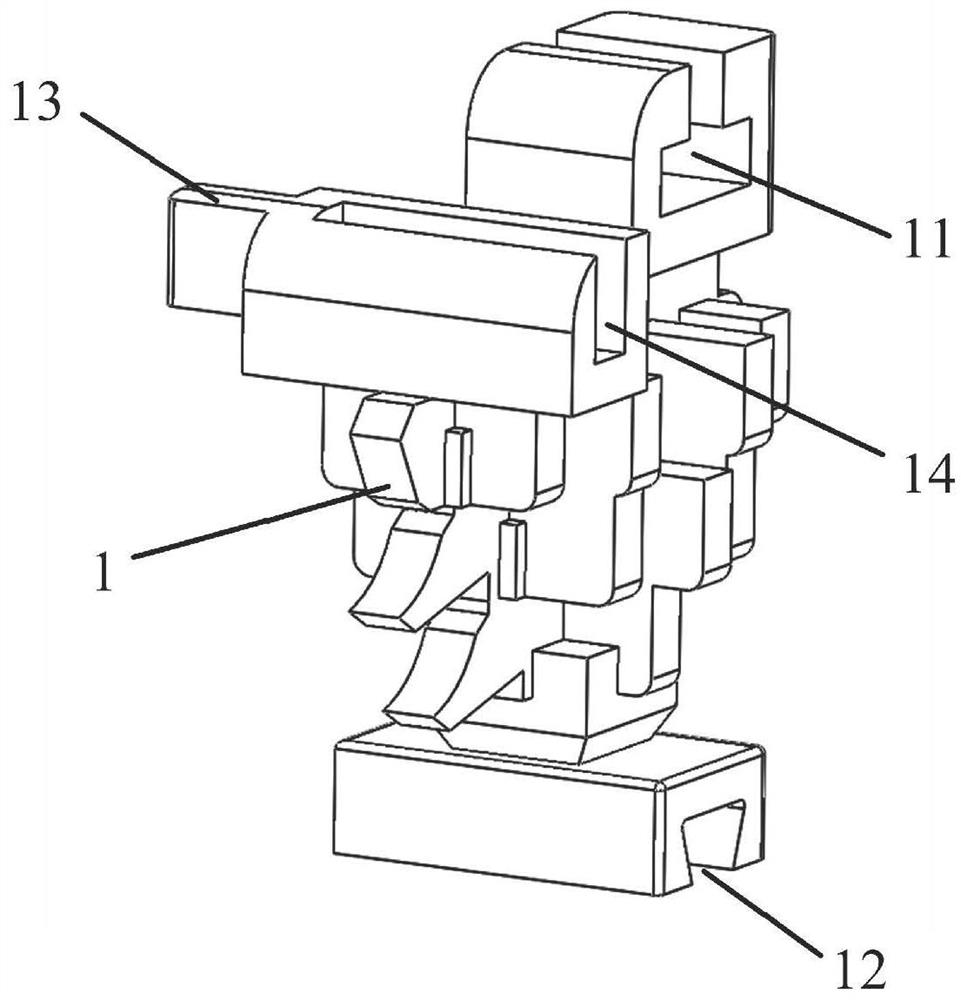

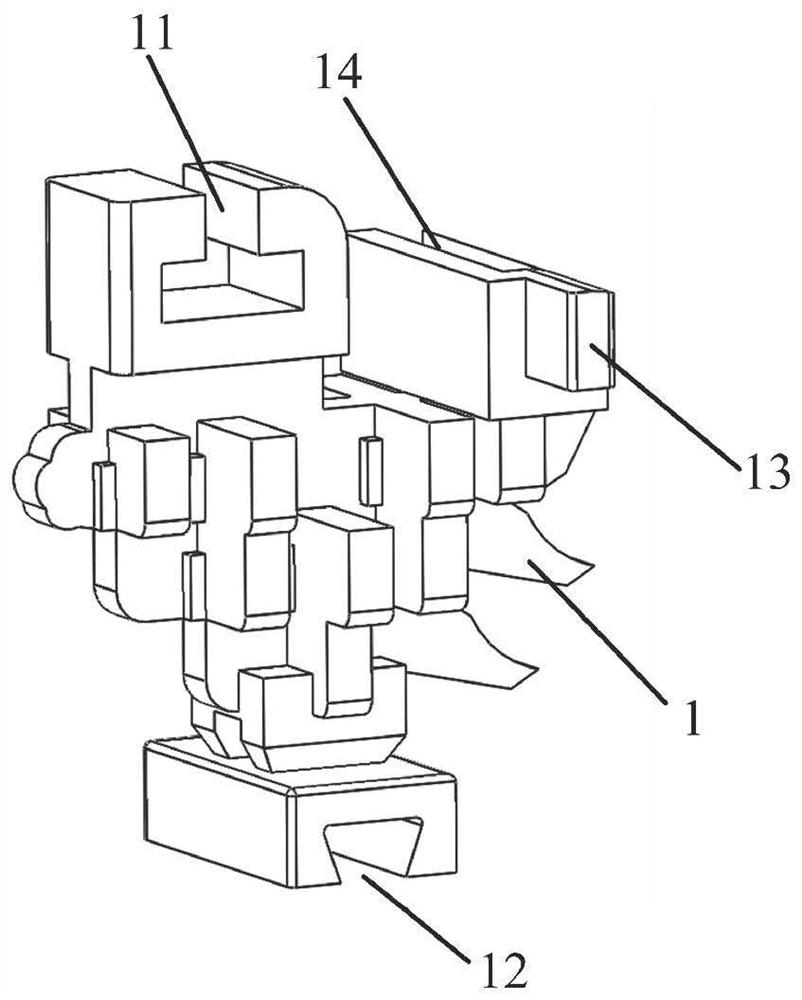

Combined plug inner frame structure

InactiveCN1822440AMeet safety requirementsMaintain stabilityContact member cases/bases manufactureSecuring/insulating coupling contact membersMechanical engineeringArchitrave

Owner:GEM TERMINAL IND

Construction method for column and architrave cornice

The invention belongs to constructional methods for architectural decoration, which is, in particular, a constructional method for pillars and architrave cornices. Prior constructional method is to fabricate the Corinthian pillars and the architrave cornices separately and to splice them during on-site installation, wherein the Corinthian pillars are cast in cement and the pillars are holistically sculpted from natural stone. Such constructional method has the disadvantages of great difficulties in sculpting and processing the pillars, inconvenience for transportation due to the heavy weight and huge volume of the pillars, high constructional cost, poor controllability during the whole construction process, severely-impacted constructional quality and delayed construction progress. Aiming to address the defects with prior constructional method, the invention provides a technical scheme for construction that all sections except the pillar heads and piers are uniformly assembled on the installation site and then cast in vertical dies. By this method, the pillars and architrave cornices are shaped at the same time, thus facilitating construction, eliminating the need to transport the pillars separately, greatly reducing the cost compared with that of pillars sculpted with stone, effectively control the construction progress and enhancing the constructional quality.

Owner:GUANGSHA CONSTR GROUP

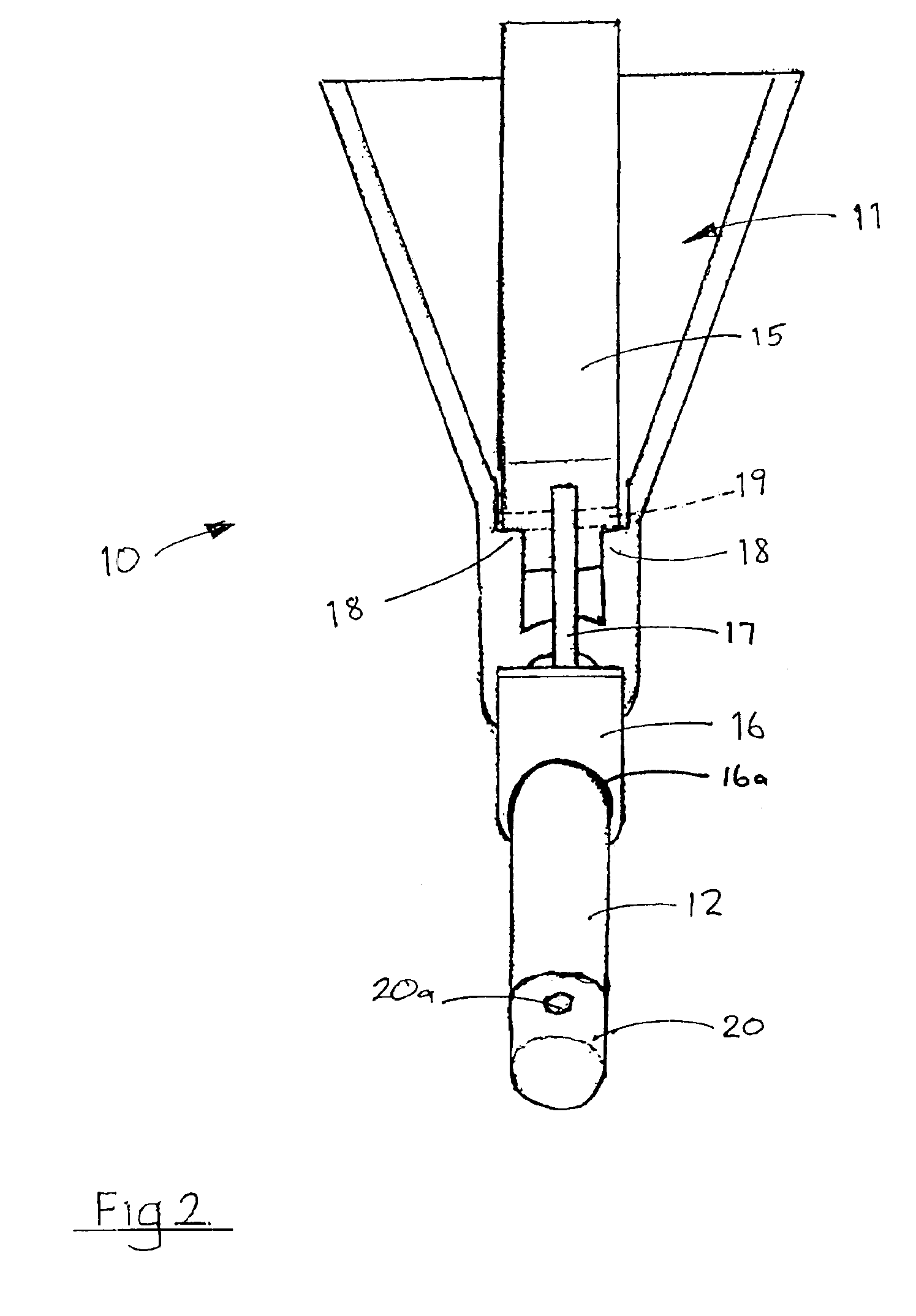

Clamp device

Owner:CLECO NEW ZEALAND

Free door controller

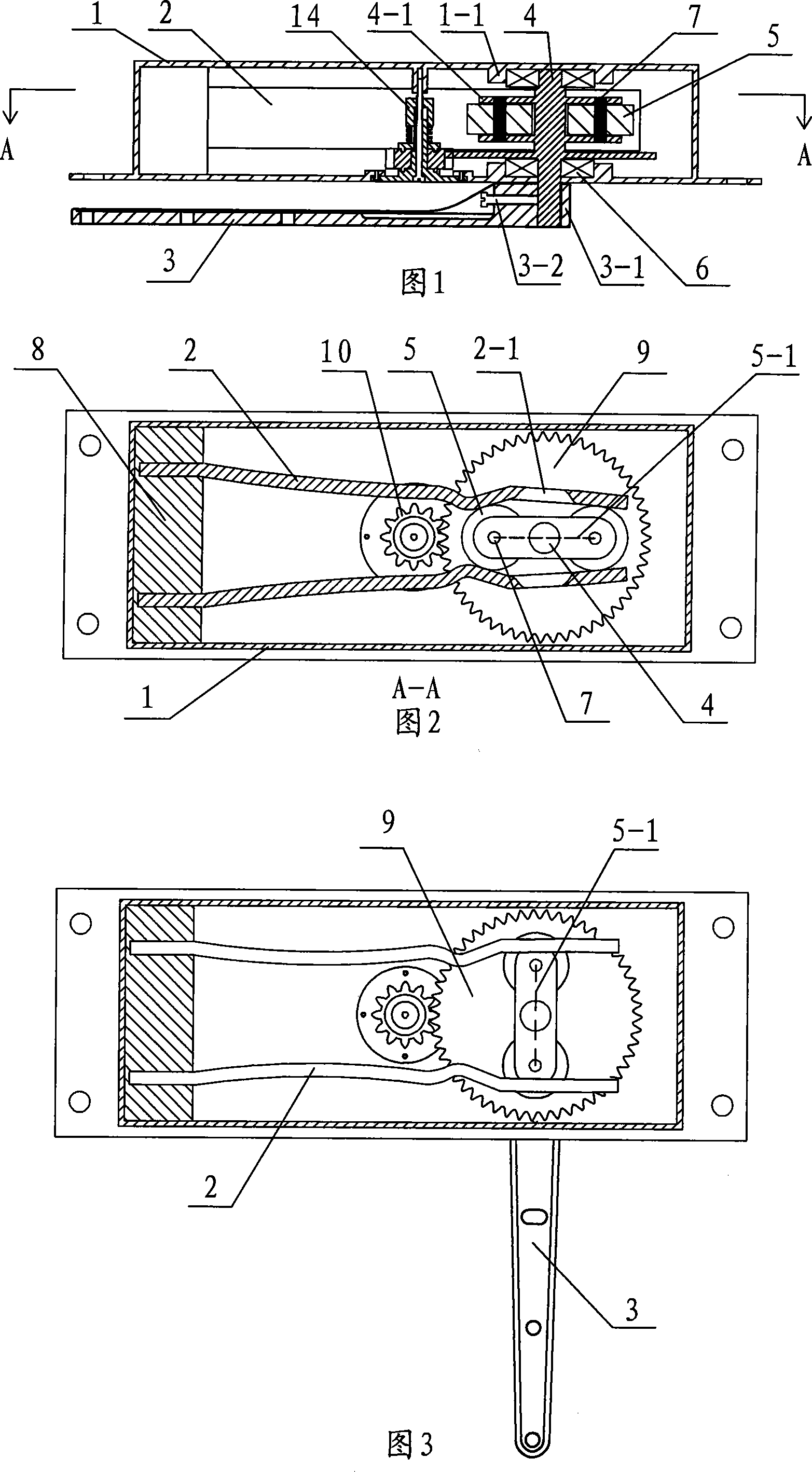

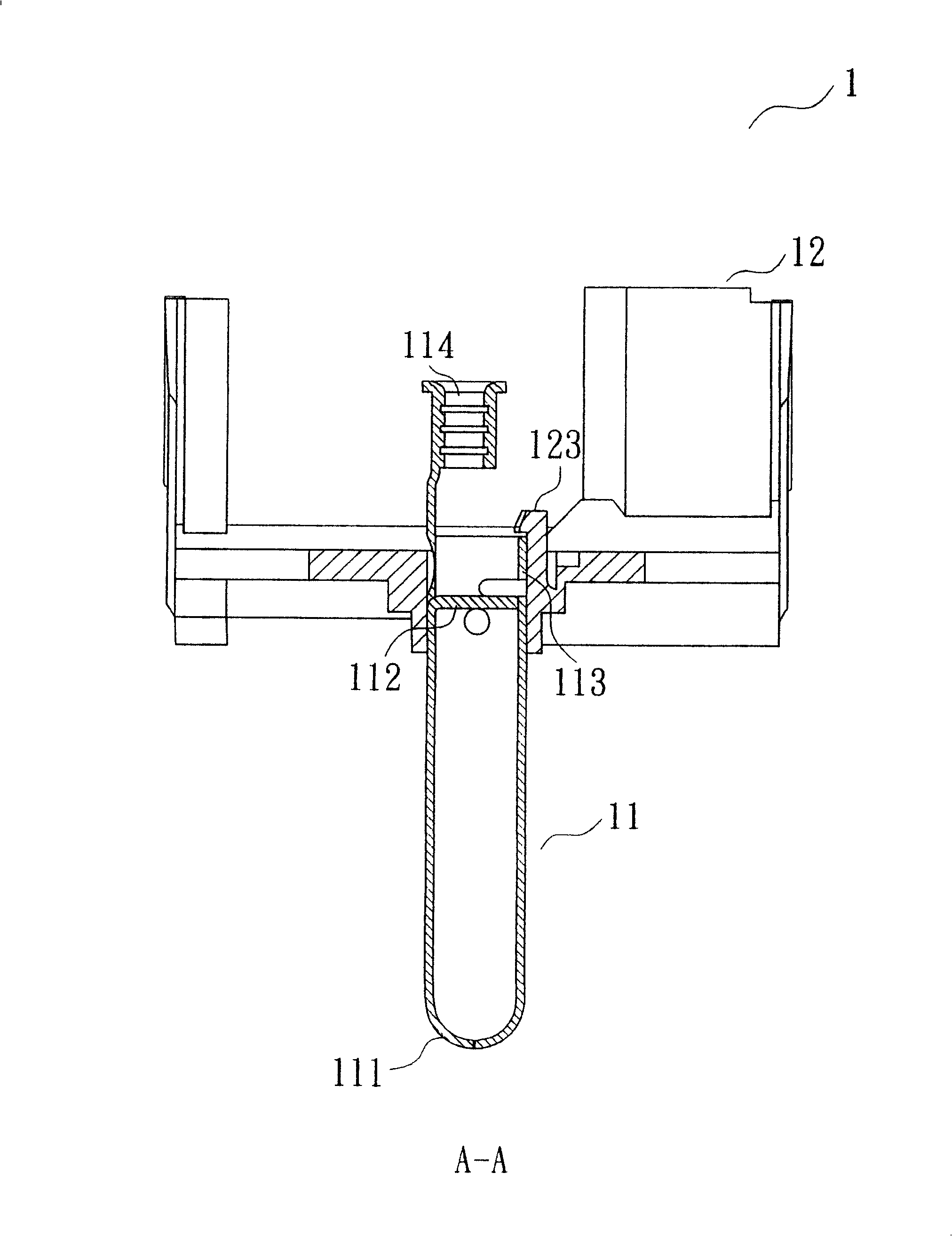

InactiveCN101200989BReduce volumeReduce weightBuilding braking devicesWing openersControl theoryRotation control

The invention relates to a free gate controller used in construction, consisting of door leaves, a door frame, an upper shaft rotation control device, a lower shaft locating device and a shaft terminal locating block. The upper shaft rotation control device is fixed on the upper frame of the door frame; the lower shaft locating device is fixed on the lower frame of the door frame or the floor; the central rotating arm of the upper shaft rotation control device is connected fixedly with the upper architrave or the upper part of the upper gate folder of the door leaves; the bearing seat of the lower shaft locating device is fixed on the lower architrave or the lower part of the lower gate folder of the door leaves; the shaft terminal locating block contacts the rotary shaft of the rotary connecting arm of the upper shaft rotation control device and is fixed in the upper architrave or the upper part of the upper gate folder of the door leaves. Compared with the prior art, the invention is characterized by: 1. Time saving and laboring assembly; 2. Small volume, light weight, little consumption of the material, simple structure, low cost, easy manufacture, easy production; and characterized in that: 3. the invention changed that the lower shaft control device bears the weight of the gate in the prior art; the rotary device of the upper shaft is connected by bearing, thereby the stress and the wear of different working components are little, the service life is long and the reliability is high.

Owner:初恒毅

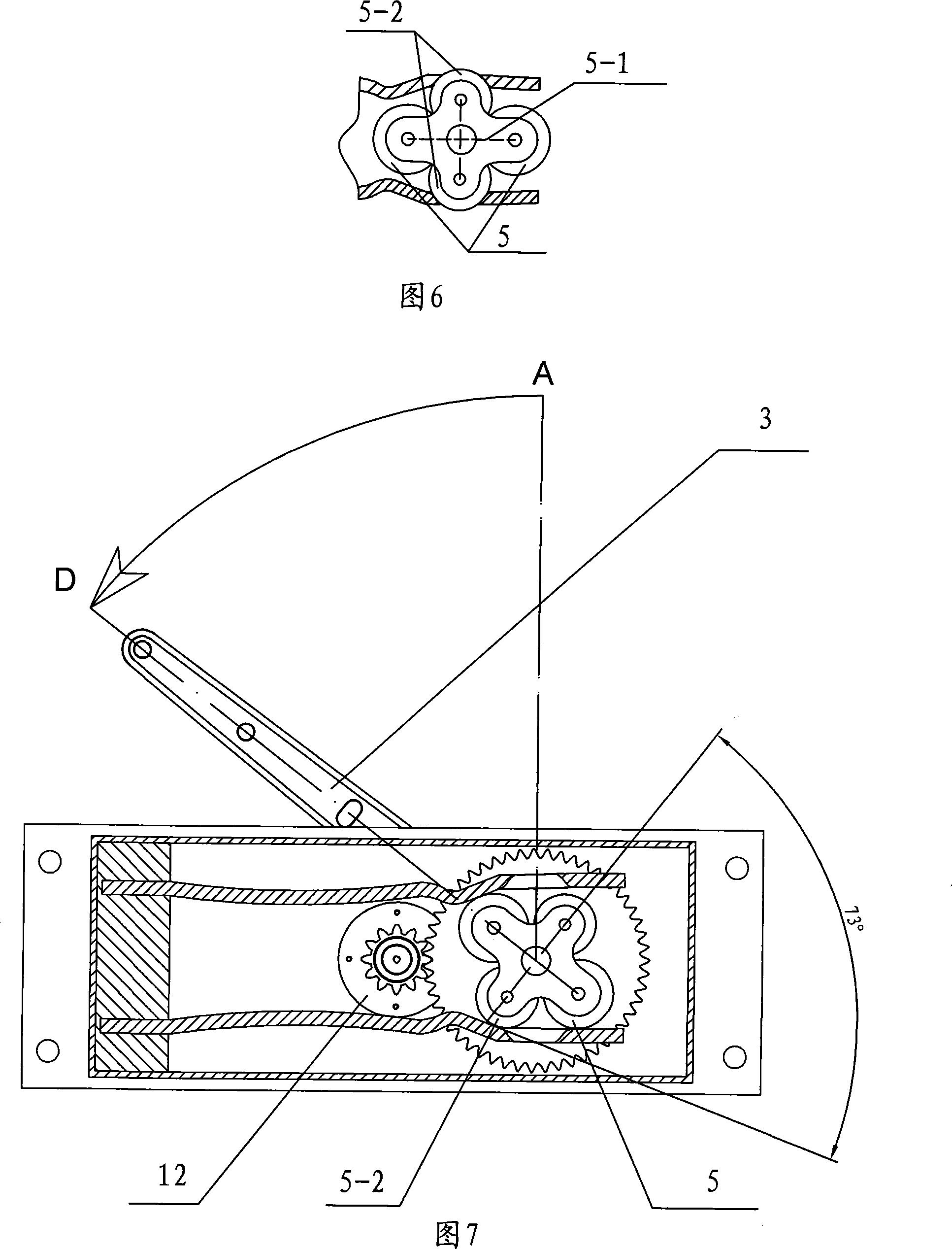

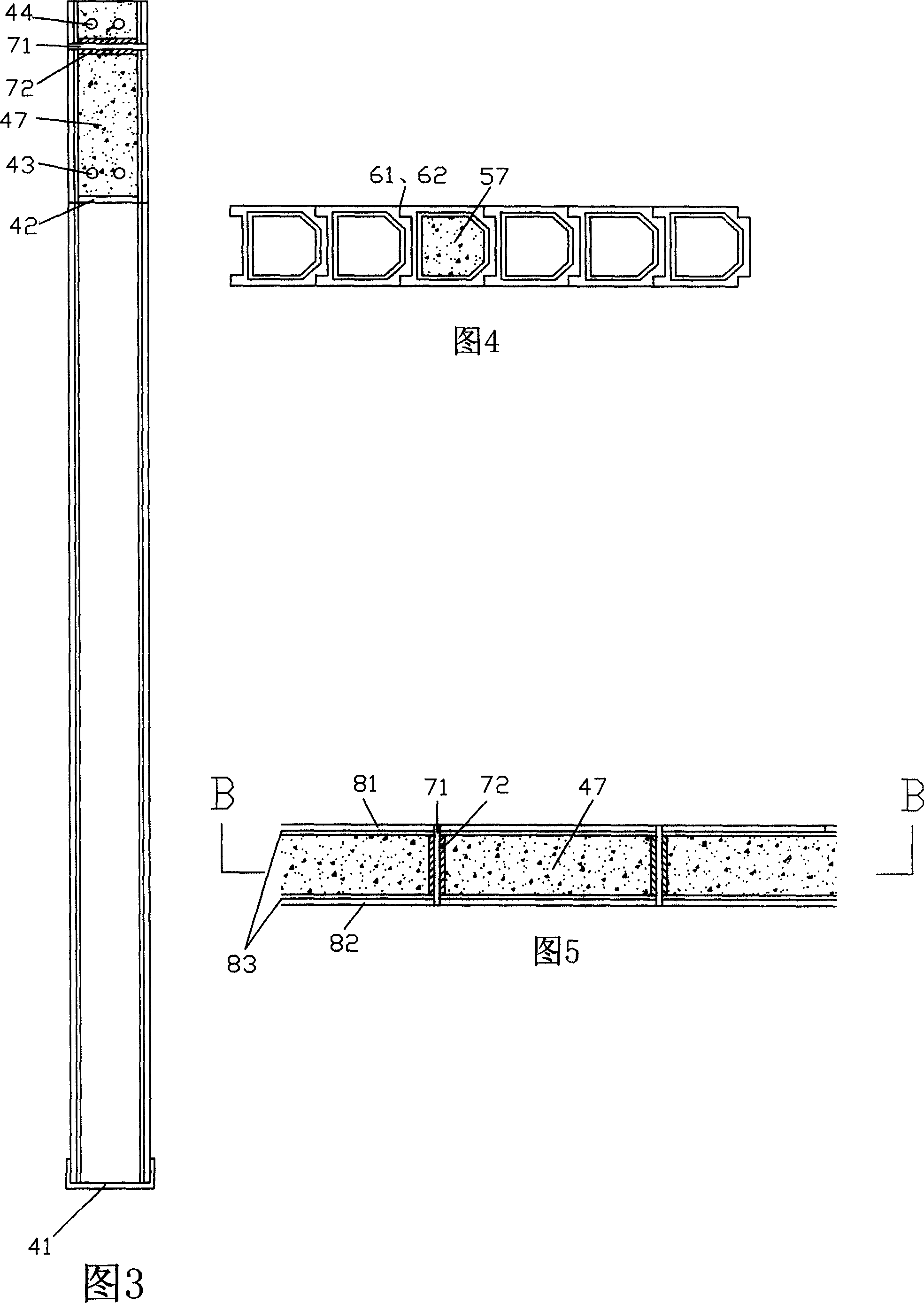

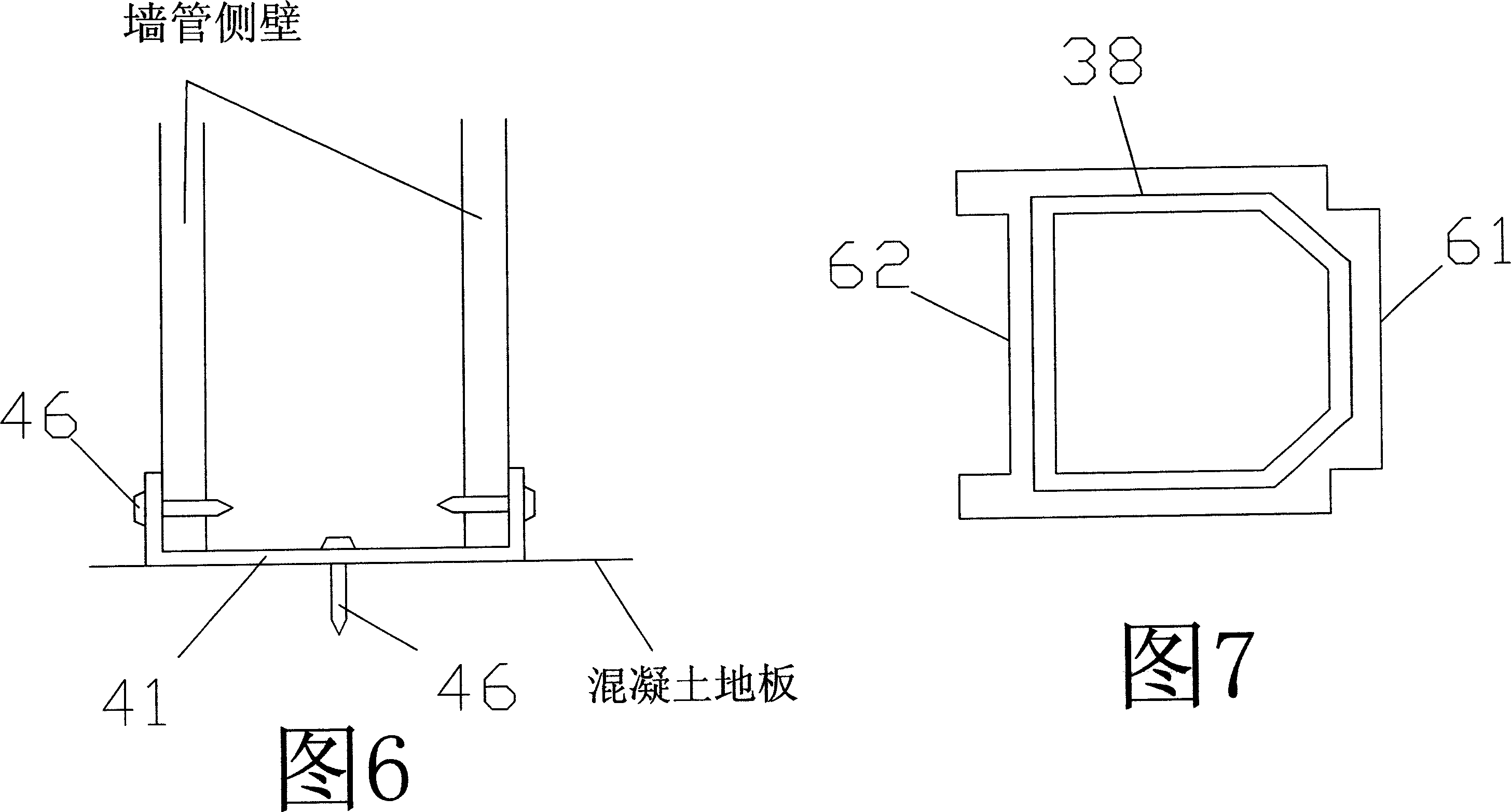

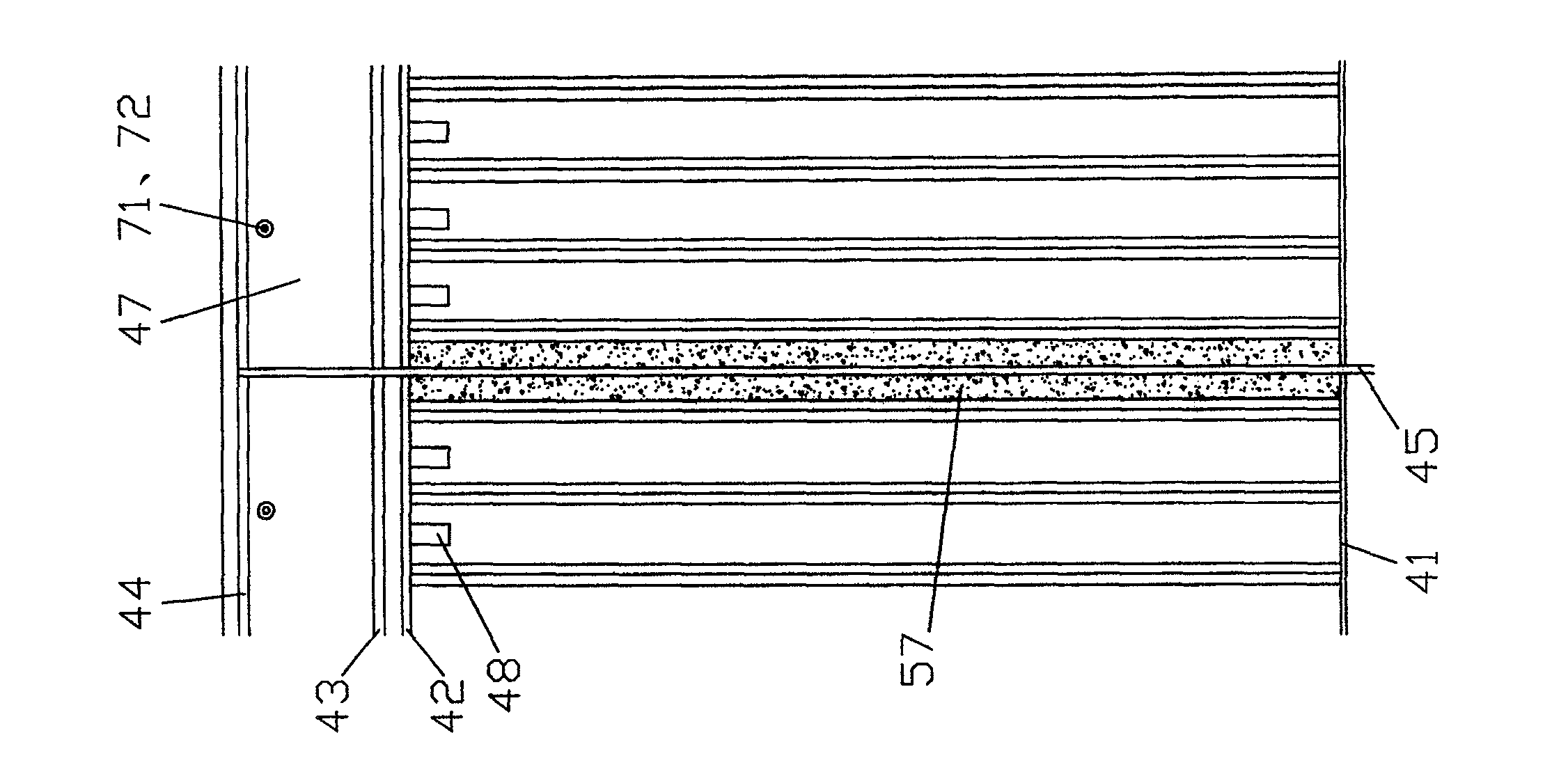

Foam concrete wall for buildings construction

The invention discloses a foamed concrete wall(CWS), comprising an iron sheet rail, a locating plate, multiple wall pipes and an architrave, where the iron sheet rail is fixed on the floor; the bottom of the wall pipe is fixed with the iron sheet rail and the top of the wall pipe is guided by the locating plate; the two sides of each wall pipe are convex-concave to make all wall pipes interconnected; the wall pipes are poured with concrete to bear weight and connect groundsill to top architrave; two fiber screen plates on the two sides of the architrave are used as templates of the architrave; the bottoms of two AAC fiber screen plates are fixed with the locating plate, and their top ends are supported by metal pull rod and support sleeve and concrete is poured in between the fiber screen plates.

Owner:钟文义

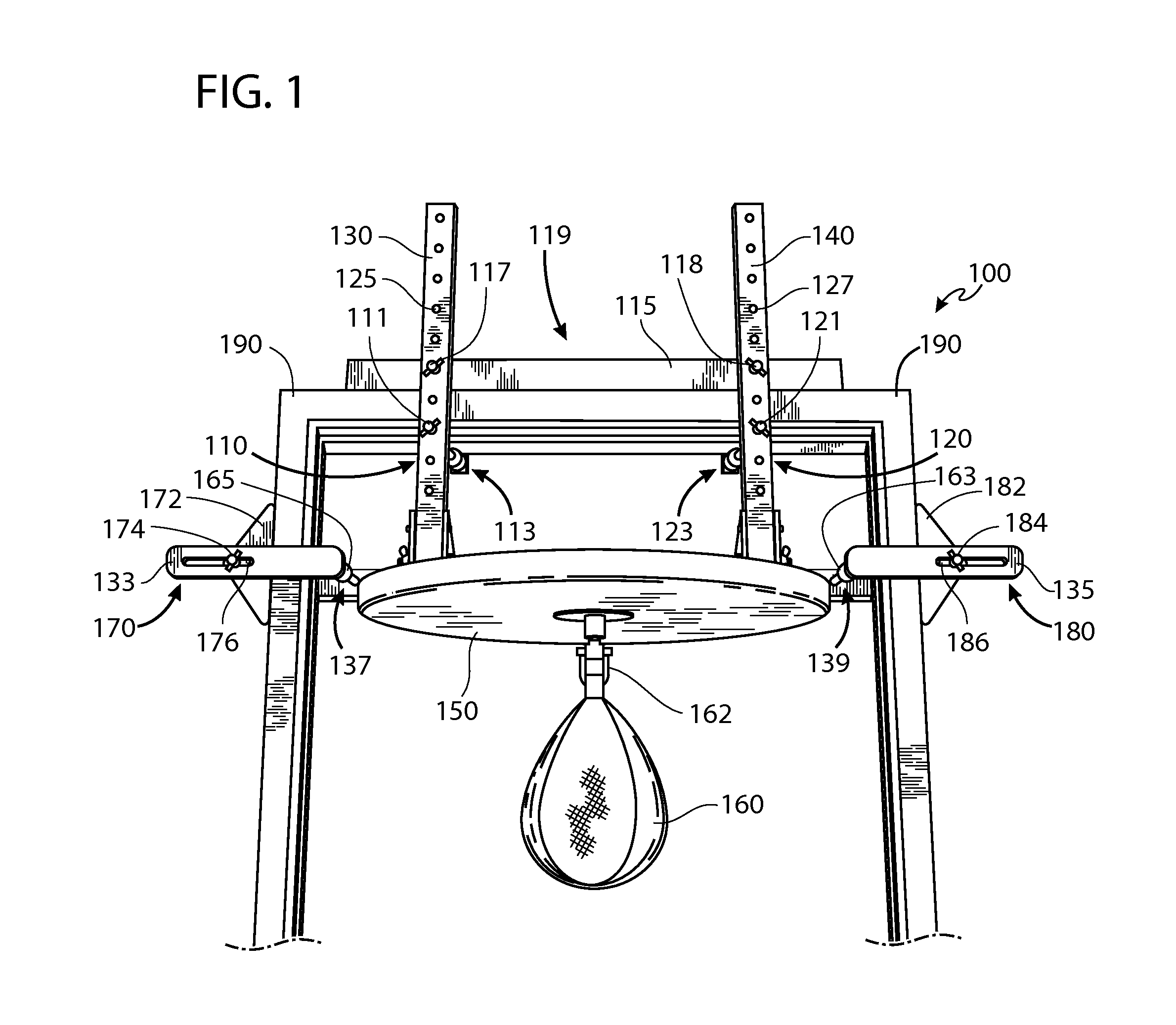

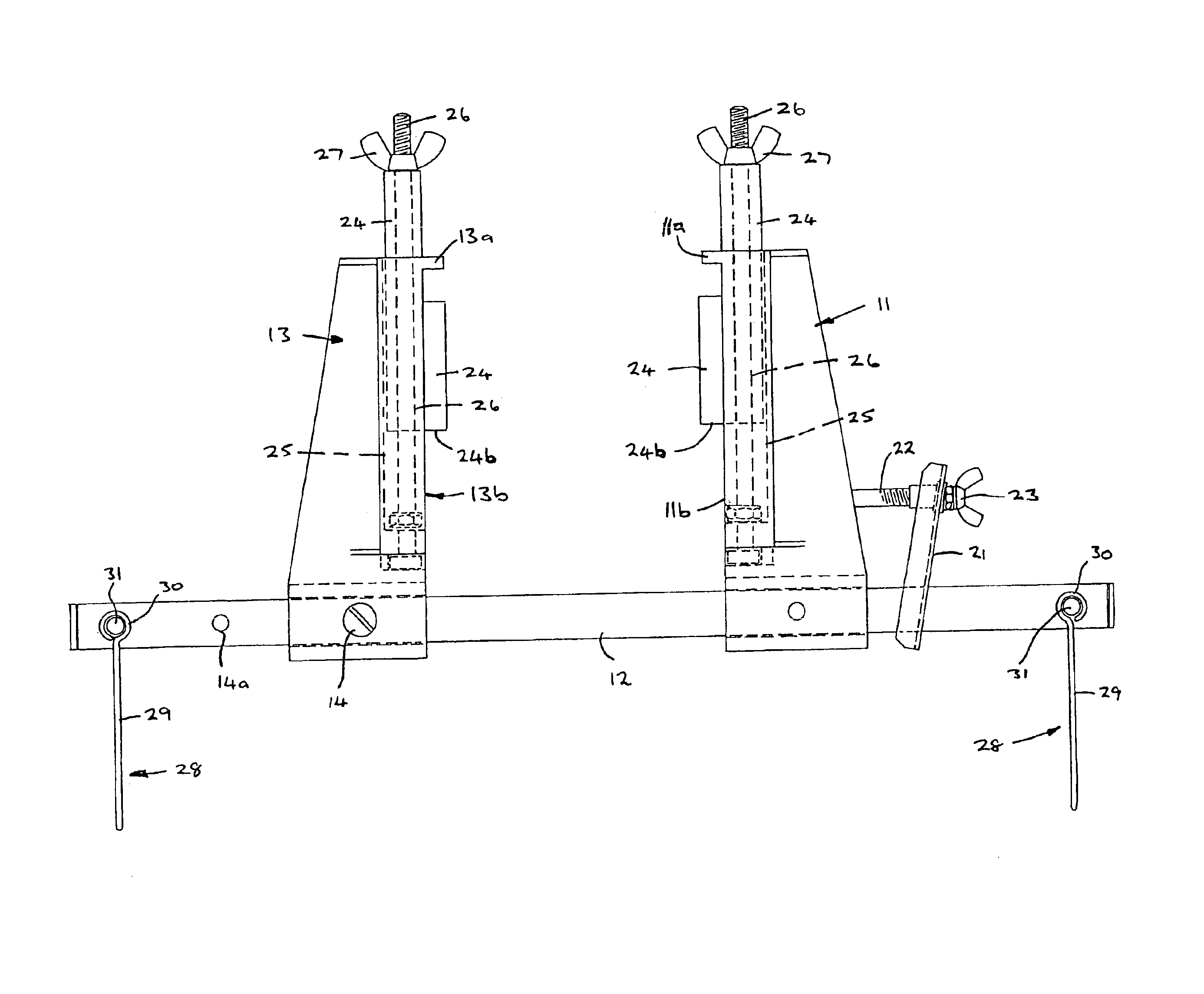

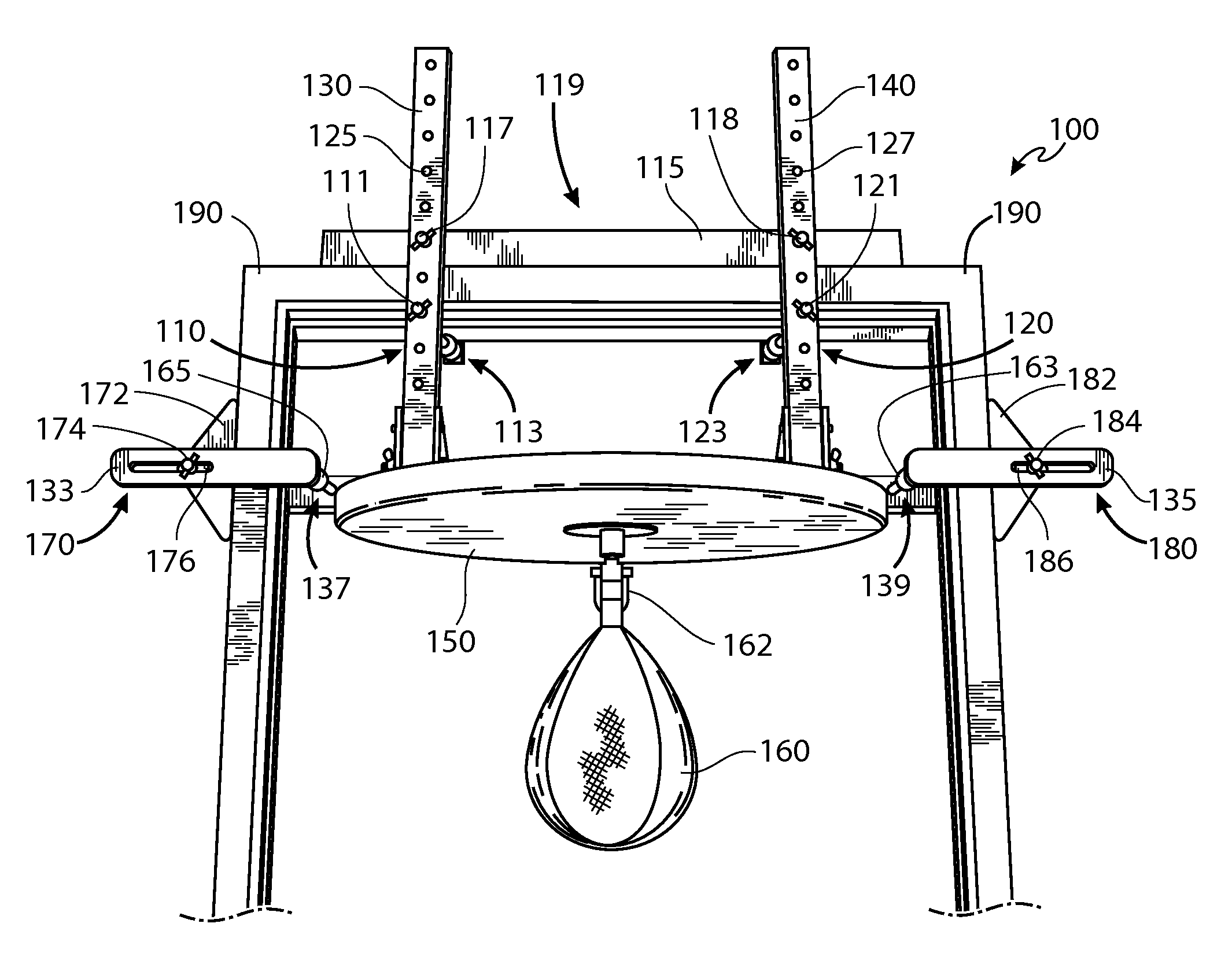

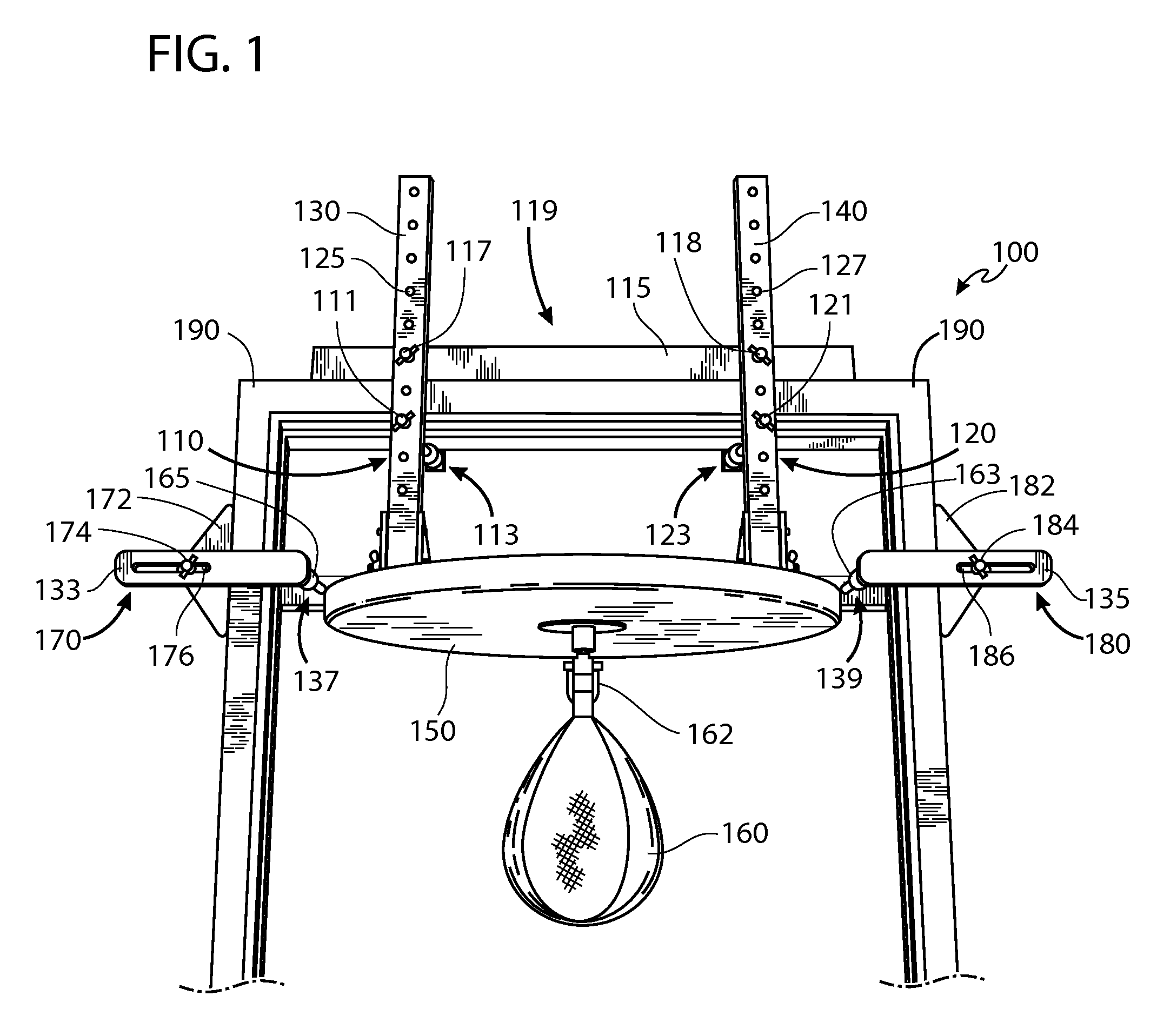

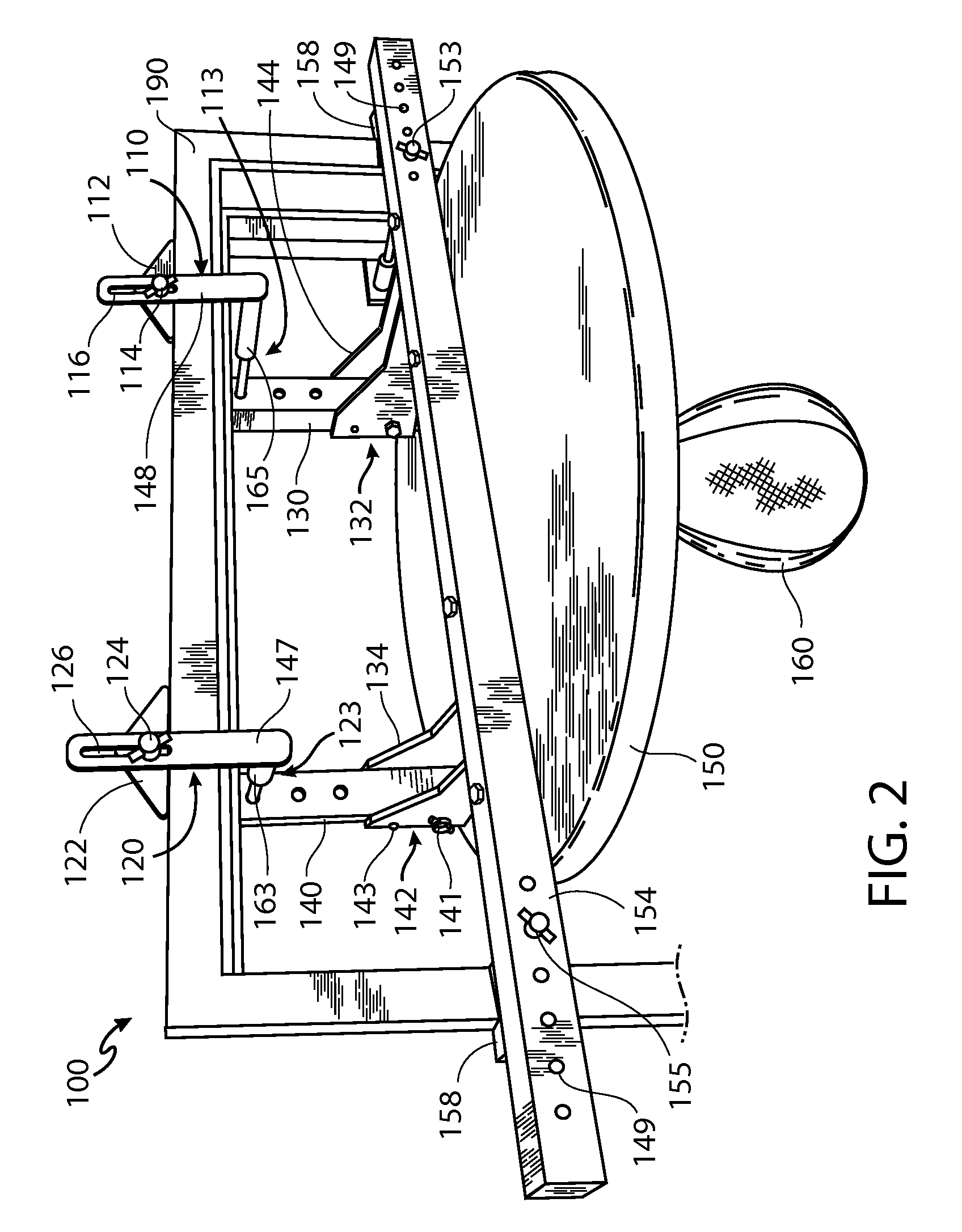

Universal punching bag support apparatus

This disclosure describes an apparatus and methods to support a punching bag, or a punching bag and rebound platform, within a doorway or other architectural opening. Mounting the apparatus does not involve modifying or altering the supporting architectural structures and surfaces (e.g., with screws, brackets, adhesives, etc.). Clamps are instrumental in safely securing the apparatus and stabilizing it for high-performance use of a plurality of punching bags. Adjustment mechanisms not only facilitate the mounting of the apparatus to a plurality of doorframes and other architraves but also accommodate the height and depth preferences of a user. In addition, a folding mechanism allows the apparatus to be compacted for storage or transport.

Owner:SAGALL JASON

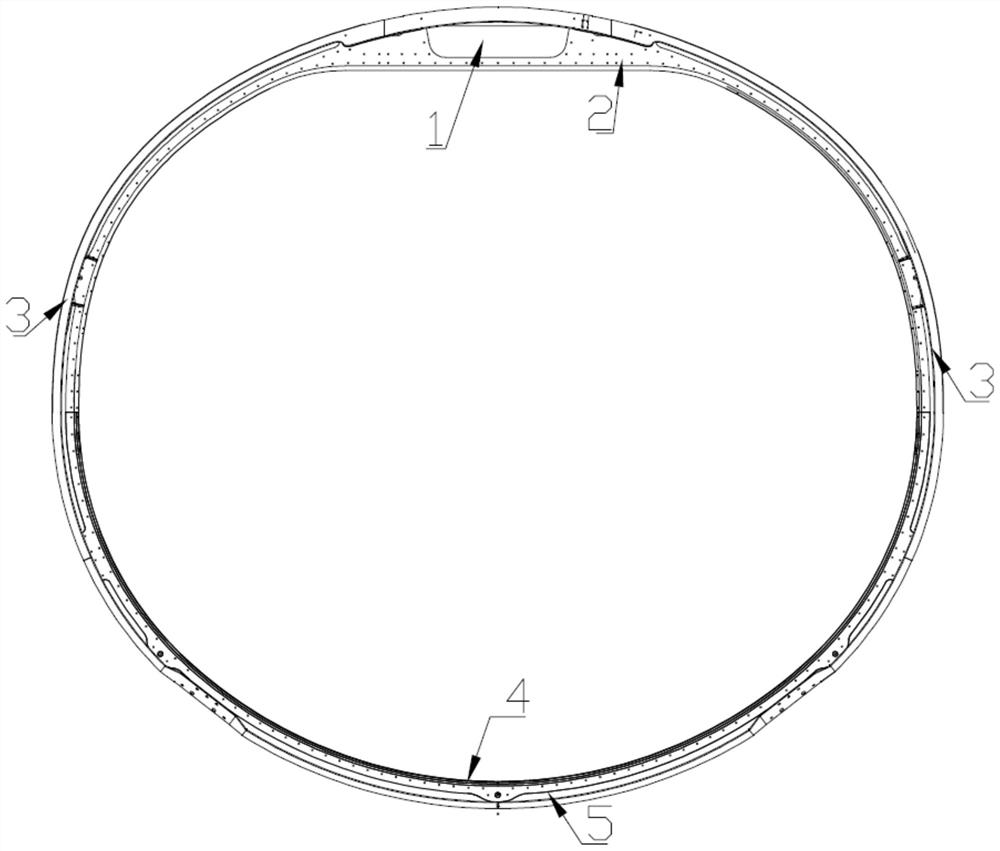

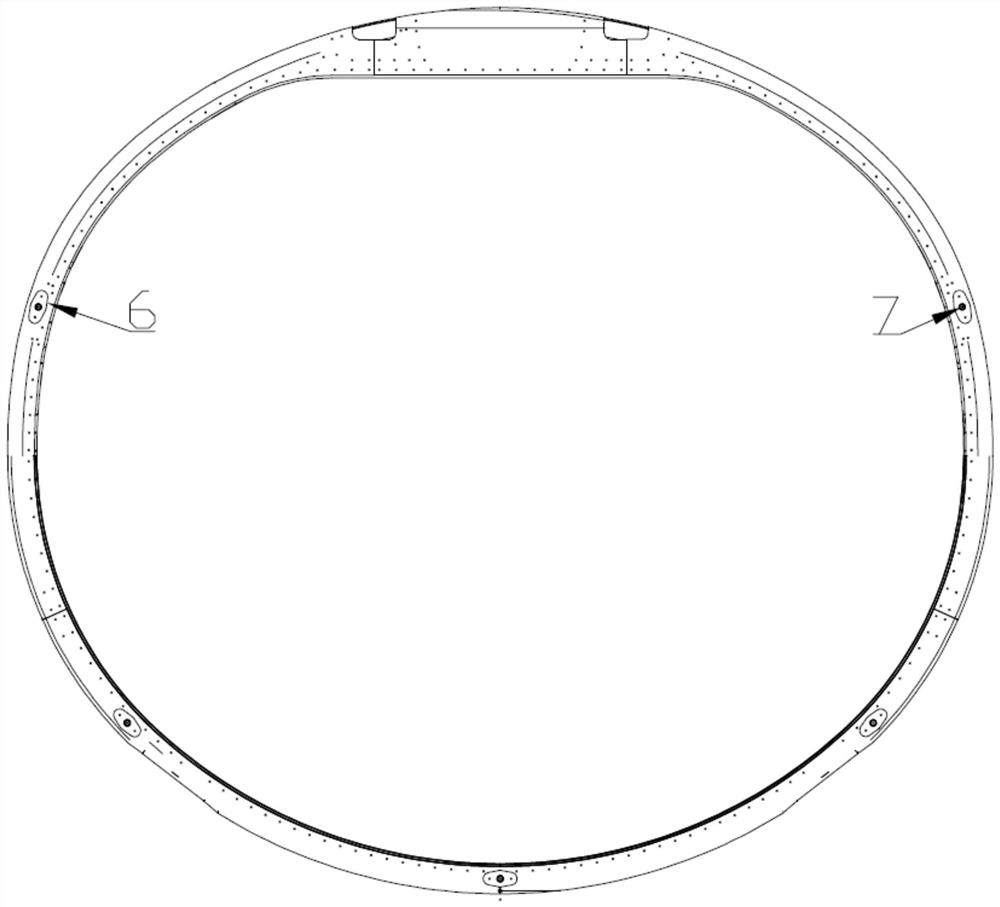

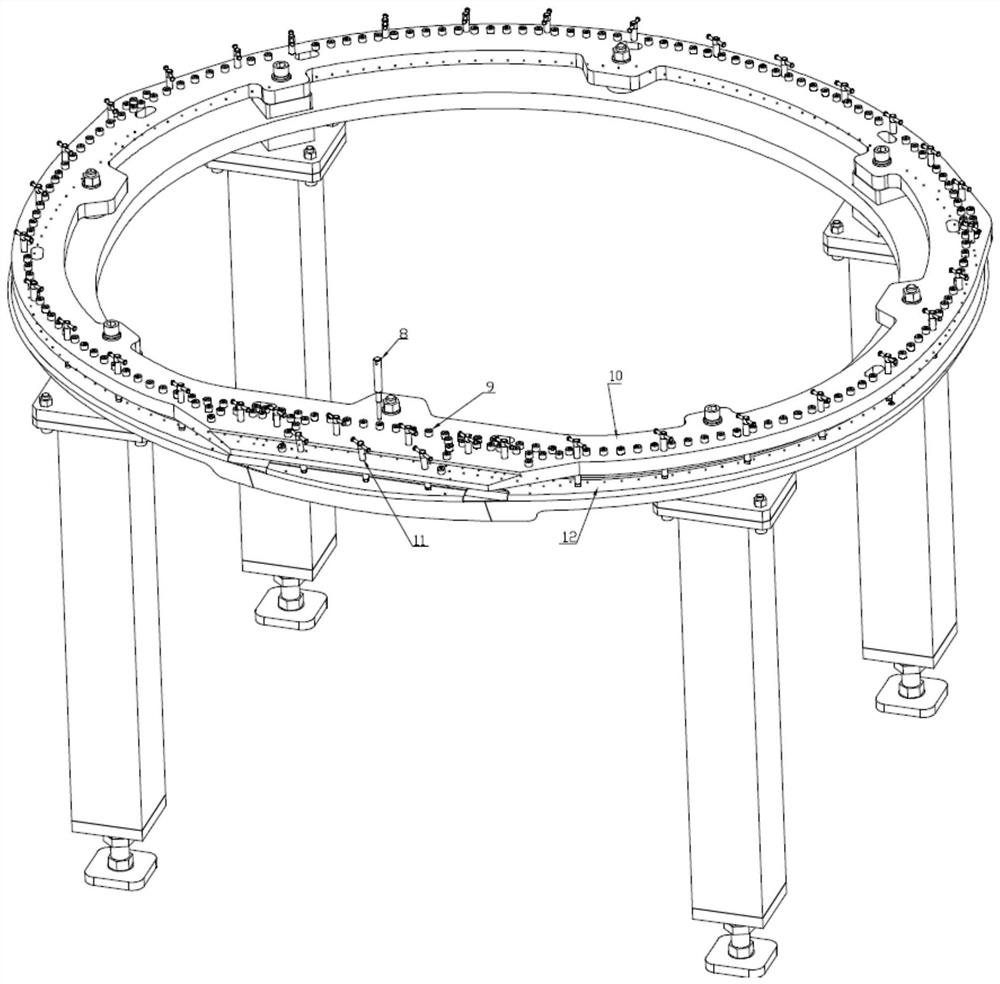

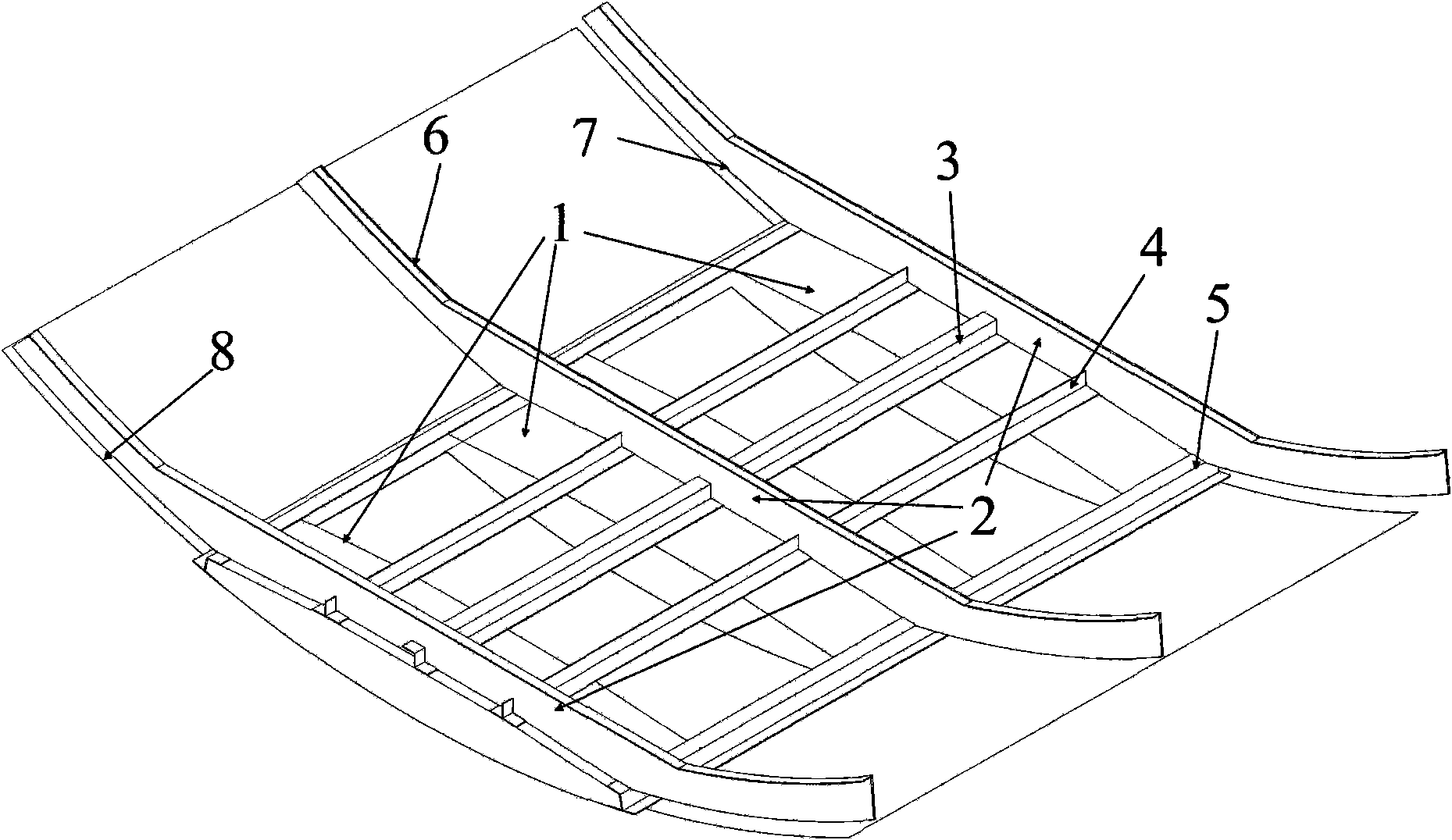

Hole-making process method adopting pre-positioning and secondary precise positioning combination

ActiveCN111958020AThe same positioning referenceAvoid errorsDrill jigsMechanical engineeringArchitrave

The invention belongs to the technical field of composite material assembly, and discloses a hole-making process method adopting pre-positioning and secondary precise positioning combination. A reinforcing ring comprises an upper frame edge, a lower frame edge, two side frame edges, an upper reinforcing frame, a lower reinforcing frame and a composite material shell, the frame edges, the reinforcing frames and the composite material shell are mounted on an assembly-inspection fixture to be pre-positioned, and the reinforcing ring is spliced; an assembly-inspection fixture drilling die is usedfor making a plurality of evenly-distributed positioning holes in the reinforcing ring; the reinforcing ring is disassembled, and the frame edges are mounted on a special hole-making drilling die forhole making; and then the frame edges, the reinforcing frames and the composite material shell are remounted on the assembly-inspection fixture, positioning is conducted through the positioning holes,and then holes of the reinforcing frames are drilled on the holes made in the frame edges by leading. According to the hole-making process method, it can be ensured that the positioning datum is uniform, the error caused by manual scribing hole-making is avoided, the precision of the hole positions is ensured, the hole-making time is greatly shortened, and the production efficiency is improved.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

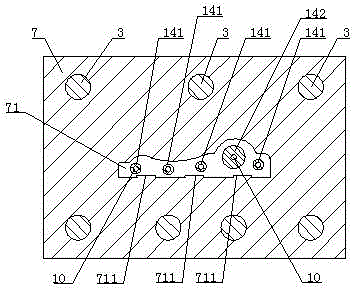

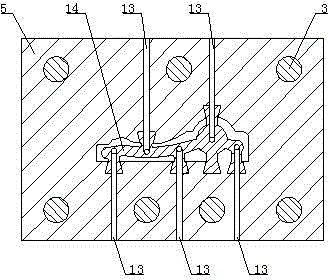

Relay coil skeleton injection mold

ActiveCN108312434AImprove production efficiencyReduce processing costsCoatingsEngineeringInjection moulding

The invention relates to the technical field of molds and particularly discloses a relay coil skeleton injection mold. The relay coil skeleton injection mold comprises a first template, a second template detachably connected to the first template, and third and fourth templates sliding between the first template and the second template. The third and fourth templates can slide toward each other oraway from each other. The first, second, third and fourth templates form a mold cavity. The third and fourth templates are respectively connected to first and second mold sheets extending into the mold cavity. The first or second template is provided with two architrave needles extending into the mold cavity. The two architrave needles respectively press against the first and second mold sheets.Through one-step injection molding, the coil skeleton is prepared without an injection molding coil skeleton and the coil skeleton is drilled through a tool so that the manufacturing efficiency of thecoil skeleton is improved and the processing cost of the coil skeleton is reduced.

Owner:SANYOU CORP LTD

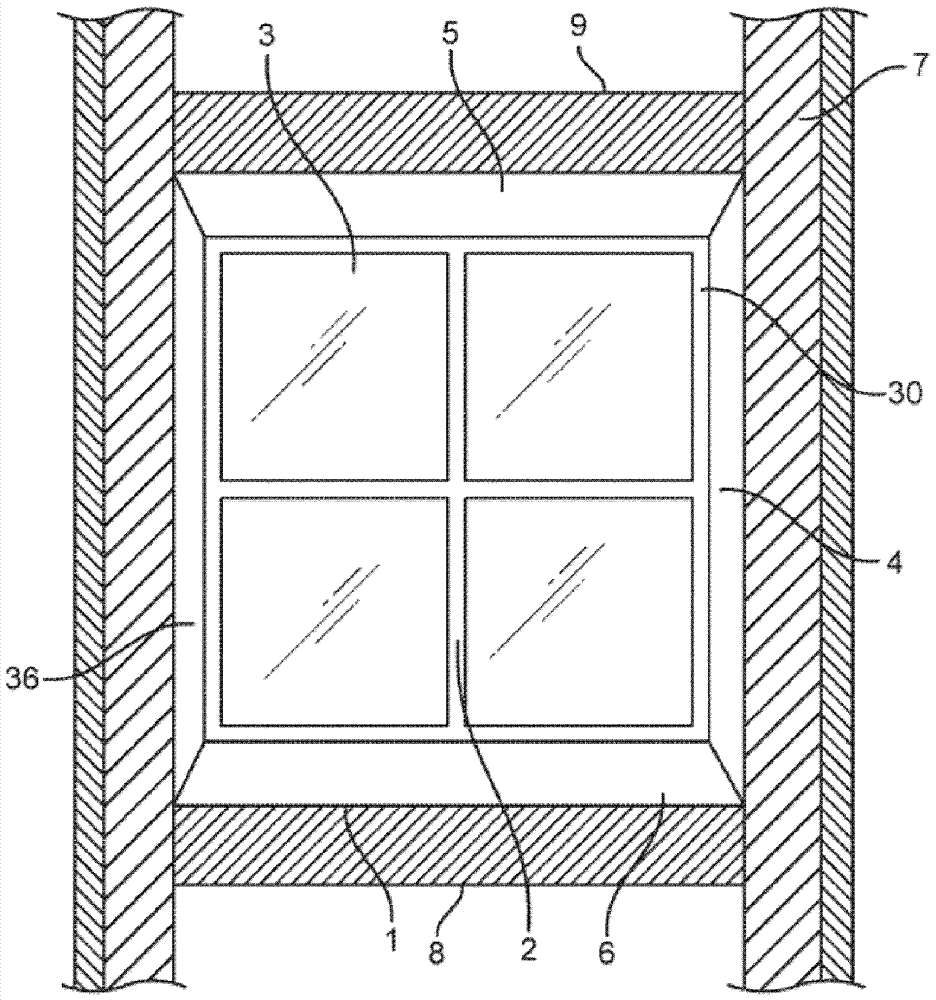

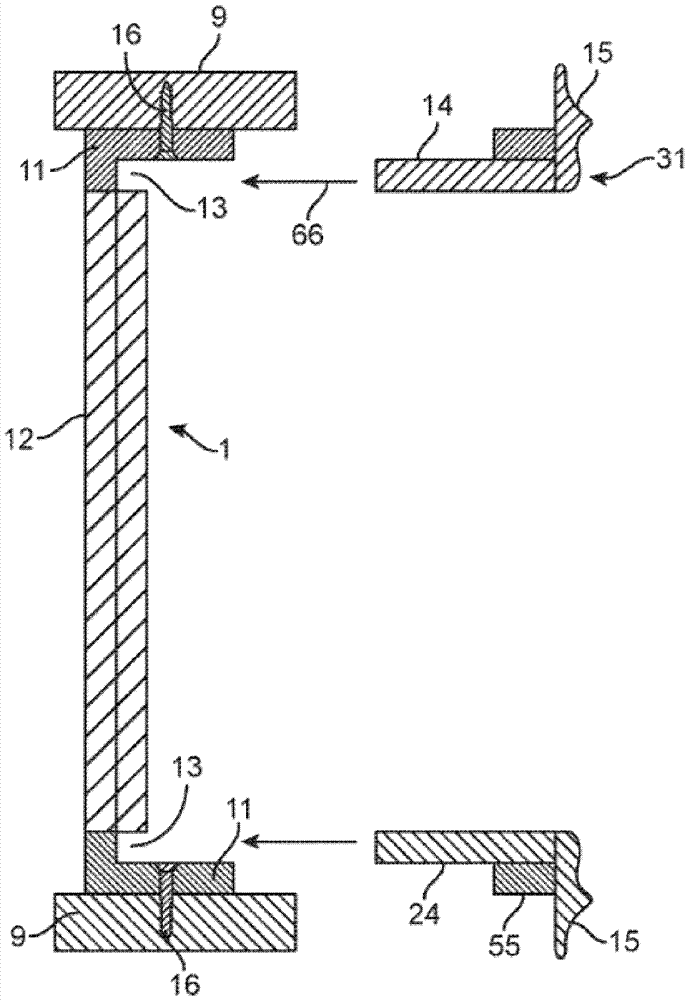

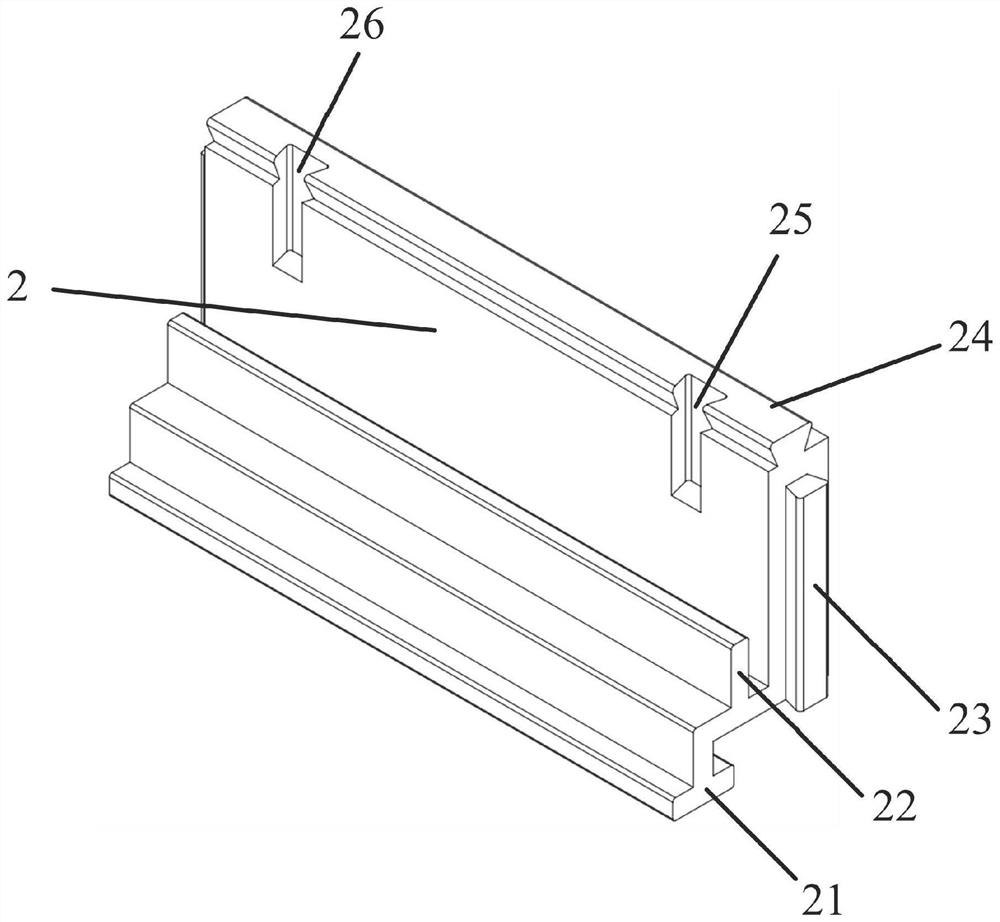

Window frame and architrave assembly

Disclosed herein is a window frame assembly for attachment to a window opening in a support structure, the assembly comprising a first frame and a second frame that engage each other from opposite sides of the window opening, wherein the first frame comprises a window and at least one abutment member adapted to be fixed to the support structure; wherein the second frame comprises at least one abutment member selected from the group consisting of a jamb, a head and a sill; and wherein the first frame comprises a recess between the at least one abutment member and the window such that, upon engagement of the first frame and the second frame from opposite sides of the window opening, the at least one abutment member of the second frame is received by the recess of the first frame.

Owner:ROPA SYST PTY LTD

Combined plug inner frame structure

InactiveCN100416934CMeet safety requirementsMaintain stabilityContact member cases/bases manufactureSecuring/insulating coupling contact membersEngineeringMechanical engineering

Owner:GEM TERMINAL IND

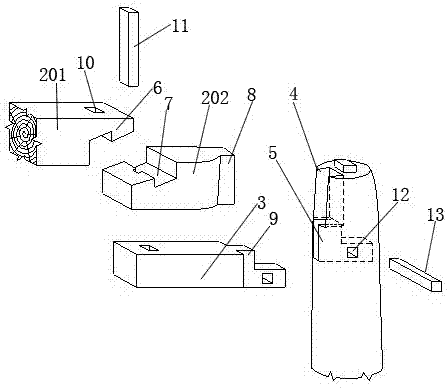

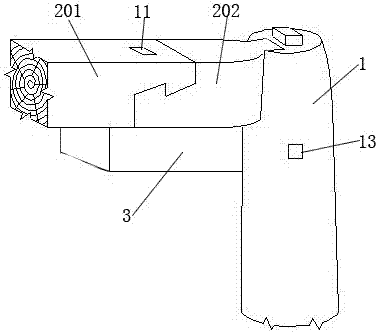

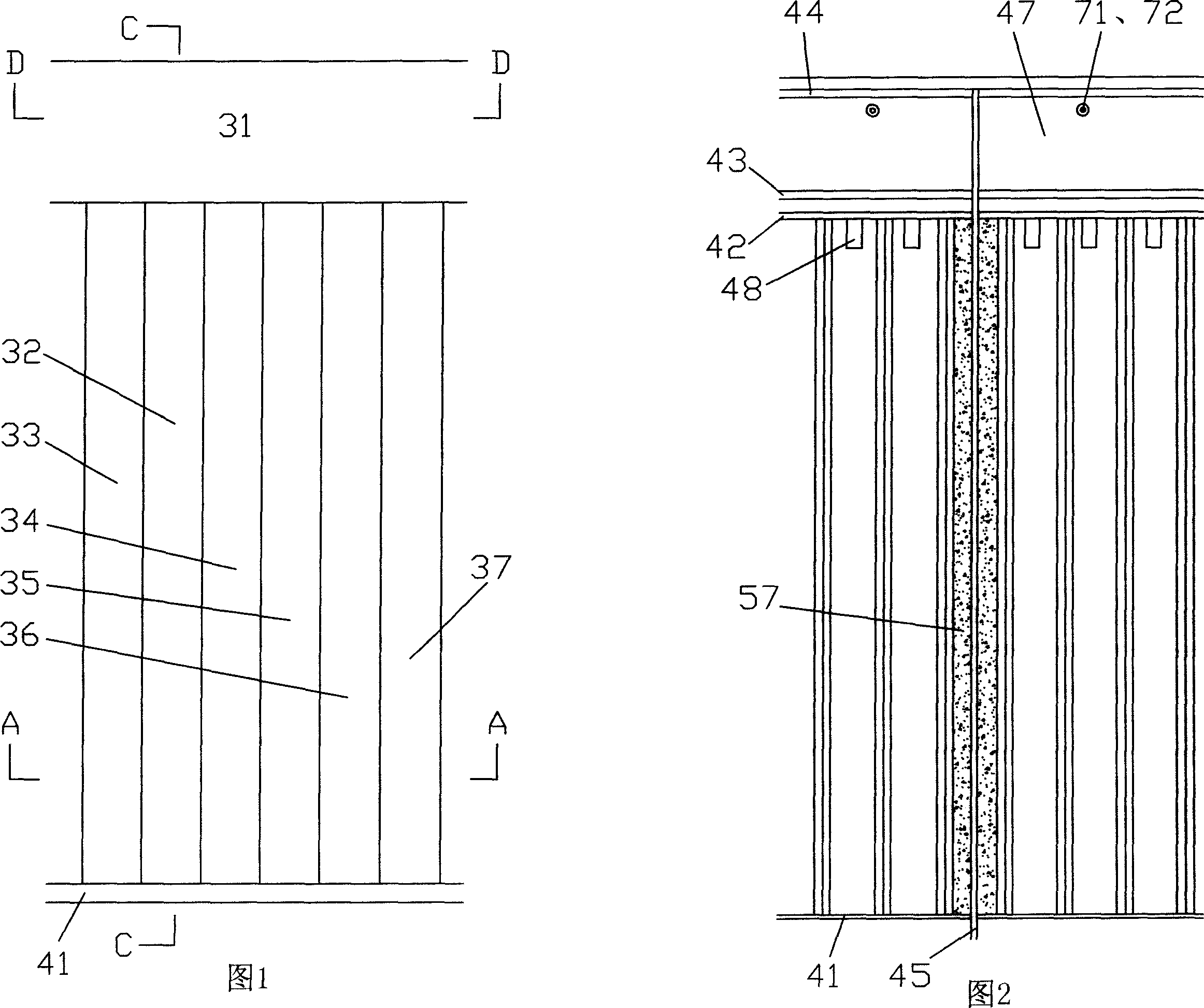

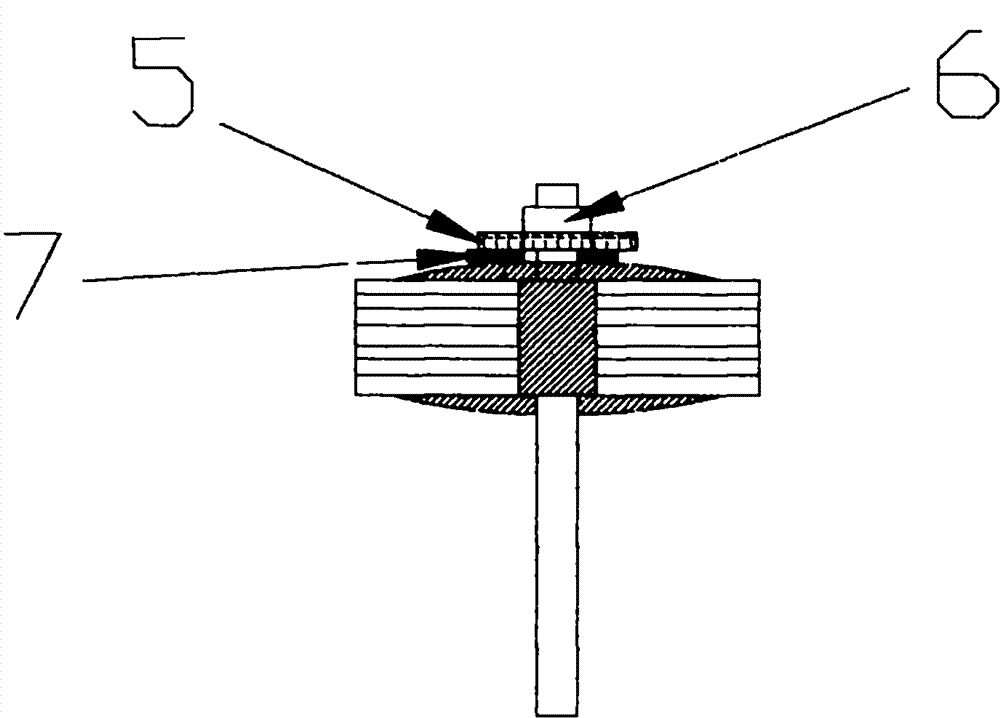

Bucket and architrave assembly in ancient building model

PendingCN114225434AReduced precision requirementsEasy to buildToysMortise and tenonConstruction engineering

The invention discloses a bracket set and architrave assembly in an ancient building model. According to one specific implementation mode of the assembly, an inverted-T-shaped mortise is arranged at the upper end of the bracket set, and an inverted-T-shaped tenon is arranged at the lower end of the upper-layer architrave. During splicing, the inverted-T-shaped mortise of the bracket set is horizontally aligned with the inverted-T-shaped tenon of the upper-layer forehead square column, then the inverted-T-shaped mortise of the bracket set is slidably arranged on the inverted-T-shaped tenon of the upper-layer forehead square column in a sleeving mode, and splicing of the bracket set and the upper-layer forehead square column is completed through the mortise and tenon structure. Close fit is not needed, the precision requirement for the bracket set and the upper-layer architrave is not high, assembling and disassembling are convenient and labor-saving, and repeated assembling is supported. And the splicing interestingness is higher.

Owner:张洋 +1

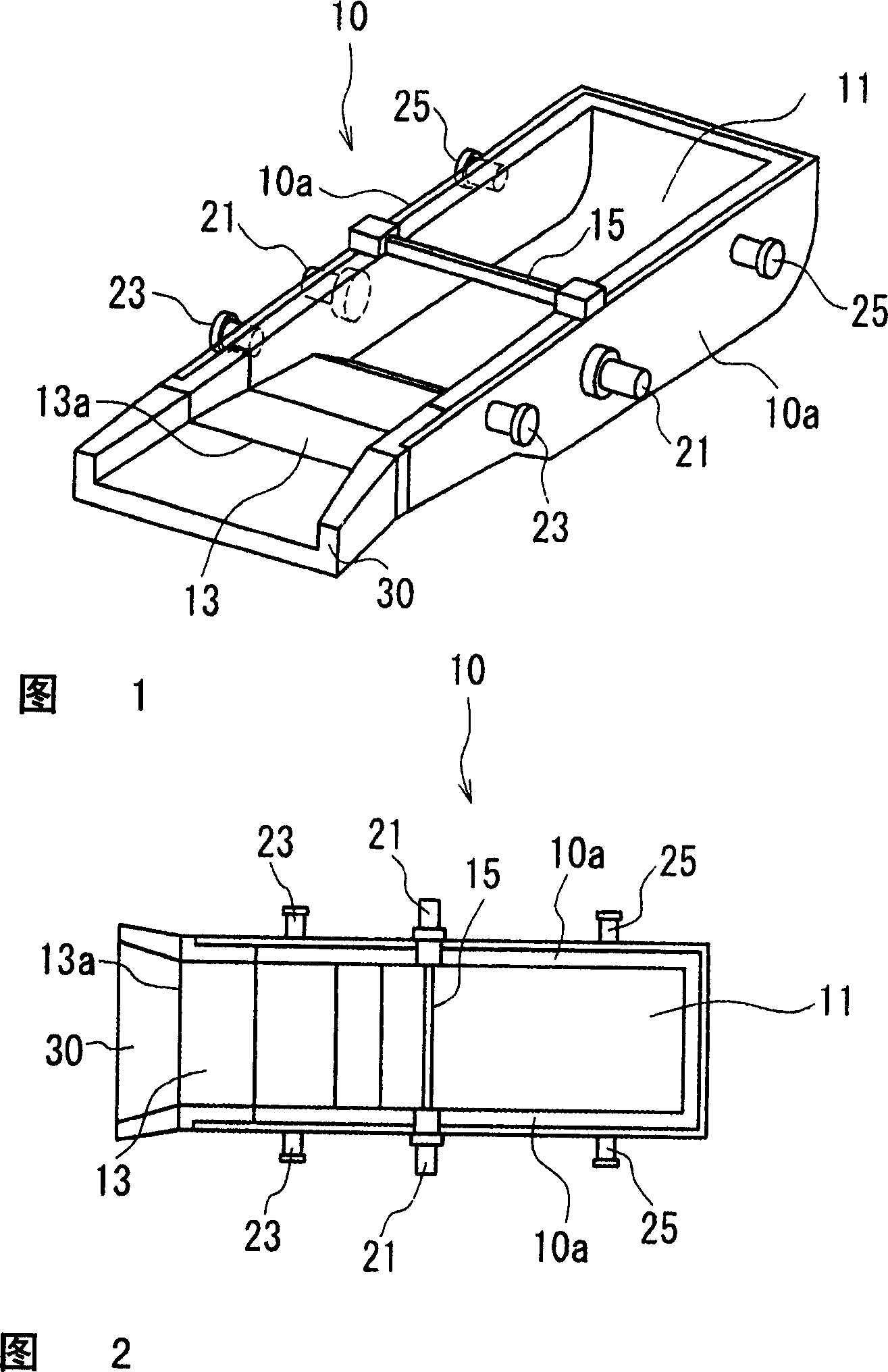

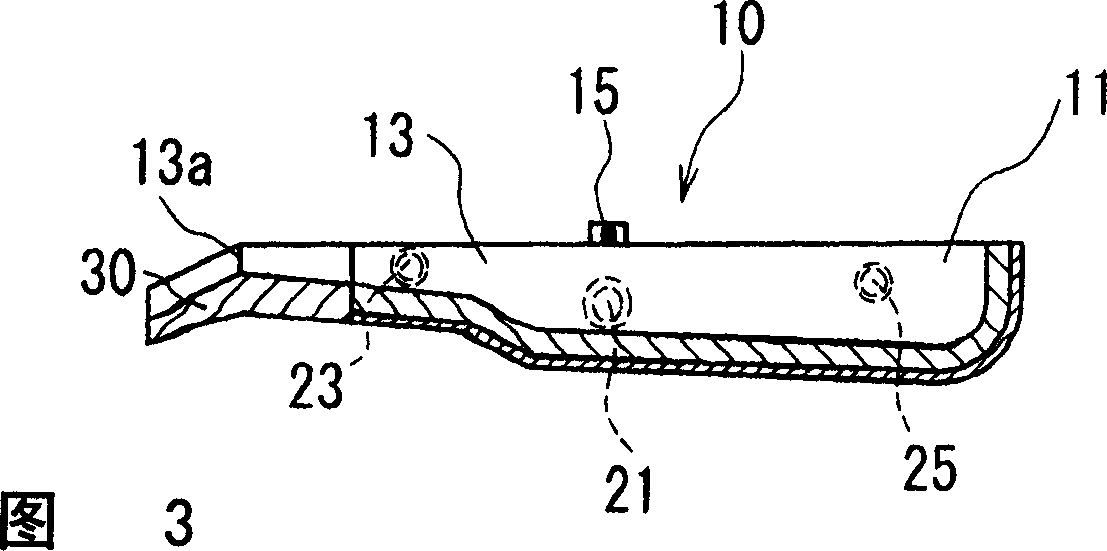

Computation hollowware for anode casting

InactiveCN101028649AReduce potential energyReduce falling speedMolten metal supplying equipmentsMetallurgyCasting mold

Provided is a metering hollowware for anode casting capable of reducing anodes' sizes in particular the architraves, prolonging service life of casting molds, and depressing casting adsorption of liquid injection port at frontend of metering hollowware. The metering hollowware for anode casting (10) used for metering specified amount of molten solution for liquid injection into casting molds (3) is characterized in that a downcomer plate protruding forwards and toward the slanting-down direction is set at the lower side of the liquid injection port (13a) for making the molten liquid accumulated at the dropsy part (11) flow to casting molds (3).

Owner:JX NIPPON MINING & METALS CO LTD

Door and window structure

PendingCN111021910AGuaranteed flexibilityReduce distortionWindow/door framesNoise insulation doors/windowsEngineeringAir tightness

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

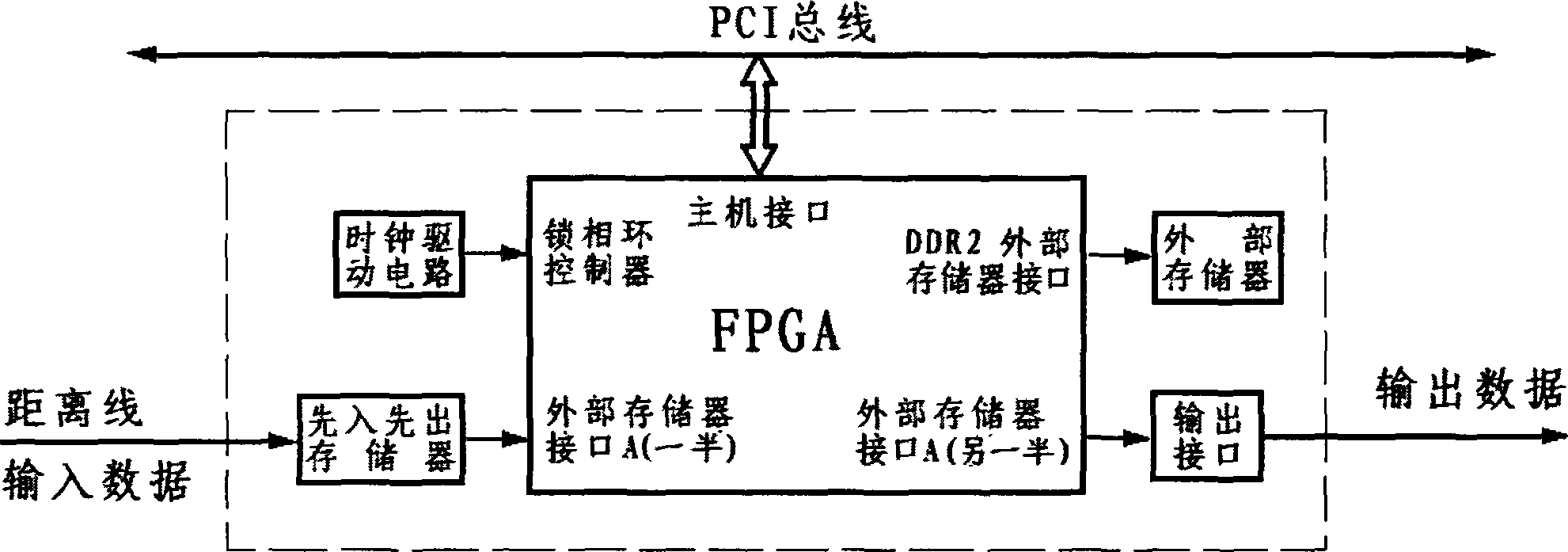

Distance compression operational circuit of imaging processing of synthetic aperture radar

InactiveCN103792514AImprove reliabilitySimple circuit structureRadio wave reradiation/reflectionSynthetic aperture sonarStatic random-access memory

The invention relates to a distance compression operational circuit of imaging processing of a synthetic aperture radar. The distance compression operational circuit consists of a programmable logic array chip FPGA, an external memory, an output interface, a FIFO (first in first out) memory and a clock drive circuit, wherein the programmable logic array chip FPGA contains an external memory interface A having a 64 bit architrave and adaptive to an SRAM (static random access memory), a DDR2 external memory interface, a phase-locked loop controller and a host interface. The distance compression operational circuit is characterized in that the external memory interface A having the 64 bit architrave of the programmable logic array chip FPGA is separated into two parts in using functions, a half includes a 32 bit architrave for receiving data from the FIFO memory, and the other half includes a 32 bit architrave for outputting an operational result to an output interface. A circuit structure, a connection mode and a control method are simple, the reliability is high, and thus a requirement for real-time performance of data processing is satisfied.

Owner:XIDIAN UNIV

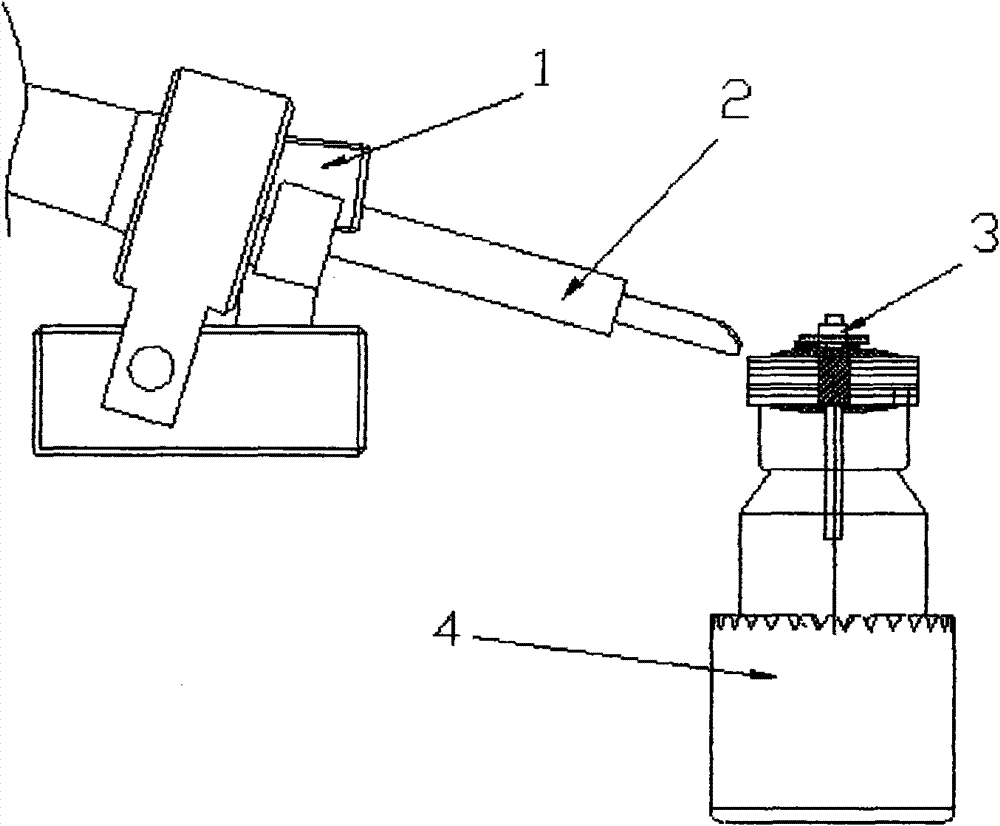

Soldering process of micro motor rotor commutator and pressure-sensitive sheet

InactiveCN101992330BMeet the process requirementsProcess structure simplificationSoldering apparatusEngineeringMaterial resources

The invention discloses a welding process of a commutator architrave and a pressure-sensitive sheet, which is characterized in that: a soldering iron welding joint advances for the first time along a work thread, stops when advancing to a position above the commutator architrave, keeps 0.3mm away from the edge of the pressure-sensitive sheet, and is pressed downward to firmly weld an enameled wire and the commutator architrave, so that the welding of the commutator architrave is finished; and the soldering iron welding joint advances for the second time to the edge of a silver coating of the pressure-sensitive sheet or a position close to the silver coating, and quickly retreats after contacting the silver coating of the pressure-sensitive sheet. The improved process is to divide the advance of a soldering iron welding device into two stages so as to finish the welding process which is divided into two steps previously, so that the process is simple and quick and meets the process requirement of welding the architrave and the pressure-sensitive sheet; meanwhile, a process structure is simplified, and manpower, material resources and cost are saved.

Owner:深圳市天豪机电科技有限公司

Foam concrete wall for buildings construction

The invention discloses a foamed concrete wall(CWS), comprising an iron sheet rail, a locating plate, multiple wall pipes and an architrave, where the iron sheet rail is fixed on the floor; the bottom of the wall pipe is fixed with the iron sheet rail and the top of the wall pipe is guided by the locating plate; the two sides of each wall pipe are convex-concave to make all wall pipes interconnected; the wall pipes are poured with concrete to bear weight and connect groundsill to top architrave; two fiber screen plates on the two sides of the architrave are used as templates of the architrave; the bottoms of two AAC fiber screen plates are fixed with the locating plate, and their top ends are supported by metal pull rod and support sleeve and concrete is poured in between the fiber screen plates.

Owner:钟文义

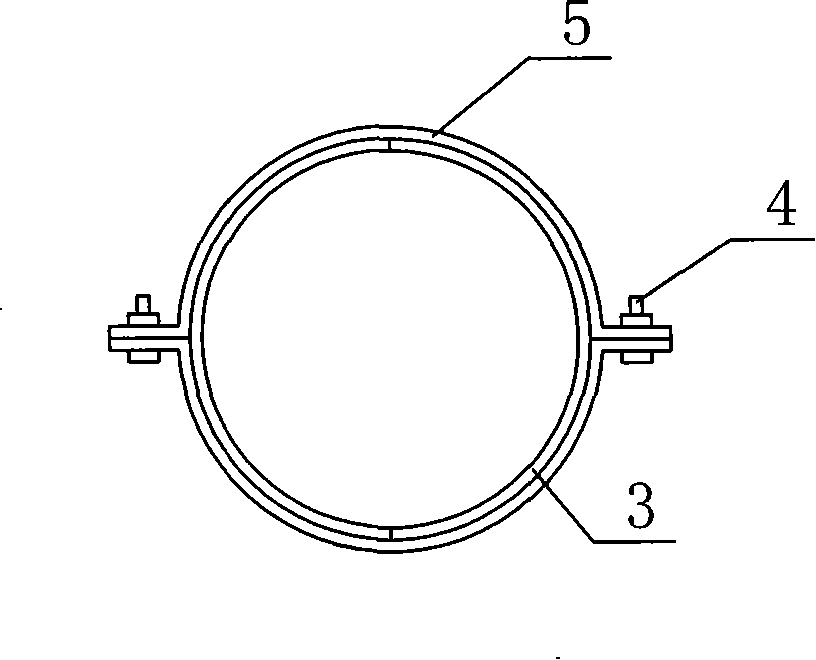

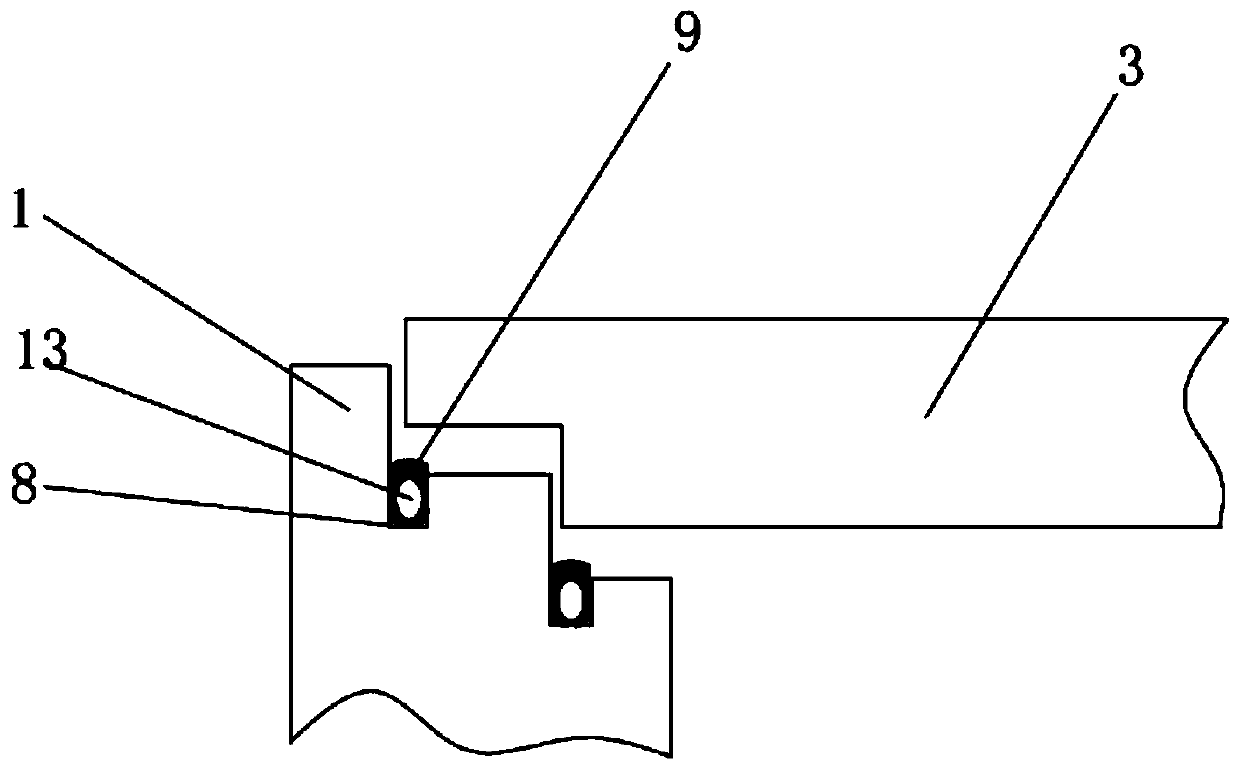

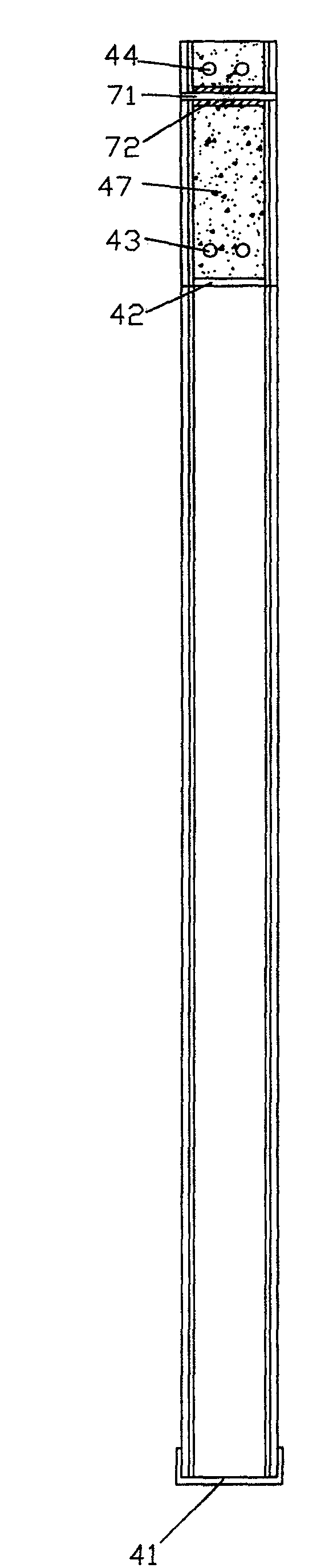

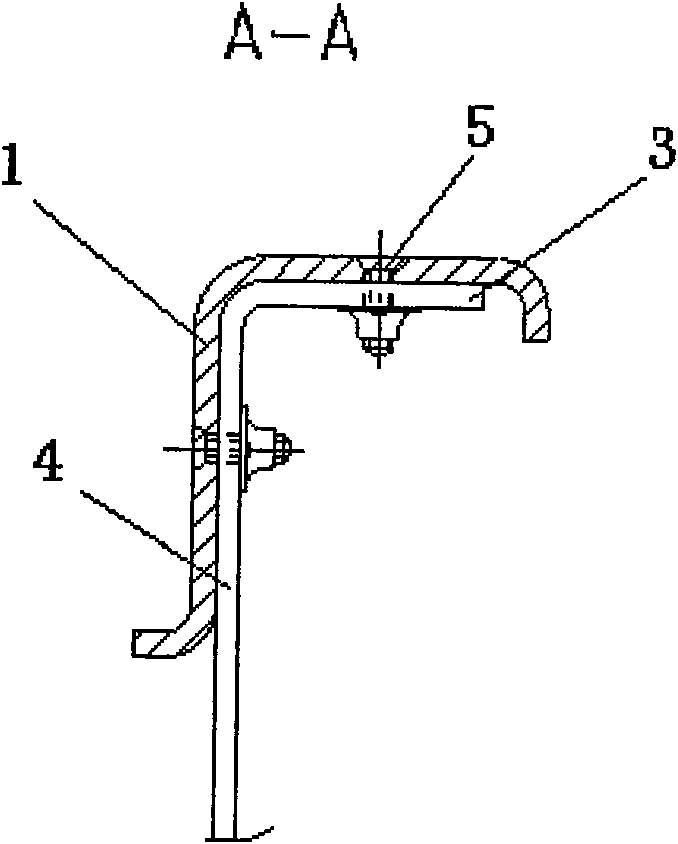

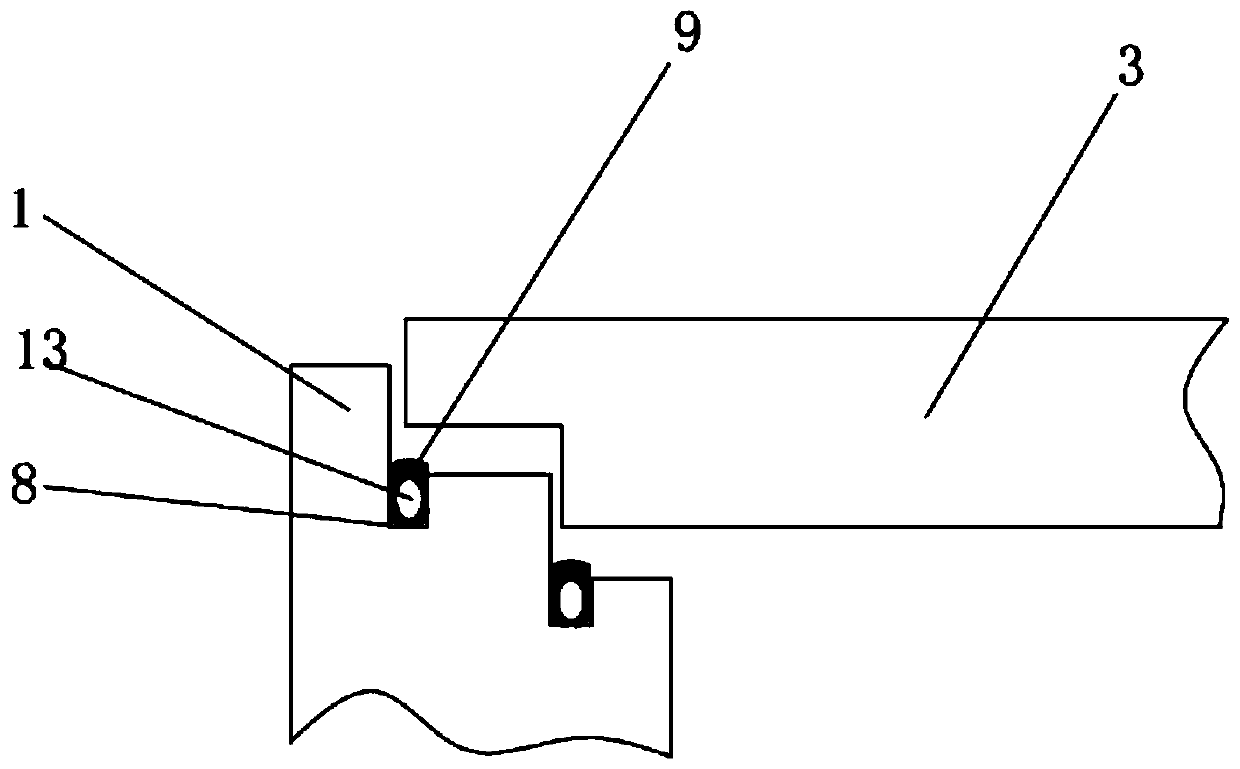

Local detachable architrave

InactiveCN101665151AIntegrity guaranteedEasy to disassemble and maintainFuselagesGround installationsEngineeringArchitrave

The invention belongs to aeroplane structure design, and relates to the local detachable improvement of an architrave, in particular to local detachable architrave. The design is characterized in thatthe architrave at the upper end of a notch along the framework is cut off and the positions 60-100mm away from two end heads of the architrave are stepped; and the local detachable architrave connects two side faces of the notch of a framework plate with the cut-off part of the architrave on the upper end into a whole through quickly detaching type bearing locks. The local detachable architrave can be used for installation of large longitudinal apparatus needing to be detached to be maintained, without breaking the architrave and affecting the entirety of the architrave, thereby guaranteeingthe force transferring property of the architrave and facilitating the installation and maintenance of the apparatus.

Owner:JIANGXI HONGDU AVIATION IND GRP

Civil aircraft fuselage bottom structure based on impact strength tests

The invention discloses a civil aircraft fuselage bottom structure considering impact strength, comprising bulkheads, outer panel skin, long purlins and foam; on the foundation of arc-shaped fuselage bulkheads, the contour of the fuselage remains unchanged, upper architraves and lower architraves of the bulkheads are hoisted upwards, the arc shape of the bulkhead bottom is changed to the flatbottom shape, the lower part of each bulkhead is symmetrically provided with a piece of foam, the ends at the two sides of the foam are provided with non-closed-angle-shaped structures in certain height, the lower part of the foam is supported by ventral outer panel skin, the top and sides of the foam adopt the outer panel skin for supporting, the two sides and the top of the foam are provided with long purlin structures which have the function of longitudinal reinforcement. The fuselage bottom foam structure of the invention can greatly improve the crash resistance of the fuselage structure, the new structure consisting of the outer panel skin and the foam contributes to bearing distributed load, as a result, the fuselage bottom structure of the invention not only has good crash resistance against ground crash but also has good crash resistance against water surface impact accidents.

Owner:BEIHANG UNIV

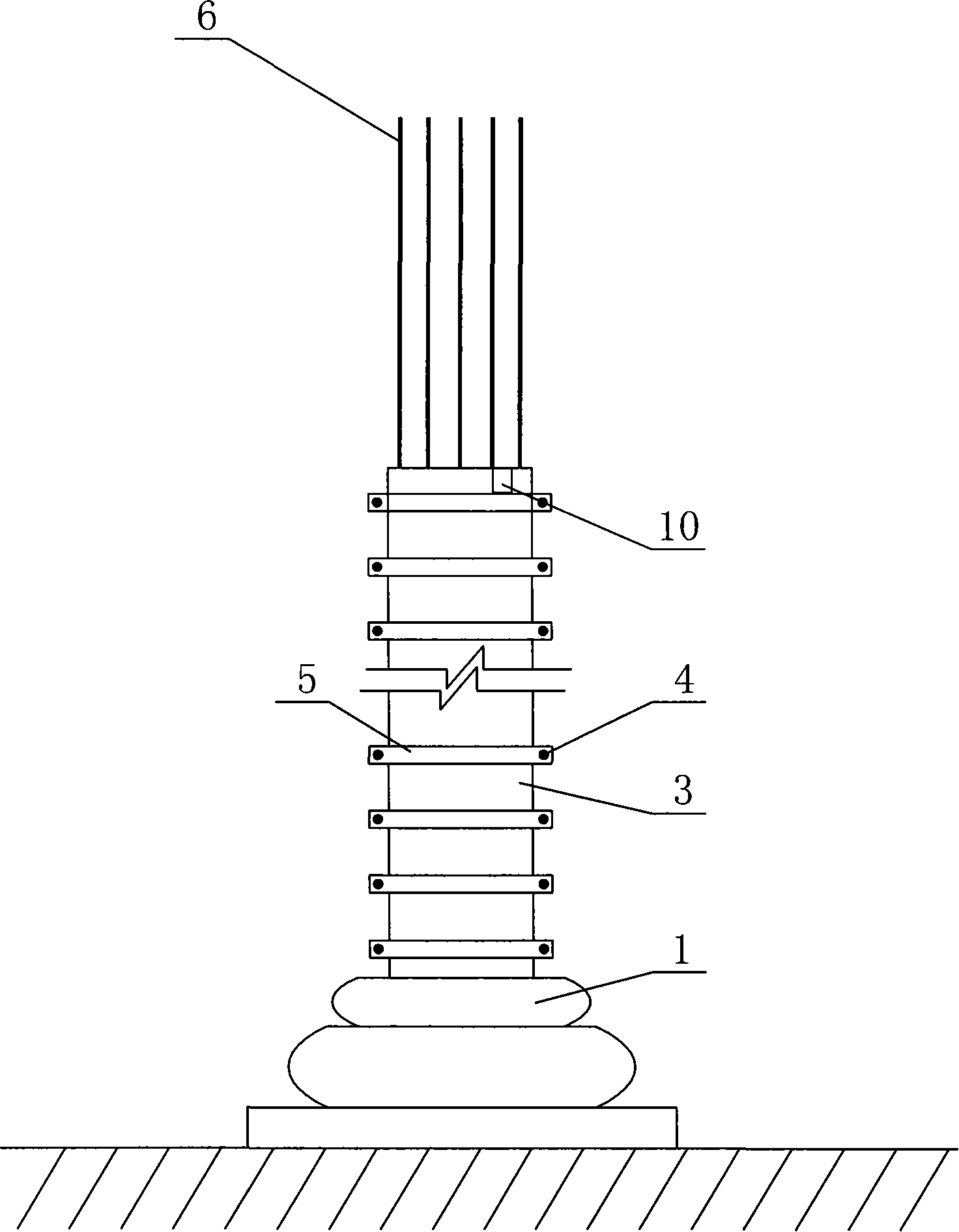

Method for determining structural parameters of circular-arch-shaped reinforcing frame for bearing antisymmetric concentrated loads

ActiveCN112699461AImproving and Perfecting the Boundary Simulation MethodImprove the accuracy of simulation analysisGeometric CADSpecial data processing applicationsMathematical modelArchitectural engineering

The invention discloses a method for determining structural parameters of a circular-arch-shaped reinforcing frame bearing an antisymmetric concentrated load, which comprises the following steps of: establishing a mathematical model of the circular-arch-shaped reinforcing frame, and analyzing the stress state and deformation coordination conditions of the circular-arch-shaped reinforcing frame when the circular-arch-shaped reinforcing frame bears the antisymmetric concentrated load, generating bending moment in the clockwise or anticlockwise direction on the supporting end face; determining expressions of bending moment and shearing force of any section of the circular-arch-shaped reinforcing frame; and determining the thickness of a web plate of any section of the reinforcing frame according to a corner corresponding to any section of the reinforcing frame on the basis of the obtained shear force expression of any section of the circular-arch-shaped reinforcing frame, and determining the area of a frame edge strip of any section of the reinforcing frame. According to the method, the problems that the boundary condition simulation is not accurate enough and the accuracy of the structural parameter optimization design is influenced due to the fact that the bending moment at the supporting end face is not considered in a traditional method are solved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Extrusion mold for artificial marble composite decoration door frame architrave sectional material

The invention discloses an extrusion mold for artificial marble composite decoration door frame architrave sectional material. The extrusion mold comprises a mold body, a transition plate, a support plate I, a support plate II, a confluence plate, a neck mold plate, a water jacket I, a water jacket II, a rear core rod set, a front core rod, a plurality of long screws and a plurality of short screws, wherein a main material feeding inlet is formed in the right side of the mold body. The extrusion mold is characterized in that the rear core rod set comprises a large round core rod and four small round core rods, and the middle of the large round core rod and the middles of the four small round core rods are each provided with an axial ventilation hole; a neck mold hole is formed in the middle of the neck mold plate; three rectangular protrusions are arranged on the bottom surface of the neck mold hole; and a co-extrusion material feeding inlet is formed in the confluence plate. A core portion round hole of the door frame architrave sectional material processed through the extrusion mold is small in deformation and free of bubbles on the inner surface, artificial marble treatment can be carried out on the outer surface of the door frame architrave sectional material, and the door frame architrave sectional material is low in cost and long in service life.

Owner:黄石金锐模具股份有限公司

Method for achieving decorative construction of softly-covered wall surface decoration during building construction

InactiveCN109424140AGuarantee the construction qualityEasy to fixCovering/liningsFlooringTectorial membraneBrick

The invention discloses a method for achieving the decorative construction of softly-covered wall surface decoration during building construction. According to the method, wood bricks are pre-buried in a structural wall, cement mortar is applied on a leveling layer, direct pasting is carried out, and a layer of varnish is painted on the surface of a base layer before pasting; actual sizes and shapes are performed on the wall surface needing the decoration sizes and shapes of the softly-covered wall surface through the processes that a plumb bob is hung from top to bottom and the position wherethe tip of the plumb bob is located is marked to make a perpendicular line, triangles are placed in the horizontal direction of the perpendicular line according to the Pythagorean theorem, bumps aremade from cement mortar on the wall surface, and two ends of a carpenter's line are hold by two workers to be ejected on the wall; the specific manufacturing method of the softly-covered wall surfaceis determined; when the direct pasting method is carried out, surface material can be pasted after the fine wood decoration of the wall surface is basically completed and border paint reaches the completing conditions; architraves or detection edge lines are selected and processed according to the design, the paint is applied according to the design requirements, and then the installation of decoration plates can be carried out, wherein firstly test splicing is carried out, the architraves and the detection edge lines are fixed and arranged at the base layer, and finally the edge paint is applied to complete the construction; dust removal and cleaning are carried out, protective film is nailed and pasted, and glue marks are removed. The method has the advantages that steps are simple, theconstruction quality of the softly-covered wall surface decoration can be ensured, soft bags are fixed firmly, and the service life is long.

Owner:成都美吉房地产营销策划有限公司

Tight fit jamb

The invention discloses a tight-fitting door cover, which belongs to the field of household products. The tight-fitting door cover includes a door frame and a door frame line. The door frame includes an upper door frame, a left door frame and a right door frame. There is a rectangular groove with a ball bulb, the groove runs through the upper door frame horizontally, and runs through the left and right door frames vertically. The opening direction of the groove is the direction of the plane where the wall is installed; Bulb protrusions fitted with rectangular grooves. Enhanced installation stability. There is no need to glue or staple the door frame wires, and the installation is easy and quick.

Owner:重庆市潼南区邦兴门业有限公司

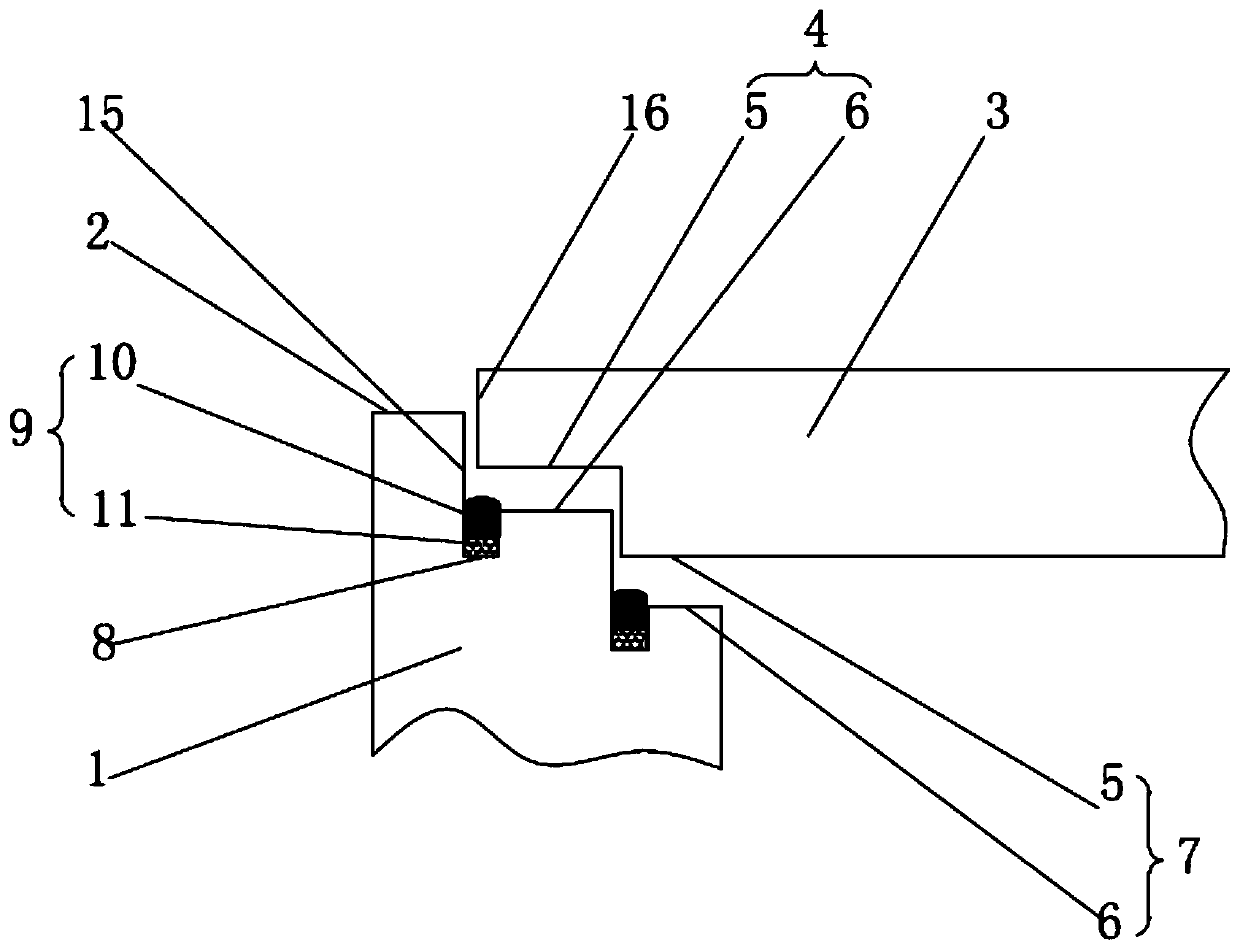

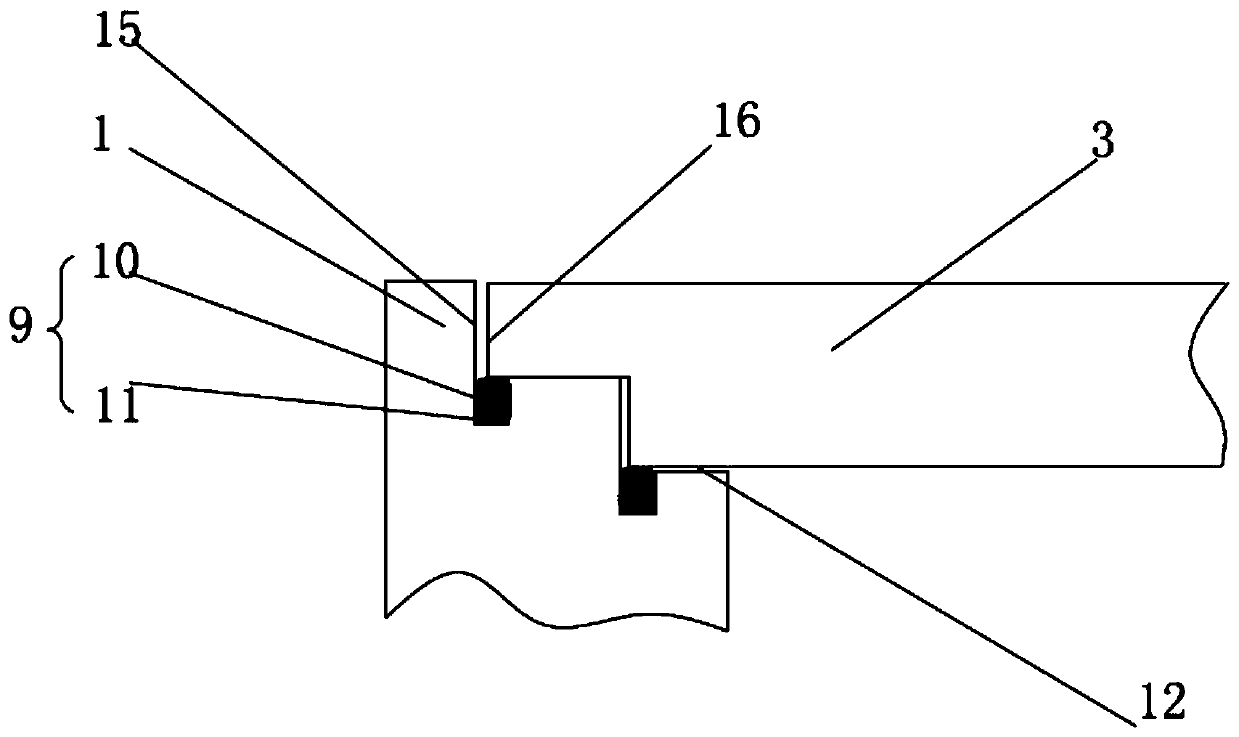

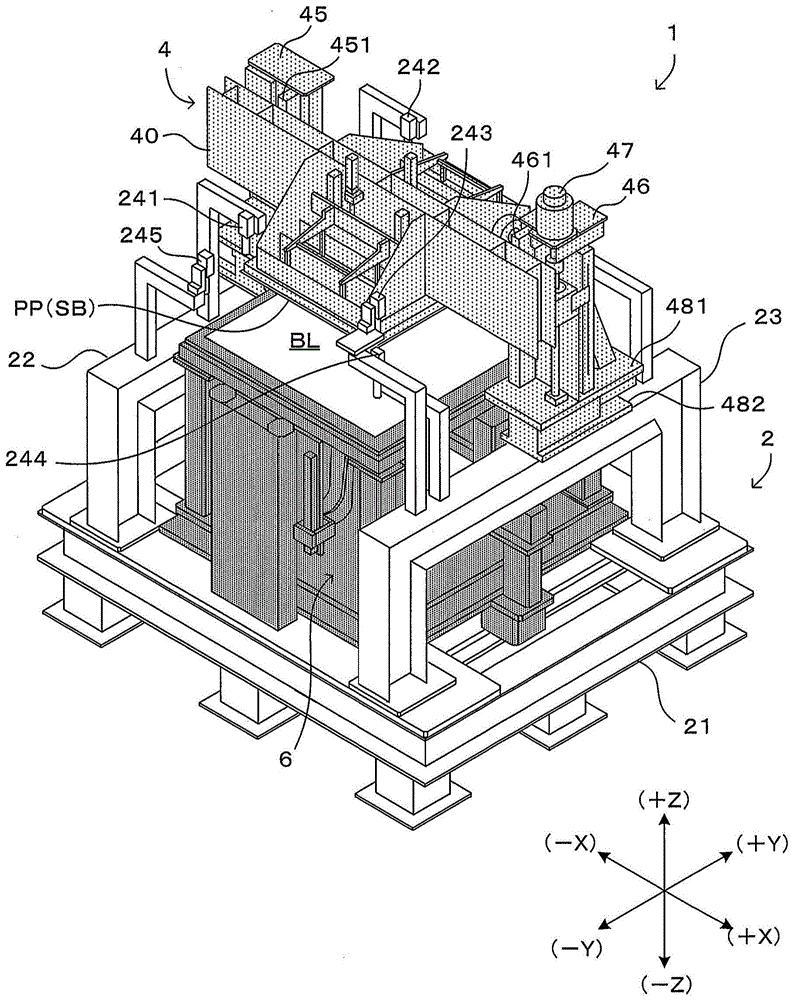

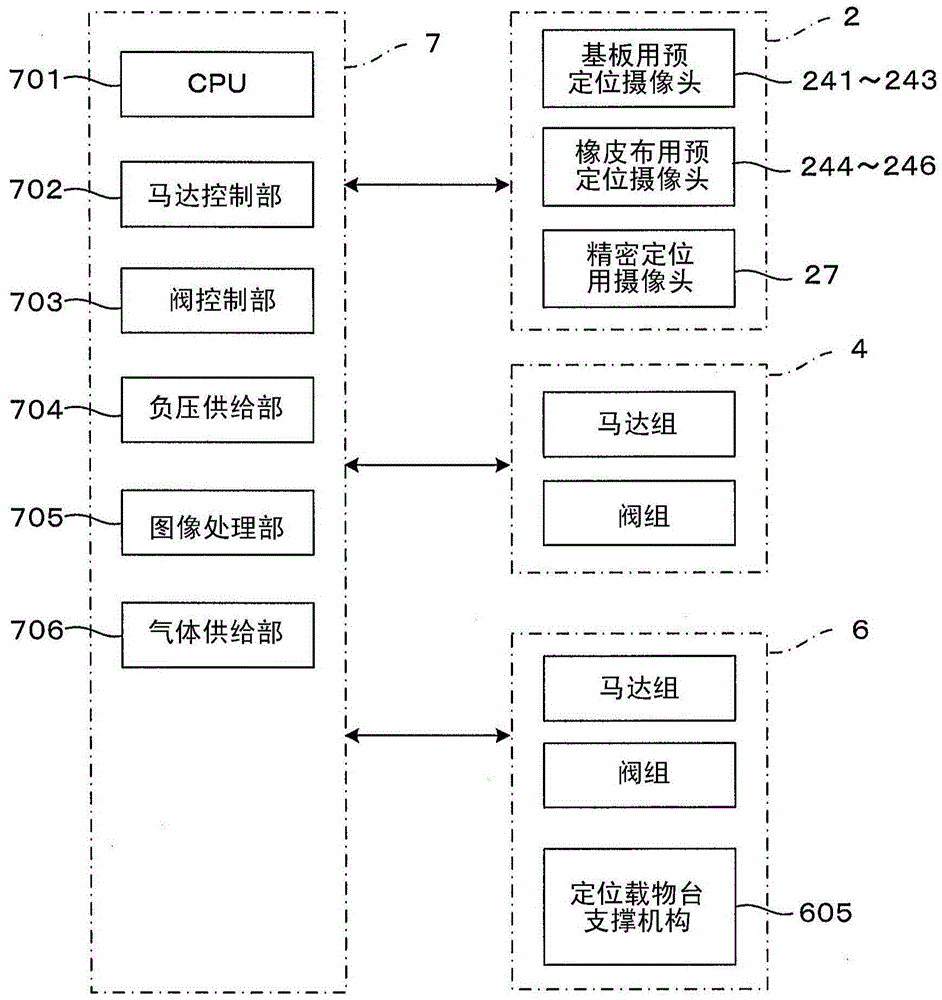

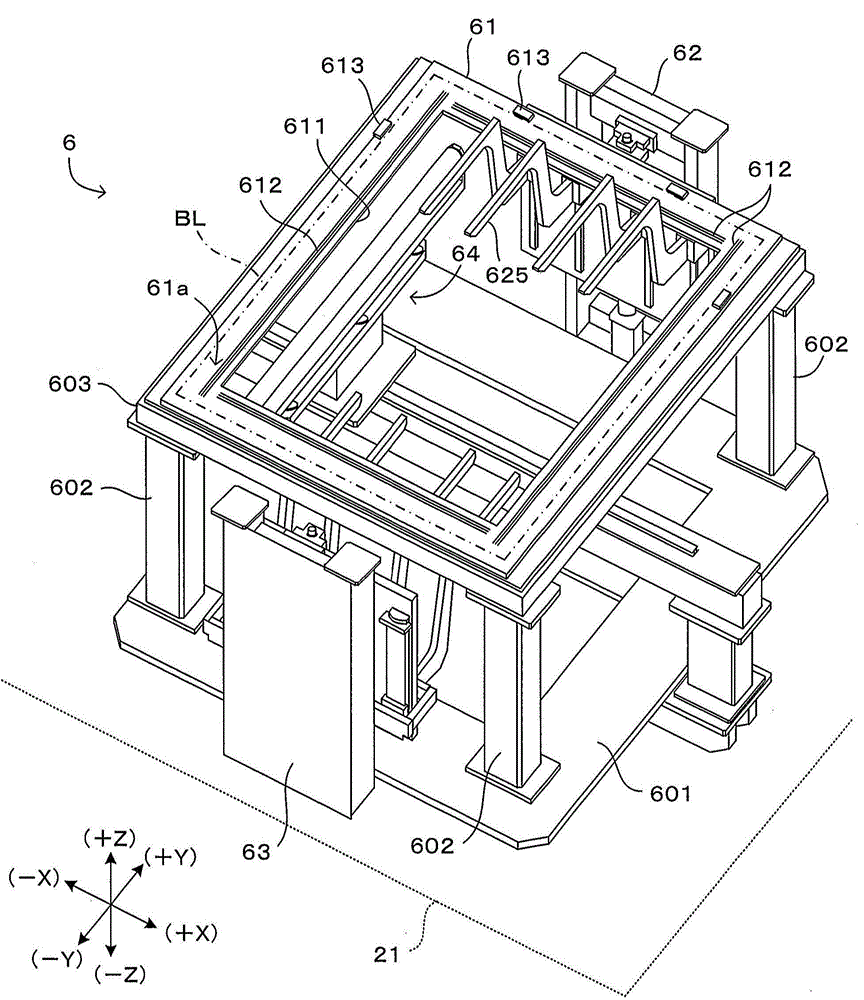

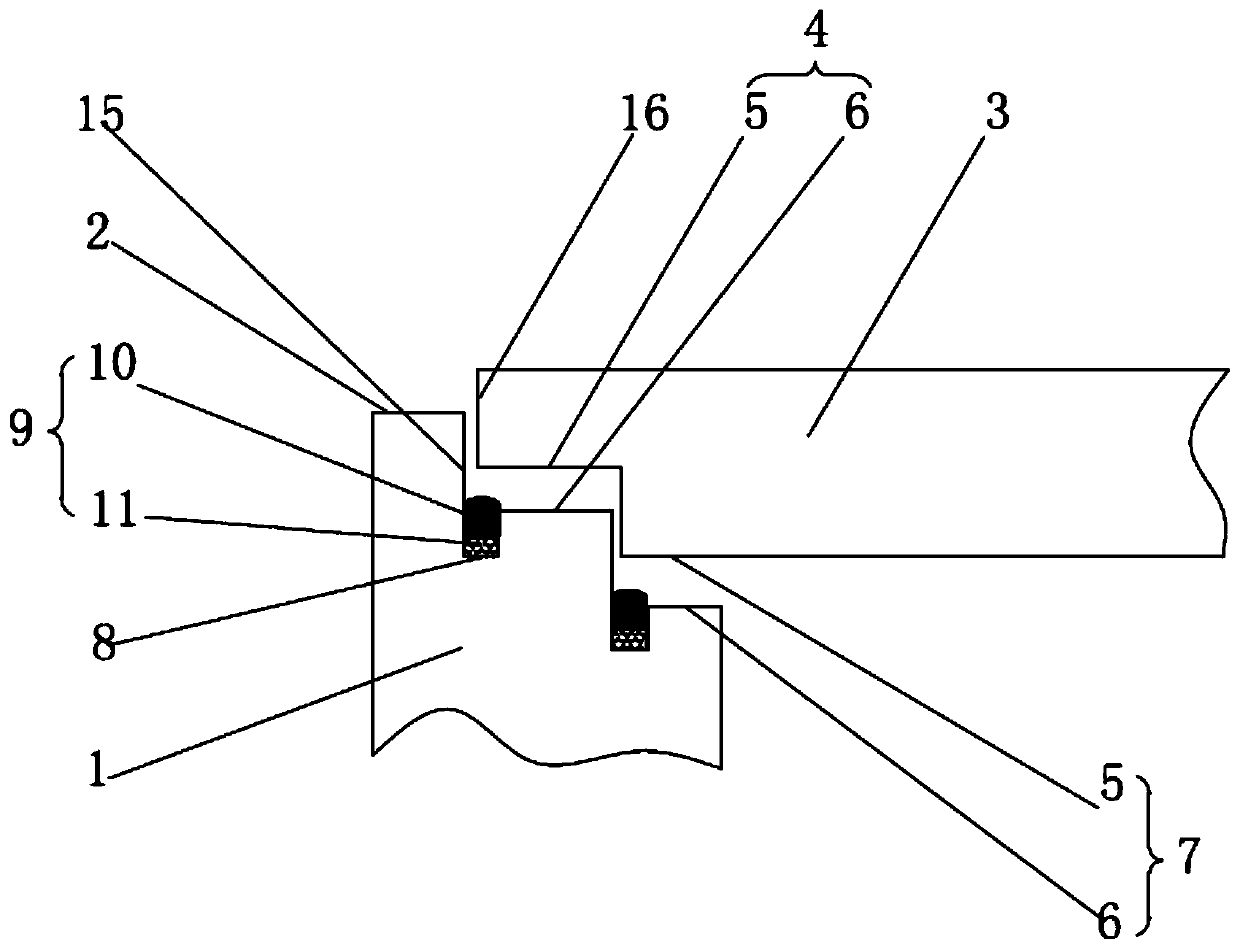

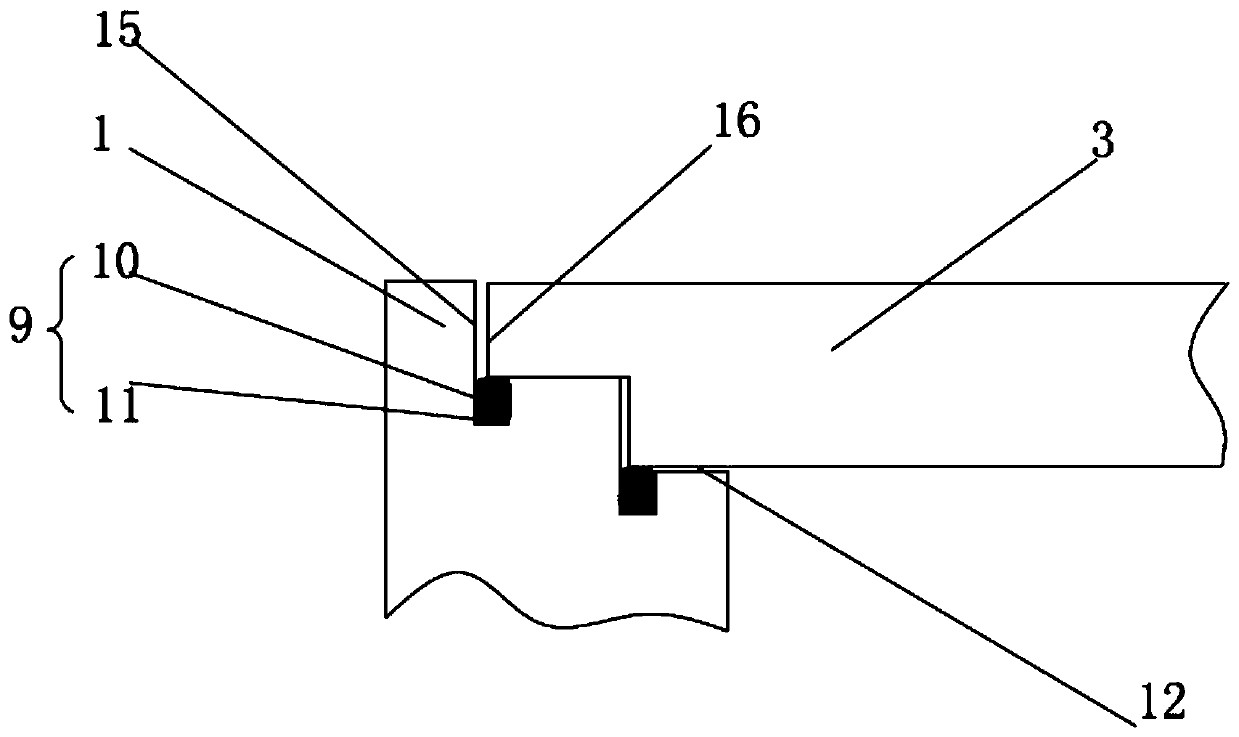

Pattern forming device and pattern forming method

InactiveCN104002546ARelatively small amount of movementSmall Position Offset SuppressionTransfer printingDuplicating/marking methodsEngineeringMechanical engineering

The invention provides a pattern forming device and a pattern forming method. An architrave shaped download object bench (16) is used for attaching rubber cloth, and a plurality of handle portions (625) capable of respectively rise and fall are used for supporting part of a central part of the rubber cloth. A printing roller unit (64) moves along the lower surface of the rubber cloth to uphold part of the rubber cloth, allowing the rubber cloth to be abutting the plane or substrate arranged above the rubber cloth. As the printing roller unit (64) moves, the handle portions (625) successively declines to retreat downwardly, so as to avoid interface between the handle portions (625) and the printing roller unit (64).

Owner:DAINIPPON SCREEN MTG CO LTD

Door and window structure

PendingCN111075328AGuaranteed noiseGuaranteed air tightnessWindow/door framesNoise insulation doors/windowsEngineeringMechanical engineering

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com