Combined plug inner frame structure

A combined, inner frame technology, used in the manufacture of contact boxes/bases, fixed/insulated contact members, etc., can solve problems such as affecting the exposed length of terminals, mutual loosening of terminals and inner frame bodies, and non-compliance with safety regulations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

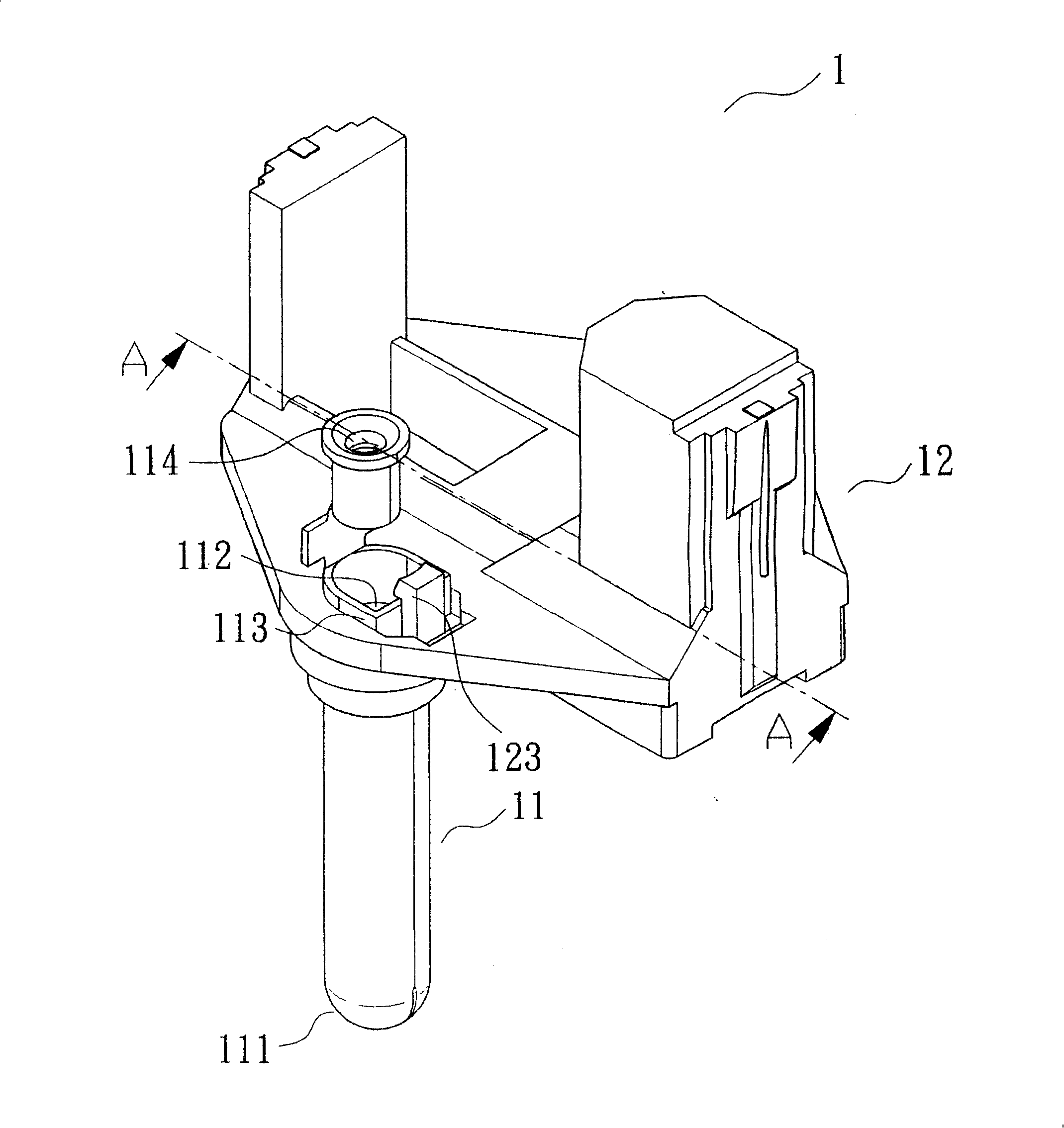

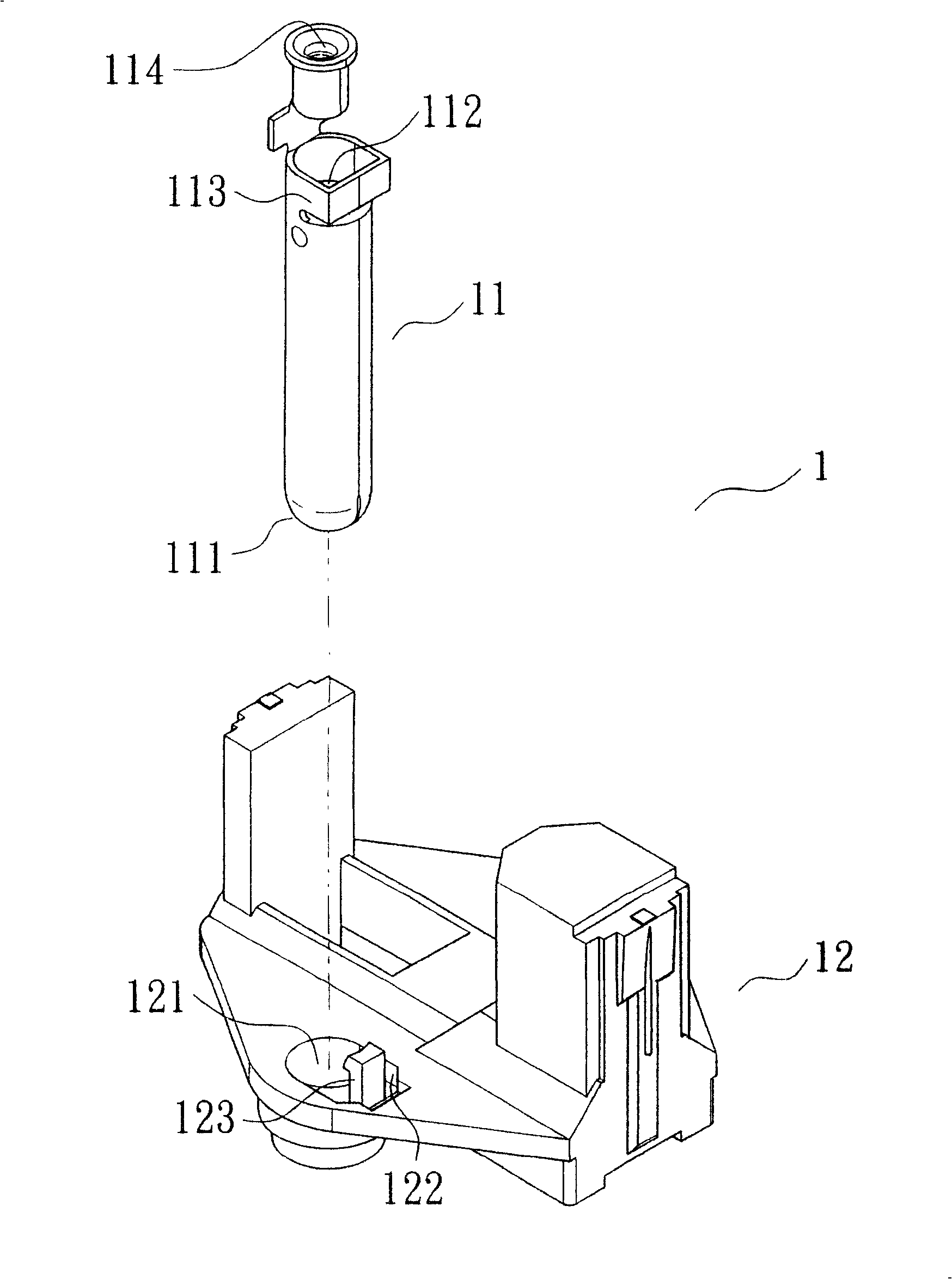

[0024] see figure 1 , figure 2 , image 3 The structure of a combined plug inner frame 1 shown in the present invention mainly includes:

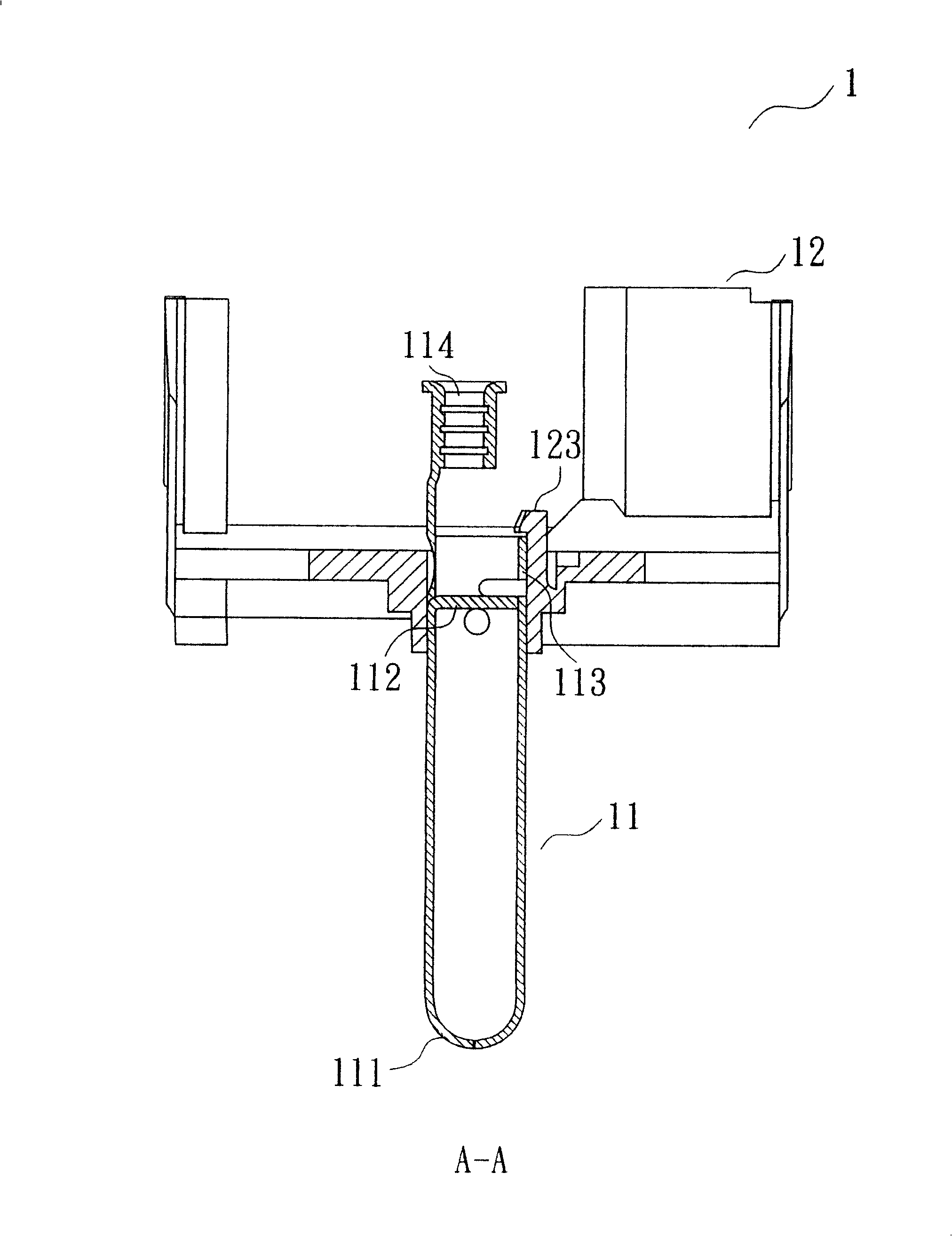

[0025] Two terminals 11, see Figure 4 , Figure 5 and Image 6 As shown, each terminal 11 itself is considered as a section, and the front section 111 can be a cylindrical pin with a circular arc shape at the front end. The rear part of the terminal 11 is provided with a wire slot 114 as a riveting part, which is used for joining with the power wire to achieve the purpose of conduction.

[0026] The terminal 11 is provided with a cover 112 at the rear end of the front section 111 to prevent the molten plastic material from overflowing from the body of the terminal 11 into the hollow part of the front section 111 during the injection molding filling process.

[0027] Each terminal 11 is provided with a frame edge 113 at a section thereof. The outer contour shape of the frame edge 113 can be generalized as a "D" shape, a rectangle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com