Local detachable architrave

A partial and frame plate technology, applied in the field of partially detachable frame edge, can solve the problems of reducing frame strength and stiffness, sacrificing frame edge integrity, affecting the overall force transmission characteristics of the frame, and achieving the effect of ensuring integrity and facilitating disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

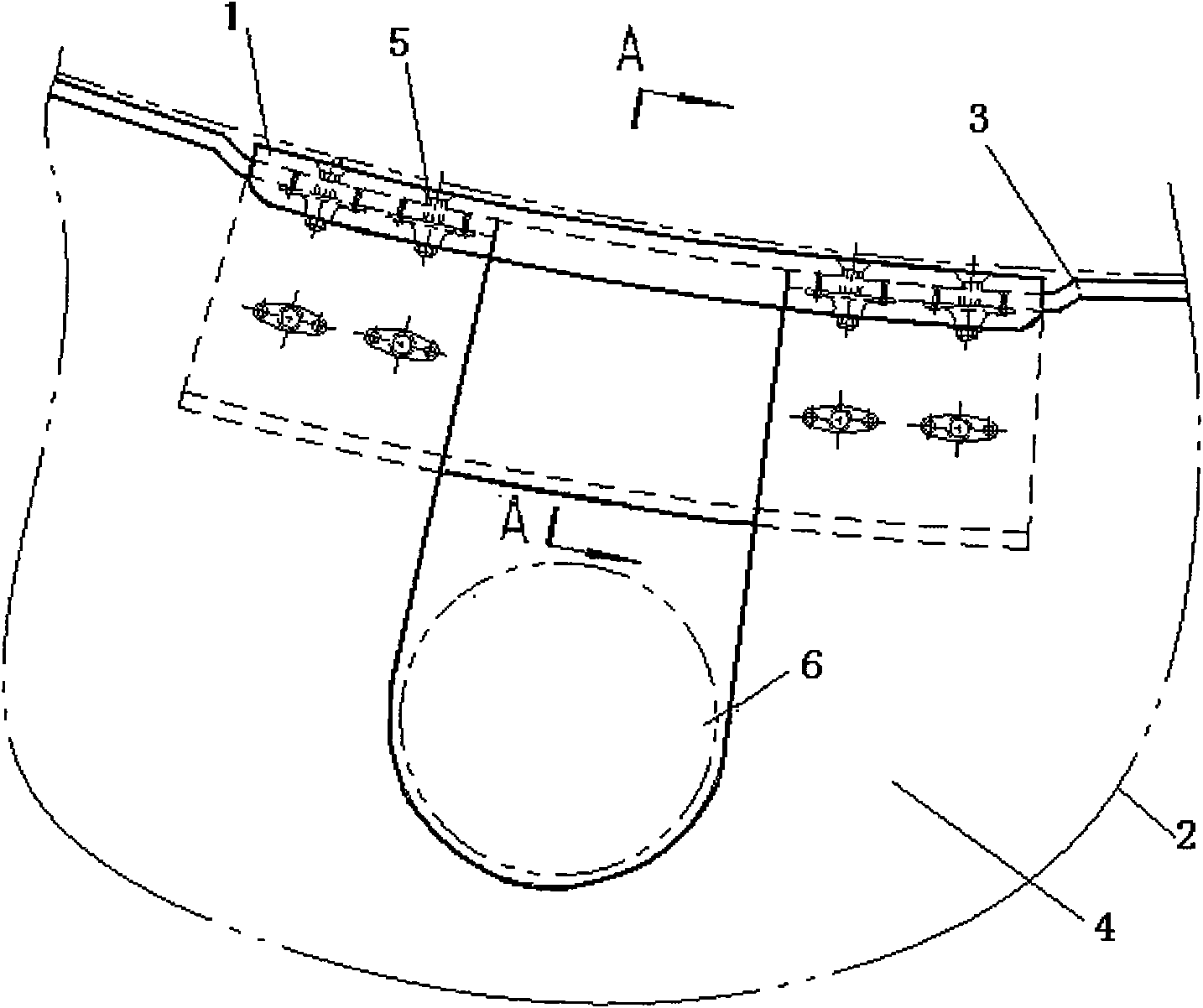

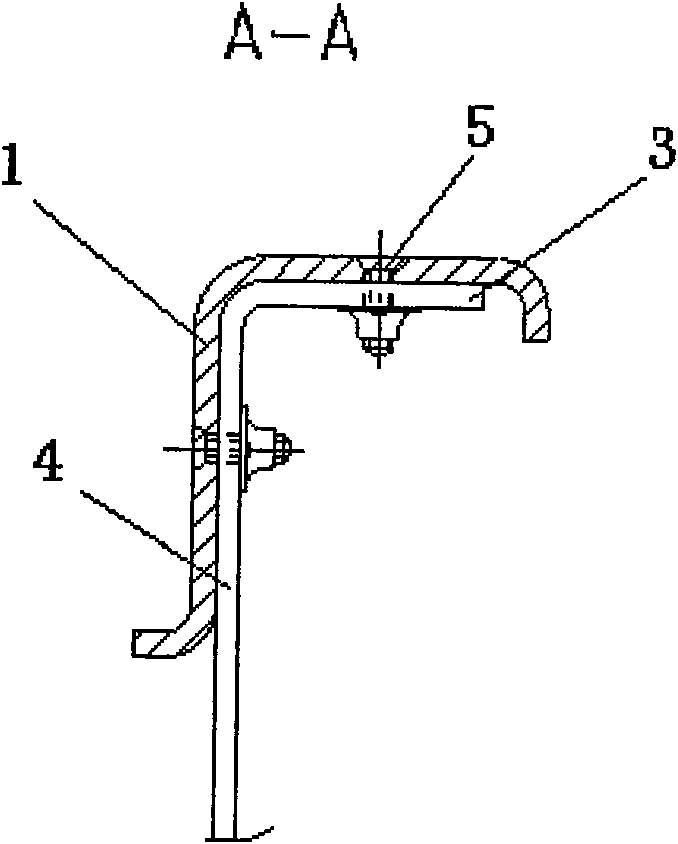

[0009] Below in conjunction with accompanying drawing, the present invention will be further described, see attached drawing figure 1 , 2 , a partially detachable frame, which is composed of a detachable frame 1, a frame 2 and a force-bearing quick release lock 5, the detachable frame 1 is a member with a "Γ" shape in section made of a plate, and the frame 2 is It is a component made of sheet material, composed of frame edge 3 and frame plate 4, and is provided with a "U"-shaped, oval, oblong or rectangular notch, and the lower lock body of the force-bearing quick release lock 5 is fixed On the inner surface of the frame 2, it is characterized in that the frame edge 3 at the upper end of the notch of the frame 2 is cut off, and the two ends of the frame edge 3 are sunken in steps at 60-100mm; the frame edge 1 and the frame plate 4 notch are detachable The two sides overlap with the step surface at the truncation of the frame edge 3, and are connected to the frame 2 as a whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com