Method and apparatus for separating component pins and soldering tin of circuit board

A circuit board, soldering technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of irreversibility, harm, and refractory degradation of metals and macromolecular organic matter, and achieves a simple method, good environmental performance, and equipment saving. effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

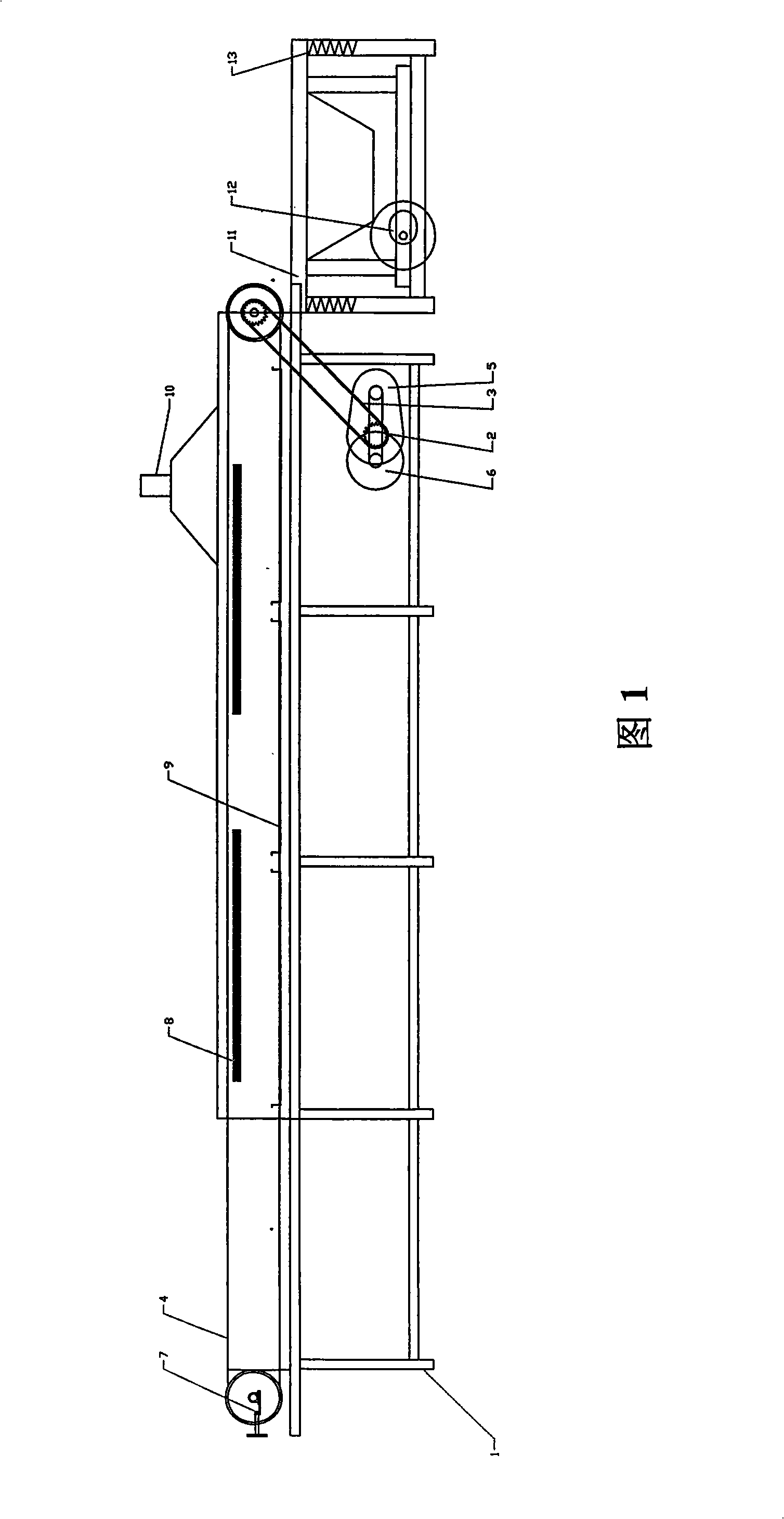

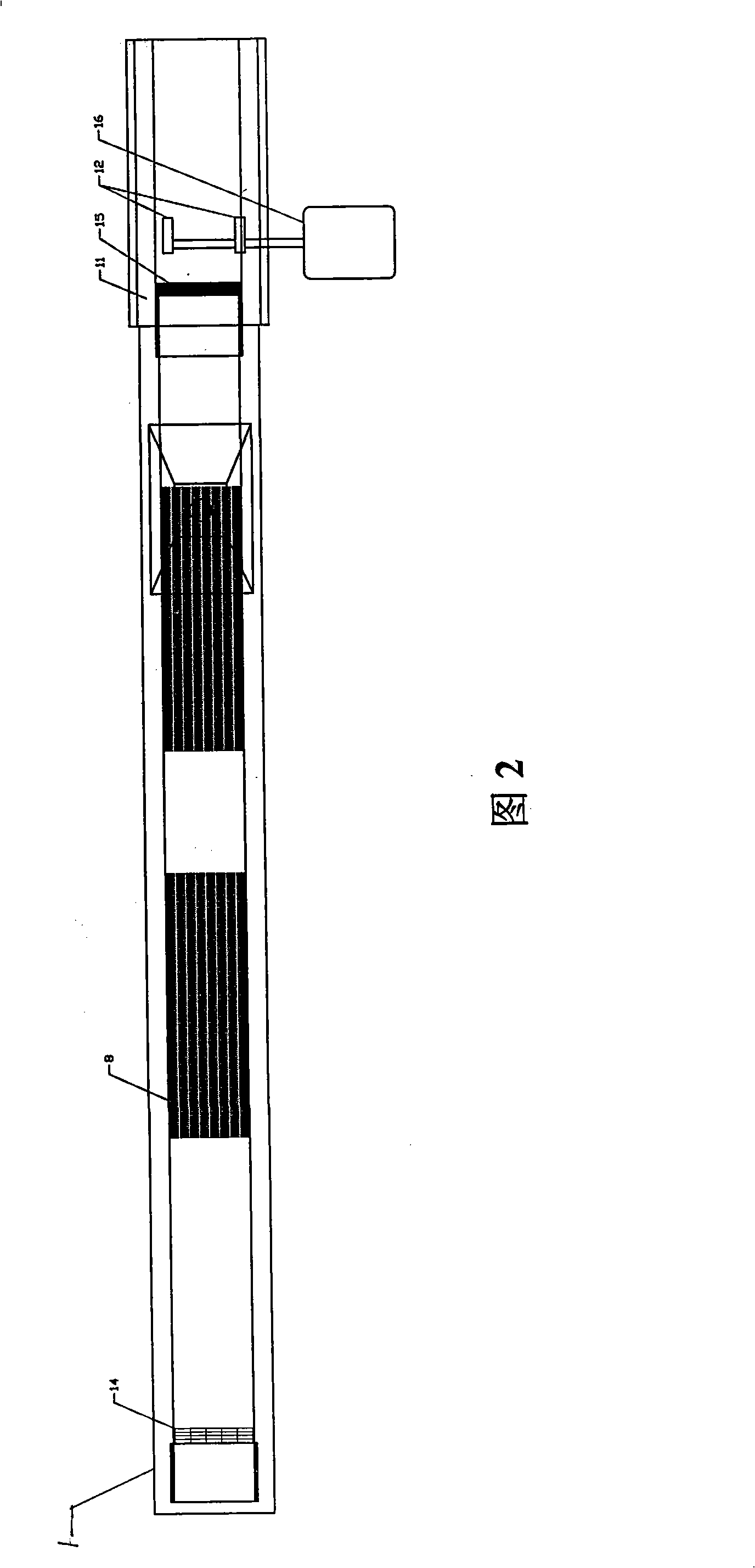

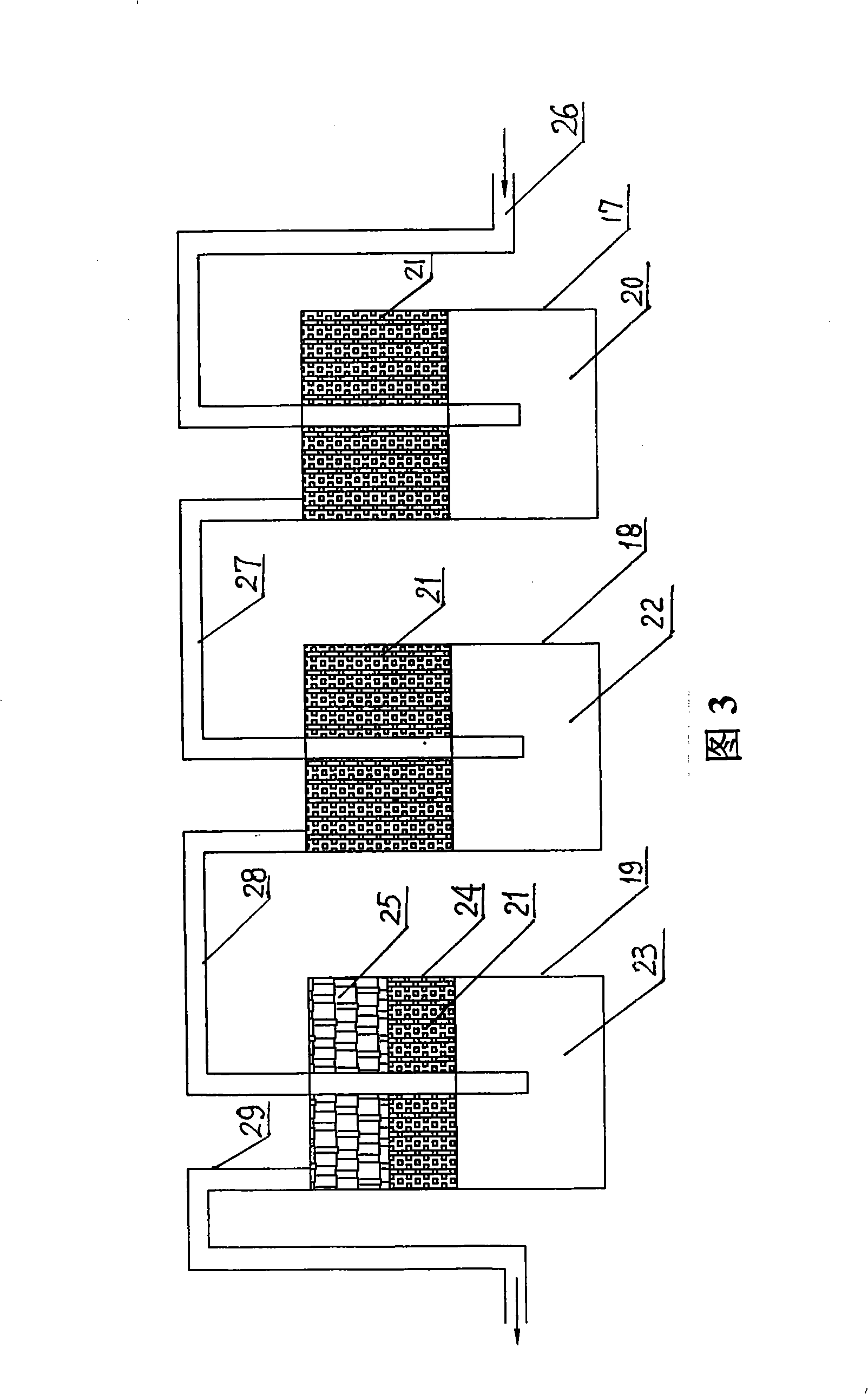

[0014] Referring to Fig. 1, Fig. 2, Fig. 3, the circuit board component foot solder detachment equipment of the present invention is made of several parts such as frame, transmission power unit, conveyor belt unit, heating unit, vibration and recovery unit, adsorption unit.

[0015] Frame 1: It is welded by square steel and steel plate, used to connect and fix the parts on it, and ensure its relative correct position.

[0016] Transmission power device: The transmission motor 6 is fixed on the frame, and the belt is transmitted to the reduction box 5, which is decelerated to reach the required linear speed. The output end of the reduction box is the sprocket 2, which is driven by the chain 3 to the rear roller (active) Conveyor belt movement.

[0017] Conveyor belt device: fixed on the frame by a roller at the front and back of the equipment, the conveyor belt 4 covers the roller, the rear roller is fixed by welding, the front roller is fixed by bolt connection 7, and the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com