Flexible thermosetting resin impregnated paper high-pressure laminated plate

A resin-impregnated, laminated board technology, applied in the direction of synthetic resin layered products, paper/cardboard layered products, layered products, etc. Short pressing time, easy maintenance, paint-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

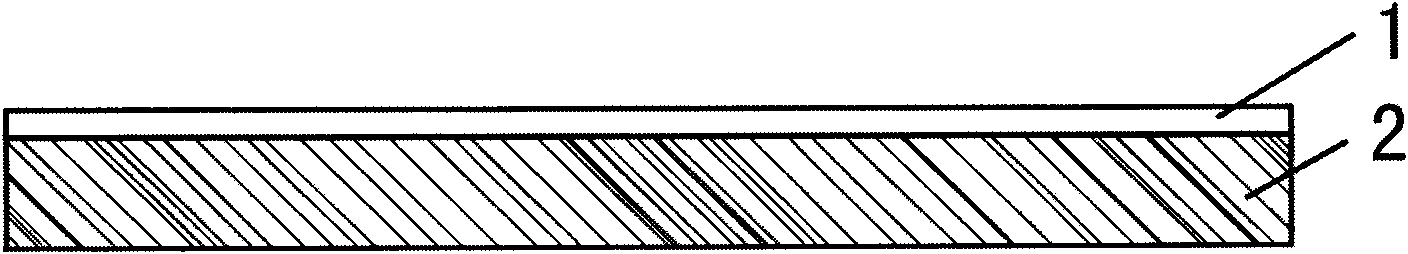

[0021] Embodiment one: if figure 1 As shown, a flexible thermosetting resin impregnated paper high-pressure laminate, which includes an impregnated film paper facing layer 1 and a non-woven fabric layer 2, and the impregnated film paper facing layer 1 and the non-woven fabric layer 2 are subjected to high temperature Thin high-pressure laminates are formed by heat-compression lamination.

[0022] Impregnated adhesive film paper finish layer 1 is the wood-based panel surface finish layer formed by impregnating special paper with initial polycondensate or prepolymer of synthetic resin, and then drying. The synthetic resin may be selected from urea-formaldehyde resin, phenol-formaldehyde resin, modified melamine resin, guanamine resin, or dipropylene phthalate resin. The synthetic resin in this embodiment has selected urea-formaldehyde resin for use.

[0023] The non-woven fabric layer 2 can be a wood fiber non-woven fabric layer or a synthetic fiber non-woven fabric layer. In...

Embodiment 2

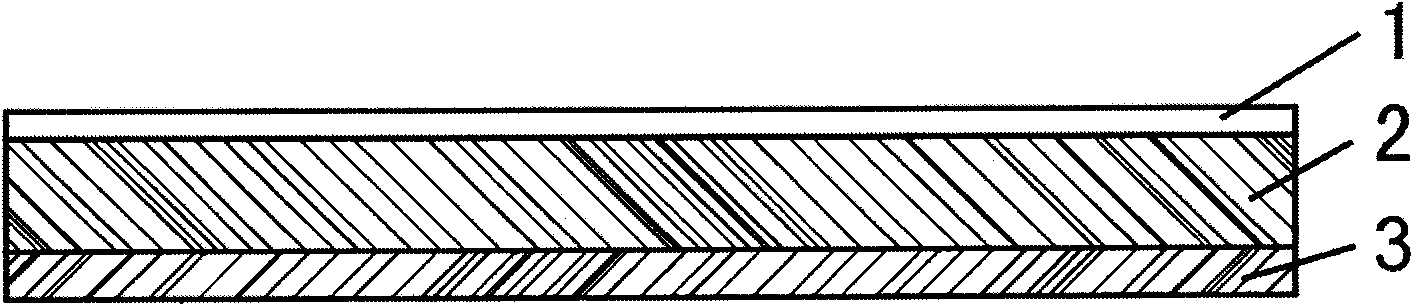

[0026] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment is that a synthetic fiber non-woven fabric layer is selected as the non-woven fabric layer 2, and a kraft paper 3 is arranged at the bottom of the non-woven fabric layer 2.

Embodiment 3

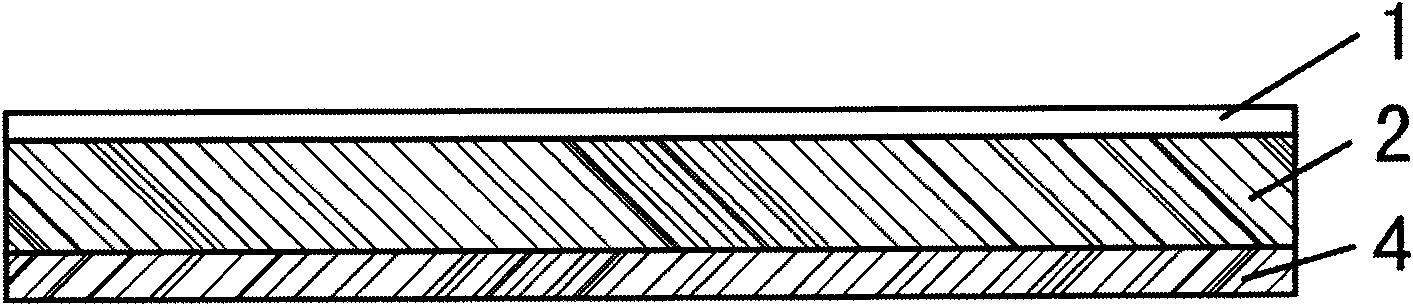

[0028] Such as image 3 As shown, the difference between the present embodiment and the first embodiment is that: the bottom of the non-woven fabric layer 2 is also provided with a veneer 4 . The veneer 4 can be selected from natural veneer, natural veneer, recombined decorative veneer, veneer obtained from laminated wood, or veneer for plywood; or the veneer obtained after the above materials have been bleached or colored or parquet or weaved. In this embodiment, recombined decorative veneer is selected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com