Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

710results about How to "Won't pile up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

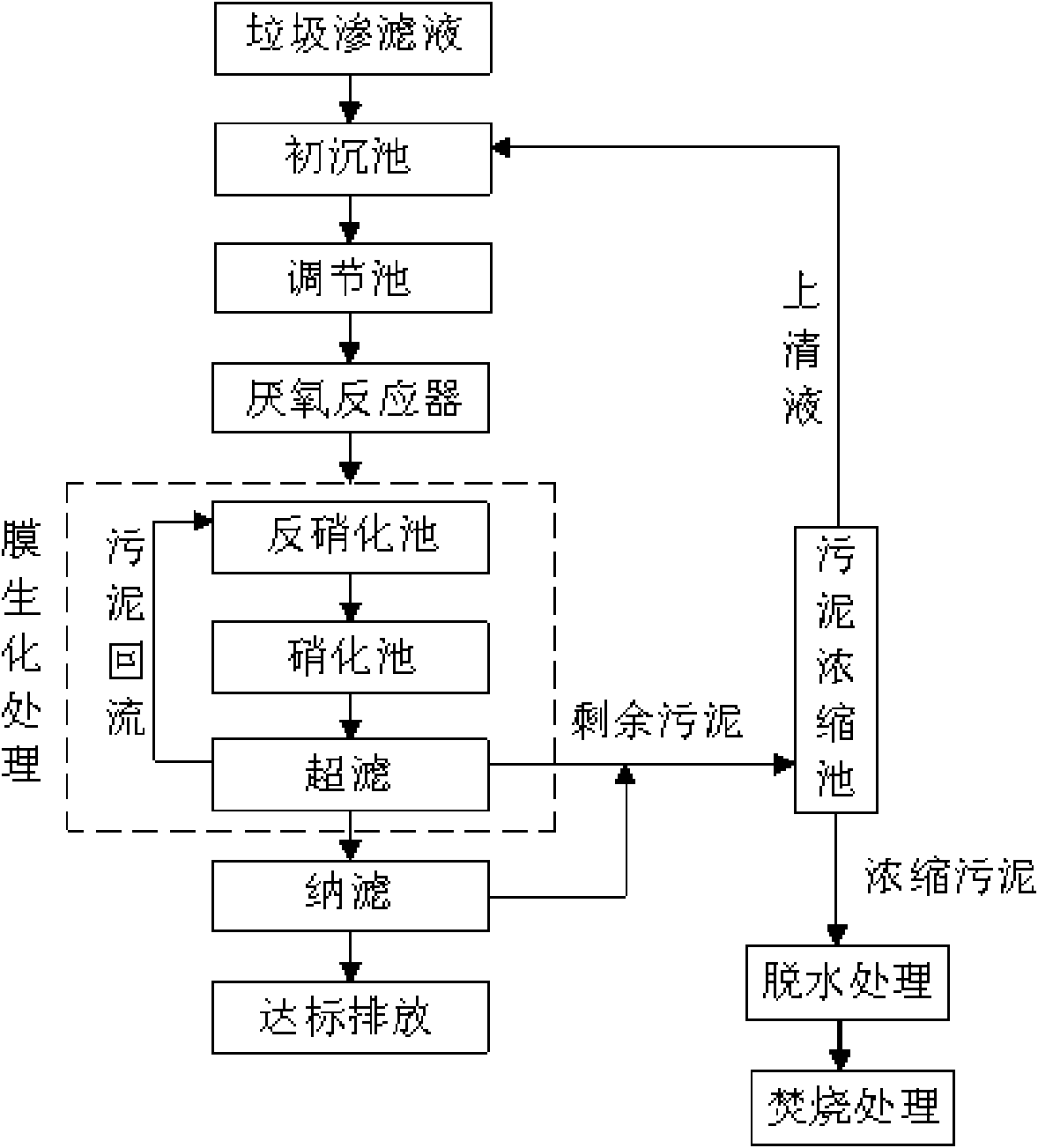

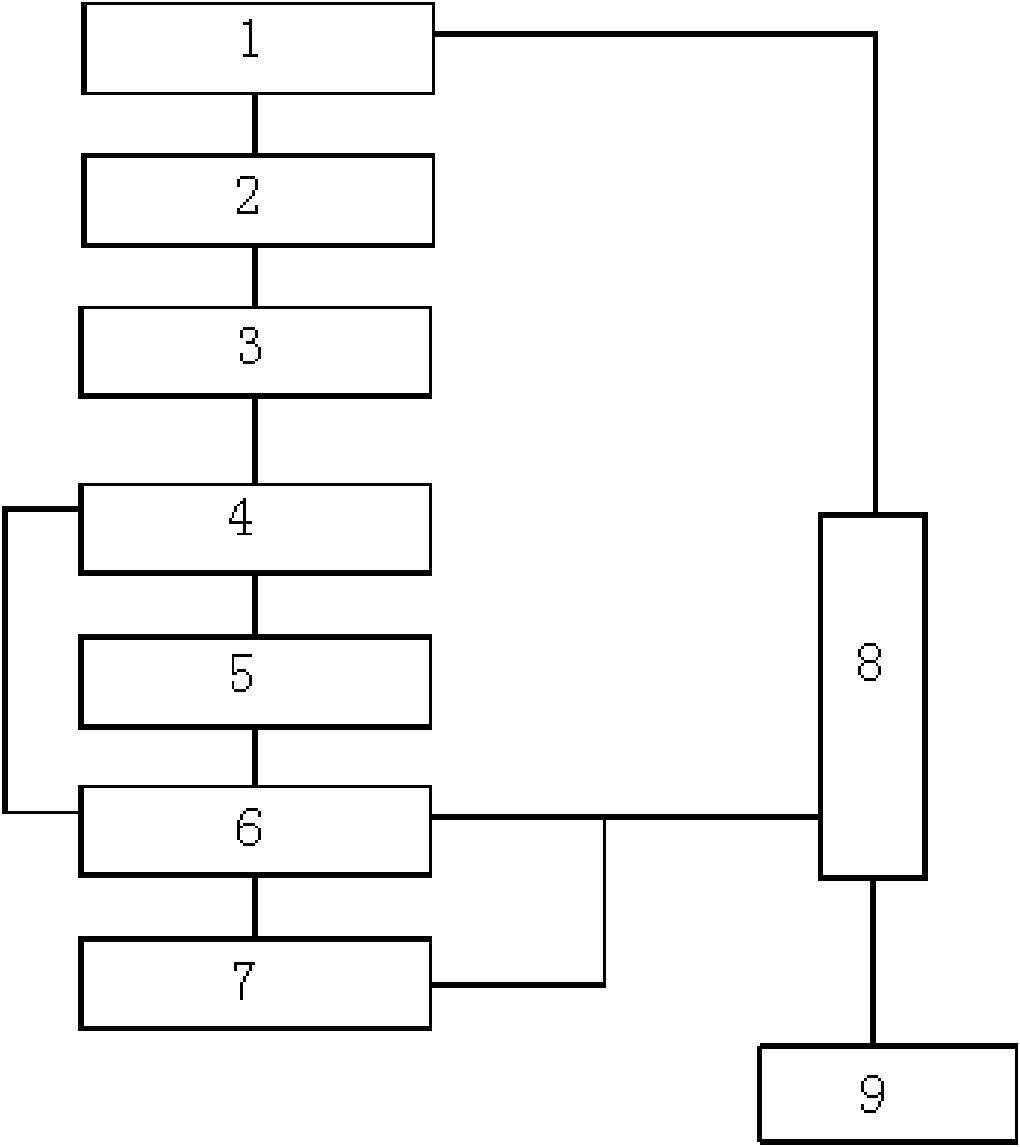

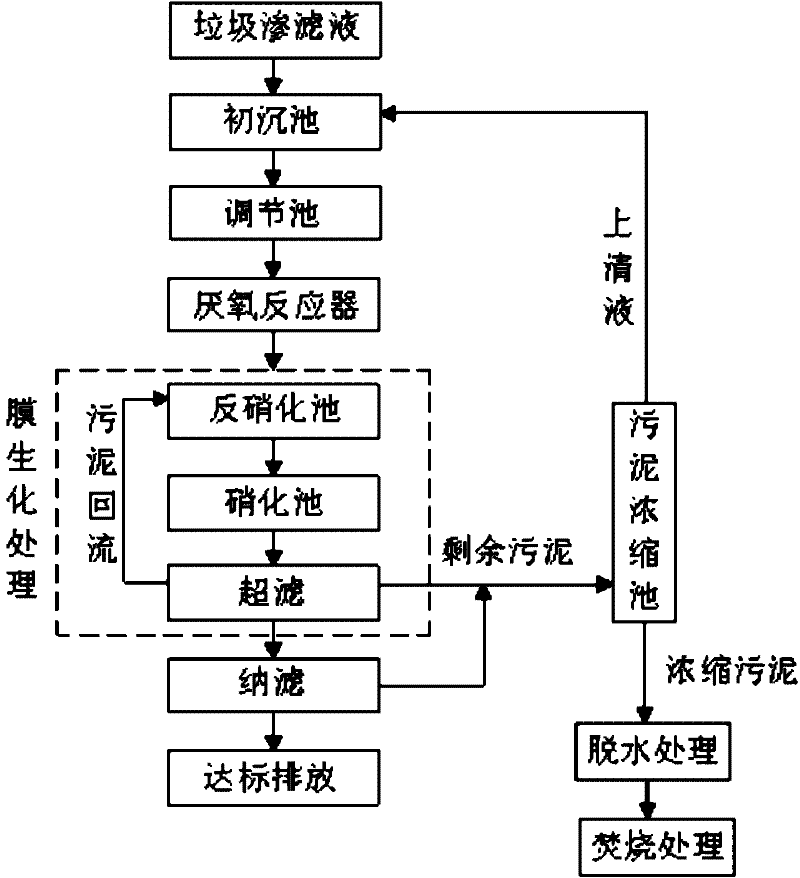

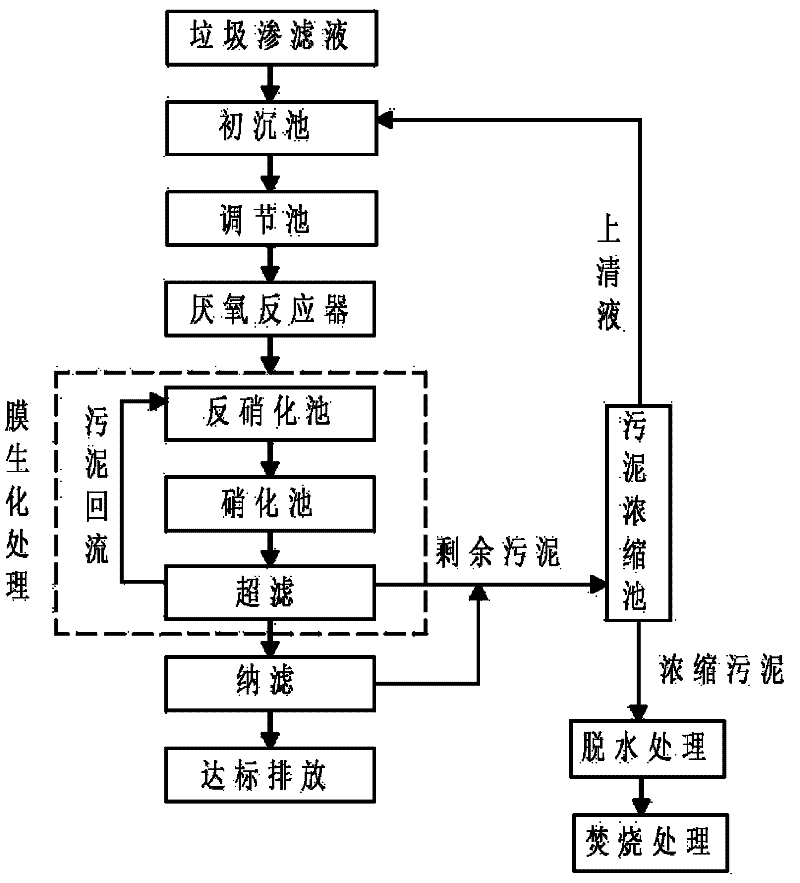

Method and device for treating garbage percolate

ActiveCN101597131AAchieving zero emissionsRelieve stressSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesHigh concentrationAfter treatment

The invention discloses a method and a device for treating garbage percolate, wherein the method comprises the steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, sludge treatment and the like; the device comprises a primary sedimentation tank (1) and an adjusting tank (2), the adjusting tank (2) is connected with an anaerobic reactor (3), the anaerobic reactor (3) is connected with a denitrification tank (4), and the denitrification tank (4) is communicated with a nitrification tank (5); and the nitrification tank (5) is connected with an ultrafiltration apparatus (6), and the ultrafiltration apparatus (6) is connected with a nanofiltration device (7). The method and the device achieve COD degradation of high-concentration wastewater so that the COD of high-concentration COD of 50,000 reaches about 50 after treatment and reaches the standard of industrial reuse water, thus the method and the device achieve zero discharge of the percolate, initiate a new attempt to treat high-concentration percolate, and fill up the domestic blank.

Owner:汕头市澄海洁源垃圾发电厂有限公司

Data transmission control method and equipment

The invention relates to a data transmission control method and data transmission control equipment. The data transmission control method comprises that: a data cache size is acquired by a cache of an intermediate node; and the intermediate node controls and regulates a congestion window value according to a magnitude relationship between the data cache size and a preset threshold value, so that a transmission link performs data transmission according to the regulated congestion window value. The embodiment of the invention realizes the regulation of the congestion window value by the magnitude relationship between the cache size of the intermediate node and the preset threshold value or a congestion window estimation value determined by throughput and round trip delay, and can keep the data size of the cache of the intermediate node be a rational value, thereby ensuring that data may not be excessively stacked at the intermediate node, further avoiding the congestion of data streams, and balancing the transmission control protocol (TCP) data streams of each service.

Owner:HUAWEI TECH CO LTD

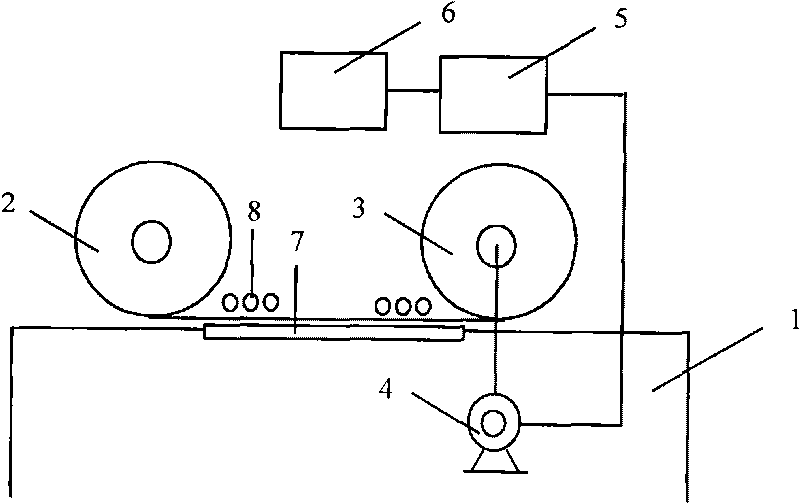

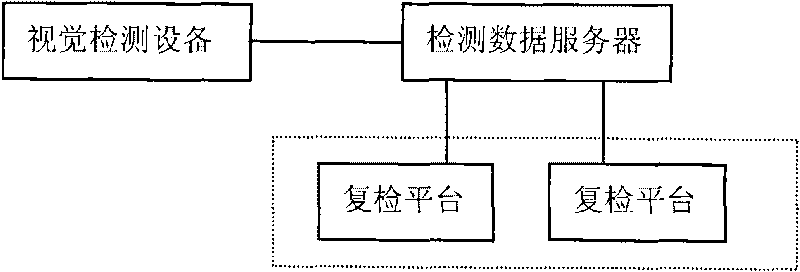

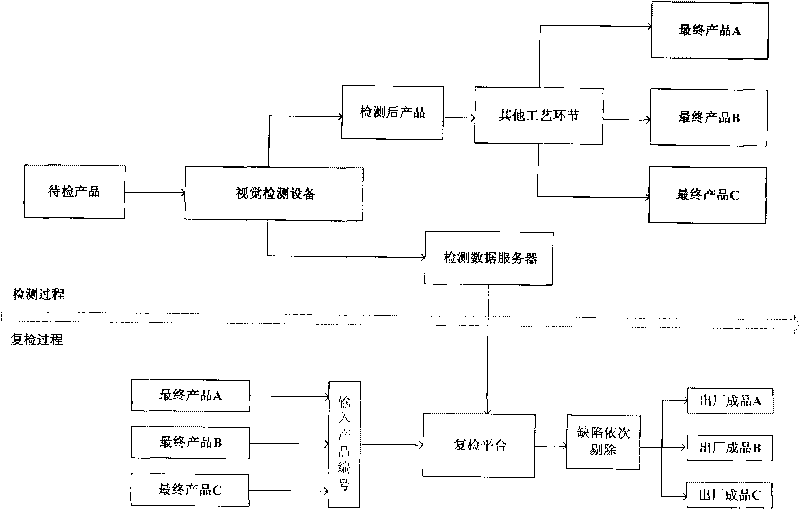

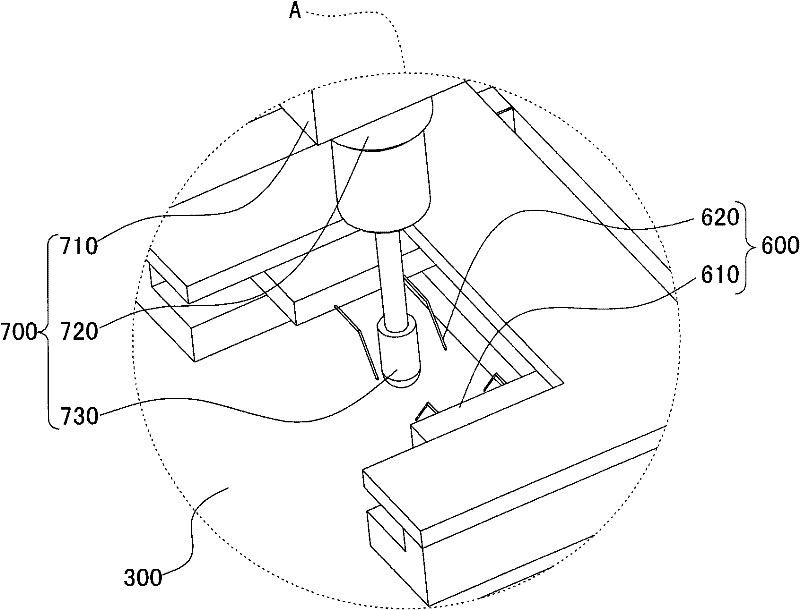

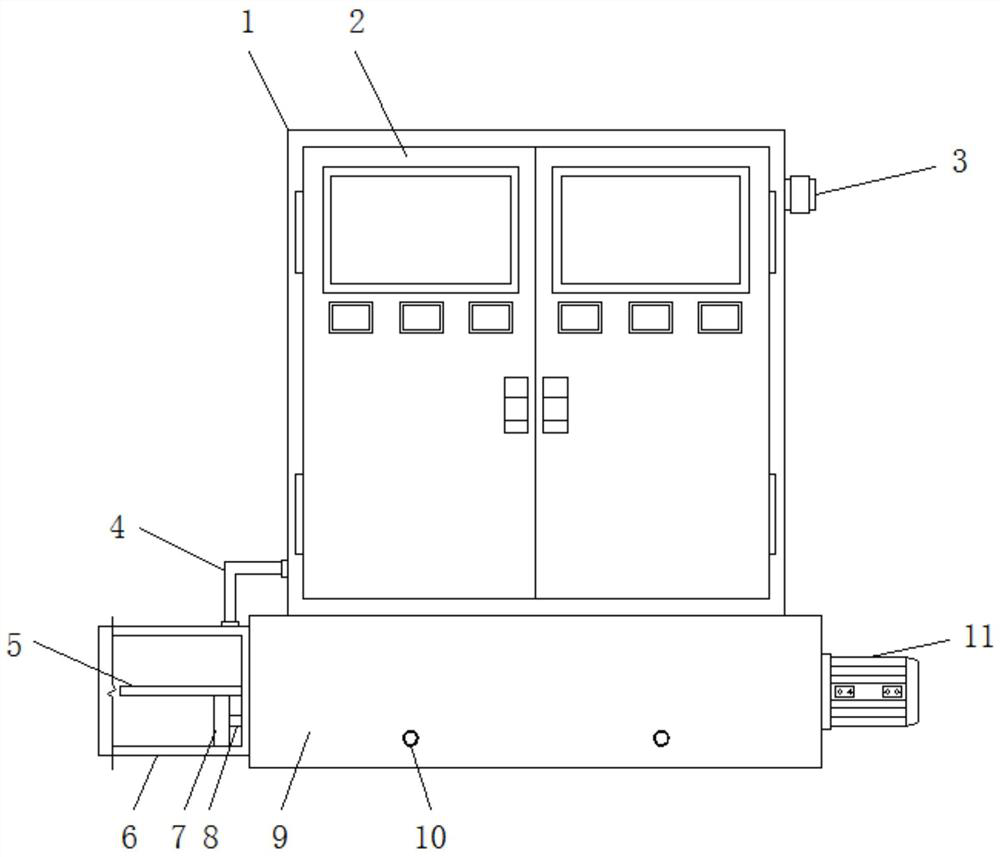

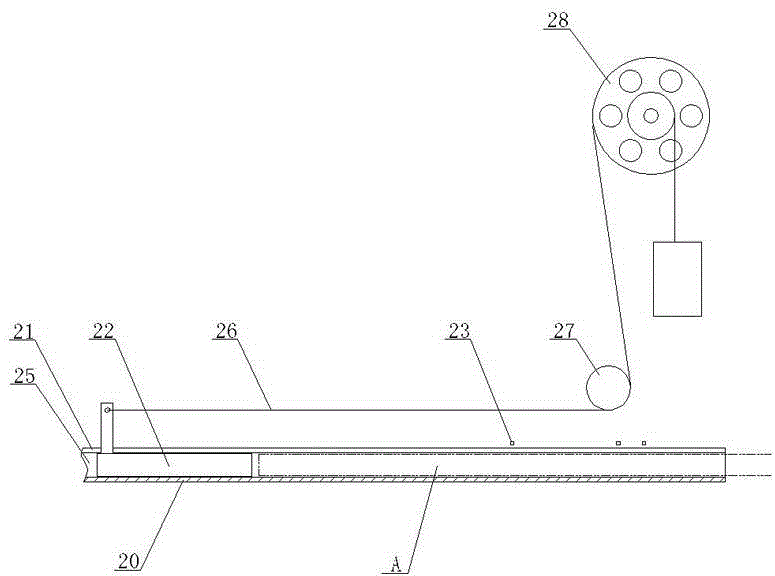

Recheck platform and quality inspection system of prints

InactiveCN101738396AReduce the burden onEasy to operateOptically investigating flaws/contaminationMicrocontrollerLocation detection

The invention discloses a recheck platform which is used for rechecking defects in quality inspection of prints and comprises a rack, a working table, an unwinding wheel, a winding wheel, a position detection device, a power device and a microcontroller, wherein, the unwinding wheel and the winding wheel are arranged on the rack; the unwinding wheel transmits the prints to the winding wheel to rewind the prints; the winding wheel is connected with a power device; the position detection device detects the position to which the prints are transmitted and is connected with the microcontroller; the microcontroller stores the position information of defects of the prints and compares with the information of the position when the prints are transmitted to control the power device. The recheck platform can lighten the burden of visual sense detection device, thus the visual sense detection device is only responsible for detection, reconstructs the detection process, separates the process links such as time consuming stopping rejection and label supplementing and the like from the detection process, lowers cost and improves the efficiency of quality detection. The invention also relates to a system adopting the platform to detect the quality of prints.

Owner:BEIJING LUSTER LIGHTTECH

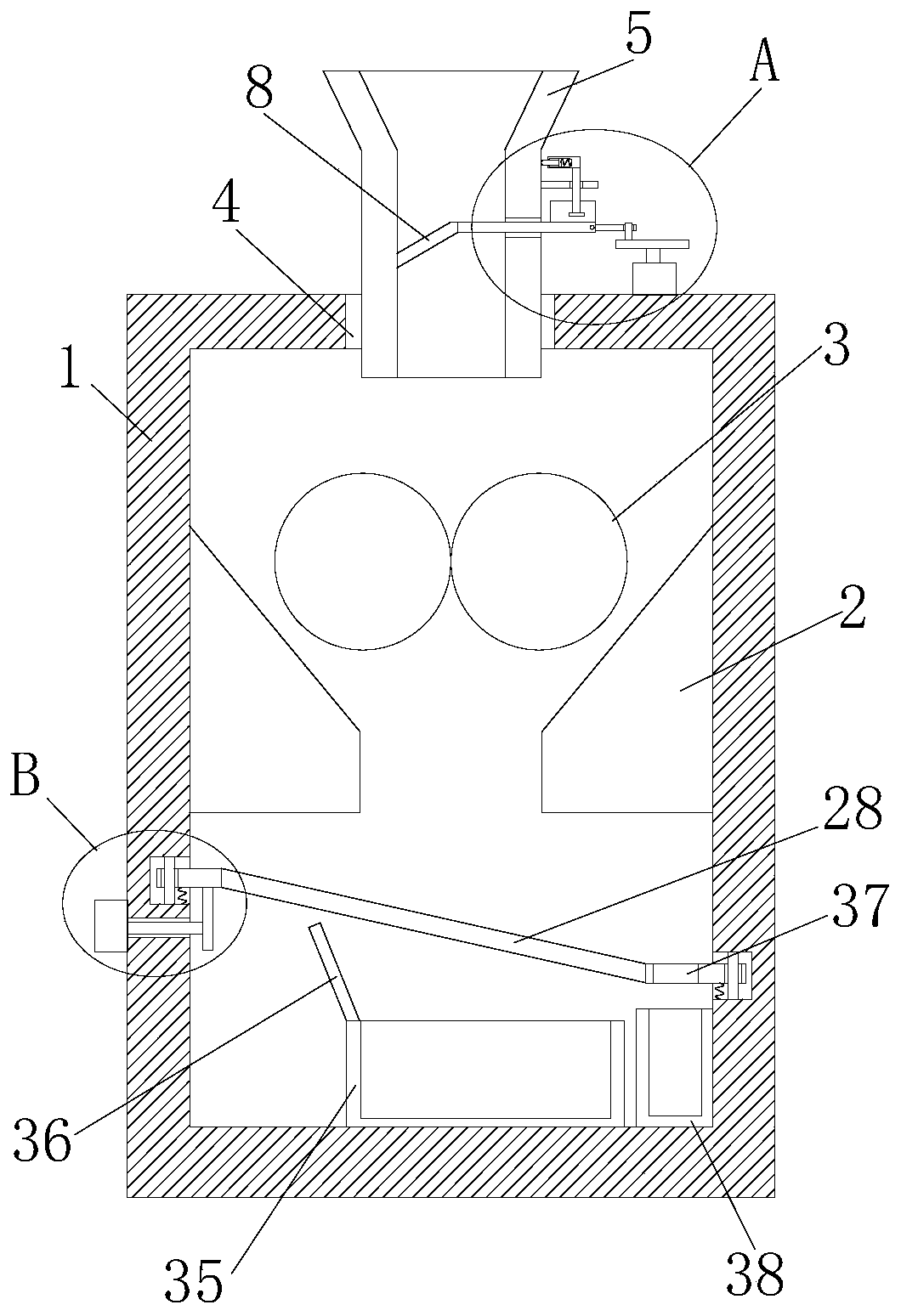

Chinese medicinal material grinder

The invention belongs to the technical field of medicinal material production equipment, and particularly relates to a Chinese medicinal material grinder. The Chinese medicinal material grinder solvesthe problems of an existing grinder that raw materials need to be fed manually, time and labor are wasted, and large powder accumulates on a filtering screen and is hard to clear. According to the technical scheme, the Chinese medicinal material grinder comprises a grinder body; trapezoid baffles are arranged on the inner walls of two sides of the grinder body; and two grinding rollers rotatablymounted on the inner wall of one side of the grinder body are arranged above the trapezoid baffles. According to the grinder, Chinese medicinal materials needing to be ground can be fed into a feedinghopper in one time, the Chinese medicinal materials intermittently fall into the grinder by shake for grinding, and therefore manual intermittent feeding is not required, and labor is saved. Ground Chinese medicinal material powder falls on an inclined filtering plate, large Chinese medicinal material powder falls into a collecting box through leakage holes, so that the Chinese medicinal materialpowder on the filtering screen does not accumulate, fine powder can quickly fall and be collected, and application requirements can be met.

Owner:肖金坚

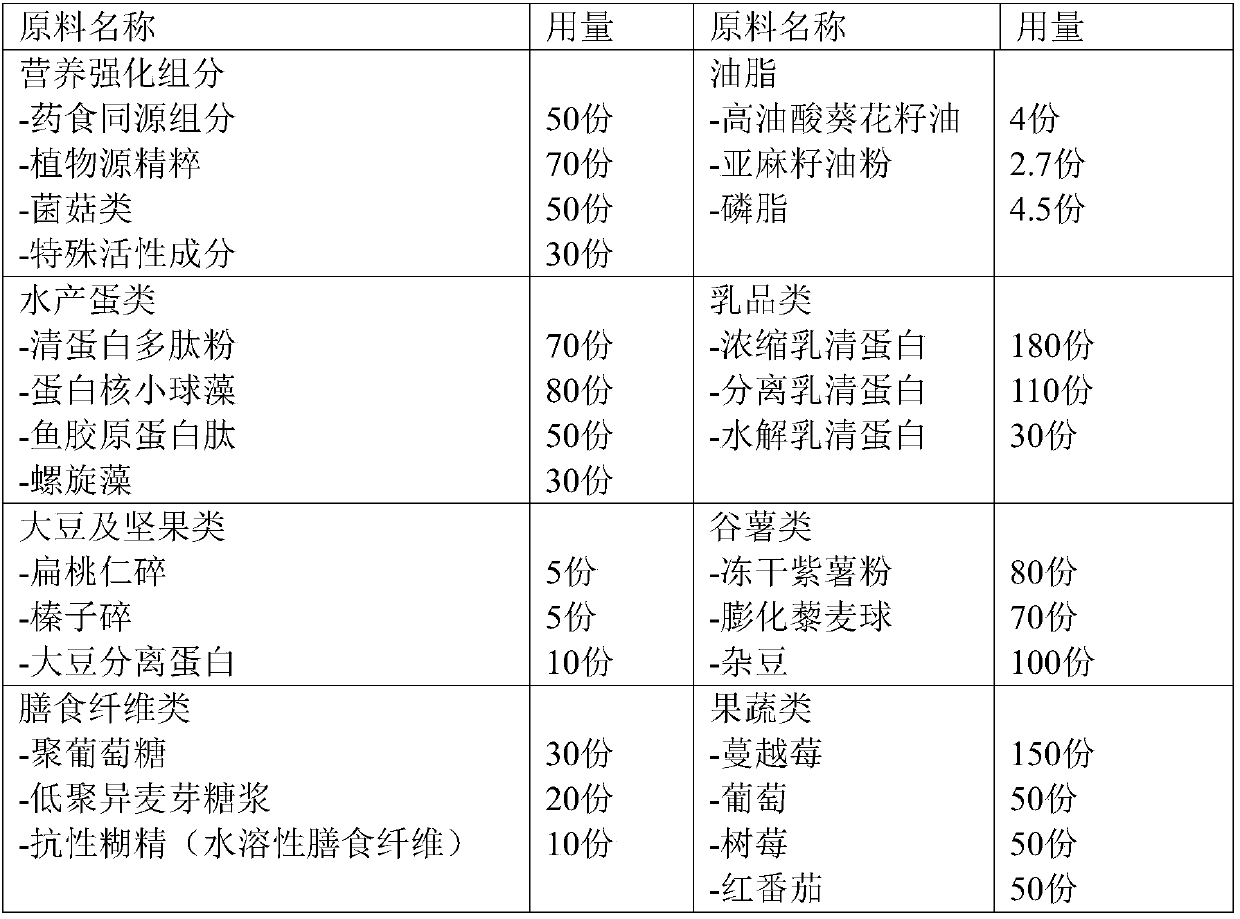

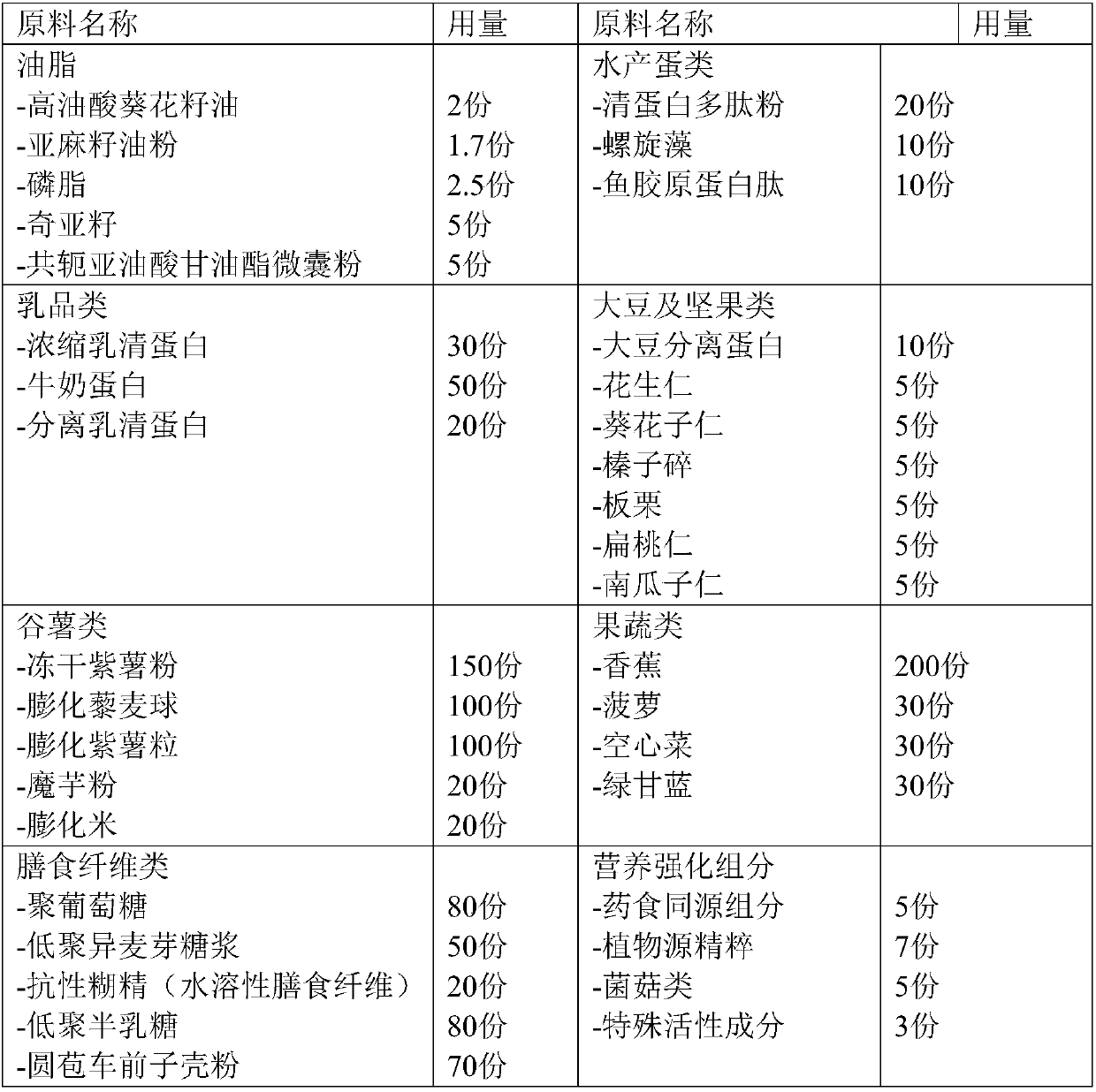

Light fasting full nutrition formula brewing instant bar and preparation method thereof

InactiveCN109645320AReasonable configurationEnsure balanceNatural extract food ingredientsFood ingredient functionsDietary fiberPreservative

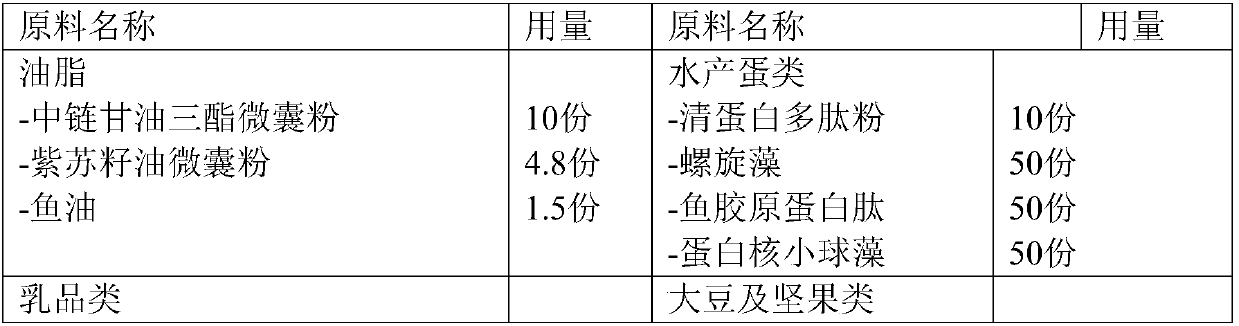

The invention provides a light fasting full nutrition formula brewing instant bar and a preparation method thereof. The formula can brew various components of instant nutrient nutrients according to the suggested configuration of the 'Chinese Dietary Guidelines', foods are diverse, and no preservatives, no sweeteners and no artificial pigments are added; the bar is prepared from, by weight, oil, aquatic eggs, dairy products, soybeans, nuts, cereal potatoes, dietary fibers, fruits and vegetables, nutritional strengthening components and the like, is convenient to eat, and is especially suitablefor meeting the full nutritional needs of a body during light fasting and fat reduction.

Owner:北京万莱康营养与健康食品科学技术研究院有限公司

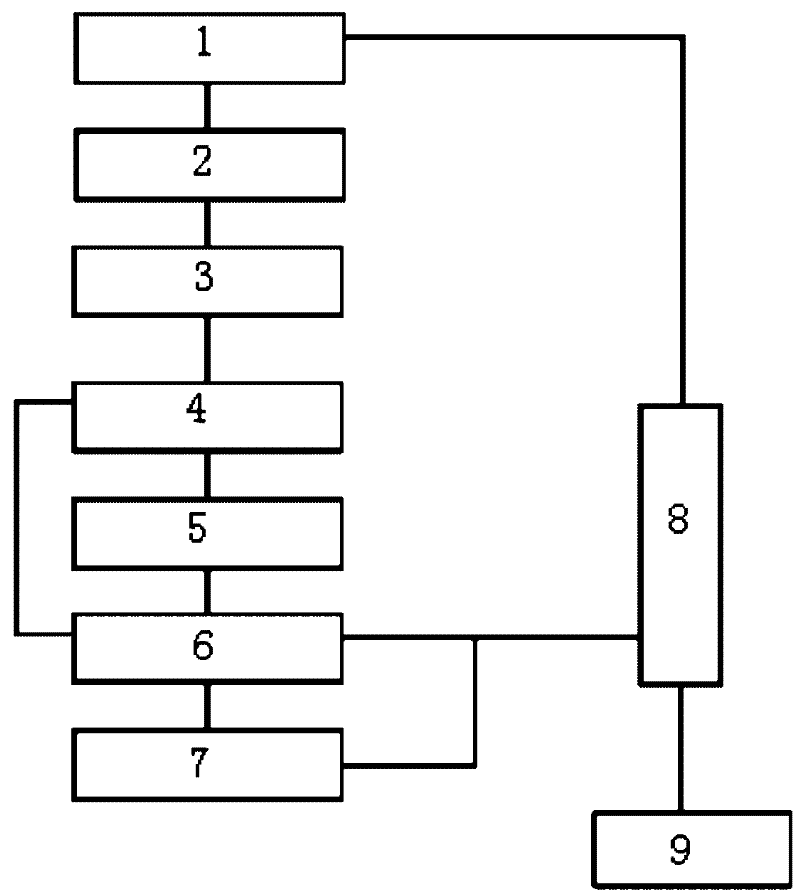

Method for applying integrated technology of combination of membrane biochemistry and nanofiltration membrane to high-density leachate advanced treatment and recycling

InactiveCN102190400ARelieve stressSolve pollutionSludge treatment by pyrolysisTreatment with aerobic and anaerobic processesHigh densityUltrafiltration

The invention discloses a processing method and a processing apparatus of landfill leachate. The processing method comprises steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, and sludge treatment and the like. And the processing apparatus includes a primary settling tank (1) and a regulating tank (2). The regulating tank (2) is connected with an anaerobic reactor (3) which is connected with a denitrifying tank (4); the denitrifying tank (4) is communicated with a nitration tank (5), which is connected with ultrafiltration equipment (6); and the ultrafiltration equipment (6) is connected with nanofiltration equipment (7). According to the invention, COD of the high-density wastewater is degraded. After processing, high-density COD of 50,000 to 60,000mg / L is degraded to COD of about 50 mg / L, which reaches the standard of industrial reused water. Moreover, zero discharge of leachate is realized. Therefore, a new attempt to treat the high-density leachate is initiated and the domestic blank is filled.

Owner:HUZHOU NANTAIHU ENVIRONMENTAL PROTECTION ENERGY

Fertilization device for crops

The invention relates to a fertilization device, in particular to a fertilization device for crops and provides the fertilization device having high fertilization efficiency and capable of realizing relatively uniform fertilization to solve the technical problem. The technical scheme is as follows: the fertilization device for the crops comprises a bottom plate, a push handle, first sleeves, firstmovable rods, wheels, nuts, mounting rods, a charging box, a feeding hopper, a discharging pipe, a first motor and the like, wherein the push handle is mounted on the left side of the top of the bottom plate, the first sleeves are mounted at four corners of the bottom of the bottom plate, the first movable rods are glidingly arranged in the first sleeves, the wheels are rotationally mounted at the bottoms of the first movable rods, and threaded holes are formed in right side surfaces of the first sleeves. The first motor is used for driving scraping pieces to turn up soil and driving a cam torotate, so that a baffle plate can be driven to discharge fertilizer intermittently. A push plate and claws are arranged, so that soil can be pushed to be flat, and the effects of higher fertilization speed and relatively uniform fertilization are realized.

Owner:浙江智霖机械有限公司

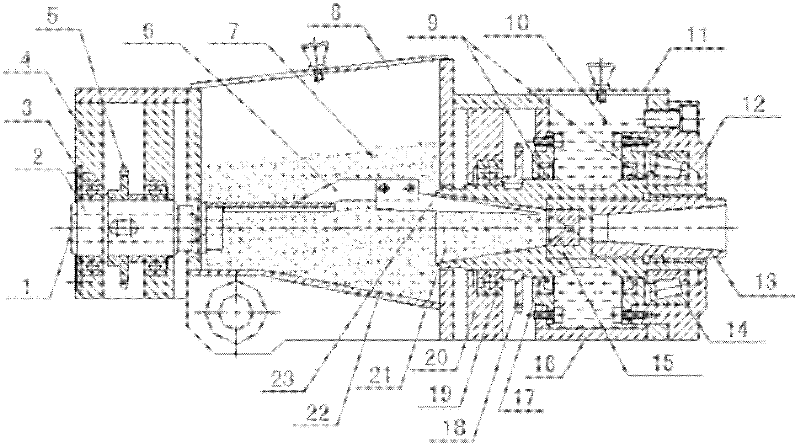

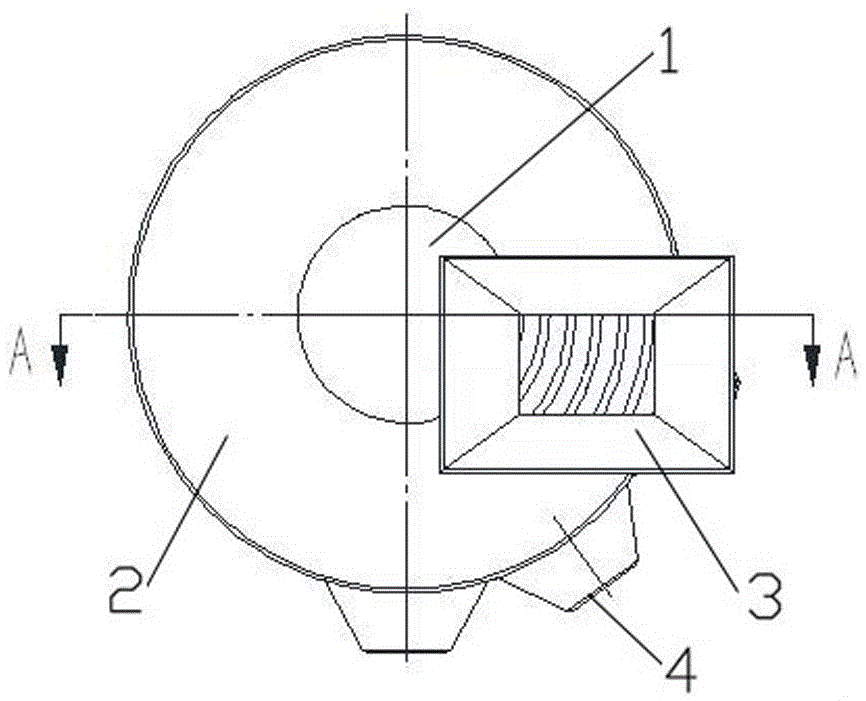

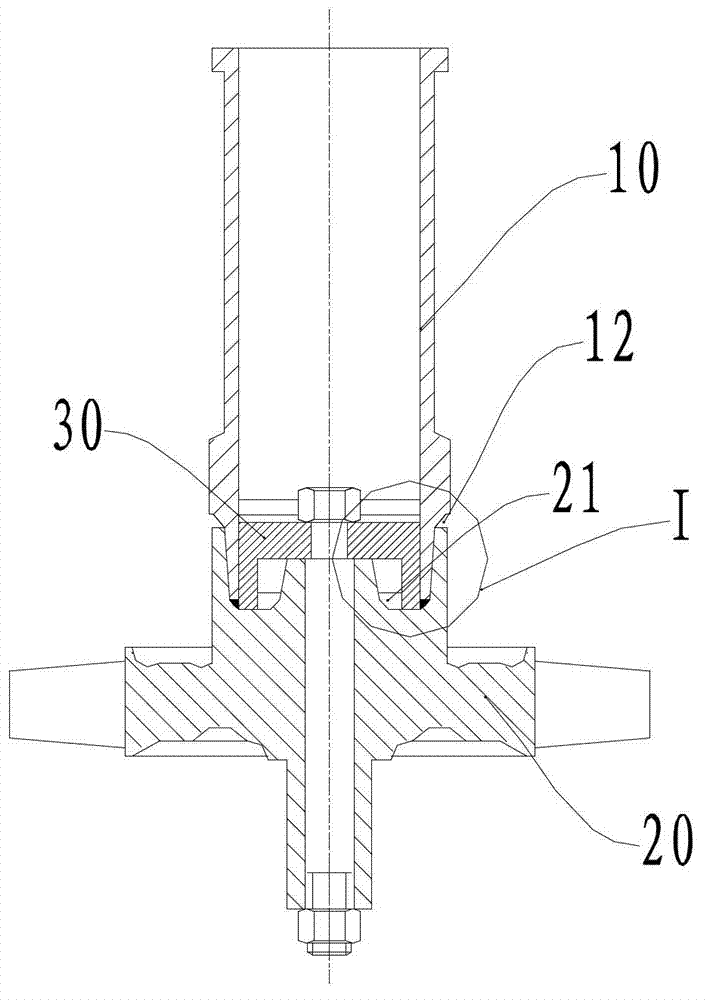

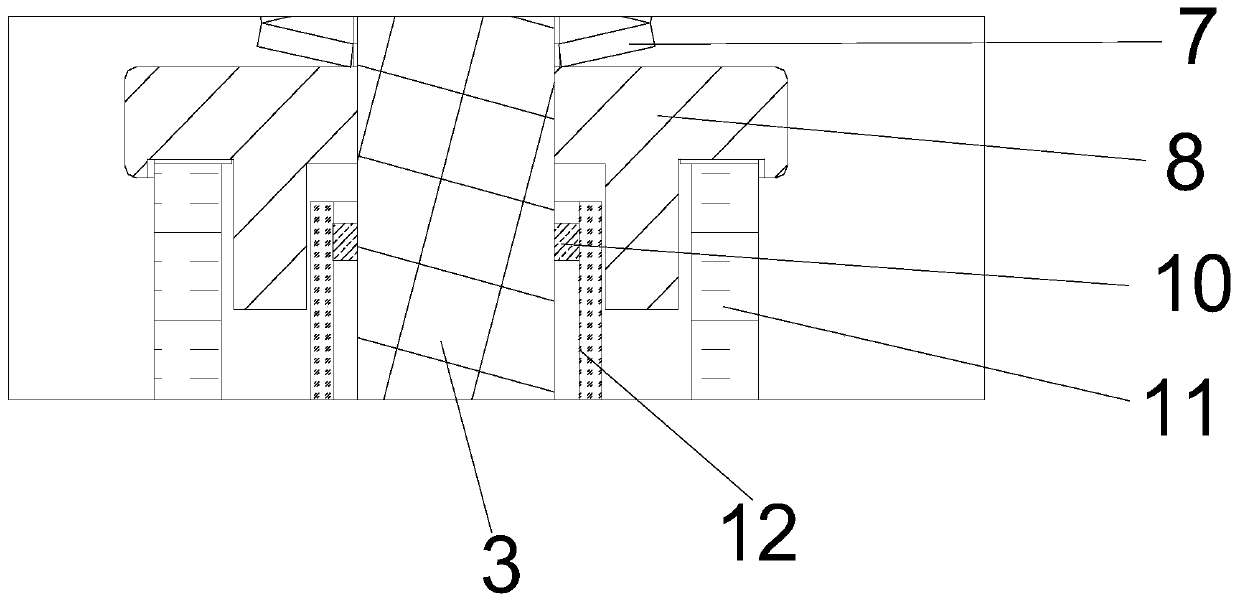

Wire drawing machine rotary die box

The invention relates to a rotary mold box for a wire drawing machine, which includes a lubricating box body and a mold box body. A wire drawing die is installed in the mold box body; a wire drawing die rotating device is installed on the mold box body, and the wire drawing die rotating device includes A hollow shaft rotatably installed on the mold box body, the drawing die is installed inside the hollow shaft. The invention installs the wire drawing die rotating device on the mold box body, which can drive the wire drawing die to rotate, so that the wire drawing die wears evenly, prolongs the service life of the wire drawing die, and ensures the stable size of the drawn steel wire.

Owner:WUXI CHANGXIN TECH

Light-emitting diode packaging structure and packaging method thereof

ActiveCN101924176AHigh thermal conductivityGuaranteed insulationSolid-state devicesSemiconductor devicesMaterial typeMetal substrate

The invention relates to the field of optoelectronic packaging and discloses a light-emitting diode (LED) packaging structure and a packaging method thereof. The invention has the following beneficial effects: not passing through a ceramic insulating layer, an LED chip directly keeps away from the low heat conductivity bottleneck, and the heat can not be accumulated in the insulating layer; a metal heat conducting layer can rapidly transfer the heat generated by the LED chip to a metal substrate; the metal substrate has sufficient width and heat dissipation space; and a glass-ceramic insulating layer is manufactured on the metal heat conducting layer by selective laser melting and then a metal electrode layer and external electrodes are manufactured on the glass-ceramic insulating layer, thus not only ensuring insulation of the tube shell with the outside but also having little effect on the overall heat dissipation effect. The required ceramic insulating layer and the metal electrodelayer are formed by laser ablation melting, thus avoiding overall high temperature sintering, dispensing with the high temperature sintering process, saving energy, protecting the environment, enlarging the material types of the selectable metal substrate and being easy to realize industrialization.

Owner:SHENZHEN UNIV

Method for producing decorating part of car boot cover

InactiveCN101654080AReduce weightProcess stabilitySynthetic resin layered productsLaminationWork in processEnvironmental resistance

The invention relates to a method for producing a decorating part of a car boot cover, which belongs to the technical field of interior parts of cars. A low-density PP plate molding material is mainlyadopted as a decorating part basal body of a boot cover and is subjected to press molding, water-jet cutting and inspection to obtain a finished product. The invention solves the problem of meeting the performance indexes of sound absorption, heat resistance, light weight, high strength, and the like of a decorating part assembly of the boot cover and the three-grade international advanced level,greatly reduces the weight of the decorating part of the boot cover, meets the requirement on the lightweight design of the whole car and has stable molding process; a product has high rigidity and can not be broken and sagged; the product is produced by an automatic production line in the whole production process, thereby greatly reducing the labor intensity of workers in the production processand improving the production efficiency; no semi-finished product is stacked in the process, and the manufacture cost is saved; and the product does not generate harmful substances in the whole production process and belongs to an environmental-friendly product.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

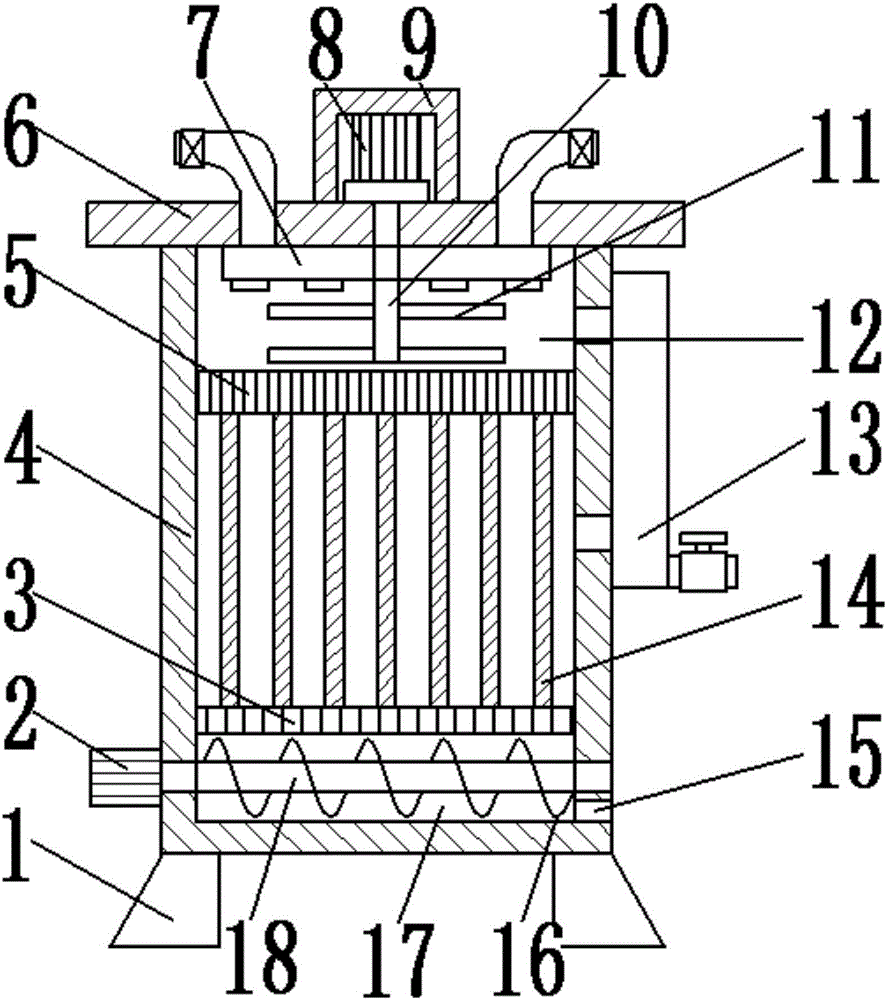

Pulse cloth bag dust remover capable of easily collecting ash

InactiveCN106377952AImprove ash removal effectBetter and faster dust removalDispersed particle filtrationSpiral bladeBaghouse

The invention discloses a pulse cloth bag dust remover capable of easily collecting ash. The pulse cloth bag dust remover comprises a box body and an ash outlet pipe, wherein a ceiling and a cage framework are fixedly connected in the box body; a plurality of filter bags are fixedly connected between the ceiling and the cage framework; beating blades are connected between the ceiling and the cage framework and at two sides of the filter bags in a rotary manner; upper ends of the filter bags are connected with a venturi tube penetrating through the ceiling; a blowing pipe is further fixedly connected with a position, located above the ceiling, in the box body; the lower part of the box body is connected with a brushing shaft in the rotary manner; the brushing shaft is fixedly connected with a plurality of brushing plates; an opening formed in the lower end of the box body is communicated with the upper end of the ash outlet pipe; the ash outlet pipe is fixedly connected below the box body; the ash outlet pipe is internally connected with a spiral blade in the rotary manner; an atomizer is further fixedly connected with the lower end of the ash outlet pipe; an outlet of the atomizer is communicated with a flow spitting box; the lower end of the flow spitting box is communicated with a plurality of humidifying nozzles introduced into the ash outlet pipe. The pulse cloth bag dust remover capable of easily collecting the ash is high in reverse blowing and ash falling efficiency, dust is not stuck and remained and does not cause secondary pollution after being discharged; energy saving and high efficiency are realized.

Owner:广西金邦泰科技有限公司

Dry powder raw material grinding device for producing fire extinguisher

InactiveCN108672054AGrind evenlyGrinding speed is fastSievingScreeningFire extinguisherGrinding wheel

The invention relates to a powder grinding device, in particular to a dry powder raw material grinding device for producing a fire extinguisher. The dry powder raw material grinding device for producing the fire extinguisher is high in smashing efficiency, smashing is uniform, and raw materials are not stacked easily in the smashing process. According to the technical scheme, the dry powder raw material grinding device for producing the fire extinguisher comprises a bottom plate, a left support, a right support, a round supporting plate, a grinding box, a collecting box, a supporting rod, a first rotating shaft, a fan-shaped gear, an air cylinder, a grinding wheel, an electric pushing rod and the like. The left support is arranged on the left side of the top of the bottom plate. The rightsupport is arranged on the right side of the top of the bottom plate. The round supporting plate is arranged in the middle of the top of the bottom plate. According to the dry powder raw material grinding device, the electric pushing rod serves as the main power source to drive the grinding wheel to swing to carry out grinding, meanwhile, by means of mutual cooperation of the fan-shaped gear and arack, a baffle moves left and right indirectly, the raw materials are discharged intermittently, the raw materials are ground while being discharged, and the raw materials are not stacked easily in the grinding process.

Owner:胡智晶

Trimmer and method for regulating resistance value of resistance component as well as electronic device

ActiveCN102243915AReduce the cost of resistance trimmingLow costResistor manufactureNon-adjustable resistorsElectrical resistance and conductanceEngineering

The invention provides a trimmer for regulating resistance value of a resistance component and a regulating method. The trimmer comprises a platform, a processor, a detection device and a trimming device. The method comprises the following steps: placing the resistance component on the platform; detecting the resistance values of the resistance component by use of the detection device, feeding back one detected resistance value to the processor and comparing the detected resistance value with a preset resistance value, thus obtaining a differential resistance value; and according to the differential resistance value, indicating the trimming device to cut the resistance component until the resistance component reaches the preset resistance value by virtue of the processor. The method provided by the invention can be used for detecting the resistance value of the resistance component and also carrying out mechanical cutting on the resistance component so as to simplify the operating complexity and improve the processing speed; and meanwhile, the electronic device which has the advantages of high precision and low error rate can be stably produced and the processing cost can also be lowered.

Owner:CYNTEC

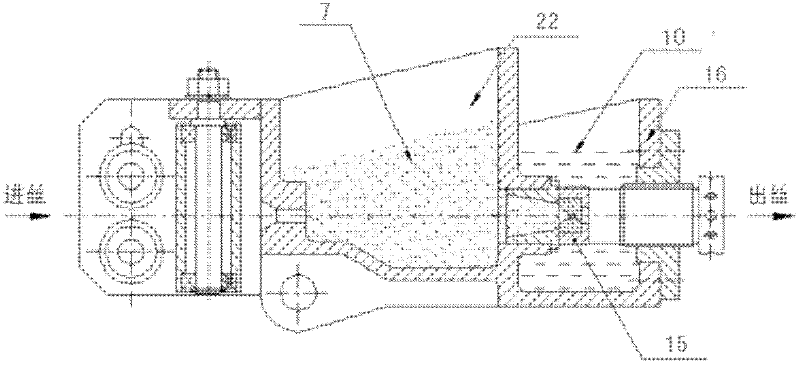

Energy-saving rotary stirring die box of wire drawing machine

The invention relates to an energy-saving rotary stirring die box of a wire drawing machine. The energy-saving rotary stirring die box comprises a lubrication box body and a die box body, wherein a wire drawing die is arranged in the die box body; a stirring device is arranged on the lubrication box body; a wire drawing die rotating device is arranged on the die box body; the stirring device and the wire drawing die rotating device share one double-output-shaft speed reduction motor; and clutches are arranged on the output shafts of the speed reduction motor. In the energy-saving rotary stirring die box, the stirring device arranged on the lubrication box body is used for stirring lubrication powder; as the lubrication powder cannot be accumulated in the lubrication box body, the lubrication effect is reliable; the wire drawing die rotating device arranged on the die box body can drive the wire drawing die to rotate, so that the wire drawing die is abraded uniformly, the service life of the wire drawing die can be prolonged, and the size of a drawn steel wire can be stabilized; and the stirring device and the wire drawing die rotating device share one double-output-shaft speed reduction motor, so that the energy-saving rotary stirring die box is compact in structure, low in cost and energy-saving.

Owner:WUXI CHANGXIN TECH

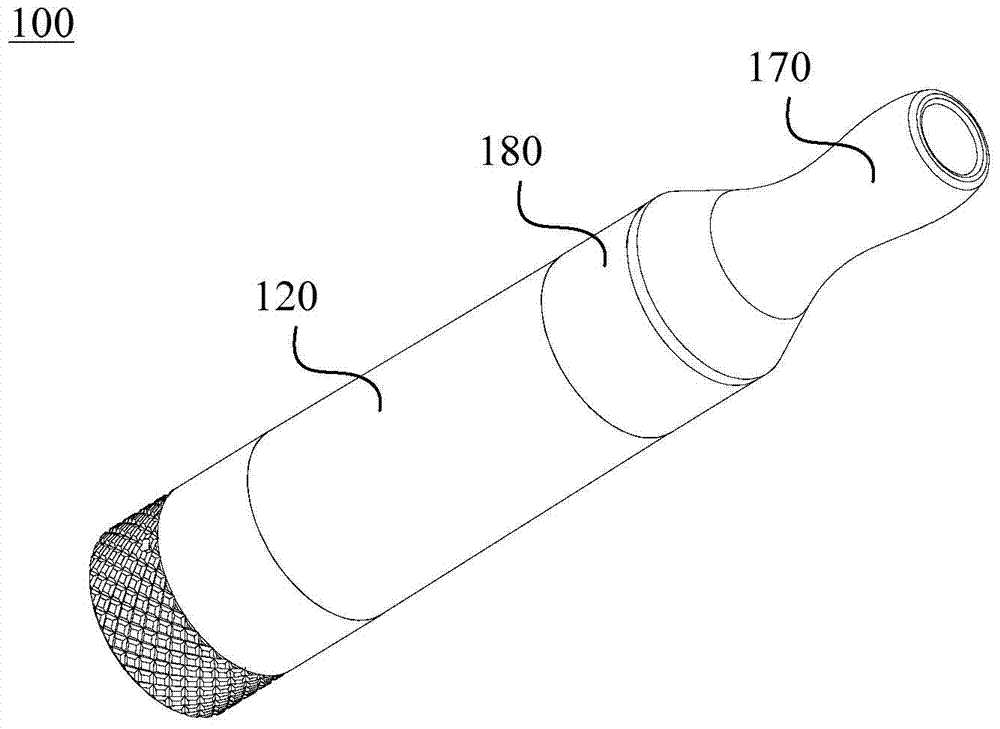

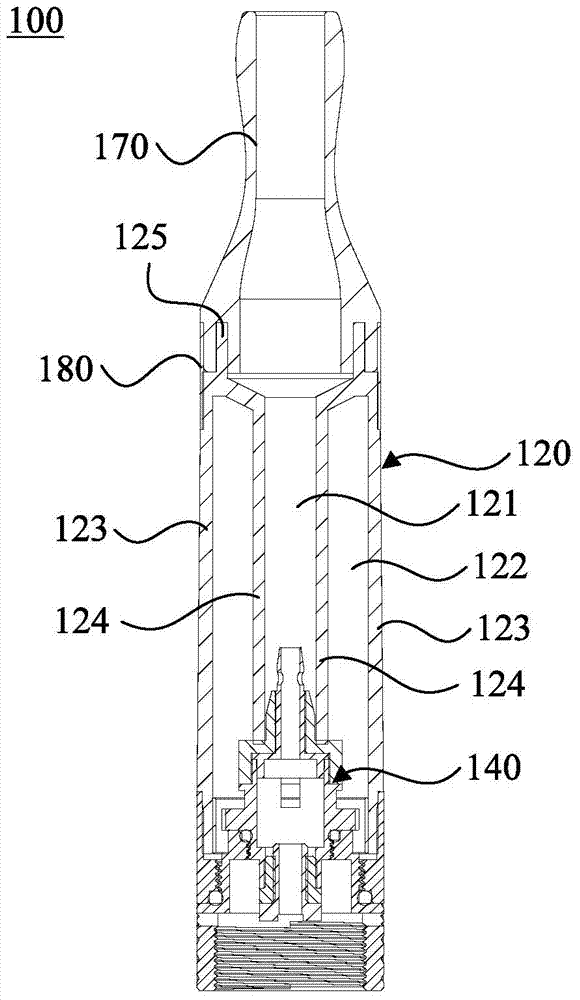

Inhaler, nebulizing unit and nebulizing core

The invention relates to an inhaler, a nebulizing unit and a nebulizing core. The nebulizing unit of the inhaler comprises a shell and the nebulizing core combined with the shell. The shell is internally provided with an air passage and a liquid storage chamber surrounding the air passage and used for storing liquid. The nebulizing core comprises a core body, an exhaust tube and a nebulizing element; the core body is internally provided with a nebulizing cavity; the exhaust tube is disposed at an exhaust opening; the nebulizing element is disposed inside the nebulizing cavity and is used for nebulizing the liquid; at least part of the exhaust tube is extended into the air passage; the sidewall of the exhaust tube is provided with a through hole or gap whereby the inside of the exhaust tube is communicated with the air passage. The through hole or gap allows the liquid condensing in the air passage to flow back to the nebulizing cavity, nebulized gas is avoided passing through the liquid accumulating in the air passage to produce plumps when the inhaler is in use, and a user is also prevented from inhaling the liquid accumulating in the air passage into the mouth.

Owner:SHENZHEN SMOORE TECH LTD

Shock absorption and heat dissipation power cabinet for power engineering

PendingCN112652983AGuaranteed cooling effectQuick liquid changeSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsElectric machineryEngineering

The invention discloses a shock absorption and heat dissipation power cabinet for power engineering, which belongs to the technical field of power cabinets, and comprises a cabinet body, a cooling liquid box, a liquid changing assembly, a machine base, a reciprocating screw rod, a cleaning assembly and a shock absorption spring, wherein a cabinet door is hinged to the exterior of the machine base through a hinge, and a driving motor and the cooling liquid box are fixedly installed on the outer walls of the two sides of the machine base respectively; an inner cabinet base is fixedly installed in the machine base. The cooling liquid pipe is mounted inside, and the cleaning assembly capable of reciprocating is mounted in the power cabinet base, so that when the power cabinet is used in ordinary times, the driving motor can be started and can drive the mounting shaft to rotate, thereby driving the reciprocating lead screw to rotate and driving the cleaning assembly to move; the cleaning brush of the cleaning assembly can effectively clean the heat dissipation opening of the power cabinet, the cleanliness of the power cabinet is kept, meanwhile, the heat dissipation opening can be effectively prevented from being blocked by dust or dirt, and the heat dissipation effect of the power cabinet is guaranteed.

Owner:GUANGDONG UNITED WATT POWER EQUIP CO LTD

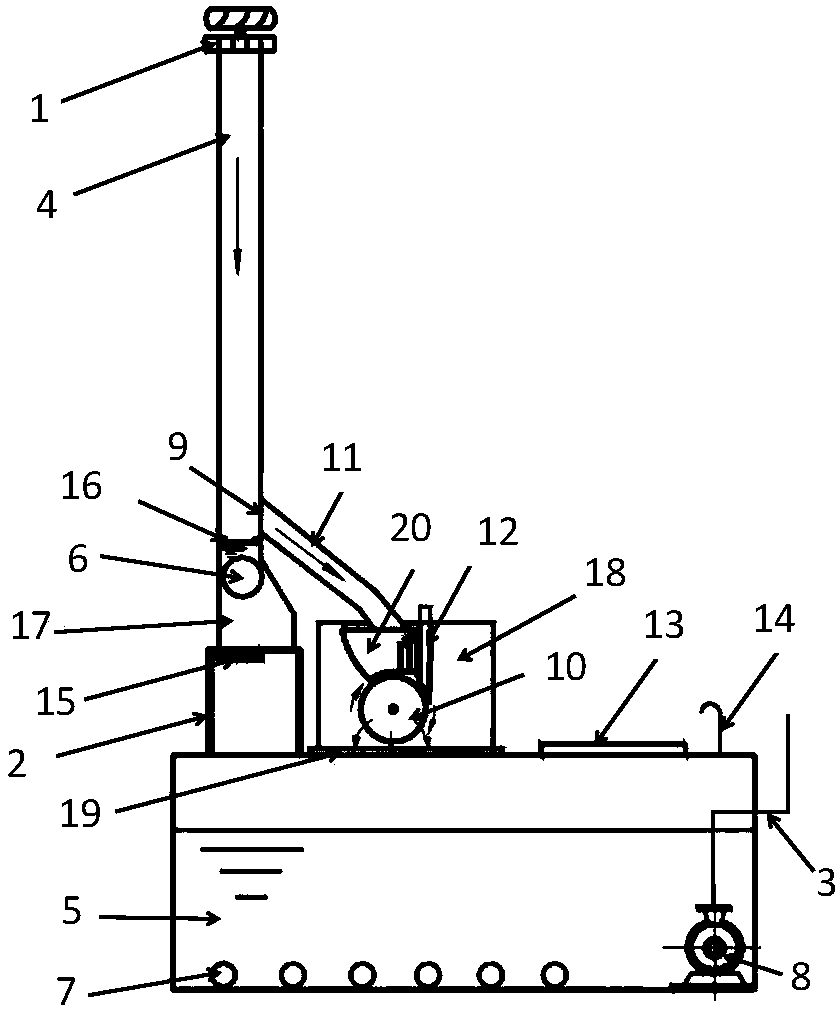

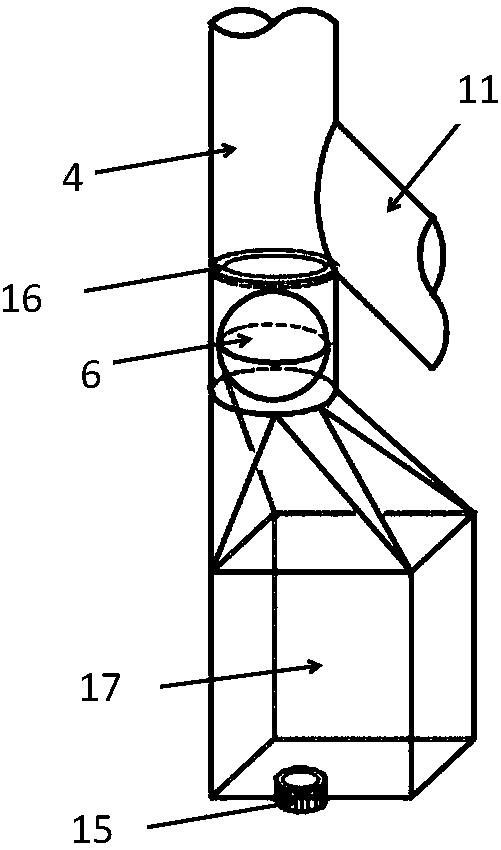

Self-powered self-cleaning roof rainwater collecting and processing system device

PendingCN107642204AAvoid cloggingSimple structureGeneral water supply conservationRoof drainageFiltrationUv disinfection

The invention relates to a self-powdered self-cleaning roof rainwater collecting and processing system device. The device comprises a rainwater bucket, an abandoned flow supporting frame, a water pipe, a water-falling pipe, a water reservoir, a water-retaining floating ball, an ultraviolet disinfection lamp tube, a submersible pump, a primary filter screen, a filter roller, a bypass branch rainwater pipe, a filter sewage interception and collection bucket, a reservoir access port, an aeration overflow pipe, a cleaning mouth, a ring floating ball baffle, an abandoned flow container, a roller filter box, a secondary filter screen, a water sink, a hook, a hook sleeve, a convex lug, a handle, and a curved scraper. The water flow first enters into the abandoned flow container through the water-falling pipe to intercept the sewage flow, the relatively clean rainwater hits the filter roller to rotate, the curved scraper scrapes off the dirt attached to the filter roller, the dirt is thrown into the filter sewage interception and collection bucket under the dual action of the filter roller rotation and the water flow impact, and the rainwater is filtered through filter holes of the filterroller and other multi-layer filtration ways to enter into the water reservoir. The self-powered self-cleaning roof rainwater collecting and processing system device can achieve self-powered self-cleaning roof rainwater collecting and processing.

Owner:YANTAI UNIV

Method for producing front wall sound insulation pad of automobile driving cabin

ActiveCN102310613AMeet the requirements of lightweight designReduce weightLamination ancillary operationsSynthetic resin layered productsThermoplasticPerformance index

The invention relates to a method for producing a front wall sound insulation pad of an automobile driving cabin, belonging to the technical field of automobile interior part processing. The method provided by the invention comprises the following steps of: placing a hard thermoplastic felt on a bottom layer, placing a hot melt film on a middle layer, placing a soft thermoplastic felt on an upper layer, and paving the raw materials on a net chain of an oven; feeding the raw materials into the oven through the net chain of the oven for drying and softening, and sufficiently dissolving the hot melt film on the middle layer; placing the materials in a mould after drying the materials in the oven, and pressing and cooling the materials in the mould to form a semi-finished product; locating the semi-finished product, and executing water jet cutting on the semi-finished product to obtain the required front wall sound insulation pad of the driving cabin; and boxing and warehousing after checking up. According to the method provided by the invention, the performance index requirements, such as sound absorption, sound insulation, environment friendliness, light weight and the like, of the front wall sound insulation pad assembly of the driving cabin can be satisfied; the weight of the front wall sound insulation pad of the driving cabin is greatly reduced; and the requirement for integral lightweight design is satisfied.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Grinding medium sorting device of grinding machine

The invention discloses a grinding medium sorting device of a grinding machine. The grinding medium sorting device of the grinding machine comprises a support central pillar, a spiral grinding medium channel and a plurality of sieving components, wherein spherical grinding media pass through the spiral grinding medium channel; the sieving components are arranged in the grinding medium channel; the support central pillar penetrates through the top to the bottom of the grinding medium channel and is used for supporting the grinding medium channel; a sphere inlet is formed in the top of the grinding medium channel; sphere outlets are formed in the bottom of the grinding medium channel; the number of the sphere outlets is equal to the number of the sieving components; each sphere outlet is communicated with the tail of a sieving component; the sieving components are arranged at intervals from the top to the bottom; a sieving gap from a top sieving component to a lower penultimate sieving component is gradually diminished. The grinding medium sorting device of the grinding machine has the advantages that various diameter ranges of the grinding media are fed into the sorting device from the sphere inlet, the sieving components are used for sorting different diameter ranges of the grinding media and discharging the grinding media from the corresponding sphere outlets, the artificial participation is avoided, the sorting device is capable of automatically sorting the grinding media, the efficiency is higher, the bin cleaning time is reduced, and the halt time of the grinding machine is short.

Owner:NANJING XIPU CEMENT ENG GROUP

Chemical raw material drying device with spiral discharge device

ActiveCN106369953AEasy dischargeKeep dryDrying solid materialsDrying machines with local agitationWater vaporEngineering

The invention discloses a chemical raw material drying device with a spiral discharge device. The chemical raw material drying device comprises a base; a discharge bin is arranged on the top of the base; a heating filter plate is arranged on the top of the discharge bin; a drying box is arranged on the top of the heating filter plate; a drying plate is arranged inside the drying box; the bottom of the drying plate is connected with the heating filter plate; the top end of the drying plate is connected with a flow-splitting plate; the flow-splitting plate is arranged on the top of the drying box; a charge bin is arranged on the top of the flow-splitting plate; and a crushing shaft, crushing blades and a charge device are arranged inside the charge bin. The chemical raw material drying device disclosed by the invention is simple in structure, is reasonable in design and is convenient to use; the flow-splitting plate is arranged, so that chemical raw materials can be uniformly discharged and are not input to be clustered, and therefore, the drying device can be used for drying more conveniently; a gas exhaust device is arranged, so that water vapor generated in a drying process can be exhausted; and a drying plate and a drying box can be arranged for drying materials, so that the materials are dried completely.

Owner:JIANSU JINSHAN BEER RAW MATERIAL CO LTD

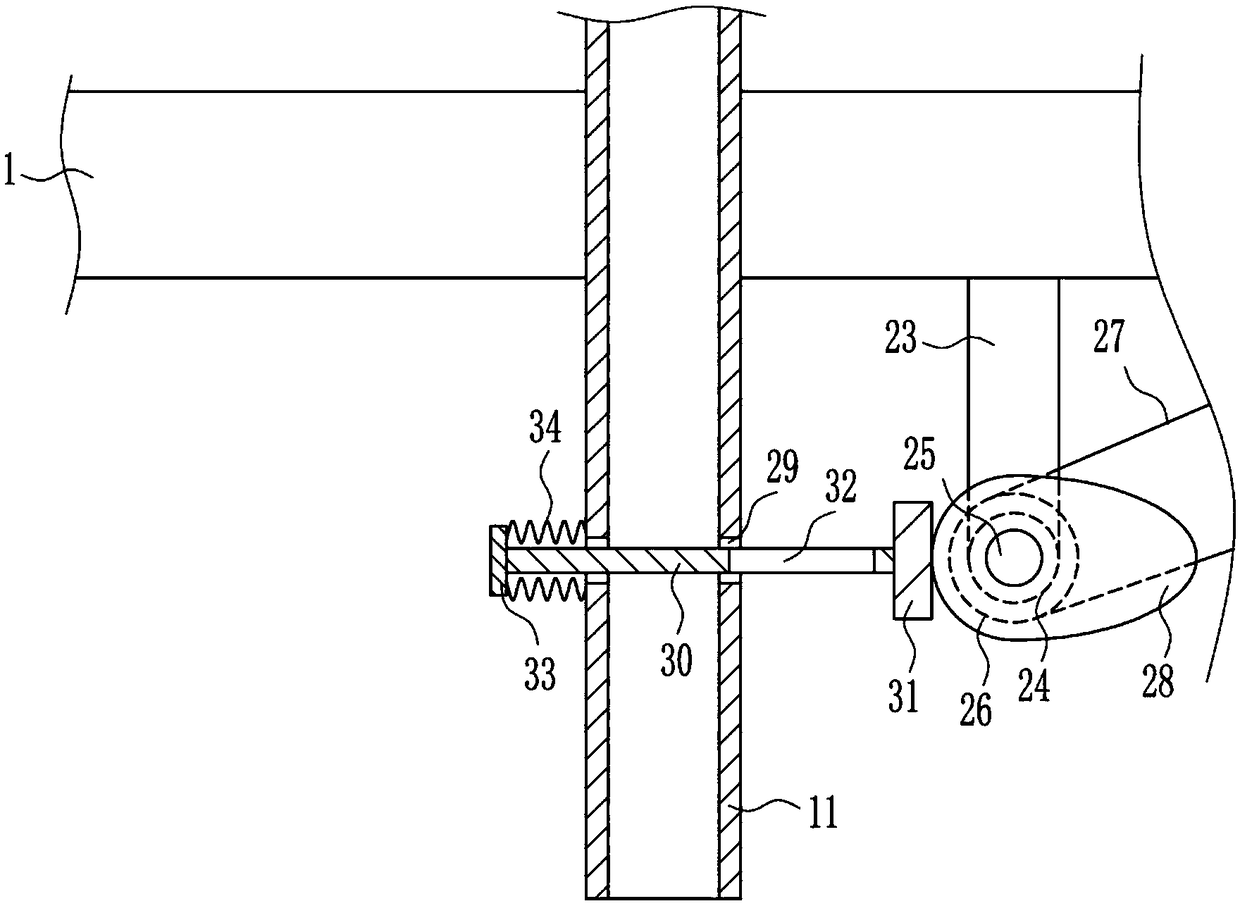

Intelligent pipeline type automatic dewaterer for oil tank and pressure tank

InactiveCN101264395AEasy to installWon't pile upLarge containersNon-miscible liquid separationTemperature controlHoneycomb

The invention discloses a smart pipeline type automatic dehydrator of the oil tank and pressure pot, comprising an entrance flange, an outlet flange, a honeycomb duct, a major detecting controller, a minor detecting controller, a major filter, a minor filter, a vapor pipe, a temperature controller, an adjusting valve and a drain-trap. The entrance flange of the honeycomb duct is connected with the spot oil tank, and the outlet flange is connected with the adjusting valve; the sensors of the major and minor detecting controllers are respectively connected with the honeycomb duct, and the major and minor filters are respectively covered on the sensors of the major and minor detecting controllers, the signal outputs of the major and minor detecting controllers are connected with the adjusting valve. Because the dehydrator is connected with the oil tank by the mounting flange, when the size is not suitable, the problem can be solved by adding a converting joint, and the mounting is very convenient. Meanwhile the honeycomb duct adopts a streamline structure, and completely without circulation dead angle. While dehydration, the solid impurity settled in the bottom medium of the dehydrator can be discharged with water without budget in the dehydrator, and the invention has a self rinsing function, and does not need periodical rinsing. The invention is suitable for the automatic dehydration field of oil tank, liquefied gas tank and pressure storage tank of chemical product.

Owner:四川大成涡轮设备再制造技术有限公司

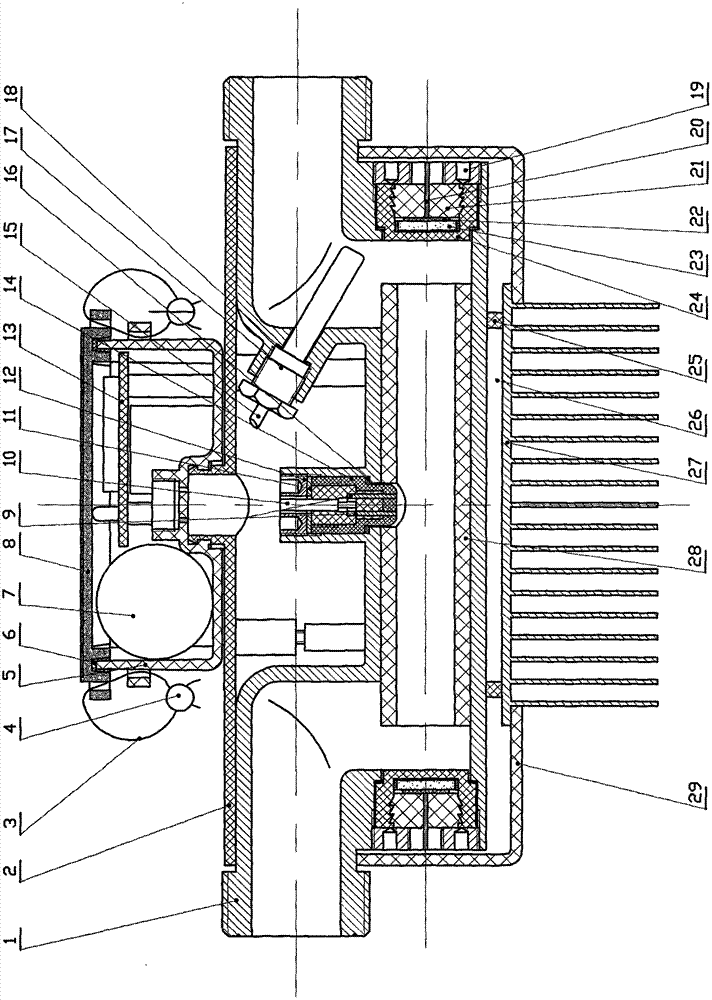

Closed type ultrasonic wave water and heat meter

ActiveCN102788617AIncreased propagation time differenceIncrease water velocityVolume/mass flow measurementCalorimeterElectricityTemperature difference

The invention discloses a closed type ultrasonic wave water and heat meter. In the water and heat meter, a meter shell (1) is formed to be in the shape of a similar U-tube; a through horizontal pipe is horizontally arranged at the bottom of the U-tube and parallel to a water inlet / outlet pipe; a speed measuring pipe (28) is inserted in the through horizontal pipe; ultrasonic transducer assemblies are mounted on two ends of the through horizontal pipe; a level and electrode assembly is filled in a side through pipe of the through horizontal pipe; one or more groups of semiconductor temperature difference electricity generating pieces (26) are fixed on the outer side of the through horizontal pipe; radiators (27) are adhered onto the semiconductor temperature difference electricity generating pieces; an upper meter shell cover (2) and a lower meter shell cover are used to close a signal measuring basic meter; a control circuit board (13) and a power supply battery (7) are fixed in an electronic seal box (5) with an opening; a trough-shaped seal ring (6) is mounted on the opening edge of the electronic seal box (5); and the control circuit board (13) and the power supply battery (7) are completely sealed in the electronic seal box (5) via a wedge-shaped sided sealing top cap (8) under the stress of a screw.

Owner:湖南常德牌水表制造有限公司

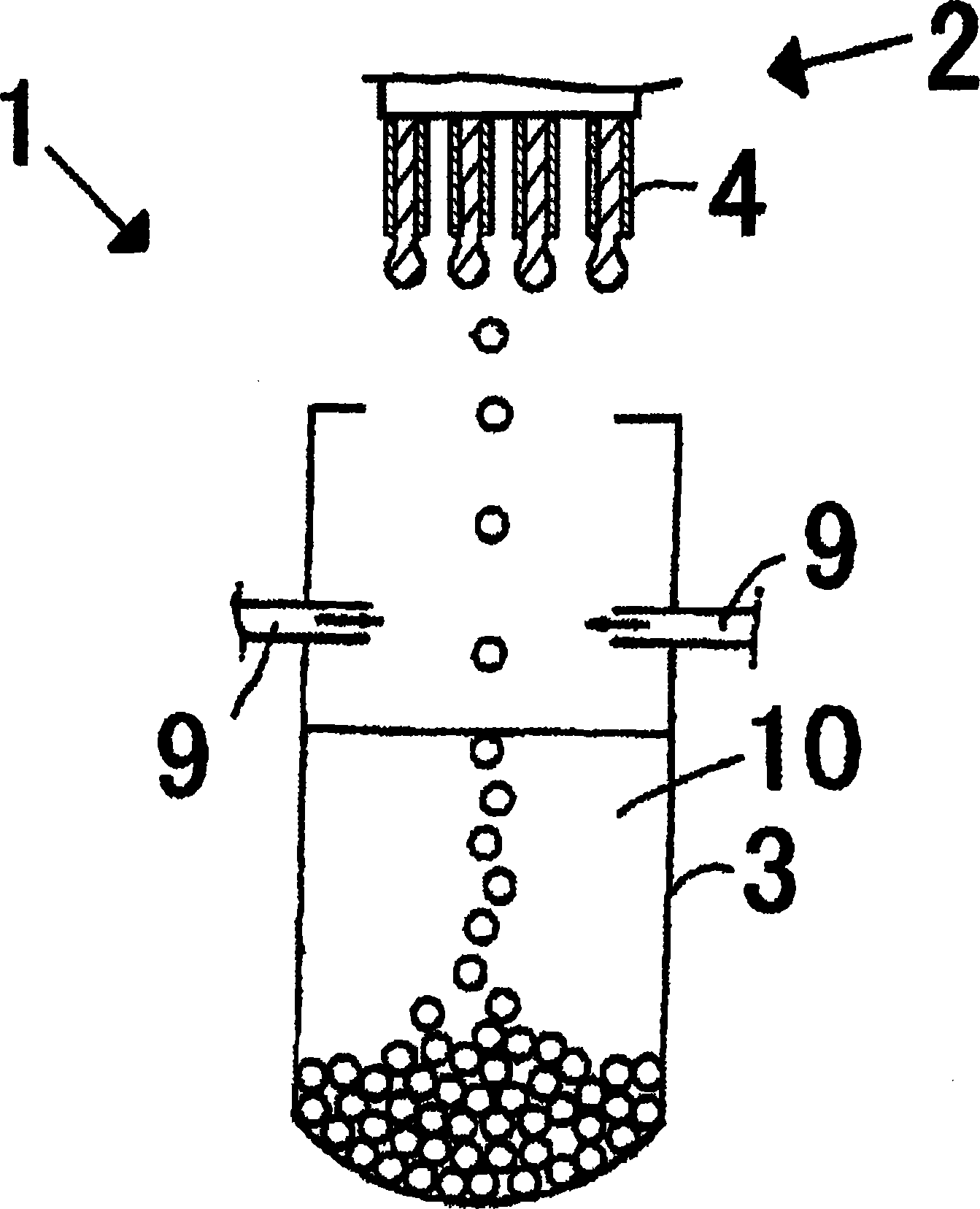

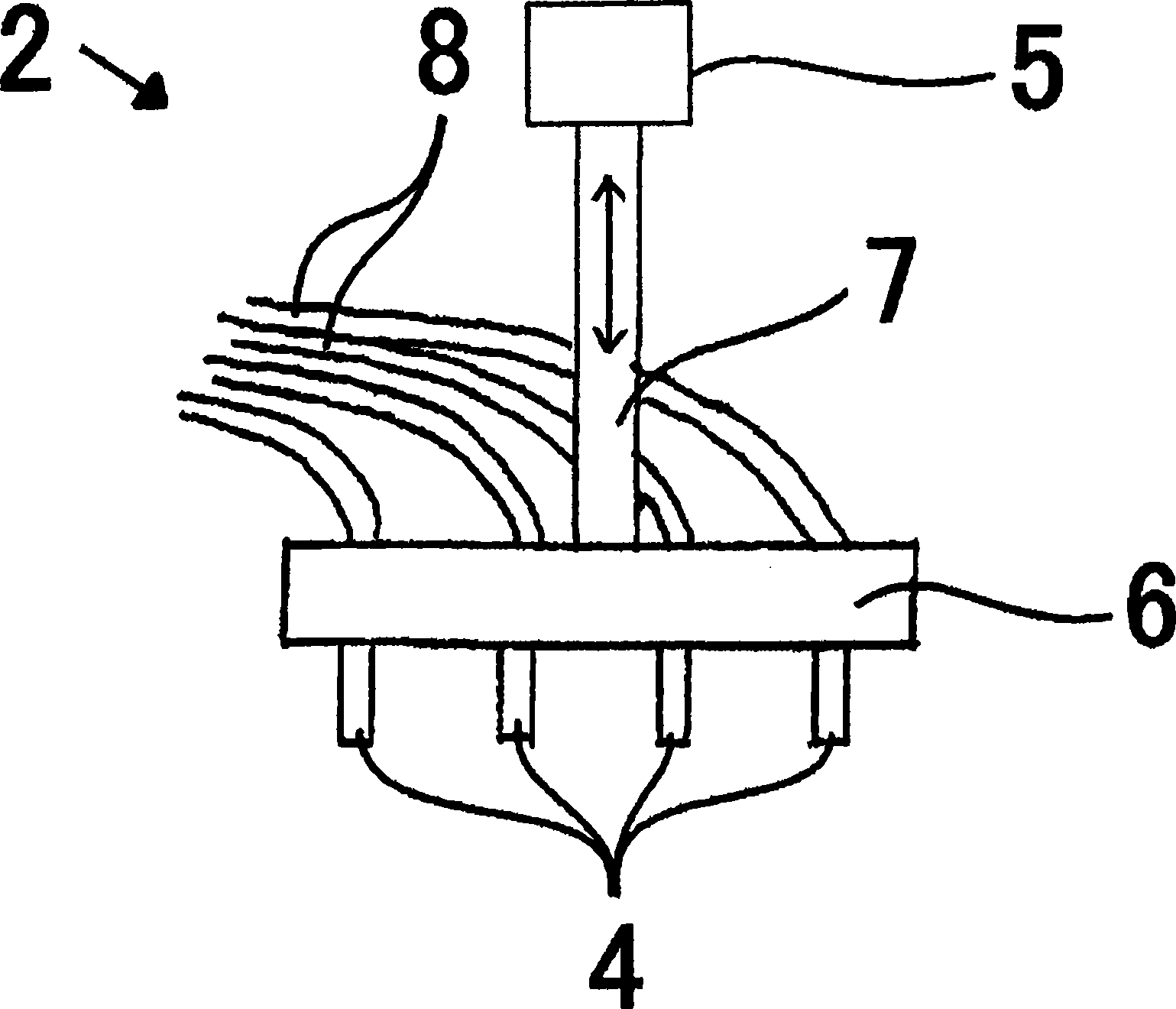

Dropping nozzle device, device for recovering dropping undiluted solution, device for supplying dropping undiluted solution, device for solidifying surface of droplet, device for circulating aqueous a

InactiveCN1867516AEasy to manufactureHigh degree of sphericityNuclear energy generationReactors manufactureEngineeringAmmonium diuranate

The object of the present invention is to provide the following devices: a dripping nozzle device that forms substantially spherical ADU particles, a dripping stock solution recovery device that prepares a homogeneous dripping stock solution, a dripping stock solution supply device that can drop liquid droplets of a uniform volume, and even liquid droplets Droplet surface solidification device that does not deform when it collides with the surface of ammonia solution when dropped, ammonia solution circulation device that can fully turn uranyl nitrate into ADU from the center of the droplet, and ADU with good sphericity The ADU particle manufacturing device for particles, the dripping nozzle device has an exciter that vibrates multiple nozzles at the same time, the dripping stock solution recovery device recovers the bottom fine stock solution in the nozzle and mixes it into the dripping stock solution, and the dripping stock solution supply device has a mechanism for falling The light irradiation mechanism that irradiates the droplet of the original solution with light, the droplet surface curing device sprays ammonia gas toward the drop path of the droplet of the original solution dripped from the nozzle, and the ammonia solution circulation device can make the droplets in the ammonia solution storage tank The ammonium diuranate particle manufacturing device uses the above-mentioned device for ascending flow in the ammonia solution in the interior.

Owner:NUCLEAR FUEL INDS

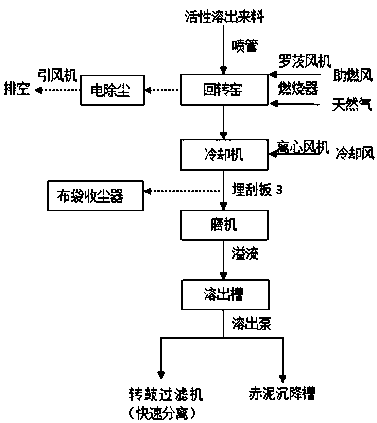

Method for treating inert aluminum ash in aluminum ash treatment technology

InactiveCN108640137AWon't pile upSafe and efficient handlingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFlue gasSlurry

The invention discloses a method for treating inert aluminum ash in an aluminum ash treatment technology. A mixture of aluminum ash and raw slurry is fired through a rotary kiln, is cooled through a cooling machine and is finally subjected to clinker leaching in a ball grinding mill in sequence. A device provided by the invention can be used for safely and efficiently treating the inert aluminum ash in the aluminum ash; lime milk is prepared and reacts with F<-> to generate CaF2, so that harmful elements and harms caused by the fact that the F<-> enter flue gas are eliminated; meanwhile, organic matters accumulated by a Bayer process can be treated. The rotary kiln is arranged and materials with different grain diameters can be uniformly mixed; the calcination efficiency and effect are improved.

Owner:YUNNAN WENSHAN ALUMINUM

Vacuum nano-electroplating waterproof breathable fabric and production process thereof

InactiveCN109367184AFunctionalNo structural damageBiochemical fibre treatmentSynthetic resin layered productsEnvironmentally friendlyEnvironmental resistance

The invention discloses a vacuum nano-electroplating waterproof breathable fabric and a production process thereof. The fabric comprises a fabric base material, a high-density waterproof layer and a nano-water-repellent plating layer, the high-density waterproof layer is combined with the surface of the fabric base material by a hot-pressing and compounding mode, a nano-water-repellent plating layer film is deposited on the high-density waterproof layer by a vacuum nano-film coating mode, and the surface of the nano-water-repellent plating layer can have 10-15 dynes. The fabric is treated by the aid of a vacuum nano-film coating technique, so that the fabric has better waterproof and hydrophobic functions, original characteristics (heat retention, breathability, comfort, portability and the like) of the fabric can be effectively kept, nano-scale film coating is implemented, dosage of materials is less, the fabric can be prepared from low-cost materials and has the advantages of low cost, adverse by-products are omitted in the whole treatment process, the fabric is green and environmentally friendly, and film layers are stable and not easy to decompose.

Owner:东莞市和域战士纳米科技有限公司

Device for treating household garbage

The invention discloses a device for treating household garbage. The device comprises an outer shell, an inner shell, a box, a first connecting pipe, a first baffle plate, a first moving piece, a second moving piece, a second baffle plate, a forward magnetostrictive film, a reverse magnetostrictive film, a coil, a first one-way film, a second one-way film and multiple cooling pipes; the inner shell is positioned on the inner side of the outer shell; a combustion cavity is formed in the inner shell; a feeding port is formed in the top wall of the inner shell; a first exhaust hole is formed in the side wall of the inner shell; the feeding port and the first exhaust hole are both communicated with the combustion cavity; the box is positioned on the outer side of the outer shell; an accommodating cavity is formed in the box; an intake hole and a second exhaust hole are formed in the side wall of the box; a first end of the first connecting pipe is connected with the first exhaust hole, and a second end of the first connecting pipe is connected with the intake hole; the first baffle plate is positioned in the accommodating cavity for dividing the accommodating cavity into a first abdominal cavity and a second abdominal cavity; and an exhaust hole is formed in the first baffle plate. The device is excellent in garbage treatment effect.

Owner:湖南未名环保科技有限公司

Brazing method for turbine rotor assembly of engine

The invention provides a brazing method for a turbine rotor assembly of an engine, which comprises the following steps: step 2, plating weldable metal on a brazing surface of a turbine rotor disc and a brazing surface of a sealed shaft sleeve; step 4, wrapping flake-like brazing filler metal on the brazing surface of the sealed shaft sleeve; step 6: assembling and coordinating the turbine rotor disc and the sealed shaft sleeve, with a feed tank arranged between the turbine rotor disc and the sealed shaft sleeve; step 8, adding powdered brazing filler metal in the feed tank and a U-shaped groove; step 10, arranging a leakproof fixture for preventing the powdered brazing filler metal from flowing away in the U-shaped groove; step 12, placing the rotor assembly subjected to the step 10 for brazing; and step 14, taking out the rotor assembly subjected to the step 12 for detecting a welding line. According to the brazing method for the turbine rotor assembly of the engine provided by the invention, the leakproof fixture for preventing the powder brazing filter metal from flowing away is arranged in the U-shaped groove, so that the brazing filler metal is prevented from flowing away and is not accumulated randomly after the brazing, and the brazing quality is ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

Valve body with filtering function

ActiveCN110115868AQuality improvementEasy to useValve arrangementsFiltration separationReciprocating motionEngineering

The invention relates to the field of water control valves, in particular to a valve body with a filtering function. The valve body comprises a valve shell, wherein the left and right sides of the valve shell are fixedly provided with a water inlet connecting pipe and a water outlet connecting pipe respectively, the center of the inner portion of the valve shell is rotatably in fixed-axis connection with a rotating shaft, the rotating shaft is fixedly provided with a filter net, the water inlet connecting pipe is connected with an intermittent reciprocating mechanism and is connected with therotating shaft through the intermittent reciprocating mechanism, the lower side of the valve shell is fixedly provided with a discharge pipe, the joint of the discharge pipe and the valve shell is fixedly provided with a brush frame cleaning the filter net, and an outlet end of the discharge pipe is provided with an automatic discharge mechanism. The valve body with the filtering function can automatically perform cleaning, keep the stable discharge value of the filter net and improve the water delivery efficiency so that the water pressure in the valve body can be kept stable in time, therefore, structural parts in the valve body are not damaged by the excessive water pressure, the pipe is also prevented from being broken, automatic discharge can also be achieved, and the time and labor are saved.

Owner:浙江鑫泰阀门科技有限公司

Electrode Boiler Heating Electrode Rod Device

ActiveCN110068001BWon't pile upStable operating parametersElectrode boilersSteam boilers componentsEngineeringElectric current flow

The invention discloses an electrode boiler heating electrode rod device which comprises a conductive rod and an insulating sleeve. The conductive rod is arranged in the insulating sleeve, the electrode boiler heating electrode rod device also comprises an electrode head, the electrode head is a solid-core electrode head, and the electrode head is directly or indirectly fixedly connected with theconductive rod. The electrode boiler heating electrode rod device has the following beneficial effects that the solid-core electrode head is adopted as the electrode head, no space exists in the electrode head, no residual substance is accumulated in the electrode head, and stable operation parameters of an electric boiler during operation are guaranteed; and meanwhile, grooves are formed in the outer wall surface of the electrode head, so that the contact area between the electrode head and water is enlarged, the resistance between the electrode head and water is increased, the surface current of the electrode head is reduced, and the safety factor of the electrode head is increased.

Owner:ZHEJIANG SHANGNENG BOILER

Special processing equipment for lining

ActiveCN103978231ADischarge in timeWon't pile upChucksMetal working apparatusEngineeringAutomatic processing

The invention discloses special processing equipment for a lining. The special processing equipment is characterized by consisting of a processing part and a feeding part, wherein the processing part comprises a body, a main shaft, an elastic chuck, a hollow rotating cylinder, a large carriage, a small carriage, a central rack and a tail rack, wherein the main shaft is driven by a belt pulley; the large carriage is arranged on the right side of a main shaft box in a manner of sliding left and right; the small carriage is arranged on the large carriage in a manner of sliding back and forth; the central rack and the tail rack are arranged on the large carriage; the elastic chuck consists of a clamping base with an inner cone and a clamping jaw with an outer cone; the clamping base is fixedly arranged on the head of the main shaft; the clamping jaw is axially movably arranged in the inner hole of the clamping base and connected with a hollow pull rod; the other end of the hollow pull rod is connected with the hollow rotating cylinder; the hollow rotating cylinder is fixedly arranged on the belt pulley; the feeding part comprises a feeding part and a material push plate; the feeding pipe is provided with a pipe cavity capable of accommodating a long rod material; the material push plate is movably arranged in the pipe cavity of the feeding pipe. The special processing equipment can be used for realizing automatic processing of the lining, is convenient in feeding, and can be used for improving the working efficiency and lowering the production cost.

Owner:浙江聚利电动工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com