Grinding medium sorting device of grinding machine

A technology of sorting device and grinding body, which is applied in the direction of solid separation, classification, chemical instruments and methods, etc., can solve the problems of low sorting efficiency, long mill downtime, and high labor intensity of workers, and achieve high sorting efficiency , Save the time of clearance and reduce the time of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

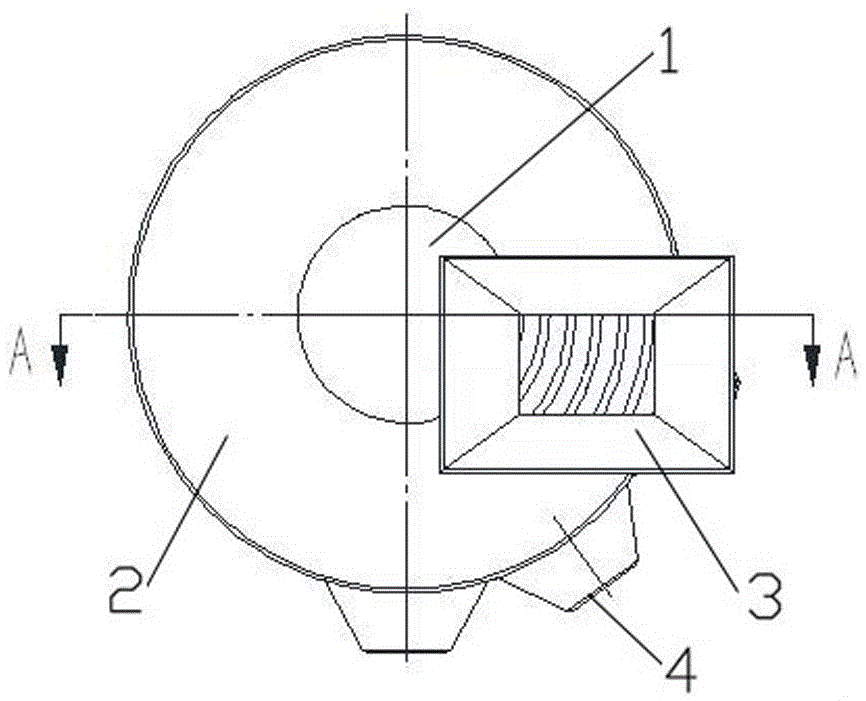

[0024] Such as Figure 1 to Figure 7 The shown ball mill grinding body sorting device includes a support center column 1, a spiral grinding body passage 2 for spherical grinding bodies to pass through and a plurality of screening assemblies arranged in the grinding body passage 2, and the support center column 1 Run through the grinding body channel 2 up and down along the centerline of the grinding body channel 2, and is used to support the grinding body channel 2. The top of the grinding body channel 2 is provided with a ball inlet 3, and the bottom is provided with ball outlets 4 equal in number to the screening assembly , each ball outlet 4 communicates with the tail of a screening assembly, the plurality of screening assemblies are arranged at intervals from top to bottom, and the screen from the top screening assembly to the penultimat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com