Special processing equipment for lining

A technology of processing equipment and bushing, which is applied in the field of processing equipment for bushing processing, and can solve the problems of high production cost and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

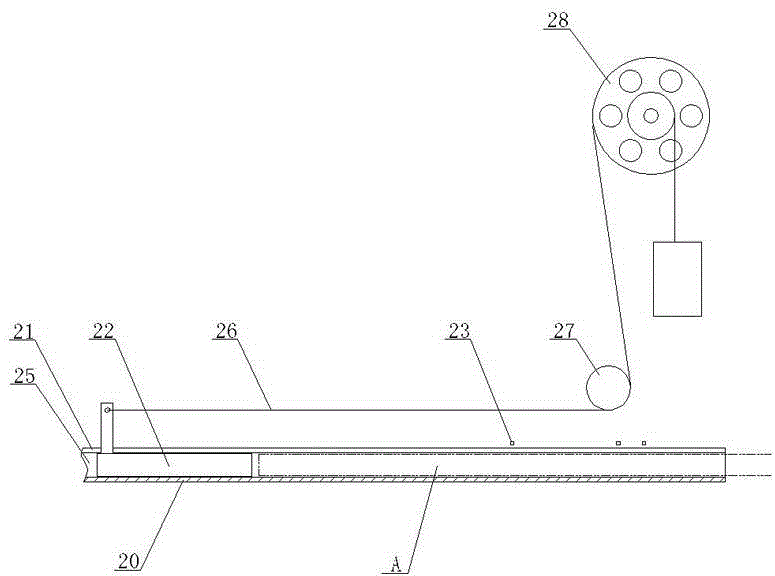

[0016] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0017] As shown in the figure, the special bushing processing equipment of the present invention is used for processing Figure 5 As shown in the bushing, the bushing is a long bar material A cut into sections and machined with an inner hole and an outer ring groove. The special processing equipment for the bushing is composed of a processing part and a feeding part. The processing part includes the body 1, the main shaft 4, and the elastic clip. head (composed of clamp seat 7 with inner cone and jaw 8 with outer cone), hollow rotary cylinder 2, large carriage 14, small carriage 13, center frame 9 and tailstock 15, the main shaft 4 has a front and rear through The main shaft inner hole 4a, the main shaft 4 is rotated in the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com