Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "Won't condense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

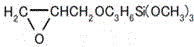

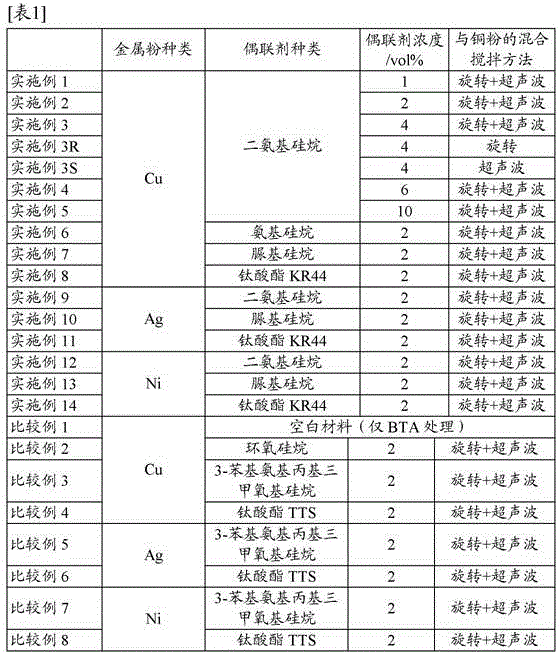

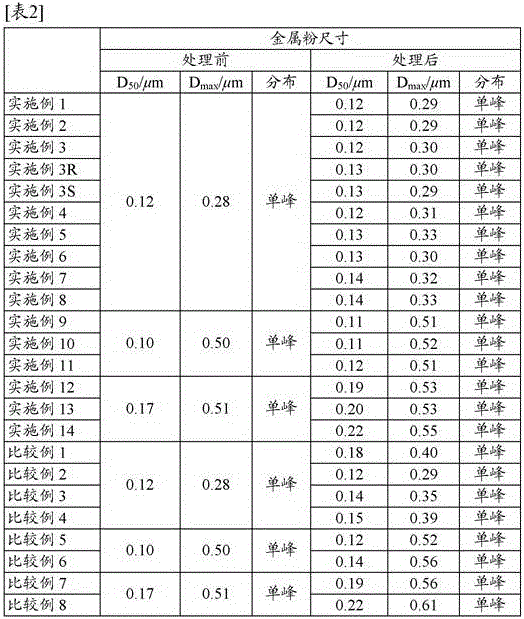

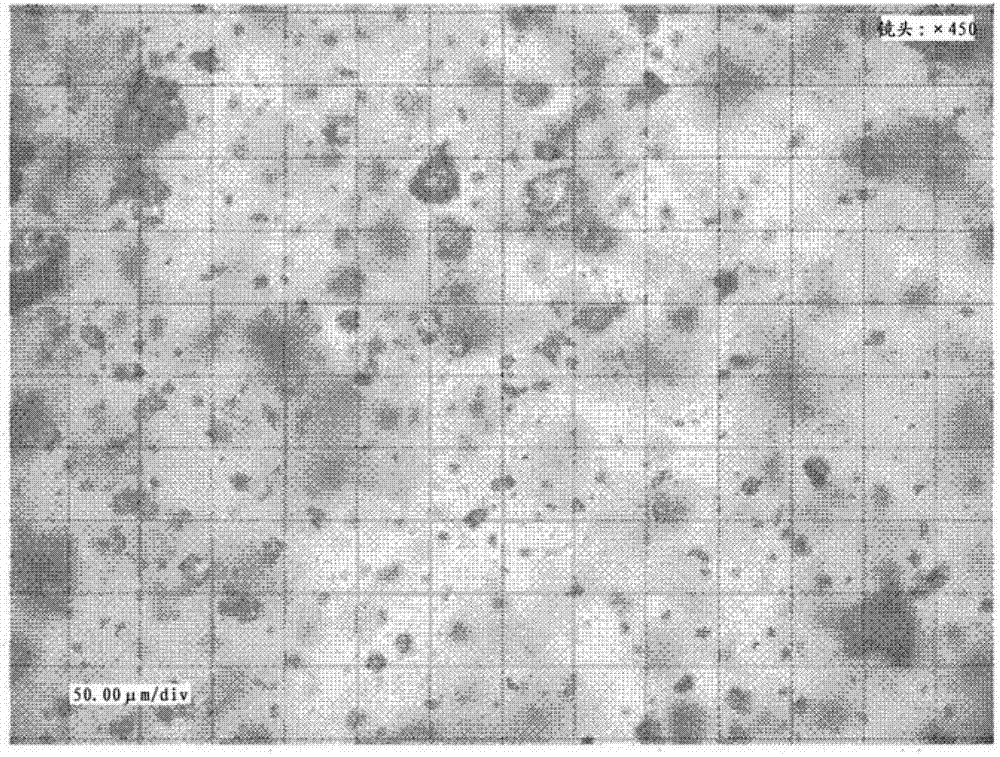

Metal powder paste and method for producing same

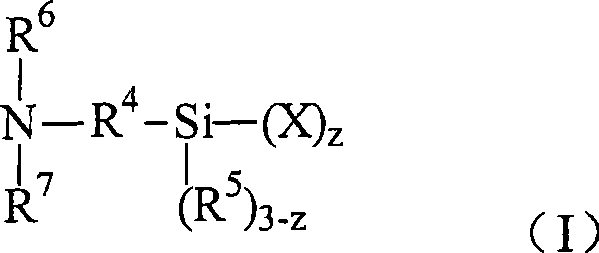

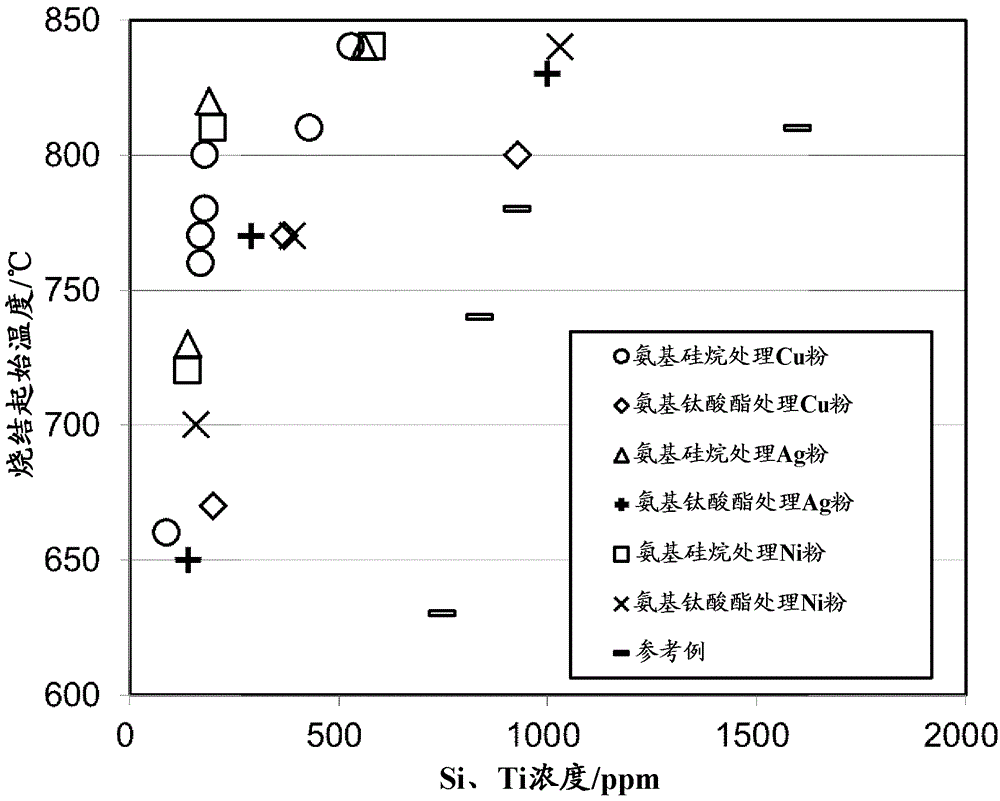

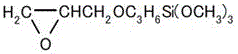

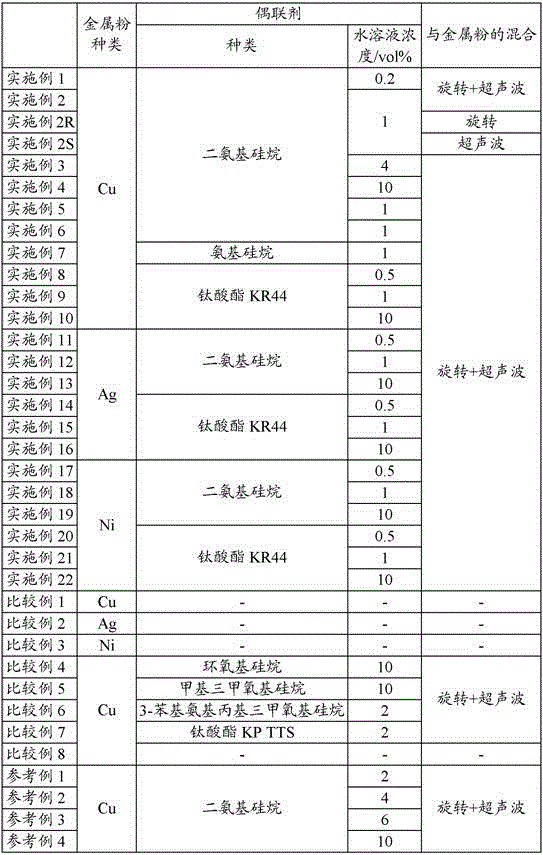

ActiveCN105612014AGood dispersionExcellent sintering delayTransportation and packagingFixed capacitor dielectricMetallurgyCeramic capacitor

A method for producing a surface-treated metal powder, which comprises: a step for preparing a metal powder dispersion liquid by mixing a metal powder with an aqueous solution of a coupling agent having an amino group; a step for recovering, as a residue, the metal powder from the metal powder dispersion liquid; and a step for cleaning the metal powder, which has been recovered as a residue, with use of an aqueous solvent. This method for producing a surface-treated metal powder provides a method for producing a surface-treated copper powder or metal powder which has excellent sintering delaying properties and is suitable for use in the production of an electrode for multilayer ceramic chip capacitors.

Owner:JX NIPPON MINING & METALS CORP

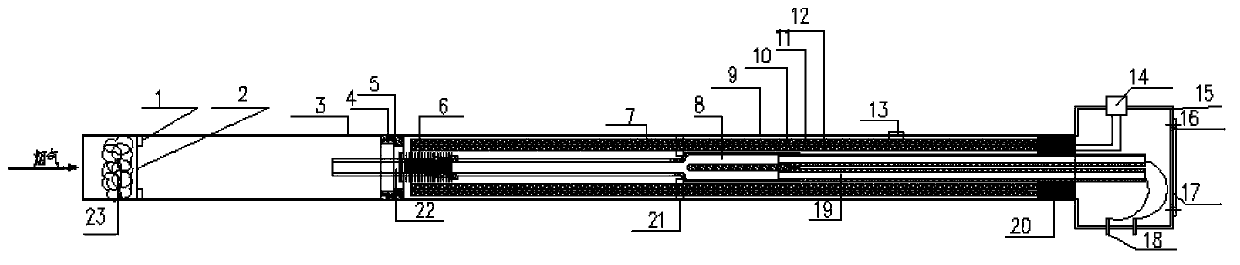

Flue gas mercury sampling gun for thermal power plant

ActiveCN103424285AWon't condenseImprove accuracyWithdrawing sample devicesPreparing sample for investigationActivated carbonSteam condensation

A flue gas mercury sampling gun for a thermal power plant comprises a stainless steel sleeve and a stainless steel shell. The stainless steel shell is disposed at the rear end of the stainless steel sleeve and provided with an end cover. A front non-heating exploring tube is detachably connected to the front end of the stainless steel sleeve. A quartz tube which is filed with activated carbon and provided with openings at two ends is disposed in the stainless steel sleeve. A heating layer is disposed between the quartz tube and the stainless steel sleeve. The front end of the quartz tube extends into the front non-heating exploring tube, and the rear end thereof is communicated with a tower mouth disposed on the stainless steel shell. The sampling gun is telescopic, multipoint sampling at low cost is achieved, and on-site operation procedures are reduced. By the heating layer, gasified mercury sedimentation caused by temperature lowering can be prevented, sampling gun inner wall corrosion caused by steam condensation can also be prevented, and sampling accuracy is increased.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

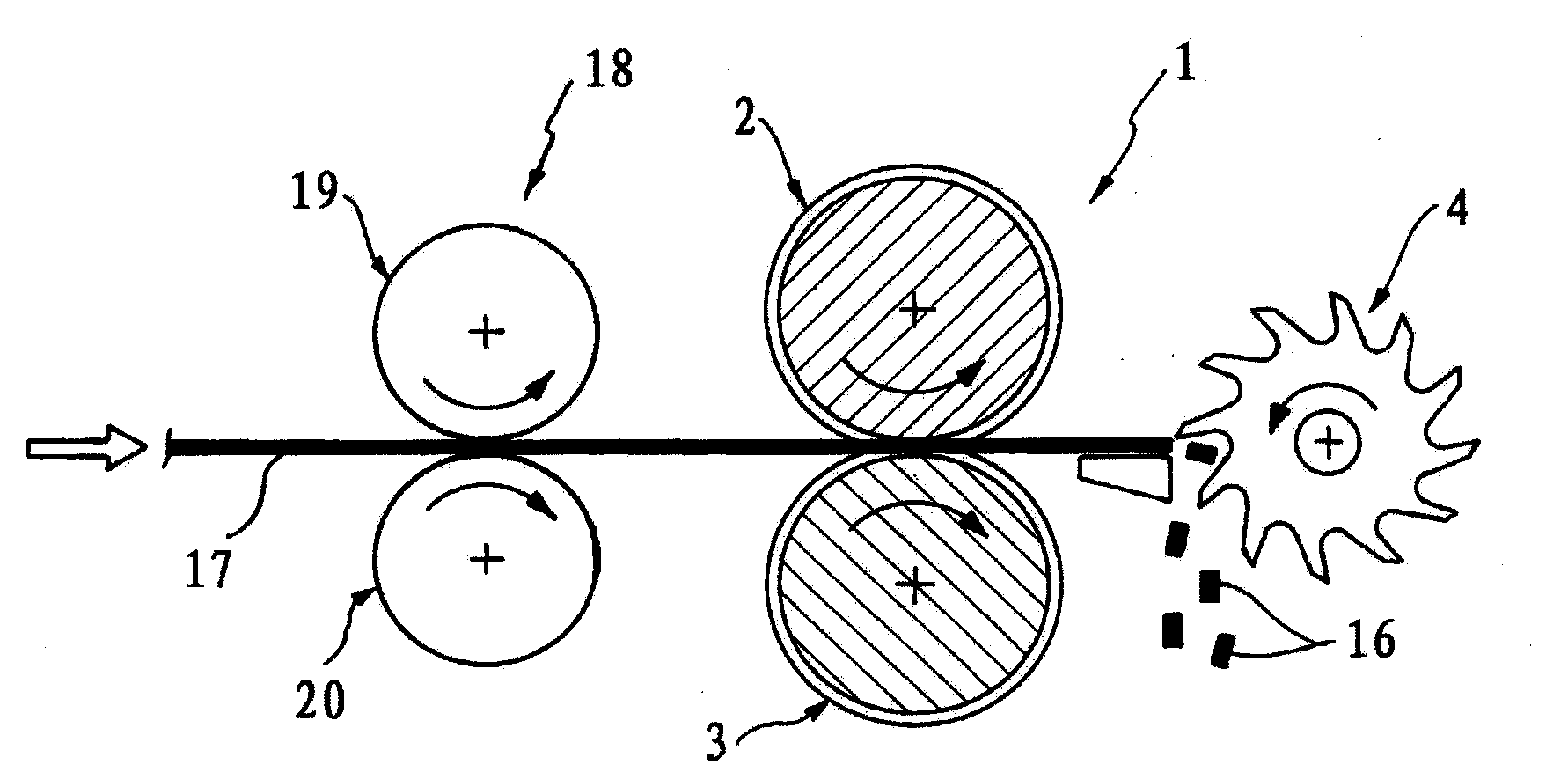

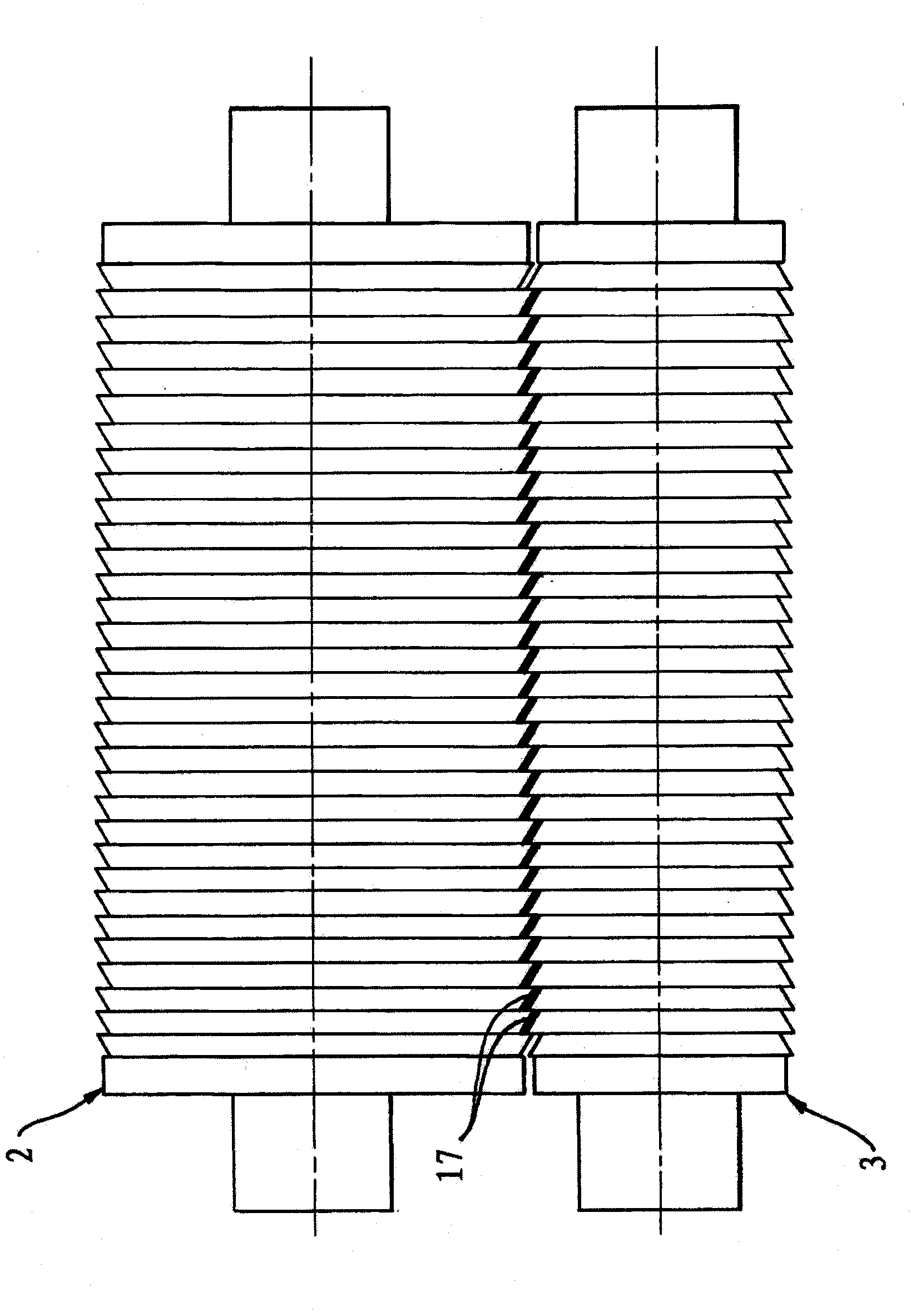

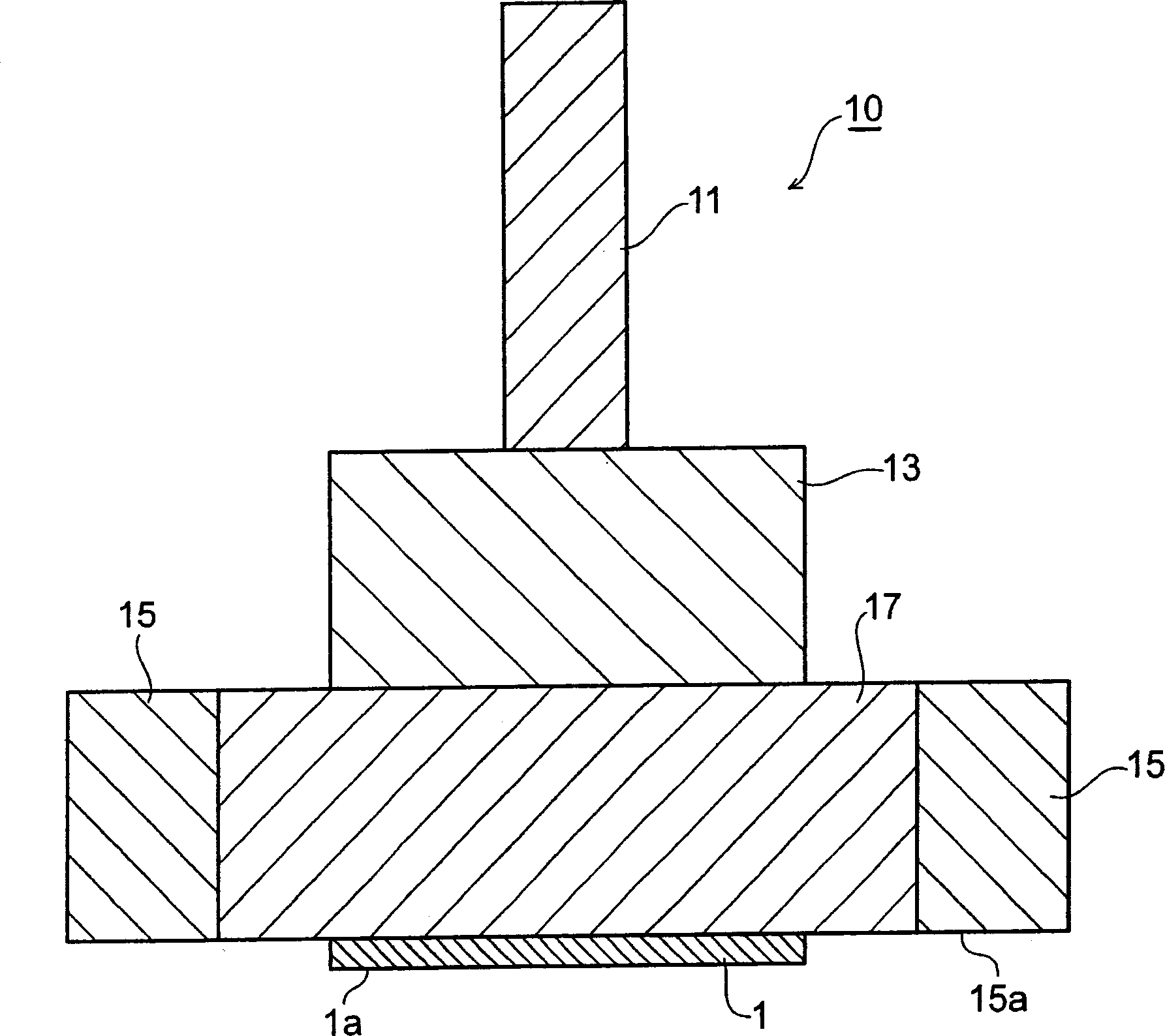

Comminution device for the production of particles from a strip-shaped material

InactiveCN102046294AFavorable resharpening effectReliable feedingGrain treatmentsMetal working apparatusEngineeringComminution

The invention relates to a comminution device for the production of particles (16) from a strip-shaped material (17), said device comprising a longitudinal cutting device (1) having a first cutting roller (2) and having a second cutting roller (3), and a transverse cutting device (4), which is disposed downstream from the longitudinal cutting device (1), wherein the first cutting roller (2) and the second cutting roller (3) each have special profiles according to the invention.

Owner:AUTOMATIK PLASTICS MASCH GMBH

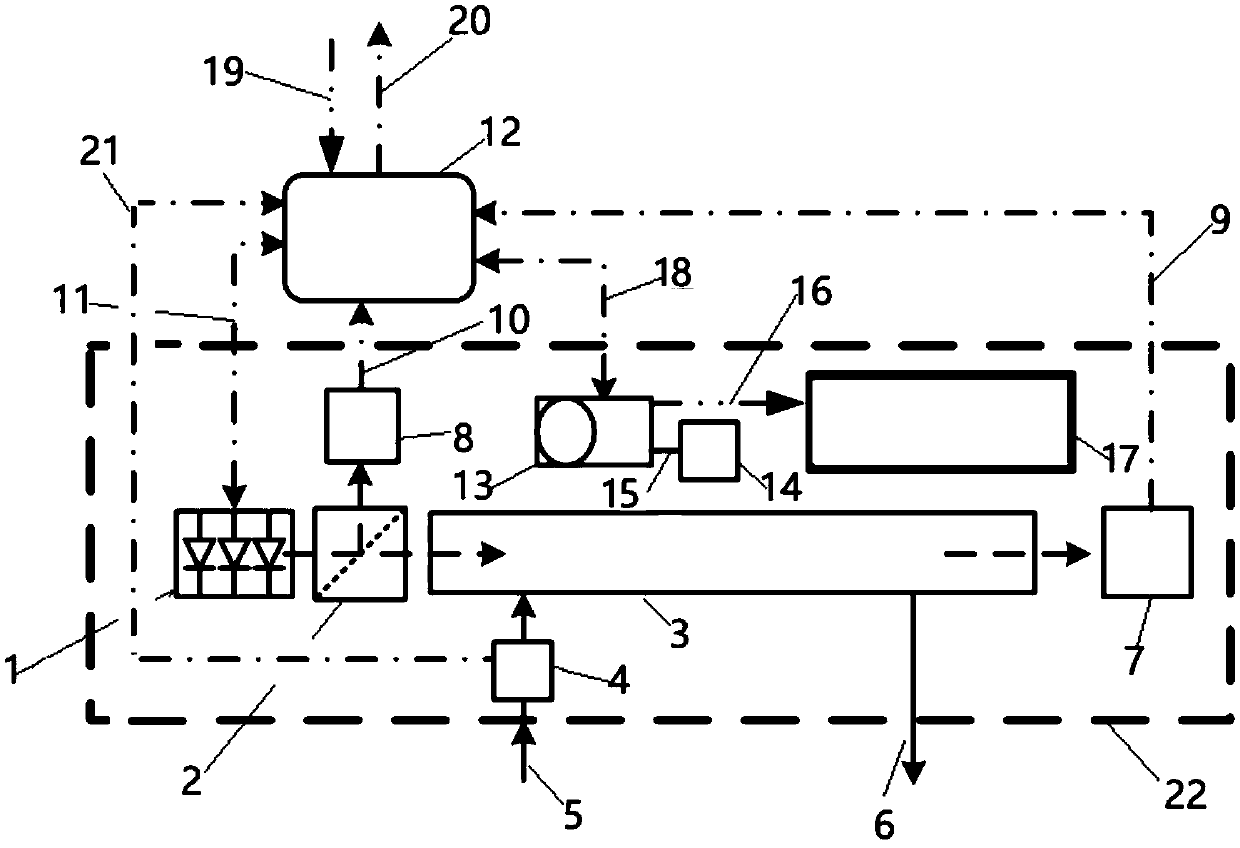

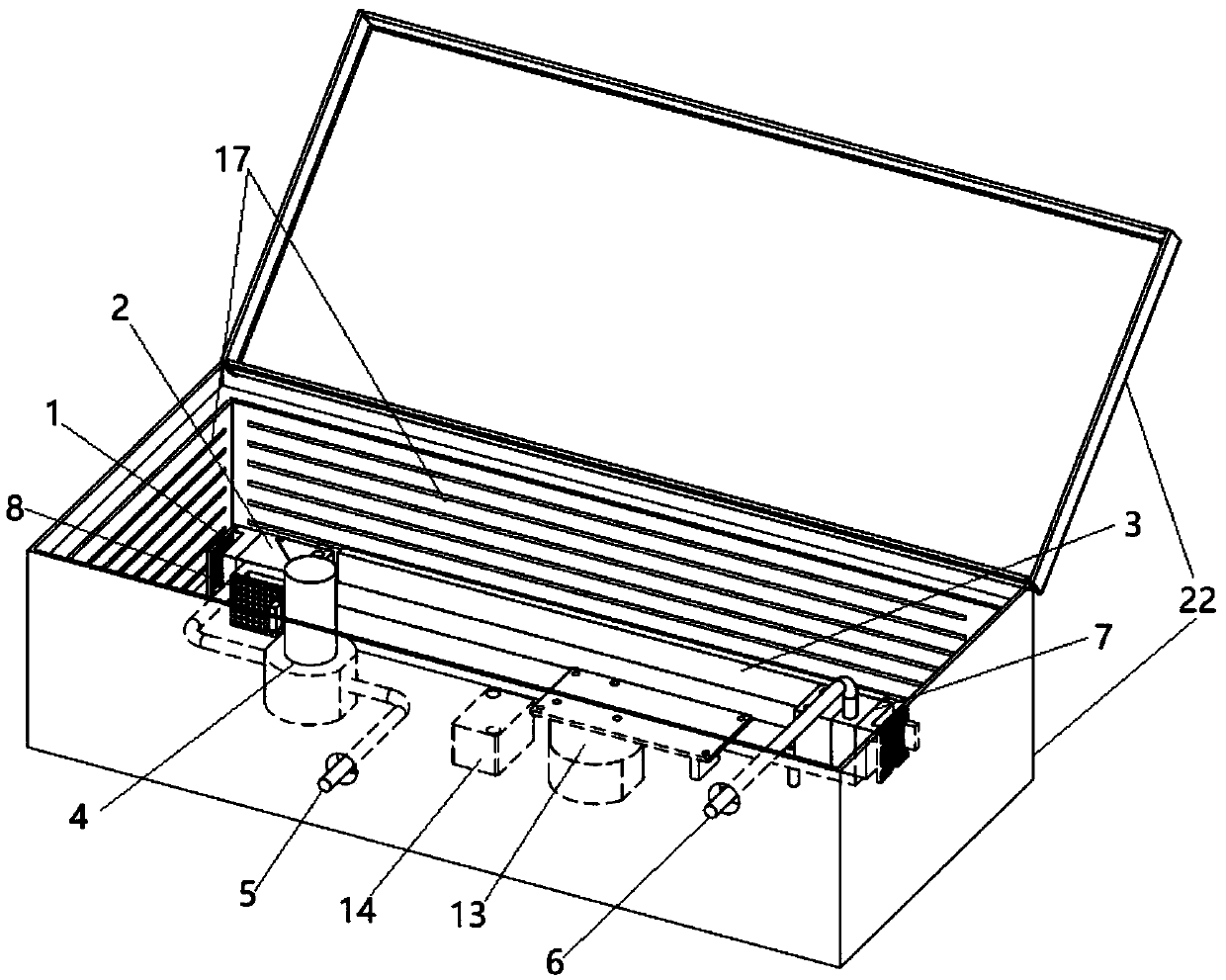

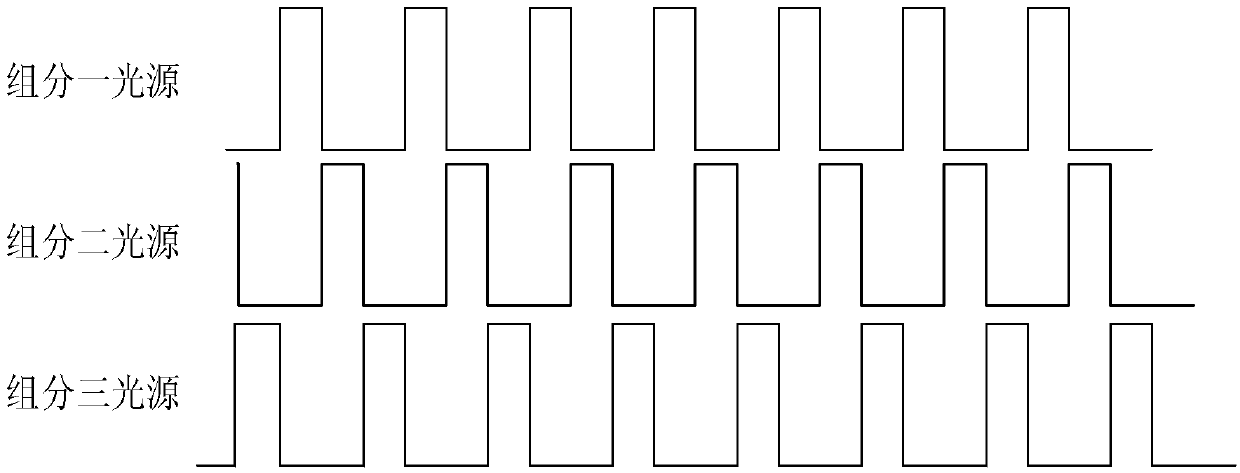

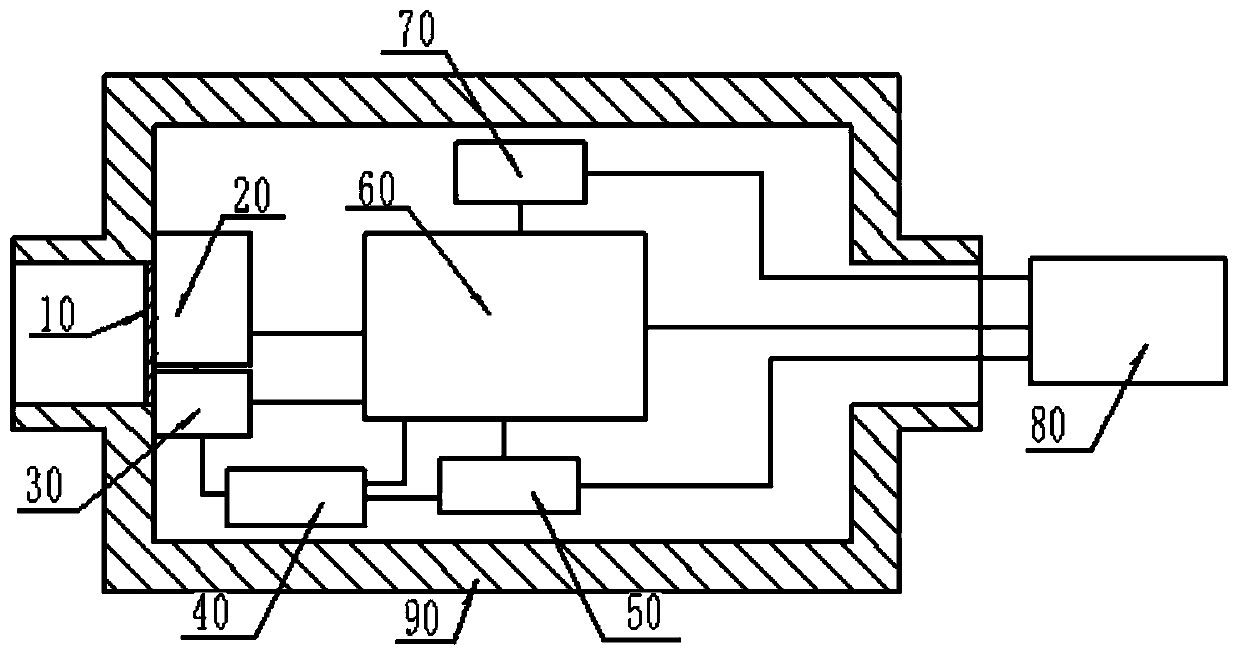

Gas concentration analyzing device and measurement equipment thereof and analyzing method

PendingCN109655423AExtended service lifeSmall signal driftColor/spectral properties measurementsTest sampleFunctional Relationship

The invention discloses measurement equipment for a gas concentration analyzing device, the gas concentration analyzing device, a gas concentration calibration method and analyzing method. The measurement equipment comprises a light source, an optical beam splitter, a measurement light pool, a measurement terminal detector and a reference terminal detector. The measurement light pool is used for storage of to-be-tested sample gas; the measurement terminal detector is used for measuring first light intensity of a first light beam passing through the measurement light pool, wherein the first light beam is formed by a light beam, emitted by a measurement light source, passing through the optical beam splitter. The reference terminal detector is used for measuring second light intensity of a second light beam, emitted by the light source, passing through the optical beam splitter. A functional relationship or a curvilinear relationship between the first light intensity and the second lightintensity is calculated according to the Lambert-Beer law to further obtain concentration of target to-be-tested gas in the sample gas.

Owner:南京木达环保科技有限公司

Deodorizing and sterilizing AB agent

InactiveCN110810434APrevent regenerationPlay a role in deodorizationBiocideGas treatmentOrganic acidChlorine dioxide

The invention discloses a deodorizing and sterilizing AB agent which comprises an A agent and an B agent which are used in a matched mode, wherein active components of the A agent include one or moreof organic acid zinc salts, and active components of the B agent include one or more of organosilicon quaternary ammonium salt, chlorine dioxide, cinnamic aldehyde, methyl ammonium salt and a nano-silver compound. Activated zinc ions in the A agent can generate bonding reaction with atoms of nitrogen, sulfur and the like in odor, so that the deodorization effect is achieved; and the A agent is used for deodorization treatment and then the B agent is used for sterilization operation, and the effect of inhibiting odor regeneration can be achieved.

Owner:GUANGZHOU BOXENERGY TECH

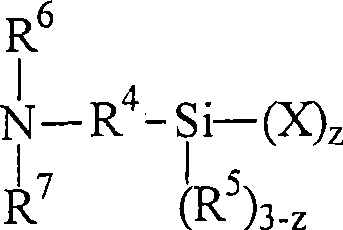

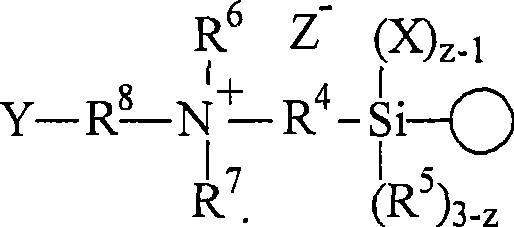

Method for nanoparticle surface modification

InactiveCN101511723AOvercome solubilityOvercoming reactivityMaterial nanotechnologyNanostructure manufactureNanoparticleOne-pot synthesis

The present disclosure discloses a method for making surface-modified nanoparticles. The surface of a nanoparticle is modified with an aminorganosilane and an alkylating agent in a one-pot synthesis to provide alkylamine surface-modified nanoparticles.

Owner:3M INNOVATIVE PROPERTIES CO

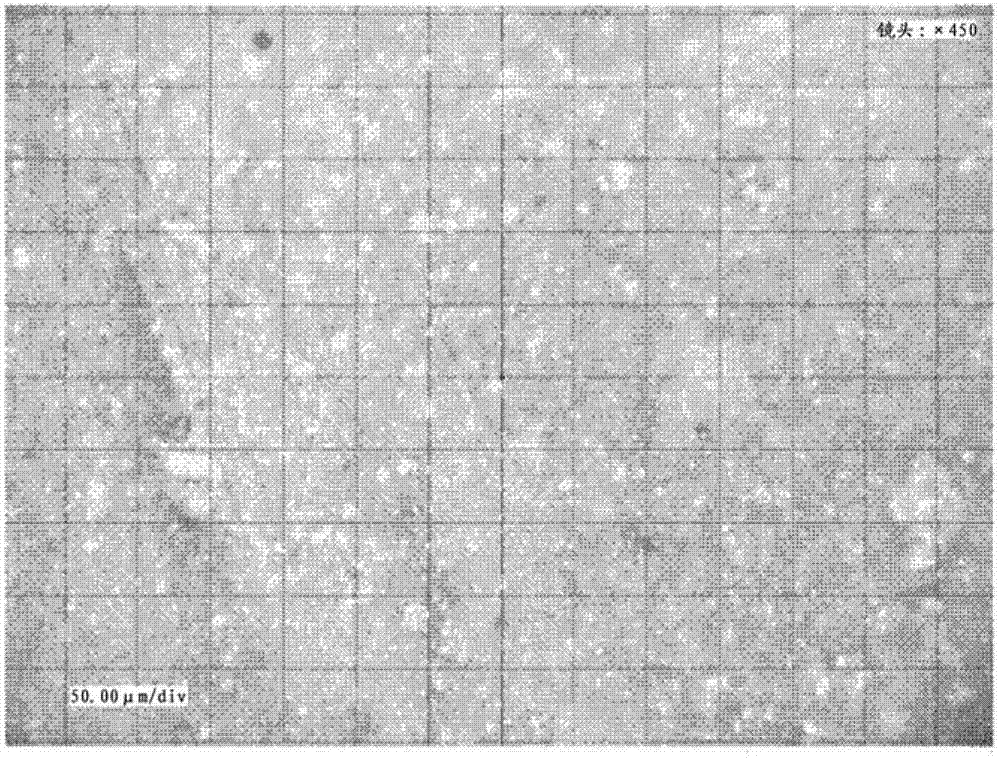

Surface-treated metal powder, and method for producing same

ActiveCN105722625AWon't condenseExcellent sintering delayNon-insulated conductorsFixed capacitor electrodesMetallurgyCeramic capacitor

Owner:JX NIPPON MINING & METALS CORP

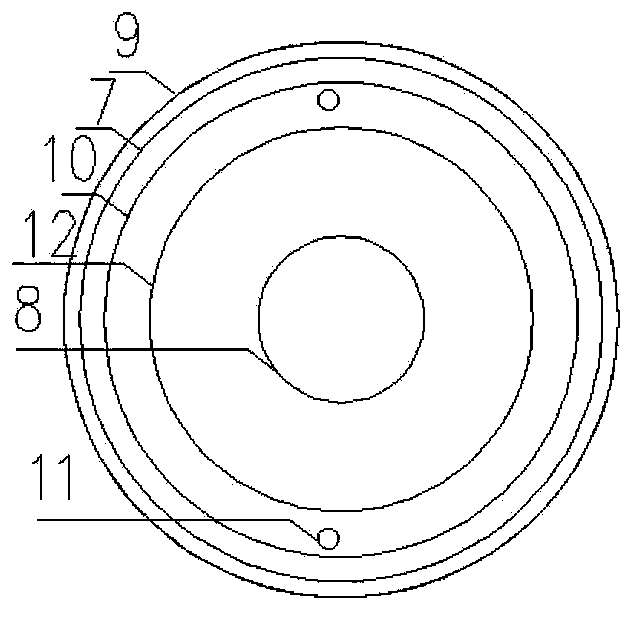

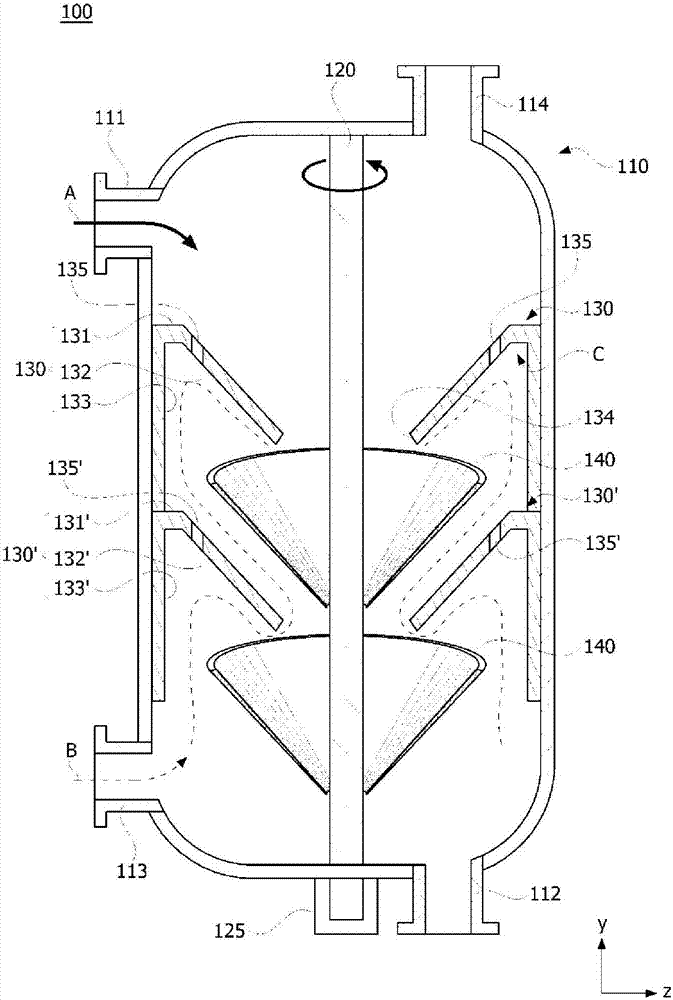

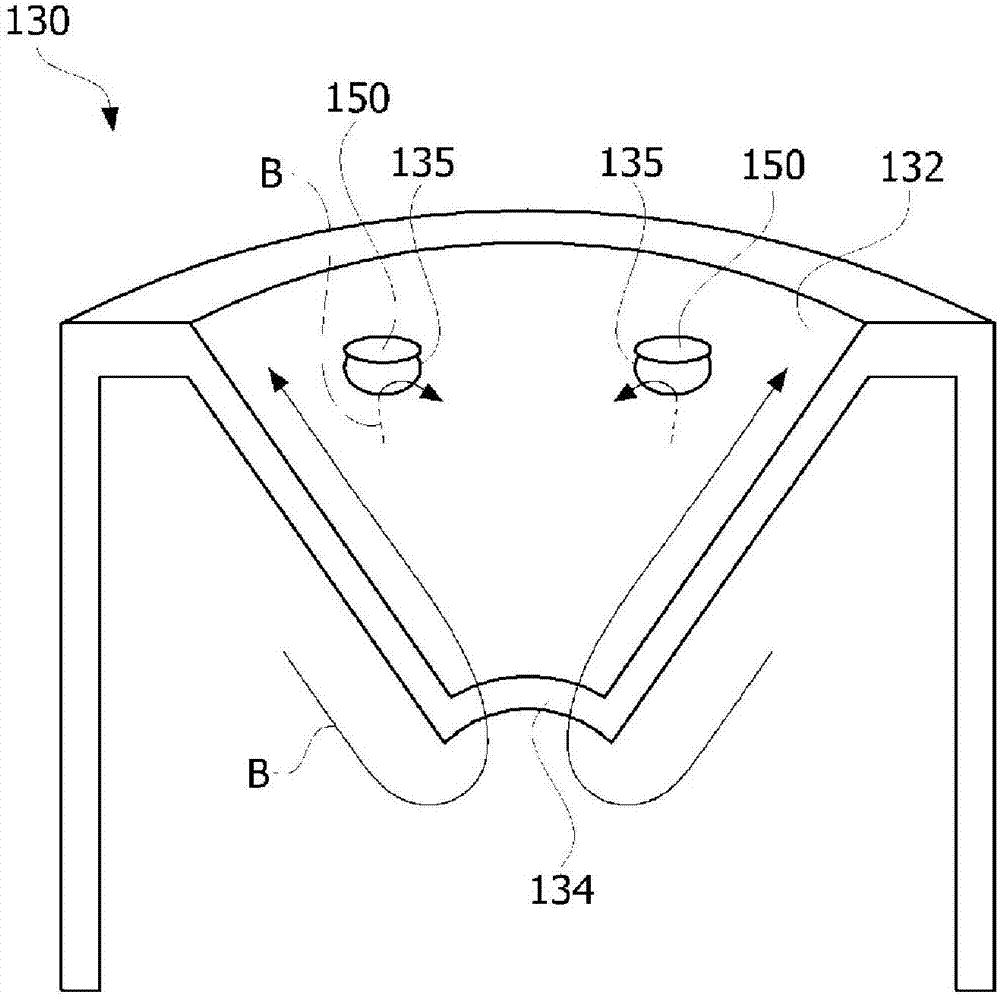

Gas-liquid separation device

ActiveCN106999801ASmooth flow toReduce concentrationLiquid degasification with auxillary substancesDispersed particle separationVapor–liquid separatorEngineering

The present invention relates to a gas-liquid separation device. One aspect of the present invention provides a gas-liquid separation device comprising: a housing provided with a first supply part and a second supply part; a rotation shaft which is rotatably provided to the housing; a driving unit for rotating the rotation shaft; a fixed cone which is placed inside the housing, includes an inclined area, the diameter of which decreases from the first supply part side to the second supply part side, and is provided with a first through-hole, through which the rotation shaft passes, and at least one second through-hole for passing a second fluid introduced through the second supply part; and a rotation cone which is placed inside the housing so as to be spaced apart from the fixed cone, and is mounted on the rotation shaft so as to be rotated with the rotation shaft.

Owner:LG CHEM LTD

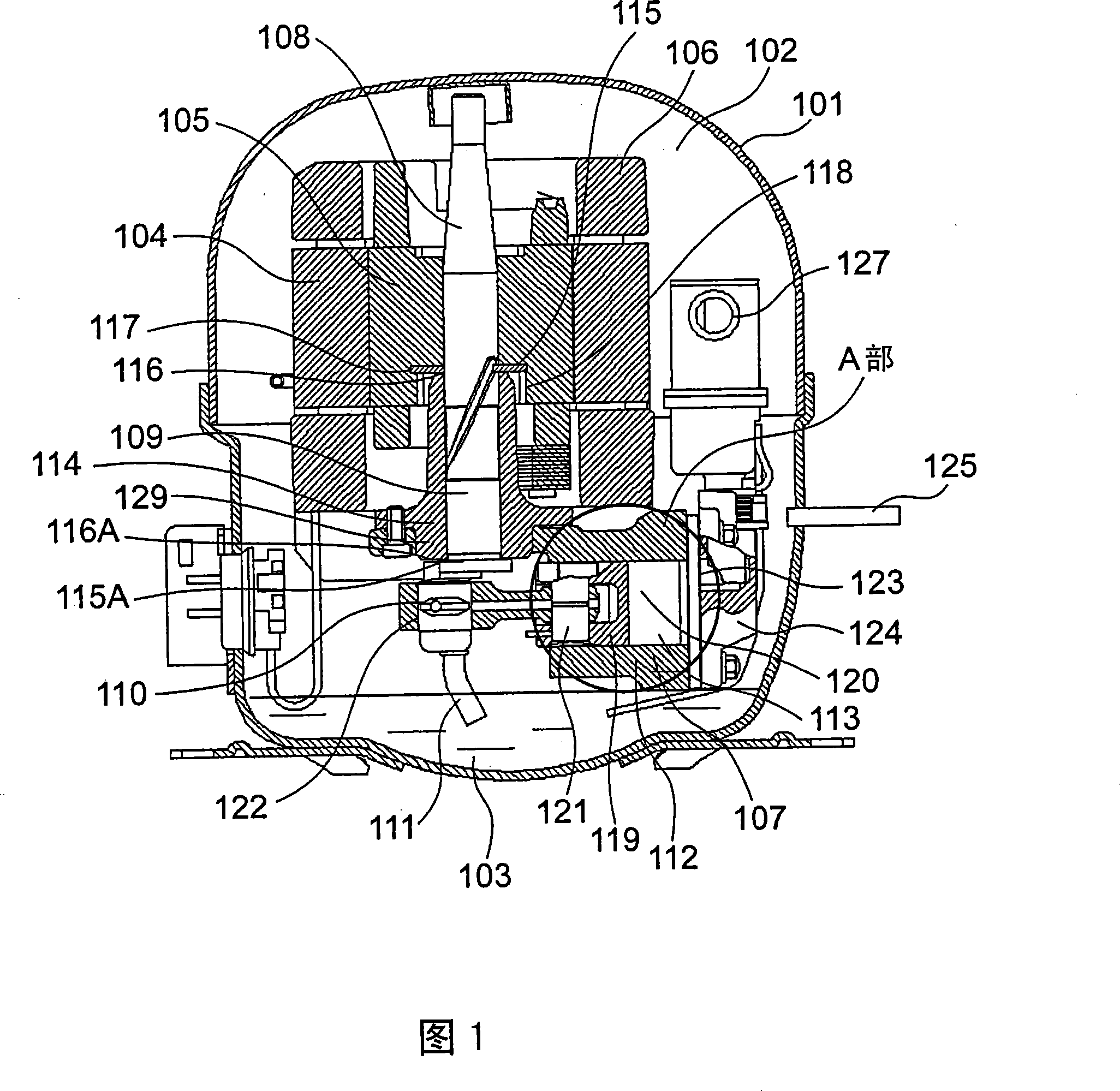

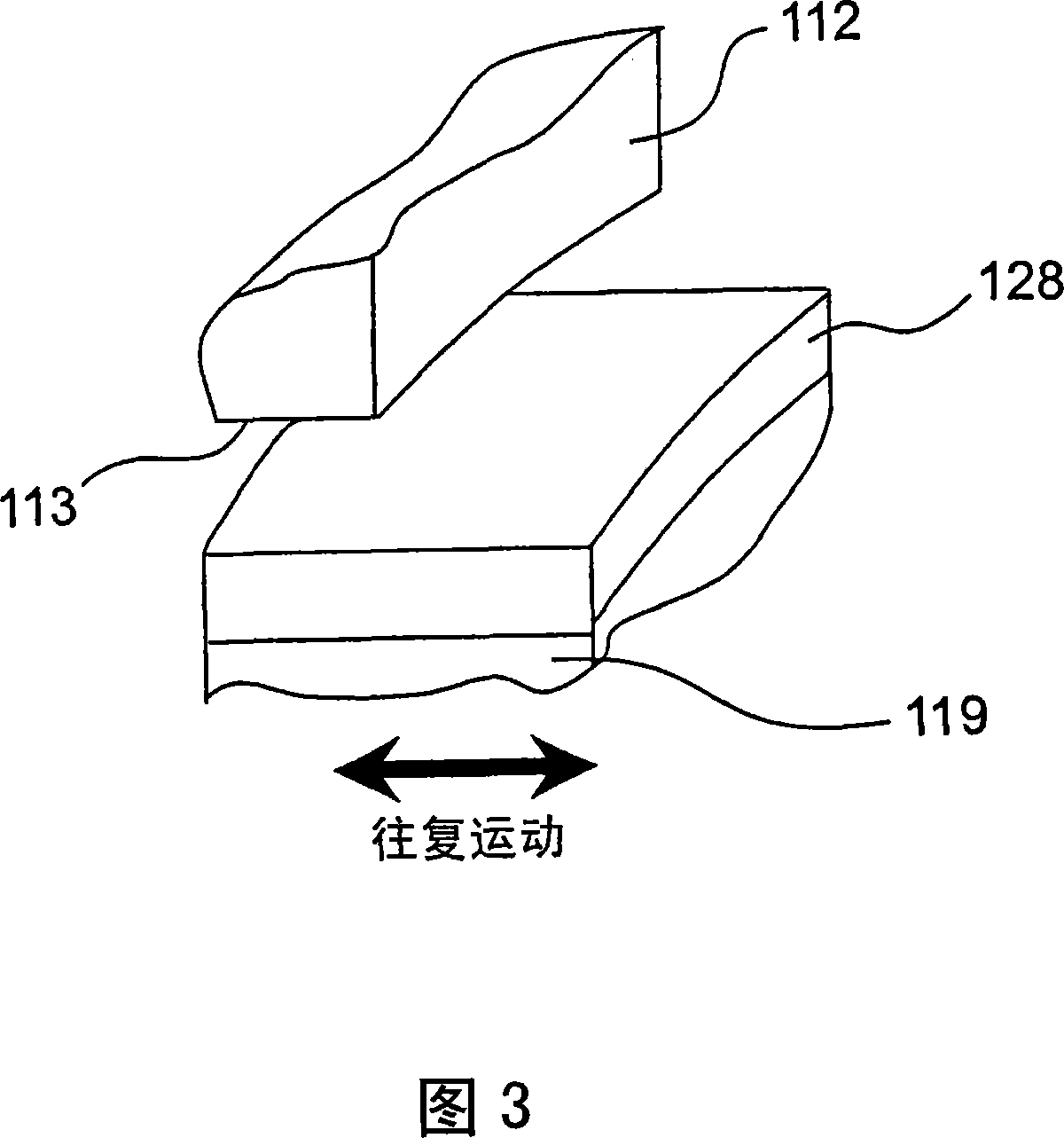

Sliding face modification material, method for producing sliding face modification material, method for using sliding face modification material, sliding members, and compressor

InactiveCN101165345AReduce adhesionIncreased energy lossPositive displacement pump componentsPositive-displacement liquid enginesMolybdenum disulfideMaterials science

A highly reliable sliding face modification material capable of forming a stable film of molybdenum disulfide on the sliding face of a sliding member, the sliding face modification material having a molybdenum disulfide content of 95 wt% or more and an organic material content of 1500 ppm or less in weight ratio, and the sliding face modification material being projected onto the sliding face to form a coating layer.

Owner:PANASONIC CORP

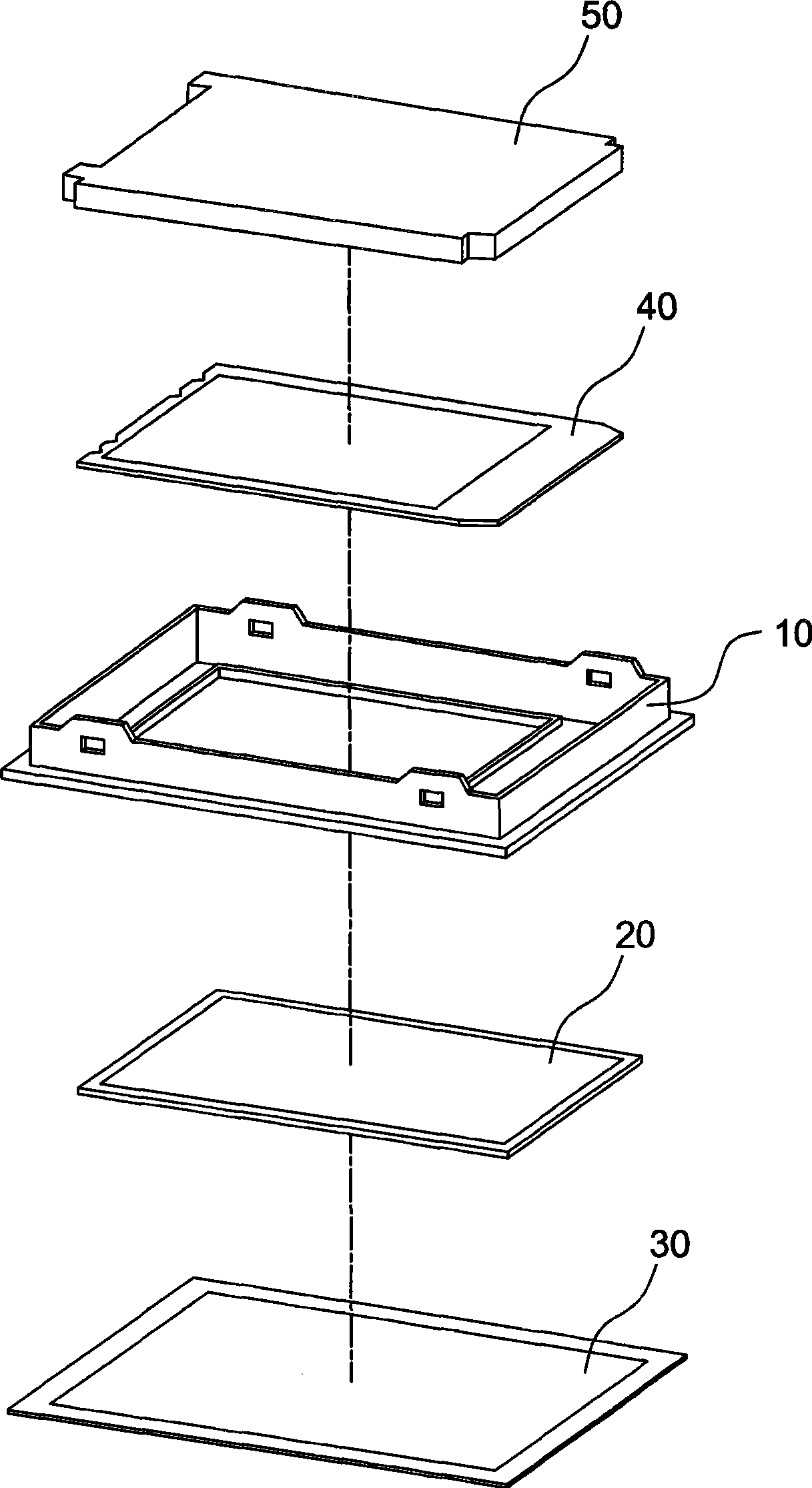

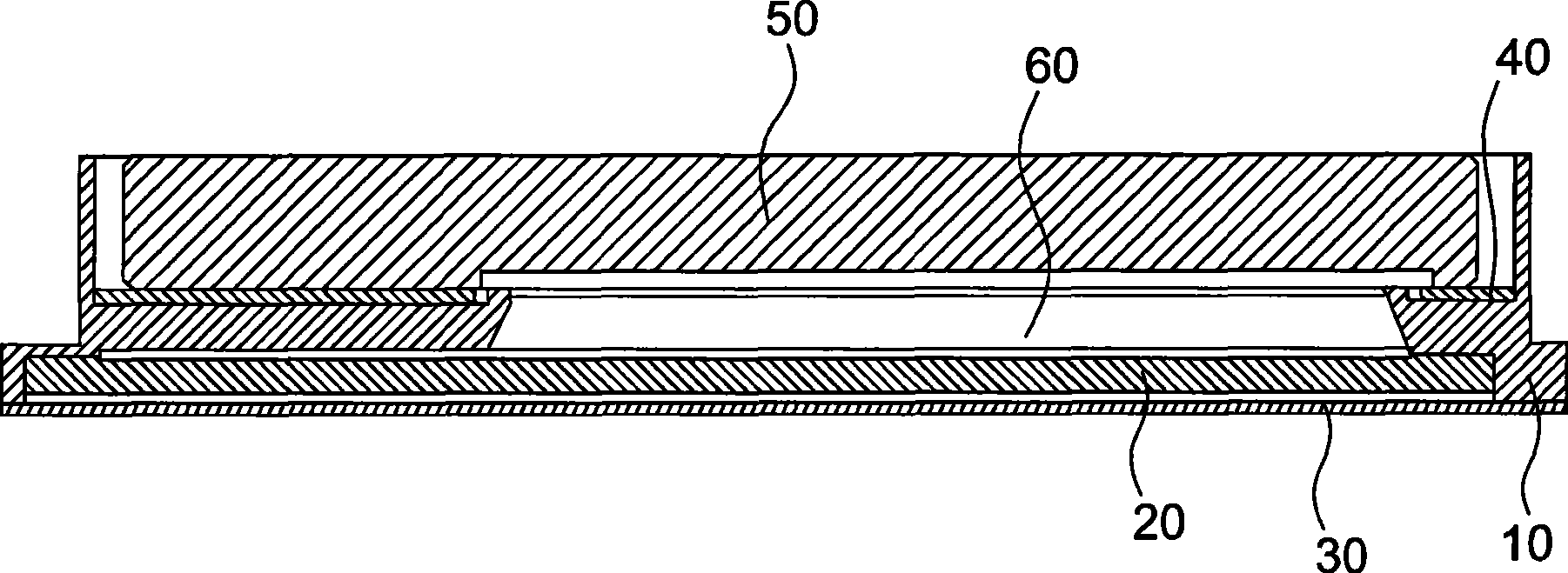

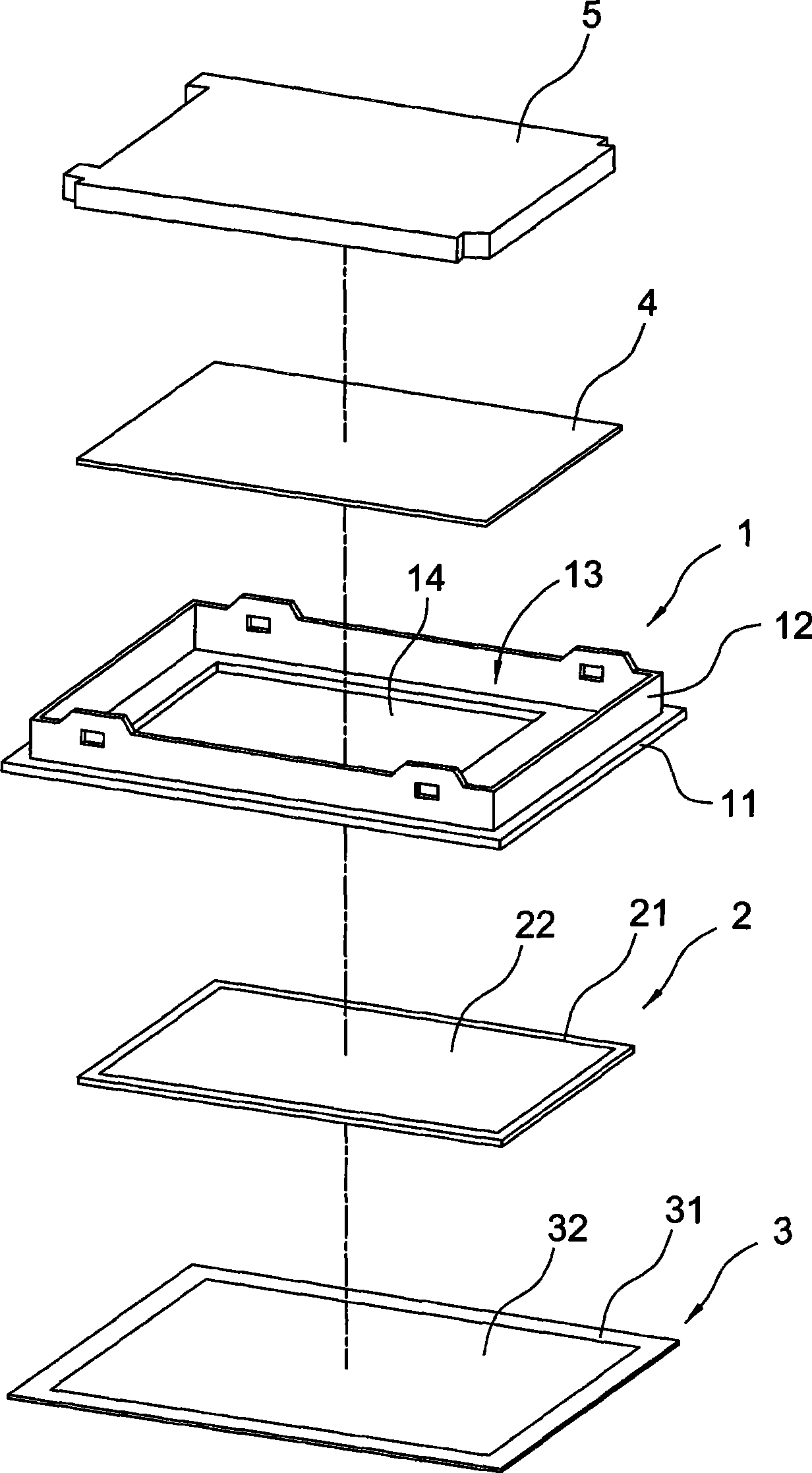

LCD device preventing water vapor generating

InactiveCN101377578AWon't condenseNot easy to produceStatic indicating devicesCooling/ventilation/heating modificationsTouch panelLiquid-crystal display

The invention relates to a liquid crystal display device for preventing the generation of vapour, which comprises a front cover, a touch panel, a nameplate, a splitter plate and a liquid crystal display module; wherein, a frame body is arranged on the front cover; the back of the frame body is provided with an enclosing wall in which a containing space forms; and the splitter plate and the liquid crystal display module are sequentially assembled and separated in the containing space. The front face of a frame is sequentially provided with the touch panel and the nameplate. The space between the touch panel and the liquid crystal display module is divided into a first space and a second space by the splitter plate; the first space which is formed from one side face of the splitter plate to the concave area of the liquid crystal display module is smaller; and the second space which is formed between the other side of the splitter plate and one side of the touch panel is larger. When the liquid crystal display module is switched on, the generated hot vapour is led out from the attaching position between the liquid crystal module and the splitter plate, so that the amount of the hot vapour in the first space is less; with the heat insulating effect of the splitter plate, the second space can not accumulate the hot vapour to easily produce a temperature difference between the second space and the external circumstance, and thus mist can not be generated.

Owner:DELTA ELECTRONICS INC

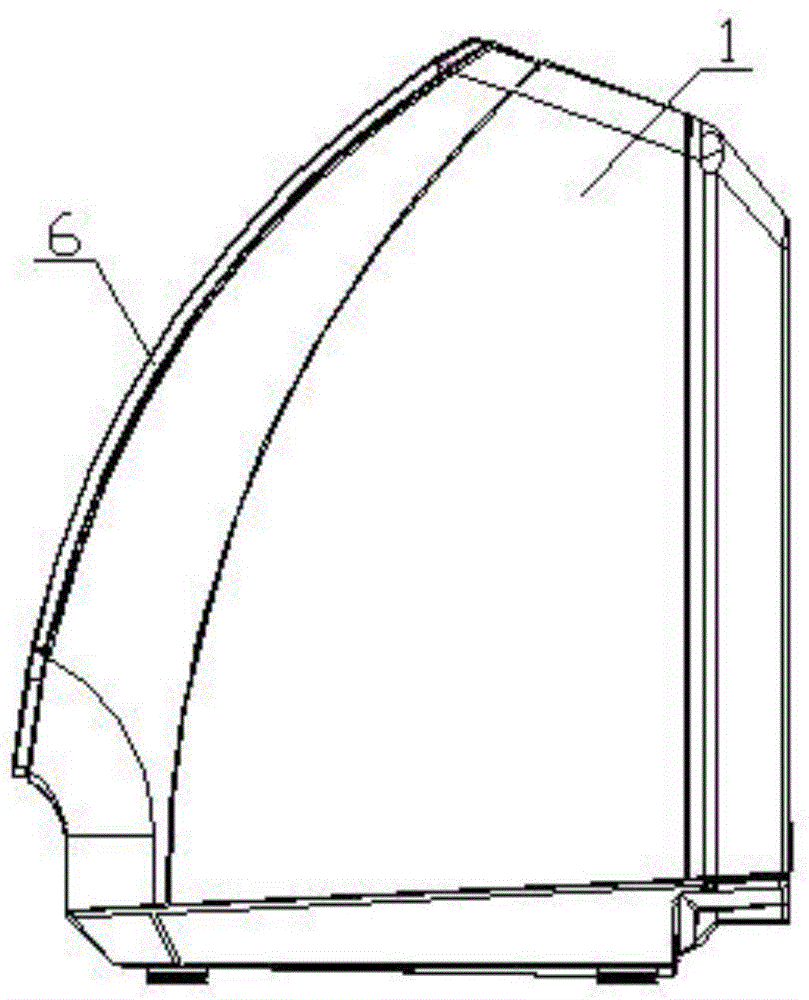

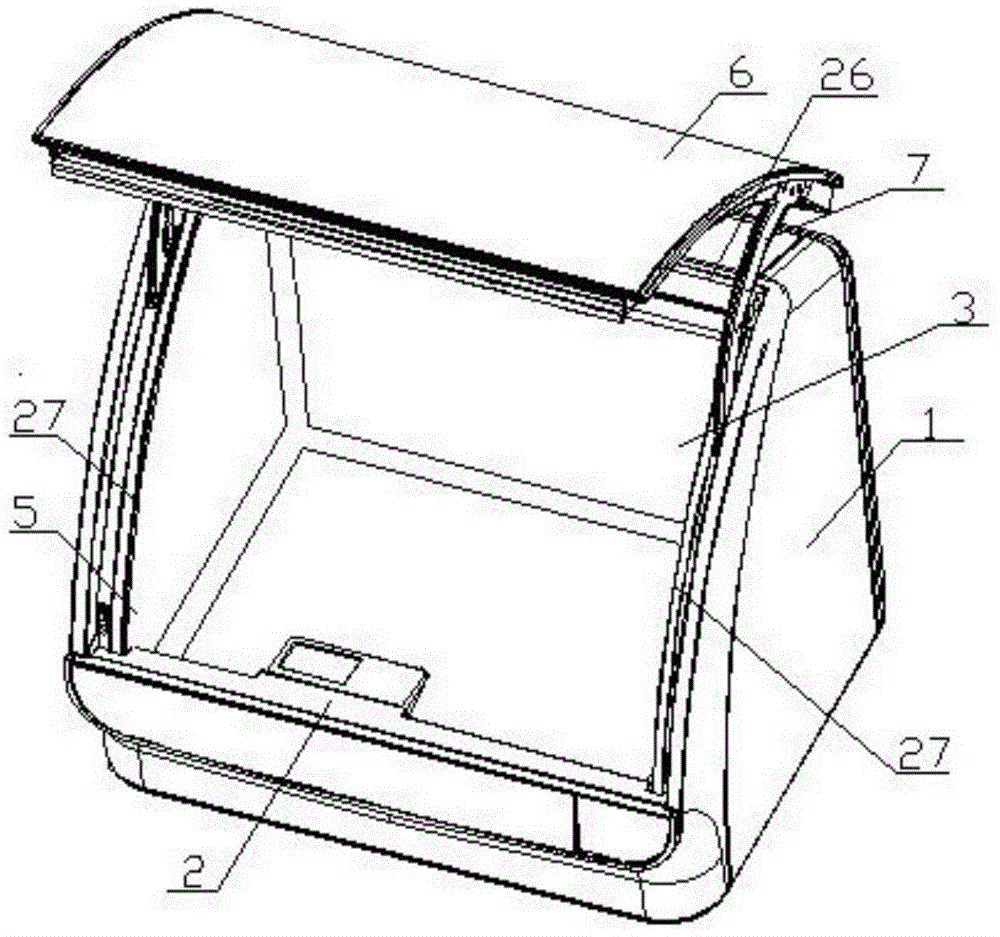

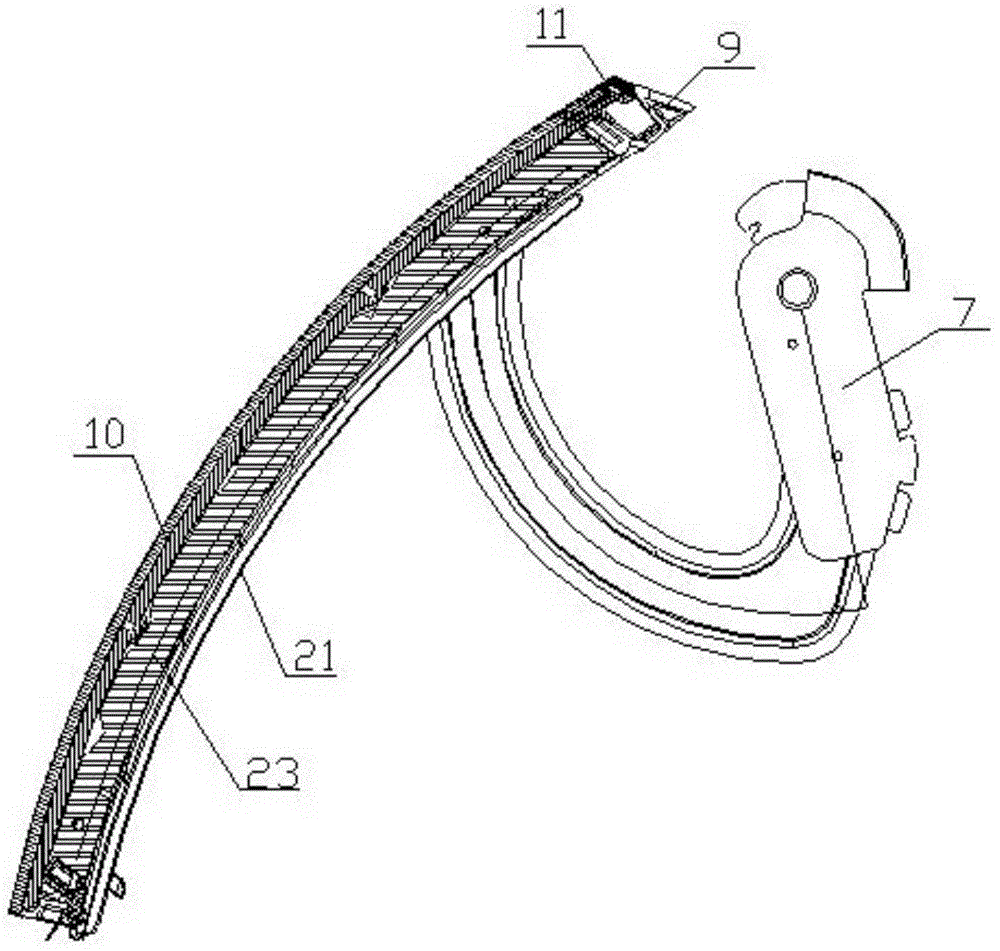

Dish-washing machine door body sealing structure and dish-washing machine

ActiveCN106468128ASimple sealing structureLow costSealing arrangementsEngineeringMechanical engineering

The invention relates to a dish-washing machine door body sealing structure and a dish-washing machine. The sealing structure comprises an inner container and a door body. Sealing is achieved between the periphery of the door body and the inner container through top sealing strips, lateral sealing strips on the two sides and bottom sealing strips, and the top sealing strips, the lateral sealing strips and the bottom sealing strips are separated with one another. The top sealing strips and the lateral sealing strips on the two sides are arranged on the inner container, and the bottom sealing strips are arranged at the bottom of the door body. The overall structure is simple, cost is low, and installation is convenient. The sealing structure can be better matched with the door body of a large radian structure so that a good sealing property between the door body and the inner container can be achieved, and reliable sealing is achieved. Moreover, the sealing structure is beneficial to prolonging the service life of the sealing strips.

Owner:QINGDAO HAIER DISHWASHER

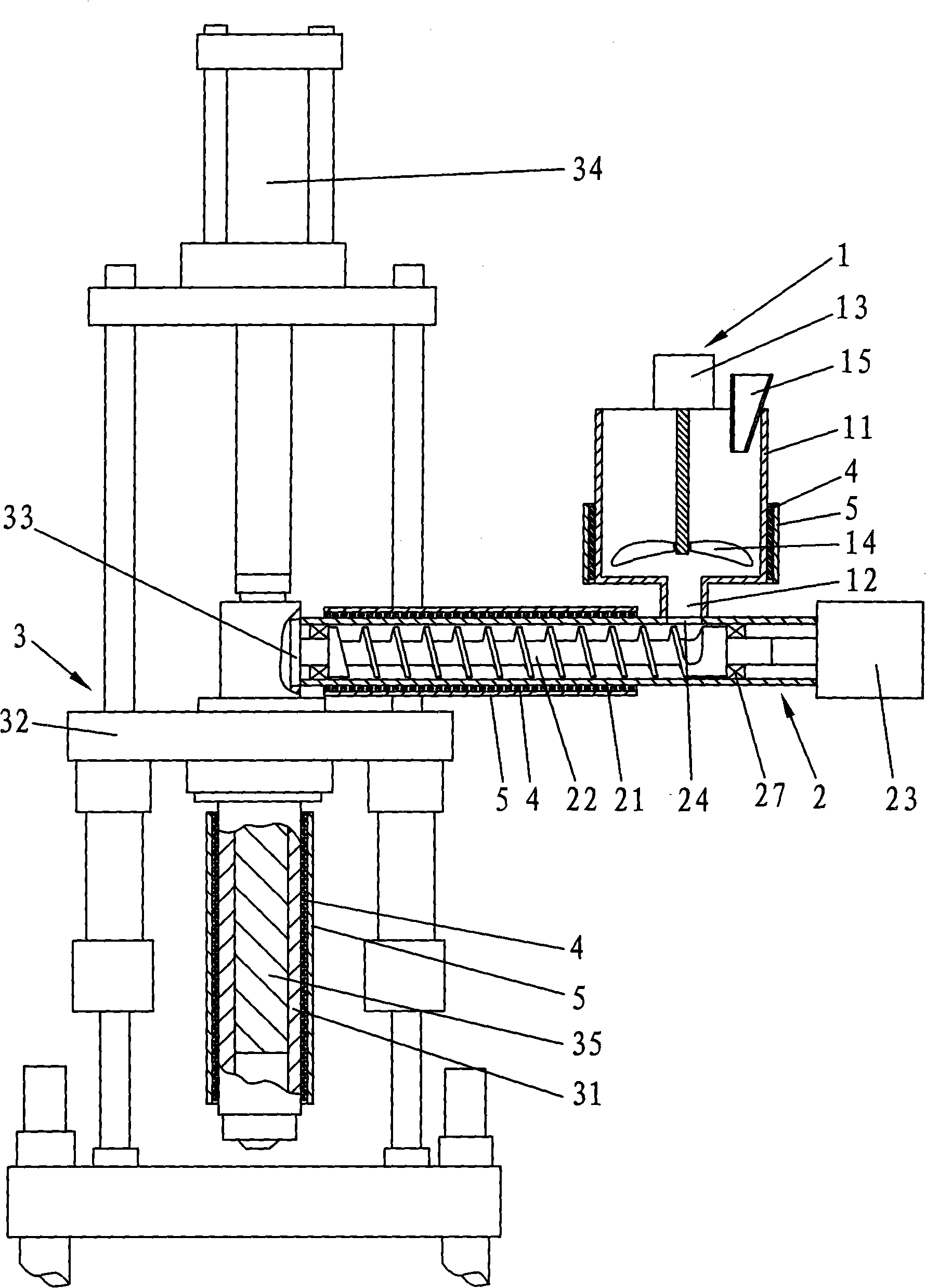

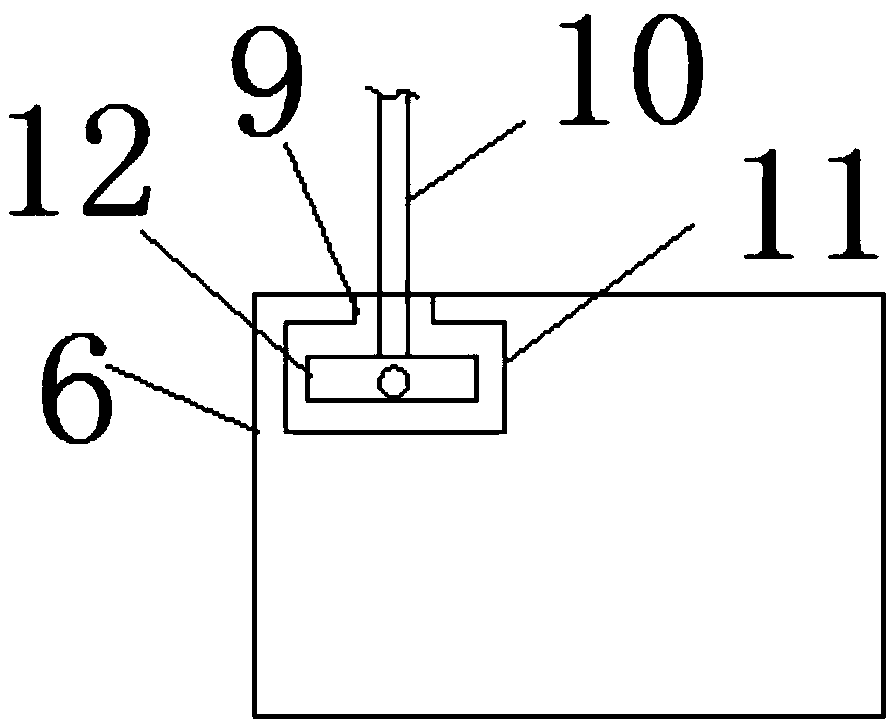

Vertical type ceramic injection machine

InactiveCN101347948ANo wasteImprove injection molding performanceCeramic shaping apparatusClay processing apparatusElectric machineryEngineering

The invention relates to the technical filed of injection machines, in particular to a vertical ceramic injection machine. The injection machine comprises a feeding device and a jet device; wherein, the feeding device comprises a charging basket; the top of the charging basket is provided with an opening, and the bottom is opened with a discharge hole. The feeding device is connected with the jet device by a conveying device. The interior of the charging basket is provided with a stirring device. The conveying device comprises a feeding barrel, a feeding screw, and a servo Motor. The feeding barrel is provided with a delivery opening communicated with the discharge hole of the charging basket. After being stirred by the stirring device, the slurry stirred by the stirring device enters the feeding barrel from the delivery opening of the feeding barrel. The feeding screw is rotated due to being driven by the servo motor and pushes the slurry to the jet device from the feeding barrel. The feeding quantity and flow speed of the slurry delivered into the jet device can be controlled by adjusting the rotational speed and the rotational time of the servo motor. After injection molding, products have good quality, therefore, the conveying device additionally arranged for vertical ceramic injection machine increases the injection molding effect of the ceramic slurry.

Owner:东莞市天合电子陶瓷制品有限公司

Oxygen detector, detection method and application

ActiveCN111579619ASolve the problem of inaccurate oxygen concentrationIncrease temperatureMaterial analysis by electric/magnetic meansFluid pressure measurement by mechanical elementsThermodynamicsControl cell

The invention provides an oxygen detector, a detection method and application. The oxygen detector comprises an air inlet provided with an oxygen permeation membrane, a heater is installed close to the air inlet, the heater is connected with a control unit, and the control unit is connected with a temperature sensor; the temperature sensor comprises a first temperature sensor mounted on the oxygenpermeation membrane and a second temperature sensor mounted in the oxygen detector and used for detecting the environment temperature; the control unit is used for receiving temperature signals of the first temperature sensor and the second temperature sensor so as to control the heater to conduct heating, and it is guaranteed that the temperature of the oxygen permeation membrane is higher thanthe environment temperature. By additionally arranging the temperature sensor, the temperature of the environment where the oxygen detector is located and the temperature of the oxygen permeation membrane can be detected, then the heater is controlled to heat the oxygen permeation membrane, the temperature of the oxygen permeation membrane is higher than the environment temperature, and thereforewater vapor is prevented from condensing on the oxygen permeation membrane.

Owner:JIANGSU JICUI DEPTH SENSING TECH RES INST CO LTD

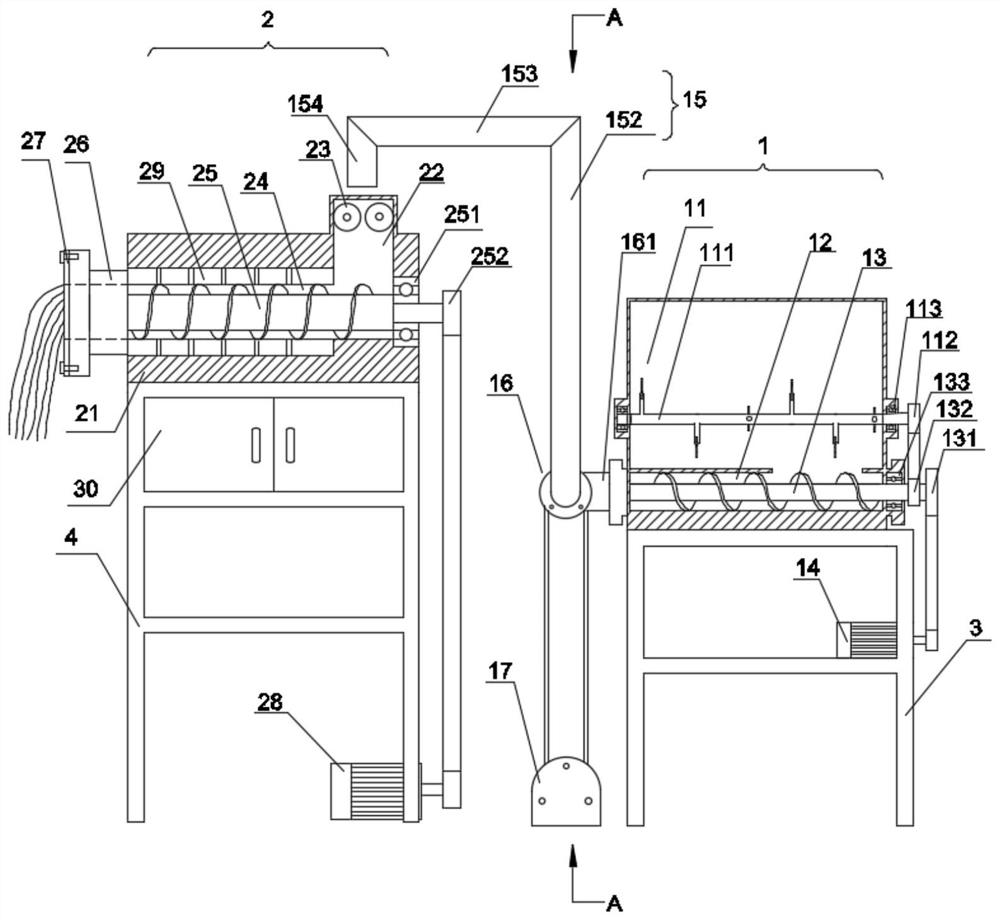

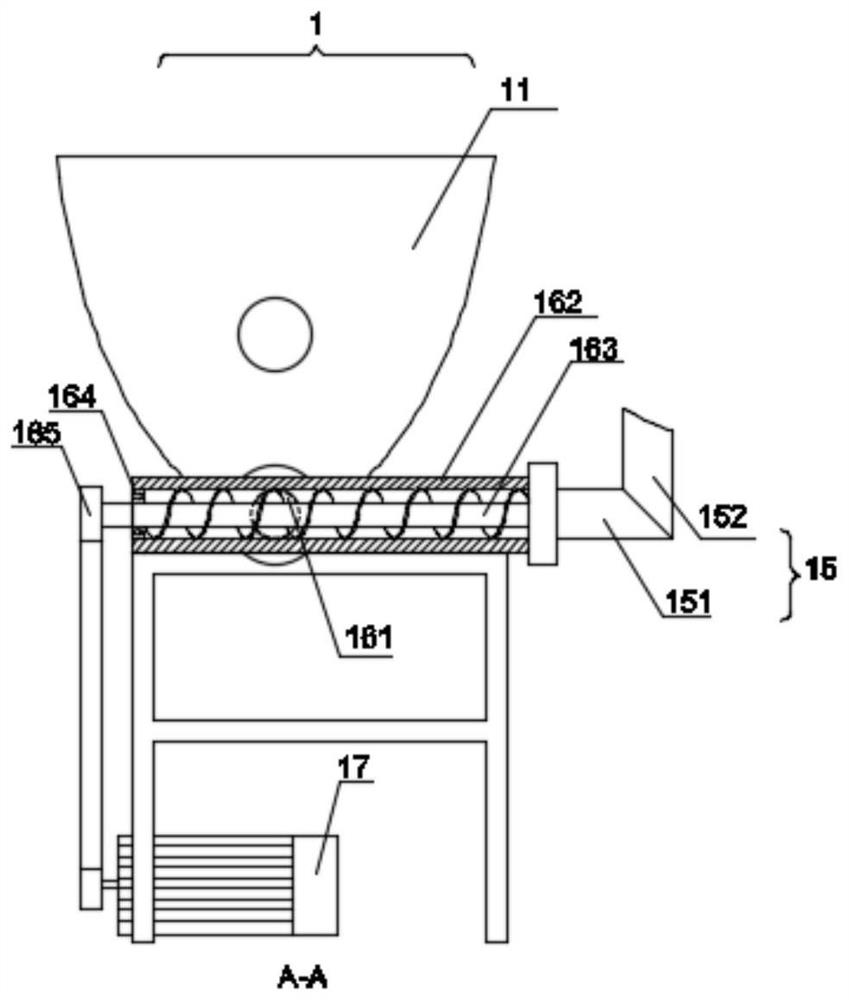

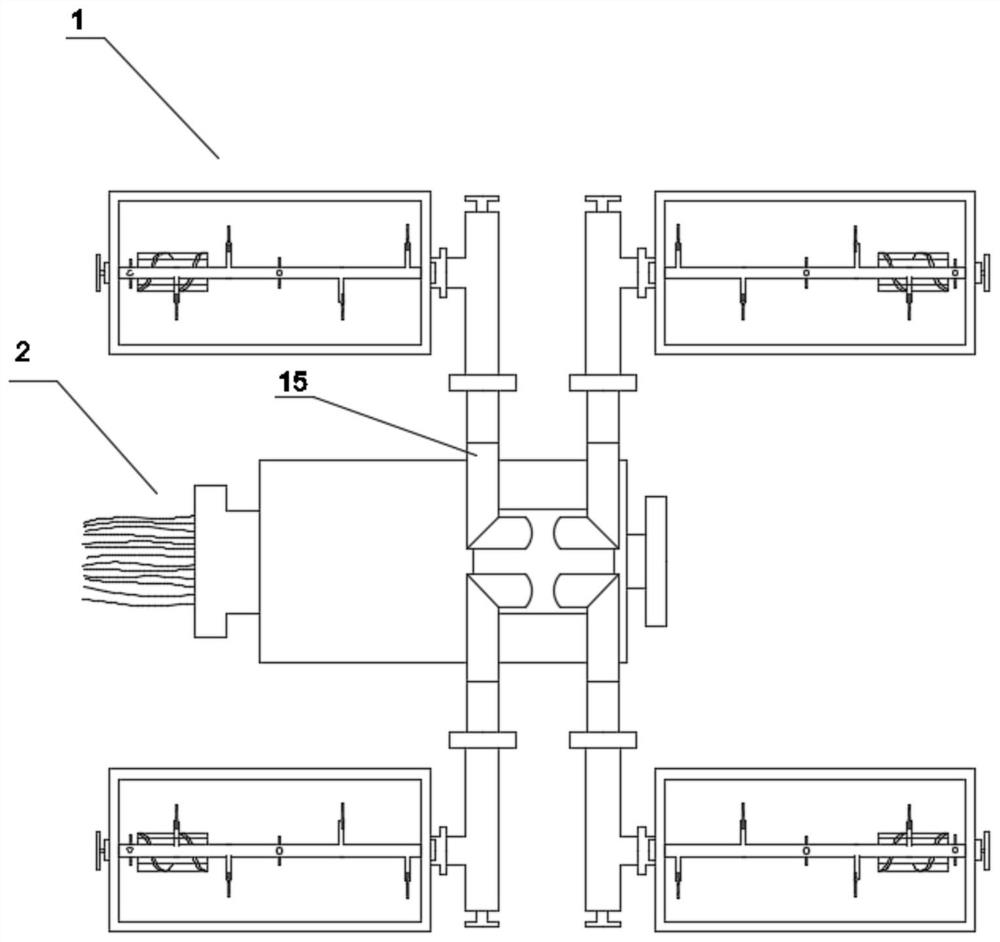

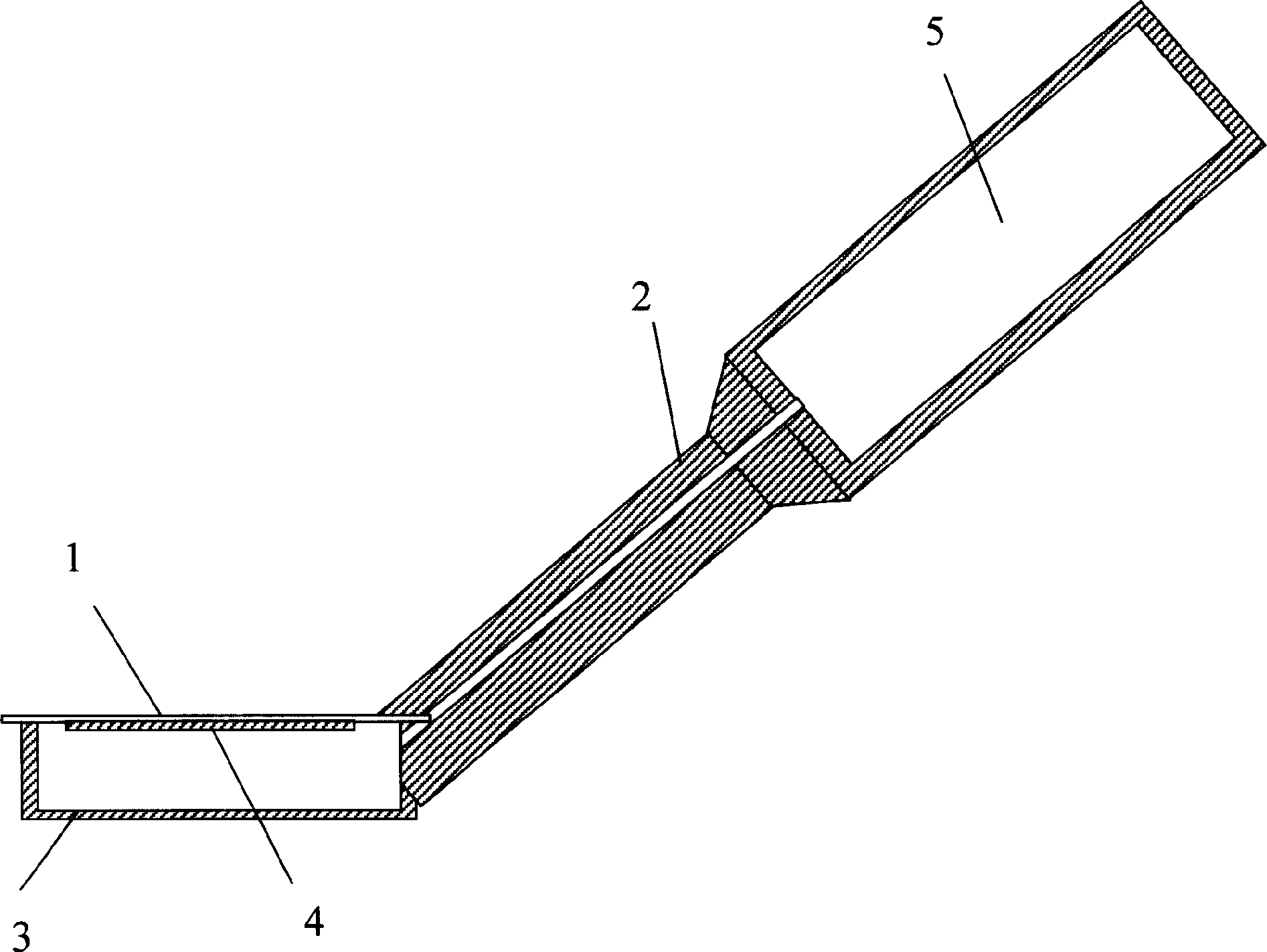

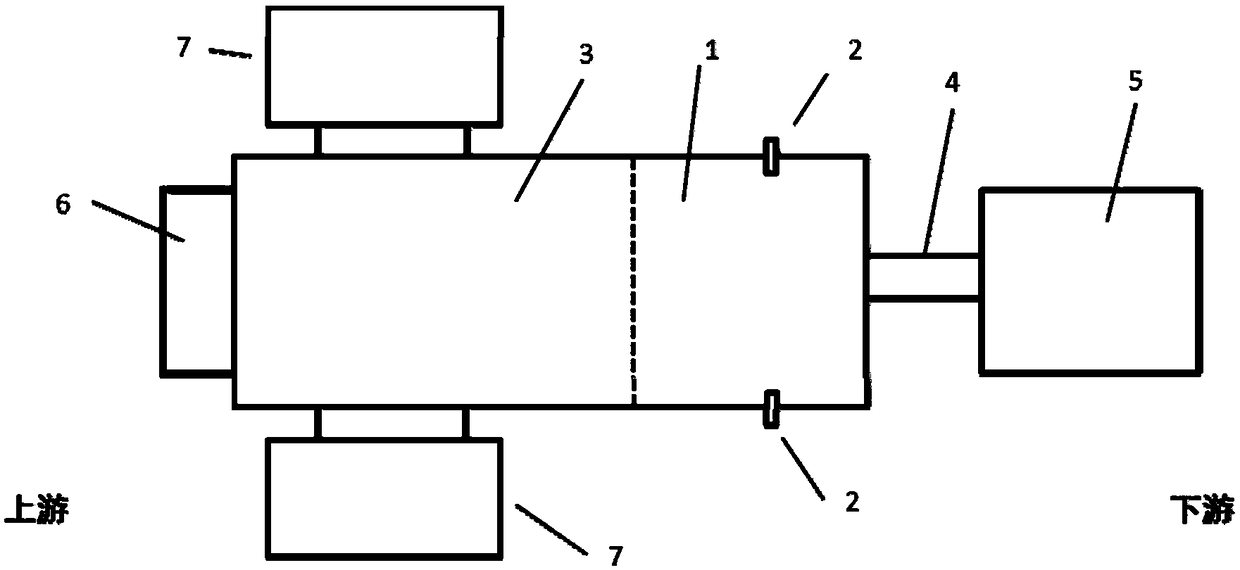

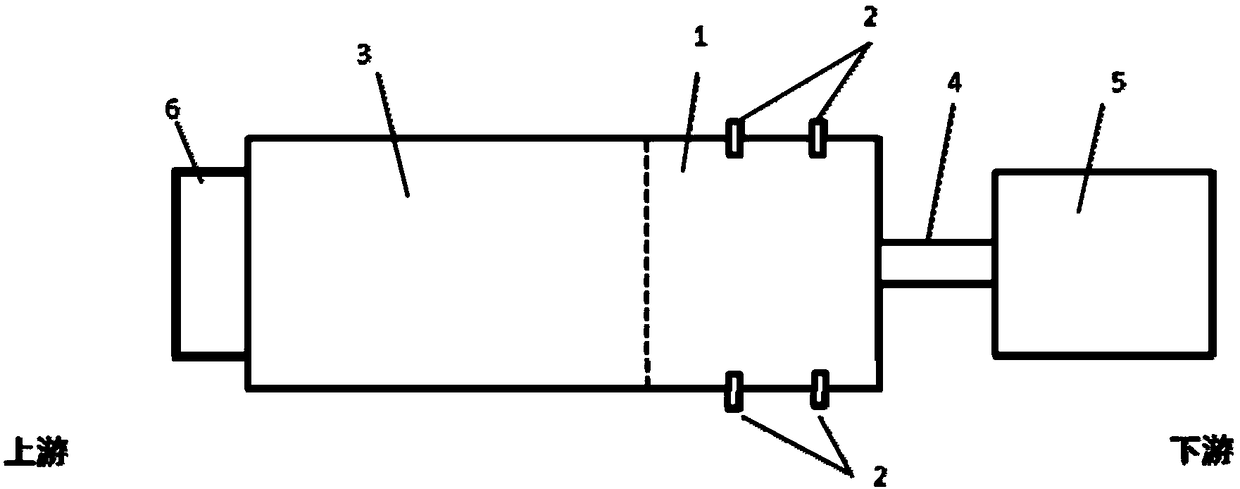

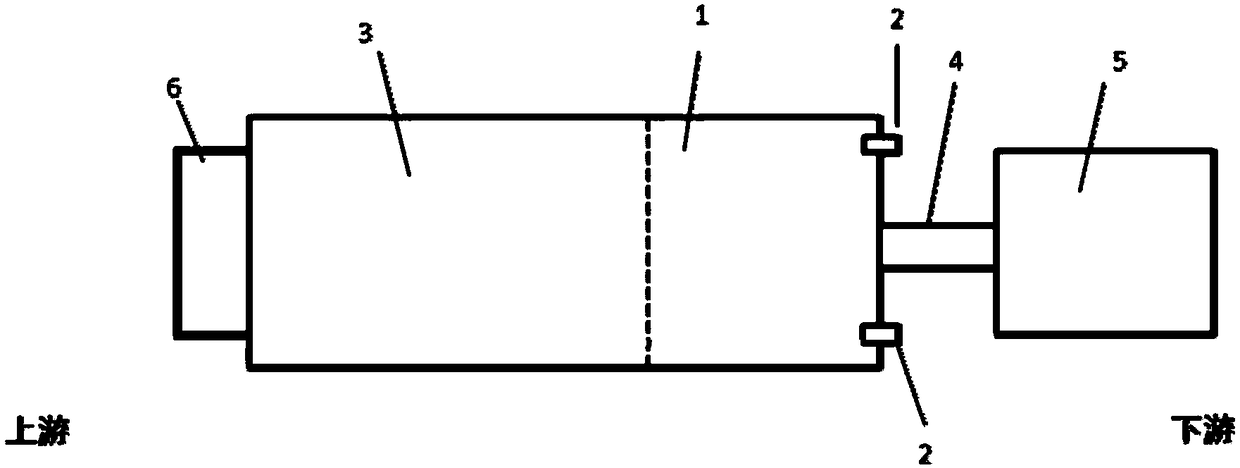

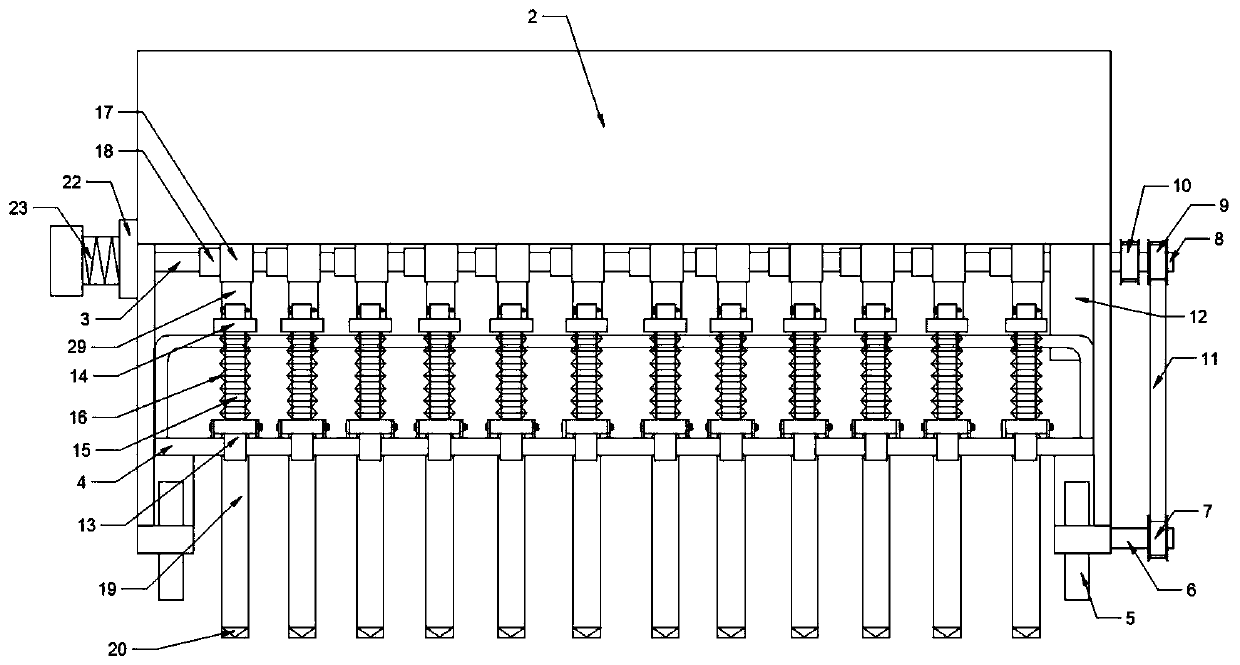

Rice noodle extrusion device

PendingCN112219980AWon't condenseEasy to eliminateFood shapingMechanical engineeringMaterials science

The invention relates to the field of rice noodle production equipment, in particular to a rice noodle extrusion device. The rice noodle extrusion equipment comprises first extruders and a second extruder, wherein each first extruder comprises a feeding pipe, and the first extruders feed extruded rice noodle pulp into the second extruder through the feeding pipes; a first feeding screw rod and a pressurized extrusion device are arranged in each first extruder, and a second feeding screw rod is arranged in the second extruder; wet rice noodles are fed into the pressurized extrusion devices through the first feeding screw rods to be extruded and then fed into the second feeding screw rod through the feeding pipes to be extruded and formed; the second extruder is provided with extrusion rollers, and bubbles can be removed after the rice noodle pulp is compacted by the extrusion rollers; a vibration device is arranged on each feeding pipe, so that bubbles can be further reduced; and meanwhile, electric heating sleeves are mounted on the second extruder, so that the rice noodle pulp can be prevented from being condensed in the second extruder during shutdown.

Owner:柳州市汇方科技有限公司

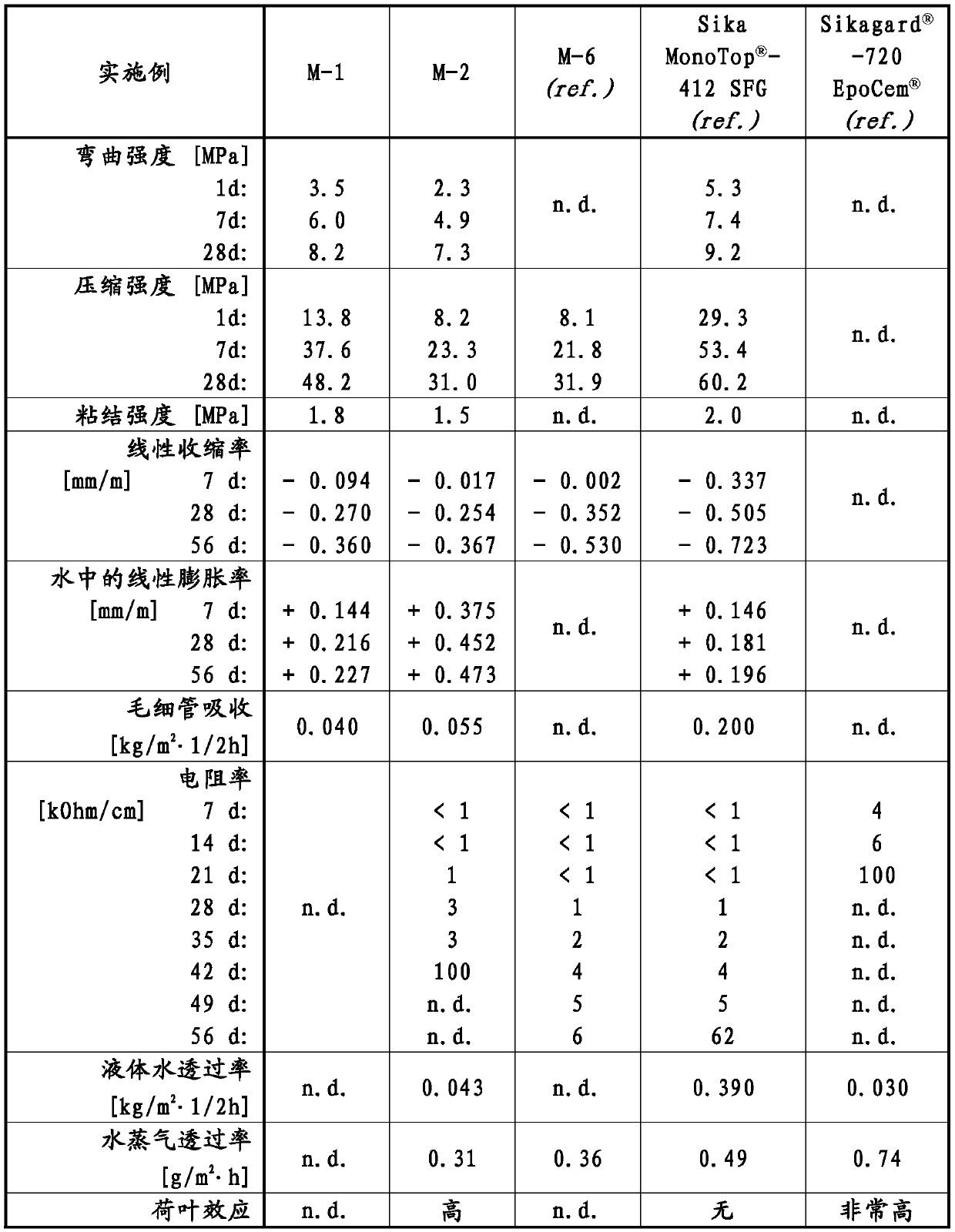

Mortar containing polyurethane dispersion with ethylene oxide units

ActiveCN110891915AGood application effectWell mixedSolid waste managementPolyurethane dispersionPolymer science

The present invention relates to a composition comprising: at least one water-based polyurethane dispersion containing ethylene oxide units, at least one cement, and at least one mineral filler. The composition can be mixed and applied without coagulation of the polyurethane dispersion. Upon curing, it has a high strength and good adhesion properties, with surprisingly low shrinkage and most surprisingly good water impermeability properties. The composition is particularly suitable for the use as repair mortar, waterproofing mortar or screed mortar.

Owner:SIKA TECH AG

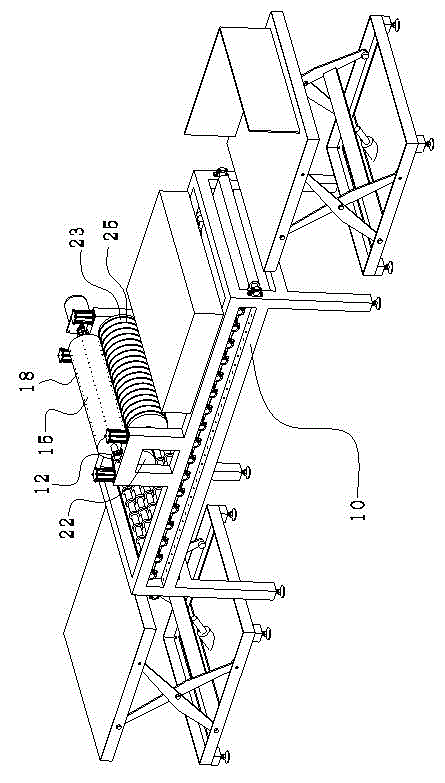

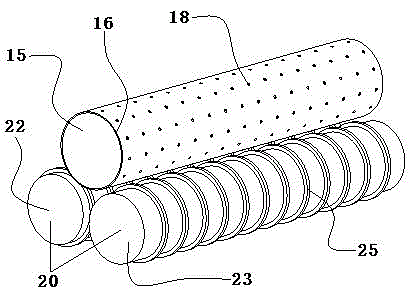

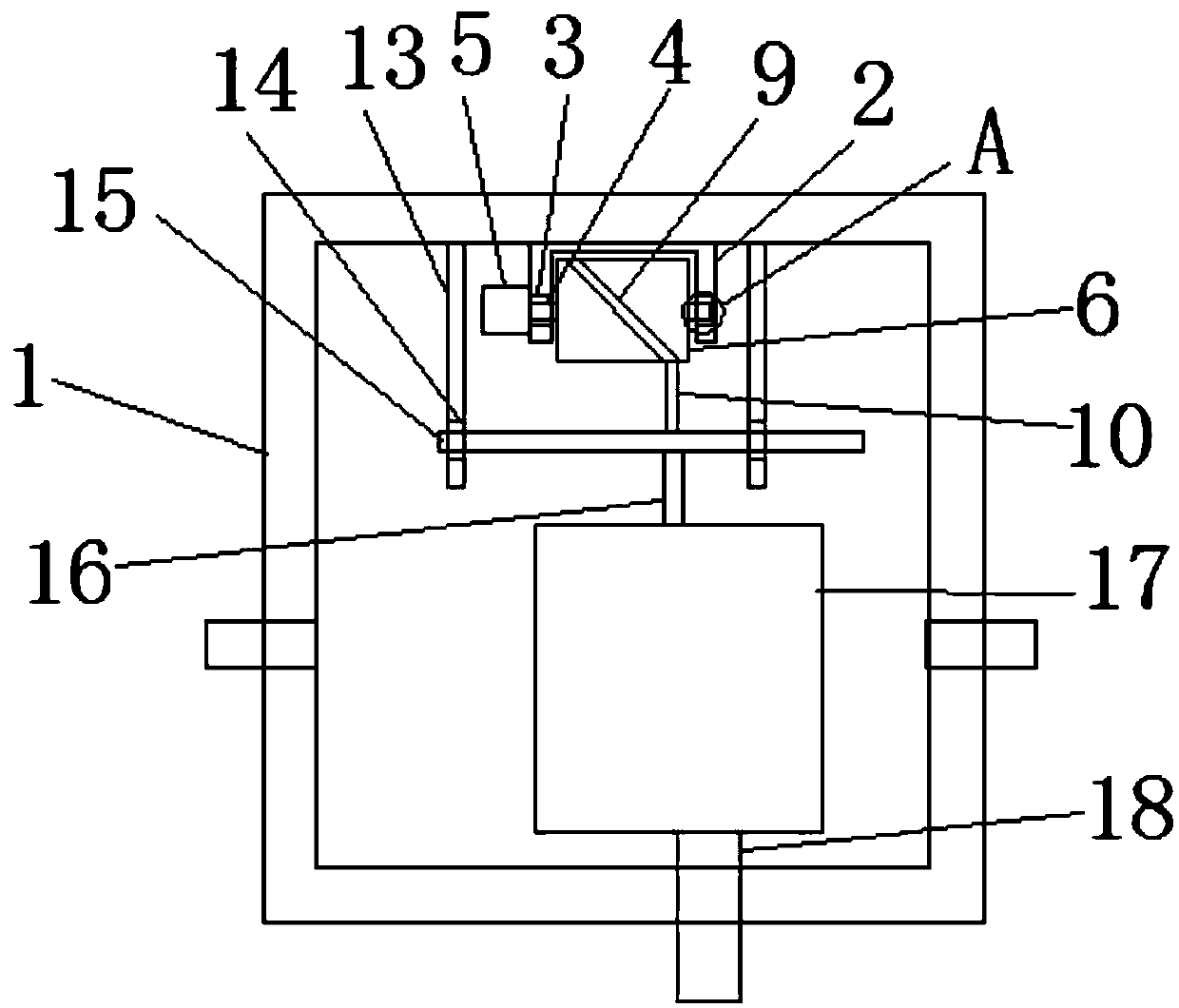

Special gluing machine for manufacturing honeycomb paper ball

ActiveCN103551274ASo as not to damageWon't condenseLiquid surface applicatorsCoatingsThin layerHoneycomb

The invention discloses a special gluing machine for manufacturing a honeycomb paper ball. The special gluing machine comprises a machine base, a roller shaft frame, a glue storage roller, and two resilience gluing rollers namely a front gluing roller and a rear gluing roller, wherein the roller shaft frame is fixedly arranged on the machine base; the glue storage roller is arranged on the roller shaft frame; the front gluing roller and the rear gluing roller are arranged on the roller shaft frame; a glue permeation layer is sleeved on the glue storage roller; a plurality of gluing rings are arranged on each gluing roller at equal intervals along the axial direction; the gluing rings of the front gluing roller and the rear gluing roller are staggered with one another. The special gluing machine is used for manufacturing the honeycomb paper ball by slightly gluing thin paper; by arranging the glue permeation layer on the glue storage roller, glue can be uniformly supplied under the condition of slight gluing. By virtue of the resilience gluing rings, uniform glue absorption can be ensured, the glue can softly contact paper needing to be glued, a thin layer of glue is uniformly applied while the paper is protected from being damaged, the glue is saved, and an environment protection effect is achieved. The glue permeation layer arranged on the glue storage roller can block glue outlets of the glue storage roller, so that the glue cannot automatically permeate under the condition of natural stop and cannot be coagulated, thus avoiding blocking the glue outlets.

Owner:佛山市南海汉唐工艺综合厂

Electrothermally defogging oral reflector

InactiveCN1887217ASimple structureEasy to useSomatoscopeElectrical resistance and conductanceEngineering

The electrothermally defogging oral reflector consists of one reflector and one handle. The handle has one pedestal set in the front end for the reflector to be set on, and there are one electrothermal element fixed in the pedestal, one battery compartment set inside the handle, and one switch connected to the electrothermal element. The handle axis and the mirror of the reflector are in one angle of 110-160 deg. The electrothermal element constituted of spiral resistive wire in the bottom of the pedestal heats the reflector to temperature higher than that of air inside oral cavity, so as to avoid vapor condensation in the mirror and to maintain clear mirror. The present invention has simple structure and convenient use.

Owner:SHANGHAI LASER MEDICAL INSTR CO LTD

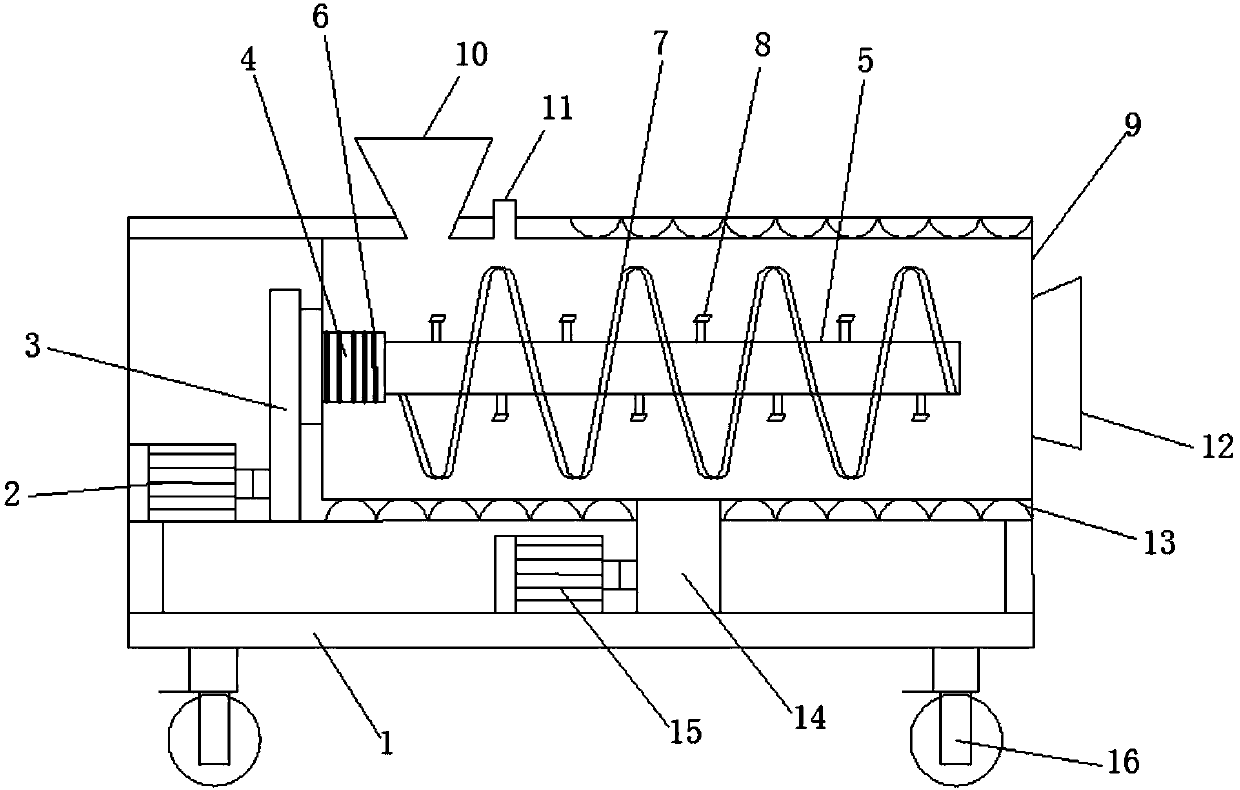

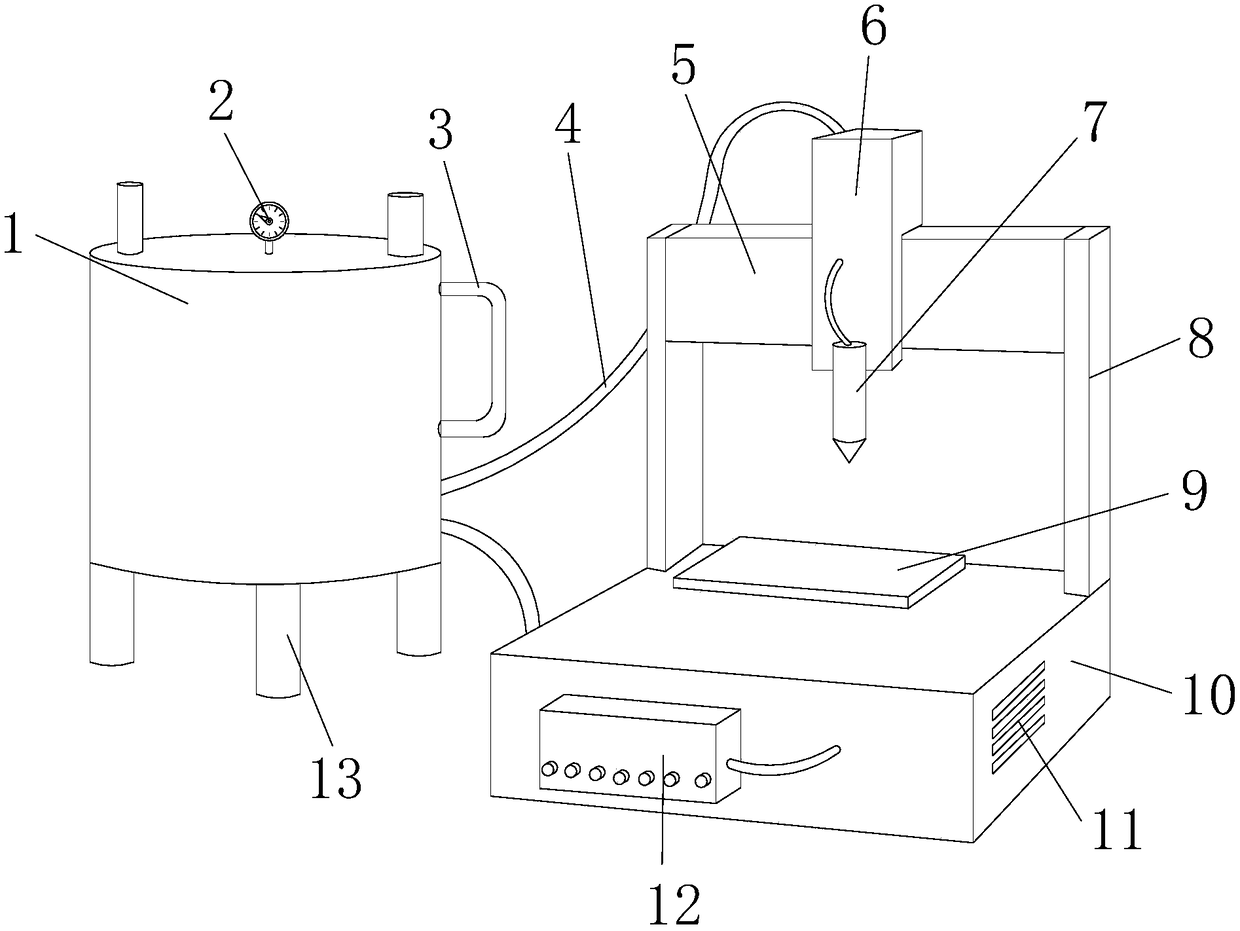

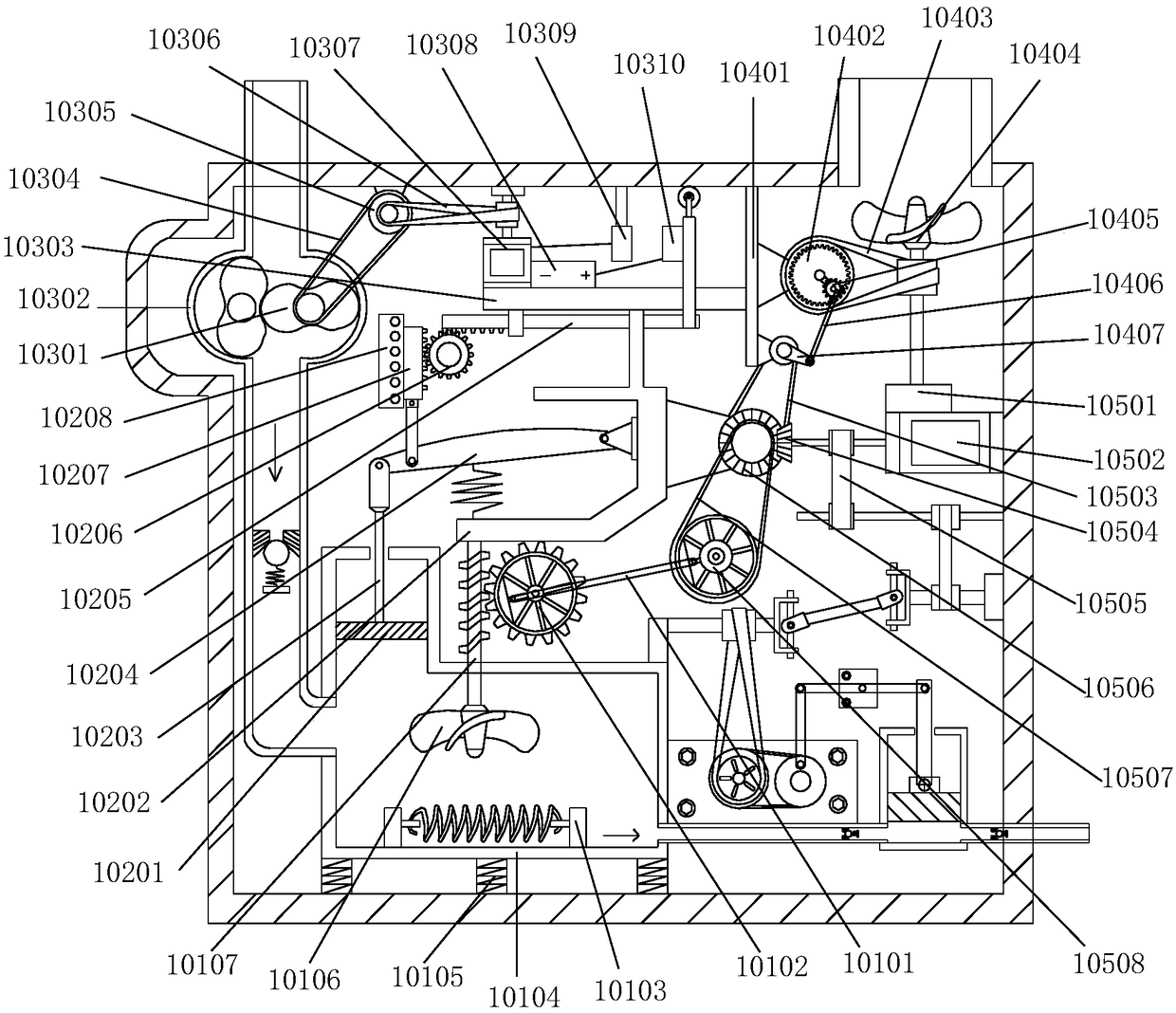

Vibration anti-holding shaft concrete mixer

The invention discloses a vibration anti-holding shaft concrete mixer. The concrete mixer comprises a support and a stirring barrel, a walking wheel is arranged at the bottom of the support, a drivingmotor is arranged on the support, an output shaft of the driving motor is connected with the input end of the speed reducing device, the output shaft of the speed reducing device is connected with astirring shaft through a coupling, the coupling is provided with a damping spring, a spiral stirring blade and a stirring knife are arranged on the stirring shaft, a feeding hole and a water inlet areformed in the upper end of the stirring barrel, and a discharging opening is formed in the side surface of the stirring barrel, elastic steel sheets are arranged on the upper side and the lower sideof the stirring barrel, the outer wall of the stirring barrel is connected with an eccentric wheel device, and the eccentric wheel device is connected with a vibration motor. The vibration anti-holding shaft concrete mixer can prolong the service life of the driving motor, meanwhile, the concrete cannot be subjected to a shaft holding accident due to condensation on the barrel wall and the stirring shaft, the operation is smooth, and the working efficiency is high.

Owner:KOORUN INTELLIGENCE TECH CO LTD

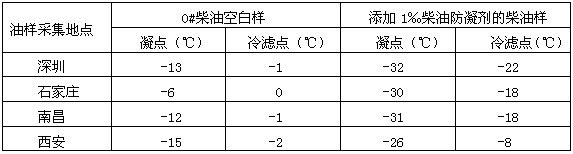

Diesel anti-condensation agent

InactiveCN102703139ASolve low temperature fluidity problemsReduce cold fluidityLiquid carbonaceous fuelsOrganic solventCold filter plugging point

The invention relates to diesel anti-condensation agent. The diesel anti-condensation agent is characterized by comprising, by weight percent, 25-55% of olefine copolymer, 5-20% of purification dispersant, 5-20% of polar nitrogenous compound, and 10-55% of organic solvent. The diesel anti-condensation agent is well sensitive to most of domestic diesels, condensation point of the diesel No.0 can be further reduced to 10-24 DEG C, cold filter plugging point of the diesel No.0 can be lowered by 5-20 DEG C, low temperature flowability of the diesel can be improved, smooth cold start of an engine can be guaranteed, and problems in driving and storage and transportation due to sudden drop in air temperature and trans-regional running are solved effectively.

Owner:SHENZHEN CHIEF CAR CARE PRODS DEV

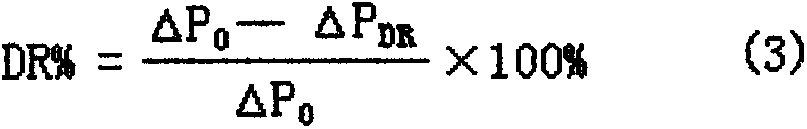

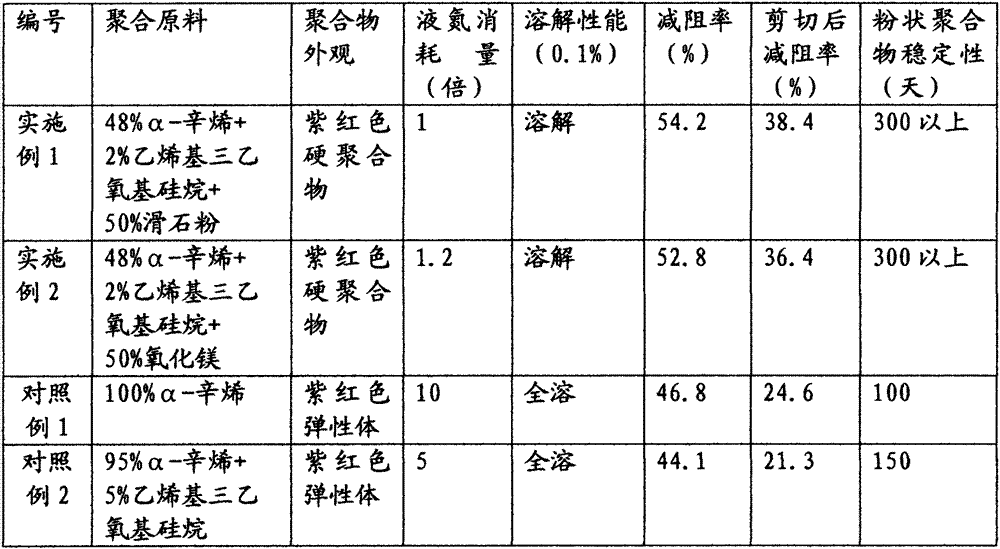

Preparation method of powdered drag reducing agent for crude oil transportation

InactiveCN103030726AWon't condenseOvercoming shear intolerancePipeline systemsDrag reducing agentVinylsilane

The invention discloses a preparation method of a powdered drag reducing agent for crude oil transportation. The preparation method is characterized in that inorganic powder is directly added to an alpha-olefin polymerization system to prepare the powdered drag reducing agent. The preparation method mainly comprises the following steps: 45-49wt% of alpha-olefin with a carbon number of C8-C18 and 1-5wt% of active ethenyl silane coupling agent are mixed and filled in a polymerization bottle; 50wt% of inorganic powder is added; a Ziegler-Natta catalyst is added for bulk polymerization to form a drag reducing polymer; the drag reducing polymer is ground by a low-temperature grinder to be under 200 meshes in the presence of a liquid nitrogen refrigerant and a disperser; and 40wt% of powdered drag reducing agent of the drag reduction copolymer is obtained. The method has the advantages that as the inorganic powder is directly added to the alpha-olefin polymerization system to prepare the powdered drag reducing agent, the problems that low temperature grinding is high in cost, and a product is coagulated easily during a storage course in the existing production process of the drag reducing agent are solved.

Owner:TIANJIN VOCATIONAL INST

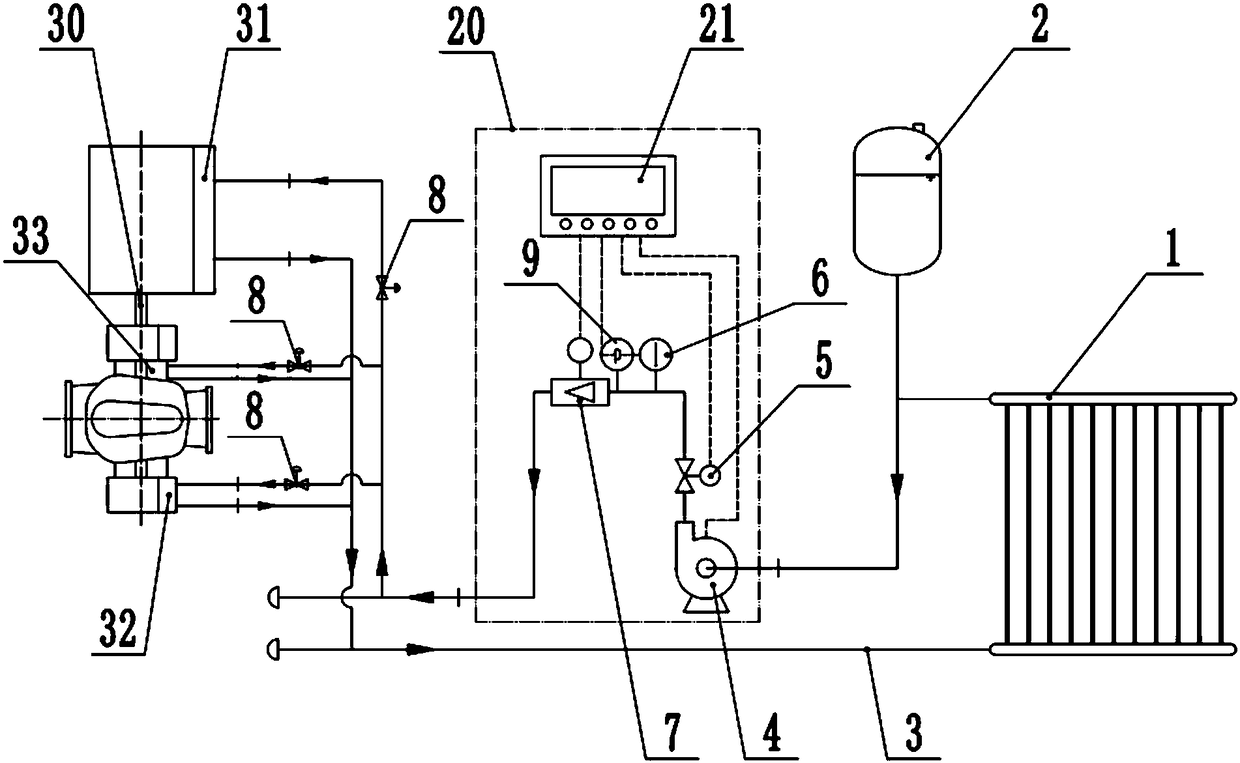

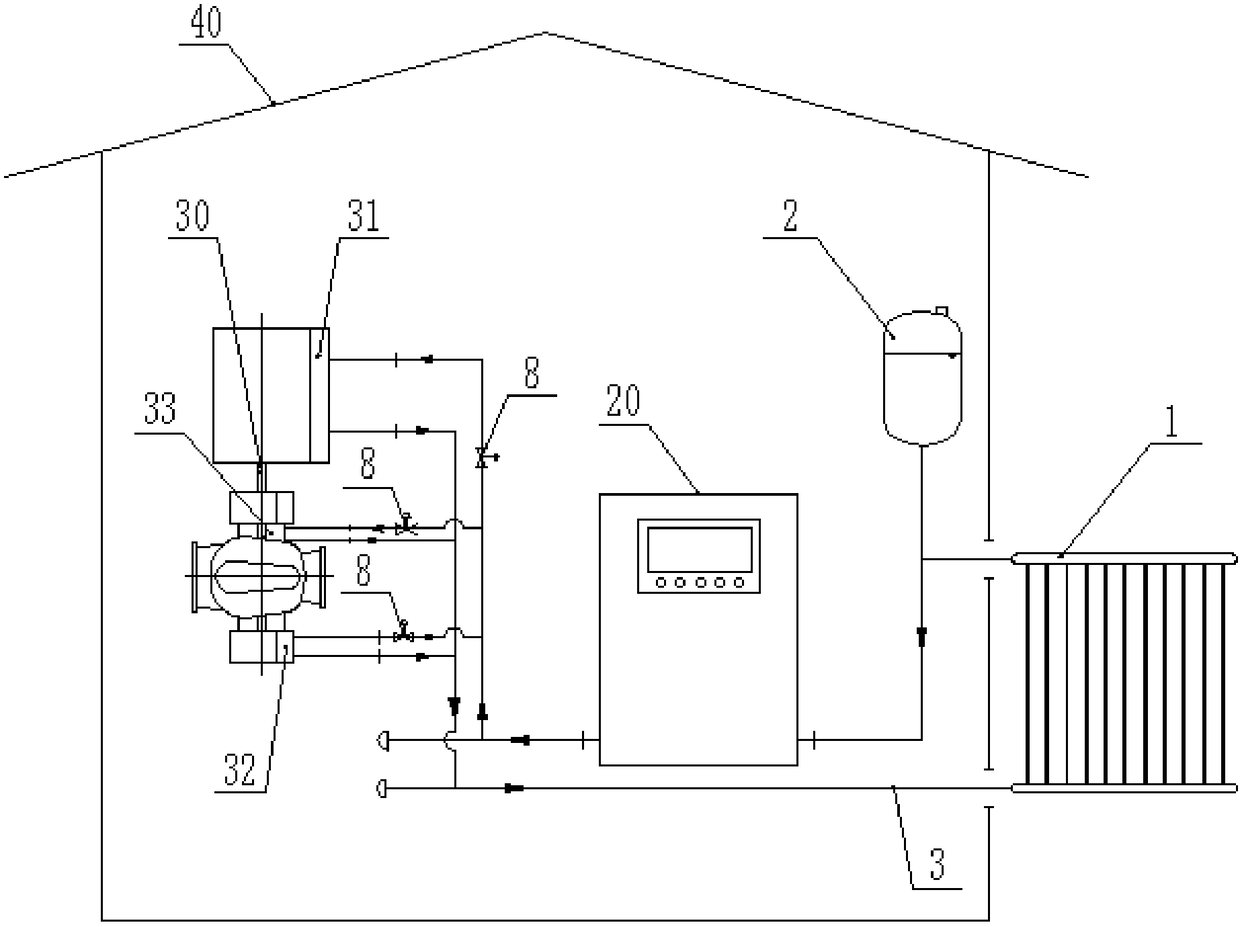

Heat pump unit closed type automatic cycle water cooling system

InactiveCN108180139AImprove heat transfer efficiencyGuarantee long-term reliable operationPositive displacement pump componentsPump controlCooling methodsBody water

The invention particularly relates to a heat pump unit closed type automatic cycle water cooling system. The heat pump unit closed type automatic cycle water cooling system mainly solves the problem that an existing heat circulation pump cooling manner is poor in cooling effect, complex in structure and high in cost, causes water resource waste and the like. The system comprises a radiator, a water supplementing tank, a pressure pump, an electromagnetic stop valve, a temperature sensor and a flowmeter, an outlet of the radiator is sequentially connected with the water supplementing tank, the pressure pump, the electromagnetic stop valve, the temperature sensor and the flowmeter through pipelines, and an outlet of the flowmeter is provided with three branch pipelines which are connected with a motor water cooling cavity inlet, a bearing body water cooling cavity inlet and a mechanical sealing water cooling cavity inlet; the electromagnetic stop valve, the pressure pump, the flowmeter and the temperature sensor are integrated in a control cabinet. According to the heat pump unit closed type automatic cycle water cooling system, the automatic cycle water cooling system is provided forlarge high-temperature-resistant pumps under the complex working condition that the temperature is above 100 DEG C, thorough cooling is carried out on sealing parts, and the heat exchange efficiencyis improved.

Owner:西安航天泵业有限公司

Process for preparing polyvinyl alcohol -based active carbon fiber

InactiveCN1840751AAvoid heating and hardeningDisadvantages of avoiding fusionFibre chemical featuresFiberPolyvinyl alcohol

The preparation method for polyvinyl alcohol active carbon fiber comprises: heating the polyvinyl alcohol fiber in air at 180-220Deg with tension as 0.01-0.1cN / dtex to weightlessness rate till 7-12%; dipping with 5-15% drier, draining; heating in air at 240-270Deg with same tension till mass as 55-65% initial value; holding for 0.5-1h in 300+-10Deg air; heating the product in inert gas or static air to 900-1100Deg, then entering CO2, vapor or holding static air for 0.5-1.5h. This invention improves product performance, and has wide application.

Owner:UNIV OF SCI & TECH OF CHINA

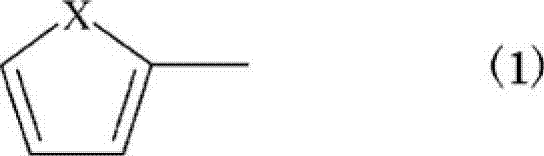

Polyolefin resin composition and process for producing same

Provided is a polyolefin resin composition which can give molded articles having a high tensile modulus and a low coefficient of linear expansion. The polyolefin resin composition is characterized by comprising a polyolefin resin, graphite flakes, and a compound having a six-membered-ring skeleton and / or a compound having a five-membered-ring skeleton. The graphite flakes hence have been evenly dispersed in the polyolefin resin. Consequently, molded articles obtained from the polyolefin resin composition are excellent in terms of mechanical strength including tensile modulus and have a low coefficient of linear expansion and hence excellent dimensional stability. The polyolefin resin composition can hence be used in various applications including exterior plate materials for motor vehicles and substitutes for steel sheets.

Owner:SEKISUI CHEM CO LTD

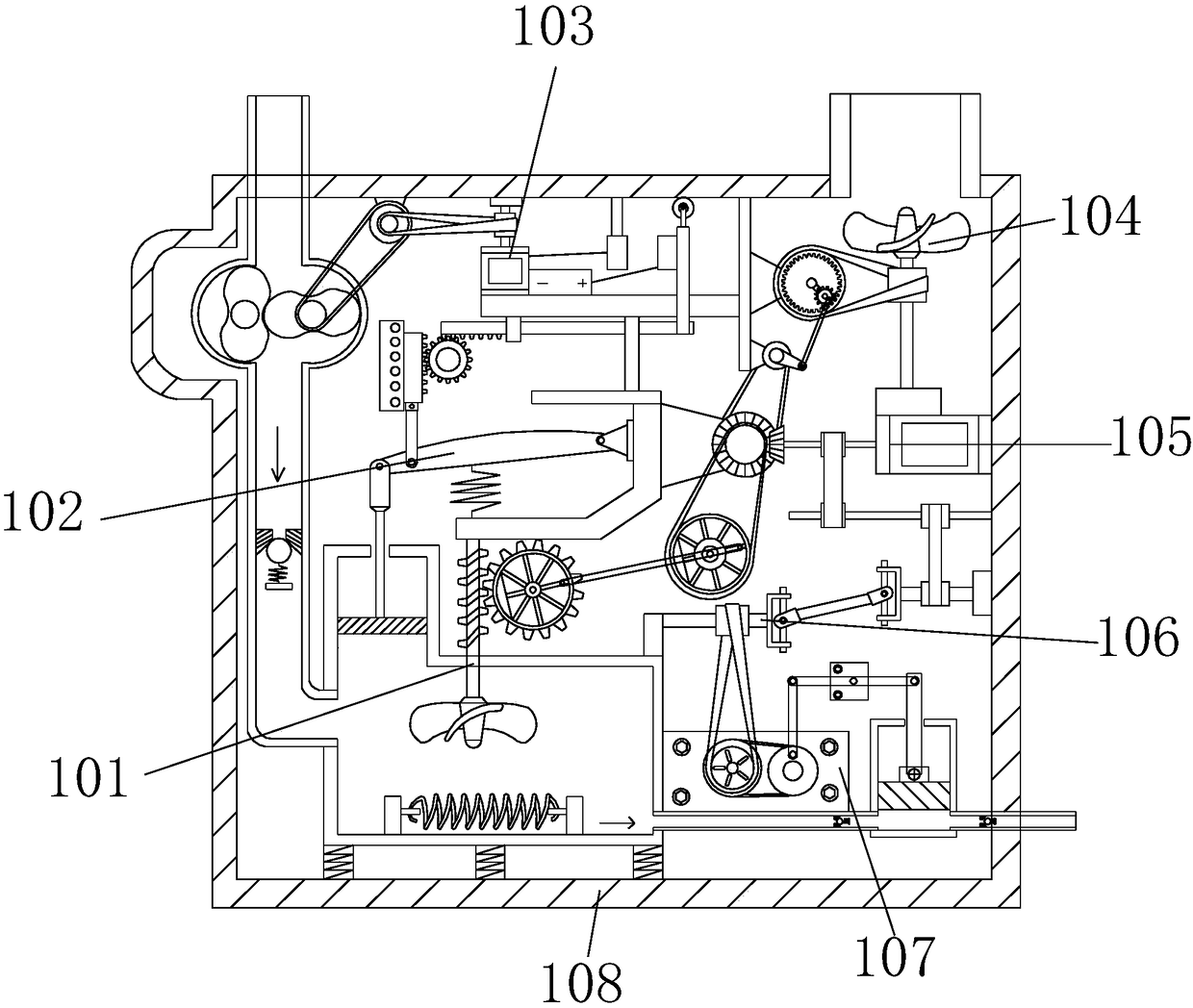

Industrial asphalt cooling device

InactiveCN108679894AWon't condenseConserve waterDomestic cooling apparatusLighting and heating apparatusEngineeringAsphalt

The invention discloses an industrial asphalt cooling device which comprises a cooling tank and an asphalt storing tank. The asphalt storing tank is movably mounted in the cooling tank, and a mountingseat is fixedly mounted on the inner wall of the top side of the cooling tank. A rotating roller is movably mounted in the mounting seat, and a rotating hole is formed in the inner wall of one side of the mounting seat in the horizontal direction. A first rotating shaft is movably mounted in the rotating hole, and the two ends of the first rotating shaft extend out of the rotating hole. One end of the first rotating shaft extends into the mounting seat and is fixedly mounted on the side, close to the rotating hole, of the rotating roller, and a moving groove is annularly formed in the rotating roller. The structure is simple, the asphalt storing tank can move back and forth during cooling, and thus asphalt in the asphalt storing tank can flow; and using water is saved, the cooling efficiency is improved, meanwhile the situation that the asphalt is congealed and consequently discharging is difficult can be avoided, thus the industrial asphalt cooling device is used more conveniently, and demands of people are met.

Owner:陈沛

Industry preparing method for sodium sand

The invention discloses an industry preparing method for sodium sand, and the problems that sodium sand prepared through a preparing technology in the prior art is uneven in particle size, operation is complex, and time is long are solved. The method comprises the steps that under nitrogen atmosphere protection, metal sodium, a dispersing agent and an organic solvent are added in a reaction kettle; and secondly, the temperature is increased till metal sodium is melted, a shearing machine runs within the given time period, shearing is conducted, and a finished product is prepared after slow cooling. The prepared sodium sand is high in activity and fine and uniform in particle, condensation cannot happen again, and the whole preparing process has the beneficial effects of being short in time, safe, reliable, good in repeatability and the like.

Owner:CHENGDU ORGANOCHEM CO LTD

High efficiency dispensing device for glass straight tube LED lighting lamp bonding

InactiveCN108525943ANot easy to solidifyDispensing continuesLiquid surface applicatorsCoatingsStraight tubeLiquid state

The invention discloses a high efficiency dispensing device for glass straight tube LED lighting lamp bonding. The structure of the device comprises an automatic glue injection and anti-hardening apparatus, a pressure gauge, a steel pipeline, a glue transmission hose, a sliding track, a sliding block, a dispensing head, a fixed mount, a workbench, a pedestal, an air vent, a control panel and a foot stand. The foot stand is welded at the lower end of the automatic glue injection and anti-hardening apparatus, the pressure gauge is in glued connection with the upper end of the automatic glue injection and anti-hardening apparatus, the steel pipeline is embedded at the right end of the automatic glue injection and anti-hardening apparatus, and the right end of the glue transmission hose is inglued connection with the back end of the sliding block. With the automatic glue injection and anti-hardening apparatus, when the glue of a heating box decreases, the high efficiency dispensing deviceprovided by the invention can automatically replenish glue without manual control, and ensures that the glue is in a liquid state all the time and does not solidify easily, guarantees continuous dispensing work, and is convenient to use.

Owner:陈潇曼

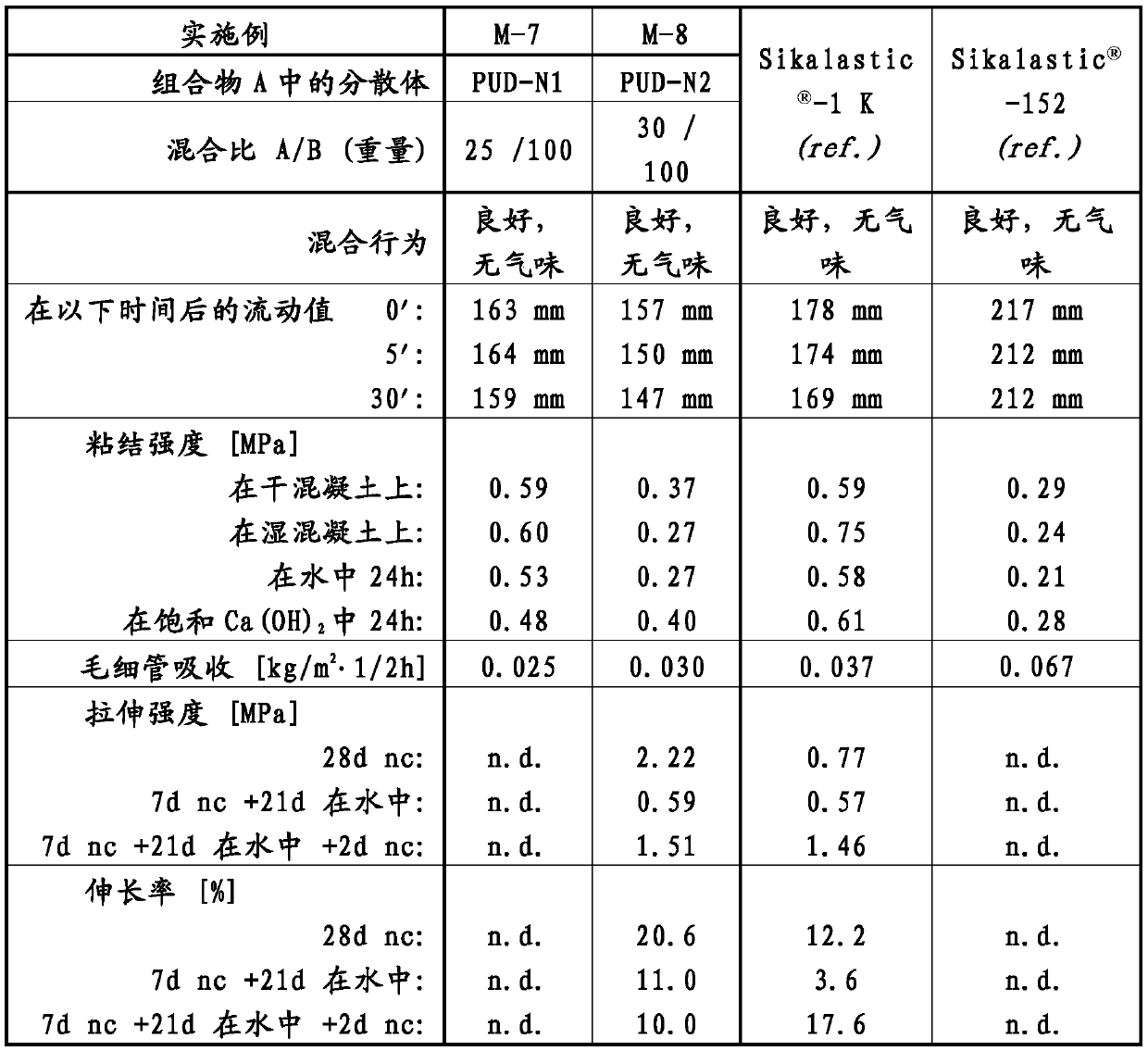

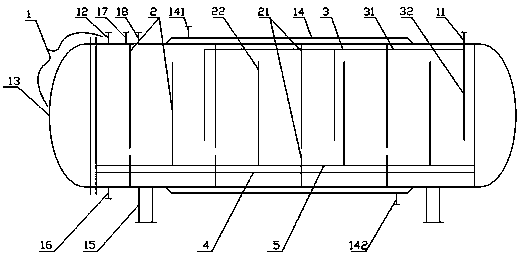

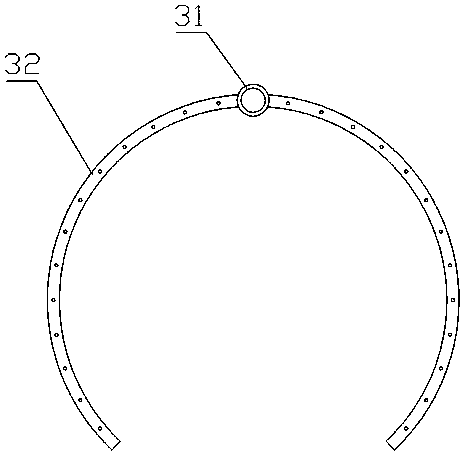

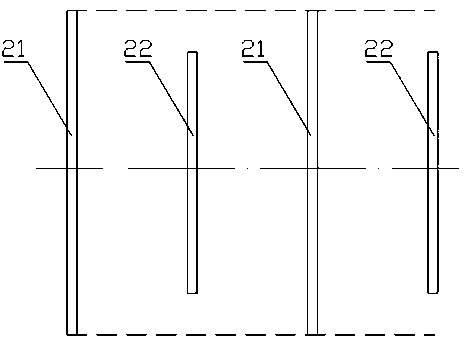

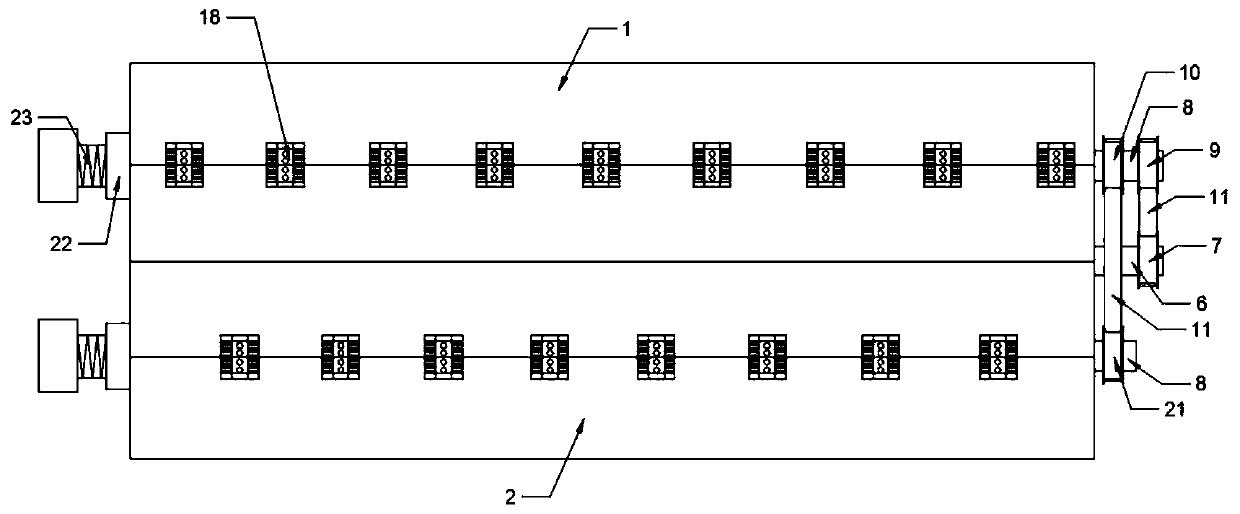

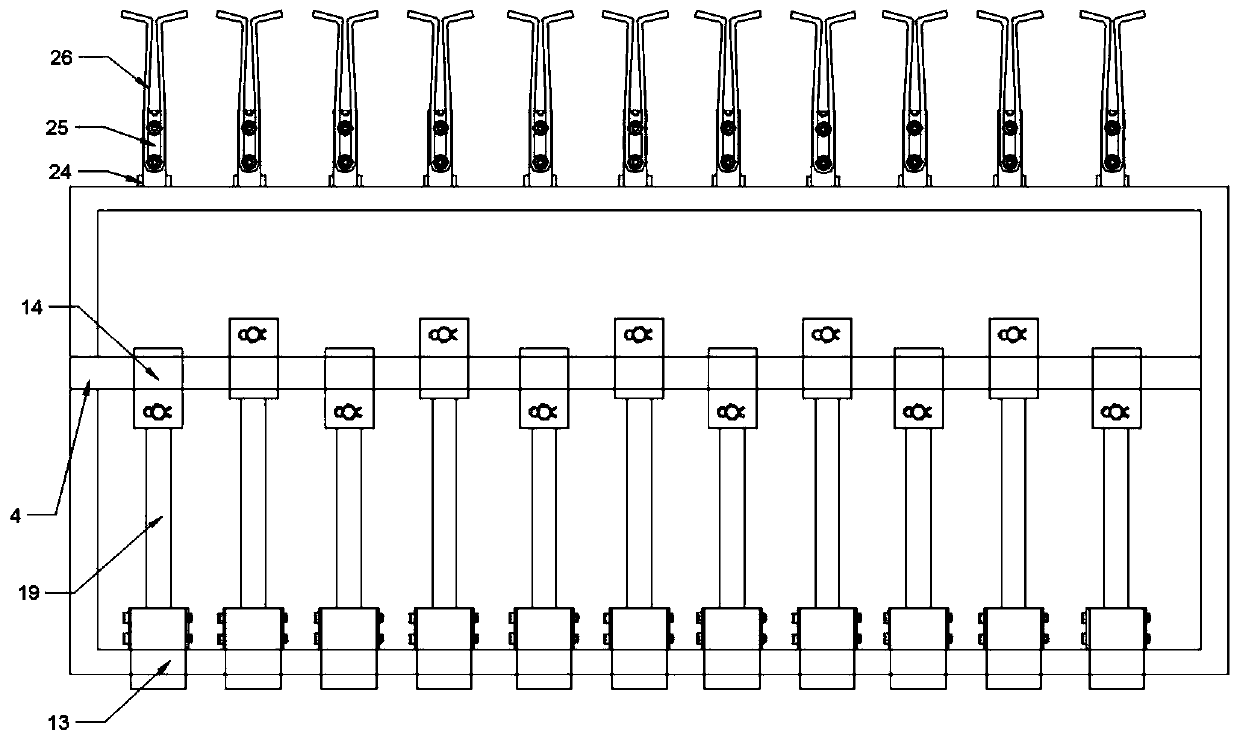

Regional superheated steam textile fabric drying and setting machine and combination thereof

PendingCN108754954ALarge heat capacityImprove heat transfer coefficientLiquid/gas/vapor removalHeating/cooling textile fabricsPulp and paper industryDistributor

The invention discloses a regional superheated steam textile fabric drying and setting machine and a combination thereof. The setting machine comprises a box body, a superheated steam inlet above is formed in one end of the box body, and the other end of the box body is a fabric inlet and outlet with an oval cover body; a steam outlet close to the fabric inlet and outlet is further formed in the upper portion of the box body; a rib type superheated steam distributor which is located at the top and communicated with the superheated steam inlet is arranged in the box body; a fabric trolley whichcan move on a guide rail through the fabric inlet and outlet is arranged in the box body, and partition plates which are arranged at intervals are further arranged in the box body. According to the drying and setting machine, superheated steam is used for making direct contact with materials to take away moisture in the materials for drying, superheated steam drying takes steam as a direct dryingmedium, and compared with hot air, the superheated steam is large in heat transfer coefficient, small in use amount and high in drying efficiency; a fabric can be preheated by adopting the combination of the drying and setting machine.

Owner:JIANGSU JM MACHINERY +1

Glass melting furnace and glass melting method

ActiveCN108751674AExtended service lifeReduce concentrationGlass furnace apparatusRefractoryGlass melting

The invention provides a glass melting furnace and a glass melting method. A clarification part of the glass melting furnace contains spray guns, and the spray guns are fixed in the clarification part. The glass melting method comprises the steps of adding raw materials for preparing glass into the glass melting furnace, performing glass melting, opening the spray guns of the clarification part ofthe glass melting furnace in the glass melting process, and obtaining a glass melting solution with the viscosity meeting molding requirements. According to the provided glass melting furnace, by arranging the spray guns in the clarification part, volatile components generated in the glass melting process are blown out of the melting furnace and can be diluted, the concentration of the volatile components in the melting furnace is decreased, the volatile components cannot be condensed on a refractory material of the melting furnace, the service life of the glass melting furnace is prolonged,and the maintenance cost is reduced. At the same time, defects, in the glass, caused by falling due to erosion of the surface of the refractory material cannot occur, and the quality of the glass melting solution is ensured.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP +1

Profiling sowing machine and using method thereof

InactiveCN110326402AStable power deliveryEasy to adjust broadcast volumePlantingFurrow making/coveringAgricultural engineeringSowing

The invention discloses a profiling sowing machine and a using method thereof, and belongs to the technical field of agricultural mechanical equipment. The profiling sowing machine comprises a rack aswell as a first seed box and a second seed box which are arranged side by side, wherein rotating rods are arranged at the bottom ends of the first seed box and the second seed box; one end of each rotating rod is fixedly connected with a second connecting shaft; a first driven wheel and a second driven wheel are arranged on the second rotating shaft connected with the rotating rod at the lower end of the first seed box; a third driven wheel movably connected with the second driven wheel through a chain is arranged on the second connecting shaft connected with the rotating rod at the lower endof the second seed box; a plurality of land wheels are movably connected with the lower end of the rack through a rotating shaft, a first connecting shaft is connected onto the land wheels, a drivingwheel is arranged on the first connecting shaft, and a gearbox connected with the rotating rods and the second connecting shafts is arranged at the bottom end of the first seed box. By means of the land wheels, the chain, the driving wheel and multiple driven wheels, power transmission is realized and is stable, the sowing quantity is adjusted and controlled by the gearbox, the sowing quantity adjustment is convenient and fast, and sowing is more uniform.

Owner:宿州市信德机械股份有限公司

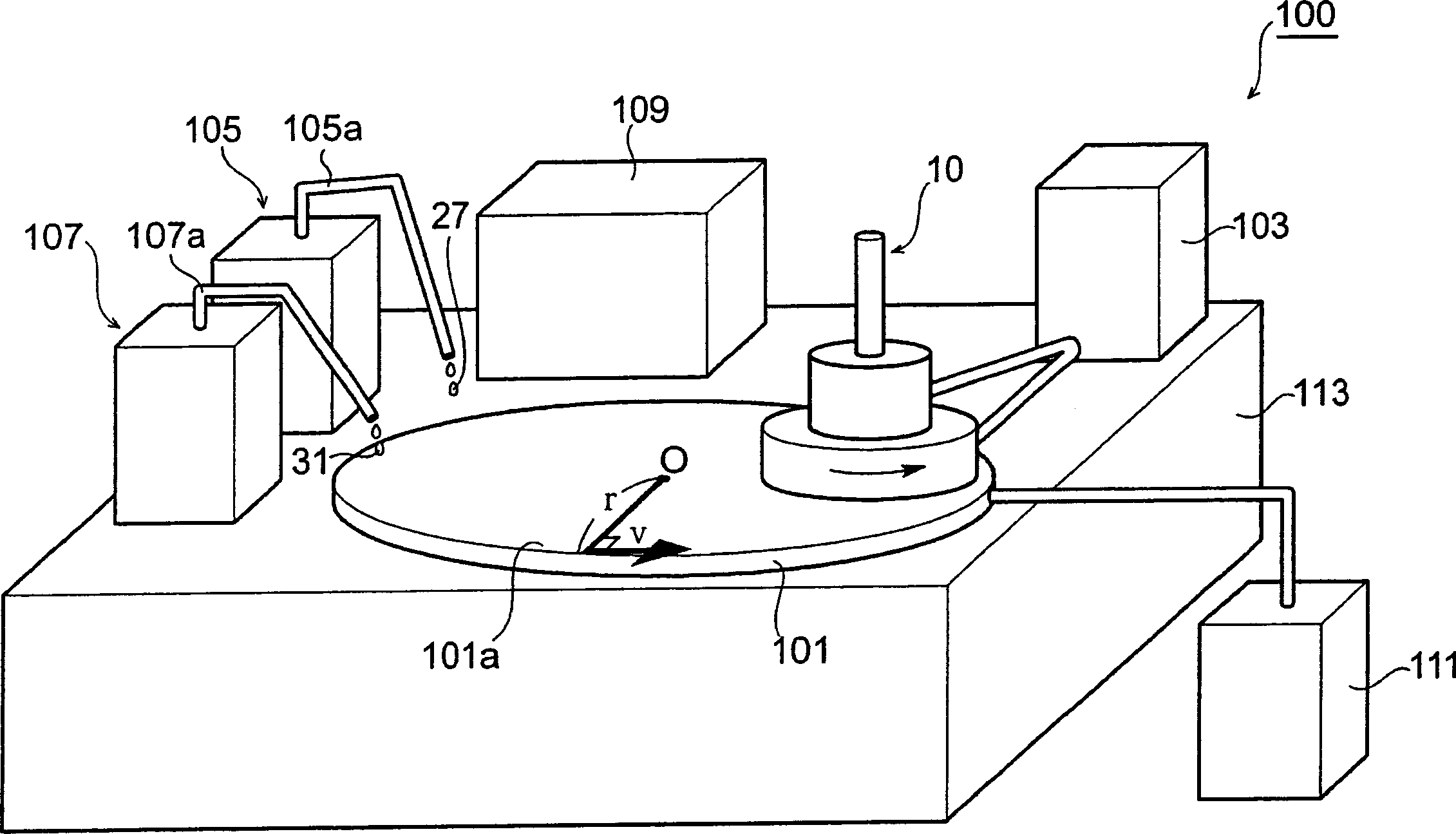

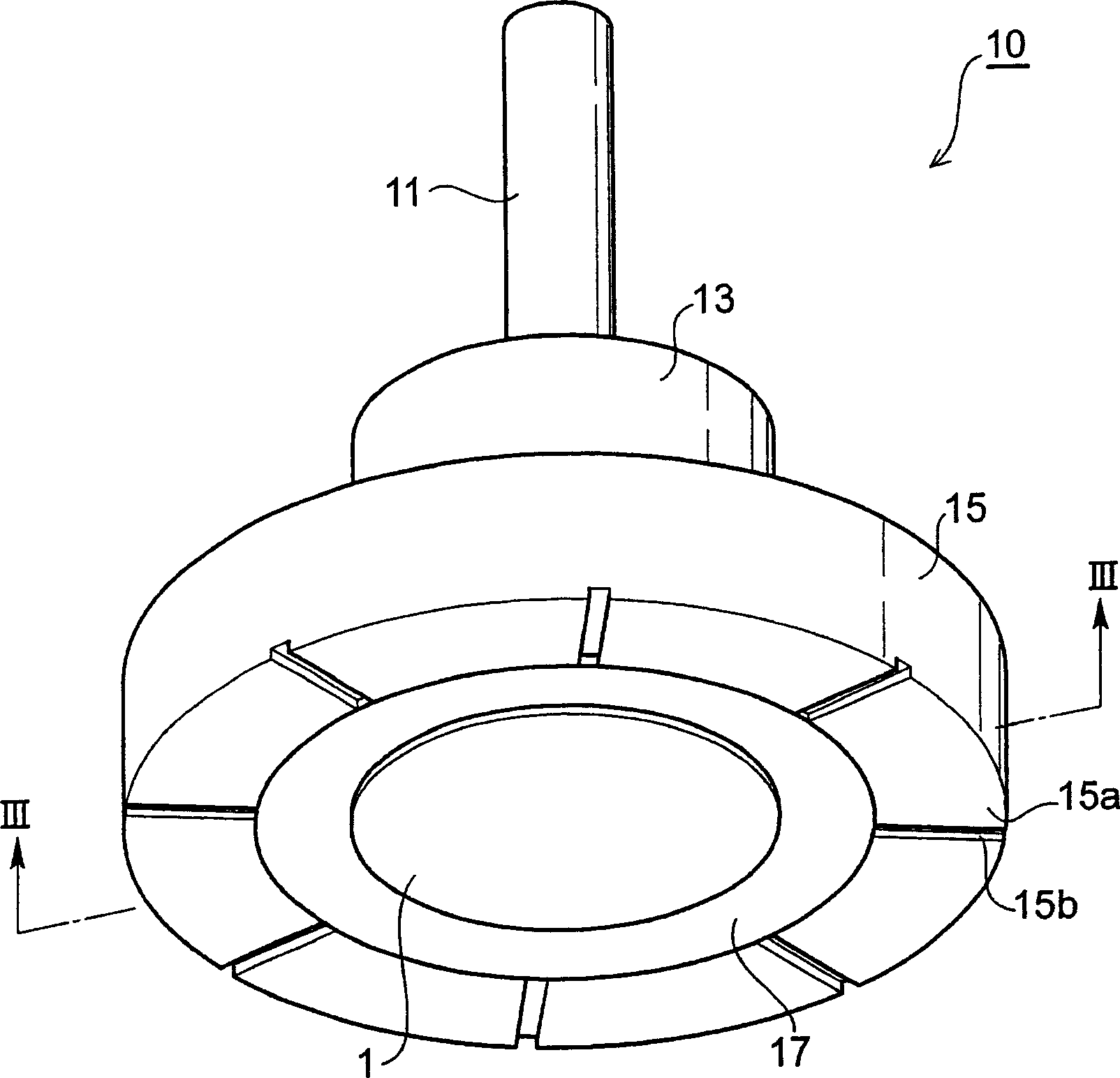

Method for grinding GaN substrate

ActiveCN1906739AWon't condenseInhibit chafingPolycrystalline material growthAfter-treatment detailsEngineeringLubricant

In a polishing method of a GaN substrate according to this invention, first, while supplying a polishing solution 27 containing abrasives 23 and a lubricant 25, onto a platen 101, the GaN substrate is polished using the platen 101 and the polishing solution 27 (first polishing step). Then the GaN substrate is polished using the platen 101 in which abrasives 29 are buried, while supplying a lubricant 31 onto the platen 101 in which the abrasives 29 are buried (second polishing step).

Owner:SUMITOMO ELECTRIC IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com