Gas-liquid separation device

A technology of gas-liquid separator and rotating shaft, applied in separation method, liquid degassing, general layout of liquid degassing, etc., can solve problems such as reduction of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the gas-liquid separator according to the example of the present invention will be described in detail with reference to the accompanying drawings.

[0039] In addition, the same or similar reference numerals in the drawings represent the same or similar elements regardless of the figure number, and repeated description will not be given. For the convenience of description, the size and shape of each illustrated element may be exaggerated or reduced.

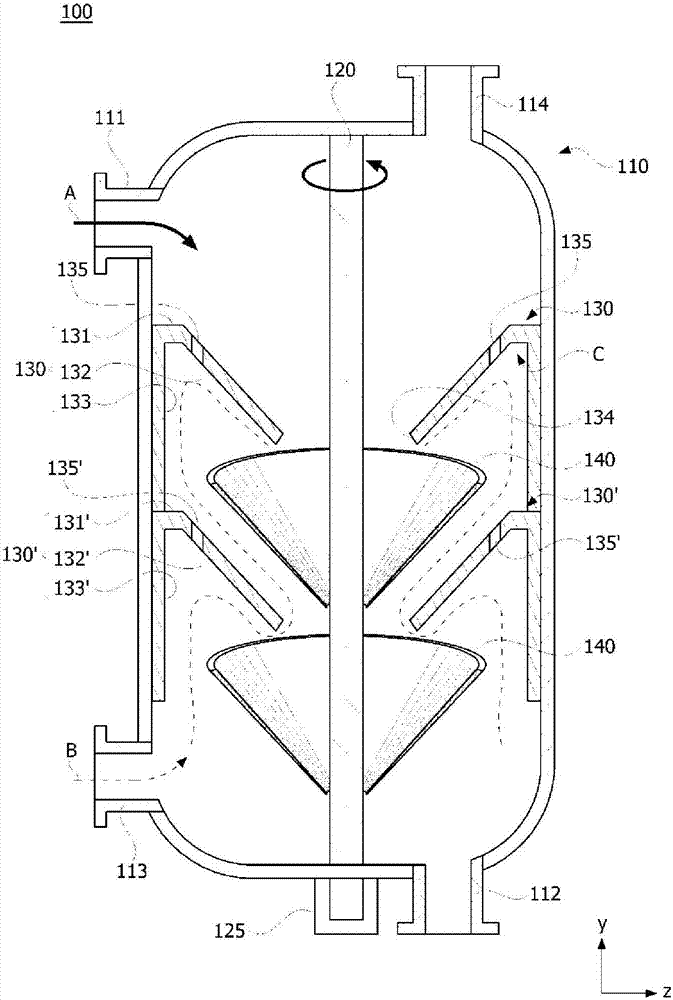

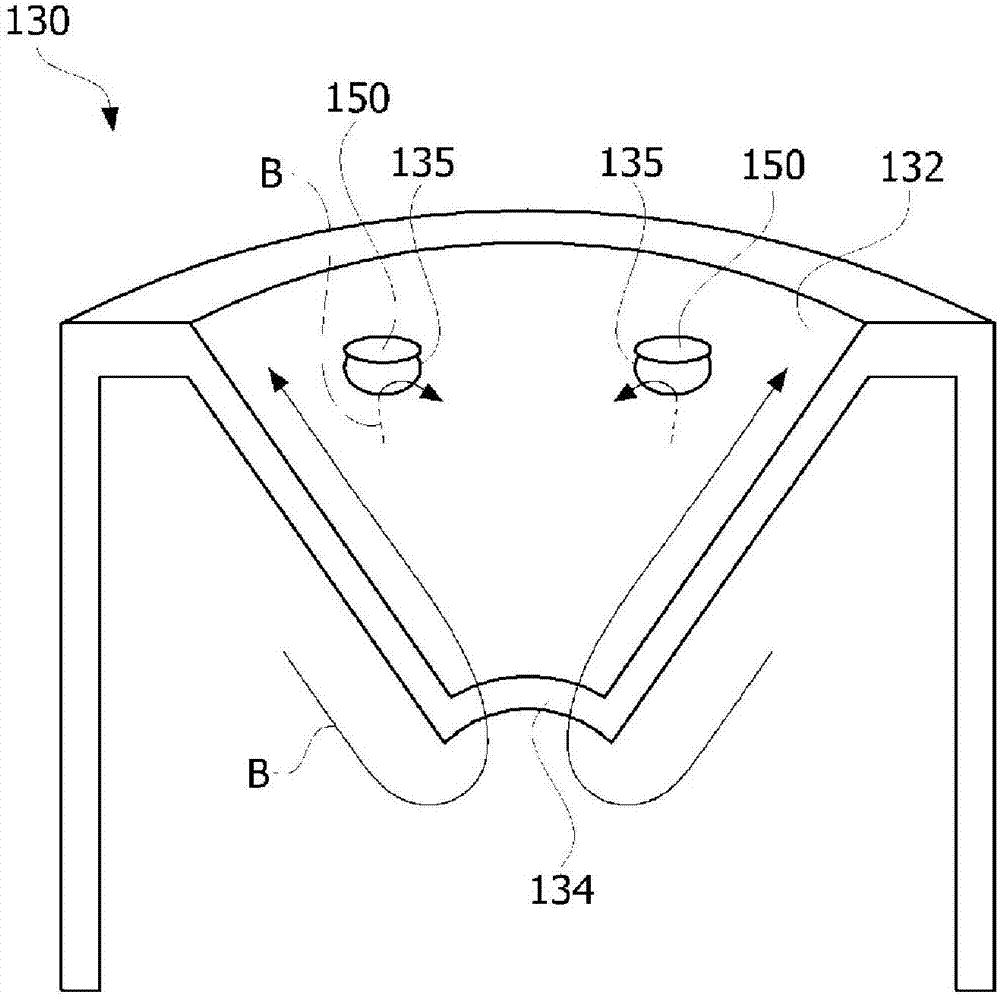

[0040] figure 1 It is a cross-sectional view showing the gas-liquid separator 100 according to an example of the present invention.

[0041] In this specification, the gas-liquid separator 100 can make the reactant A (also referred to as "first fluid" or "liquid raw material") and steam B (also referred to as "second fluid" or "stripping agent") The process of reacting to remove volatile organic compounds (VOC) from reactant A.

[0042] Here, the chemical reaction between the first fluid and the second fluid is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com